Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Production of Chinese Dried Noodles

2.2.2. Water Activity Measurement

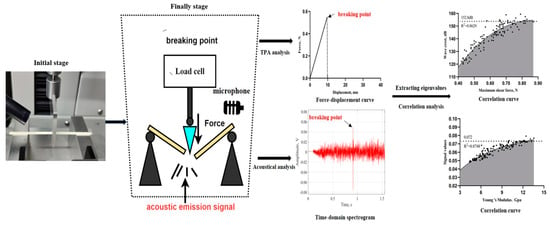

2.2.3. Coupled Acoustic–Mechanical Detection

2.2.4. Statistical Analysis

3. Results and Discussions

3.1. Water Activity

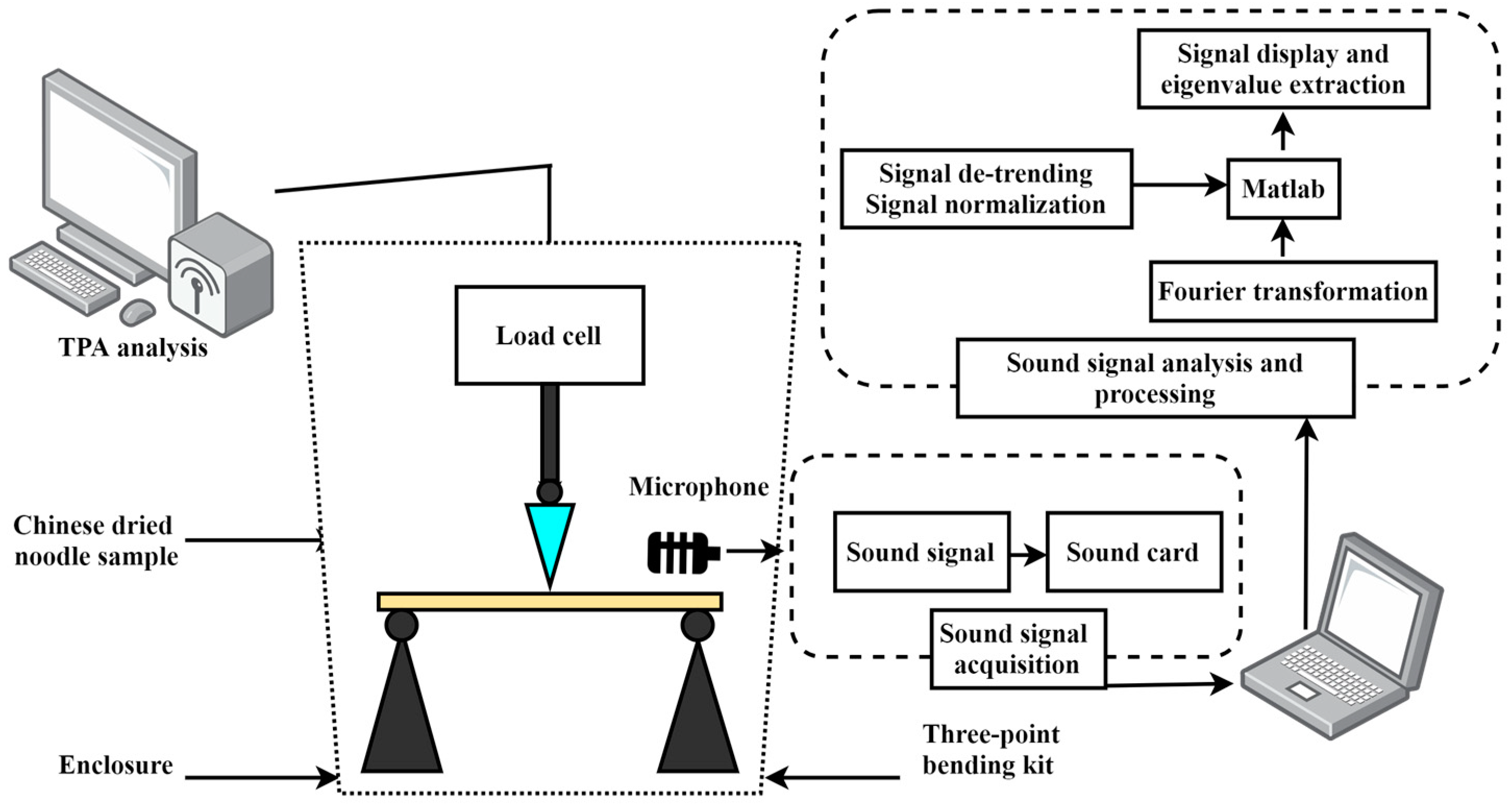

3.2. Force–Displacement Curve and Time Domain Spectrogram

