Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain

Abstract

1. Introduction

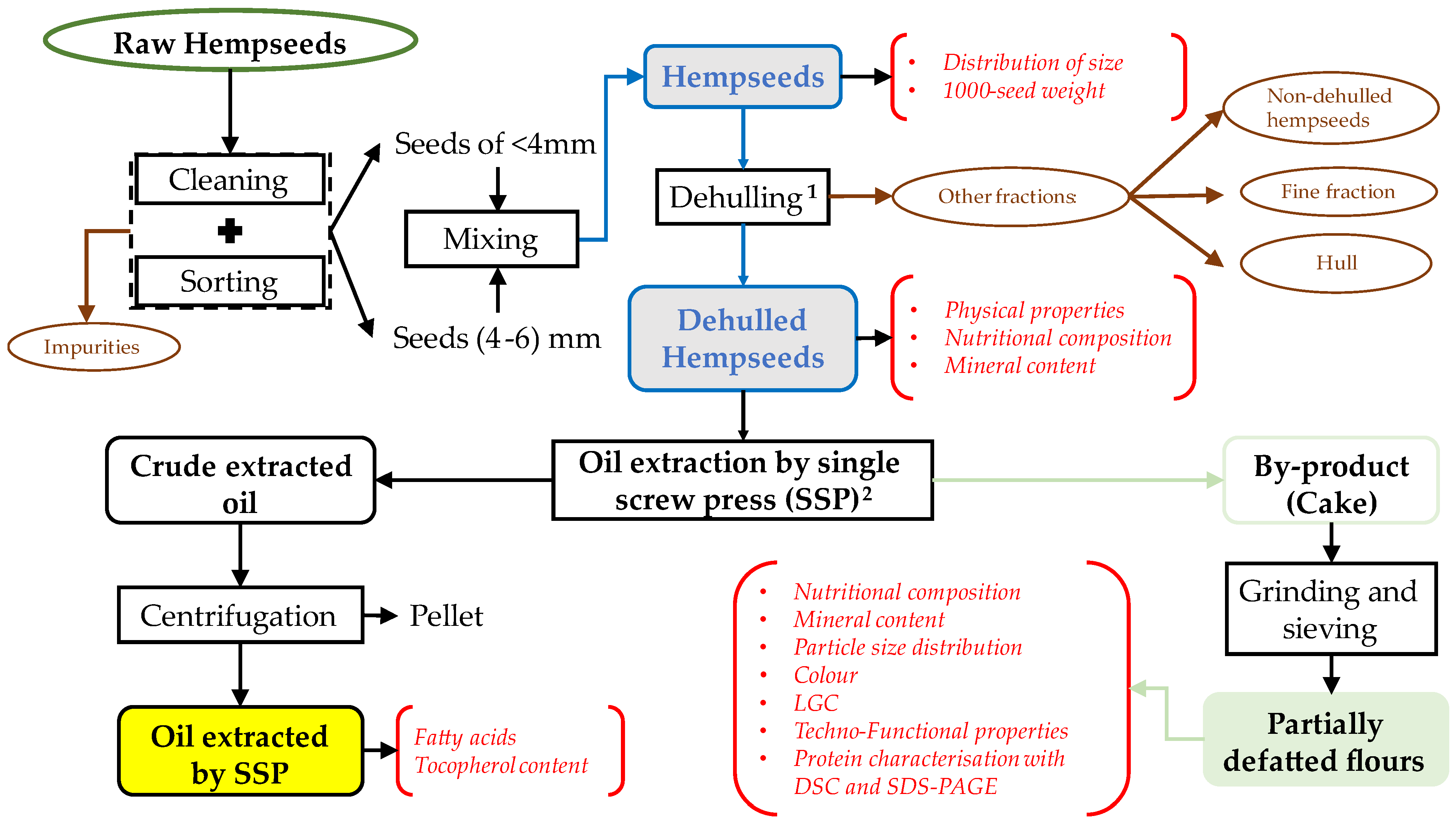

2. Materials and Methods

2.1. Hempseeds

2.2. Dehulling and Physical Characterisation

2.3. Dehulled Hempseed Processing

2.4. Nutritional Composition

2.5. Characterisation of the Extracted Oil

2.6. Characterisation of the Partially Defatted Hempseed Flour (PDHF)

2.6.1. Particle Size Distribution

2.6.2. Colour

2.6.3. Least Gelation Concentration (LGC)

2.6.4. Techno-Functional Properties

