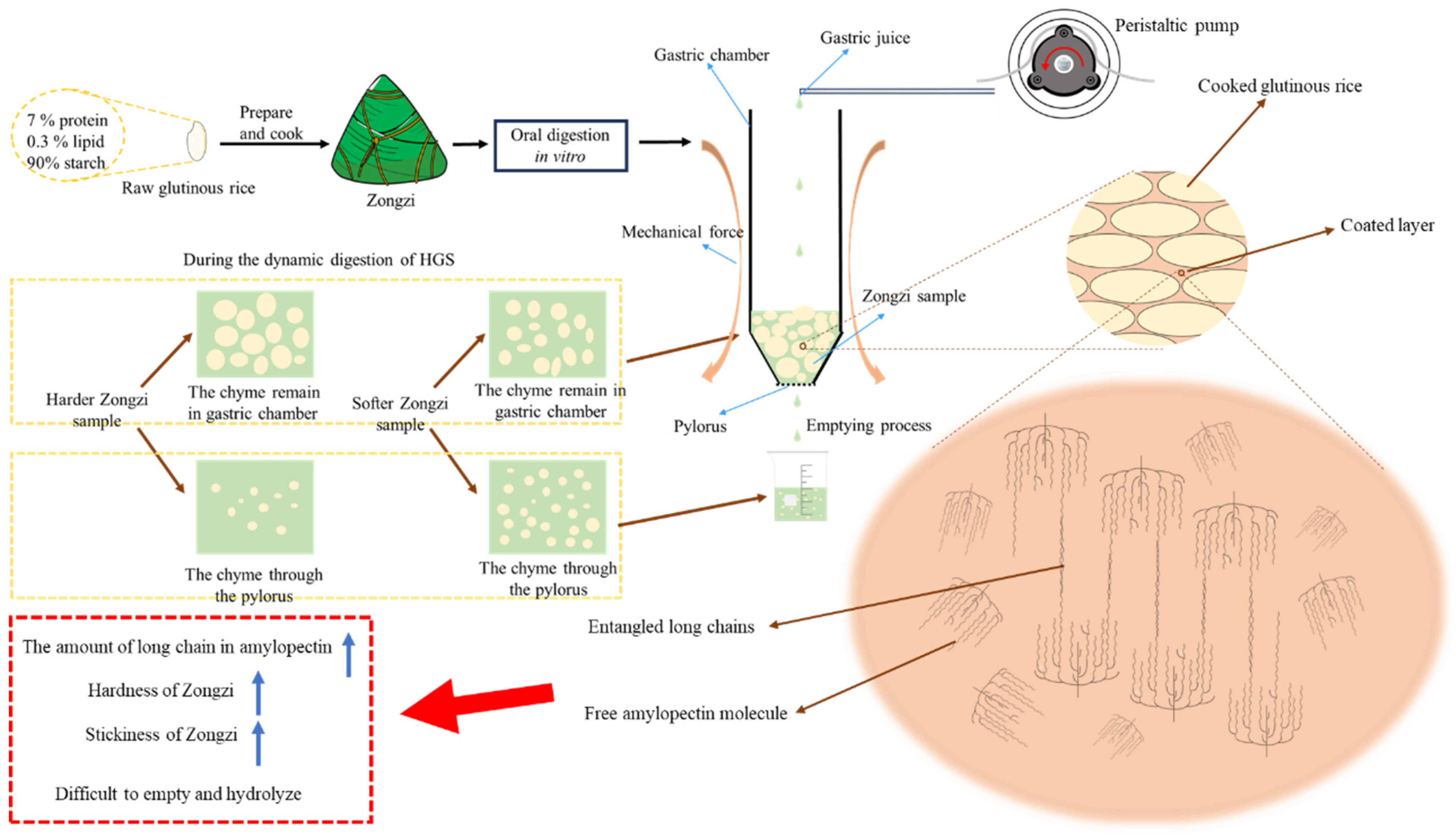

Influence of Long-Chain Amylopectin on Physicochemical and External Digestion Properties of Glutinous Rice in Zongzi