3.3. Acoustic Characteristic Spectrograms

3.4. Mechanical and Acoustic Parameters

3.4.1. Maximum Shear Force and Wave Crest

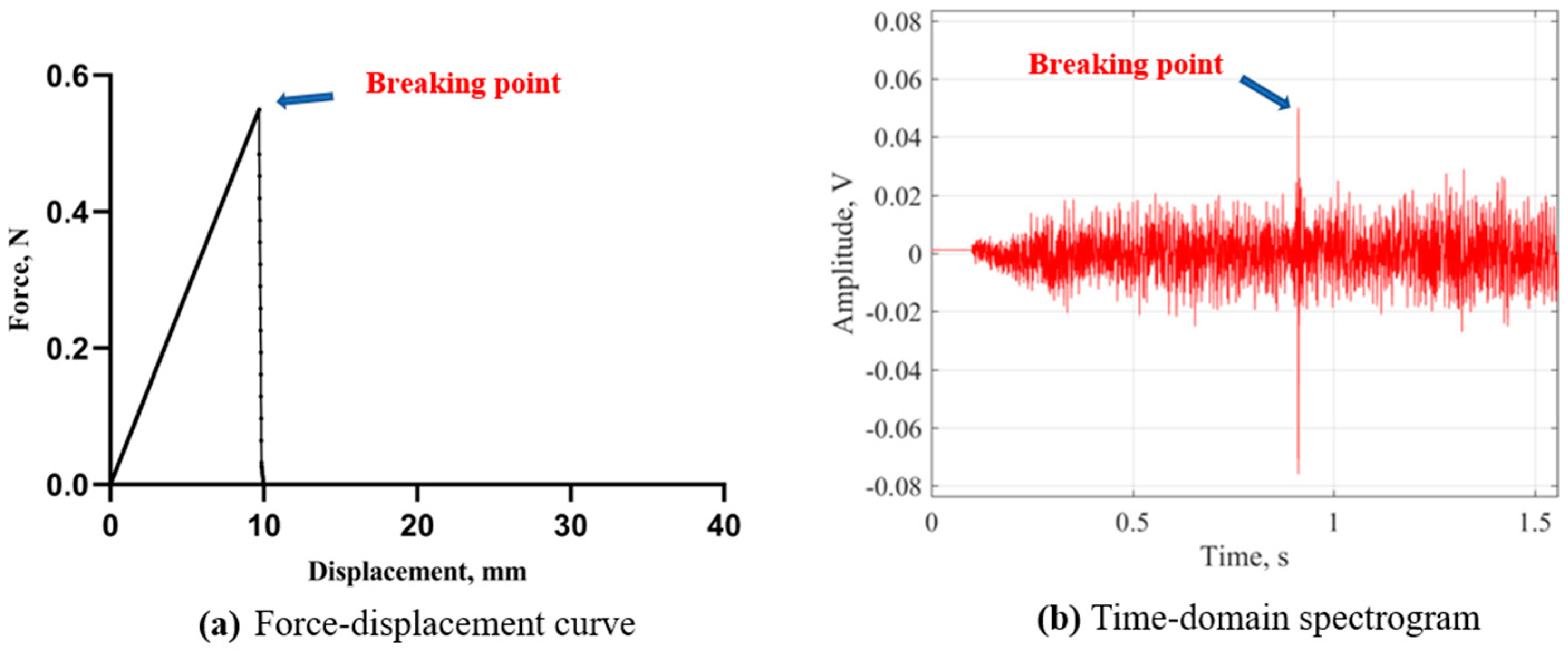

3.4.2. Displacements and Shear Work

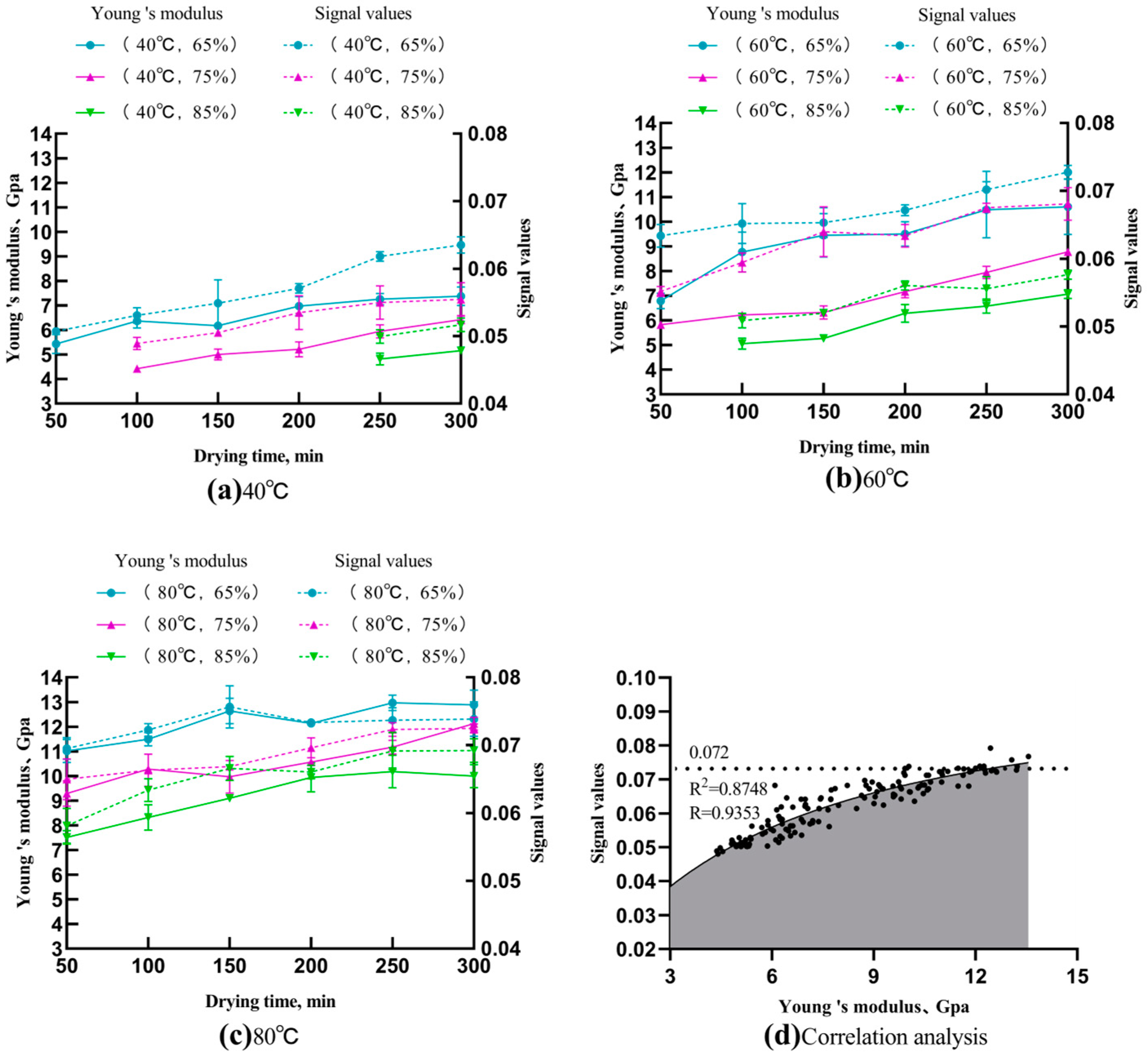

3.4.3. Young’s Modulus and the Signal Maximum

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Guo, X.; Xing, J.; Zhu, K. Revealing the effect mechanism of NaCl on the rheological properties of dough of Chinese traditional hand-stretched dried noodles. Food Chem. 2020, 320, 126606. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Zhang, B.; Yang, F.; Yu, X.; Zhao, B.; Wei, Y. Analysis on energy consumption of drying process for dried Chinese noodles. Appl. Therm. Eng. 2017, 110, 941–948. [Google Scholar] [CrossRef]