2.6.5. Protein Characterisation of Hempseed Flours

2.7. Statistical Analysis

3. Results and Discussion

3.1. Agronomic Yield of Hemp Varieties and the Seed Dehulling Process Yield

3.2. Physicochemical Characterisation of Dehulled Hempseeds

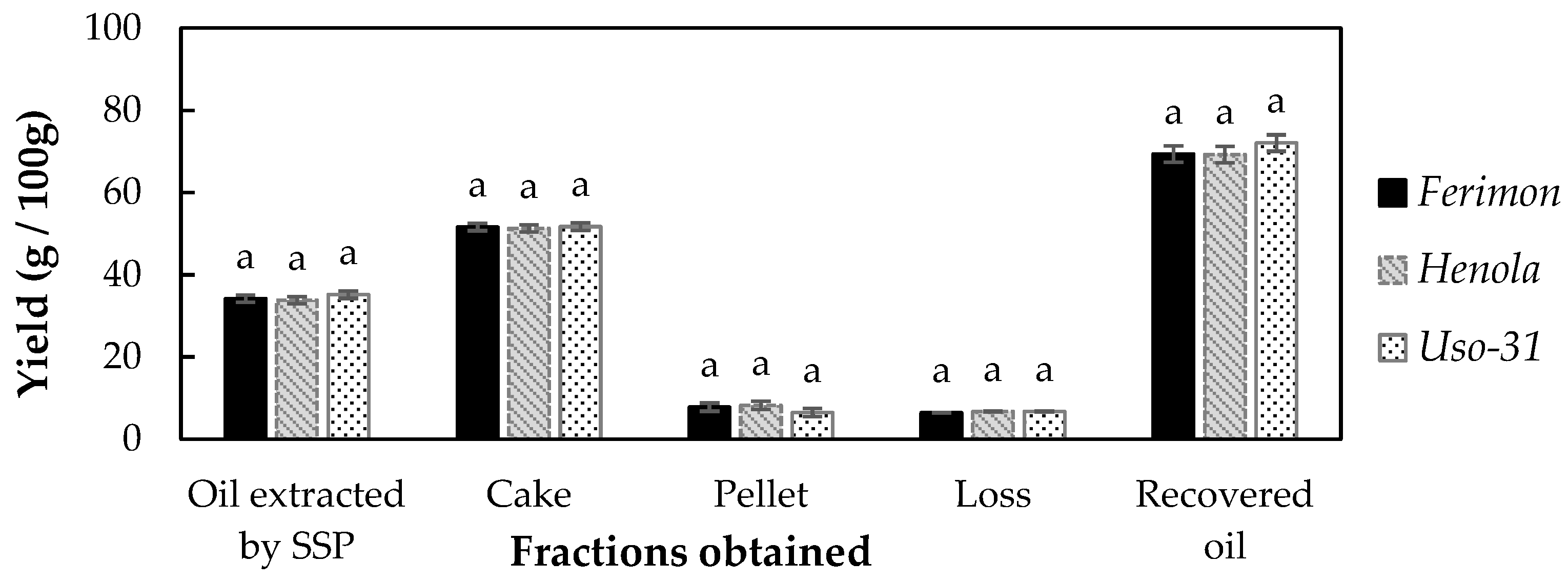

3.3. Characterisation of the Oil Extracted from Hempseeds

3.4. Characterisation of the Partially Defatted Hempseed Flour (PDHF)

3.4.1. Proximal and Mineral Compositions

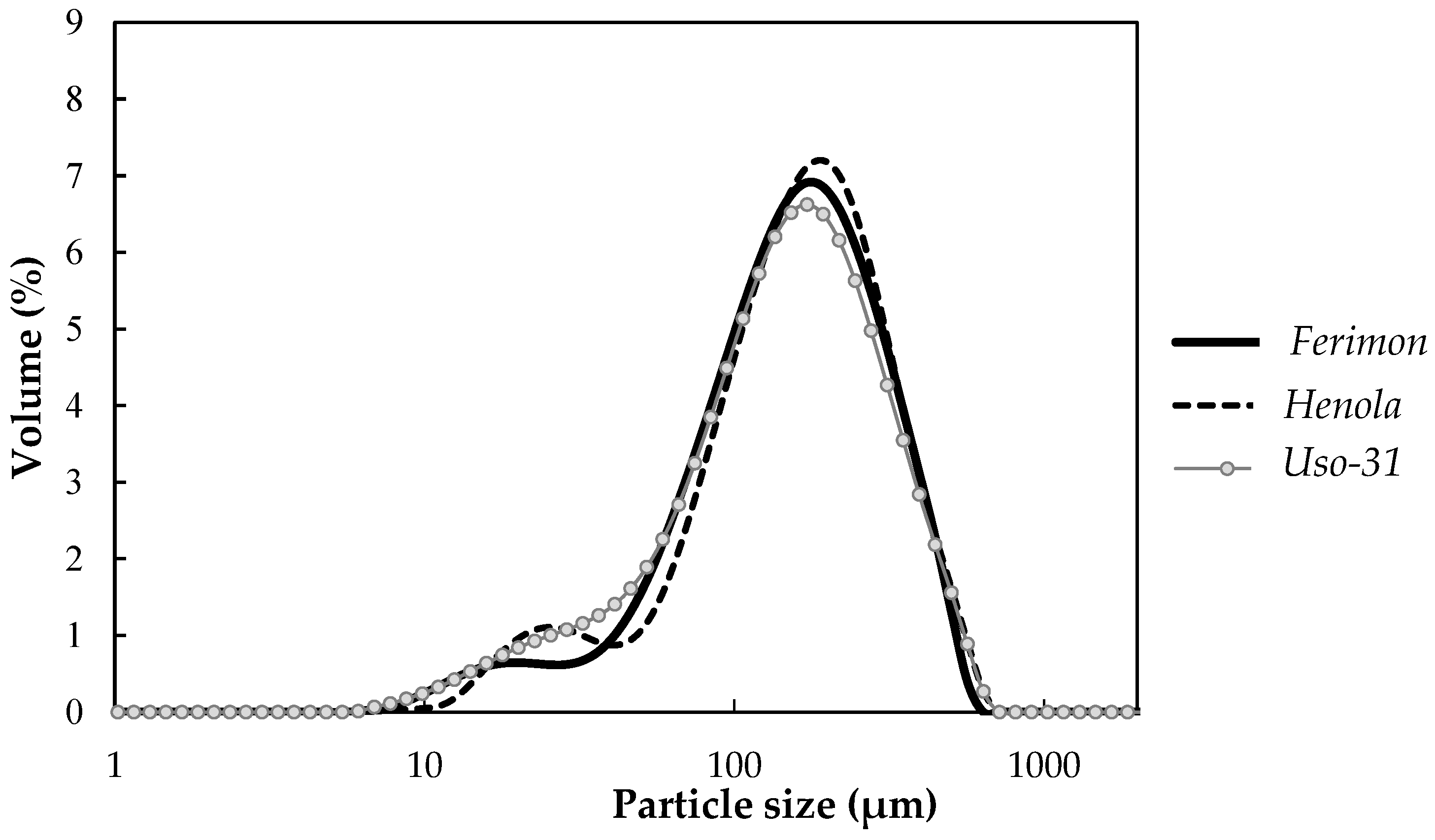

3.4.2. Particle Size Distribution

