Fat Reduction in Peruvian Carrot (Arracacia xanthorrhiza) Snacks: Effectiveness of Edible Coatings and Optimization of Frying Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Peruvian Carrot Root Preparation (Snack Preparation)

2.2.1. Peruvian Carrot Root Sanitization

2.2.2. Frying the Peruvian Carrot Root

2.2.3. Frying Process Optimization

2.3. Edible Coating Preparation and Application

2.3.1. Film-Forming Solution Preparation

2.3.2. Coating Peruvian Carrot Root Slices

2.4. Quality Parameters Evaluated for the Peruvian Carrot Snacks

2.4.1. Peruvian Carrot Snacks’ Water Content

2.4.2. Fat Content

2.4.3. Sensory Evaluation of Peruvian Carrot Snacks

2.4.4. Color Assessment

2.5. Statistical Analysis

3. Results

3.1. Frying Optimization of Peruvian Carrot Snacks

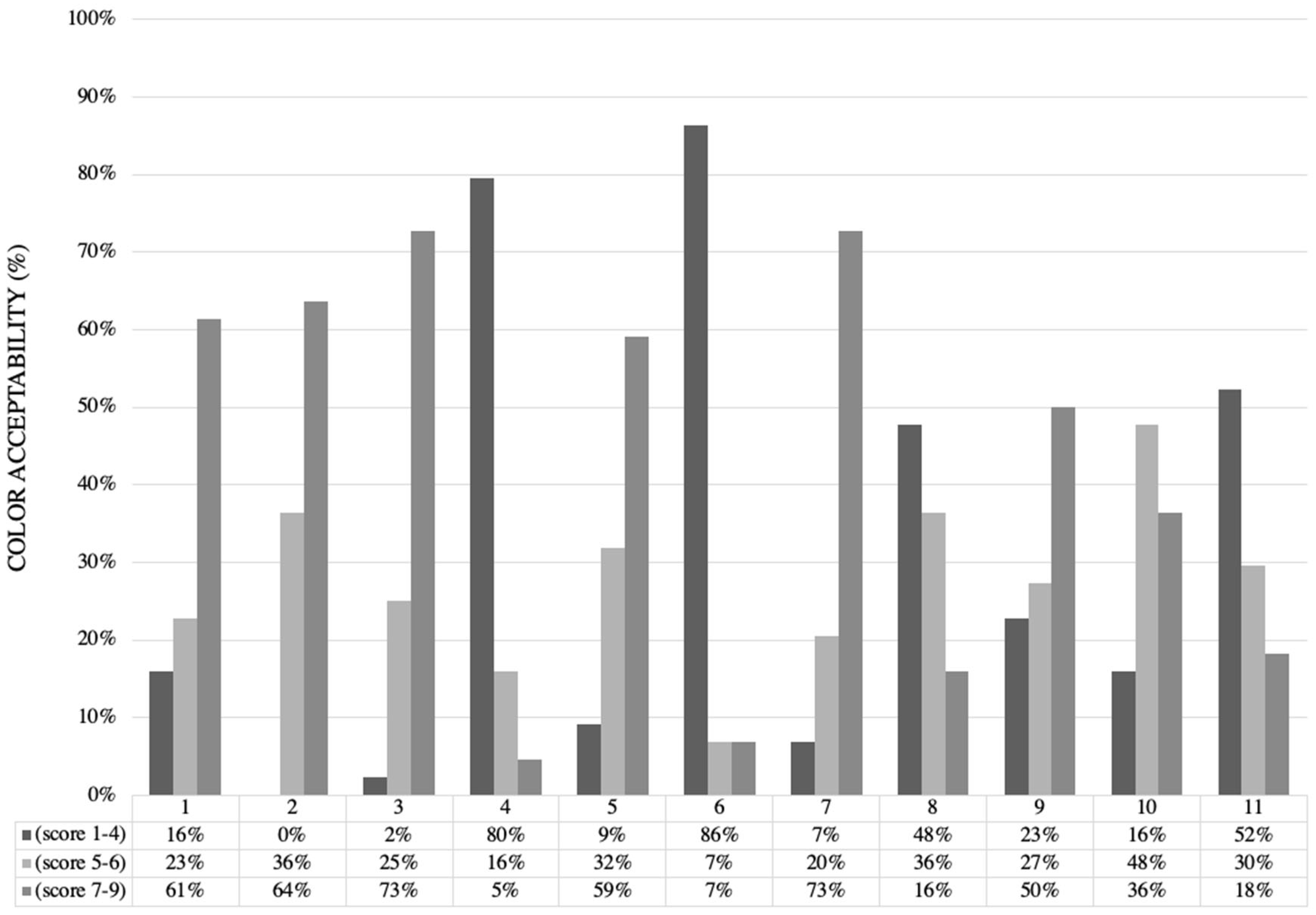

3.2. Sensory Evaluation of Peruvian Carrot Snacks

3.3. Frying Peruvian Carrot Snacks with an Edible Coating Made of Peruvian Carrot Starch

3.4. Sensory Evaluation of Coated Peruvian Carrot Snacks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soares de Mendonça, K.; Gomes Corrêa, J.L.; Junqueira, J.R.d.J.; Nunes de Carvalho, E.E.; Silveira, P.G.; Santos Uemura, J.H. Peruvian carrot chips obtained by microwave and microwave-vacuum drying. LWT 2023, 187, 115346. [Google Scholar] [CrossRef]

- Thereza, M.; Pedroso, M. A Cadeia Produtiva da Mandioquinha-Salsa: Implicações Para a Agenda Tecnológica e a Pesquisa Agronômica [Internet]. Brasília: Embrapa Hortaliças. 2020. Available online: https://www.embrapa.br/fale-conosco/sac (accessed on 17 October 2022).

- TACO. Tabela Brasileira de Composição de Alimentos, 4th ed.; NEPA, Ed.; UNICAMP: Campinas, Brazil, 2011. [Google Scholar]

- Leonel, M.; Cereda, M.P. Caracterização físico-química de algumas tuberosas amiláceas. Ciência Tecnol. Alimentos 2002, 22, 65–69. [Google Scholar] [CrossRef]

