Changes in Nutritional and Techno-Functional Properties of Whole Grain Maize Flours Induced by Dry-Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Dry-Heat Treatment of Maize Flour Samples

2.3. Chemical Procedure

2.3.1. Analysis of Total Protein Content in Maize Flour Samples

2.3.2. Analysis of Starch Content in Maize Flour Samples

2.3.3. Analysis of Dietary Fibre Content in Maize Flour Samples

2.3.4. Extraction of Free and Bound Phenolic Compounds from Maize Flour Samples

2.3.5. Analysis of Total Phenolic Content in Maize Flour Samples (TPC)

2.3.6. Analysis of Total Anthocyanin Content in Maize Flour Samples (TAC)

2.3.7. Analysis of the Total Antioxidant Capacity of Maize Flour Samples

2.4. Solvent Retention Capacity (SRC)

2.5. Gelling Properties of Maize Flour Samples

2.6. Analysis of Starch Damage Level in Maize Flour Samples

2.7. Analysis of Pasting Properties of Maize Flour Samples

2.8. In Vitro Multistep Enzymatic Digestion Protocol

2.9. Measurement of Colour of Maize Flour Samples

2.10. Statistical Analysis

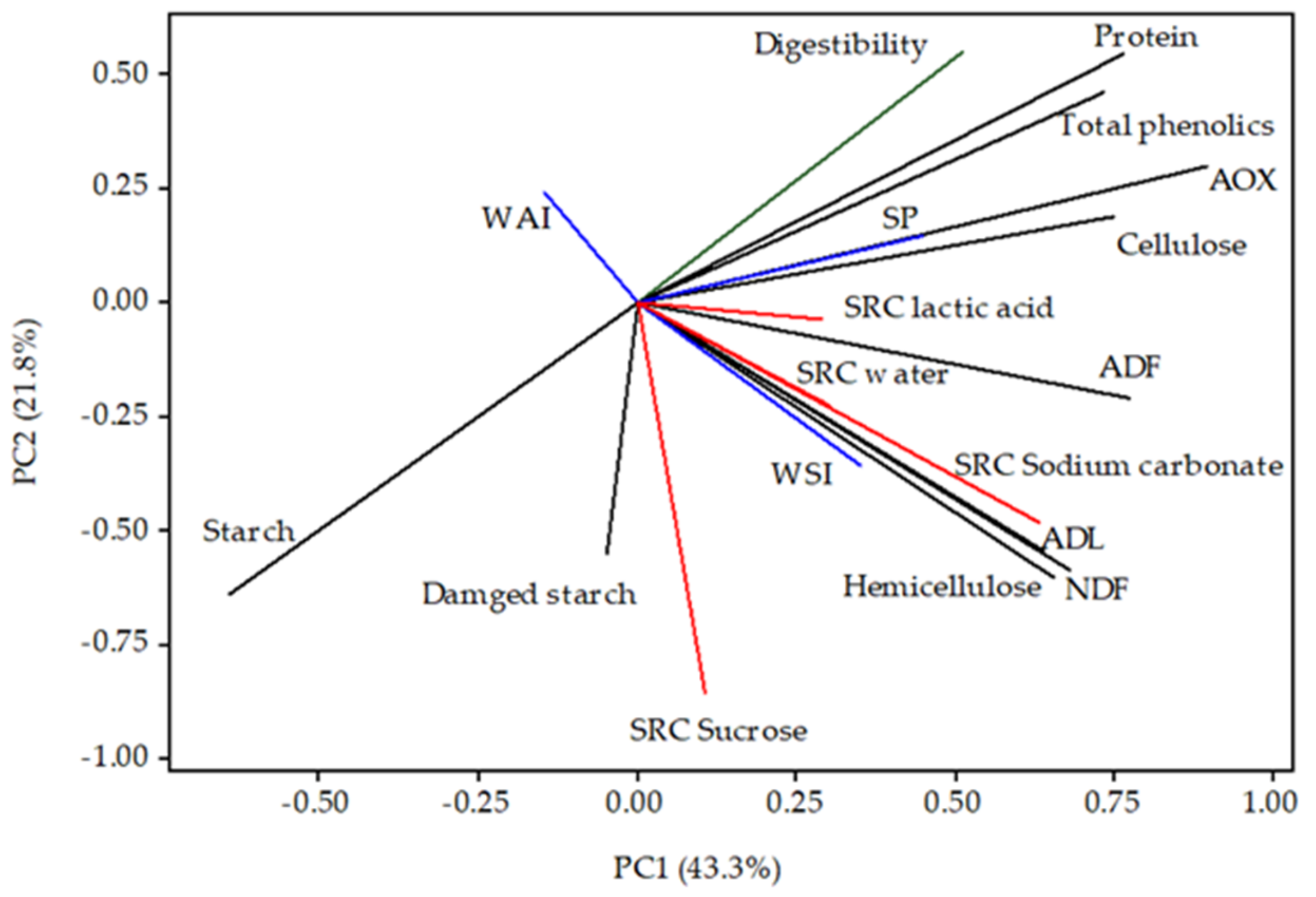

3. Results and Discussion

3.1. Chemical Composition of Maize Flour Samples

3.2. Bioactive Compounds of Maize Flour Samples

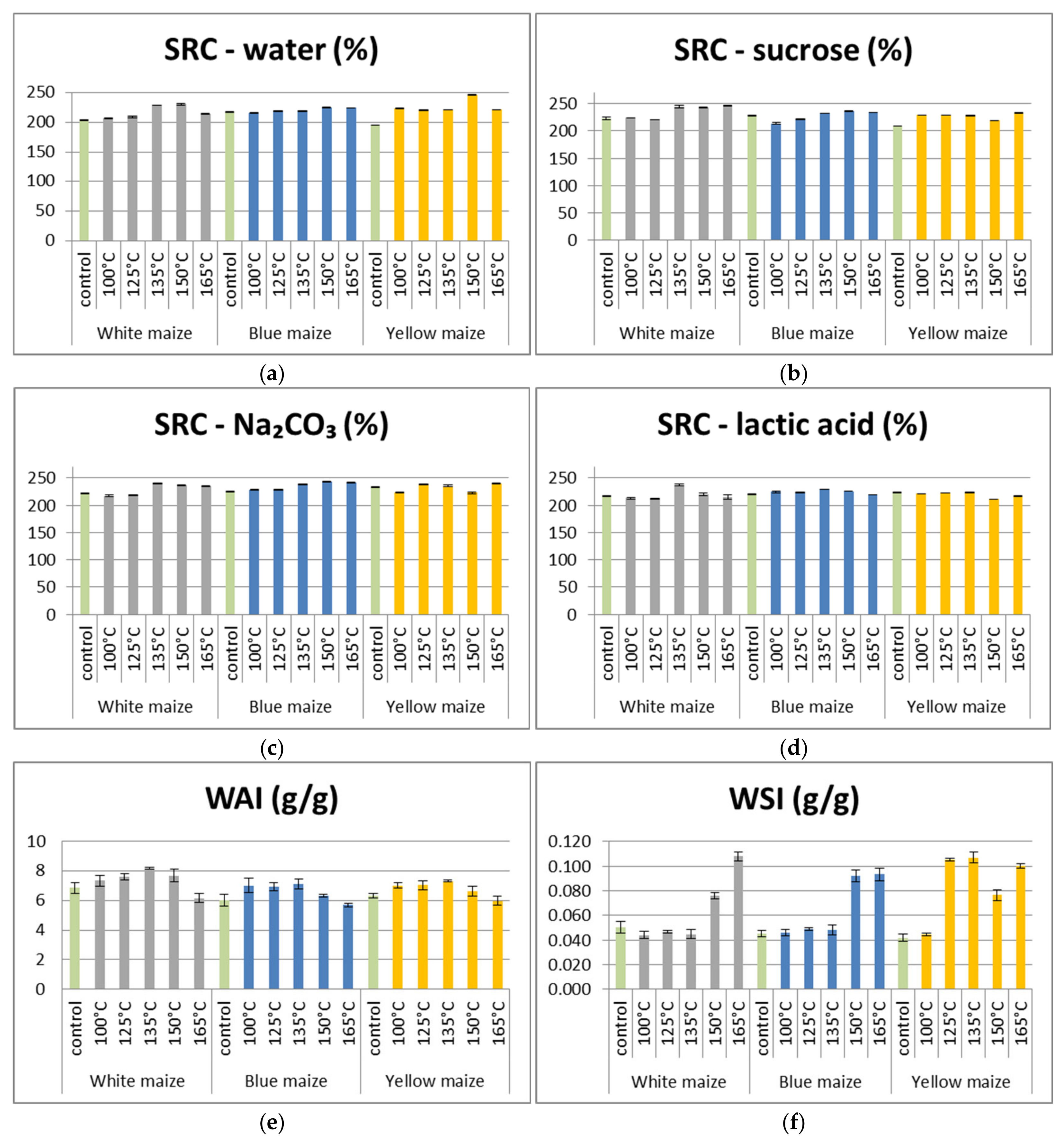

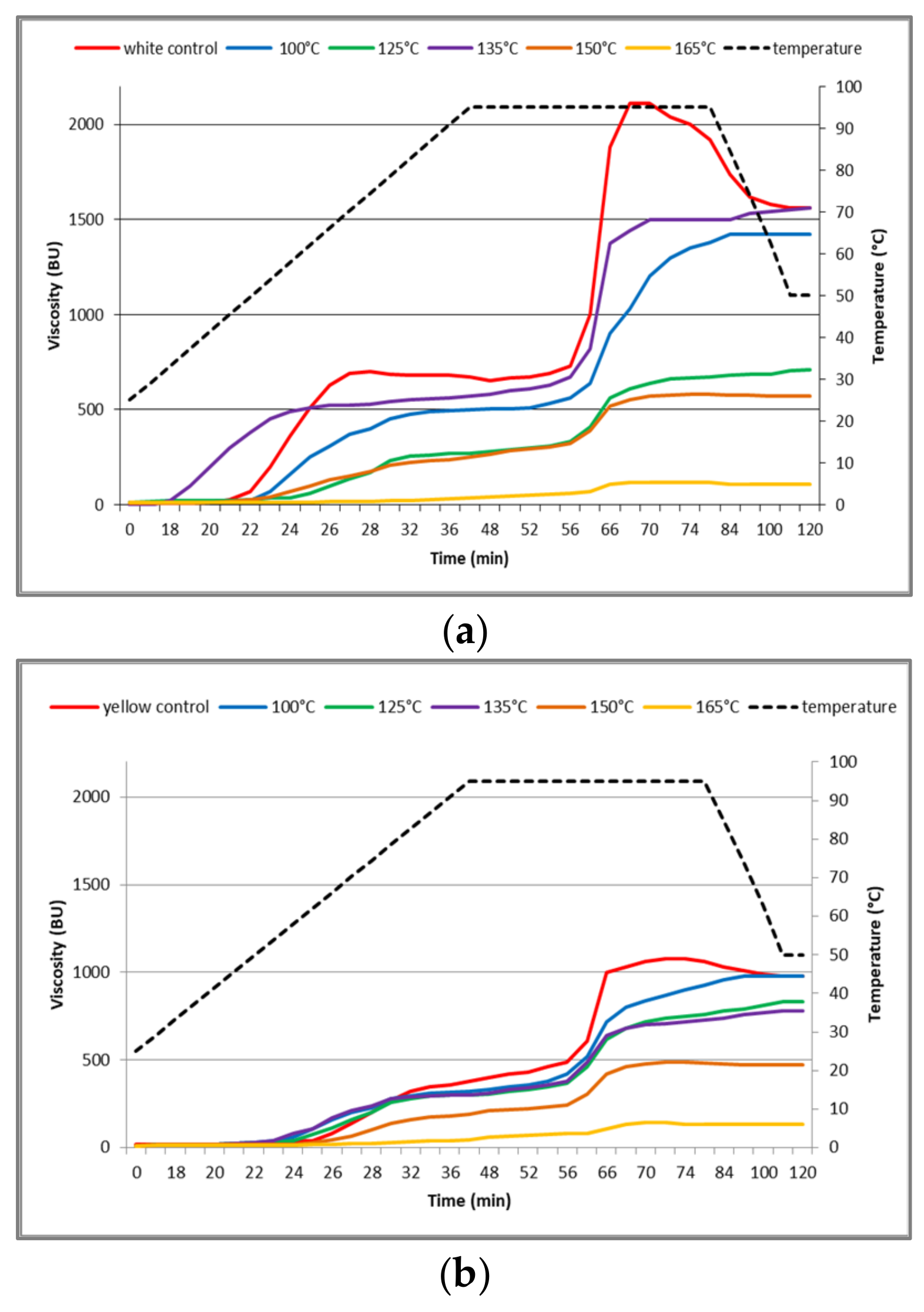

3.3. Techno-Functional Properties of Maize Flour Samples

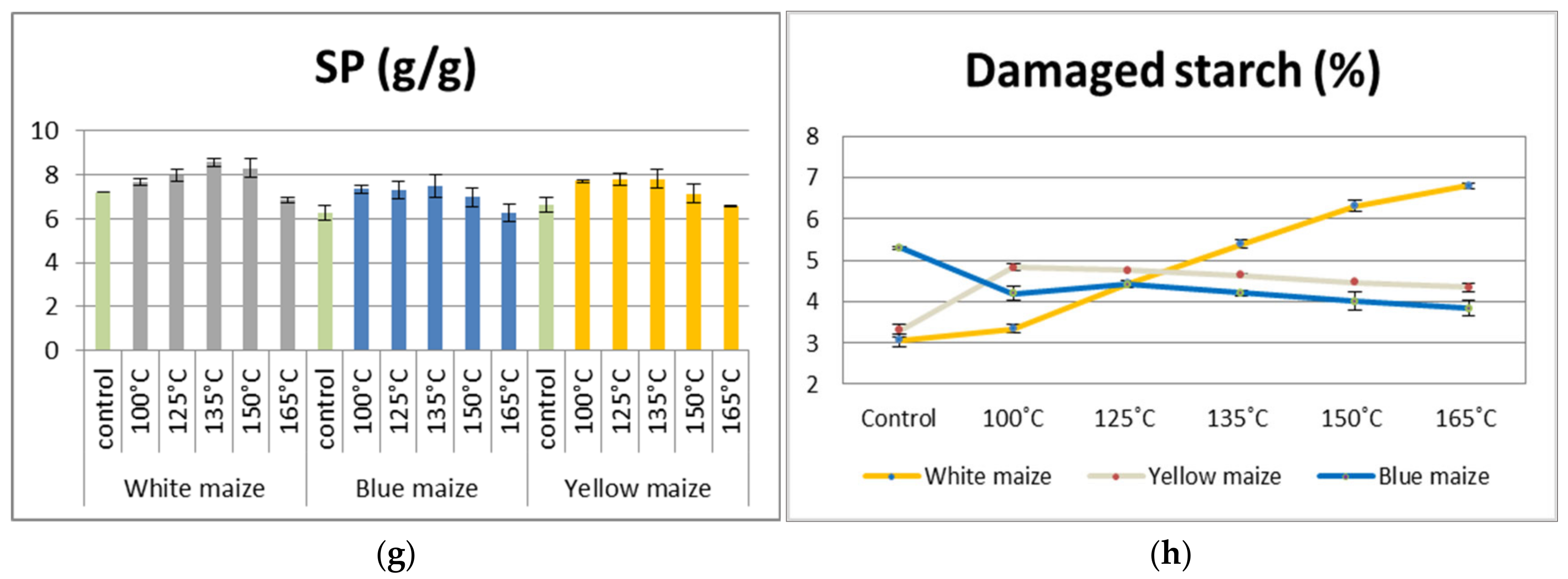

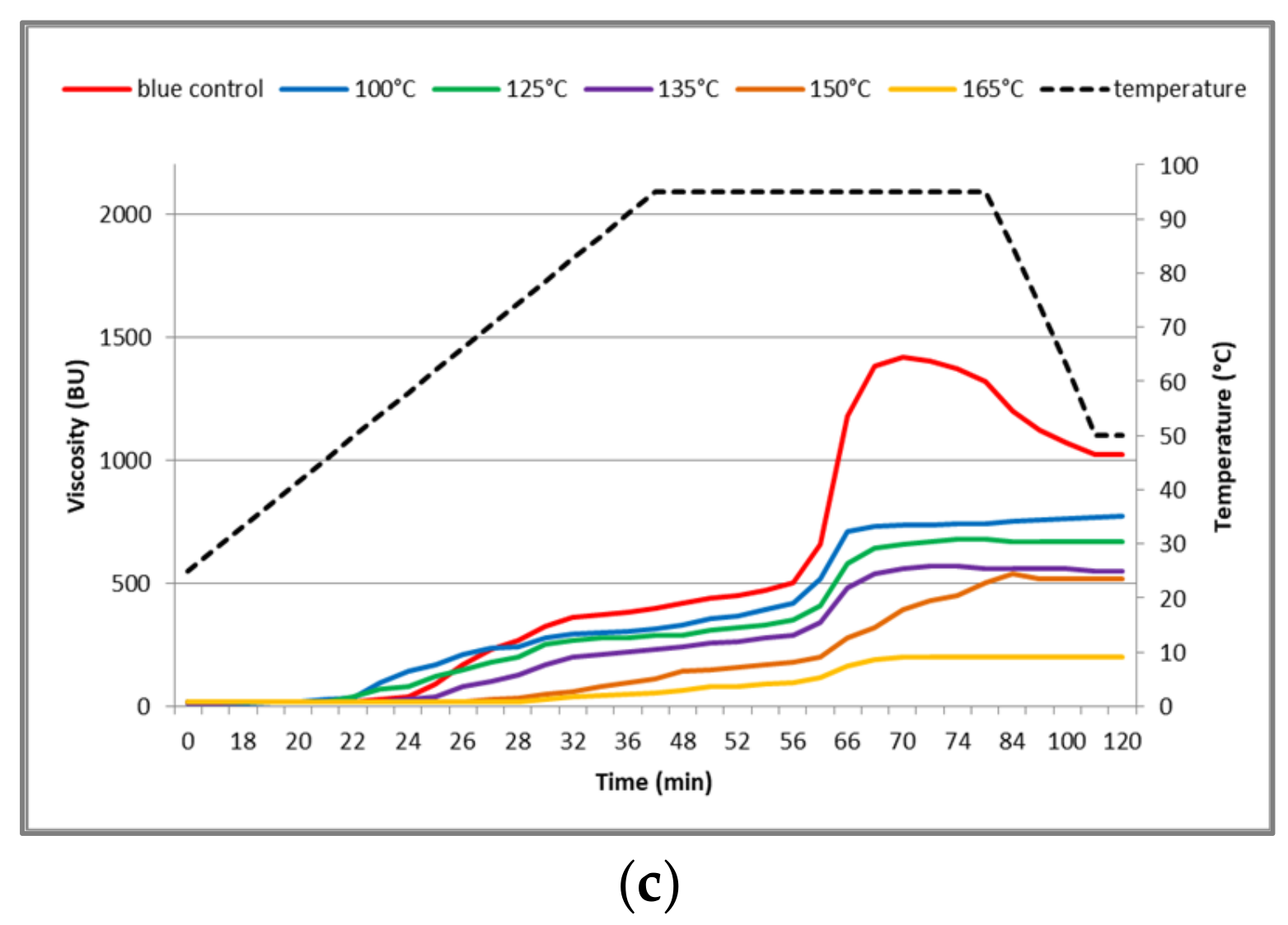

3.4. Pasting Properties of Maize Flour Samples

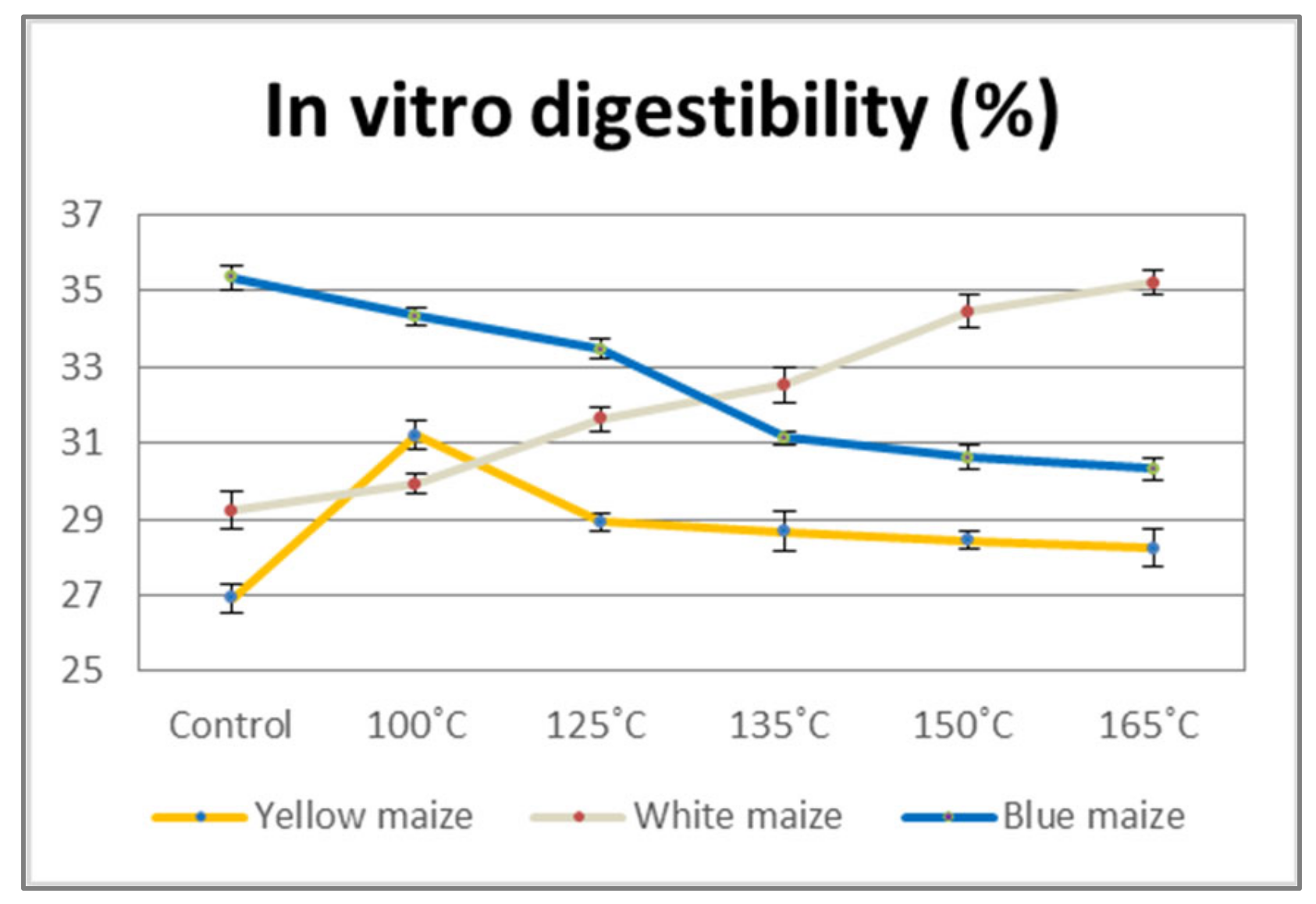

3.5. In Vitro Digestibility

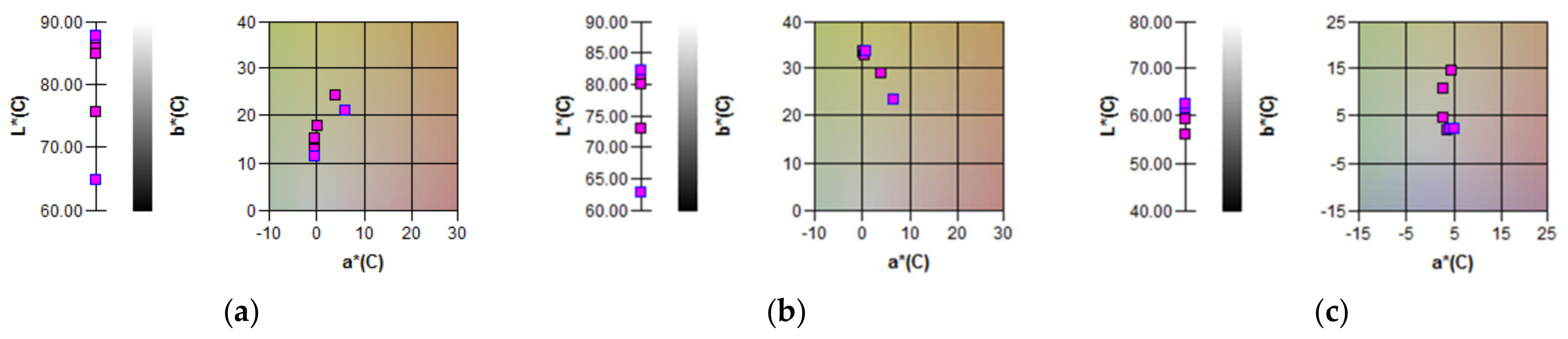

