Influence of Algal Incorporation on Sensory and Physicochemical Attributes of Caseless Sausage—Ćevap (CSC)

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients

2.2. Meat Preparation

2.3. Measurements

2.4. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition of CSC

3.2. pH, aw, and Cooking Loss

3.3. Texture

3.4. Color

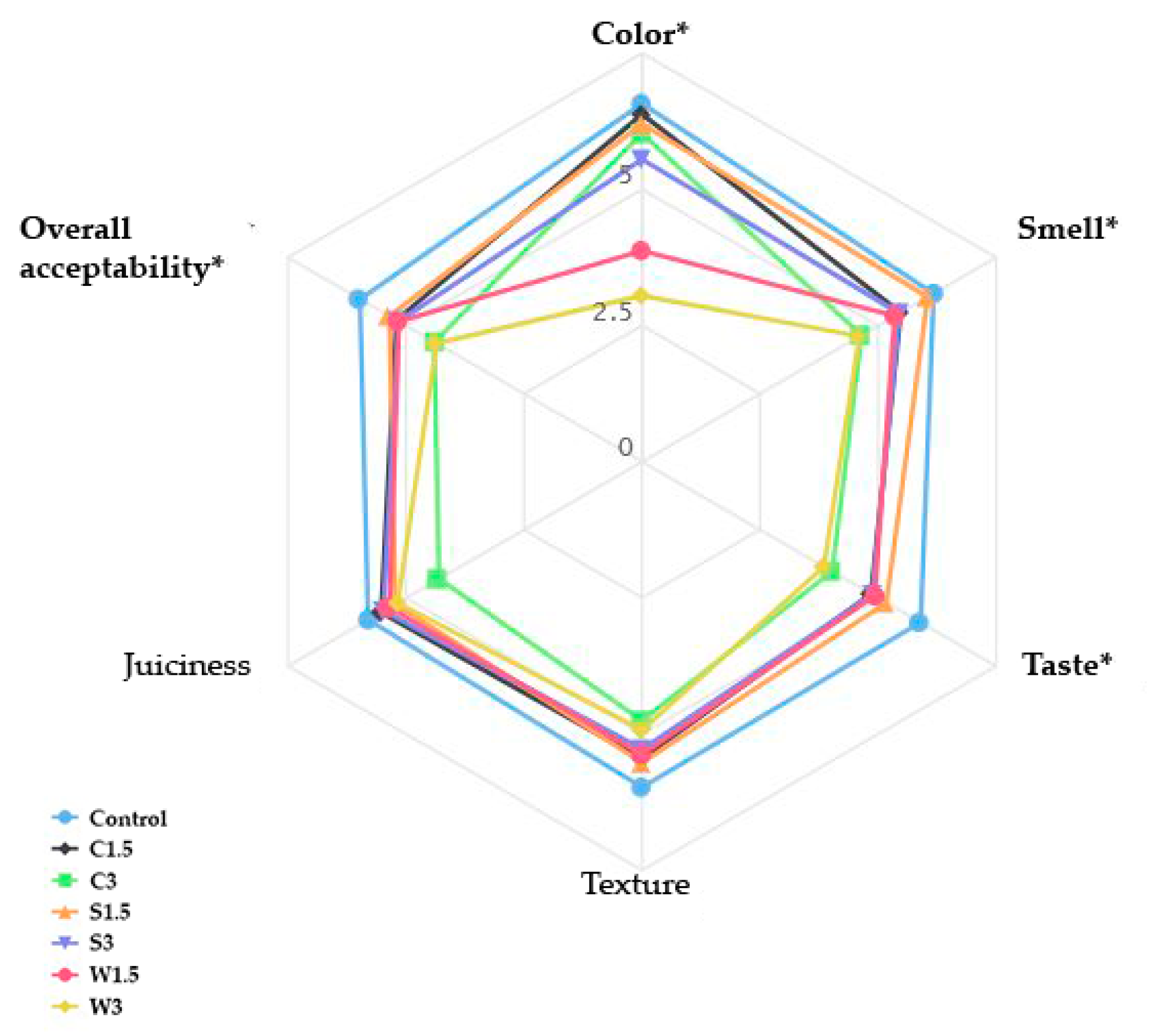

3.5. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sloan, A.E. The new market: Foods for the not-so-healthy. Food Technol. 1999, 53, 54–60. [Google Scholar]