- Henz, G.P.; Reifschneider, F.J.B. Formas de apresentação e embalagens de mandioquinha-salsa no varejo brasileiro. Hortic. Bras. 2005, 23, 61–67. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Guo, X.; Qiang, J.; Cao, Y.; Zhang, S.; Yu, X. Influence of triacylglycerol structure on the formation of lipid oxidation products in different vegetable oils during frying process. Food Chem. 2025, 464, 141783. [Google Scholar] [CrossRef]

- Huang, X.; Wu, G.; Liang, X.; Li, H.; Zhang, H.; Jin, Q.; Wang, X. Physical fields assisted frying technologies for reducing oil content of fried food. Trends Food Sci. Technol. 2025, 155, 104806. [Google Scholar] [CrossRef]

- Brasil. Ministério da Saúde. RESOLUÇÃO N° 216, DE 15 DE SETEMBRO DE 2004 Dispõe sobre Regulamento Técnico de Boas Práticas Para Serviços de Alimentação [Internet]. 2004. Available online: https://bvsms.saude.gov.br/bvs/saudelegis/anvisa/2004/res0216_15_09_2004.html (accessed on 15 October 2024).

- Mohamed Latif, N.A.; Mat Ropi, A.A.; Dos Mohamad, A.M.; Shaharuddin, S. Fat reduction and characteristic enhancement of edible composite coating (Pectin-Maltodextrin) on fried potato chips. Mater. Today Proc. 2020, 31, A79–A84. [Google Scholar] [CrossRef]

- López, P.L.; Juncos, N.S.; Grosso, N.R.; Olmedo, R.H. Use of Humulus lupulus and Origanum vulgare as Protection Agents Against Oxidative Deterioration in “Deep-Fried Process”: Frying Model Assay with Sunflower Oil and High-Oleic Peanuts. Food Bioproc. Tech. 2024, 17, 1970–1984. [Google Scholar] [CrossRef]

- Abrante-Pascual, S.; Nieva-Echevarría, B.; Goicoechea-Oses, E. Vegetable Oils and Their Use for Frying: A Review of Their Compositional Differences and Degradation. Foods 2024, 13, 4186. [Google Scholar] [CrossRef]

- Jorge, N.; Lunardi, V.M. Influência dos tipos de óleos e tempos de fritura na perda de umidade e absorção de óleo em batatas fritas. Ciência Agrotecnologia 2005, 29, 635–641. [Google Scholar] [CrossRef]