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Zongzi

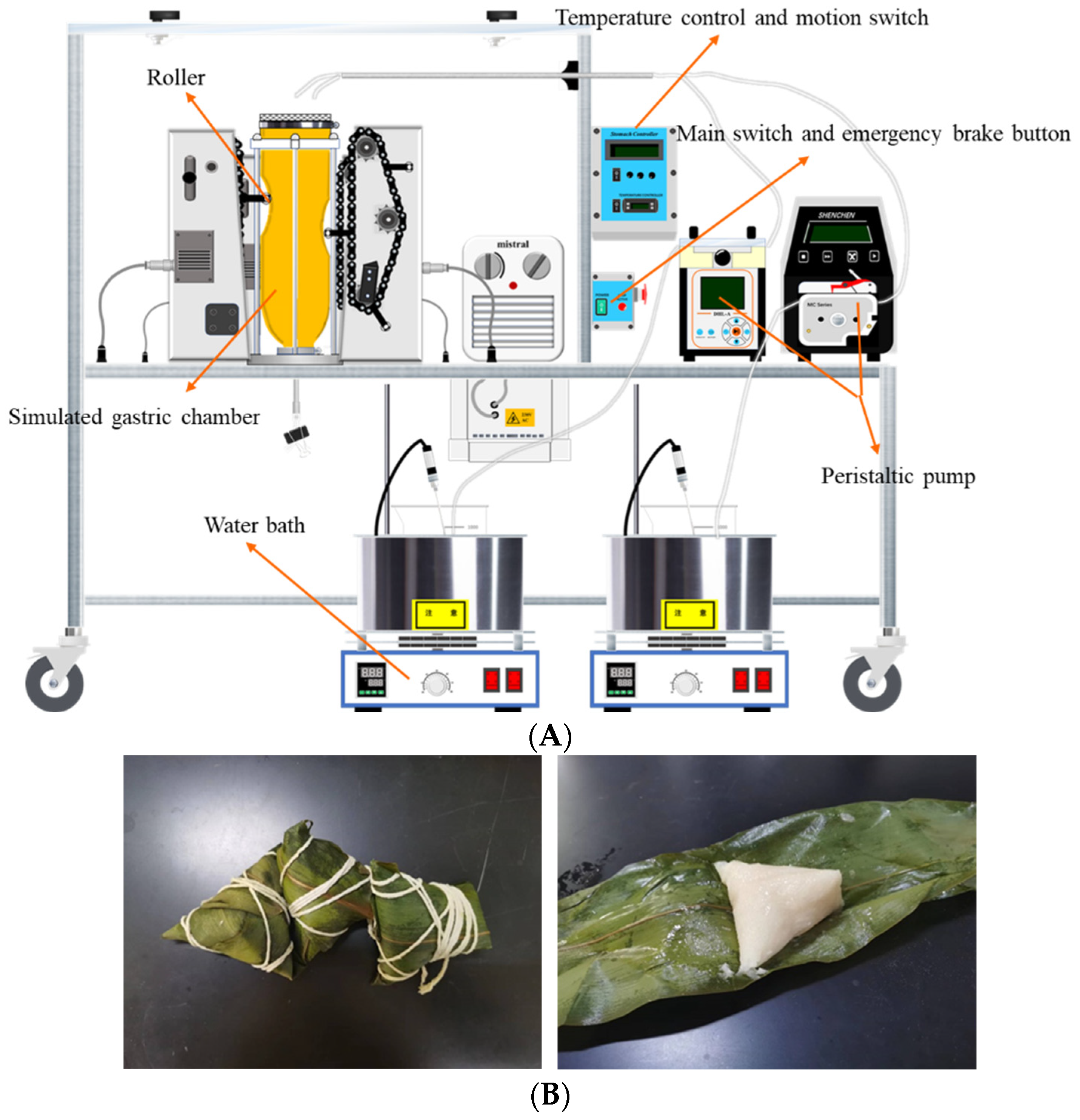

2.3. Dynamic Digestion Experiment of Zongzi In Vitro

2.3.1. Chyme Emptying Characteristics during the Gastric Digestion Phase

2.3.2. Changes in the Size of Emptying Chyme during the Gastric Digestion Phase

2.3.3. Changes in Viscosity of Emptying Chyme during Gastric Digestion Phase

2.3.4. Changes in pH Value of Emptying Chyme during Gastric Digestion Phase

2.3.5. Protein Digestion during Gastric Digestion Phase

2.3.6. Glucose Release during In Vitro Small Intestine Digestion Phase

2.4. Determination of Texture Properties of Zongzi

2.5. Extraction of a Coated Layer of Cooked Zongzi

2.6. The Analysis of the Coated Layer of Cooked Zongzi

2.6.1. Components of the Coated Layer of Cooked Zongzi

2.6.2. Starch Molecular Structure of the Coated Layer of Cooked Zongzi

Molecular Weight of Starch in Coated Layer

Chain Length Distribution of Starch in the Coated Layer

2.7. Components of Glutinous Rice

2.8. Extraction of Glutinous Rice Starch

2.9. Determination of the Molecular Structure of Glutinous Rice Starch

2.10. Differential Scanning Calorimeter (DSC) Analysis

2.11. Statistical Analysis

3. Results and Discussion

3.1. Analysis of Digestion Characteristics of Zongzi In Vitro

3.1.1. Analysis of Gastric Emptying Characteristics of Zongzi In Vitro

3.1.2. Analysis of Protein Digestion of Zongzi In Vitro

3.1.3. Starch Hydrolysis Rate during Static Small Intestine Digestion

3.2. Texture Attribute Analysis of Zongzi

3.3. Mechanism of Zongzi Stickiness Differences

3.3.1. Composition and Starch Molecular Structure of Coated Layer from Zongzi

3.3.2. Correlation Analysis of Zongzi Stickiness and Coated-Layer Physicochemical Properties

3.4. Components of Glutinous Rice