- Jimenez-Colmenero, F.; Carballo, J.; Cofrades, S. Healthier meat and meat products: Their role as functional foods. Meat Sci. 2001, 59, 5–13. [Google Scholar] [CrossRef] [PubMed]

- Henchion, M.; McCarthy, M.; Resconi, V.C.; Troy, D. Meat consumption: Trends and quality matters. Meat Sci. 2014, 98, 561–568. [Google Scholar] [CrossRef] [PubMed]

- Sans, P.; Combris, P. World meat consumption patterns: An overview of the last fifty years (1961–2011). Meat Sci. 2015, 109, 106–111. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef]

- Bruno de Sousa, C.; Gangadhar, K.N.; Macridachis, J.; Pavão, M.; Morais, T.R.; Campino, L.; Varela, J.; Lago, J.H.G. Cystoseira algae (Fucaceae): Update on their chemical entities and biological activities. Tetrahedron Asymmetry 2017, 28, 1486–1505. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, J.; Fan, J.; Clark, J.; Shen, P.; Li, Y.; Zhang, C. Microwave assisted extraction of phenolic compounds from four economic brown macroalgae species and evaluation of their antioxidant activities and inhibitory effects on alpha-amylase, alpha-glucosidase, pancreatic lipase and tyrosinase. Food Res. Int. 2018, 113, 288–297. [Google Scholar] [CrossRef]

- Bleakley, S.; Hayes, M. Algal Proteins: Extraction, Application, and Challenges Concerning Production. Foods 2017, 6, 33. [Google Scholar] [CrossRef]

- Khan, M.I.; Shin, J.H.; Kim, J.D. The promising future of microalgae: Current status, challenges, and optimization of a sustainable and renewable industry for biofuels, feed, and other products. Microb. Cell Factories 2018, 17, 36. [Google Scholar] [CrossRef]

- Gullón, B.; Gagaoua, M.; Barba, F.J.; Gullón, P.; Zhang, W.; Lorenzo, J.M. Seaweeds as promising resource of bioactive compounds: Overview of novel extraction strategies and design of tailored meat products. Trends Food Sci. Technol. 2020, 100, 1–18. [Google Scholar] [CrossRef]

- Zhou, L.; Li, K.; Duan, X.; Hill, D.; Barrow, C.; Dunshea, F.; Martin, G.; Suleria, H. Bioactive compounds in microalgae and their potential health benefits. Food Biosci. 2022, 49, 101932. [Google Scholar] [CrossRef]

- Wells, M.L.; Potin, P.; Craigie, J.S.; Raven, J.A.; Merchant, S.S.; Helliwell, K.E.; Smith, A.G.; Camire, M.E.; Brawley, S.H. Algae as nutritional and functional food sources: Revisiting our understanding. J. Appl. Phycol. 2017, 29, 949–982. [Google Scholar] [CrossRef] [PubMed]

- Samani, S.A.; Jafari, M.; Sahafi, S.M.; Roohinejad, S. Applications of Algae and Algae Extracts in Human Food and Feed. In Recent Advances in Micro- and Macroalgal Processing; Rajauria, G., Yuan, Y., Eds.; Wiley: Hoboken, NJ, USA, 2021; pp. 467–481. [Google Scholar]

- Stengel, D.B.; Connan, S.; Popper, Z.A. Algal chemodiversity and bioactivity: Sources of natural variability and implications for commercial application. Biotechnol. Adv. 2011, 29, 483–501. [Google Scholar] [CrossRef] [PubMed]

- Siladji, C.; Djordjevic, V.; Milijasevic, J.B.; Heinz, V.; Terjung, N.; Sun, W.; Tomasevic, I. Micro- and Macroalgae in Meat Products. Foods 2024, 13, 826. [Google Scholar] [CrossRef]

- Bošković Cabrol, M.; Glišić, M.; Baltić, M.; Jovanović, D.; Silađi, Č.; Simunović, S.; Tomašević, I.; Raymundo, A. White and honey Chlorella vulgaris: Sustainable ingredients with the potential to improve nutritional value of pork frankfurters without compromising quality. Meat Sci. 2023, 198, 109123. [Google Scholar] [CrossRef]

- Lopez-Lopez, I.; Cofrades, S.; Ruiz-Capillas, C.; Jimenez-Colmenero, F. Design and nutritional properties of potential functional frankfurters based on lipid formulation, added seaweed and low salt content. Meat Sci. 2009, 83, 255–262. [Google Scholar] [CrossRef]

