Development of a Reverse-Yield Factor Database Disaggregating Japanese Composite Foods into Raw Primary Commodity Ingredients Based on the Standard Tables of Food Composition in Japan

Abstract

1. Introduction

2. Materials and Methods

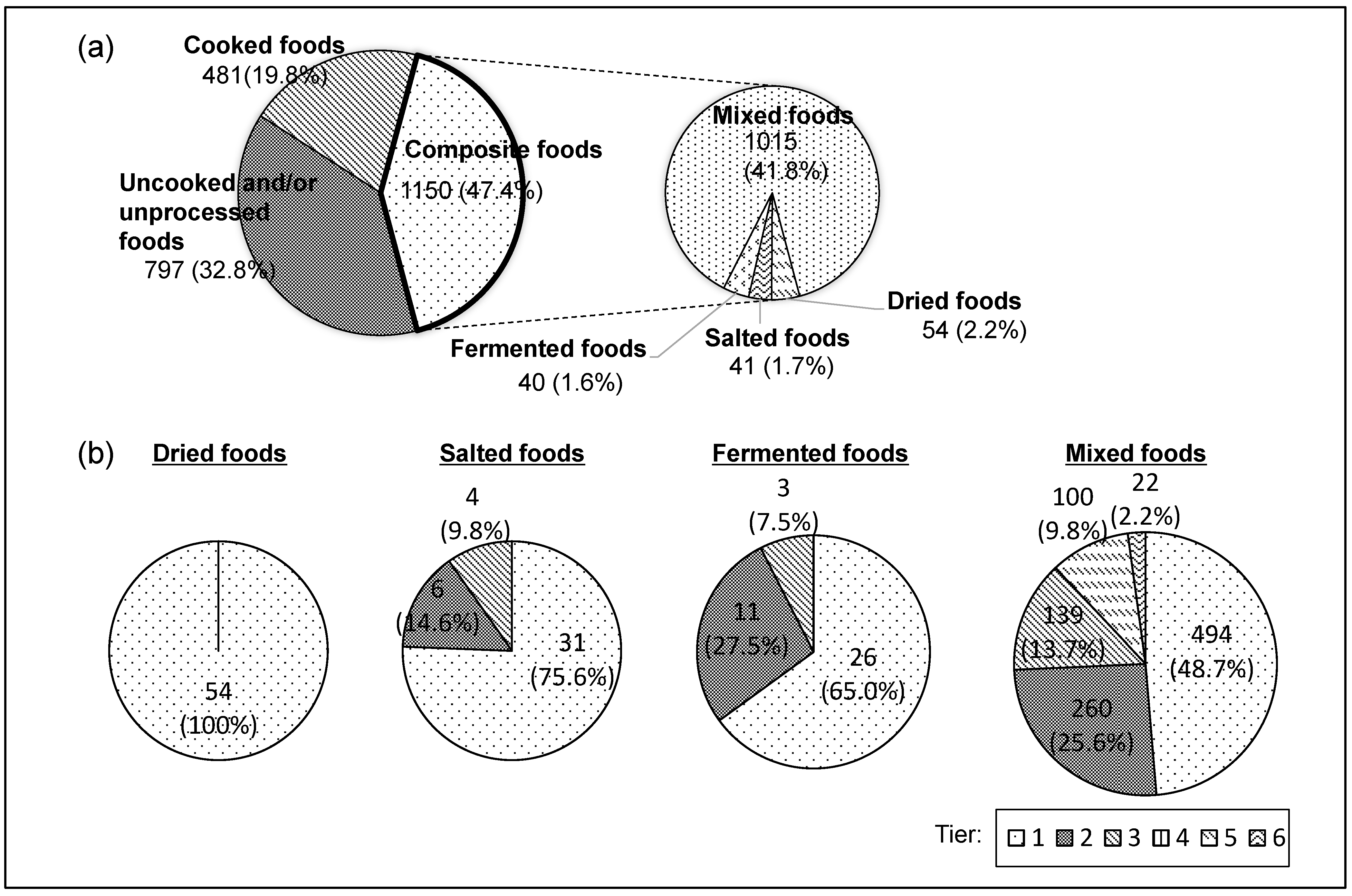

2.1. Categorization of Composite Foods

2.2. RFs for Dried Foods

2.3. RFs for Salted Foods

2.4. RFs for Fermented Foods

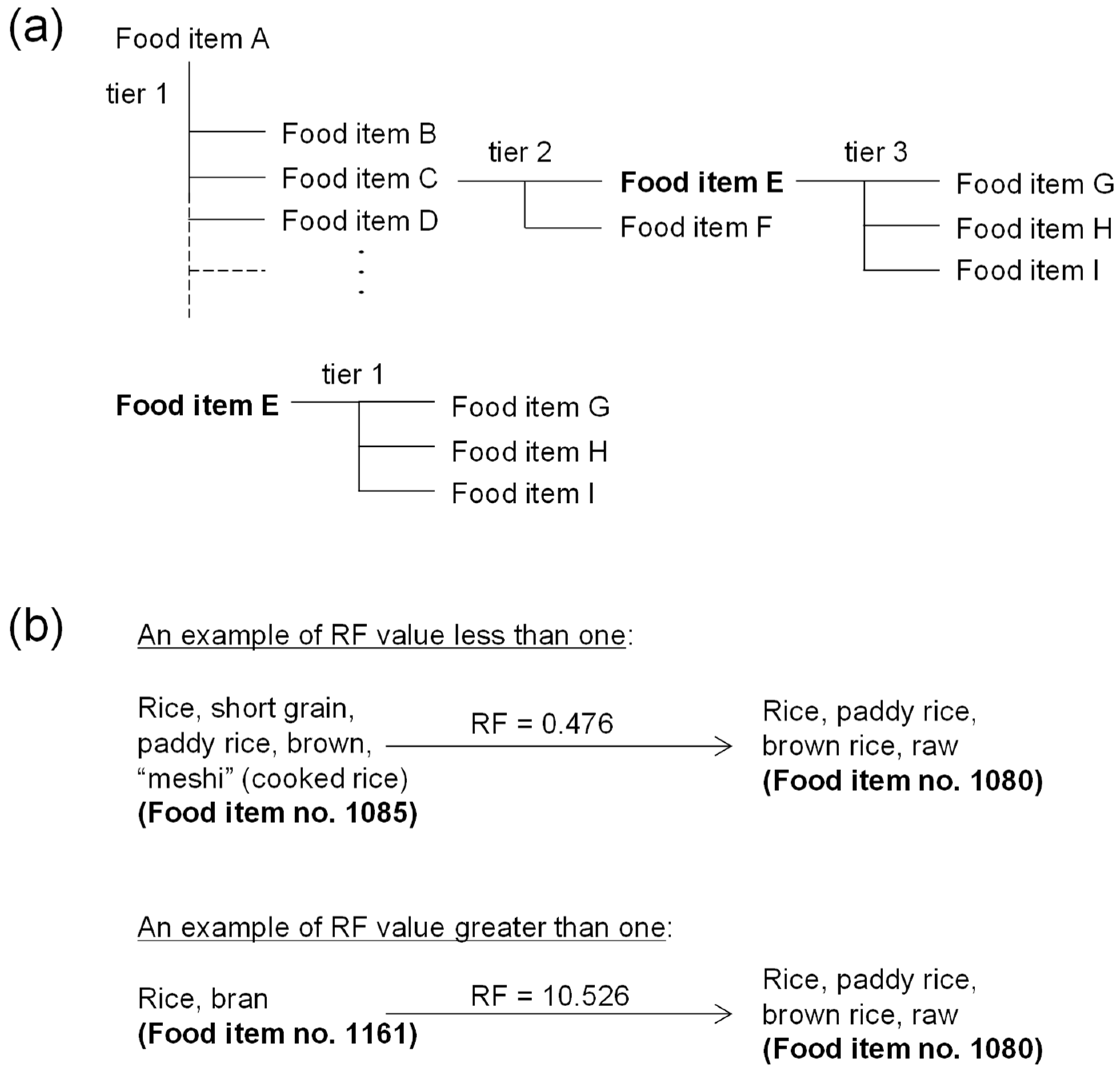

2.5. RFs for Mixed Foods

3. Results and Discussion

3.1. Definition of Food Types

3.2. RFs for Dried Food Items

3.3. RFs for Salted Food Items

3.4. RFs for Fermented Food Items

3.5. RFs for Mixed Food Items

3.6. Composite Foods for Which RFs Could Not Be Calculated

3.7. Limitations of RF Calculation for Composite Food Items

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abe, A.; Koyama, K.; Uehara, C.; Hirakawa, A.; Horiguchi, I. Changes in the risk perception of food safety between 2004 and 2018. Food Saf. 2020, 8, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Dujardin, B.; Kirwan, L. The raw primary commodity (RPC) model: Strengthening EFSA’s capacity to assess dietary exposure at different levels of the food chain, from raw primary commodities to foods as consumed. EFSA Tech. Rep. 2019, 16, 1532E. [Google Scholar] [CrossRef]

- Global Dietary Database, Dietary Survey Data. Available online: https://www.globaldietarydatabase.org/ (accessed on 29 February 2024).

- Jardim, A.N.; Caldas, E.D. Brazilian monitoring programs for pesticide residues in food–Results from 2001 to 2010. Food Control 2012, 25, 607–616. [Google Scholar] [CrossRef]

- Jallow, M.F.; Awadh, D.G.; Albaho, M.S.; Devi, V.Y.; Ahmad, N. Monitoring of pesticide residues in commonly used fruits and vegetables in Kuwait. Int. J. Environ. Res. Public Health 2017, 14, 833. [Google Scholar] [CrossRef] [PubMed]

- Carrasco Cabrera, L.; Di Piazza, G.; Dujardin, B.; Medina Pastor, P. The 2021 European Union report on pesticide residues in food. EFSA J. 2023, 21, e07939. [Google Scholar] [PubMed]

- Ambrus, Á.; Vásárhelyi, A.; Ripka, G.; Szemánné-Dobrik, H.; Szenczi-Cseh, J. Evaluation of the results of pesticide residue analysis in food sampled between 2017 and 2021. Agrochemicals 2023, 2, 409–435. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, Y.; Fang, Z.; Liang, J.; Tan, Y.; Liao, C.; Gong, D.; Liu, W.; Liu, G. Trends of pesticide residues in agricultural products in the Chinese market from 2011 to 2020. J. Food Compost. Anal. 2023, 25, 105482. [Google Scholar] [CrossRef]

- Monteiro, C.A.; Cannon, G.; Moubarac, J.C.; Levy, R.B.; Louzada, M.L.C.; Jaime, P.C. The UN Decade of Nutrition, the NOVA food classification and the trouble with ultra-processing. Public Health Nutr. 2018, 21, 5–17. [Google Scholar] [CrossRef]

- Van der Velde-Koerts, T.; Sieke, C. IESTI Calculation for FAO/WHO Acute Dietary Intake Assessment (Version 20). Available online: https://cdn.who.int/media/docs/default-source/food-safety/gems-food/iesti-calculation20-model.xlsx?sfvrsn=cb8f77c_2 (accessed on 29 February 2024).

- Dujardin, B.; Kirwan, L. Annex A to the Technical Report on the Raw Primary Commodity (RPC) Model—Input Data; Zenodo: Geneva, Switzerland, 2019; Available online: https://doi.org/10.5281/zenodo.2537955 (accessed on 29 February 2024).