3.5. Molecular Structure of Glutinous Rice Starch

3.6. Thermal Properties of Glutinous Rice Starch Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, J.; Corke, H.; Sun, M. Genetic diversity in the physicochemical properties of waxy rice (Oryza sativa L) starch. J. Sci. Food Agric. 2004, 84, 1299–1306. [Google Scholar] [CrossRef]

- Nawaz, M.A.; Fukai, S.; Prakash, S.; Bhandari, B. Effect of starch modification in the whole white rice grains on physicochemical properties of two contrasting rice varieties. J. Cereal Sci. 2018, 80, 143–149. [Google Scholar] [CrossRef]

- Schiller, J.M. Rice in Laos; IRRI: Los Baños, Philippines, 2006. [Google Scholar]

- Kong, F.; Singh, R.P. Disintegration of solid foods in human stomach. J. Food Sci. 2008, 73, R67–R80. [Google Scholar] [CrossRef]

- Li, H.Y.; Gilbert, R.G. Starch molecular structure: The basis for an improved understanding of cooked rice texture. Carbohydr. Polym. 2018, 195, 9–17. [Google Scholar] [CrossRef]

- Ikeda, H. Relationship between the saccharides extracted from rice grains during cooking and the sensory taste of cooked rice. J. Home Econ. Jpn. 2001, 52, 401–409. [Google Scholar]

- Chung, H.J.; Liu, Q.A.; Lee, L.; Wei, D.Z. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocoll. 2011, 25, 968–975. [Google Scholar] [CrossRef]

- Li, H.Y.; Prakash, S.; Nicholson, T.M.; Fitzgerald, M.A.; Gilbert, R.G. Instrumental measurement of cooked rice texture by dynamic rheological testing and its relation to the fine structure of rice starch. Carbohydr. Polym. 2016, 146, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Li, H.Y.; Wen, Y.Y.; Wang, J.; Sun, B.G. The molecular structures of leached starch during rice cooking are controlled by thermodynamic effects, rather than kinetic effects. Food Hydrocoll. 2017, 73, 295–299. [Google Scholar] [CrossRef]

