Power Converter Design for Pulsed Electric Field-Based Milk Processing: A Proof of Concept

Abstract

1. Introduction

- Pasteurization: Both pasteurization processes cause the death of most pathogens, vegetative bacteria, yeasts, and molds. Moreover, they cause the denaturation of several enzymes and several whey proteins [5]. They inactivate non-spore-forming pathogens, psychrotrophic spoilage bacteria, and thermoducric bateria [5,6,7].

- Sterilization: This method heats milk at 110 °C for 30 min or at 130 °C for 40 s, which results in the extermination of all microorganisms, deactivation of most enzymes, denaturation of whey proteins, and aggregation of caseins (casein micelles), but it affects the sensory characteristics of the product, leading to weakened flavor intensity and color darkening [5,6,7].

- Microorganisms contained in food:

- Type;

- Size;

- Cell surface structure;

- Concentration growth phase.

- Ionic strength;

- pH;

- Water activity;

- Viscosity;

- Presence of solid particles or oil droplets.

- Field strength;

- Treatment time;

- Intensity.

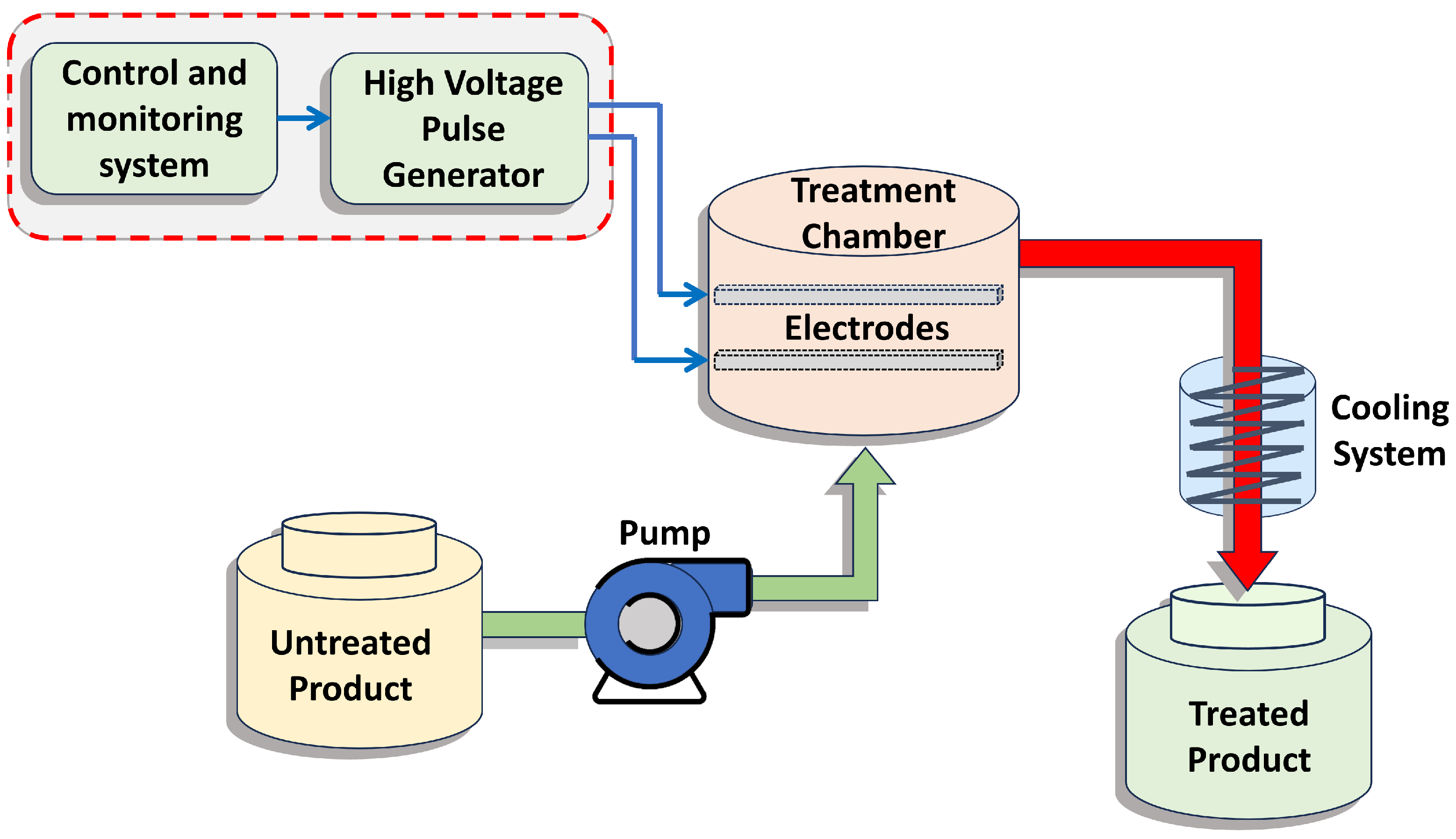

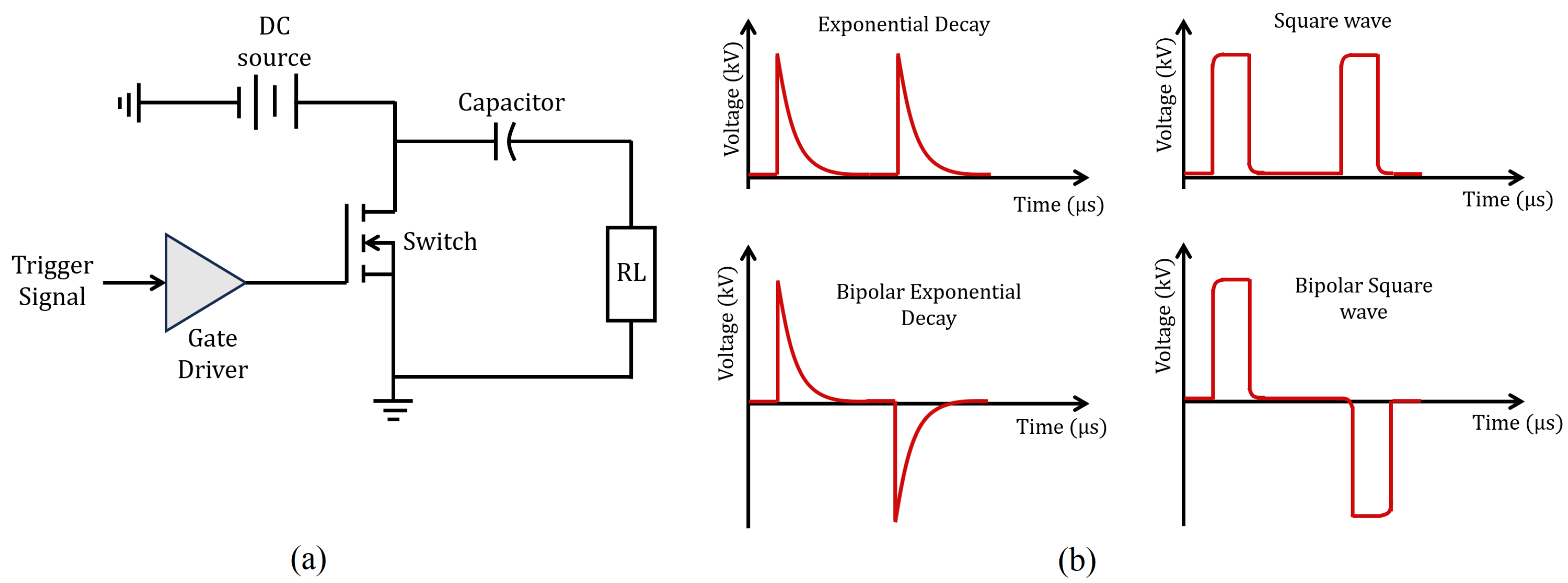

2. Mechanism of PEF and Power Converter Basis

Milk Conductivity Characterization

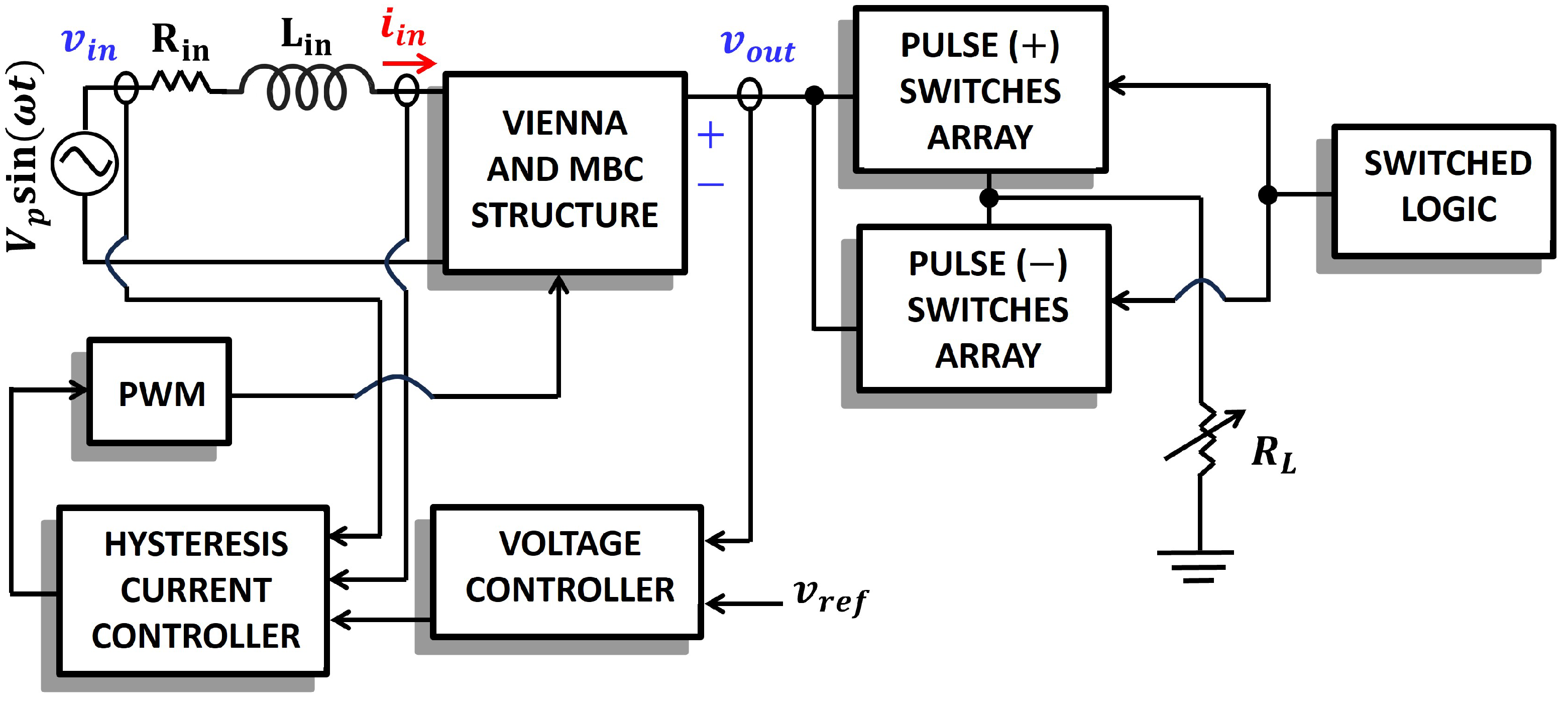

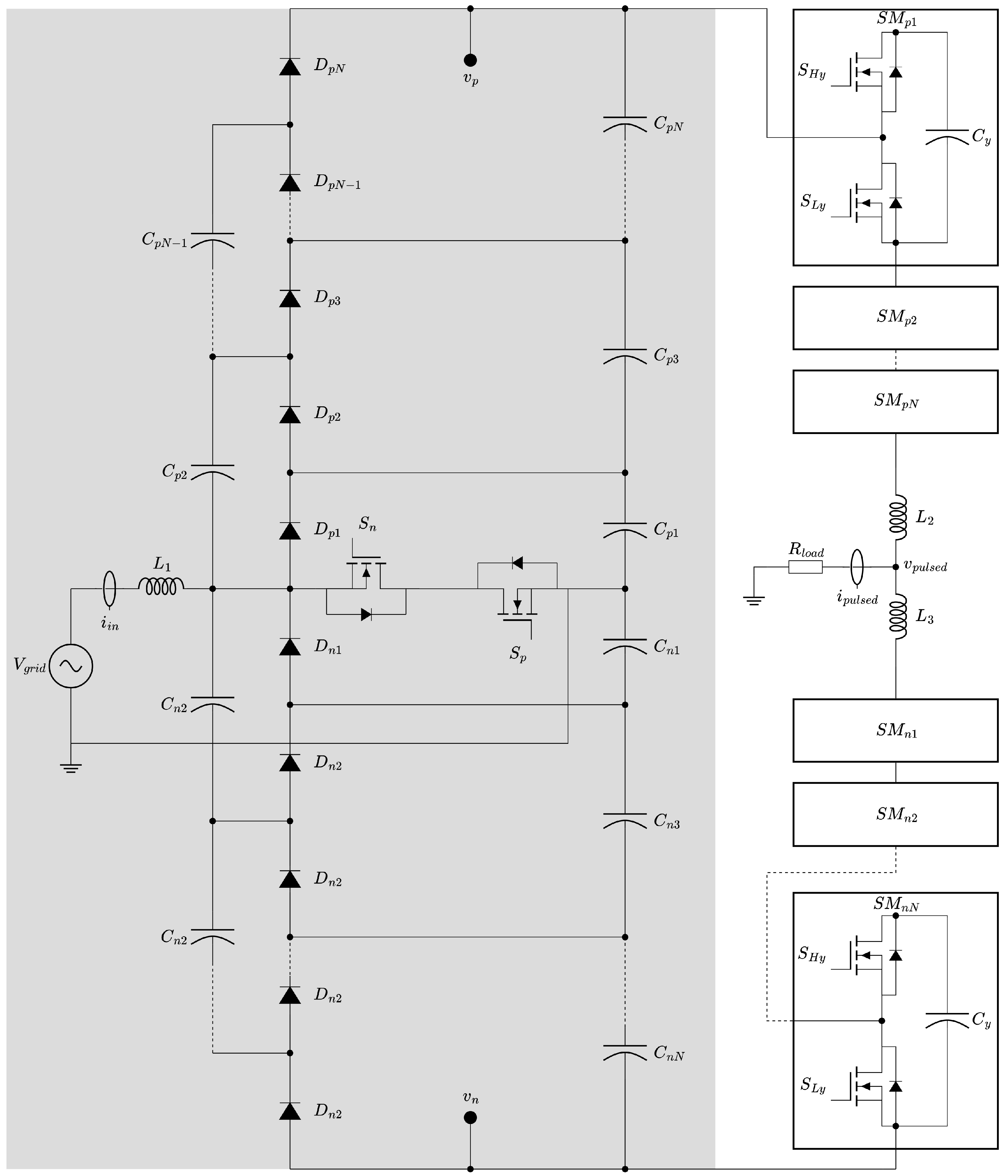

3. Proposed Power Converter and Control Law Design

Proposed Controller

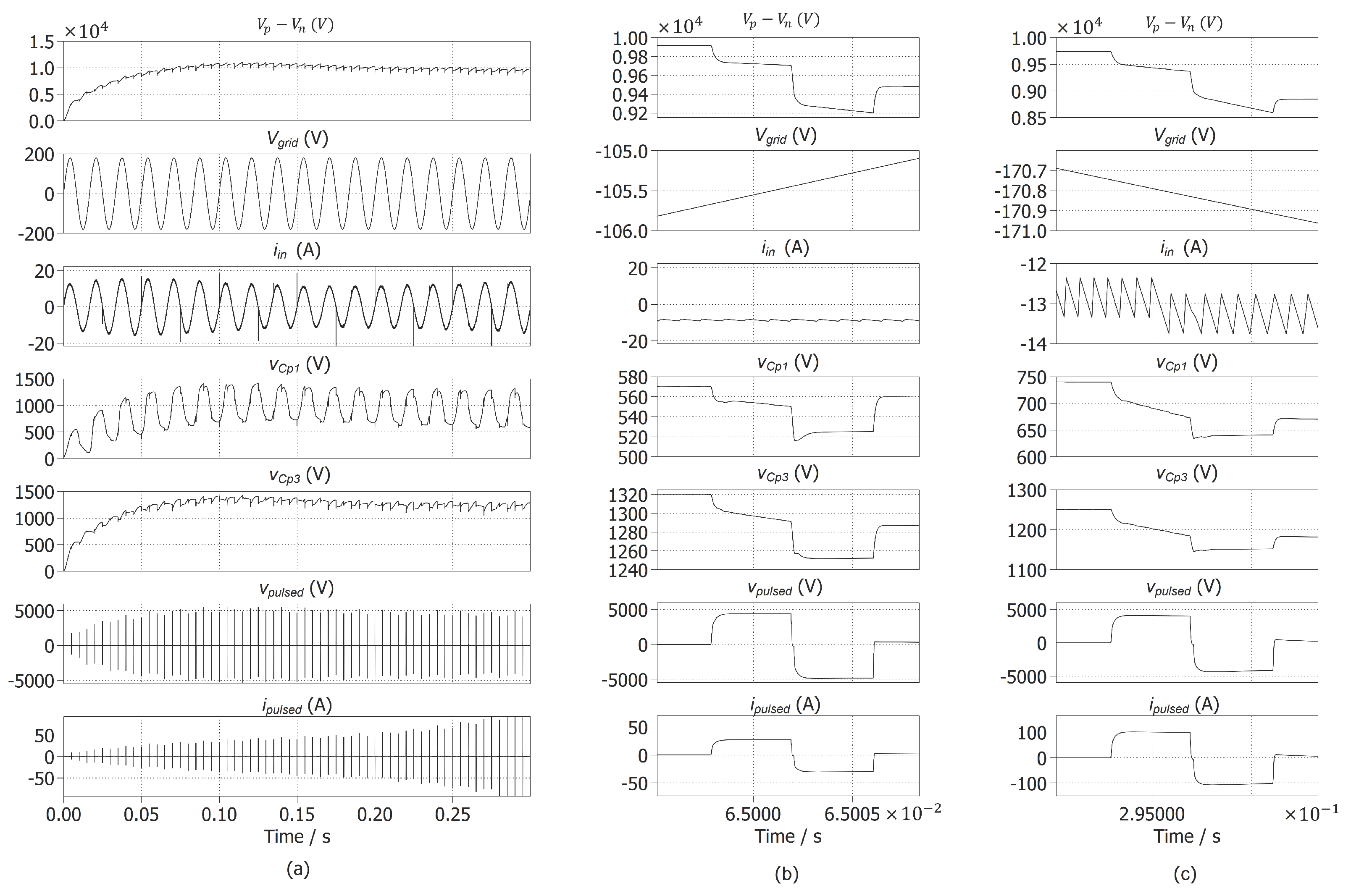

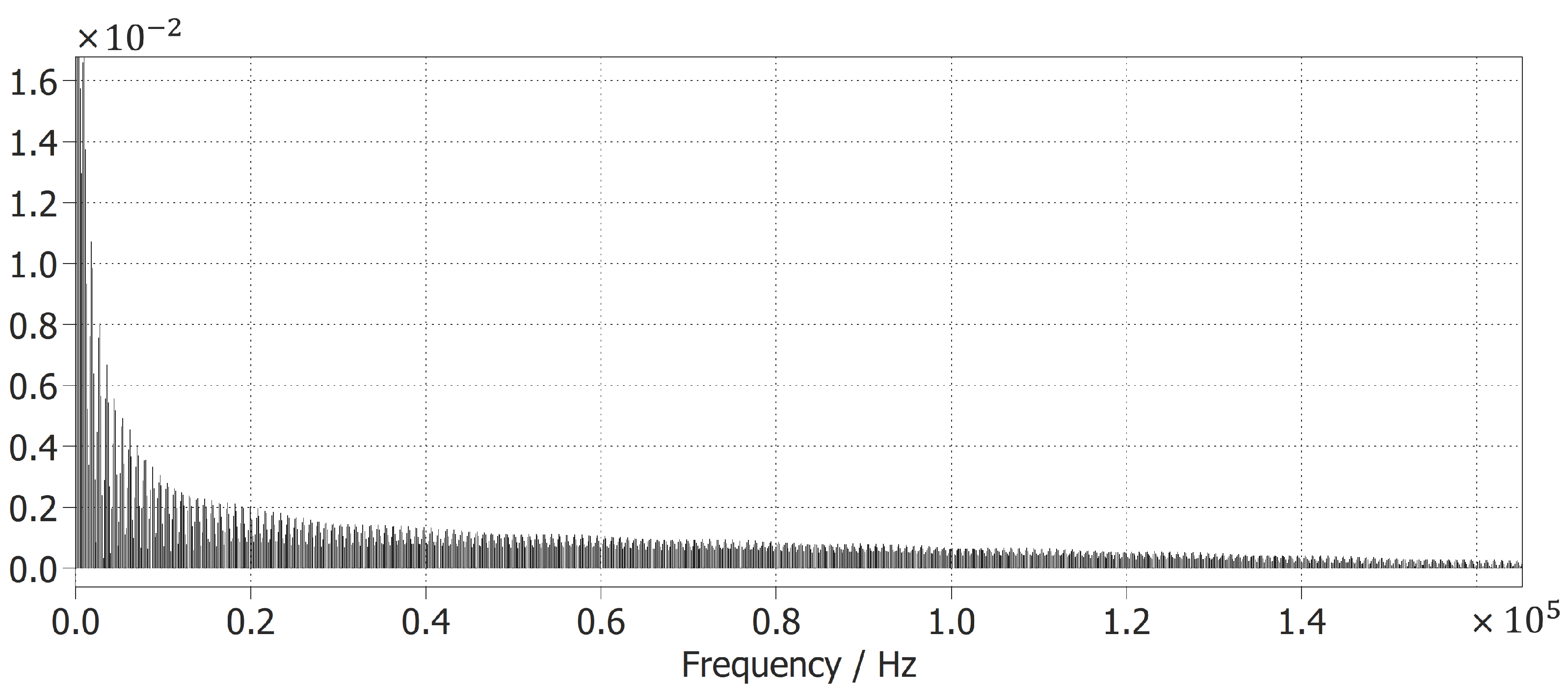

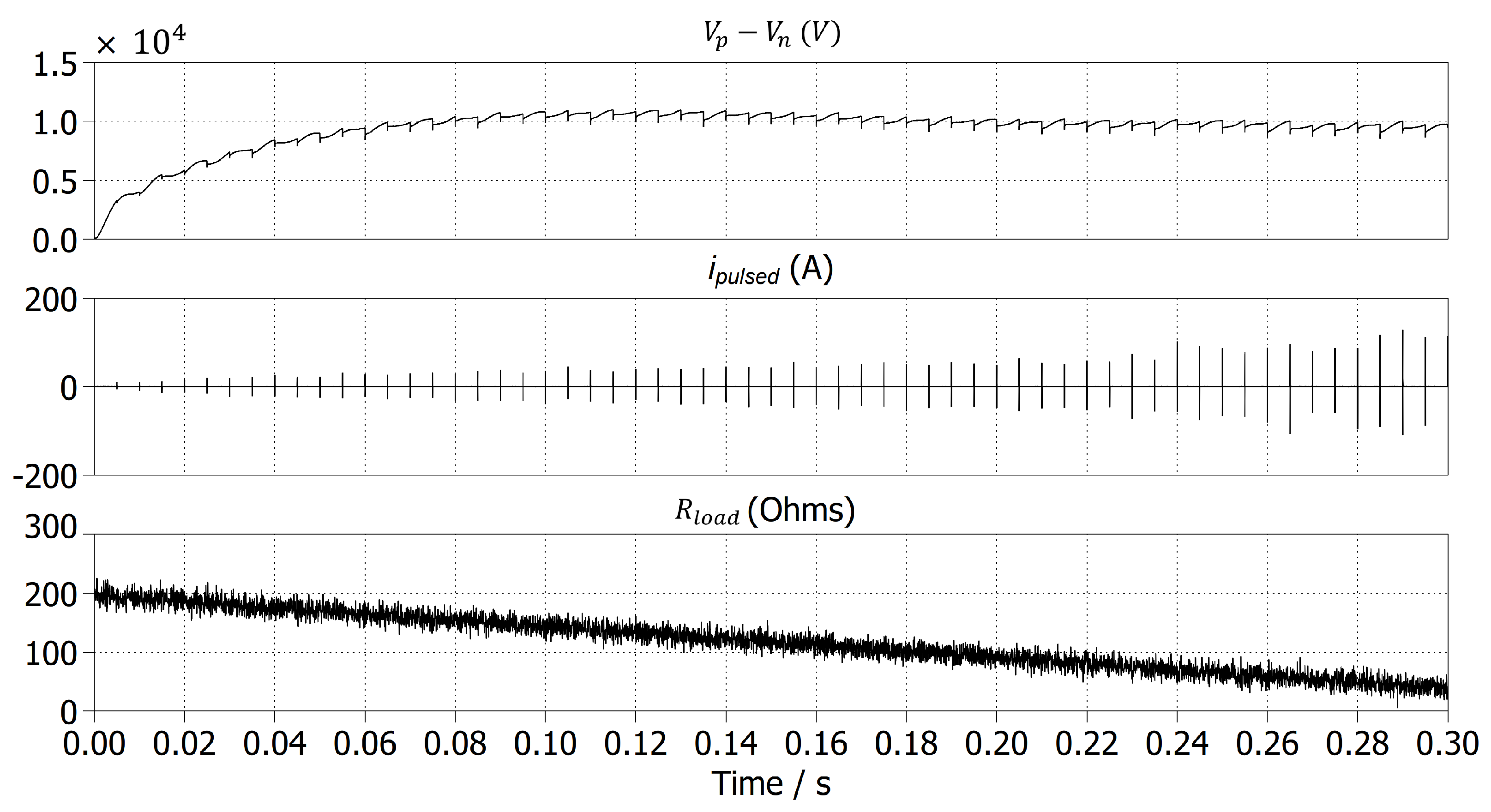

4. Simulation Results

5. Discussion

6. Conclusions

- An operation and design of the proposed PEF converter through simulation.

- This device and its proposed controller produce high output voltage and adaptive bipolar pulse generation, using a Vienna rectifier and Modular Multilevel Converter.

- The system is validated using characteristic load impedance that emulates the change in resistivity from an untreated milk sample to one treated using PEF.