Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods

Abstract

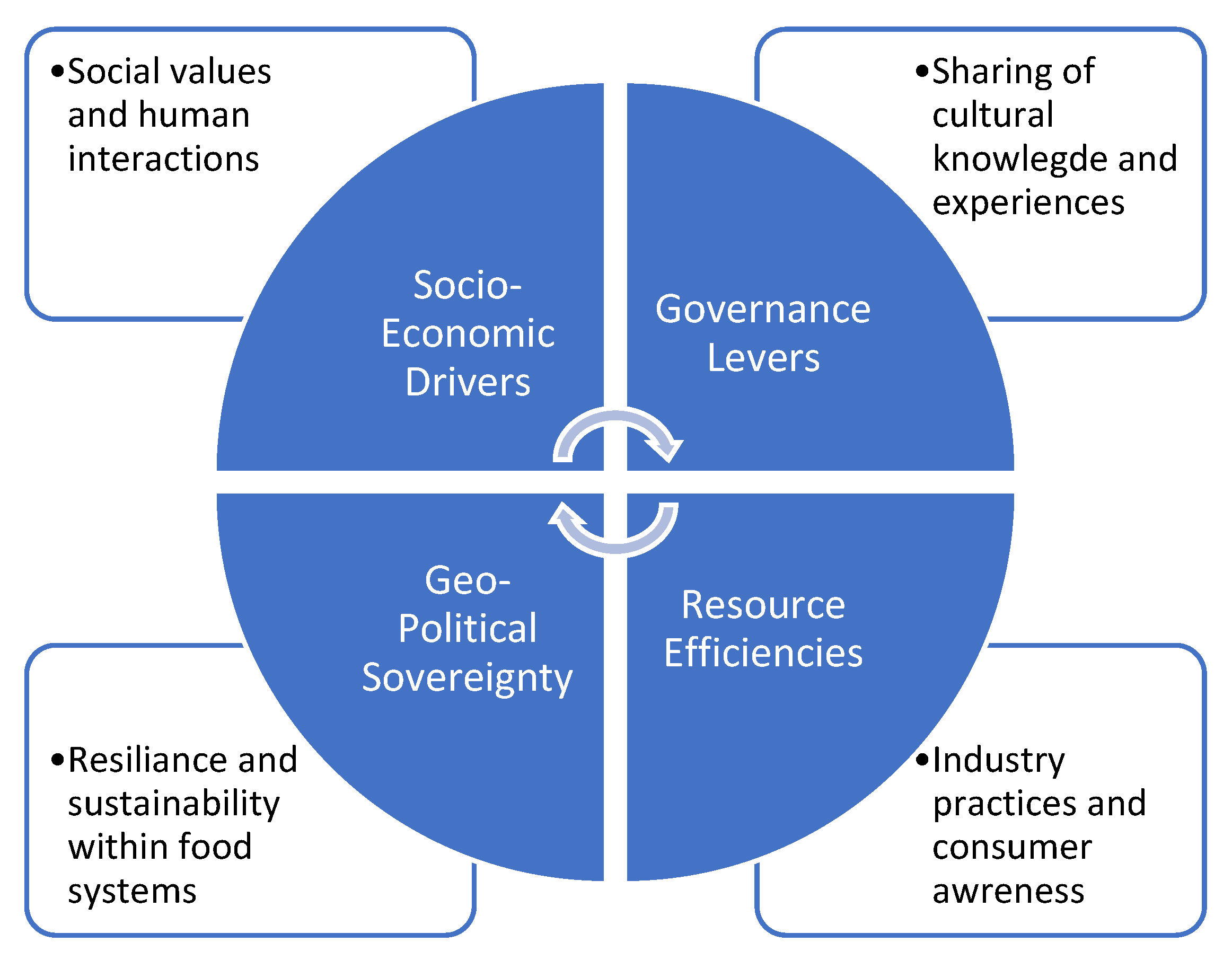

1. Food Waste and Sustainability Impact

1.1. Distribution of Origins of Food Waste and Loss across the Globe

1.2. Potential of Digital Technology in Guiding Us through Process Optimisation

1.3. Sustainability, Food Waste and Environmental Concerns on Food Valorisation

1.4. Can Valorisation Be the Answer to Sustainability and Regeneration

2. Consumers and Their Focus

2.1. Consumer Perception and Food Valorisation

2.2. Levers of Adaptation Related to Consumer Taste and Texture

2.3. Examples of the Application of Valorised Material into Food Produce

3. Refining Extraction Techniques to Enhance Safety and Biological Activities

3.1. Food Safety and Environmental Considerations for Waste Recovery

3.2. Extraction Processes Which May Be Regarded as Novel

3.3. Valorised Food Materials and Their Impact on Consumer Health and Wellbeing

3.4. Practical Applications of Isolated Food Components on Consumer Nutrition

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Read, Q.D.; Muth, M.K. Cost-effectiveness of four food waste interventions: Is food waste reduction a “win–win”? Resour. Conserv. Recycl. 2021, 168, 105448. [Google Scholar] [CrossRef]

- Martindale, W.; Hollands, T.Æ.; Jagtap, S.; Hebishy, E.; Duong, L. Turn-key research in food processing and manufacturing for reducing the impact of climate change. Int. J. Food Sci. Technol. 2023, 58, 5568–5577. [Google Scholar] [CrossRef]

- UNEP. Food Waste Index Report 2021; UN Environment Programme: Nairobi, Kenya, 2021; p. 100. ISBN 978-92-807-3868-1. [Google Scholar]

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- FAO. Sustainable Development Goals. 2020. Available online: https://www.fao.org/sustainable-development-goals-data-portal/data/ (accessed on 16 January 2024).

- Costello, C.; Birischi, E.; McGarvey, R.G. Food waste in campus dining operations: Inventory of pre- and post-consumer mass by food category, and estimation of embodied greenhouse gas emissions. Renew. Agric. Food Syst. 2015, 31, 191–201. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from agri-food wastes: Present insights and future challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [PubMed]