- Masato, O.; Kentaro, M.; Tatsuro, M.; Akio, F.; Yukako, H.; Yasuki, M. Effects of drying temperature on the properties of starch in pasta. LWT 2021, 145, 111171. [Google Scholar] [CrossRef]

- Mercier, S.; Moresoli, C.; Villeneuve, S.; Mondor, M.; Marcos, B. Sensitivity analysis of parameters affecting the drying behaviour of durum wheat pasta. J. Food Eng. 2013, 118, 108–116. [Google Scholar] [CrossRef]

- Ogawa, T.; Adachi, S. Drying and rehydration of pasta. Dry Technol. 2017, 35, 1919–1949. [Google Scholar] [CrossRef]

- Chen, L.; Opara, U.L. Texture measurement approaches in fresh and processed foods—A review. Food Res. Int. 2013, 51, 823–835. [Google Scholar] [CrossRef]

- Torrico, D.D.; Mehta, A.; Borssato, A.B. New methods to assess sensory responses: A brief review of innovative techniques in sensory evaluation. Curr. Opin. Food Sci. 2023, 49, 100978. [Google Scholar] [CrossRef]

- Piazza, L.; Gigli, J.; Ballabio, D. On the application of chemometrics for the study of acoustic-mechanical properties of crispy bakery products. Chemometr. Intell. Lab. 2007, 86, 52–59. [Google Scholar] [CrossRef]

- Chen, J.; Karlsson, C.; Povey, M. Acoustic envelope detector for crispness assessment of biscuits. J. Texture Stud. 2005, 36, 139–156. [Google Scholar] [CrossRef]

- Oraguzie, N.; Alspach, P.; Volz, R.; Whitworth, C.; Ranatunga, C.; Weskett, R.; Harker, R. Postharvest assessment of fruit quality parameters in apple using both instruments and an expert panel. Postharvest Biol. Technol. 2009, 52, 279–287. [Google Scholar] [CrossRef]

- Taniwaki, M.; Sakurai, N. Texture measurement of cabbages using an acoustical vibration method. Postharvest Biol. Technol. 2008, 50, 176–181. [Google Scholar] [CrossRef]

- Heidenreich, S.; Jaros, D.; Rohm, H.; Ziems, A. Relationship between water activity and crispness of extruded rice crisps. J. Texture Stud. 2004, 35, 621–633. [Google Scholar] [CrossRef]

- Sanahuja, S.; Fédou, M.; Briesen, H. Classification of puffed snacks freshness based on crispiness-related mechanical and acoustical properties. J. Food Eng. 2018, 226, 53–64. [Google Scholar] [CrossRef]

- Mahiuddin, M.; Khan, M.I.H.; Kumar, C.; Rahman, M.M.; Karim, M.A. Shrinkage of food materials during drying: Current status and challenges. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1113–1126. [Google Scholar] [CrossRef]

- Arimi, J.M.; Duggan, E.; O Sullivan, M.; Lyng, J.G.; O Riordan, E.D. Effect of water activity on the crispiness of a biscuit (Crackerbread): Mechanical and acoustic evaluation. Food Res. Int. 2010, 43, 1650–1655. [Google Scholar] [CrossRef]

- Witczak, T.; Gałkowska, D. Sorption and thermal characteristics of ancient grain pasta of various compositions. LWT 2021, 137, 110433. [Google Scholar] [CrossRef]