- Pan, Y.; Hou, Y.; Yang, H.; Zhang, T.; Jin, W.; Yi, M.; Han, J.; Liu, W. In vitro dynamic digestion properties of cooked rice and effect of the digesta on gut microbiota in a colonic fermentation model. J. Cereal Sci. 2023, 113, 103747. [Google Scholar] [CrossRef]

- Guo, Q.; Ye, A.Q.; Lad, M.; Ferrua, M.; Dalgleish, D.; Singh, H. Disintegration kinetics of food gels during gastric digestion and its role on gastric emptying: An in vitro analysis. Food Funct. 2015, 6, 756–764. [Google Scholar] [CrossRef]

- Kong, F.B.; Singh, R.P. A Human Gastric Simulator (HGS) to Study Food Digestion in Human Stomach. J. Food Sci. 2010, 75, E627–E635. [Google Scholar] [CrossRef] [PubMed]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D.; et al. A standardised static in vitro digestion method suitable for food—An international consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, S.; Zhang, P.; Wu, P.; Ge, A.; Ge, F.; Deng, R.; Chen, X.D. Evolutions of rheology, microstructure and digestibility of parboiled rice during simulated semi-dynamic gastrointestinal digestion. LWT 2021, 148, 111700. [Google Scholar] [CrossRef]

- Siegel, J.; Urbain, J.; Adler, L.; Charkes, N.; Maurer, A.; Krevsky, B.; Knight, L.; Fisher, R.; Malmud, L. Biphasic nature of gastric emptying. Gut 1988, 29, 85. [Google Scholar] [CrossRef] [PubMed]

- Nadia, J.; Olenskyj, A.G.; Stroebinger, N.; Hodgkinson, S.M.; Estevez, T.G.; Subramanian, P.; Singh, H.; Singh, R.P.; Bornhorst, G.M. Cooked Rice-Based and Wheat-Based Food Structure Influenced Digestion Kinetics and Glycemic Response in Growing Pigs. J. Nutr. 2023, 153, 1373–1388. [Google Scholar] [CrossRef] [PubMed]

- Jarunglumlert, T.; Nakagawa, K.; Adachi, S. Digestibility and structural parameters of spray-dried casein clusters under simulated gastric conditions. Food Res. Int. 2015, 75, 166–173. [Google Scholar] [CrossRef]

- Englyst, H.N.; Kingman, S.M.; Cummings, J.H. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar]

- Goni, I.; GarciaAlonso, A.; SauraCalixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Tao, K.; Yu, W.W.; Prakash, S.; Gilbert, R.G. High-amylose rice: Starch molecular structural features controlling cooked rice texture and preference. Carbohydr. Polym. 2019, 219, 251–260. [Google Scholar] [CrossRef]

- Lin, Z.M.; Zheng, D.Y.; Zhang, X.C.; Wang, Z.X.; Lei, J.C.; Liu, Z.H.; Li, G.H.; Wang, S.H.; Ding, Y.F. Chalky part differs in chemical composition from translucent part of japonica rice grains as revealed by a notched-belly mutant with white-belly. J. Sci. Food Agric. 2016, 96, 3937–3943. [Google Scholar] [CrossRef]

- Hanashiro, I.; Abe, J.; Hizukuri, S. A periodic distribution of the chain length of amylopectin as revealed by high-performance anion-exchange chromatography. Carbohydr. Res. 1996, 283, 151–159. [Google Scholar] [CrossRef]

- Koch, K.; Andersson, R.; Åman, P. Quantitative analysis of amylopectin unit chains by means of high-performance anion-exchange chromatography with pulsed amperometric detection. J. Chromatogr. A 1998, 800, 199–206. [Google Scholar] [CrossRef]

- GB/T 15683-2008; Rice-Determination of Amylose Content. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- GB 5009.5-2016; Determination of Protein in Food. China Food and Drug Administration: Beijing, China, 2016.