- Bhatkar, N.S.; Shirkole, S.S.; Brennan, C.; Thorat, B.N. Pre-processed fruits as raw materials: Part I—Different forms, process conditions and applications. Int. J. Food Sci. Technol. 2022, 57, 4945–4962. [Google Scholar] [CrossRef]

- Bhatkar, N.S.; Shirkole, S.S.; Brennan, C.; Thorat, B.N. Pre-processed fruits as raw materials: Part II—Process conditions, demand and safety aspects. Int. J. Food Sci. Technol. 2022, 57, 4918–4935. [Google Scholar] [CrossRef]

- Pop, C.; Suharoschi, R.; Pop, O.L. Dietary Fiber and Prebiotic Compounds in Fruits and Vegetables Food Waste. Sustainability 2021, 13, 7219. [Google Scholar] [CrossRef]

- Moslemy, N.; Sharifi, E.; Asadi-Eydivand, M.; Abolfathi, N. Review in edible materials for sustainable cultured meat: Scaffolds and microcarriers production. Int. J. Food Sci. Technol. 2023, 58, 6182–6191. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.J.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.S.M.; Lynch, J. Perspectives on “Game Changer” Global Challenges for Sustainable 21st Century: Plant-Based Diet, Unavoidable Food Waste Biorefining, and Circular Economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Ali, A.; Wei, S.; Liu, Z.; Fan, X.; Sun, Q.; Xia, Q.; Liu, S.; Hao, J.; Deng, C. Non-thermal processing technologies for the recovery of bioactive compounds from marine by-products. LWT 2021, 147, 111549. [Google Scholar] [CrossRef]

- Conrad, Z.; Blackstone, N.T. Identifying the links between consumer food waste, nutrition, and environmental sustainability: A narrative review. Nutr. Rev. 2021, 79, 301–314. [Google Scholar] [CrossRef]

- Hassoun, A.; Prieto, M.A.; Carpena, M.; Bouzembrak, Y.; Marvin, H.J.P.; Pallares, N.; Barba, F.J.; Punia, S. Exploring the role of green and Industry 4.0 technologies om achievingsustainable development goals in food sectors. Food Res. Int. 2022, 162, 112068. [Google Scholar] [CrossRef]

- Lai, M.; Rangan, A.; Grech, A. Enablers and barriers of harnessing food waste to address food insecurity: A scoping review. Nutr. Rev. 2020, 80, 1836–1855. [Google Scholar] [CrossRef]

