The Importance of Molecular Structure for Textural and Physicochemical Properties of Extruded Wheat Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extrusion

2.3. Fine Molecular Structure of Starch

2.4. Physicochemical Properties of Extrudates

2.4.1. Sectional Expansion Index (SEI) and Apparent Density

2.4.2. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.4.3. Color

2.4.4. Hardness and Crispness

2.5. Statistical Analysis

3. Results

3.1. Proximate Composition Analysis

3.2. SME with Varied Extrusion Conditions and Wheat Varieties

3.3. Changes in the Molecular Structure of Wheat Flour Extrudates and Wheat Starch

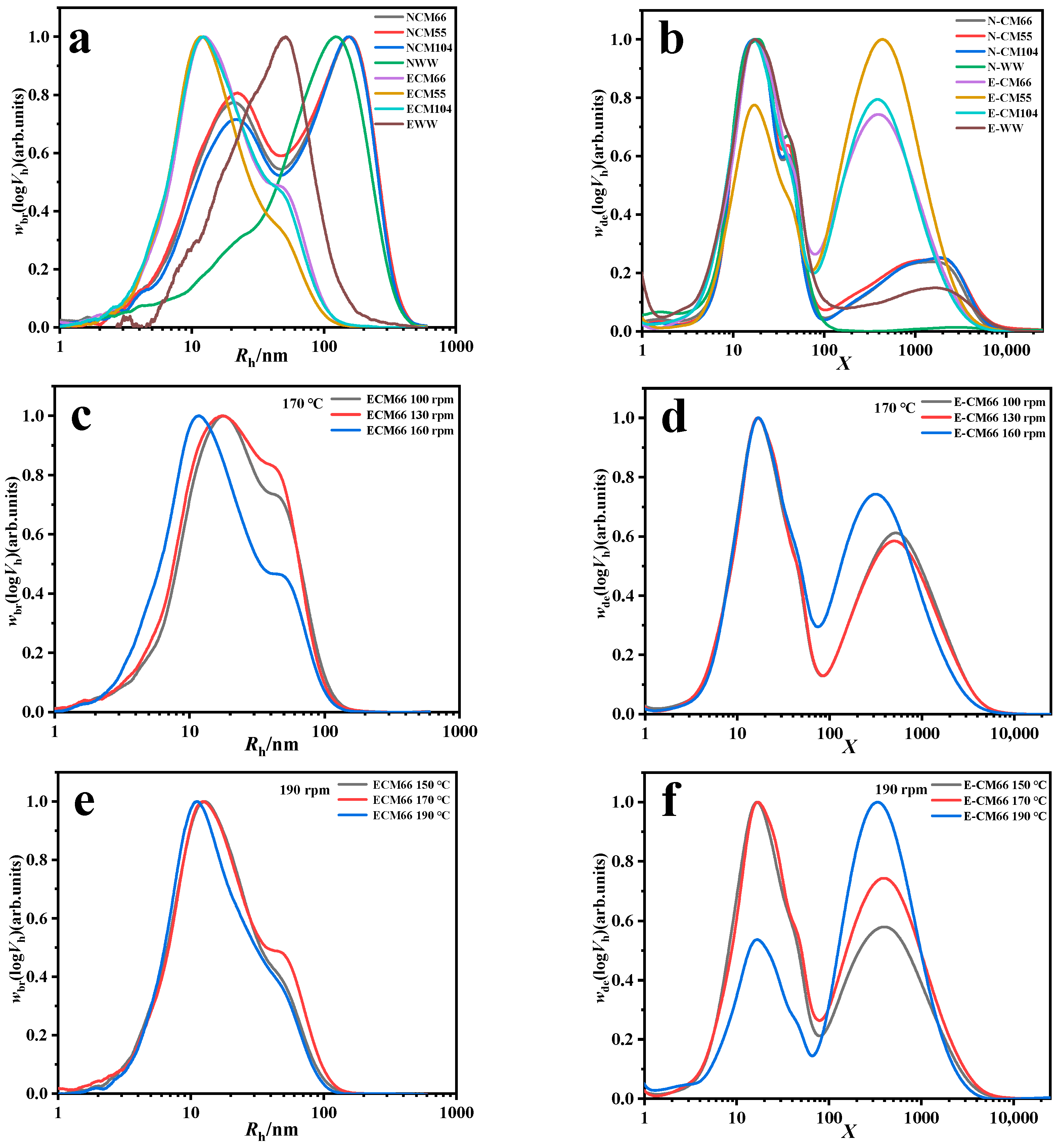

3.3.1. Molecular Structure of Native Starch from Different Wheat Varieties

3.3.2. Changes in Starch Molecular Structure of Different Wheat Flour Varieties Under Extrusion

3.3.3. Changes in Starch Molecular Structure of CM 66 Under Different Extrusion Conditions