- European Food Safety Authority (EFSA); European Medicines Agency (EMA). Report on Development of a Harmonised Approach to Human Dietary Exposure Assessment for Residues from Veterinary Medicinal Products, Feed Additives and Pesticides in Food of Animal Origin. Amsterdam: EFSA, EMA. EMA/CVMP/499555/2021. Available online: https://www.ema.europa.eu/en/documents/report/ema/efsa-report-development-harmonised-approach-human-dietary-exposure_en.pdf (accessed on 29 February 2024).

- Regulations for Enforcement of the Food Sanitation Act, the Ministry of Health, Labour and Welfare of Japan. Available online: https://www.japaneselawtranslation.go.jp/ja/laws/view/3991#je_ch1at11 (accessed on 29 February 2024).

- Fujita, M.; Yajima, T.; Iijima, K.; Sato, K. Effect of sampling size on the determination of accurate pesticide residue levels in Japanese agricultural commodities. J. Agric. Food Chem. 2012, 60, 4457–4464. [Google Scholar] [CrossRef]

- Article 13, Food Sanitation Act of Japan. Available online: https://www.japaneselawtranslation.go.jp/ja/laws/view/3991#je_ch1at13 (accessed on 29 February 2024).

- Pesticide Residues in Food, the Ministry of Health, Labour and Welfare of Japan. Available online: https://www.mhlw.go.jp/stf/seisakunitsuite/bunya/kenkou_iryou/shokuhin/zanryu/index.html (accessed on 29 February 2024).

- World Health Organization. Report of the 1975 Joint FAO/WHO Meeting on Pesticide Residues, FAO Plant Production and Protection Series No.1, WHO Technical Report Series 1976, No. 592. Available online: https://apps.who.int/iris/bitstream/handle/10665/41205/WHO_TRS_592.pdf?sequence=1&isAllowed=y (accessed on 29 February 2024).

- FAO; WHO. Joint FAO/WHO Meeting on Pesticide Residues (JMPR) Further guidance on derivation of the acute RfD, Pesticide residues in food—2002. In Report of the JMPR, FAO Plant Production and Protection Paper; FAO: Rome, Italy; WHO: Geneva, Switzerland, 2002; Volume 172, pp. 4–8. [Google Scholar]

- Ioannidou, S.; Cascio, C.; Gilsenan, M.B. European Food Safety Authority open access tools to estimate dietary exposure to food chemicals. Environ. Int. 2021, 149, 106357. [Google Scholar] [CrossRef]

- Asano, A.W.; Miyoshi, M.; Arai, Y.; Yoshita, K.; Yamamoto, S.; Yoshiike, N. Association between vegetable intake and dietary quality in Japanese adults: A secondary analysis from the National Health and Nutrition Survey, 2003. J. Nutr. Sci. Vitaminol. 2008, 54, 384–391. [Google Scholar] [CrossRef][Green Version]

- Suzuki, M.; Taniguchi, T.; Furihata, R.; Yoshita, K.; Arai, Y.; Yoshiike, N.; Uchiyama, M. Seasonal changes in sleep duration and sleep problems: A prospective study in Japanese community residents. PLoS ONE 2019, 14, e0215345. [Google Scholar] [CrossRef] [PubMed]

- Murakami, K.; Livingstone, M.; Masayasu, S.; Sasaki, S. Eating patterns in a nationwide sample of Japanese aged 1–79 years from MINNADE study: Eating frequency, clock time for eating, time spent on eating and variability of eating patterns. Public Health Nutr. 2022, 25, 1515–1527. [Google Scholar] [CrossRef] [PubMed]

- Standard Tables of Food Composition in Japan 2020—(The Eighth Version), the Ministry of Education, Culture, Sports, Science and Technology of Japan. Available online: https://www.mext.go.jp/a_menu/syokuhinseibun/mext_01110.html (accessed on 29 February 2024).