- Tittonell, P.; El Mujtar, V.; Georges, F.; Kebede, Y.; Laborda, L.; Luján, S.R.; de Vente, J. Regenerative agriculture—Agroecology without politics? Front. Sustain. Food Syst. 2022, 6, 844261. [Google Scholar] [CrossRef]

- Das, S.; Barve, A.; Sahu, N.C.; Muduli, K.; Kumar, A.; Luthra, S. Analysing the challenges to sustainable food grain storage management: A path to food security in emerging nations. Int. J. Food Sci. Technol. 2023, 58, 5501–5509. [Google Scholar] [CrossRef]

- Brennan, J.; Germond, B. A methodology for analysing the impacts of climate change on maritime security. Clim. Chang. 2024, 177, 15. [Google Scholar] [CrossRef]

- Galanakis, C. (Ed.) Food waste valorization opportunities for different food industries. In The Interaction of Food Industry and Environment; Academic Press: Cambridge, MA, USA, 2020; pp. 341–422. ISBN 9780128164495. [Google Scholar] [CrossRef]

- Zaraska, M. Fighting food waste. New Sci. 2021, 245, 42–45. [Google Scholar] [CrossRef]

- Rao, M.; Bast, A.; de Boer, A. Understanding the phenomenon of food waste valorisation from the perspective of supply chain actors engaged in it. Agric. Econ. 2023, 11, 40. [Google Scholar] [CrossRef]

- Crawford, B.; Low, J.Y.Q.; Newman, L. Understanding barriers of eating unfamiliar fruits and vegetables in children using ‘Sensory Play’: A narrative review. Int. J. Food Sci. Technol. 2023, 58, 4075–4087. [Google Scholar] [CrossRef]

- Munialo, C.D. A review of alternative plant protein sources, their extraction, functional characterisation, application, nutritional value and pinch points to being the solution to sustainable food production. Int. J. Food Sci. Technol. 2023, 59, 462–472. [Google Scholar] [CrossRef]

- Allai, F.M.; Azad, Z.; Gul, K.; Dar, B.N. Wholegrains: A review on the amino acid profile, mineral content, physicochemical, bioactive composition and health benefits. Int. J. Food Sci. Technol. 2022, 57, 1849–1865. [Google Scholar] [CrossRef]

- Ross, C.F. The texture factor: Food product development for discrete populations including orally compromised elderly consumers and children with Down syndrome. Int. J. Food Sci. Technol. 2023, 58, 6151–6157. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, N.; Umesh, M.; Selvaraj, M.; Al-Shehri, B.M.; Chakraborty, P.; Duhan, L.; Sharma, S.; Pasrija, R.; Awasthi, M.K.; et al. Emerging challenges for the agro-industrial food waste utilization: A review on food waste biorefinery. Bioresour. Technol. 2022, 362, 127790. [Google Scholar] [CrossRef] [PubMed]

- Oluwole, O.; Fernando, W.B.; Lumanlan, J.; Ademuyiwa, O.; Jayasena, V. Role of phenolic acid, tannins, stilbenes, lignans and flavonoids in human health—A review. Int. J. Food Sci. Technol. 2022, 57, 6326–6335. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional and sensory properties of pasta fortified with agro-industrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Panzella, L.; Moccia, F.; Nasti, R.; Marzorati, S.; Verotta, L.; Napoltano, A. Bioactive Phenolic Compounds from Agri-Food Wastes: An Update on Green and Sustainable Extraction Methodologies. Front. Nutr. Food Sci. Technol. 2020, 7, 60. [Google Scholar] [CrossRef]

- Villacís-Chiriboga, J.; Elst, K.; Van Camp, J.; Vera, E.; Ruales, J. Valorization of byproducts from tropical fruits: Extraction methodologies, applications, environmental and economic assessment—A Review (Part 1: General overview of the byproducts, traditional biorefinery practices and possible applications). Compr. Rev. Food Sci. Food Saf. 2020, 19, 405–447. [Google Scholar] [CrossRef]