3.4. The Impact of Extrusion Parameters on the Physicochemical Properties of Extrudates

3.4.1. SEI, Apparent Density, Hardness, and Crispness

3.4.2. WAI and WSI

3.4.3. Color

3.5. Selection of Different Wheat Varieties

3.6. Extrusion Parameter Modulation for Better Physicochemical Properties of Wheat Flour Extrudates

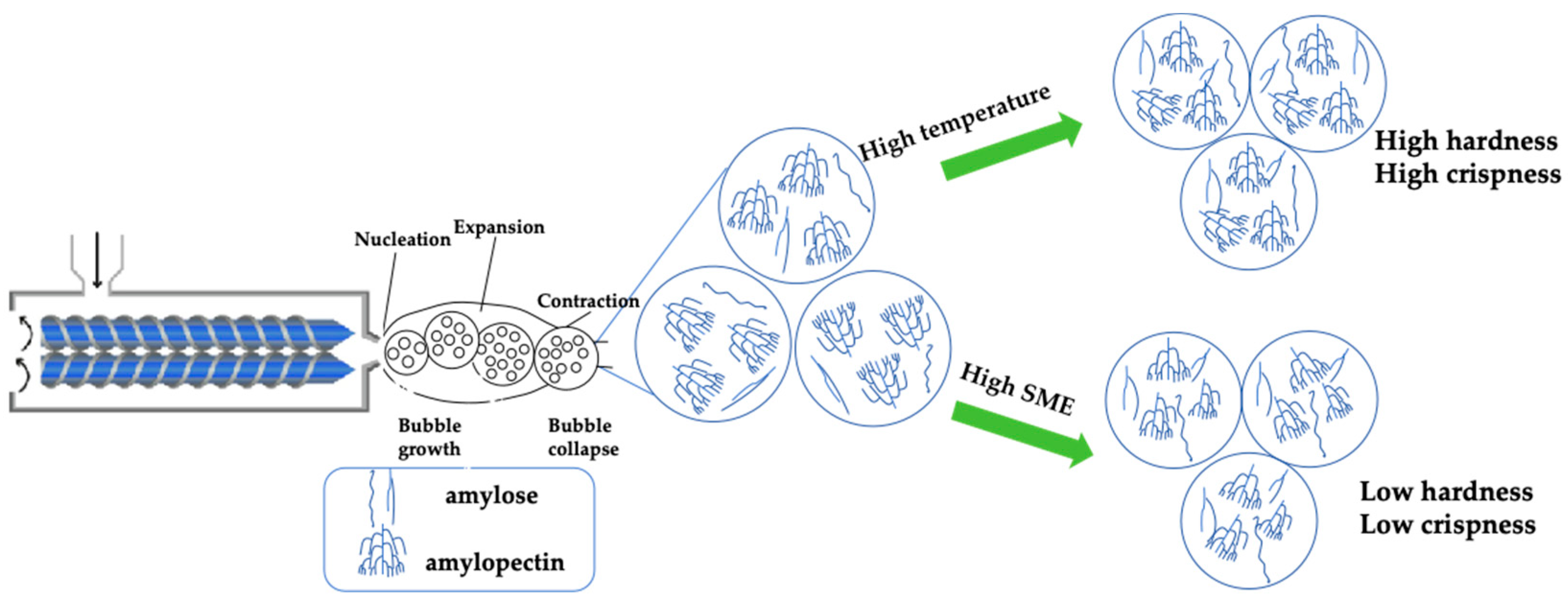

3.7. Screw Speed and Temperature Effects on the Texture of Extruded Grains: Hardness and Crispness

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lisiecka, K.; Wójtowicz, A.; Samborska, K.; Mitrus, M.; Oniszczuk, T.; Combrzyński, M.; Soja, J.; Lewko, P.; Kasprzak Drozd, K.; Oniszczuk, A. Structure and texture characteristics of novel snacks expanded by various methods. Materials 2023, 16, 1541. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Yu, L.; Su, B.; Liu, P.; Wang, J.; Liu, H.; Chen, L. Rheological properties of starches with different amylose/amylopectin ratios. J. Cereal Sci. 2009, 49, 371–377. [Google Scholar] [CrossRef]