- Watanabe, T. Food composition tables of Japan and the nutrient table/database. J. Nutr. Sci. Vitaminol. 2015, 61, S25–S27. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T. Features and utilization of the Standard Tables of Food Composition in Japan 2020 (Eighth Revised Edition). JPN J. Nutr. Diet 2021, 79, 253–264. [Google Scholar] [CrossRef]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes 3rd Edition: The Art of Scientific Computing; Cambridge University Press: Cambridge, UK, 2007; ISBN 978-0521880688. [Google Scholar]

- Leeuwendaal, N.K.; Stanton, C.; O’Toole, P.W.; Beresford, T.P. Fermented foods, health and the gut microbiome. Nutrients 2022, 14, 1527. [Google Scholar] [CrossRef] [PubMed]

- Castellone, V.; Bancalari, E.; Rubert, J.; Gatti, M.; Neviani, E.; Bottari,, B. Eating fermented: Health benefits of LAB-fermented foods. Foods 2021, 10, 2639. [Google Scholar] [CrossRef] [PubMed]

- Lynch, K.M.; Zannini, E.; Wilkinson, S.; Daenen, L.; Arendt, E.K. Physiology of acetic acid bacteria and their role in vinegar and fermented beverages. Compr. Rev. Food Sci. Food Saf. 2019, 18, 587–625. [Google Scholar] [CrossRef] [PubMed]

- Ameyama, M.; Ohtsuka, S. (Eds.) Su no Kagaku; Asakura Shoten: Tokyo, Japan, 1990; ISBN 978-4254430301. [Google Scholar]

- Bohn, K.; Amberg, M.; Meier, T.; Forner, F.; Stangl, G.I.; Mäder, P. Estimating food ingredient compositions based on mandatory product labeling. J. Food Compos. Anal. 2022, 110, 104508. [Google Scholar] [CrossRef]

- Marcoe, K.K.; Haytowitz, D.B. Estimating nutrient values of mixed dishes from label information: Method accurately calculates the nutrient value of a food without requiring complete analytical data. Food Technol. 1993, 47, 69–75. [Google Scholar]

- Westrich, B.J.; Buzzard, I.M.; Gatewood, L.C.; McGovern, P.G. Accuracy and efficiency of estimating nutrient values in commercial food products using mathematical optimization. J. Food Compos. Anal. 1994, 7, 223–239. [Google Scholar] [CrossRef]

- Lee, S.J.; Park, A.; Im, M. Feasibility study on mathematically estimating food commodity intake using the limited sources of food recipes in Korea. J. Food Compos. Anal. 2010, 23, 821–827. [Google Scholar] [CrossRef]

| Food Group No. and Name in STFCJ (Total Number of Food Items Listed) | Uncooked and/or Unprocessed Foods, Including Raw Agricultural Crops | Cooked Foods | Composite Foods | ||||