- Morejón Caraballo, S.; Rohm, H.; Struck, S. Green solvents for deoiling pumpkin and sunflower press cakes: Impact on composition and technofunctional properties. Int. J. Food Sci. Technol. 2023, 58, 1931–1939. [Google Scholar] [CrossRef]

- Banerjee, J.; Singh, R.; Vijayaraghavan, R.; MacFarlane, D.; Patti, A.F.; Arora, A. Bioactives from fruit processing wastes: Green approaches to valuable chemicals. Food Chem. 2017, 225, 10–22. [Google Scholar] [CrossRef] [PubMed]

- Melini, V.; Melini, F.; Luziatelli, F.; Ruzzi, M. Functional Ingredients from Agri-Food Waste: Effect of Inclusion Thereof on Phenolic Compound Content and Bioaccessibility in Bakery Products. Antioxidants 2020, 9, 1216. [Google Scholar] [CrossRef]

- Nunes, A.; Marto, J.; Gonçalves, L.; Martins, A.M.; Fraga, C.; Ribeiro, H.M. Potential therapeutic of olive oil industry by-products in skin health: A review. Int. J. Food Sci. Technol. 2022, 57, 173–187. [Google Scholar] [CrossRef]

- Farràs, M.; Martinez-Gili, L.; Portune, K.; Arranz, S.; Frost, G.; Tondo, M.; Blanco-Vaca, F. Modulation of the Gut Microbiota by Olive Oil Phenolic Compounds: Implications for Lipid Metabolism, Immune System, and Obesity. Nutrients 2020, 12, 2200. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Lopez, C.; Carpena, M.; Lourenço-Lopes, C.; Gallardo-Gomez, M.; Lorenzo, J.M.; Barba, F.J.; Prieto, M.A.; Simal-Gandara, J. Bioactive Compounds and Quality of Extra Virgin Olive Oil. Foods 2020, 9, 1014. [Google Scholar] [CrossRef] [PubMed]

- Cedola, A.; Cardinali, A.; D’Antuono, I.; Conte, A.; Del Nobile, M.A. Cereal foods fortified with by-products from the olive oil industry. Food Biosci. 2020, 33, 100490. [Google Scholar] [CrossRef]

- Bartkiene, E.; Bartkevics, V.; Pugajeva, I.; Borisova, A.; Zokaityte, E.; Lele, V.; Sakiene, V.; Zavistanaviciute, P.; Klupsaite, D.; Zadeike, D.; et al. Challenges Associated with Byproducts Valorization—Comparison Study of Safety Parameters of Ultrasonicated and Fermented Plant-Based Byproducts. Foods 2020, 9, 614. [Google Scholar] [CrossRef] [PubMed]

- Rao, M.; Bast, A.; de Boer, A. Valorized Food Processing By-Products in the EU: Finding the Balance between Safety, Nutrition, and Sustainability. Sustainability 2021, 13, 4428. [Google Scholar] [CrossRef]

- Romano, R.; De Luca, L.; Aiello, A.; Rossi, D.; Pizzolongo, F.; Masi, P. Bioactive compounds extracted by liquid and supercritical carbon dioxide from citrus peels. Int. J. Food Sci. Technol. 2022, 57, 3826–3837. [Google Scholar] [CrossRef]

- Tylewicz, U.; Tappi, S.; Nowacka, M.; Wiktor, A. Safety, Quality, and Processing of Fruits and Vegetables. Foods 2019, 8, 569. [Google Scholar] [CrossRef]

- Azinheiro, S.; Carvalho, J.; Prado, M.; Garrido-Maestu, A. Application of Recombinase Polymerase Amplification with Lateral Flow for a Naked-Eye Detection of Listeria monocytogenes on Food Processing Surfaces. Foods 2020, 9, 1249. [Google Scholar] [CrossRef]

- Chai, T.T.; Tan, Y.N.; Ee, K.Y.; Xiao, J.; Wong, F.C. Seeds, fermented foods, and agricultural by-products as sources of plant-derived antibacterial peptides. Crit. Rev. Food Sci. Nutr. 2019, 59 (Suppl. S1), S162–S177. [Google Scholar] [CrossRef]