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sanjulián, L.; Fernández-Rico, S.; González-Rodríguez, N.; Cepeda, A.; Miranda, J.M.; Fente, C.; Lamas, A.; Regal, P. The Role of Dairy in Human Nutrition: Myths and Realities. Nutrients 2025, 17, 646. [Google Scholar] [CrossRef] [PubMed]

- Ozaybi, N. High-Pressure Processing of Milk and Dairy Products: Latest Update. Processes 2024, 12, 2073. [Google Scholar] [CrossRef]

- Shabbir, M.A.; Ahmed, H.; Maan, A.A.; Rehman, A.; Afraz, M.T.; Iqbal, M.W.; Khan, I.M.; Aadil, R.M.; Ashraf, W.; Khan, M.R.; et al. Effect of non-thermal processing techniques on pathogenic and spoilage microorganisms of milk and milk products. Food Sci. Technol. 2021, 41, 279–294. [Google Scholar] [CrossRef]

- Freire, P.; Zambrano, A.; Zamora, A.; Castillo, M. Thermal Denaturation of Milk Whey Proteins: A Comprehensive Review on Rapid Quantification Methods Being Studied, Developed and Implemented. Dairy 2022, 3, 500–512. [Google Scholar] [CrossRef]

- Sfakianakis, P.; Tzia, C. Conventional and Innovative Processing of Milk for Yogurt Manufacture; Development of Texture and Flavor: A Review. Foods 2014, 3, 176–193. [Google Scholar] [CrossRef] [PubMed]

- IDF. Heat Treatment of Milk—Overview, IDF Factsheet 001/2018-02; International Dairy Federation: Brussels, Belgium, 2018. [Google Scholar]

- Lindsay, D.; Robertson, R.; Fraser, R.; Engstrom, S.; Jordan, K. Heat induced inactivation of microorganisms in milk and dairy products. Int. Dairy J. 2021, 121, 105096. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, D.-W.; Han, Z. Applications of electromagnetic fields for nonthermal inactivation of microorganisms in foods: An overview. Trends Food Sci. Technol. 2017, 64, 13–22. [Google Scholar] [CrossRef]

- Soltanzadeh, M.; Peighambardoust, S.H.; Gullon, P.; Hesari, J.; Gullón, B.; Alirezalu, K.; Lorenzo, J. Quality aspects and safety of pulsed electric field (PEF) processing on dairy products: A comprehensive review. Food Rev. Int. 2020, 38 (Suppl. S1), 96–117. [Google Scholar] [CrossRef]