3.4.3. Colour

3.4.4. Least Gelation Concentration

3.4.5. Techno-Functional Properties

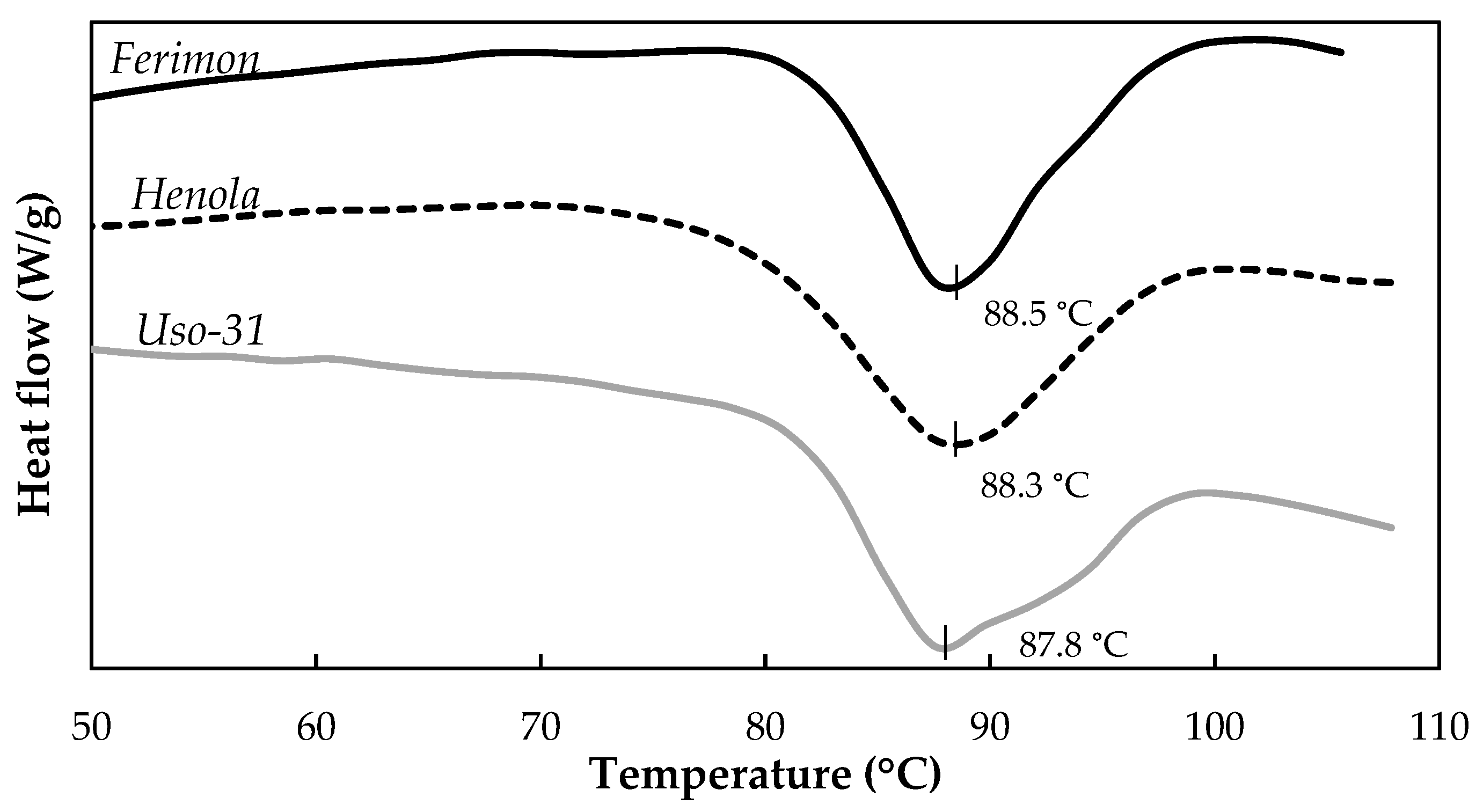

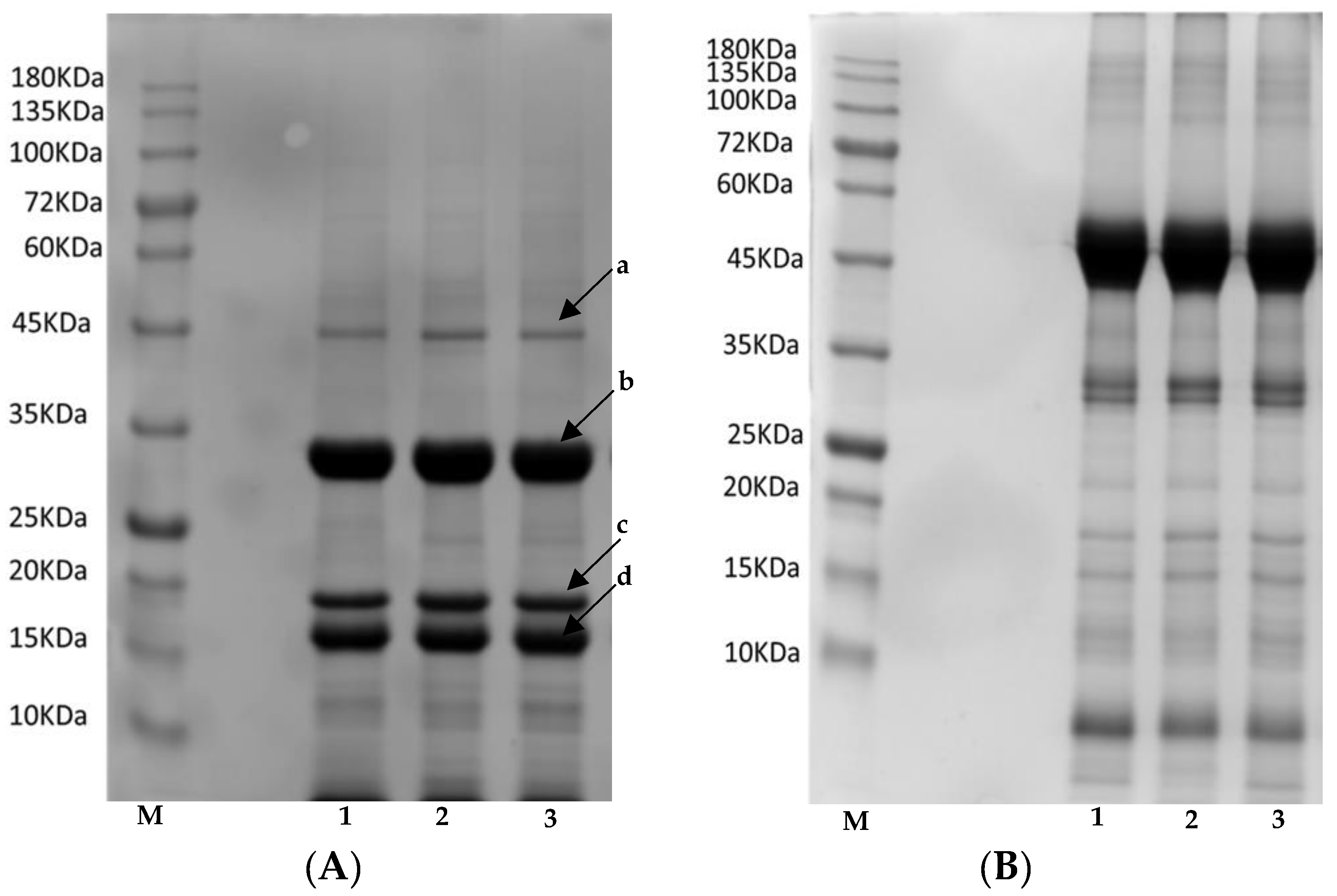

3.4.6. Protein Characterisation of Hempseed Flours

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tura, M.; Mandrioli, M.; Valli, E.; Rubino, R.C.; Parentela, D.; Gallina Toschi, T. Changes in the Composition of a Cold-Pressed Hemp Seed Oil during Three Months of Storage. J. Food Compos. Anal. 2022, 106, 104270. [Google Scholar] [CrossRef]