- GB 5009.6-2016; Determination of Fat in Food. China Food and Drug Administration: Beijing, China, 2016.

- GB 5009.4-2016; Determination of Ash Content in Food. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- GB 5009.3-2016; Determination of Moisture in Food. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- Ranganathan, S.; Vasikaran, E.M.; Elumalai, A.; Moses, J.A.; Anandharamakrishnan, C. Gastric emptying pattern and disintegration kinetics of cooked rice in a 3D printed in vitro dynamic digestion model ARK®. Int. J. Food Eng. 2021, 17, 385–393. [Google Scholar] [CrossRef]

- Mat, D.J.L.; Cattenoz, T.; Souchon, I.; Michon, C.; Le Feunteun, S. Monitoring protein hydrolysis by pepsin using pH-stat: In vitro gastric digestions in static and dynamic pH conditions. Food Chem. 2018, 239, 268–275. [Google Scholar] [CrossRef]

- Bao, J. 3—Rice starch. In Rice, 4th ed.; Bao, J., Ed.; AACC International Press: St. Paul, MN, USA, 2019; pp. 55–108. [Google Scholar]

- Klostermann, C.E.; Endika, M.F.; ten Cate, E.; Buwalda, P.L.; de Vos, P.; Bitter, J.H.; Zoetendal, E.G.; Schols, H.A. Type of intrinsic resistant starch type 3 determines in vitro fermentation by pooled adult faecal inoculum. Carbohydr. Polym. 2023, 319, 121187. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, X.; Peng, S.; Liu, X.; Zhang, H.; Zhang, Y. Controlling the digestibility and multi-level structure of waxy rice starch by complexation with Artemisia sphaerocephala Kracsh Gum. Food Hydrocoll. 2023, 145, 109149. [Google Scholar] [CrossRef]

- Ayabe, S.; Kasai, M.; Ohishi, K.; Hatae, K. Textural Properties and Structures of Starches from Indica and Japonica Rice with Similar Amylose Content. Food Sci. Technol. Res. 2009, 15, 299–306. [Google Scholar] [CrossRef]

- Li, H.Y.; Lei, N.Y.; Yan, S.; Gao, M.Y.; Yang, J.Y.; Wang, J.; Sun, B.G. Molecular causes for the effect of cooking methods on rice stickiness: A mechanism explanation from the view of starch leaching. Int. J. Biol. Macromol. 2019, 128, 49–53. [Google Scholar] [CrossRef]

- Li, H.Y.; Yu, L.; Yu, W.W.; Li, H.T.; Gilbert, R. Autoclaved rice: The textural property and its relation to starch leaching and the molecular structure of leached starch. Food Chem. 2019, 283, 199–205. [Google Scholar] [CrossRef]

- Han, Y.P.; Xu, M.L.; Liu, X.Y.; Yan, C.J.; Korban, S.S.; Chen, X.L.; Gu, M.H. Genes coding for starch branching enzymes are major contributors to starch viscosity characteristics in waxy rice (Oryza sativa L.). Plant Sci. 2004, 166, 357–364. [Google Scholar] [CrossRef]

- You, S.Y.; Oh, S.G.; Han, H.M.; Jun, W.; Hong, Y.S.; Chung, H.J. Impact of germination on the structures and in vitro digestibility of starch from waxy brown rice. Int. J. Biol. Macromol. 2016, 82, 863–870. [Google Scholar] [CrossRef]

- Mennah-Govela, Y.A.; Cai, H.C.; Chu, J.; Kim, K.; Maborang, M.K.; Sun, W.Y.; Bornhorst, G.M. Buffering capacity of commercially available foods is influenced by composition and initial properties in the context of gastric digestion. Food Funct. 2020, 11, 2255–2267. [Google Scholar] [CrossRef] [PubMed]