- Cella, R.C.F.; Regitano-D’Arce, M.A.B.; Spoto, M.H.F. Comportamento do óleo de soja refinado utilizado em fritura por imersão com alimentos de origem vegetal. Ciência Tecnol. Alimentos 2002, 22, 111–116. [Google Scholar] [CrossRef]

- Jorge, N.; Soares, B.B.P.; Lunardi, V.M.; Malacrida, C.R. Alterações físico-químicas dos óleos de girassol, milho e soja em frituras. Quim Nova 2005, 28, 947–951. [Google Scholar] [CrossRef]

- Dodoo, D.; Adjei, F.; Tulashie, S.K.; Adukpoh, K.E.; Agbolegbe, R.K.; Gawou, K.; Manu, G.P. Quality evaluation of different repeatedly heated vegetable oils for deep-frying of yam fries. Meas. Food 2022, 7, 100035. [Google Scholar] [CrossRef]

- Márquez-Ruiz, G.; Velasco, J.; Holgado, F. Major dietary lipids in nutrition and health. In Advances in Food and Nutrition Research; Academic Press Inc.: Cambridge, MA, USA, 2023; pp. 1–49. [Google Scholar]

- Ateş, E.; Unal, K. The effects of deep-frying, microwave, oven and sous vide cooking on the acrylamide formation of gluten-free chicken nuggets. Int. J. Gastron. Food Sci. 2023, 31, 100666. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Yu, X.; Zhang, F.; Wang, A.; Wan, X.; Zhuang, P.; Jiao, J.; Zhang, Y. Foodomics-based chemical profiling and signature compound characterization of air-fried potato chips: The effect of thermal processing and fish oil treatment on advancing safety, nutrition, and flavor attributes. Food Biosci. 2025, 66, 106211. [Google Scholar] [CrossRef]

- Karnwal, A.; Kumar, G.; Singh, R.; Selvaraj, M.; Malik, T.; Al Tawaha, A.R.M. Natural biopolymers in edible coatings: Applications in food preservation. Food Chem. X 2025, 25, 102171. [Google Scholar] [CrossRef]

- Rodrigues, M.I.; Iemma, A.F. Estratégia experimental para fatoriais fracionados e delineamento composto central rotacional (DCCR). In Planejamento de Experimentos e Otimização de Processos, 2nd ed.; Casa do Espírito Amigo fraternidade Fé e, amor, Ed.; Taylor & Francis: Campinas, Brazil, 2009; pp. 135–152. [Google Scholar]

- Zhang, J.; Li, J.; Fan, L. Effect of starch granule size on the properties of dough and the oil absorption of fried potato crisps. Int. J. Biol. Macromol. 2024, 268, 131844. [Google Scholar] [CrossRef]

- Li, Y.; Bai, X.; Zhao, M.; Wang, H.; Feng, J.; Xia, X.; Liu, Q. Sodium alginate edible coating to reduce oil absorption of French fries with maintaining overall acceptability: Based on a water replacement mechanism. Int. J. Biol. Macromol. 2023, 236, 124042. [Google Scholar] [CrossRef]

- Salehi, F.; Ghazvineh, S.; Amiri, M. Effect of basil seed gum coating and ultrasound pretreatment on frying time, oil uptake, hardness, color indexes, and sensory properties of potato slices. Ultrason. Sonochem. 2024, 110, 107035. [Google Scholar] [CrossRef]

- Abdolshah, M.; Najafi, A.; Razavi, R.; Marboutian, S. Effect of curcumin loaded in nanoemulsion basil seed gum coating on the reduction of acrylamide and oil absorption in fried potato strips. Food Res. Int. 2025, 200, 115467. [Google Scholar] [CrossRef]

- Fakhouri, F.M. Bioplásticos Flexíveis e Biodegradáveis à Base de Amido e Gelatina; Universidade Estadual de Campinas: Campinas, Brazil, 2009. [Google Scholar]

- AOAC. Association of Official Analytical Chemists. In Official Methods of Analysis of the Association Analytical Chemists, 16th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1995; Volume 1. [Google Scholar]