- Chinnaswamy, R.; Hanna, M. Macromolecular and functional properties of native and extrusion-cooked corn starch. Cereal Chem. 1990, 67, 490–499. [Google Scholar]

- Carvalho, C.W.P.; Mitchell, J.R. Effect of Sucrose on Starch Conversion and Glass Transition of Nonexpanded Maize and Wheat Extrudates. Cereal Chem. 2001, 78, 342–348. [Google Scholar] [CrossRef]

- Mezreb, K.; Goullieux, A.; Ralainirina, R.; Queneudec, M. Application of image analysis to measure screw speed influence on physical properties of corn and wheat extrudates. J. Food Eng. 2003, 57, 145–152. [Google Scholar] [CrossRef]

- Pamies, B.V.; Roudaut, G.; Dacremont, C.; Meste, M.L.; Mitchell, J.R. Understanding the texture of low moisture cereal products: Mechanical and sensory measurements of crispness. J. Sci. Food Agric. 2000, 80, 1679–1685. [Google Scholar] [CrossRef]

- Ding, Q.-B.; Ainsworth, P.; Tucker, G.; Marson, H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J. Food Eng. 2005, 66, 283–289. [Google Scholar] [CrossRef]

- Kristiawan, M.; Micard, V.; Maladira, P.; Alchamieh, C.; Maigret, J.-E.; Réguerre, A.-L.; Emin, M.; Della Valle, G. Multi-scale structural changes of starch and proteins during pea flour extrusion. Food Res. Int. 2018, 108, 203–215. [Google Scholar] [CrossRef]

- Kristiawan, M.; Chaunier, L.; Sandoval, A.J.; Della Valle, G. Extrusion—Cooking and expansion. In Breakfast Cereals and How They Are Made; Elsevier: Amsterdam, The Netherlands, 2020; pp. 141–167. [Google Scholar]

- Zambrano, Y.; Contardo, I.; Moreno, M.C.; Bouchon, P. Effect of extrusion temperature and feed moisture content on the microstructural properties of rice-flour pellets and their impact on the expanded product. Foods 2022, 11, 198. [Google Scholar] [CrossRef]

- Della Valle, G.; Vergnes, B.; Colonna, P.; Patria, A. Relations between rheological properties of molten starches and their expansion behaviour in extrusion. J. Food Eng. 1997, 31, 277–295. [Google Scholar] [CrossRef]

- Rangira, I.; Gu, B.J.; Ek, P.; Ganjyal, G.M. Pea starch exhibits good expansion characteristics under relatively lower temperatures during extrusion cooking. J. Food Sci. 2020, 85, 3333–3344. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Li, M.; Chen, S.; Hui, Y.; Tang, A.; Wei, Y. Effects of flour dynamic viscosity on the quality properties of buckwheat noodles. Carbohydr. Polym. 2019, 207, 815–823. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Hasjim, J.; Xie, F.; Halley, P.J.; Gilbert, R.G. Shear degradation of molecular, crystalline, and granular structures of starch during extrusion. Starch-Stärke 2014, 66, 595–605. [Google Scholar] [CrossRef]

- Wang, K.; Tan, C.; Tao, H.; Yuan, F.; Guo, L.; Cui, B. Effect of different screw speeds on the structure and properties of starch straws. Carbohydr. Polym. 2024, 328, 121701. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, I.O. Interaction of starch with some food macromolecules during the extrusion process and its effect on modulating physicochemical and digestible properties. A review. Carbohydr. Polym. Technol. Appl. 2023, 5, 100294. [Google Scholar] [CrossRef]

- Shi, M.; Chen, S.; Liu, Z.; Ji, X.; Yan, Y. Effects of soy protein isolate hydrolysate on the structural and functional properties of yam starch during extrusion. Int. J. Biol. Macromol. 2025, 287, 138551. [Google Scholar] [CrossRef]

- Chanvrier, H.; Uthayakumaran, S.; Lillford, P. Rheological properties of wheat flour processed at low levels of hydration: Influence of starch and gluten. J. Cereal Sci. 2007, 45, 263–274. [Google Scholar] [CrossRef]