- Reynaud, Y.; Buffière, C.; David, J.; Cohade, B.; Vauris, M.; Lopez, M.; Souchon, I.; Dupont, D.; Remond, D. Temporal changes in postprandial intragastric pH: Comparing measurement methods, food structure effects, and kinetic modelling. Food Res. Int. 2020, 128, 108784. [Google Scholar] [CrossRef] [PubMed]

- Tao, K.Y.; Li, C.; Yu, W.W.; Gilbert, R.G.; Li, E.P. How amylose molecular fine structure of rice starch affects functional properties. Carbohydr. Polym. 2019, 204, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, R.G.; Witt, T.; Hasjim, J. What Is Being Learned About Starch Properties from Multiple-Level Characterization. Cereal Chem. 2013, 90, 312–325. [Google Scholar] [CrossRef]

- Ong, M.; Blanshard, J. Texture determinants in cooked, parboiled rice. I: Rice starch amylose and the fine stucture of amylopectin. J. Cereal Sci. 1995, 21, 251–260. [Google Scholar] [CrossRef]

- Tsuiki, K.; Fujisawa, H.; Itoh, A.; Sato, M.; Fujita, N. Alterations of starch structure lead to increased resistant starch of steamed rice: Identification of high resistant starch rice lines. J. Cereal Sci. 2016, 68, 88–92. [Google Scholar] [CrossRef]

| Sample | k | β | Tlag (min) | t1/2 (min) |

|---|---|---|---|---|

| IGR-1 | 0.02 ± 0.00 c | 2.38 ± 0.09 ab | 52.17 ± 0.23 a | 83.33 ± 1.61 a |

| IGR-2 | 0.02 ± 0.00 b | 2.45 ± 0.03 ab | 47.26 ± 0.74 b | 73.80 ± 0.64 b |

| IGR-3 | 0.02 ± 0.00 ab | 2.51 ± 0.31 a | 43.81 ± 2.60 bc | 68.18 ± 0.35 c |

| JGR-1 | 0.02 ± 0.00 b | 2.15 ± 0.09 ab | 40.44 ± 2.32 c | 68.06 ± 2.10 c |

| JGR-2 | 0.02 ± 0.00 a | 2.37 ± 0.15 ab | 40.10 ± 1.68 c | 63.79 ± 0.46 d |

| JGR-3 | 0.02 ± 0.00 a | 2.09 ± 0.12 b | 34.23 ± 1.39 d | 58.83 ± 0.23 e |

| Sample | RDS (%) | SDS (%) | RS (%) | C∞ (%) | k (min−1) |

|---|---|---|---|---|---|

| IGR-1 | 47.18 ± 0.27 e | 27.18 ± 0.53 a | 25.64 ± 0.27 a | 70.27 ± 0.74 e | 0.06 ± 0.00 d |

| IGR-2 | 56.93 ± 1.19 d | 21.57 ± 1.33 b | 21.50 ± 0.13 b | 71.88 ± 0.21 e | 0.08 ± 0.00 c |

| IGR-3 | 62.00 ± 1.38 b | 20.91 ± 1.04 b | 17.09 ± 0.35 c | 79.82 ± 1.82 c | 0.10 ± 0.00 b |

| JGR-1 | 59.30 ± 1.07 c | 23.65 ± 0.24 b | 17.04 ± 1.30 c | 77.31 ± 0.33 d | 0.10 ± 0.00 b |

| JGR-2 | 64.28 ± 0.35 b | 22.66 ± 2.79 b | 13.07 ± 2.44 d | 83.36 ± 0.28 b | 0.10 ± 0.00 b |

| JGR-3 | 72.23 ± 0.74 a | 11.35 ± 0.42 c | 16.41 ± 0.32 c | 92.34 ± 0.33 a | 0.15 ± 0.01 a |

| Sample | Harness (g) | Stickiness (g·s) | Springiness | Cohesiveness | Chewiness |

|---|---|---|---|---|---|

| IGR-1 | 562.21 ± 35.94 a | 464.30 ± 38.00 ab | 0.75 ± 0.03 a | 0.44 ± 0.03 a | 177.94 ± 12.99 a |