3.6. Color of Maize Flour Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kurt, A.R.; Evers, A.D. Flour treatments, applications, quality, storage and transport. In Kent’s Technology of Cereals, 5th ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 515–564. [Google Scholar] [CrossRef]

- Torbica, A.; Belović, M.; Tomić, J. Novel breads of non-wheat flours. Food Chem. 2019, 282, 134–140. [Google Scholar] [CrossRef] [PubMed]

- Lei, N.; Chai, S.; Xu, M.; Ji, J.; Mao, H.; Yan, S.; Gao, Y.; Li, H.; Wang, J.; Sun, B. Effect of dry heating treatment on multi-levels of structure and physicochemical properties of maize starch: A thermodynamic study. Int. J. Biol. Macromol. 2020, 147, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Rolandelli, G.; Gallardo-Navarro, Y.T.; Pinilla, S.G.; Farroni, A.E.; Gutiérrez-López, G.F.; Buera, M.P. Components interactions and changes at molecular level in maize flour-based blends as affected by the extrusion process. A multi-analytical approach. J. Cereal Sci. 2021, 99, 103186. [Google Scholar] [CrossRef]

- Hong, T.; Ma, Y.; Wu, F.; Jin, Y.; Xu, D.; Xu, X. Understanding the effects of dry heat treatment on wheat flour pasting: Insights from protein and starch structural changes. J. Cereal Sci. 2023, 113, 103740. [Google Scholar] [CrossRef]

- Oh, I.K.; Bae, I.Y.; Lee, H.G. Effect of dry heat treatment on physical property and in vitro starch digestibility of high amylose rice starch. Int. J. Biol. Macromol. 2018, 108, 568–575. [Google Scholar] [CrossRef]

- Lim, H.S.; Han, J.A.; Bemiller, J.N.; Lim, S.T. Physical modification of waxy maize starch by dry heating with ionic gums. J. Appl. Glycosci. 2006, 53, 281–286. [Google Scholar] [CrossRef]