- Zou, X.; Wang, X.; Peng, P.; Ma, Q.; Zhang, X.; Zou, L.; Zhou, J.; Hu, X. Glutenin-gliadin ratio changes combining heat-moisture treatment significantly influences the in vitro digestibility of starch in recombinant wheat flours. Int. J. Biol. Macromol. 2023, 248, 125920. [Google Scholar] [CrossRef]

- Ge, F.; Sun, Y.; Yang, C.; Cheng, W.; Wang, Z.; Xia, X.; Wu, D.; Tang, X. Exploring the relationship between starch structure and physicochemical properties: The impact of extrusion on highland barley flour. Food Res. Int. 2024, 183, 114226. [Google Scholar] [CrossRef]

- Vilaplana, F.; Gilbert, R.G. Two-Dimensional Size/Branch Length Distributions of a Branched Polymer. Macromolecules 2010, 43, 7321–7329. [Google Scholar] [CrossRef]

- Castro, J.V.; Dumas, C.; Chiou, H.; Fitzgerald, M.A.; Gilbert, R.G. Mechanistic information from analysis of molecular weight distributions of starch. Biomacromolecules 2005, 6, 2248–2259. [Google Scholar] [CrossRef] [PubMed]

- Syahariza, Z.A.; Sar, S.; Hasjim, J.; Tizzotti, M.J.; Gilbert, R.G. The importance of amylose and amylopectin fine structures for starch digestibility in cooked rice grains. Food Chem. 2013, 136, 742–749. [Google Scholar] [CrossRef] [PubMed]

- Antwi, C.K.; Rosa-Sibakov, N.; Emmambux, M.N. Impact of added enzyme-treated bran on the techno-functional properties of puffed-extruded sorghum snack. J. Cereal Sci. 2024, 120, 104051. [Google Scholar] [CrossRef]

- Nascimento, T.A.; Calado, V.; Carvalho, C.W.P. Effect of Brewer’s spent grain and temperature on physical properties of expanded extrudates from rice. LWT—Food Sci. Technol. 2017, 79, 145–151. [Google Scholar] [CrossRef]

- Acharya, S.; Kalahal, S.P.; Prajapati, S.; Patria, D.G.; Lin, J. Utilization of flaxseed by-product to develop a healthy brown rice extruded snack and identification of its physicochemical properties. Future Foods 2025, 11, 100566. [Google Scholar] [CrossRef]

- Ačkar, Đ.; Jozinović, A.; Babić, J.; Miličević, B.; Panak Balentić, J.; Šubarić, D. Resolving the problem of poor expansion in corn extrudates enriched with food industry by-products. Innov. Food Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Altan, A.; Yağci, S. Physicochemical characteristics and structural changes of fermented faba bean extrudates prepared by twin-screw extrusion. Food Chem. 2023, 411, 135502. [Google Scholar] [CrossRef]

- Meng, X.; Threinen, D.; Hansen, M.; Driedger, D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res. Int. 2010, 43, 650–658. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Q.; Zhao, S.; Guo, L.; Zhuang, X.; Chen, X.; Tao, T.; Ding, C. Effect of extrusion processing on the structural, functional, and physicochemical properties of wheat and wheat-based products: A review. Food Phys. 2025, 2, 100050. [Google Scholar] [CrossRef]

- Liu, W.-C.; Halley, P.J.; Gilbert, R.G. Mechanism of degradation of starch, a highly branched polymer, during extrusion. Macromolecules 2010, 43, 2855–2864. [Google Scholar] [CrossRef]

- Tang, Y.; Huang, Y.; Li, M.; Zhu, W.; Zhang, W.; Luo, S.; Zhang, Y.; Ma, J.; Jiang, Y. Balancing Maillard reaction products formation and antioxidant activities for improved sensory quality and health benefit properties of pan baked buns. Food Res. Int. 2024, 195, 114984. [Google Scholar] [CrossRef]

- Yaylayan, V.A.; Fichtali, J.; van de Voort, F.R. Production of Maillard reaction flavour precursors by extrusion processing. Food Res. Int. 1992, 25, 175–180. [Google Scholar] [CrossRef]

- Helou, C.; Jacolot, P.; Niquet-Léridon, C.; Gadonna-Widehem, P.; Tessier, F.J. Maillard reaction products in bread: A novel semi-quantitative method for evaluating melanoidins in bread. Food Chem. 2016, 190, 904–911. [Google Scholar] [CrossRef]