| IGR-2 | 533.06 ± 27.31 ab | 501.68 ± 9.10 a | 0.75 ± 0.07 a | 0.47 ± 0.01 a | 172.00 ± 11.78 a |

| IGR-3 | 460.67 ± 15.77 bc | 423.98 ± 32.26 abc | 0.76 ± 0.01 a | 0.47 ± 0.09 a | 166.32 ± 26.19 a |

| JGR-1 | 523.95 ± 53.54 abc | 342.92 ± 3.79 c | 0.65 ± 0.01 bc | 0.45 ± 0.03 a | 148.33 ± 11.63 a |

| JGR-2 | 438.49 ± 49.67 cd | 395.52 ± 92.91 abc | 0.72 ± 0.00 ab | 0.45 ± 0.00 a | 156.03 ± 24.80 a |

| JGR-3 | 356.76 ± 2.04 d | 376.78 ± 4.97 bc | 0.59 ± 0.01 c | 0.42 ± 0.09 a | 87.78 ± 19.49 b |

| Sample | Coated Layer Weight (mg) | Total Starch Content (%) | Protein Content (%) | Mw (×107 g/mol) |

|---|---|---|---|---|

| IGR-1 | 408.70 ± 9.90 a | 81.59 ± 3.12 a | 0.50 ± 0.06 ab | 1.06 |

| IGR-2 | 411.40 ± 4.67 a | 82.25 ± 0.58 a | 0.34 ± 0.14 bc | 1.32 |

| IGR-3 | 423.60 ± 13.86 a | 83.60 ± 0.47 a | 0.68 ± 0.08 a | 1.09 |

| JGR-1 | 413.00 ± 0.57 a | 82.98 ± 2.63 a | 0.19 ± 0.06 c | 1.12 |

| JGR-2 | 415.50 ± 4.81 a | 78.97 ± 4.90 a | 0.34 ± 0.02 bc | 1.10 |

| JGR-3 | 413.75 ± 5.02 a | 83.61 ± 1.82 a | 0.56 ± 0.07 a | 1.19 |

| Sample | A (DP 6–12) | B1 (DP 13–24) | B2 (DP 25–36) | B3 (DP≥37) | ACL |

|---|---|---|---|---|---|

| IGR-1 | 30.97 | 45.99 | 11.46 | 11.59 | 19.72 |

| IGR-2 | 33.43 | 43.12 | 11.09 | 12.36 | 19.78 |

| IGR-3 | 33.11 | 44.81 | 10.60 | 11.48 | 19.30 |

| JGR-1 | 31.64 | 46.07 | 11.01 | 11.28 | 19.52 |

| JGR-2 | 33.64 | 44.25 | 10.74 | 11.38 | 19.30 |

| JGR-3 | 35.60 | 43.43 | 10.19 | 10.78 | 18.84 |

| Coated Layer Weight | Total Starch Content | Protein Content | |

|---|---|---|---|

| Stickiness | −0.24 | −0.12 | 0.23 |

| Mw | A | B1 | B2 | B3 | ACL | |

|---|---|---|---|---|---|---|

| Stickiness | 0.41 | −0.16 | −0.31 | 0.5 | 0.83 * | 0.62 |

| Sample | Apparent Amylose Content (%) | Protein Content (%) | Water Content (%) | Lipid Content (%) | Ash Content (%) | Total Starch Content (%) |

|---|---|---|---|---|---|---|

| IGR-1 | 5.37 ± 0.10 a | 6.44 ± 0.15 e | 12.37 ± 0.04 c | 0.15 ± 0.01 c | 0.15 ± 0.01 bcd | 90.07 ± 0.04 a |

| IGR-2 | 2.84 ± 0.24 b | 7.11 ± 0.00 c | 10.99 ± 0.08 d | 0.18 ± 0.00 c | 0.20 ± 0.02 ab | 89.18 ± 0.06 d |