- Meng, L.; Sun, X.; Zhang, Y.; Tang, X. Effects of high temperature and high relative humidity drying on moisture distribution, starch microstructure and cooking characteristics of extruded whole buckwheat noodles. J. Future Foods 2024, 4, 159–166. [Google Scholar] [CrossRef]

- Veladat, R.; Ashtiani, F.Z.; Rahmani, M. A rigorous analysis of simultaneous heat and mass transfer in the pasta drying process. Heat Mass Transf. 2013, 49, 1481–1488. [Google Scholar] [CrossRef]

- Oikonomopoulou, V.P.; Krokida, M.K. Novel aspects of formation of food structure during drying. Dry Technol. 2013, 31, 990–1007. [Google Scholar] [CrossRef]

- Funami, T.; Nakauma, M. Instrumental food texture evaluation in relation to human perception. Food Hydrocoll. 2022, 124, 107253. [Google Scholar] [CrossRef]

- Saeleaw, M.; Schleining, G. A review: Crispness in dry foods and quality measurements based on acoustic–mechanical destructive techniques. J. Food Eng. 2011, 105, 387–399. [Google Scholar] [CrossRef]

- Maruyama, T.T.; Céspedes Arce, A.I.; Ribeiro, L.P.; Xavier Costa, E.J. Time–frequency analysis of acoustic noise produced by breaking of crisp biscuits. J. Food Eng. 2008, 86, 100–104. [Google Scholar] [CrossRef]

- Singh, M.K.; Kumar, S.; Nandan, D. Faulty voice diagnosis of automotive gearbox based on acoustic feature extraction and classification technique. J. Eng. Res.-Kuwait 2023, 11, 100051. [Google Scholar] [CrossRef]

- Ogawa, T.; Chuma, A.; Aimoto, U.; Adachi, S. Effects of drying temperature and relative humidity on spaghetti characteristics. Dry Technol. 2017, 35, 1214–1224. [Google Scholar] [CrossRef]

- Koirala, S.; Prakash, S.; Karim, A.; Bhandari, B. Shape morphing of foods: Mechanism, strategies, and applications. Trends Food Sci. Technol. 2023, 139, 104135. [Google Scholar] [CrossRef]

- Wang, X.; Stephen Njehia, N.; Katsuno, N.; Nishizu, T. An Acoustic Study on the Texture of Cellular Brittle Foods. Rev. Agric. Sci. 2020, 8, 170–185. [Google Scholar] [CrossRef]

- Mercier, S. Contribution of external resistance to mass transfer during pasta drying. Dry Technol. 2019, 37, 59–68. [Google Scholar] [CrossRef]

- Sinha, A.; Bhargav, A. Effect of state transition, drying kinetics and moisture content on Young’s modulus variation during thermal drying of hygroscopic food materials. J. Food Eng. 2020, 279, 109957. [Google Scholar] [CrossRef]

- Skowronek, K.; Barszcz, T.; Antoni, J.; Zimroz, R.; Wyłomańska, A. Assessment of background noise properties in time and time–frequency domains in the context of vibration-based local damage detection in real environment. Mech. Syst. Signal Process. 2023, 199, 110465. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Z.; Wang, Z.; Zhang, M.; Zhang, A.; Ye, G.; Liang, S.; Ren, X. Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods. Foods 2024, 13, 268. https://doi.org/10.3390/foods13020268

Cai Z, Wang Z, Zhang M, Zhang A, Ye G, Liang S, Ren X. Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods. Foods. 2024; 13(2):268. https://doi.org/10.3390/foods13020268

Chicago/Turabian StyleCai, Zhendong, Zhenhua Wang, Min Zhang, Aojie Zhang, Guodong Ye, Shan Liang, and Xin Ren. 2024. "Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods" Foods 13, no. 2: 268. https://doi.org/10.3390/foods13020268

APA StyleCai, Z., Wang, Z., Zhang, M., Zhang, A., Ye, G., Liang, S., & Ren, X. (2024). Texture Analysis of Chinese Dried Noodles during Drying Based on Acoustic–Mechanical Detection Methods. Foods, 13(2), 268. https://doi.org/10.3390/foods13020268