- Zhang, G.; Ni, C.; Ding, Y.; Zhou, H.; Caizhi, O.; Wang, Q.; Wang, J.; Cheng, J. Effects of Low Moisture Extrusion on the Structural and Physicochemical Properties of Adlay (Coix lacryma-jobi L.) Starch-Based Polymers. Process Biochem. 2020, 96, 30–37. [Google Scholar] [CrossRef]

- Mesquita, C.D.B.; Leonel, M.; Mischan, M.M. Effects of processing on physical properties of extruded snacks with blends of sour cassava starch and flaxseed flour. Food Sci. Technol. 2013, 33, 404–410. [Google Scholar] [CrossRef]

- Baik, B.K.; Powers, J.; Nguyen, L.T. Extrusion of regular and waxy barley flours for production of expanded cereals. Cereal Chem. 2004, 81, 94–99. [Google Scholar] [CrossRef]

- Reyniers, S.; De Brier, N.; Ooms, N.; Matthijs, S.; Piovesan, A.; Verboven, P.; Brijs, K.; Gilbert, R.; Delcour, J. Amylose molecular fine structure dictates water–oil dynamics during deep-frying and the caloric density of potato crisps. Nat. Food 2020, 1, 736–745. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Luo, S.; Li, C.; Ye, J.; Liu, C.; Gilbert, R.G. Physicochemical and structural properties of pregelatinized starch prepared by improved extrusion cooking technology. Carbohydr. Polym. 2017, 175, 265–272. [Google Scholar] [CrossRef]

- Sanchez-Jimenez, V.; Fariñas, L.; Giacomozzi, A.S.; Ginel, A.; Quiles-Chuliá, A.; Gomez Alvarez-Arenas, T.E.; Benedito, J.; Garcia-Perez, J.V. Non-invasive textural assessment of puffed corn cakes using air-coupled ultrasound. J. Food Eng. 2025, 392, 112470. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, K.L.; Maskan, M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

- Liu, Y.; Hsieh, F.; Heymann, H.; Huff, H.E. Effect of Process Conditions on the Physical and Sensory Properties of Extruded Oat-Corn Puff. J. Food Sci. 2000, 65, 1253–1259. [Google Scholar] [CrossRef]

- Naveena, B.; Singh, M. Effects of extrusion parameters on physical & textural properties of sorghum, barley, and chickpea-based composite extruded products. J. Food Process. Preserv. 2022, 46, e16564. [Google Scholar]

| Sample | T /°C | SS /rpm | MC /% | SME /W·h/kg | SEI | AD /g/cm3 | Hardness /N | Crispness /N/mm |

|---|---|---|---|---|---|---|---|---|

| ECM66-170-100 | 170 | 100 | 16 | 326.51 ± 6.53 g | 3.64 ± 0.30 a | 0.120 ± 0.031 cd | 69.36 ± 8.33 b | 9.11 ± 4.05 bc |

| ECM66-170-130 | 170 | 130 | 16 | 418.05 ± 7.37 e | 3.15 ± 0.24 b | 0.104 ± 0.013 cd | 58.8 ± 7.75 c | 8.40 ± 2.90 bcd |

| ECM66-170-160 | 170 | 160 | 16 | 510.77 ± 7.48 d | 2.85 ± 0.22 d | 0.165 ± 0.027 b | 39.26 ± 3.92 e | 6.02 ± 1.50 cd |

| ECM66-170-190 | 170 | 190 | 16 | 604.74 ± 27.18 b | 2.53 ± 0.17 e | 0.075 ± 0.008 d | 34.92 ± 5.21 e | 5.56 ± 1.08 d |

| ECM66-150-190 | 150 | 190 | 16 | 576.52 ± 9.40 c | 3.16 ± 0.62 b | 0.103 ± 0.011 cd | 43.61 ± 12.2 de | 5.65 ± 1.37 d |

| ECM66-190-190 | 190 | 190 | 16 | 617.05 ± 36.98 b | 1.59 ± 0.34 f | 0.329 ± 0.087 a | 54.69 ± 12.83 c | 9.52 ± 4.82 ab |

| ECM55-170-190 | 170 | 190 | 16 | 603.51 ± 25.55 b | 3.05 ± 0.26 cd | 0.144 ± 0.023 bc | 44.66 ± 6.61 de | 6.16 ± 1.70 cd |

| ECM104-170-190 | 170 | 190 | 16 | 660.24 ± 8.17 a | 1.78 ± 0.32 f | 0.120 ± 0.038 cd | 49.45 ± 6.44 cd | 7.43 ± 3.01 bcd |