- Lopez-Lopez, I.; Bastida, S.; Ruiz-Capillas, C.; Bravo, L.; Larrea, M.T.; Sanchez-Muniz, F.; Cofrades, S.; Jimenez-Colmenero, F. Composition and antioxidant capacity of low-salt meat emulsion model systems containing edible seaweeds. Meat Sci. 2009, 83, 492–498. [Google Scholar] [CrossRef]

- Marti-Quijal, F.J.; Zamuz, S.; Galvez, F.; Roohinejad, S.; Tiwari, B.K.; Gómez, B.; Barba, F.J.; Lorenzo, J.M. Replacement of soy protein with other legumes or algae in turkey breast formulation: Changes in physicochemical and technological properties. J. Food Process. Preserv. 2018, 42, e13845. [Google Scholar] [CrossRef]

- Petit, G.; Jury, V.; de Lamballerie, M.; Duranton, F.; Pottier, L.; Martin, J.L. Salt Intake from Processed Meat Products: Benefits, Risks and Evolving Practices. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1453–1473. [Google Scholar] [CrossRef]

- Djekic, I.; Stajic, S.; Udovicki, B.; Siladji, C.; Djordjevic, V.; Terjung, N.; Heinz, V.; Tomasevic, I. Quality and Oral Processing Characteristics of Traditional Serbian Cevap Influenced by Game Meat. Foods 2023, 12, 2070. [Google Scholar] [CrossRef]

- Hack, K.-H.; Gerhardt, U.; Staffe, E. Verarbeitungsmaterial-Atlas für die Fleisch- und Wurstwarenproduktion, 3rd ed.; Gewürzmüller: Stuttgart, Germany, 1976. [Google Scholar]

- Schiel, L.; Wind, C.; Krueger, S.; Braun, P.G.; Koethe, M. Applicability of analytical methods for determining the composition of edible insects in German Food Control. J. Food Compos. Anal. 2022, 112, 104676. [Google Scholar] [CrossRef]

- Baune, M.-C.; Schroeder, S.; Witte, F.; Heinz, V.; Bindrich, U.; Weiss, J.; Terjung, N. Analysis of protein-network formation of different vegetable proteins during emulsification to produce solid fat substitutes. J. Food Meas. Charact. 2021, 15, 2399–2416. [Google Scholar] [CrossRef]

- Bundesamt für Verbraucherschutz und Lebensmittelsicherheit. Amtliche Sammlung von Untersuchungsverfahren Nach § 64 Lebensmittel- und Futtermittelgesetzbuch (LFGB); Bundesamt für Verbraucherschutz und Lebensmittelsicherheit: Braunschweig, Germany, 2014. [Google Scholar]

- Witte, F.; Smetana, S.; Heinz, V.; Terjung, N. High-pressure processing of usually discarded dry aged beef trimmings for subsequent processing. Meat Sci. 2020, 170, 108241. [Google Scholar] [CrossRef] [PubMed]

- Honikel, K.O. Reference methods for the assessment of physical characteristics of meat. Meat Sci. 1998, 49, 447–457. [Google Scholar] [CrossRef]

- Tomasevic, I.; Tomovic, V.; Milovanovic, B.; Lorenzo, J.; Dordevic, V.; Karabasil, N.; Djekic, I. Comparison of a computer vision system vs. traditional colorimeter for color evaluation of meat products with various physical properties. Meat Sci. 2019, 148, 5–12. [Google Scholar] [CrossRef]

- Djekic, I.; Lorenzo, J.M.; Munekata, P.E.S.; Gagaoua, M.; Tomasevic, I. Review on characteristics of trained sensory panels in food science. J. Texture Stud. 2021, 52, 501–509. [Google Scholar] [CrossRef]

- RS, S.l. Serbian Regulations 34/2023, Quality Requirements for Meat Products. 2023. Available online: https://pravno-informacioni-sistem.rs/eli/rep/sgrs/ministarstva/pravilnik/2019/50/11/reg (accessed on 28 April 2023).