- Anwar, F. Analytical Characterization of Hemp (Cannabis sativa) Seed Oil from Different Agro-Ecological Zones of Pakistan. J. Am. Oil Chem. Soc. 2006, 83, 323–329. [Google Scholar] [CrossRef]

- Putnam, A.; Brussels Staff, F. Market Trends and Regulations for Industrial Hemp in the European Union; USEU: Brussels, Belgium, 2022.

- Vonapartis, E.; Aubin, M.P.; Seguin, P.; Mustafa, A.F.; Charron, J.B. Seed Composition of Ten Industrial Hemp Cultivars Approved for Production in Canada. J. Food Compos. Anal. 2015, 39, 8–12. [Google Scholar] [CrossRef]

- Chen, T.; He, J.; Zhang, J.; Zhang, H.; Qian, P.; Hao, J.; Li, L. Analytical Characterization of Hempseed (Seed of Cannabis sativa L.) Oil from Eight Regions in China. J. Diet Suppl. 2010, 7, 117–129. [Google Scholar] [CrossRef]

- Da Porto, C.; Decorti, D.; Tubaro, F. Fatty Acid Composition and Oxidation Stability of Hemp (Cannabis sativa L.) Seed Oil Extracted by Supercritical Carbon Dioxide. Ind. Crops Prod. 2012, 36, 401–404. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I.; Jurinová, I. Chemometrics of Wheat Composites with Hemp, Teff, and Chia Flour: Comparison of Rheological Features. Int. J. Food Sci. 2013, 2013, 968020. [Google Scholar] [CrossRef]

- Lan, Y.; Zha, F.; Peckrul, A.; Hanson, B.; Johnson, B.; Rao, J.; Chen, B. Genotype x Environmental Effects on Yielding Ability and Seed Chemical Composition of Industrial Hemp (Cannabis sativa L.) Varieties Grown in North Dakota, USA. J. Am. Oil Chem. Soc. 2019, 96, 1417–1425. [Google Scholar] [CrossRef]

- Siano, F.; Moccia, S.; Picariello, G.; Russo, G.L.; Sorrentino, G.; Di Stasio, M.; La Cara, F.; Volpe, M.G. Comparative Study of Chemical, Biochemical Characteristic and ATR-FTIR Analysis of Seeds, Oil and Flour of the Edible Fedora Cultivar Hemp (Cannabis sativa L.). Molecules 2019, 24, 83. [Google Scholar] [CrossRef] [PubMed]

- Teleszko, M.; Zając, A.; Rusak, T. Hemp Seeds of the Polish ‘Bialobrzeskie’ and ‘Henola’ Varieties (Cannabis sativa L. var. sativa) as Prospective Plant Sources for Food Production. Molecules 2022, 27, 1448. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, J.; Hu, R.; Wang, W.; Griffin, J.; Li, Y.; Sun, X.S.; Wang, D. Effect of Genotype on the Physicochemical, Nutritional, and Antioxidant Properties of Hempseed. J. Agric. Food Res. 2021, 3, 100119. [Google Scholar] [CrossRef]

- House, J.D.; Neufeld, J.; Leson, G. Evaluating the Quality of Protein from Hemp Seed (Cannabis sativa L.) Products through the Use of the Protein Digestibility-Corrected Amino Acid Score Method. J. Agric. Food Chem. 2010, 58, 11801–11807. [Google Scholar] [CrossRef]

- Shen, P.; Gao, Z.; Xu, M.; Rao, J.; Chen, B. Physicochemical and Structural Properties of Proteins Extracted from Dehulled Industrial Hempseeds: Role of Defatting Process and Precipitation PH. Food Hydrocoll. 2020, 108, 106065. [Google Scholar] [CrossRef]

- European Commision Agriculture and Rural Development. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 12 November 2023).

- Aladić, K.; Jarni, K.; Barbir, T.; Vidović, S.; Vladić, J.; Bilić, M.; Jokić, S. Supercritical CO2 Extraction of Hemp (Cannabis sativa L.) Seed Oil. Ind. Crops Prod. 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Rabrenović, B.B.; Vujasinović, V.B. Industrial Hempseed Oil and Lipids: Processing and Properties. In Industrial Hemp: Food and Nutraceutical Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 95–124. ISBN 9780323909105. [Google Scholar]

- Liang, J.; Appukuttan Aachary, A.; Hollader, U.T. Hemp Seed Oil: Minor Components and Oil Quality. Lipid Technol. 2015, 27, 231–233. [Google Scholar] [CrossRef]

- Faugno, S.; Piccolella, S.; Sannino, M.; Principio, L.; Crescente, G.; Baldi, G.M.; Fiorentino, N.; Pacifico, S. Can Agronomic Practices and Cold-Pressing Extraction Parameters Affect Phenols and Polyphenols Content in Hempseed Oils? Ind. Crops Prod. 2019, 130, 511–519. [Google Scholar] [CrossRef]

- Malomo, S.A.; Aluko, R.E. A Comparative Study of the Structural and Functional Properties of Isolated Hemp Seed (Cannabis sativa L.) Albumin and Globulin Fractions. Food Hydrocoll. 2015, 43, 743–752. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Androsova, N.V.; Toshev, A.D.; El Enshasy, H.A. Nutritional Quality, Chemical, and Functional Characteristics of Hemp (Cannabis sativa ssp. sativa) Protein Isolate. Plants 2022, 11, 2825. [Google Scholar] [CrossRef] [PubMed]

- Royal Decree 17/29/1999, of November 12; Ministerio de Agricultura, Pesca y Alimentacion: Madrid, Spain, 1999.

- Food Safety. Agricultural and Vegetable Species. Plant Variety Catalogues, Databases & Information Systems. 2023. Available online: https://food.ec.europa.eu/document/download/79b91903-aa0f-41cb-92aa-d8ef5481a87d_en?filename=plant-variety-catalogues_agricultural-plant-species.pdf. (accessed on 11 November 2023).