| EWW-170-190 | 170 | 190 | 16 | 396.60 ± 3.46 f | 2.36 ± 0.25 e | 0.166 ± 0.064 b | 84.17 ± 17.25 a | 12.22 ± 5.4 a |

| Wheat Variety | Protein /% | Starch /% | AM /% | Ai /% | Lipid /% | Ash /% | WAI | WSI /% |

|---|---|---|---|---|---|---|---|---|

| CM55 | 9.27 ± 0.01 b | 77.33 ± 1.13 b | 27.98 ± 0.91 b | 94.99 ± 0.16 a | 0.53 ± 0.01 a | 0.51 ± 0.02 a | 2.32 ± 0.01 a | 8.52 ± 0.15 b |

| CM66 | 9.10 ± 0.26 b | 77.98 ± 0.49 ab | 31.08 ± 0.10 a | 92.86 ± 0.17 c | 0.31 ± 0.06 b | 0.43 ± 0.09 ab | 2.04 ± 0.01 b | 6.20 ± 0.05 c |

| CM104 | 8.09 ± 0.13 c | 79.60 ± 0.27 a | 29.01 ± 0.68 b | 93.53 ± 0.22 b | 0.47 ± 0.05 a | 0.36 ± 0.04 b | 2.05 ± 0.02 b | 6.30 ± 0.05 c |

| WW | 13.1 ± 0.11 a | 72.44 ± 0.26 c | 3.01 ± 0.48 c | 70.36 ± 0.11 d | 0.21 ± 0.05 b | 0.40 ± 0.01 b | 2.03 ± 0.01 b | 10.82 ± 0.08 a |

| Samples | 6 < X ≤ 12 | 12 < X ≤ 24 | 24 < X ≤ 36 | 36 < X ≤ 100 | X > 100 | /nm |

|---|---|---|---|---|---|---|

| NCM66 | 14.65 ± 0.09 B | 30.05 ± 0.15 B | 12.34 ± 0.10 B | 12.87 ± 0.92 B | 27.98 ± 0.91 B | 84.40 ± 1.19 B |

| NCM55 | 13.06 ± 0.25 C | 28.35 ± 0.22 C | 12.15 ± 0.41 B | 13.74 ± 0.41 B | 31.08 ± 0.10 A | 85.37 ± 2.27 B |

| NCM104 | 14.23 ± 0.92 BC | 30.00 ± 0.44 B | 12.37 ± 0.02 B | 12.81 ± 0.22 B | 29.01 ± 0.68 B | 86.66 ± 0.61 B |

| NWW | 19.33 ± 0.43 A | 37.95 ± 0.07 A | 16.94 ± 0.12 A | 19.02 ± 0.27 A | 3.01 ± 0.48 C | 102.35 ± 0.26 A |

| ECM66-170-100 | 11.59 ± 0.25 b | 21.02 ± 0.38 b | 9.38 ± 0.67 bcd | 9.91 ± 0.18 cd | 45.63 ± 0.92 e | 28.19 ± 0.52 b |

| ECM66-170-130 | 11.30 ± 0.40 b | 21.37 ± 0.09 b | 9.85 ± 0.12 b | 10.21 ± 0.60 c | 44.56 ± 0.11 f | 26.77 ± 0.22 c |

| ECM66-170-160 | 10.27 ± 0.57 cd | 19.02 ± 0.15 c | 8.77 ± 0.37 cd | 12.28 ± 0.45 b | 47.69 ± 0.21 d | 21.70 ± 0.36 ef |

| ECM66-170-190 | 9.57 ± 0.18 d | 18.63 ± 0.10 c | 8.96 ± 0.04 bcd | 11.75 ± 0.13 b | 48.80 ± 0.48 c | 23.21 ± 0.21 d |

| ECM66-150-190 | 11.91 ± 0.25 b | 20.98 ± 0.23 b | 9.44 ± 0.60 bc | 11.71 ± 0.61 b | 43.52 ± 0.19 f | 21.16 ± 0.21 f |

| ECM66-190-190 | 6.34 ± 0.17 f | 11.67 ± 0.19 e | 5.20 ± 0.11 f | 7.36 ± 0.30 e | 67.80 ± 0.35 a | 19.64 ± 0.58 g |