- Barsotti, L.; Merle, P.; Cheftel, J.C. Food Processing by Pulsed Electric Fields. I. Physical Aspects. Food Rev. Int. 1999, 15, 163–180. [Google Scholar] [CrossRef]

- Mazumder, J.A.; Ali, A.H.; Banat, F. Emerging non-thermal treatment approaches for camel milk: A review. NFS J. 2024, 37, 100198. [Google Scholar] [CrossRef]

- El Kantar, S.; Koubaa, M. Pulsed electric field treatment for the stimulation of microorganisms: Applications in food production. Res. Agric. Eng. 2022, 68, 80–92. [Google Scholar] [CrossRef]

- Li, L.; Yang, R.; Zhao, W. The Effect of Pulsed Electric Fields (PEF) Combined with Temperature and Natural Preservatives on the Quality and Microbiological Shelf-Life of Cantaloupe Juice. Foods 2021, 10, 2606. [Google Scholar] [CrossRef]

- Šalaševičius, A.; Uždavinytė, D.; Visockis, M.; Ruzgys, P.; Šatkauskas, S. Effect of Pulsed Electric Field (PEF) on Bacterial Viability and Whey Protein in the Processing of Raw Milk. Appl. Sci. 2021, 11, 11281. [Google Scholar] [CrossRef]