- Choi, Y.-S.; Jeong, T.-J.; Kim, H.-W.; Hwang, K.-E.; Sung, J.-M.; Seo, D.-H.; Kim, Y.-B.; Kim, C.-J. Combined Effects of Sea Mustard and Transglutaminase on the Quality Characteristics of Reduced-Salt Frankfurters. J. Food Process. Preserv. 2017, 41, e12945. [Google Scholar] [CrossRef]

- Cofrades, S.; Lopez-Lopez, I.; Solas, M.T.; Bravo, L.; Jimenez-Colmenero, F. Influence of different types and proportions of added edible seaweeds on characteristics of low-salt gel/emulsion meat systems. Meat Sci. 2008, 79, 767–776. [Google Scholar] [CrossRef]

- Mohammed, H.O.; O’Grady, M.N.; O’Sullivan, M.G.; Hamill, R.M.; Kilcawley, K.N.; Kerry, J.P. Acceptable Inclusion Levels for Selected Brown and Red Irish Seaweed Species in Pork Sausages. Foods 2022, 11, 1522. [Google Scholar] [CrossRef]

- Cofrades, S.; Lopez-Lopez, I.; Ruiz-Capillas, C.; Triki, M.; Jimenez-Colmenero, F. Quality characteristics of low-salt restructured poultry with microbial transglutaminase and seaweed. Meat Sci. 2011, 87, 373–380. [Google Scholar] [CrossRef]

- Abdel-Moatamed, B.R.; El-Fakhrany, A.M.A.; Elneairy, N.A.A.; Shaban, M.M.; Roby, M.H.H. The Impact of Chlorella vulgaris Fortification on the Nutritional Composition and Quality Characteristics of Beef Burgers. Foods 2024, 13, 1945. [Google Scholar] [CrossRef] [PubMed]

- Vilar, E.G.; Ouyang, H.; O’Sullivan, M.G.; Kerry, J.P.; Hamill, R.M.; O’Grady, M.N.; Mohammed, H.O.; Kilcawley, K.N. Effect of salt reduction and inclusion of 1% edible seaweeds on the chemical, sensory and volatile component profile of reformulated frankfurters. Meat Sci. 2020, 161, 108001. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.S.; Choi, J.H.; Han, D.J.; Kim, H.Y.; Kim, H.W.; Lee, M.A.; Chung, H.J.; Kim, C.J. Effects of Laminaria japonica on the physico-chemical and sensory characteristics of reduced-fat pork patties. Meat Sci. 2012, 91, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Kim, S.-Y.; Kim, C.-J. Effects of Sea Tangle (Lamina japonica) Powder on Quality Characteristics of Breakfast Sausages. Food Sci. Anim. Resour. 2010, 30, 55–61. [Google Scholar]

- Voloschenko, L.V.; Baidina, I.A.; Shevchenko, N.P.; Trubchaninova, N.C. Functional meat and vegetable pate with Spirulina. Earth Environ. Sci. 2021, 845, 012123. [Google Scholar] [CrossRef]

- Cox, S.; Abu-Ghannam, N. Enhancement of the phytochemical and fibre content of beef patties with Himanthalia elongata seaweed. Int. J. Food Sci. Technol. 2013, 48, 2239–2249. [Google Scholar] [CrossRef]

- Munsu, E.; Mohd Zaini, H.; Matanjun, P.; Ab Wahab, N.; Sulaiman, N.S.; Pindi, W. Physicochemical, Sensory Properties and Lipid Oxidation of Chicken Sausages Supplemented with Three Types of Seaweed. Appl. Sci. 2021, 11, 11347. [Google Scholar] [CrossRef]

- Lopez-Santamarina, A.; Sinisterra-Loaiza, L.; Mondragon-Portocarrero, A.; Ortiz-Viedma, J.; Cardelle-Cobas, A.; Abuin, C.M.F.; Cepeda, A. Potential prebiotic effect of two Atlantic whole brown seaweeds, Saccharina japonica and Undaria pinnatifida, using in vitro simulation of distal colonic fermentation. Front. Nutr. 2023, 10, 1170392. [Google Scholar] [CrossRef]

- De Medeiros, V.P.B.; Pimentel, T.C.; Sant’Ana, A.S.; Magnani, M. Microalgae in the meat processing chain: Feed for animal production or source of techno-functional ingredients. Curr. Opin. Food Sci. 2021, 37, 125–134. [Google Scholar] [CrossRef]

- Altmann, B.A.; Gertheiss, J.; Tomasevic, I.; Engelkes, C.; Glaesener, T.; Meyer, J.; Schäfer, A.; Wiesen, R.; Mörlein, D. Human perception of color differences using computer vision system measurements of raw pork loin. Meat Sci. 2022, 188, 108766. [Google Scholar] [CrossRef]