| ECM55-170-190 | 7.32 ± 0.55 e | 14.21 ± 0.08 d | 6.46 ± 0.33 e | 8.91 ± 0.70 d | 61.97 ± 0.54 b | 20.94 ± 0.33 f |

| ECM104-170-190 | 10.45 ± 0.42 c | 18.85 ± 0.34 c | 8.48 ± 0.51 d | 10.18 ± 0.96 c | 49.79 ± 0.63 c | 22.61 ± 0.38 de |

| EWW-170-190 | 15.61 ± 0.03 a | 28.85 ± 0.06 a | 14.49 ± 0.03 a | 17.36 ± 0.04 a | 19.47 ± 0.17 g | 48.71 ± 0.72 a |

| T | SS | SME | A | B1 | B2 | B3 | AM | ||

|---|---|---|---|---|---|---|---|---|---|

| A | −0.852 * | −0.509 | −0.598 | ||||||

| B1 | −0.803 | −0.523 | −0.602 | 0.984 ** | |||||

| B2 | −0.785 | −0.464 | −0.538 | 0.952 ** | 0.990 ** | ||||

| B3 | −0.758 | 0.069 | −0.001 | 0.661 | 0.696 | 0.749 | |||

| AM | 0.844 * | 0.422 | 0.505 | −0.972 ** | −0.990 ** | −0.991 ** | −0.789 | ||

| −0.143 | −0.901 * | −0.905 * | 0.607 | 0.664 | 0.645 | 0.066 | −0.573 | ||

| Hardness | 0.268 | −0.776 | −0.755 | 0.121 | 0.077 | −0.022 | −0.626 | 0.060 | 0.637 |

| Crispness | 0.668 | −0.509 | −0.444 | −0.350 | −0.374 | −0.446 | −0.892 * | 0.498 | 0.333 |

| WSI | −0.425 | 0.842 * | 0.790 | −0.066 | −0.082 | −0.030 | 0.291 | −0.004 | −0.582 |

| WAI | 0.034 | −0.933 ** | −0.927 ** | 0.430 | 0.408 | 0.328 | −0.059 | −0.325 | 0.694 |

| L* | 0.692 | −0.687 | −0.612 | −0.253 | −0.235 | −0.286 | −0.701 | 0.350 | 0.491 |

| a* | −0.465 | 0.797 | 0.750 | 0.019 | 0.035 | 0.117 | 0.644 | −0.164 | −0.600 |

| b* | −0.169 | 0.830* | 0.820 * | −0.239 | −0.191 | −0.087 | 0.517 | 0.059 | −0.662 |

| ΔE | −0.600 | 0.746 | 0.682 | 0.150 | 0.144 | 0.208 | 0.680 | −0.267 | −0.551 |

| SEI | −0.703 | −0.705 | −0.776 | 0.961 ** | 0.945 ** | 0.898 * | 0.528 | −0.909 * | 0.751 |

| AD | 0.770 | 0.278 | 0.347 | −0.850 * | −0.909 * | −0.950 ** | −0.777 | 0.930 ** | −0.563 |

| Sample | WAI | WSI | L* | a* | b* | ΔE |

|---|---|---|---|---|---|---|

| ECM66-170-100 | 1.66 ± 0.07 a | 81.30 ± 0.85 de | 77.66 ± 0.33 b | 2.46 ± 0.06 g | 18.08 ± 0.17 e | 25.44 ± 0.31 g |

| ECM66-170-130 | 1.39 ± 0.08 b | 83.60 ± 1.13 cd | 75.98 ± 0.49 c | 2.98 ± 0.18 f | 18.96 ± 0.52 d | 27.33 ± 0.71 ef |

| ECM66-170-160 | 1.41 ± 0.09 b | 83.33 ± 1.01 cd | 72.25 ± 0.44 e | 4.04 ± 0.09 c | 21.14 ± 0.32 b | 31.71 ± 0.36 c |

| ECM66-170-190 | 0.91 ± 0.07 c | 89.23 ± 0.08 a | 69.41 ± 0.60 f | 4.77 ± 0.17 a | 22.36 ± 0.37 a | 34.77 ± 0.69 b |

| ECM66-150-190 | 1.06 ± 0.13 c | 90.40 ± 1.54 a | 66.96 ± 0.73 g | 4.60 ± 0.17 b | 20.87 ± 0.36 b | 35.92 ± 0.81 a |