- Lima, R.S.; de Carvalho, A.P.A.; Conte-Junior, C.A. Health from Brazilian Amazon food wastes: Bioactive compounds, antioxidants, antimicrobials, and potentials against cancer and oral diseases. Crit. Rev. Food Sci. Nutr. 2020, 63, 12453–12475. [Google Scholar] [CrossRef]

- Beltrán-Medina, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Mondragón-Cortez, P.M.; Arriola-Guevara, E. Evaluation of the Use of a Coffee Industry By-Product in a Cereal-Based Extruded Food Product. Foods 2020, 9, 1008. [Google Scholar] [CrossRef]

- Park, J.-S.; Nkurunziza, D.; Roy, V.C.; Ho, T.C.; Kim, S.-Y.; Lee, S.-C.; Chun, B.-S. Pretreatment processes assisted subcritical water hydrolysis for valorisation of spent coffee grounds. Int. J. Food Sci. Technol. 2022, 57, 5090–5101. [Google Scholar] [CrossRef]

- Tien, N.N.T.; Le, N.L.; Khoi, T.T.; Richel, A. Characterisation of dragon fruit peel pectin extracted with natural deep eutectic solvent and sequential microwave-ultrasound-assisted approach. Int. J. Food Sci. Technol. 2022, 57, 3735–3749. [Google Scholar] [CrossRef]

- Velusamy, M.; Rajan, A.; Radhakrishnan, M. Valorisation of food processing wastes using PEF and its economic advances—Recent update. Int. J. Food Sci. Technol. 2023, 58, 2021–2041. [Google Scholar] [CrossRef]

- Ratanpaul, V.; Stanley, R.; Brennan, C.; Eri, R. Manipulating the kinetics and site of colonic fermentation with different fibre combinations—A review. Int. J. Food Sci. Technol. 2023, 58, 2216–2227. [Google Scholar] [CrossRef]

- Hossain, A.K.M.M.; Brennan, M.A.; Mason, S.L.; Guo, X.; Zeng, X.A.; Brennan, C.S. The Effect of Astaxanthin-Rich Microalgae “Haematococcus pluvialis” and Wholemeal Flours Incorporation in Improving the Physical and Functional Properties of Cookies. Foods 2017, 6, 57. [Google Scholar] [CrossRef] [PubMed]

- Benito-González, I.; Martínez-Sanz, M.; Fabra, M.J.; López-Rubio, A. Health effect of dietary fibers. In Dietary Fiber: Properties, Recovery, and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 125–163. [Google Scholar]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of grape pomace: An approach that is increasingly reaching its maturity—A review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Cui, J.; Lian, Y.; Zhao, C.; Du, H.; Han, Y.; Gao, W.; Xiao, H.; Zheng, J. Dietary Fibers from Fruits and Vegetables and Their Health Benefits via Modulation of Gut Microbiota. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1514–1532. [Google Scholar] [CrossRef] [PubMed]

- Grasso, S.; Omoarukhe, E.; Wen, X.; Papoutsis, K.; Methven, L. The Use of Upcycled Defatted Sunflower Seed Flour as a Functional Ingredient in Biscuits. Foods 2019, 8, 305. [Google Scholar] [CrossRef]

- Hsu, C.T.; Chang, Y.H.; Shiau, S.Y. Color, antioxidation, and texture of dough and Chinese steamed bread enriched with pitaya peel powder. Cereal Chem. 2019, 96, 76–85. [Google Scholar] [CrossRef]

- Pansai, N.; Detarun, P.; Chinnaworn, A.; Sangsupawanich, P.; Wichienchot, S. Effects of dragon fruit oligosaccharides on immunity, gut micrbiome, and their metabolites in healthy adults—A randomized double-blind placebo controlled study. Food Res. Int. 2023, 167, 112657. [Google Scholar] [CrossRef]

- Schmid, V.; Trabert, A.; Schäfer, J.; Bunzel, M.; Karbstein, H.P.; Emin, M.A. Modification of Apple Pomace by Extrusion Processing: Studies on the Composition, Polymer Structures, and Functional Properties. Foods 2020, 9, 1385. [Google Scholar] [CrossRef]

- Rana, S.; Singh, A.; Surasani, V.K.R.; Kapoor, S.; Desai, A.; Kumar, S. Fish processing waste: A novel source of non-conventional functional proteins. Int. J. Food Sci. Technol. 2023, 58, 2637–2644. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture 2022. 2022. Available online: https://www.fao.org/publications/sofia/2022 (accessed on 16 January 2024).