- Espinosa-Ramirez, J.; Mondragon-Portocarrero, A.C.; Rodriguez, J.A.; Lorenzo, J.M.; Santos, E.M. Algae as a potential source of protein meat alternatives. Front. Nutr. 2023, 10, 1254300. [Google Scholar] [CrossRef]

- Quitral, V.; Jofré, M.J.; Rojas, N.; Romero, N.; Valdés, I. Seaweed as functional ingredient in meat products. Rev. Chil. Nutr. 2019, 46, 181–189. [Google Scholar] [CrossRef]

| Ingredients (g) | Groups | ||||||

|---|---|---|---|---|---|---|---|

| Control | C1.5 | C3 | S1.5 | S3 | W1.5 | W3 | |

| Beef meat (R II) | 2450 | 2450 | 2450 | 2450 | 2450 | 2450 | 2450 |

| Pork meat (S III) | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| Ice | 550 | 550 | 550 | 550 | 550 | 550 | 550 |

| Salt | 80 | 78.5 | 75 | 78.5 | 75 | 78.5 | 75 |

| Dextrose | 27.5 | 27.5 | 27.5 | 27.5 | 27.5 | 27.5 | 27.5 |

| White C. vulgaris | / | 75 | 150 | / | / | / | / |

| Sea spaghetti | / | / | / | 75 | 150 | / | / |

| Wakame | / | / | / | / | / | 75 | 150 |

| Parameters | Control | C1.5 | C3 | S1.5 | S3 | W1.5 | W3 |

|---|---|---|---|---|---|---|---|

| Protein (%) | 15.60 ± 0.40 | 15.67 ± 0.32 | 15.90 ± 0.10 | 15.70 ± 0.20 | 15.73 ± 0.25 | 15.87 ± 0.30 | 15.90 ± 0.35 |

| Fat (%) | 13.97 ± 0.29 | 13.93 ± 0.28 | 14.10 ± 0.32 | 14.08 ± 0.24 | 14.08 ± 0.26 | 14.02 ± 0.16 | 14.03 ± 0.17 |

| Moisture (%) | 67.72 ± 0.83 a | 67.36 ± 0.98 a | 66.72 ± 1.05 a | 67.27 ± 0.72 a | 64.74 ± 0.85 b | 66.90 ± 1.16 a | 65.00 ± 1.05 b |

| NaCl (g/100 g) | 2.57 ± 0.17 a | 2.73 ± 0.18 ab | 2.60 ± 0.15 a | 2.77 ± 0.10 ab | 2.87 ± 0.03 ab | 2.79 ± 0.06 ab | 3.09 ± 0.16 b |

| Parameters | Control | C1.5 | C3 | S1.5 | S3 | W1.5 | W3 |

|---|---|---|---|---|---|---|---|

| pH day 0 | 5.63 ab | 5.62 a | 5.62 a | 5.61 a | 5.60 a | 5.67 b | 5.68 b |

| pH day 1 | 5.66 a | 5.65 ab | 5.64 ab | 5.64 ab | 5.62 bc | 5.70 cd | 5.72 d |

| pH day 3 | 5.54 ab | 5.48 ab | 5.4 a | 5.52 ab | 5.58 abc | 5.60 bc | 5.67 c |

| pH day 7 | 5.36 a | 5.00 bc | 4.96 c | 5.11 de | 5.08 cd | 5.19 ef | 5.20 f |

| aw | 0.983 a | 0.977 ab | 0.978 ab | 0.977 ab | 0.972 b | 0.977 ab | 0.970 b |

| CL (%) | 23.06 ab | 24.21 a | 23.81 a | 22.74 ab | 20.79 b | 17.15 c | 12.40 d |

| Parameters | Control | C1.5 | C3 | S1.5 | S3 | W1.5 | W3 |

|---|---|---|---|---|---|---|---|

| Hardness (N) | 20.39 ± 1.98 a | 17.47 ± 1.87 b | 14.34 ± 1.82 c | 16.10 ± 1.74 bd | 15.79 ± 1.99 cd | 22.16 ± 1.99 e | 24.21 ± 2.03 f |