- Torbica, A.; Belović, M.; Popović, L.; Čakarević, J. Heat and hydrothermal treatments of non-wheat flours. Food Chem. 2021, 334, 127523. [Google Scholar] [CrossRef]

- Marston, K.; Khouryieh, H.; Aramouni, F. Effect of heat treatment of sorghum flour on the functional properties of gluten-free bread and cake. LWT—Food Sci. Technol. 2016, 65, 637–644. [Google Scholar] [CrossRef]

- Sun, Q.; Gong, M.; Li, Y.; Xiong, L. Effect of dry heat treatment on the physicochemical properties and structure of proso millet flour and starch. Carbohydr. Polym. 2014, 110, 128–134. [Google Scholar] [CrossRef]

- Radosavljević, M.; Filipović, N.; Božović, I.; Jovanović, R. Utilization possibility of different ZP maize genotypes in bread production. J. Process Energy Agric. 2003, 7, 20–22. [Google Scholar]

- Filipović, N.; Šoronja-Simović, D.; Filipović, J. Bread with extruded corn ’products. Acta Agric. Serb. 2006, 11, 29–36. [Google Scholar]

- Giordano, D.; Vanara, F.; Reyneri, A.; Blandino, M. Effect of dry-heattreatments on the nutritional value of maize germ. Int. J. Food Sci. Technol. 2016, 51, 2468–2473. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis: Official Method for Protein; Method No. 920.87; AOAC—Association of Official Analytical Chemists: Washington DC, USA, 1995. [Google Scholar]

- ISO 10520; Determination of Starch Content-Ewers Polarimetric Method. ISO—International Organization for Standardization: Geneva, Switzerland, 1997.

- Mertens, D.R. Critical Conditions in determining detergent fiber. In Proceedings of the Forage Analysis Workshop, Denver, Colorado, 16–17 September 1992. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Abdel-Aal, E.S.M.; Hucl, P. A rapid method for quantifying total anthocyanins in blue aleurone and purple pericarp wheats. Cereal Chem. 1999, 76, 350–354. [Google Scholar] [CrossRef]

- Serpen, A.; Gökmen, V.; Pellegrini, N.; Fogliano, V. Direct measurement of the total antioxidant capacity of cereal products. J. Cereal Sci. 2008, 48, 816–820. [Google Scholar] [CrossRef]

- Haynes, L.C.; Bettge, A.D.; Slade, L. Soft wheat and flour products methods review: Solvent retention capacity equation correction. Cereal Foods World 2009, 54, 174–175. [Google Scholar] [CrossRef]

- Cornejo, F.; Rosell, C.M. Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. LWT—Food Sci. Technol. 2015, 62, 1203–1210. [Google Scholar] [CrossRef]

- AACC International Approved Methods of Analysis, 11th ed.; AACC International Method 76-31.01; AACC—American Association of Cereal Chemists, AACC International Press: St. Paul, MN, USA, 2009.

- ICC. Official Method for Using the Brabender Viscograph 169; ICC—International Association for Cereal Science and Technology: Viena, Austria, 2000. [Google Scholar]

- Papillo, V.A.; Vitaglione, P.; Graziani, G.; Gokmen, V.; Fogliano, V. Release of antioxidant capacity from five plant foods during a multistep enzymatic digestion protocol. J. Agric. Food Chem. 2014, 62, 4119–4126. [Google Scholar] [CrossRef]

- Hamzalıoğlu, A.; Gökmen, V. Formation and elimination reactions of 5-hydroxymethylfurfural during in vitro digestion of biscuits. Food Res. Int. 2017, 99, 308–314. [Google Scholar] [CrossRef]

- Félix-Medina, J.V.; Montes-Avila, J.; Reyes-Moreno, C.; Perales-Sánchez, J.X.K.; Gomez-´Favela, M.A.; Aguilar-Palazuelos, E.; Gutiérrez-Dorado, R. Second-generation snacks with high nutritional and antioxidant value produced by an optimized extrusion process from corn/common bean flours mixtures. LWT—Food Sci. Technol. 2020, 124, 109172. [Google Scholar] [CrossRef]

- Téllez-Morales, J.A.; Herman-Lara, E.; Gomez-Aldapa, Ć.A.; Rodríguez-Miranda, J. Techno-functional properties of the starch-protein interaction during extrusion-cooking of a model system (corn starch and whey protein isolate). LWT—Food Sci. Technol. 2020, 132, 109789. [Google Scholar] [CrossRef]

- Jebalia, I.; Maigret, J.-E.; Réguerre, A.-L.; Novales, B.; Guessasma, S.; Lourdin, D.; DellaValle, G.; Kristiawan, M. Morphology and mechanical behavior of pea-based starch-protein composites obtained by extrusion. Carbohydr. Polym. 2019, 223, 115086. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Díaz, J.M.; Rinnan, Å.; Jouppila, K. Application of NIR imaging to the study of expanded snacks containing amaranth, quinoa and kaniwa. LWT—Food Sci. Technol. 2019, 102, 8–14. [Google Scholar] [CrossRef]

- Sun, C.; Dai, L.; He, X.; Liu, F.; Yuan, F.; Gao, Y. Effect of heat treatment on physical, structural, thermal and morphological characteristics of zein in ethanol-water solution. Food Hydrocoll. 2016, 58, 11–19. [Google Scholar] [CrossRef]

- Qiu, C.; Cao, J.; Xiong, L.; Sun, Q. Differences in physicochemical, morphological, and structural properties between rice starch and rice flour modified by dry heat treatment. Starch Stärke 2015, 67, 756–764. [Google Scholar] [CrossRef]

- Vashisht, D.; Pandey, A.; Hermenean, A.; Yanez-Gascon, M.J.; Perez-Sanchez, H.; Kumar, K.J. Effect of dry heating and ionic gum on the physicochemical and release properties of starch from Dioscorea. Int. J. Biol. Macromol. 2017, 95, 557–563. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Shoemaker, C.F.; Xu, Z.; Zhu, S.; Zhong, F. Effect of dry heat treatment with xanthan on waxy rice starch. Carbohydr. Polym. 2013, 92, 1647–1652. [Google Scholar] [CrossRef]

- Chang, M.C. The Effect of Heat Treatments on Dietary Fiber as Assessed by Chemical Analysis and Scanning Electron Microscopy. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 1989. [Google Scholar]

- Watson, S.A. Corn: Chemistry and Technology. In Description, Development, Structure, and Composition of the Corn Kernel, 2nd ed.; White, P.J., Johnson, L.A., Eds.; American Association of Cereal Chemists: St. Paul, MN, USA, 2003; pp. 69–101. [Google Scholar]

- Del Pozo-Insfram, D.; Selna Saldivar, S.O.; Brenes, C.H.; Talcott, S.T. Polyphenolics and antioxidant capacity of white and blue corn processed into tortillas and chips. Cereal Chem. 2007, 84, 162–168. [Google Scholar] [CrossRef]