- Mohamed, M.E.A.; Eissa, A.H.A. Pulsed Electric Fields for Food Processing Technology. In Structure and Function of Food Engineering; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef]

- Roodenburg, B. Pulsed Electric Field Treatment of Packaged Food; Dutch Technology Foundation STW: Utrecht, The Netherlands, 2011; ISBN 978-90-5335-475-9. [Google Scholar]

- Sanders, J.M.; Kuthi, A.; Wu, Y.-H.; Vernier, P.T.; Gundersen, M.A. A linear, single-stage, nanosecond pulse generator for delivering intense electric fields to biological loads. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1048–1054. [Google Scholar] [CrossRef]

- Coban, M.; Fidan, M. High Voltage Pulse Generator for Pulsed Electric Field Treatments. In Proceedings of the 2019 3rd International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Ankara, Turkey, 11–13 October 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Bagarinao, N.C.; King, J.; Leong, S.Y.; Agyei, D.; Sutton, K.; Oey, I. Effect of Germination on Seed Protein Quality and Secondary Metabolites and Potential Modulation by Pulsed Electric Field Treatment. Foods 2024, 13, 1598. [Google Scholar] [CrossRef] [PubMed]

- Razola-Díaz, M.d.C.; Sevenich, R.; Schlüter, O.K.; Verardo, V.; Gómez-Caravaca, A.M. Improving Olive Leaf Phenolic Extraction with Pulsed Electric Field Technology Pre-Treatment. Foods 2025, 14, 368. [Google Scholar] [CrossRef]

- Morales-de la Peña, M.; Salvia-Trujillo, L.; Rojas-Graü, M.A.; Martín-Belloso, O. Impact of high intensity pulsed electric field on antioxidant properties and quality parameters of a fruit juice–soymilk beverage in chilled storage. LWT Food Sci. Technol. 2010, 43, 872–881. [Google Scholar] [CrossRef]

- Sritakaew, P.; Silapunt, R. Pulse Electric Field by Half Bridge Modular Multilevel Inverter for Liquid Food Sterilization. In Proceedings of the 2019 10th International Conference on Power Electronics and ECCE Asia (ICPE 2019—ECCE Asia), Busan, Republic of Korea, 27–30 May 2019; pp. 2122–2125. [Google Scholar] [CrossRef]

- Behrend, M.; Kuthi, A.; Gu, X.; Vernier, P.T.; Marcu, L.; Craft, C.M.; Gundersen, M.A. Pulse generators for pulsed electric field exposure of biological cells and tissues. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 820–825. [Google Scholar] [CrossRef]

- Akiyama, M.; Shiraishi, E.; Sakugawa, T.; Hosseini, S.H.R.; Akiyama, H.; Shiraki, N.; Kume, S. Influence of 60 ns pulsed electric fields on embryonic stem cells. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1119–1123. [Google Scholar] [CrossRef]

- Mitsutake, K.; Satoh, A.; Mine, S.; Abe, K.; Katsuki, S.; Akiyama, H. Effect of pulsing sequence of nanosecond pulsed electric fields on viability of HeLa S3 cells. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 337–342. [Google Scholar] [CrossRef]

- Salengke, S.; Sastry, S.K.; Zhang, H.Q. Pulsed electric field technology: Modeling of electric field and temperature distributions within continuous flow PEF treatment chamber. Int. Food Res. J. 2012, 19, 1137–1144. [Google Scholar]

- Pradhan, T.; Ram, R.; Thomas, M.J. Design and Development of a Pulsed Electric Field-Based Liquid Food Sterilization System. In Proceedings of the 2023 IEEE Pulsed Power Conference (PPC), San Antonio, TX, USA, 25–29 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Huang, K.; Wang, J. Designs of pulsed electric fields treatment chambers for liquid foods pasteurization process: A review. J. Food Eng. 2009, 95, 227–239. [Google Scholar] [CrossRef]

- Abadi, M.R.Q.R.; Marzebali, M.H.; Abolghasemi, V.; Anisi, M.H. High-Voltage Pulse Generators for Electroporation Applications: A Systematic Review. IEEE Access 2022, 10, 64933–64951. [Google Scholar] [CrossRef]

- Sundararajan, R.; Shao, J.; Soundarajan, E.; Gonzales, J.; Chaney, A. Performance of solid-state high-voltage pulsers for biological applications-a preliminary study. IEEE Trans. Plasma Sci. 2004, 32, 2017–2025. [Google Scholar] [CrossRef]

- Azli, N.A.; Jambari, H.; Sultan, P.I.; Piah, M.A.M.; Ramlan, N.H. Implementation of cascaded H-bridge multilevel inverter for liquid food sterilization using pulsed electric field. In Proceedings of the 2014 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 13–14 October 2014; pp. 316–320. [Google Scholar] [CrossRef]

- He, Y.; Ma, J.; Yu, L.; Dong, S.; Gao, L.; Zeng, W.; Yao, C. 10-MHz High-Power Pulse Generator on Boost Module. IEEE Trans. Ind. Electron. 2021, 68, 6286–6296. [Google Scholar] [CrossRef]

- Li, L.; Peng, Z.; Liu, N.; Xie, J.; Zhang, Q.; Liu, Y.; Li, H.; Lin, F. A Distributed High-Voltage Arbitrary Waveform Generator Based on Versatile Pulsed Power Module. IEEE Trans. Plasma Sci. 2023, 51, 2309–2320. [Google Scholar] [CrossRef]

- Elgenedy, M.A.; Massoud, A.M.; Ahmed, S.; Williams, B.W. A High-Gain, High-Voltage Pulse Generator Using Sequentially Charged Modular Multilevel Converter Submodules, for Water Disinfection Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1394–1406. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Z.; Jiang, T.; Xie, J.; Ding, T.; Han, X. A Hybrid Power Supply Based on Capacitor and Battery for Accurate Regulation of the Pulsed High Current for Inductive Load. IEEE Trans. Power Electron. 2024, 39, 7144–7155. [Google Scholar] [CrossRef]

- Elgenedy, M.A.; Massoud, A.M.; Ahmed, S.; Williams, B.W.; McDonald, J.R. A Modular Multilevel Voltage-Boosting Marx Pulse-Waveform Generator for Electroporation Applications. IEEE Trans. Power Electron. 2019, 34, 10575–10589. [Google Scholar] [CrossRef]