|---|---|---|---|---|---|---|---|

| Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | ||

| 1. | Grains (205) | 12 | 5.9 | 60 | 29.3 | 133 | 64.9 |

| 2. | Potatoes and Starches (70) | 16 | 22.9 | 28 | 40.0 | 26 | 37.1 |

| 3. | Sugars and Sweeteners (30) | 2 | 6.7 | 0 | 0 | 28 | 93.3 |

| 4. | Pulses (108) | 19 | 17.6 | 19 | 17.6 | 70 | 64.8 |

| 5. | Nuts and Seeds (46) | 12 | 26.1 | 8 | 17.4 | 26 | 56.5 |

| 6. | Vegetables (401) | 185 | 46.1 | 138 | 34.4 | 78 | 19.5 |

| 7. | Fruit (183) | 101 | 55.2 | 2 | 1.1 | 80 | 43.7 |

| 8. | Mushrooms (55) | 21 | 38.2 | 27 | 49.1 | 7 | 12.7 |

| 9. | Algae (57) | 4 | 7.0 | 9 | 15.8 | 44 | 77.2 |

| 10. | Fish and Shellfish (453) | 205 | 45.3 | 105 | 23.2 | 143 | 31.6 |

| 11. | Meat (310) | 206 | 66.5 | 69 | 22.3 | 35 | 11.3 |

| 12. | Eggs (23) | 5 | 21.7 | 7 | 30.4 | 11 | 47.8 |

| 13. | Dairy Products (59) | 4 | 6.8 | 0 | 0 | 55 | 93.2 |

| 14. | Fats and Oils (34) | 0 | 0 | 0 | 0 | 34 | 100 |

| 15. | Confectionaries (185) | 0 | 0 | 0 | 0 | 185 | 100 |

| 16. | Beverages (61) | 0 | 0 | 9 | 14.8 | 52 | 85.2 |

| 17. | Seasonings and Spices (148) | 5 | 3.4 | 0 | 0 | 143 | 96.6 |

| Subtotal (2428) | 797 | 32.8 | 481 | 19.8 | 1150 | 47.4 | |

| 18. | Prepared and Processed Foods (50) | ||||||

| Total (2478) | |||||||

| Food Group No. and Name in STFCJ (Total Number of Composite Food Items Listed) | Dried Food | Salted Food | Fermented food | Mixed food | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items with No Information on Content Ratio | Percentage within Each Food Group (%) | Number of Food Items with Information on Content Ratio for RF Calculation | Percentage within Each Food Group (%) | ||

| 1. | Grains (133) | 0 | 0 | 0 | 0 | 0 | 0 | 92 | 69.2 | 41 | 30.8 |

| 2. | Potatoes and Starches (26) | 0 | 0 | 0 | 0 | 0 | 0 | 24 | 92.3 | 2 | 7.7 |

| 3. | Sugars and Sweeteners (28) | 0 | 0 | 0 | 0 | 0 | 0 | 27 | 96.4 | 1 | 3.6 |

| 4. | Pulses (70) | 2 | 2.9 | 0 | 0 | 0 | 0 | 61 | 87.1 | 7 | 10.0 |

| 5. | Nuts and Seeds (26) | 0 | 0 | 0 | 0 | 0 | 0 | 26 | 100 | 0 | 0 |

| 6. | Vegetables (78) | 7 | 9.0 | 28 | 35.9 | 0 | 0 | 37 | 47.4 | 6 | 7.7 |

| 7. | Fruit (80) | 6 | 7.5 | 3 | 3.8 | 0 | 0 | 71 | 88.8 | 0 | 0 |

| 8. | Mushrooms (7) | 3 | 42.9 | 0 | 0 | 0 | 0 | 4 | 57.1 | 0 | 0 |

| 9. | Algae (44) | 5 | 11.4 | 0 | 0 | 0 | 0 | 39 | 88.6 | 0 | 0 |

| 10. | Fish and Shellfish (143) | 26 | 18.2 | 10 | 7.0 | 0 | 0 | 107 | 74.8 | 0 | 0 |

| 11. | Meat (35) | 0 | 0 | 0 | 0 | 0 | 0 | 35 | 100 | 0 | 0 |

| 12. | Eggs (11) | 3 | 27.3 | 0 | 0 | 0 | 0 | 3 | 27.3 | 5 | 45.5 |

| 13. | Dairy Products (55) | 2 | 3.6 | 0 | 0 | 0 | 0 | 50 | 90.9 | 3 | 5.5 |

| 14. | Fats and Oils (34) | 0 | 0 | 0 | 0 | 0 | 0 | 34 | 100 | 0 | 0 |

| 15. | Confectionaries (185) | 0 | 0 | 0 | 0 | 0 | 0 | 18 | 9.7 | 167 | 90.3 |

| 16. | Beverages (52) | 0 | 0 | 0 | 0 | 34 | 65.4 | 18 | 34.6 | 0 | 0 |

| 17. | Seasonings and Spices (143) | 0 | 0 | 0 | 0 | 6 | 4.2 | 85 | 59.4 | 52 | 36.4 |