| Cohesiveness | 0.44 ± 0.03 a | 0.40 ± 0.04 b | 0.36 ± 0.03 c | 0.40 ± 0.03 b | 0.37 ± 0.04 bc | 0.46 ± 0.02 a | 0.46 ± 0.03 a |

| Springiness (mm) | 1.00 ± 0.01 a | 1.06 ± 0.08 b | 1.05 ± 0.07 b | 1.04 ± 0.06 ab | 1.03 ± 0.05 ab | 1.01 ± 0.02 a | 1.01 ± 0.02 a |

| Chewiness (N × mm) | 9.25 ± 0.99 a | 7.57 ± 1.00 b | 5.52 ± 0.74 c | 6.72 ± 0.84 d | 5.92 ± 1.02 c | 10.22 ± 1.09 e | 11.33 ± 1.21 f |

| Control | C1.5 | C3 | S1.5 | S3 | W1.5 | W3 | |

|---|---|---|---|---|---|---|---|

| Surface | |||||||

| L* | 34.67 ± 6.30 a | 29.37 ± 6.57 b | 31.47 ± 7.19 ab | 30.77 ± 6.50 ab | 28.63 ± 6.23 b | 27.50 ± 5.72 b | 16.93 ± 6.72 c |

| a* | 8.20 ± 2.32 ab | 8.20 ± 2.28 ab | 8.77 ± 1.75 a | 8.70 ± 2.07 a | 6.87 ± 1.38 bc | 6.00 ± 2.68 c | 2.07 ± 1.84 d |

| b* | 21.43 ± 3.58 a | 20.13 ± 3.10 ab | 21.83 ± 3.26 a | 22.37 ± 3.24 a | 19.70 ± 3.82 ab | 17.63 ± 3.81 b | 12.47 ± 3.59 c |

| ΔE | 9.42 ± 3.13 a | 10.11 ± 5.02 a | 9.83 ± 5.00 a | 8.39 ± 4.02 a | 11.28 ± 3.86 a | 21.49 ± 6.01 b | |

| Cross | |||||||

| L* | 41.00 ± 5.14 a | 41.07 ± 4.51 a | 41.30 ± 4.53a | 37.83 ± ab | 34.33 ± 6.18 bc | 32.50 ± 7.19 c | 24.23 ± 7.05 d |

| a* | 7.97 ± 1.92 ab | 8.53 ± 1.38 a | 6.97 ± 2.11 abc | 6.77 ± 2.34 bc | 5.97 ± 2.52 c | 2.77 ± 2.04 d | 0.67 ± 2.84 e |

| b* | 14.47 ± 2.21 a | 15.13 ± 1.72 ab | 15.90 ± 2.52 abc | 17.10 ± 2.71 bc | 17.90 ± 2.50 c | 15.57 ± 3.09 ab | 15.50 ± 3.63 ab |

| ΔE | 6.01 ± 2.65 a | 7.03 ± 2.85 ab | 7.68 ± 3.08 ab | 9.39 ± 3.96 b | 12.66 ± 4.88 c | 18.67 ± 5.44 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siladji, C.; Djordjevic, V.; Borovic, B.; Heinz, V.; Terjung, N.; Katanic, N.; Tomasevic, I. Influence of Algal Incorporation on Sensory and Physicochemical Attributes of Caseless Sausage—Ćevap (CSC). Foods 2024, 13, 4037. https://doi.org/10.3390/foods13244037

Siladji C, Djordjevic V, Borovic B, Heinz V, Terjung N, Katanic N, Tomasevic I. Influence of Algal Incorporation on Sensory and Physicochemical Attributes of Caseless Sausage—Ćevap (CSC). Foods. 2024; 13(24):4037. https://doi.org/10.3390/foods13244037

Chicago/Turabian StyleSiladji, Caba, Vesna Djordjevic, Branka Borovic, Volker Heinz, Nino Terjung, Nenad Katanic, and Igor Tomasevic. 2024. "Influence of Algal Incorporation on Sensory and Physicochemical Attributes of Caseless Sausage—Ćevap (CSC)" Foods 13, no. 24: 4037. https://doi.org/10.3390/foods13244037

APA StyleSiladji, C., Djordjevic, V., Borovic, B., Heinz, V., Terjung, N., Katanic, N., & Tomasevic, I. (2024). Influence of Algal Incorporation on Sensory and Physicochemical Attributes of Caseless Sausage—Ćevap (CSC). Foods, 13(24), 4037. https://doi.org/10.3390/foods13244037