- Žilić, S.; Serpen, A.; Akıllıoğlu, G.; Gökmen, V.; Vančetović, J. Phenolic Compounds, Carotenoids, Anthocyanins, and Antioxidant Capacity of Colored Maize (Zea mays L.) Kernels. J. Agric. Food Chem. 2012, 60, 1224–1231. [Google Scholar] [CrossRef]

- Simić, M.; Šimurina, O.; Nježić, Z.; Vančetović, J.; Kandić, V.; Nikolić, V.; Žilić, S. Effects of ascorbic acid and sugar on physical, textural and sensory properties of composite breads. Food Feed. Res. 2021, 48, 185–200. [Google Scholar] [CrossRef]

- Žilić, S.; Kocadagli, T.; Vančetović, J.; Gokmen, V. Effects of baking conditions and dough formulations on phenolic compound stability, antioxidant capacity and color of cookies made from anthocyanin-rich corn flour. LWT—Food Sci. Technol. 2016, 65, 597–603. [Google Scholar] [CrossRef]

- Dewanto, V.; Wu, X.; Adom, K.K.; Liu, R.H. Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J. Agric. Food Chem. 2002, 50, 3010–3014. [Google Scholar] [CrossRef] [PubMed]

- Multari, S.; Marsol-Vall, A.; Keskitalo, M.; Yang, B.; Suomela, J.P. Effects of different drying temperatures on the content of phenolic compounds and carotenoids in quinoa seeds (Chenopodium quinoa) from Finland. J. Food Compos. Anal. 2018, 72, 75–82. [Google Scholar] [CrossRef]

- Abd-Ghani, A.; Abd Rashid, N.Y.; Abd Razak, D.L.; Jamaluddin, A.; Abdul Manan, M.; Mansor, A. The effects of heat treatments on the bioactive compounds, antioxidant activity, and cosmeceutical properties (anti-pigmentation and anti-ageing) of fermented broken rice. Food Res. 2023, 6, 155–162. [Google Scholar] [CrossRef]

- Simić, M.; Slađana, Ž.; Olivera, Š.; Bojana, F.; Dubravka, Š.; Jelena, V. Effects of anthocyanin-rich popping maize flour on the phenolic profile and the antioxidant capacity of mix-bread and its physical and sensory properties. Pol. J. Food Nutr. Sci. 2018, 68, 299–308. [Google Scholar] [CrossRef]

- Blanch, G.P.; Ruiz del Castillo, M.L. Effect of baking temperature on the phenolic content and antioxidant activity of black corn (Zea mays L.) bread. Foods 2021, 10, 1202. [Google Scholar] [CrossRef]

- De la Parra, C.; Saldivar, S.O.S.; Liu, R.H. Effect of processing on the phytochemical profiles and antioxidant activity of corn for production of masa, tortillas, and tortilla chips. J. Agric. Food Chem. 2007, 55, 4177–4183. [Google Scholar] [CrossRef]

- Li, W.; Pickard, M.D.; Beta, T. Effect of thermal processing on antioxidant properties of purple wheat bran. Food Chem. 2007, 104, 1080–1086. [Google Scholar] [CrossRef]

- Wessels, R.; Wentzel, B.; Labuschagne, M.T. Solvent retention capacity and swelling index of glutenin in hard red wheat flour as possible indicators of rheological and baking quality characteristics. J. Cereal Sci. 2020, 93, 102983. [Google Scholar] [CrossRef]

- Guttieri, M.J.; Bowen, D.; Gannon, D.; O’Brien, K.; Souza, E. Solvent retention capacities of irrigated soft white spring wheat flours. Crop Sci. 2001, 41, 1054–1061. [Google Scholar] [CrossRef]

- Ram, S.; Dawar, V.; Singh, R.P.; Shoran, J. Application of solvent retention capacity tests for the prediction of mixing properties of wheat flour. J. Cereal Sci. 2005, 42, 261–266. [Google Scholar] [CrossRef]

- Xu, A.; Qiu, J.; Yin, Z.; Wei, C. Morphological characteristics of endosperm in different regions of maize kernels with different vitreousness. J. Cereal Sci. 2019, 87, 273–279. [Google Scholar] [CrossRef]

- Boyacı, İ.H.; Williams, P.C.; Köksel, H. A rapid method for the estimation of damaged starch in wheat flours. J. Cereal Sci. 2004, 39, 139–145. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2014, 51, 1342–1348. [Google Scholar] [CrossRef]

- Patil, S.; Kaur, C.; Puniya, M.K.; Mahapatra, A.; Dhakane, J.; Jalgaonkar, K.; Mahawar, M.K. Functional Properties of Extruded Corn Flour. Turk. J. Agric. Eng. Res. 2021, 2, 167–174. [Google Scholar] [CrossRef]

- Osundahunsi, O.F.; Fagbemi, T.N.; Kesselman, E.; Shimoni, E. Comparison of the physicochemical properties and pasting characteristics of flour and starch from red and white sweet potato cultivars. J. Agric. Food Chem. 2003, 51, 2232–2236. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, K.; Maskan, M. Effect of Extrusion Cooking on Functional Properties and in vitro Starch Digestibility of Barley-Based Extrudates from Fruit and Vegetable By-Products. J. Food Sci. 2009, 74, E77–E86. [Google Scholar] [CrossRef]

- Bryant, R.J.; Kadan, R.S.; Champagrte, E.T.; Vinyard, B.T.; Boykin, D. Functional and digestive characteristics of extruded rice flour. Cereal Chem. 2001, 78, 131–137. [Google Scholar] [CrossRef]

- Ge, X.; Shen, H.; Su, C.; Zhang, B.; Zhang, Q.; Jiang, H.; Li, W. The improving effects of cold plasma on multi-scale structure, physicochemical and digestive properties of dry heated red adzuki bean starch. Food Chem. 2021, 349, 129159. [Google Scholar] [CrossRef]

- Kokić, B.; Dokić, L.; Pezo, L.; Jovanović, R.; Spasevski, N.; Kojić, J.; Hadnađev, M. Physicochemical changes of heat-treated corn grain used in ruminant nutrition. Animals 2022, 12, 2234. [Google Scholar] [CrossRef]

- Sun, Q.; Si, F.; Xiong, L.; Chu, L. Effect of dry heating with ionic gums on physicochemical properties of starch. Food Chem. 2013, 136, 1421–1425. [Google Scholar] [CrossRef] [PubMed]

- Mahajan, P.; Bera, M.B.; Panesar, P.S.; Chauhan, A. Millet starch: A review. Int. J. Biol. Macromol. 2021, 180, 61–79. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Wichers, H.J.; Hettinga, K.A. Heat-induced unfolding facilitates plant protein digestibility during in vitro static infant digestion. Food Chem. 2022, 375, 131878. [Google Scholar] [CrossRef] [PubMed]