| Total (1150) | 54 | 4.7 | 41 | 3.6 | 40 | 3.5 | 731 | 63.6 | 284 | 24.7 | |

| Food Group No. and Name in STFCJ (Total Number of Applicable Food Items) | Ingredients Unknown | Too Many Ingredients | Complicated Processing | ||||

|---|---|---|---|---|---|---|---|

| Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | Number of Food Items | Percentage within Each Food Group (%) | ||

| 1. | Grains (4) | 4 | 100 | 0 | 0 | 0 | 0 |

| 2. | Potatoes and Starches (6) | 6 | 100 | 0 | 0 | 0 | 0 |

| 3. | Sugars and Sweeteners (27) | 27 | 100 | 0 | 0 | 0 | 0 |

| 4. | Pulses (0) | ||||||

| 5. | Nuts and Seeds (17) | 17 | 100 | 0 | 0 | 0 | 0 |

| 6. | Vegetables (5) | 4 | 80 | 1 | 20 | 0 | 0 |

| 7. | Fruit (7) | 6 | 86 | 0 | 0 | 1 | 14 |

| 8. | Mushrooms (2) | 2 | 100 | 0 | 0 | 0 | 0 |

| 9. | Algae (26) | 26 | 100 | 0 | 0 | 0 | 0 |

| 10. | Fish and Shellfish (15) | 14 | 93 | 0 | 0 | 1 | 7 |

| 11. | Meat (3) | 3 | 100 | 0 | 0 | 0 | 0 |

| 12. | Eggs (0) | ||||||

| 13. | Dairy Products (4) | 4 | 100 | 0 | 0 | 0 | 0 |

| 14. | Fats and Oils (13) | 13 | 100 | 0 | 0 | 0 | 0 |

| 15. | Confectionaries (2) | 2 | 100 | 0 | 0 | 0 | 0 |

| 16. | Beverages (24) | 24 | 100 | 0 | 0 | 0 | 0 |

| 17. | Seasonings and Spices (42) | 35 | 83 | 7 | 17 | 0 | 0 |

| Total (197) | 187 | 95 | 8 | 4 | 2 | 1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koyama, T.; Nakamura, K.; Kiuchi, T.; Chiba, S.; Akiyama, H.; Yoshiike, N. Development of a Reverse-Yield Factor Database Disaggregating Japanese Composite Foods into Raw Primary Commodity Ingredients Based on the Standard Tables of Food Composition in Japan. Foods 2024, 13, 988. https://doi.org/10.3390/foods13070988

Koyama T, Nakamura K, Kiuchi T, Chiba S, Akiyama H, Yoshiike N. Development of a Reverse-Yield Factor Database Disaggregating Japanese Composite Foods into Raw Primary Commodity Ingredients Based on the Standard Tables of Food Composition in Japan. Foods. 2024; 13(7):988. https://doi.org/10.3390/foods13070988

Chicago/Turabian StyleKoyama, Tatsuya, Kosuke Nakamura, Takashi Kiuchi, Shinji Chiba, Hiroshi Akiyama, and Nobuo Yoshiike. 2024. "Development of a Reverse-Yield Factor Database Disaggregating Japanese Composite Foods into Raw Primary Commodity Ingredients Based on the Standard Tables of Food Composition in Japan" Foods 13, no. 7: 988. https://doi.org/10.3390/foods13070988

APA StyleKoyama, T., Nakamura, K., Kiuchi, T., Chiba, S., Akiyama, H., & Yoshiike, N. (2024). Development of a Reverse-Yield Factor Database Disaggregating Japanese Composite Foods into Raw Primary Commodity Ingredients Based on the Standard Tables of Food Composition in Japan. Foods, 13(7), 988. https://doi.org/10.3390/foods13070988