- IAL. Instituto Adolfo Lutz. In Normas Analíticas do Instituto Adolfo Lutz. Métodos Químicos e Físicos Para Análise de Alimentos, 4th ed.; Instituto Adolfo Lutz: São Paulo, Brazil, 2008; Volume 1, pp. 122–124. [Google Scholar]

- Macfie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L.V. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- Hua, X.; Wang, K.; Yang, R.; Kang, J.; Yang, H. Edible coatings from sunflower head pectin to reduce lipid uptake in fried potato chips. LWT—Food Sci. Technol. 2015, 62, 1220–1225. [Google Scholar] [CrossRef]

- Faloye, O.R.; Sobukola, O.P.; Shittu, T.A.; Bakare, H.A.; Omidiran, A.T.; Akinlade, F.A.; Bamidele, O.P. Effect of assisted drying methods on the microstructure and related quality attributes of fried chicken nuggets. J. Agric. Food Res. 2024, 16, 101196. [Google Scholar] [CrossRef]

- Makinson, J.H.; Greenfield, H.; Wong, M.L.; Wills, R.B.H. Fat uptake during deep-fat frying of coated and uncoated foods. J. Food Compos. Anal. 1987, 1, 93–101. [Google Scholar] [CrossRef]

- Brannan, R.G.; Mah, E.; Schott, M.; Yuan, S.; Casher, K.L.; Myers, A.; Herrick, C. Influence of ingredients that reduce oil absorption during immersion frying of battered and breaded foods. Eur. J. Lipid Sci. Technol. 2014, 116, 240–254. [Google Scholar] [CrossRef]

- Gutiérrez-Silva, G.; Vásquez-Lara, F.; Heredia-Sandoval, N.G.; Islas-Rubio, A.R. Effect of High-Protein and High-Fiber Breaders on Oil Absorption and Quality Attributes in Chicken Nuggets. Foods 2023, 12, 4463. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, J.; Hu, B.; Yu, P.; Fan, L. Relationship between crust characteristics and oil uptake of potato strips with hot-air pre-drying during frying process. Food Chem. 2021, 360, 130045. [Google Scholar] [CrossRef]

- Rahman, M.S. Food stability beyond water activity and glass transtion: Macro-micro region concept in the state diagram. Int. J. Food Prop. 2009, 12, 726–740. [Google Scholar] [CrossRef]

- Pão de Açúcar. Batata Frita Ondulada Original Elma Chips Ruffles Pacote 68g [Internet]. Pão de açúcar. 2024. Available online: https://www.paodeacucar.com/produto/1623316/batata-frita-ondulada-original-elma-chips-ruffles-pacote-68g (accessed on 15 October 2024).

- Relva Verde. Relva Verde Alimentos Ltd.a: Batata-Baroa Chips (Mandioquinha) 80g [Internet]. 2024. Available online: https://www.lojarelvaverde.com.br/batata-baroa-chips-mandioquinha-80g-p2800?srsltid=AfmBOoqJKw6cwP62B46056tn8FbHV71rjcHQQZupPkbNOG9zTIxLPLl3 (accessed on 15 October 2024).

- Damy, P.d.C.; Jorge, N. Absorção de óleo de soja refinado e gordura vegetal hidrogenada durante o processo de fritura descontínua de batata chips. Aliment. Nutrição 2003, 14, 23–26. [Google Scholar]

- Kita, A.; Lisińska, G.; Gołubowska, G. The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chem. 2007, 102, 1–5. [Google Scholar] [CrossRef]

- Okon, U.B.; Sobukola, O.P.; Adebowale, A.A.; Bakare, H.A.; Omidiran, A.T.; Akinlade, F.A. Effect of process variables on some quality attributes of instant ‘Akara iwe’-a cassava based fried snack from grits. Appl. Food Res. 2022, 2, 100115. [Google Scholar] [CrossRef]

- Cardello, H.M.A.B.; Cardello, L. Teor de vitamina, C atividade de ascorbato oxidase e perfil sensorial de manga (Mangífera índica L.) Var. Haden, durante o amadurecimento. Ciência Tecnol. Alimentos 1998, 18, 211–217. [Google Scholar] [CrossRef]

- Sanibal, E.A.A.; Rodas, M.A.d.B.; Della Torre, J.C.d.M.; Mancini-Filho, J. Avaliação da qualidade sensorial de batata frita, óleo de soja e gordura parcialmente hidrogenada de soja em tempos de fritura variáveis. Rev. Inst. Adolfo Lutz 2004, 63, 80–86. [Google Scholar] [CrossRef]