- Nikolić, V.; Simić, M.; Žilić, S.; Vasić, M.; Milovanović, D.; Sarić, B. The influence of particle size distribution on in vitro digestibility and nutritional quality of differently coloured wholegrain maize flours. J. Food Nutr. Res. 2023, 62, 245–253. [Google Scholar]

- Singh, J.; Dartois, A.; Kaur, L. Starch Digestibility in Food Matrix: A Review. Trends Food Sci. Technol. 2010, 21, 168–180. [Google Scholar] [CrossRef]

- Schefer, S.; Oest, M.; Rohn, S. Interactions between Phenolic Acids, Proteins, and Carbohydrates-Influence on Dough and Bread Properties. Foods 2021, 10, 2798. [Google Scholar] [CrossRef]

- Pramodrao, K.S.; Riar, C.S. Comparative study of effect of modification with ionic gums and dry heating on the physicochemical characteristic of potato, sweet potato and taro starches. Food Hydrocolloid. 2014, 35, 613–619. [Google Scholar] [CrossRef]

- Boyd, L.; Storsley, J.; Ames, N. Effect of heat treatments on starch pasting, particle size, and color of whole-grain barley. Cereal Chem. 2017, 94, 325–332. [Google Scholar] [CrossRef]

- González, M.; Vernon-Carter, E.J.; Alvarez-Ramirez, J.; Carrera-Tarela, Y. Effects of dry heat treatment temperature on the structure of wheat flour and starch in vitro digestibility of bread. Int. J. Biol. Macromol. 2021, 166, 1439–1447. [Google Scholar] [CrossRef]

| Solution | SSF | SGF | SDF | |||

|---|---|---|---|---|---|---|

| pH = 7.0 | pH = 3.0 | pH = 7.0 | ||||

| Volume (mL) | Stock (g/L) | Volume (mL) | Stock (g/L) | Volume (mL) | Stock (g/L) | |

| KCl | 10 | 46.7 | 28.0 | 46.7 | 5.4 | 46.7 |

| KH2PO4 | 20 | 68.0 | 0.9 | 68.0 | 0.8 | 68.0 |

| NaHCO3 | 4 | 84.0 | 6.5 | 168.0 | 42.5 | 42.5 |

| NaCl | 1 | 120.0 | 10.0 | 120.0 | 8.0 | 120.0 |

| MgCl2(H2O)6 | 1 | 30.0 | 2.0 | 30.0 | 1.1 | 30.0 |

| Sample | Temperature (°C) | Total Protein | Total Starch | NDF | ADF | ADL | Hemicellulose | Cellulose |

|---|---|---|---|---|---|---|---|---|

| White maize | control | 8.36 ± 0.01 b | 71.06 ± 0.08 c | 11.48 ± 0.52 c | 3.56 ± 0.10 ab | 0.45 ± 0 b | 7.92 ± 0.62 c | 3.11 ± 0.10 a |

| 100 | 8.34 ± 0.04 b | 71.07 ± 0.37 c | 12.35 ± 0.87 c | 2.67 ± 0.04 bc | 0.35 ± 0.09 b | 9.68 ± 0.91 c | 2.33 ± 0.13 ab | |

| 125 | 8.68 ± 0.06 a | 70.08 ± 0.11 d | 11.45 ± 0.58 c | 2.28 ± 0.01 c | 0.27 ± 0.04 b | 9.17 ± 0.57 c | 2.01 ± 0.03 b | |

| 135 | 8.35 ± 0.04 b | 73.76 ± 0.09 ab | 15.60 ± 0.58 b | 3.38 ± 0.45 ab | 0.33 ± 0.01 b | 12.72 ± 0.58 b | 3.22 ± 0.13 a | |

| 150 | 8.29 ± 0.06 b | 74.45 ± 0.08 a | 14.65 ± 0.10 b | 2.19 ± 0.08 c | 0.31 ± 0.06 b | 12.47 ± 0.18 b | 1.88 ± 0.14 b | |

| 165 | 8.24 ± 0.06 b | 73.34 ± 0.17 b | 44.35 ± 0.06 a | 4.02 ± 0.37 a | 1.62 ± 0.21 a | 40.34 ± 0.32 a | 2.40 ± 0.17 ab | |

| Yellow maize | control | 12.36 ± 0.27 a | 69.60 ± 0.07 ab | 14.19 ± 0.82 d | 3.58 ± 0.73 ab | 0.40 ± 0.02 bc | 10.62 ± 0.09 d | 3.18 ± 0.07 a |

| 100 | 12.20 ± 0.09 a | 68.43 ± 0.11 c | 16.79 ± 0.01 d | 3.98 ± 0.05 ab | 0.25 ± 0.01 c | 12.82 ± 0.04 c | 1.73 ± 0.06 a | |

| 125 | 12.31 ± 0.30 a | 68.58 ± 0.46 bc | 14.30 ± 0.20 d | 3.64 ± 0.45 ab | 0.42 ± 0.04 bc | 10.67 ± 0.64 d | 3.22 ± 0.08 a | |

| 135 | 12.39 ± 0.01 a | 69.18 ± 0.09 abc | 18.06 ± 0.40 c | 2.48 ± 0.12 ab | 0.30 ± 0.05 bc | 15.58 ± 0.28 c | 2.18 ± 0.07 a | |

| 150 | 11.97 ± 0.04 a | 69.61 ± 0.28 a | 23.88 ± 0.35 b | 3.10 ± 0.71 ab | 0.50 ± 0.09 b | 20.79 ± 1.07 b | 2.60 ± 0.08 a | |

| 165 | 11.99 ± 0.04 a | 68.37 ± 0.28 c | 37.84 ± 0.54 a | 4.41 ± 0.56 a | 1.13 ± 0.06 a | 33.43 ± 1.10 a | 3.28 ± 0.03 a | |

| Blue maize | control | 13.00 ± 0.17 a | 66.82 ± 0.07 a | 15.59 ± 0.05 e | 3.77 ± 0.29 b | 0.54 ± 0.11 a | 11.82 ± 0.34 e | 3.23 ± 0.10 a |

| 100 | 13.02 ± 0.08 a | 64.63 ± 0.11 d | 16.79 ± 0.63 de | 3.51 ± 0.01 b | 0.48 ± 0.03 b | 13.28 ± 0.62 de | 3.03 ± 0.02 a | |

| 125 | 13.05 ± 0.03 a | 64.81 ± 0.08 cd | 18.09 ± 0.59 d | 3.64 ± 0.38 b | 0.50 ± 0.03 b | 14.45 ± 0.21 d | 3.14 ± 0.07 a | |

| 135 | 13.03 ± 0.01 a | 65.40 ± 0.24 bc | 29.98 ± 0.46 b | 3.65 ± 0.04 b | 0.58 ± 0.11 b | 26.33 ± 0.50 b | 3.07 ± 0.07 a | |

| 150 | 12.94 ± 0.04 a | 67.33 ± 0 a | 25.42 ± 0.21 c | 3.87 ± 0.07 b | 0.85 ± 0.19 b | 21.55 ± 0.98 c | 3.02 ± 0.07 a | |