| ECM66-190-190 | 1.09 ± 0.14 c | 85.60 ± 1.98 bc | 76.33 ± 0.23 c | 3.23 ± 0.09 e | 20.04 ± 0.17 c | 27.78 ± 0.25 e |

| ECM55-170-190 | 1.02 ± 0.11 c | 86.45 ± 1.26 b | 74.10 ± 0.36 d | 3.71 ± 0.08 d | 20.88 ± 0.16 b | 30.07 ± 0.35 d |

| ECM104-170-190 | 1.65 ± 0.08 a | 80.93 ± 0.84 e | 76.03 ± 0.14 c | 2.97 ± 0.05 f | 18.60 ± 0.15 d | 27.07 ± 0.09 f |

| EWW-170-190 | 0.99 ± 0.03 c | 84.72 ± 1.77 bc | 82.68 ± 0.26 a | 0.80 ± 0.05 h | 16.16 ± 0.19 f | 20.33 ± 0.32 h |

| SME | A | B1 | B2 | B3 | AM | Hardness | Crispness | WSI | WAI | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | −0.840 | ||||||||||

| B1 | −0.870 | 0.996 ** | |||||||||

| B2 | −0.899 | 0.986 * | 0.997 ** | ||||||||

| B3 | −0.928 | 0.957 * | 0.979 * | 0.992 ** | |||||||

| AM | 0.884 | −0.992 ** | −0.999 ** | −0.999 ** | −0.986 * | ||||||

| −0.967 * | 0.948 | 0.960 * | 0.969 * | 0.969 * | −0.964 * | ||||||

| Hardness | −0.887 | 0.898 | 0.886 | 0.878 | 0.850 | −0.881 | 0.948 | ||||

| Crispness | −0.886 | 0.940 | 0.929 | 0.919 | 0.889 | −0.923 | 0.963 * | 0.994 ** | |||

| WSI | −0.098 | −0.276 | −0.189 | −0.114 | 0.008 | 0.151 | −0.112 | −0.372 | −0.369 | ||

| WAI | 0.505 | −0.055 | −0.143 | −0.222 | −0.342 | 0.182 | −0.288 | −0.060 | −0.046 | −0.895 | |

| L* | −0.759 | 33 | 0.776 | 0.754 | 0.705 | −0.764 | 0.843 | 0.970 * | 0.951 * | −0.559 | 0.135 |

| a* | 0.794 | −0.861 | −0.834 | −0.813 | −0.766 | 0.823 | −0.884 | −0.985 * | −0.976 * | 0.524 | −0.104 |

| b* | 0.681 | −0.844 | −0.803 | −0.769 | −0.701 | 0.785 | −0.814 | −0.941 | −0.940 | 0.662 | −0.281 |

| ΔE | 0.736 | −0.819 | −0.784 | −0.758 | −0.703 | 0.770 | −0.835 | −0.965 * | −0.951 * | 0.595 | −0.182 |

| SEI | −0.122 | −0.434 | −0.370 | −0.301 | −0.194 | 0.338 | −0.135 | −0.204 | −0.276 | 0.731 | −0.780 |

| AD | −0.636 | 0.475 | 0.451 | 0.444 | 0.419 | −0.444 | 0.630 | 0.813 | 0.746 | −0.435 | 0.013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, Y.; Wang, R.; Zhang, B.; Tang, Y.; Li, C.; Guo, B.; Li, M. The Importance of Molecular Structure for Textural and Physicochemical Properties of Extruded Wheat Flour. Foods 2025, 14, 1829. https://doi.org/10.3390/foods14101829

Chai Y, Wang R, Zhang B, Tang Y, Li C, Guo B, Li M. The Importance of Molecular Structure for Textural and Physicochemical Properties of Extruded Wheat Flour. Foods. 2025; 14(10):1829. https://doi.org/10.3390/foods14101829

Chicago/Turabian StyleChai, Yuan, Ruibin Wang, Bo Zhang, Yonglu Tang, Chaosu Li, Boli Guo, and Ming Li. 2025. "The Importance of Molecular Structure for Textural and Physicochemical Properties of Extruded Wheat Flour" Foods 14, no. 10: 1829. https://doi.org/10.3390/foods14101829

APA StyleChai, Y., Wang, R., Zhang, B., Tang, Y., Li, C., Guo, B., & Li, M. (2025). The Importance of Molecular Structure for Textural and Physicochemical Properties of Extruded Wheat Flour. Foods, 14(10), 1829. https://doi.org/10.3390/foods14101829