| IGR-3 | 2.34 ± 0.02 c | 6.83 ± 0.03 d | 12.53 ± 0.01 c | 0.42 ± 0.01 a | 0.14 ± 0.02 cd | 87.57 ± 0.02 f |

| JGR-1 | 1.72 ± 0.12 d | 7.86 ± 0.15 a | 13.08 ± 0.08 b | 0.30 ± 0.02 b | 0.11 ± 0.04 d | 89.55 ± 0.03 c |

| JGR-2 | 1.12 ± 0.30 e | 6.53 ± 0.05 e | 10.99 ± 0.06 d | 0.43 ± 0.03 a | 0.18 ± 0.02 abc | 88.48 ± 0.04 e |

| JGR-3 | 0.65 ± 0.11 f | 7.53 ± 0.02 b | 14.70 ± 0.18 a | 0.17 ± 0.02 c | 0.21 ± 0.00 a | 89.72 ± 0.01 b |

| Sample | A (DP 6–12) | B1 (DP 13–24) | B2 (DP 25–36) | B3 (DP≥37) | ACL | Mw (×108 g/mol) |

|---|---|---|---|---|---|---|

| IGR-1 | 22.43 | 49.35 | 13.18 | 15.05 | 21.84 | 1.23 |

| IGR-2 | 29.82 | 45.44 | 12.04 | 12.71 | 20.31 | 1.21 |

| IGR-3 | 30.68 | 45.49 | 13.51 | 10.32 | 19.64 | 1.16 |

| JGR-1 | 29.90 | 47.06 | 11.27 | 11.77 | 19.93 | 1.23 |

| JGR-2 | 30.73 | 46.89 | 12.62 | 9.76 | 19.30 | 1.14 |

| JGR-3 | 35.35 | 43.59 | 9.90 | 11.16 | 19.01 | 1.21 |

| Sample | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| IGR-1 | 76.23 ± 0.11 a | 81.35 ± 0.06 a | 85.47 ± 0.47 a | 13.87 ± 0.51 a |

| IGR-2 | 64.13 ± 0.01 b | 70.13 ± 0.37 b | 75.60 ± 0.51 bc | 11.28 ± 1.14 b |

| IGR-3 | 64.30 ± 0.10 b | 68.81 ± 0.08 c | 76.43 ± 0.33 b | 9.03 ± 0.65 bc |

| JGR-1 | 59.15 ± 3.39 c | 66.42 ± 0.16 e | 73.31 ± 3.55 bcd | 10.89 ± 1.57 b |

| JGR-2 | 62.73 ± 0.04 b | 67.45 ± 0.21 d | 72.30 ± 0.06 bcd | 8.10 ± 0.23 c |

| JGR-3 | 58.92 ± 0.28 c | 64.92 ± 0.41 f | 69.80 ± 0.17 d | 7.27 ± 1.49 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Chen, L.; Xu, F.; Liu, F.; Chen, M.; Zhong, F. Influence of Long-Chain Amylopectin on Physicochemical and External Digestion Properties of Glutinous Rice in Zongzi. Foods 2024, 13, 820. https://doi.org/10.3390/foods13060820

Li G, Chen L, Xu F, Liu F, Chen M, Zhong F. Influence of Long-Chain Amylopectin on Physicochemical and External Digestion Properties of Glutinous Rice in Zongzi. Foods. 2024; 13(6):820. https://doi.org/10.3390/foods13060820

Chicago/Turabian StyleLi, Guangquan, Ling Chen, Feifei Xu, Fei Liu, Maoshen Chen, and Fang Zhong. 2024. "Influence of Long-Chain Amylopectin on Physicochemical and External Digestion Properties of Glutinous Rice in Zongzi" Foods 13, no. 6: 820. https://doi.org/10.3390/foods13060820

APA StyleLi, G., Chen, L., Xu, F., Liu, F., Chen, M., & Zhong, F. (2024). Influence of Long-Chain Amylopectin on Physicochemical and External Digestion Properties of Glutinous Rice in Zongzi. Foods, 13(6), 820. https://doi.org/10.3390/foods13060820