- Argaw, G.A. Sugar Crystal Size Characterization Using Digital Image Processing. Ph.D. Thesis, University of KwaZulu-Natal, Durban, South Africa, 2007. [Google Scholar]

- Solaesa, Á.G.; Villanueva, M.; Vela, A.J.; Ronda, F. Protein and Lipid Enrichment of Quinoa (Cv.Titicaca) by Dry Fractionation. Techno-Functional, Thermal and Rheological Properties of Milling Fractions. Food Hydrocoll. 2020, 105, 105770. [Google Scholar] [CrossRef]

- Abebe, W.; Collar, C.; Ronda, F. Impact of Variety Type and Particle Size Distribution on Starch Enzymatic Hydrolysis and Functional Properties of Tef Flours. Carbohydr. Polym. 2015, 115, 260–268. [Google Scholar] [CrossRef] [PubMed]

- AACC International Method 30-25.01: Crude Fat in Wheat, Corn, and Soy Flour, Feeds, and Mixed Feeds. In AACC International Approved Methods; AACC International: St. Paul, MN, USA, 2009.

- AACC. AACC International Methods, 44-19.01: Moisture-Air-Oven Method. In AACC International Approved Methods; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- UNE-EN ISO 2171:2007; Cereals, Pulses and by-Products—Determination of Ash Yield by Incineration. ISO: Geneva, Switzerland, 2007.

- AOAC. Total, Soluble, and Insoluble Dietary Fibre in Foods, Official Method 991.43; AOAC: Rockwood, MD, USA, 1995. [Google Scholar]

- Ronda, F.; Abebe, W.; Pérez-Quirce, S.; Collar, C. Suitability of Tef Varieties in Mixed Wheat Flour Bread Matrices: A Physico-Chemical and Nutritional Approach. J. Cereal Sci. 2015, 64, 139–146. [Google Scholar] [CrossRef]

- AOAC. Fatty Acids in Encapsulated Fish Oils and Fish Oil Methyl and Ethyl Esters, Official Methods of Analysis (AOAC) 41.1.30; AOAC: Rockwood, MD, USA, 1995. [Google Scholar]

- Rebolleda, S.; Rubio, N.; Beltrán, S.; Sanz, M.T.; González-Sanjosé, M.L. Supercritical Fluid Extraction of Corn Germ Oil: Study of the Influence of Process Parameters on the Extraction Yield and Oil Quality. J. Supercrit. Fluids 2012, 72, 270–277. [Google Scholar] [CrossRef]

- Vela, A.J.; Villanueva, M.; Ronda, F. Low-Frequency Ultrasonication Modulates the Impact of Annealing on Physicochemical and Functional Properties of Rice Flour. Food Hydrocoll. 2021, 120, 106933. [Google Scholar] [CrossRef]

- Calix-Rivera, C.S.; Villanueva, M.; Náthia-Neves, G.; Ronda, F. Changes on Techno-Functional, Thermal, Rheological, and Microstructural Properties of Tef Flours Induced by Microwave Radiation—Development of New Improved Gluten-Free Ingredients. Foods 2023, 12, 1345. [Google Scholar] [CrossRef] [PubMed]

- Náthia-Neves, G.; Calix-Rivera, C.S.; Villanueva, M.; Ronda, F. Microwave Radiation Induces Modifications in the Protein Fractions of Tef Flours and Modulates Their Derived Techno-Functional Properties. Int. J. Biol. Macromol. 2023, 253, 126908. [Google Scholar] [CrossRef]

- Wang, X.S.; Tang, C.H.; Yang, X.Q.; Gao, W.R. Characterization, Amino Acid Composition and in Vitro Digestibility of Hemp (Cannabis sativa L.) Proteins. Food Chem. 2008, 107, 11–18. [Google Scholar] [CrossRef]

- Baldini, M.; Ferfuia, C.; Piani, B.; Sepulcri, A.; Dorigo, G.; Zuliani, F.; Danuso, F.; Cattivello, C. The Performance and Potentiality of Monoecious Hemp (Cannabis sativa L.) Cultivars as a Multipurpose Crop. Agronomy 2018, 8, 162. [Google Scholar] [CrossRef]

- Abdollahi, M.; Sefidkon, F.; Calagari, M.; Mousavi, A.; Fawzi Mahomoodally, M. A Comparative Study of Seed Yield and Oil Composition of Four Cultivars of Hemp (Cannabis sativa L.) Grown from Three Regions in Northern Iran. Ind. Crops Prod. 2020, 152, 112397. [Google Scholar] [CrossRef]

- Sood, S.; Mondal, T.; Pal, R.S.; Joshi, D.C.; Kant, L.; Pattanayak, A. Comparison of Dehulling Efficiency and Grain Nutritional Parameters of Two Cultivated Barnyard Millet Species (Echinochloa spp.). Heliyon 2023, 9, e21594. [Google Scholar] [CrossRef]

- Gupta, A.; Sood, S.; Agrawal, P.K.; Bhatt, J.C. B 29: An Easy Dehulling Barnyard Millet (Echinochloa frumentacea Link) Genotype. Natl. Acad. Sci. Lett. 2015, 38, 21–24. [Google Scholar] [CrossRef]

- El Hanafi, L.; Mssillou, I.; Nekhla, H.; Bessi, A.; Bakour, M.; Laaroussi, H.; Ben Khadda, Z.; Slimani, C.; Giesy, J.P.; Greche, H.; et al. Effects of Dehulling and Roasting on the Phytochemical Composition and Biological Activities of Sesamum indicum L. Seeds. J. Chem. 2023, 2023, 5394315. [Google Scholar] [CrossRef]

- Taheri-Garavand, A.; Nassiri, A.; Gharibzahedi, S.M.T. Physical and Mechanical Properties of Hemp Seed. Int. Agrophys. 2012, 26, 211–215. [Google Scholar] [CrossRef]

- Ratnawati, L.; Desnilasari, D.; Surahman, D.N.; Kumalasari, R. Evaluation of Physicochemical, Functional and Pasting Properties of Soybean, Mung Bean and Red Kidney Bean Flour as Ingredient in Biscuit. IOP Conf. Ser. Earth Environ. Sci. 2019, 251, 012026. [Google Scholar] [CrossRef]

- Saini, P.; Panghal, A.; Mittal, V.; Gupta, R. Hempseed (Cannabis sativa L.) Bulk Mass Modeling Based on Engineering Properties. J. Food Process. Eng. 2022, 45, e13929. [Google Scholar] [CrossRef]