- Querido, A.F. Estudo da Influência de Técnicas na Minimização da Incorporação de Óleo Durante o Processo de Fritura de Maçã [Tese (Doutorado em Tecnologia de Alimentos)]; Universidade Estadual de Campinas: Campinas, Brazil, 2005. [Google Scholar]

- Sothornvit, R. Edible coating and post-frying centrifuge step effect on quality of vacuum-fried banana chips. J. Food Eng. 2011, 107, 319–325. [Google Scholar] [CrossRef]

- Yu, L.; Li, J.; Ding, S.; Hang, F.; Fan, L. Effect of guar gum with glycerol coating on the properties and oil absorption of fried potato chips. Food Hydrocoll. 2016, 54, 211–219. [Google Scholar] [CrossRef]

- Gao, Y.; Si, X.; Nian, X.; Lian, M.; Wang, M. Effect of Lycium barbarum L. polysaccharides on the quality of potato chips under low temperature frying and the mechanism of its action. LWT 2024, 206, 116588. [Google Scholar] [CrossRef]

- Khalil, A. Quality of french fried potatoes as influenced by coating with hydrocolloids. Food Chem. 1999, 66, 201–208. [Google Scholar] [CrossRef]

| Factors | Responses | |||||||

|---|---|---|---|---|---|---|---|---|

| Treatment | Factor Level (x) | Time (s) | Factor Level (y) | Temperature (°C) | Water Content (%) * | Fat Content (%) * | Sensorial Color (Score) | Delta E (ΔE) |

| 1 | −1 | 30 | −1 | 146 | 8.14 ± 0.10 b | 7.43 ± 0.10 d | 6.81 a | 26.05 bc |

| 2 | 1 | 90 | −1 | 146 | 6.23 ± 0.09 d | 5.63 ± 0.08 g | 7.02 a | 21.51 cd |

| 3 | −1 | 30 | 1 | 174 | 3.37 ± 0.10 h | 8.08 ± 0.09 c | 7.18 a | 37.74 ab |

| 4 | 1 | 90 | 1 | 174 | 2.11 ± 0.08 i | 6.06 ± 0.02 f | 3.04 c | 29.92 abc |

| 5 | 0 | 60 | −1.414 | 140 | 10.17 ± 0.11 a | 6.50 ± 0.09 e | 6.63 a | 13.30 d |

| 6 | 0 | 60 | 1.414 | 180 | 3.66 ± 0.10 g | 6.62 ± 0.08 e | 3.00 c | 29.64 abc |

| 7 | −1.414 | 18 | 0 | 160 | 4.84 ± 0.02 f | 7.35 ± 0.15 d | 7.09 a | 32.66 abc |

| 8 | 1.414 | 102 | 0 | 160 | 6.75 ± 0.06 c | 8.65 ± 0.03 b | 4.61 b | 31.24 abc |