- Li, H.; Zhang, C.; Wang, L.; Li, Z.; An, Y.; Liu, X.; Liang, X. A Repetitive High-Current Pulse Generator Circuit Based on Multistage Pulse Transformers. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 3189–3200. [Google Scholar] [CrossRef]

- Darwish, A.; Elgenedy, M.A.; Finney, S.J.; Williams, B.W.; McDonald, J.R. A Step-Up Modular High-Voltage Pulse Generator Based on Isolated Input-Parallel/Output-Series Voltage-Boosting Modules and Modular Multilevel Submodules. IEEE Trans. Ind. Electron. 2019, 66, 2207–2216. [Google Scholar] [CrossRef]

- Palanas, P.J.; Yu, K.; Zeng, Y.; Xie, X. Analysis and Design of a Novel LLC CCPS for Repetitive Pulsed Power Applications. IEEE Trans. Power Electron. 2023, 38, 14004–14016. [Google Scholar] [CrossRef]

- Kouro, S.; Malinowski, M.; Gopakumar, K.; Pou, J.; Franquelo, L.G.; Wu, B.; Rodriguez, J.; Perez, M.A.; Leon, J.I. Recent Advances and Industrial Applications of Multilevel Converters. IEEE Trans. Ind. Electron. 2010, 57, 2553–2580. [Google Scholar] [CrossRef]

- Li, W.; Grégoire, L.A.; Bélanger, J. A Modular Multilevel Converter Pulse Generation and Capacitor Voltage Balance Method Optimized for FPGA Implementation. IEEE Trans. Ind. Electron. 2015, 62, 2859–2867. [Google Scholar] [CrossRef]

- Rosas-Caro, J.C.; Ramirez, J.M.; Peng, F.Z.; Valderrabano, A. A DC–DC multilevel boost converter. IET Power Electron. 2008, 3, 129–137. [Google Scholar] [CrossRef]

- Arvindan, A.N.; Akshay, D.K.; Siby, E.; Keerthana, K.M. Efficacy of hysteresis current control in the single-phase vienna rectifier topologies for improved power quality. In Proceedings of the 2017 International Conference on Power and Embedded Drive Control (ICPEDC), Chennai, India, 16–18 March 2017; pp. 318–325. [Google Scholar] [CrossRef]

- Mucchetti, G.; Gatti, M.; Neviani, E. Electrical Conductivity Changes in Milk Caused by Acidification: Determining Factors. J. Dairy Sci. 1994, 77, 940–944. [Google Scholar] [CrossRef]

- Norberg, E.; Hogeveen, H.; Korsgaard, I.R.; Friggens, N.C.; Sloth, K.H.M.N.; Løvendahl, P. Electrical Conductivity of Milk: Ability to Predict Mastitis Status. J. Dairy Sci. 2004, 87, 1099–1107. [Google Scholar] [CrossRef]

- Lopes, A.M.; Machado, J.A.T.; Ramalho, E.; Silva, E. Milk Characterization Using Electrical Impedance Spectroscopy and Fractional Models. Food Anal. Methods 2017, 11, 901–912. [Google Scholar] [CrossRef]

- Scandurra, G.; Cardillo, E.; Ciofi, C.; Ferro, L. UHT Milk Characterization by Electrical Impedance Spectroscopy. Appl. Sci. 2022, 12, 7559. [Google Scholar] [CrossRef]

- Nannam, H.C.; Banerjee, A. A Detailed Modeling and Comparative Analysis of Hysteresis Current Controlled Vienna Rectifier and Space Vector Pulse Width Modulated Vienna Rectifier in Mitigating the Harmonic Distortion on the Input Mains. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 371–375. [Google Scholar] [CrossRef]

- Kolar, J.W.; Zach, F.C. A novel three-phase utility interface minimizing line current harmonics of high-power telecommunications rectifier modules. IEEE Trans. Ind. Electron. 1997, 44, 456–467. [Google Scholar] [CrossRef]

- Kolar, J.W.; Drofenik, U.; Zach, F.C. Space vector based analysis of the variation and control of the neutral point potential of hysteresis current controlled three-phase/switch/level PWM rectifier systems. In Proceedings of the 1995 International Conference on Power Electronics and Drive Systems, PEDS 95, Singapore, 21–24 February 1995; pp. 22–33. [Google Scholar] [CrossRef]

- Lesnicar, A.; Marquardt, R. An innovative modular multilevel converter topology suitable for a wide power range. In Proceedings of the 2003 IEEE Bologna Power Tech Conference Proceedings, Bologna, Italy, 23–26 June 2003; Volume 3, pp. 272–277. [Google Scholar] [CrossRef]

- Martinez-Rodrigo, F.; Ramirez, D.; Rey-Boue, A.B.; De Pablo, S.; Herrero-de Lucas, L.C. Modular Multilevel Converters: Control and Applications. Energies 2017, 10, 1709. [Google Scholar] [CrossRef]

- Ricco, M.; Mathe, L.; Monmasson, E.; Teodorescu, R. FPGA-Based Implementation of MMC Control Based on Sorting Networks. Energies 2018, 11, 2394. [Google Scholar] [CrossRef]

- Darbas, C.; Olivier, J.-C.; Ginot, N.; Poitiers, F.; Batard, C. Cascaded Smart Gate Drivers for Modular Multilevel Converters Control: A Decentralized Voltage Balancing Algorithm. Energies 2021, 14, 3589. [Google Scholar] [CrossRef]

- IEEE Std 519-2022 (Revision of IEEE Std 519-2014); IEEE Standard for Harmonic Control in Electric Power Systems. IEEE: Piscataway, NJ, USA, 2022; pp. 1–31. [CrossRef]

- Żbik, K.; Onopiuk, A.; Górska-Horczyczak, E.; Wierzbicka, A. Trends and Opportunities in the Dairy Industry: A2 Milk and Processing Methods. Appl. Sci. 2024, 14, 6513. [Google Scholar] [CrossRef]