- Cerino, P.; Buonerba, C.; Cannazza, G.; D’Auria, J.; Ottoni, E.; Fulgione, A.; Di Stasio, A.; Pierri, B.; Gallo, A. A Review of Hemp as Food and Nutritional Supplement. Cannabis Cannabinoid Res. 2021, 6, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Li, J.; Zhao, J.; Wang, W.; Griffin, J.; Li, Y.; Bean, S.; Tilley, M.; Wang, D. Hempseed as a Nutritious and Healthy Human Food or Animal Feed Source: A Review. Int. J. Food Sci. Technol. 2021, 56, 530–543. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in Food Industry: Nutritional Value, Health Benefits, and Industrial Applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 282–308. [Google Scholar] [CrossRef] [PubMed]

- Todea, D.A.; Cadar, O.; Simedrus, D.; Roman, C.; Tanaselia, C.; Suatean, I.; Naghiu, A. Determination of Major-to-Trace Minerals and Polyphenols in Different Apple Cultivars. Not. Bot. Horti Agrobot. Cluj Napoca 2014, 42, 523–529. [Google Scholar] [CrossRef]

- Metin, Ş.; Üniversitesi, K.O.; Ozkutlu, F.; Üniversitesi, O.; Gul, V. Monitoring of Heavy Metals and Selected Micronutrients in Hempseeds from North-Western Turkey. Afr. J. Agric. Res. 2010, 5, 463–467. [Google Scholar]

- Senila, L.; Neag, E.; Cadar, O.; Kovacs, M.H.; Becze, A.; Senila, M. Chemical, Nutritional and Antioxidant Characteristics of Different Food Seeds. Appl. Sci. 2020, 10, 1589. [Google Scholar] [CrossRef]

- Kabutey, A.; Herák, D.; Mizera, Č. Assessment of Quality and Efficiency of Cold-Pressed Oil from Selected Oilseeds. Foods 2023, 12, 3636. [Google Scholar] [CrossRef]

- Mohamed Ahmed, I.A.; Özcan, M.M.; AlJuhaimi, F.; Ghafoor, K.; Babiker, E.E.; Osman, M.A.; Alqah, H.A.S. Quality Characteristics of Caper Seed Oils—The Impact of Extraction: Soxhlet versus Cold Pressing. J. Food Process. Preserv. 2021, 45, e15266. [Google Scholar] [CrossRef]

- Aiello, A.; Pizzolongo, F.; Scognamiglio, G.; Romano, A.; Masi, P.; Romano, R. Effects of Supercritical and Liquid Carbon Dioxide Extraction on Hemp (Cannabis sativa L.) Seed Oil. Int. J. Food Sci. Technol. 2020, 55, 2472–2480. [Google Scholar] [CrossRef]

- Barta, J.; Bartova, V.; Jarosova, M.; Svajner, J.; Smetana, P.; Kadlec, J.; Filip, V.; Kyselka, J.; Bercikova, M.; Zdrahal, Z.; et al. Oilseed Cake Flour Composition, Functional Properties and Antioxidant Potential as Effects of Sieving and Species Differences. Foods 2021, 10, 2766. [Google Scholar] [CrossRef] [PubMed]

- Shen, P.; Gao, Z.; Xu, M.; Ohm, J.B.; Rao, J.; Chen, B. The Impact of Hempseed Dehulling on Chemical Composition, Structure Properties and Aromatic Profile of Hemp Protein Isolate. Food Hydrocoll. 2020, 106, 105889. [Google Scholar] [CrossRef]

- Malomo, S.A.; He, R.; Aluko, R.E. Structural and Functional Properties of Hemp Seed Protein Products. J. Food Sci. 2014, 79, C1512–C1521. [Google Scholar] [CrossRef] [PubMed]

- Zając, M.; Guzik, P.; Kulawik, P.; Tkaczewska, J.; Florkiewicz, A.; Migdał, W. The Quality of Pork Loaves with the Addition of Hemp Seeds, de-Hulled Hemp Seeds, Hemp Protein and Hemp Flour. LWT 2019, 105, 190–199. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Attar, H.; Arfat, Y.A. Effect of Particle Size on Compositional, Functional, Pasting and Rheological Properties of Commercial Water Chestnut Flour. Food Hydrocoll. 2016, 52, 888–895. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N. Studies on Functional, Thermal and Pasting Properties of Flours from Different Chickpea (Cicer arietinum L.) Cultivars. Food Chem. 2005, 91, 403–411. [Google Scholar] [CrossRef]

- Fang, B.; Gu, Z.; Ohm, J.B.; Chen, B.; Rao, J. Reverse Micelles Extraction of Hemp Protein Isolate: Impact of Defatting Process on Protein Structure, Functionality, and Aromatic Profile. Food Hydrocoll. 2023, 135, 108158. [Google Scholar] [CrossRef]

- Ling, B.; Zhang, B.; Li, R.; Wang, S. Nutritional Quality, Functional Properties, Bioactivity, and Microstructure of Defatted Pistachio Kernel Flour. J. Am. Oil Chem. Soc. 2016, 93, 689–699. [Google Scholar] [CrossRef]

- Shen, P.; Gao, Z.; Fang, B.; Rao, J.; Chen, B. Ferreting out the Secrets of Industrial Hemp Protein as Emerging Functional Food Ingredients. Trends Food Sci. Technol. 2021, 112, 1–15. [Google Scholar] [CrossRef]

- Tang, C.H.; Ten, Z.; Wang, X.S.; Yang, X.Q. Physicochemical and Functional Properties of Hemp (Cannabis sativa L.) Protein Isolate. J. Agric. Food Chem. 2006, 54, 8945–8950. [Google Scholar] [CrossRef] [PubMed]

- Hadnađev, M.; Dapčević-Hadnađev, T.; Lazaridou, A.; Moschakis, T.; Michaelidou, A.M.; Popović, S.; Biliaderis, C.G. Hempseed Meal Protein Isolates Prepared by Different Isolation Techniques. Part I. Physicochemical Properties. Food Hydrocoll. 2018, 79, 526–533. [Google Scholar] [CrossRef]