- Ananey-Obiri, D.; Tahergorabi, R. Development and characterization of fish-based superfoods. In Current Topics on Superfoods; Shiomi, N., Ed.; IntechOpen: London, UK, 2018; Volume 395, pp. 116–124. [Google Scholar]

- Bhuimbar, M.V.; Bhagwat, P.K.; Dandge, P.B. Extraction and characterization of acid soluble collagen from fish waste: Development of collagen-chitosan blend as food packaging film. J. Environ. Chem. Eng. 2019, 7, 102983. [Google Scholar] [CrossRef]

- Blanco, M.; Vázquez, J.A.; Pérez-Martín, R.I.; Sotelo, C.G. Hydrolysates of fish skin collagen: An opportunity for valorizing fish industry byproducts. Mar. Drugs 2017, 15, 131. [Google Scholar] [CrossRef]

- Desai, A.S.; Brennan, M.; Gangan, S.S.; Brennan, C. Utilization of fish waste as a value-added ingredient: Sources and bioactive properties of fish protein hydrolysate. In Sustainable Fish Production and Processing 2022; Galanakis, C.M., Ed.; Academic Press: London, UK, 2022; pp. 203–225. [Google Scholar]

- Tahergorabi, R.; Matak, K.E.; Jaczynski, J. Fish protein isolate: Development of functional foods with nutraceutical ingredients. J. Funct. Foods 2015, 18, 746–756. [Google Scholar] [CrossRef]

- Villamil, O.; Váquiro, H.; Solanilla, J.F. Fish viscera protein hydrolysates: Production, potential applications and functional and bioactive properties. Food Chem. 2017, 224, 160–171. [Google Scholar] [CrossRef] [PubMed]

- Wasswa, J.; Tang, J.; Gu, X. Utilization of fish processing by-products in the gelatin industry. Food Rev. Int. 2007, 23, 159–174. [Google Scholar] [CrossRef]

- Lin, L.; Regenstein, J.M.; Lv, S.; Lu, J.; Jiang, S. An overview of gelatin derived from aquatic animals: Properties and modification. Trends Food Sci. Technol. 2017, 68, 102–112. [Google Scholar] [CrossRef]

- Mirzapour-Kouhdasht, A.; Moosavi-Nasab, M. Shelf-life extension of whole shrimp using an active coating containing fish skin gelatin hydrolysates produced by a natural protease. Food Sci. Nutr. 2019, 8, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.M.M.; Kishimura, H.; Benjakul, S. Physicochemical and molecular properties of gelatin from skin of golden carp (Probarbus jullieni) as influenced by acid pretreatment and prior-ultrasonication. Food Hydrocoll. 2018, 82, 164–172. [Google Scholar] [CrossRef]

- Brennan, C.S. Regenerative food innovation delivering foods for the future: A viewpoint on how science and technology can aid food sustainability and nutritional well-being in the food industry. Int. J. Food Sci. Technol. 2024, 59, 1–5. [Google Scholar] [CrossRef]

| Country | Total Annual Food Waste (Tonnes) | Food Waste per Capita (kg per Person) |

|---|---|---|

| China | 91,646,213 | 64 |

| India | 68,760,163 | 50 |

| United States | 19,359,951 | 59 |

| Japan | 8,159,891 | 64 |

| Germany | 6,263,775 | 75 |

| Australia | 2,562,110 | 102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brennan, C.S. Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods. Foods 2024, 13, 427. https://doi.org/10.3390/foods13030427

Brennan CS. Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods. Foods. 2024; 13(3):427. https://doi.org/10.3390/foods13030427

Chicago/Turabian StyleBrennan, Charles Stephen. 2024. "Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods" Foods 13, no. 3: 427. https://doi.org/10.3390/foods13030427

APA StyleBrennan, C. S. (2024). Regenerative Food Innovation: The Role of Agro-Food Chain By-Products and Plant Origin Food to Obtain High-Value-Added Foods. Foods, 13(3), 427. https://doi.org/10.3390/foods13030427