- Góngora-Nieto, M.M.; Sepúlveda, D.R.; Pedrow, P.; Barbosa-Cánovas, G.V.; Swanson, B.G. Food Processing by Pulsed Electric Fields: Treatment Delivery, Inactivation Level, and Regulatory Aspects. LWT Food Sci. Technol. 2002, 35, 375–388. [Google Scholar] [CrossRef]

| Heat Treatment | Temperature (°C) | Time | Main Effects | Drinkable | Odor (Cooked Milk, Caramelization, Sulfurous Notes) | Flavor (Cooked Milk, Caramelization, Sulfurous Notes) | Color | Texture (Viscosity) |

|---|---|---|---|---|---|---|---|---|

| Thermalization | 57–68 | 5 s to 30 min | Mildest treatment. Not suitable for drinking milk, but extends raw milk shelf life before further processing (e.g., cheese). | ✓ | ✓ | |||

| Pasteurization (LTLT) | 63–65 | 30 min | Traditional pasteurization. Produces drinkable milk. | ✓ | ✓ | ✓ | ✓ | |

| Pasteurization (HTST) | 72–80 | 15–30 s | Standard method for drinking milk. Kills pathogens, limited protein denaturation. | ✓ | ✓ | ✓ | ✓ | |

| High Pasteurization/ Yogurt | 90–95 | 3–5 min | Used mainly in yogurt production. Not typical for drinking milk due to flavor changes. | ✓ | ✓ | ✓ | ✓ | ✓ |

| Extended Shelf Life (ESL) | 125–140 | 1–10 s | Prolongs milk shelf life under refrigeration. Suitable for drinking milk if kept cold. | ✓ | ✓ | ✓ | ✓ | ✓ |

| Ultra-High Temperature (UHT) | 135–150 | 1–10 s | Enables ambient shelf life. Standard for shelf-stable drinking milk. | ✓ | ✓ | ✓ | ✓ | ✓ |

| In-Container Sterilization | 110–125 | 5 min or 10–20 min | Harshest treatment. Ambient-stable drinking milk, but with significant sensory changes (cooked notes, color darkening, thicker texture). | ✓ | ✓ | ✓ | ✓ | ✓ |

| [32] | [33] | [34] | [35] | [36] | [37] | [38] | [39] | [17,18] | [22,31] | Proposed | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of switches | 2 (at input) | 5 (per stage) | 2 (at input), 2 (per MMC module) | 5 (IGBT and thyristors) | 2 (at input), 14 (series MMC) | 9 (all structure) | 1 (per VBM—Voltage Boost Module), 2 (per MMC module) | 2 (at input) | 1 and 2, respectively | 8 and 12, respectively | 2 (at input), 2 (per MMC module) |

| Power supply | HVDC (DC source) | LVDC (DC source) | LVDC (DC source) | HVDC (battery bank) | LVDC (DC source) | LVDC (DC source) | LVDC (DC source) | LVDC (DC source) | HVDC | HVDC (several sources) | LVAC (voltage grid) |

| Output level | 500 V | 20 kV (peak to peak) | 20 kV (peak to peak) | 10 kV | 10 kV | 500 V | 10 kV | 1 kV | 2.5 kV and 4.5 kV, respectively | Input source-dependent | 10 kV (peak to peak) |

| Switch stress | High | High | High (input), Low (output MMC) | High (input), High (output filter) | High (input), Low (output MMC) | Low | Low | Low | High | High | Low |

| Waveform type | Unipolar pulse | Multiple waveforms | Bipolar pulse | Unipolar pulse | Multiple waveforms | Unipolar pulse | Unipolar pulse | Unipolar pulse | Unipolar pulse | Bipolar pulse | Bipolar pulse |

| Boost structure | DC-DC Boost | MARX circuit | MBC (Multilevel Boost Converter) | DC-DC Boost | Dual Boost converter | Transformer ratio | Multiple conventional DC-DC Boost with coupled Transformer | Half bridge with coupled Transformer | Without Boost structure | Without Boost structure | MBC (Multilevel Boost Converter) |

| Pulse structure | RLC circuit (Blumlein) | H-Bridge Transistor arrays | MMC half-bridge modules | Capacitor discharge by thyristor | Series Modular Multilevel Converter (SMMC) | Secondary Transformer induction | MMC half-bridge modules | Charge–discharge capacitor with diode bridge structures | Capacitor discharge by switches | H-bridge transistor arrays | MMC modules |

| Pulse duration | nS | mS | mS | mS | nS, |

| Item | Model | Description |

|---|---|---|

| , | 2× GC2M0160120D | SiC transistor 1.2 kV 160 mOhm |

| , | 2× GC2M0160120D | SiC transistor 1.2 kV 160 mOhm |

| Gate driver | Si8233AD | High-side/low-side 5 kV isolated driver |

| and | CI02S120C3 | 1.2 kV SiC diode 10 A |

| Measurement | ADE9113 | Isolated voltage and current amplifier |

| and | MPP105J2000D01 | Film capacitor 1 uF 2 kV |

| MPC104J1200D01 | Film capacitor 100 nF 1.2 kV | |

| EEF432130C | 170 uH 35 A inductor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domínguez-Soberanes, J.; Ruiz-Martinez, O.F.; Davalos Hernandez, F. Power Converter Design for Pulsed Electric Field-Based Milk Processing: A Proof of Concept. Foods 2025, 14, 2177. https://doi.org/10.3390/foods14132177

Domínguez-Soberanes J, Ruiz-Martinez OF, Davalos Hernandez F. Power Converter Design for Pulsed Electric Field-Based Milk Processing: A Proof of Concept. Foods. 2025; 14(13):2177. https://doi.org/10.3390/foods14132177

Chicago/Turabian StyleDomínguez-Soberanes, Julieta, Omar F. Ruiz-Martinez, and Fernando Davalos Hernandez. 2025. "Power Converter Design for Pulsed Electric Field-Based Milk Processing: A Proof of Concept" Foods 14, no. 13: 2177. https://doi.org/10.3390/foods14132177

APA StyleDomínguez-Soberanes, J., Ruiz-Martinez, O. F., & Davalos Hernandez, F. (2025). Power Converter Design for Pulsed Electric Field-Based Milk Processing: A Proof of Concept. Foods, 14(13), 2177. https://doi.org/10.3390/foods14132177