- Cabral, E.M.; Poojary, M.M.; Lund, M.N.; Curtin, J.; Fenelon, M.; Tiwari, B.K. Effect of Solvent Composition on the Extraction of Proteins from Hemp Oil Processing Stream. J. Sci. Food Agric. 2022, 102, 6293–6298. [Google Scholar] [CrossRef] [PubMed]

| Yield Parameters | Ferimon | Henola | Uso-31 | SE | p-Values |

|---|---|---|---|---|---|

| Production yield in the test fields | |||||

| Seed yield (kg/ha) | 1373 b | 1337 b | 955 a | 20 | * |

| Distribution (g/100 g seeds) of hempseed size | |||||

| <4 mm | 89 b | 93 b | 76 a | 9 | ** |

| 4–6 mm | 10 a | 6 a | 24 b | 4 | ** |

| 1000-seed weight (g) | 11.1 b | 8.5 a | 12.5 c | 0.2 | *** |

| Yield from the dehulling process (g/100 g whole hempseeds) | |||||

| Dehulled hempseeds | 36 a | 34 a | 38 b | 1 | ** |

| Hull | 26 a | 33 ab | 26 a | 3 | * |

| Fine fraction | 15 b | 12 ab | 16 b | 2 | * |

| Non-dehulled seeds | 6.6 a | 8.6 b | 6.8 a | 0.7 | * |

| Process loss | 16 a | 13 a | 13 a | 2 | ns |

| Properties | Ferimon | Henola | Uso-31 | SE | p-Values |

|---|---|---|---|---|---|

| Physical properties | |||||

| Granulometry | |||||

| Average seed size (mm) | 1.64 a | 1.62 a | 1.79 b | 0.02 | ** |

| Coefficient of variation (%) | 13.2 a | 12.8 a | 14.3 a | 0.6 | ns |

| Bulk density (kg/m3) | 609 a | 611 a | 608 a | 6 | ns |

| True density (kg/m3) | 1109 b | 1117 b | 1090 a | 3 | * |

| Proximal composition (g/100 g dehulled seed) | |||||

| Moisture content | 6.02 a | 6.49 b | 5.92 a | 0.08 | ** |

| Protein | 31.9 a | 32.4 a | 31.7 a | 0.4 | ns |

| Fat | 49.3 a | 48.8 a | 48.8 a | 0.2 | ns |

| Ash | 5.2 a | 6.2 ab | 6.6 b | 0.2 | * |

| Fibre | 6 a | 6 a | 5 a | 1 | ns |

| Mineral composition (mg/100 g) | |||||

| Phosphorus (P) | 1129 a | 1351 a | 1402 a | 113 | ns |

| Magnesium (Mg) | 566 a | 598 a | 627 a | 38 | ns |

| Potassium (K) | 818 a | 937 a | 996 a | 82 | ns |

| Calcium (Ca) | 73 a | 87 a | 73 a | 10 | ns |

| Sodium (Na) | <0.4 | <0.4 | <0.4 | - | - |

| Iron (Fe) | 11 a | 30 b | 18 ab | 4 | * |

| Zinc (Zn) | 8.7 a | 9.8 a | 10.0 a | 0.6 | ns |

| Manganese (Mn) | 6.6 a | 8.1 a | 7.6 a | 0.5 | ns |

| Copper (Cu) | 1.6 a | 1.7 a | 1.5 a | 0.1 | ns |

| Cobalt (Co) | 0.007 a | 0.009 a | 0.009 a | 0.002 | ns |

| Selenium (Se) | 0.009 a | 0.005 a | 0.005 a | 0.003 | ns |

| Parameters | Solvent Extraction | Single Screw Press (SSP) | Analysis of Variance and Significance (p-Values) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ferimon | Henola | Uso-31 | SE | Ferimon | Henola | Uso-31 | SE | F1 | F2 | F1xF2 | |

| Fatty acids (g/100 g oil) | |||||||||||

| Palmitic (C16:0) | 5.53 bA | 6.11 cA | 5.33 aA | 0.01 | 5.79 bB | 6.24 cB | 5.60 aB | 0.04 | *** | *** | ns |

| Stearic (C18:0) | 2.58 aA | 2.61 aA | 2.72 aA | 0.03 | 2.65 aA | 2.69 aA | 2.78 aA | 0.04 | * | * | ns |

| Oleic (C18:1n9) | 13.3 aA | 12.7 aA | 14.9 bA | 0.1 | 13.3 aA | 13.3 aA | 14.7 bA | 0.1 | *** | ns | * |

| Vaccenic (C18:1n7) | 0.79 aA | 0.83 bA | 0.76 aA | 0.01 | 0.81 bB | 0.84 cA | 0.78 aB | 0.01 | *** | * | ns |

| Linoleic (C18:2n6) | 52.6 aA | 51.2 aA | 52.2 aA | 0.4 | 53.4 bA | 52.2 aA | 52.8 abA | 0.2 | ** | * | ns |

| Arachidic (C20:0) | 0.83 aA | 0.80 aA | 0.88 bA | 0.01 | 0.87 abA | 0.83 aA | 0.92 bA | 0.02 | ** | * | ns |

| γ-Linolenic (C18:3n6) | 2.95 cA | 1.59 aA | 2.42 bA | 0.02 | 3.09 cB | 1.72 aB | 2.47 bA | 0.01 | *** | *** | ns |

| Eicosenoic (C20:1n9) | 0.38 aA | 0.42 bA | 0.42 bA | 0.01 | 0.38 aA | 0.39 bA | 0.42 cA | 0.01 | *** | ns | * |

| α-Linolenic (C18:3n3) | 14.88 aA | 18.97 bA | 15.14 aA | 0.08 | 15.22 aB | 18.58 cA | 15.60 bA | 0.08 | *** | ns | ** |

| Stearidonic (C18:4n3) | 0.94 cA | 0.70 aA | 0.84 bA | 0.01 | 1.00 cA | 0.72 aA | 0.89 bA | 0.02 | *** | ** | ns |

| Behenic (C22:0) | 0.32 aA | 0.30 aA | 0.36 bA | 0.01 | 0.34 abA | 0.31 aA | 0.38 bA | 0.01 | *** | * | ns |

| Lignoceric (C24:0) | 0.13 bA | 0.12 aA | 0.14 cA | 0.002 | 0.14 abA | 0.13 aA | 0.15 bA | 0.01 | ** | * | ns |

| SFA | 9.4 aA | 10.0 bA | 9.4 aA | 0.1 | 9.8 aA | 10.2 aA | 9.8 aA | 0.1 | ** | ** | ns |

| MUFA | 14.5 aA | 14.0 aA | 16.1 bA | 0.2 | 14.6 aA | 14.6 aA | 16.0 bA | 0.1 | *** | ns | ns |