| 165 | 12.83 ± 0 a | 65.79 ± 0.25 b | 45.86 ± 0.36 a | 5.33 ± 0.35 a | 2.29 ± 0.45 b | 40.47 ± 0.80 a | 3.04 ± 0.10 a |

| Sample | Temperature (°C) | Soluble Free Phenolics (mg GAE/kg) | Insoluble Bound Phenolics (mg GAE/kg) | Anthocyanins (mg CGE/kg) | Antioxidant Capacity (mmol trolox/kg) |

|---|---|---|---|---|---|

| White maize | control | 145.89 ± 5.12 cd | 2181.27 ± 7.46 a | n.d. | 12.07 ± 2.25 a |

| 100 | 131.33 ± 4.80 d | 1964.08 ± 15.67 c | n.d. | 10.05 ± 0.01 a | |

| 125 | 206.88 ± 2.76 bc | 1792.47 ± 11.99 d | n.d. | 10.85 ± 1.19 a | |

| 135 | 217.76 ± 6.04 b | 1817.00 ± 5.66 d | n.d. | 13.01 ± 0.49 a | |

| 150 | 251.82 ± 1.52 b | 2050.47 ± 12.06 b | n.d. | 13.04 ± 2.00 a | |

| 165 | 336.41 ± 8.23 a | 2049.65 ± 6.57 b | n.d. | 13.32 ± 0.29 a | |

| Yellow maize | control | 300.83 ± 12.33 ab | 2812.76 ± 6.49 a | n.d. | 17.05 ± 0.98 a |

| 100 | 266.76 ± 3.08 b | 2296.43 ± 5.77 d | n.d. | 14.83 ± 0.40 ab | |

| 125 | 312.94 ± 14.33 ab | 2413.24 ± 4.59 c | n.d. | 15.89 ± 0.14 b | |

| 135 | 322.33 ± 13.58 ab | 2745.59 ± 4.83 b | n.d. | 16.41 ± 0.35 ab | |

| 150 | 345.10 ± 7.62 a | 2757.16 ± 2.61 b | n.d. | 16.89 ± 0.13 a | |

| 165 | 366.56 ± 10.24 a | 2756.68 ± 7.72 b | n.d. | 17.15 ± 0.18 a | |

| Blue maize | control | 390.21 ± 7.24 bc | 3726.57 ± 21.82 a | 894.62 ± 9.56 c | 24.03 ± 0.09 a |

| 100 | 337.69 ± 7.39 c | 2729.09 ± 15.69 d | 948.78 ± 0.03 b | 20.51 ± 0.13 b | |

| 125 | 390.96 ± 2.45 b | 2593.54 ± 8.69 e | 1011.87 ± 12.79 a | 22.29 ± 0.39 ab | |

| 135 | 408.04 ± 9.74 b | 2601.64 ± 16.06 e | 927.48 ± 10.12 bc | 23.09 ± 1.01 ab | |

| 150 | 411.28 ± 11.90 b | 2825.41 ± 10.73 c | 706.37 ± 14.23 d | 23.74 ± 0.28 a | |

| 165 | 546.16 ± 3.63 a | 2903.46 ± 14.79 b | 368.72 ± 11.38 e | 23.96 ± 1.46 a |

| Sample | Temperature (°C) | L* | a* | b* |

|---|---|---|---|---|

| White maize | control | 87.200 ± 0.056 a | −0.390 ± 0.000 f | 10.130 ± 0.000 f |

| 100 | 86.440 ± 0.028 ab | −0.360 ± 0.000 e | 12.990 ± 0.013 e | |

| 125 | 85.690 ± 0.042 b | −0.320 ± 0.000 d | 15.200 ± 0.000 d | |

| 135 | 84.800 ± 0.025 c | 0.130 ± 0.000 c | 17.770 ± 0.000 c | |

| 150 | 75.650 ± 0.001 d | 3.930 ± 0.001 b | 24.380 ± 0.001 b | |

| 165 | 64.770 ± 0.03 e | 6.140 ± 0.000 a | 21.120 ± 0.000 a | |

| Yellow maize | control | 82.040 ± 0.000 a | 0.660 ± 0.001 c | 33.640 ± 0.002 b |

| 100 | 81.150 ± 0.001 b | 0.330 ± 0.000 e | 33.270 ± 0.002 c | |

| 125 | 80.980 ± 0.001 c | 0.210 ± 0.002 f | 33.670 ± 0.002 a | |

| 135 | 79.900 ± 0.001 d | 0.630 ± 0.001 d | 32.790 ± 0.002 d | |

| 150 | 73.010 ± 0.001 e | 4.070 ± 0.001 b | 29.020 ± 0.000 e | |

| 165 | 62.900 ± 0.000 f | 6.510 ± 0.000 a | 23.440 ± 0.001 f | |

| Blue maize | control | 62.550 ± 0.001 a | 5.250 ± 0.000 a | 2.220 ± 0.000 d |

| 100 | 61.710 ± 0.002 b | 4.130 ± 0.000 c | 2.150 ± 0.001 e | |

| 125 | 61.490 ± 0.001 c | 3.570 ± 0.001 d | 2.000 ± 0.001 f | |

| 135 | 61.670 ± 0.002 d | 2.700 ± 0.001 e | 4.420 ± 0.001 c | |

| 150 | 59.380 ± 0.000 e | 2.870 ± 0.001 f | 10.560 ± 0.002 b | |

| 165 | 56.170 ± 0.000 f | 4.600 ± 0.001 b | 14.550 ± 0.000 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simić, M.; Nikolić, V.; Sarić, B.; Milovanović, D.; Kostadinović, M.; Žilić, S. Changes in Nutritional and Techno-Functional Properties of Whole Grain Maize Flours Induced by Dry-Heat Treatment. Foods 2024, 13, 3314. https://doi.org/10.3390/foods13203314

Simić M, Nikolić V, Sarić B, Milovanović D, Kostadinović M, Žilić S. Changes in Nutritional and Techno-Functional Properties of Whole Grain Maize Flours Induced by Dry-Heat Treatment. Foods. 2024; 13(20):3314. https://doi.org/10.3390/foods13203314

Chicago/Turabian StyleSimić, Marijana, Valentina Nikolić, Beka Sarić, Danka Milovanović, Marija Kostadinović, and Slađana Žilić. 2024. "Changes in Nutritional and Techno-Functional Properties of Whole Grain Maize Flours Induced by Dry-Heat Treatment" Foods 13, no. 20: 3314. https://doi.org/10.3390/foods13203314

APA StyleSimić, M., Nikolić, V., Sarić, B., Milovanović, D., Kostadinović, M., & Žilić, S. (2024). Changes in Nutritional and Techno-Functional Properties of Whole Grain Maize Flours Induced by Dry-Heat Treatment. Foods, 13(20), 3314. https://doi.org/10.3390/foods13203314