| 9 | 0 | 60 | 0 | 160 | 5.40 ± 0.05 e | 9.21 ± 0.08 a | 6.09 a | 38.67 a |

| 10 | 0 | 60 | 0 | 160 | 5.30 ± 0.06 e | 9.03 ± 0.07 a | 6.04 a | 33.21 abc |

| 11 | 0 | 60 | 0 | 160 | 5.42 ± 0.09 e | 9.25 ± 0.09 a | 4.70 b | 36.53 ab |

| SS | df | MS | F calc | F tab (5%) | p | |

|---|---|---|---|---|---|---|

| Water content | ||||||

| Regression | 42.46 | 4 | 10.62 | 7.72 | 4.53 | 0.0005 |

| Residue | 8.25 | 6 | 1.38 | |||

| Lack of Fit | 8.25 | 4 | 2.06 | 528.62 | 19.25 | |

| Pure error | 0.01 | 2 | 0.00 | |||

| Total | 50.72 | 10 | ||||

| Fat | ||||||

| Regression | 12.4 | 3 | 4.13 | 6.05 | 4.35 | 0.0001 |

| Residue | 4.78 | 7 | 0.68 | |||

| Lack of Fit | 4.76 | 5 | 0.95 | 66.39 | 19.30 | |

| Pure error | 0.03 | 2 | 0.01 | |||

| Total | 17.19 | 10 | ||||

| Sensorial color | ||||||

| Regression | 21.20 | 3 | 7.07 | 13.9 | 3.07 | 0.08 |

| Residue | 3.56 | 7 | 0.51 | |||

| Lack of Fit | 2.32 | 5 | 0.46 | 0.74 | 9.29 | |

| Pure error | 1.24 | 2 | 0.62 | |||

| Total | 24.76 | 10 | ||||

| Delta E | ||||||

| Regression | 482.63 | 2 | 241.31 | 23.86 | 4.46 | 0.03 |

| Residue | 80.90 | 8 | 10.11 | |||

| Lack of Fit | 65.73 | 6 | 10.95 | 1.44 | 19.33 | |

| Pure error | 15.18 | 2 | 7.59 | |||

| Total | 563.53 | 10 | ||||

| Treatment | Starch (%) | Glycerol (%) | Temperature (°C) | Time (s) | Water Content (%) | Water Content Reduction | Fat Content (%) | Fat Absorption Reduction |

|---|---|---|---|---|---|---|---|---|

| 1 | C | C | 160 | 18 | 4.84 ± 0.02 a | 7.35 ± 0.15 a | ||

| 2 | C | C | 174 | 30 | 3.37 ± 0.10 b | 8.08 ± 0.09 a | ||

| 3 | 3 | 20 | 160 | 18 | 2.51 ± 0.11 c | 48% | 5.52 ± 0.22 b | 25% |

| 4 | 3 | 20 | 174 | 30 | 1.69 ± 0.16 d | 50% | 5.17 ± 0.40 b | 36% |

| 5 | 5 | 10 | 160 | 18 | 3.32 ± 0.39 b | 31% | 3.65 ± 0.46 c | 50% |

| 6 | 5 | 10 | 174 | 30 | 1.28 ± 0.19 d | 63% | 5.50 ± 0.41 b | 32% |

| Treatment | Global Appearance | Shininess | Color | Flavor | Texture |

|---|---|---|---|---|---|

| 1 | 7.23 a | 7.15 a | 7.46 a | 6.15 a | 6.21 a |

| 2 | 5.06 b | 5.06 b | 4.92 b | 5.75 a | 6.38 a |

| 3 | 7.48 a | 7.27 a | 7.44 a | 6.40 a | 6.52 a |

| 4 | 6.08 a | 6.04 a | 6.27 a | 5.98 a | 6.54 a |

| 5 | 7.77 a | 7.54 a | 7.81 a | 6.60 a | 6.52 a |

| 6 | 6.56 a | 6.54 a | 6.48 a | 6.17 a | 6.44 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, V.d.S.; Arias, L.V.A.; Velasco, J.I.; Fakhouri, F.M.; de Oliveira, R.A. Fat Reduction in Peruvian Carrot (Arracacia xanthorrhiza) Snacks: Effectiveness of Edible Coatings and Optimization of Frying Conditions. Foods 2025, 14, 1895. https://doi.org/10.3390/foods14111895

Silva VdS, Arias LVA, Velasco JI, Fakhouri FM, de Oliveira RA. Fat Reduction in Peruvian Carrot (Arracacia xanthorrhiza) Snacks: Effectiveness of Edible Coatings and Optimization of Frying Conditions. Foods. 2025; 14(11):1895. https://doi.org/10.3390/foods14111895

Chicago/Turabian StyleSilva, Viviane de Souza, Luna Valentina Angulo Arias, José Ignacio Velasco, Farayde Matta Fakhouri, and Rafael Augustus de Oliveira. 2025. "Fat Reduction in Peruvian Carrot (Arracacia xanthorrhiza) Snacks: Effectiveness of Edible Coatings and Optimization of Frying Conditions" Foods 14, no. 11: 1895. https://doi.org/10.3390/foods14111895

APA StyleSilva, V. d. S., Arias, L. V. A., Velasco, J. I., Fakhouri, F. M., & de Oliveira, R. A. (2025). Fat Reduction in Peruvian Carrot (Arracacia xanthorrhiza) Snacks: Effectiveness of Edible Coatings and Optimization of Frying Conditions. Foods, 14(11), 1895. https://doi.org/10.3390/foods14111895