| PUFA | 71.3 aA | 72.4 aA | 70.6 aA | 0.5 | 72.8 abA | 73.2 bA | 71.8 aA | 0.2 | * | * | ns |

| PUFA/SFA | 7.60 cA | 7.29 aB | 7.49 bA | 0.01 | 7.43 aA | 7.18 aA | 7.30 aA | 0.08 | * | * | ns |

| ω-6 | 55.5 bA | 52.8 aA | 54.6 bA | 0.4 | 56.5 cA | 53.9 aA | 55.3 bA | 0.2 | *** | * | ns |

| ω-3 | 15.82 aA | 19.66 bA | 15.97 aA | 0.09 | 16.23 aB | 19.28 bA | 16.49 aA | 0.07 | *** | * | ** |

| ω-6/ω-3 | 3.51 cA | 2.68 aA | 3.42 bB | 0.01 | 3.48 cA | 2.79 aB | 3.35 bA | 0.01 | *** | ns | *** |

| Tocopherol content (mg/g oil) | |||||||||||

| γ-tocopherols | 0.643 bA | 0.718 cB | 0.498 aA | 0.001 | 0.678 bB | 0.669 bA | 0.585 aB | 0.006 | *** | *** | *** |

| α-tocopherols | 0.033 aA | 0.052 cA | 0.034 bA | 0.001 | 0.099 cB | 0.081 bB | 0.039 aB | 0.002 | *** | *** | *** |

| δ-tocopherols | 0.0060 cA | 0.0040 bA | 0.0028 aB | 0.0003 | 0.0157 cB | 0.0069 bB | 0.0022 aA | 0.0015 | *** | *** | *** |

| β-tocopherols | n.d. | n.d. | n.d. | - | n.d. | n.d. | n.d. | - | - | - | - |

| Nutritional Properties | Ferimon | Henola | Uso-31 | SE | p-Values |

|---|---|---|---|---|---|

| Proximal composition (g/100 g) | |||||

| Moisture content | 7.21 b | 7.22 b | 6.90 a | 0.02 | *** |

| Protein | 52.8 b | 51.8 a | 52.3 b | 0.3 | * |

| Fat | 15.61 c | 15.09 b | 13.68 a | 0.03 | *** |

| Ash | 9.6 a | 10.1 a | 10.8 a | 0.4 | ns |

| Fibre | 12 a | 9 a | 11 a | 2 | ns |

| Mineral composition (mg/100 g) | |||||

| Calcium (Ca) | 253 a | 198 a | 198 a | 11 | ns |

| Copper (Cu) | 2.7 a | 2.8 a | 2.8 a | 0.1 | ns |

| Iron (Fe) | 51 a | 54 a | 52 a | 7 | ns |

| Potassium (K) | 1776 a | 1513 a | 1716 a | 93 | ns |

| Magnesium (Mg) | 956 a | 985 a | 1031 a | 44 | ns |

| Manganese (Mn) | 11.6 a | 13.5 a | 13.1 a | 0.5 | ns |

| Phosphorus (P) | 2434 a | 2197 a | 2358 a | 127 | ns |

| Zinc (Zn) | 15.0 a | 16.1 a | 17.4 a | 0.7 | ns |

| Cobalt (Co) | 0.03 a | 0.03 a | 0.03 a | 0.01 | ns |

| Selenium (Se) | 0.02 a | 0.02 a | 0.02 a | 0.01 | ns |

| Properties | Ferimon | Henola | Uso-31 | SE | p-Values |

|---|---|---|---|---|---|

| Particle size distribution | |||||

| D50 (µm) | 165 c | 154 b | 140 a | 3 | ** |

| (D90 − D10)/D50 | 1.86 a | 1.85 a | 2.04 b | 0.03 | ** |

| The colour | |||||

| L* | 63.8 b | 61.0 a | 66.9 c | 0.7 | *** |

| C* | 28.5 b | 32.0 c | 26.5 a | 0.2 | *** |

| h | 93.3 b | 96.2 c | 90.3 a | 0.2 | *** |

| Least gelation concentration | |||||

| LGC (%) | 10 a | 10 a | 12 b | * | |

| Functional properties | |||||

| WAC (g/g) | 1.25 a | 1.34 b | 1.39 c | 0.01 | *** |

| WSI (g/100 g) | 13.02 b | 12.40 a | 12.60 a | 0.09 | ** |

| WAI (g/g) | 3.61 a | 3.57 a | 3.67 a | 0.06 | ns |

| SP (g/g) | 4.15 a | 4.07 a | 4.19 a | 0.05 | ns |

| FC (mL) | 27.0 a | 29.0 a | 27.0 a | 0.6 | ns |

| FS (%) | 61 a | 60 a | 64 a | 2 | ns |

| EA (%) | 29.9 b | 30.6 b | 26.1 a | 0.6 | * |

| ES (%) | 13.2 c | 10.8 a | 12.1 b | 0.2 | *** |

| Thermal properties | |||||

| ΔH (J/g) | 8.5 a | 9.0 a | 7.9 a | 0.9 | ns |

| TO (°C) | 82.3 a | 79.7 a | 81.7 a | 0.6 | ns |

| TP (°C) | 88.5 a | 88.3 a | 87.8 a | 0.8 | ns |

| TE (°C) | 95.6 a | 97.6 b | 97.8 c | 0.1 | *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendoza-Pérez, R.J.; Náthia-Neves, G.; Blanco, B.; Vela, A.J.; Caballero, P.A.; Ronda, F. Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain. Foods 2024, 13, 531. https://doi.org/10.3390/foods13040531

Mendoza-Pérez RJ, Náthia-Neves G, Blanco B, Vela AJ, Caballero PA, Ronda F. Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain. Foods. 2024; 13(4):531. https://doi.org/10.3390/foods13040531

Chicago/Turabian StyleMendoza-Pérez, Rito J., Grazielle Náthia-Neves, Beatriz Blanco, Antonio J. Vela, Pedro A. Caballero, and Felicidad Ronda. 2024. "Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain" Foods 13, no. 4: 531. https://doi.org/10.3390/foods13040531

APA StyleMendoza-Pérez, R. J., Náthia-Neves, G., Blanco, B., Vela, A. J., Caballero, P. A., & Ronda, F. (2024). Physicochemical Characterisation of Seeds, Oil and Defatted Cake of Three Hempseed Varieties Cultivated in Spain. Foods, 13(4), 531. https://doi.org/10.3390/foods13040531