Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Flour Sample

2.2. Proximate and Physicochemical Properties

2.3. Particle Size Distribution

2.4. Functional Properties

2.4.1. Water and Oil Absorption/Holding Capacity

2.4.2. Emulsion Ability and Stability

2.4.3. Foaming Capacity and Stability

2.4.4. Water Solubility Index (WSI)

2.4.5. Swelling Power

2.4.6. Gel Formation Capacity

2.4.7. Bulk Density

2.5. Pasting Properties

2.6. In Vitro Digestibility

2.7. Bread Production

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition and Physicochemical Properties

3.2. Pasting Properties

3.3. Particle Size Distribution

3.4. Functional Properties

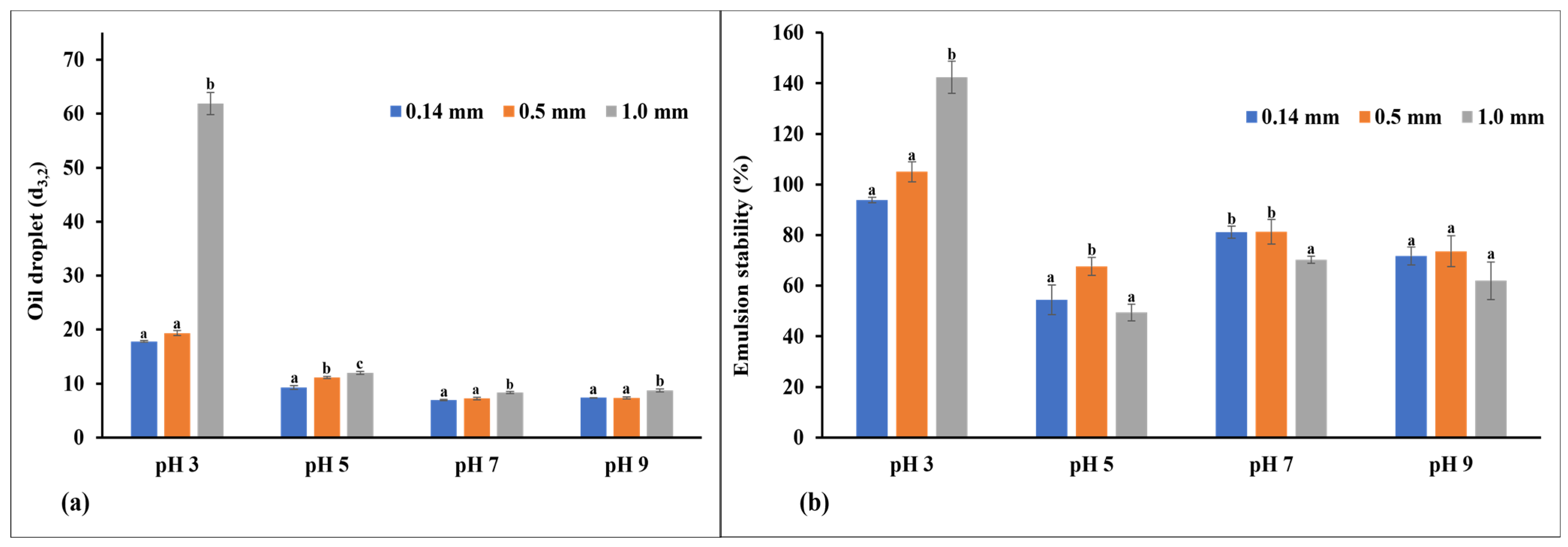

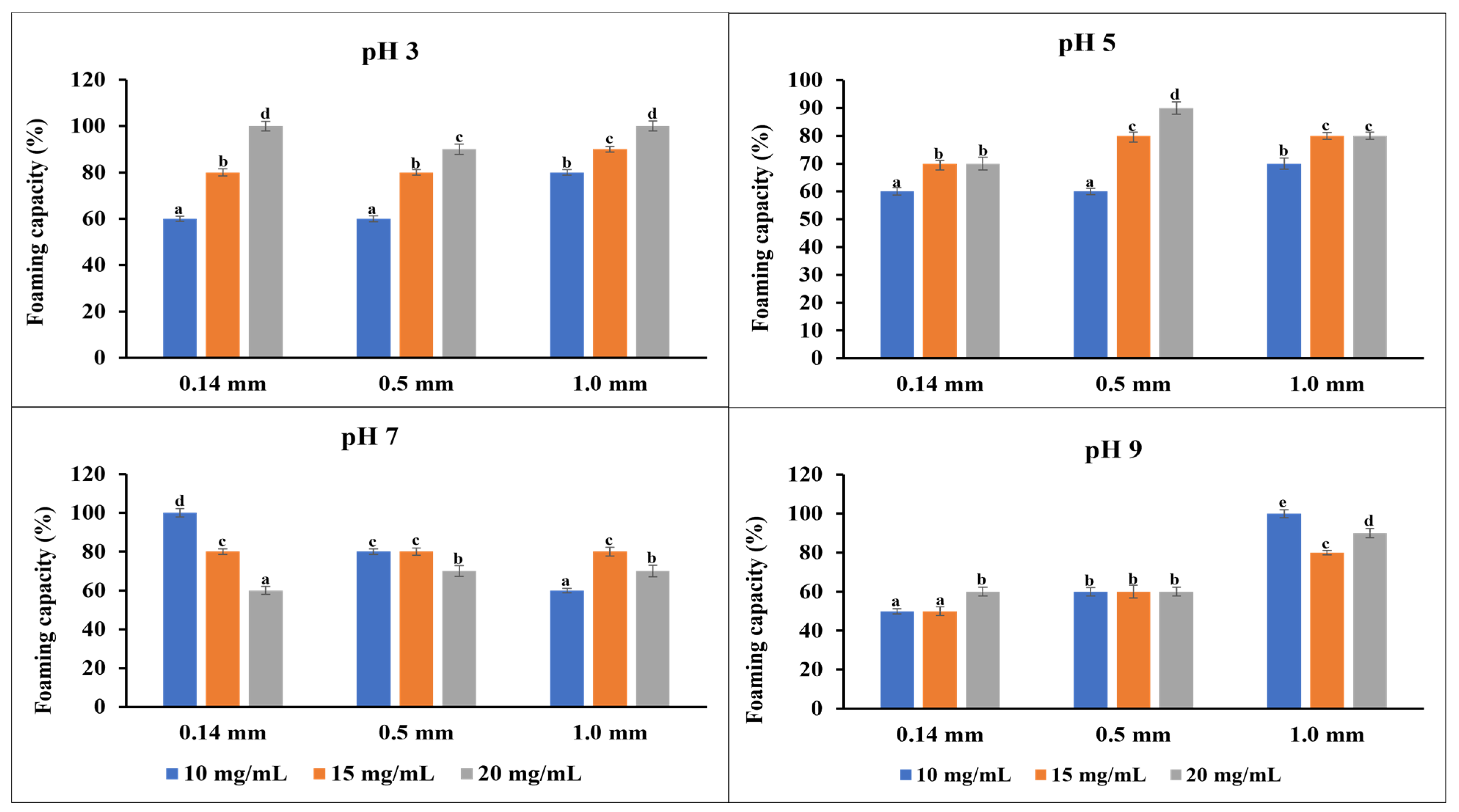

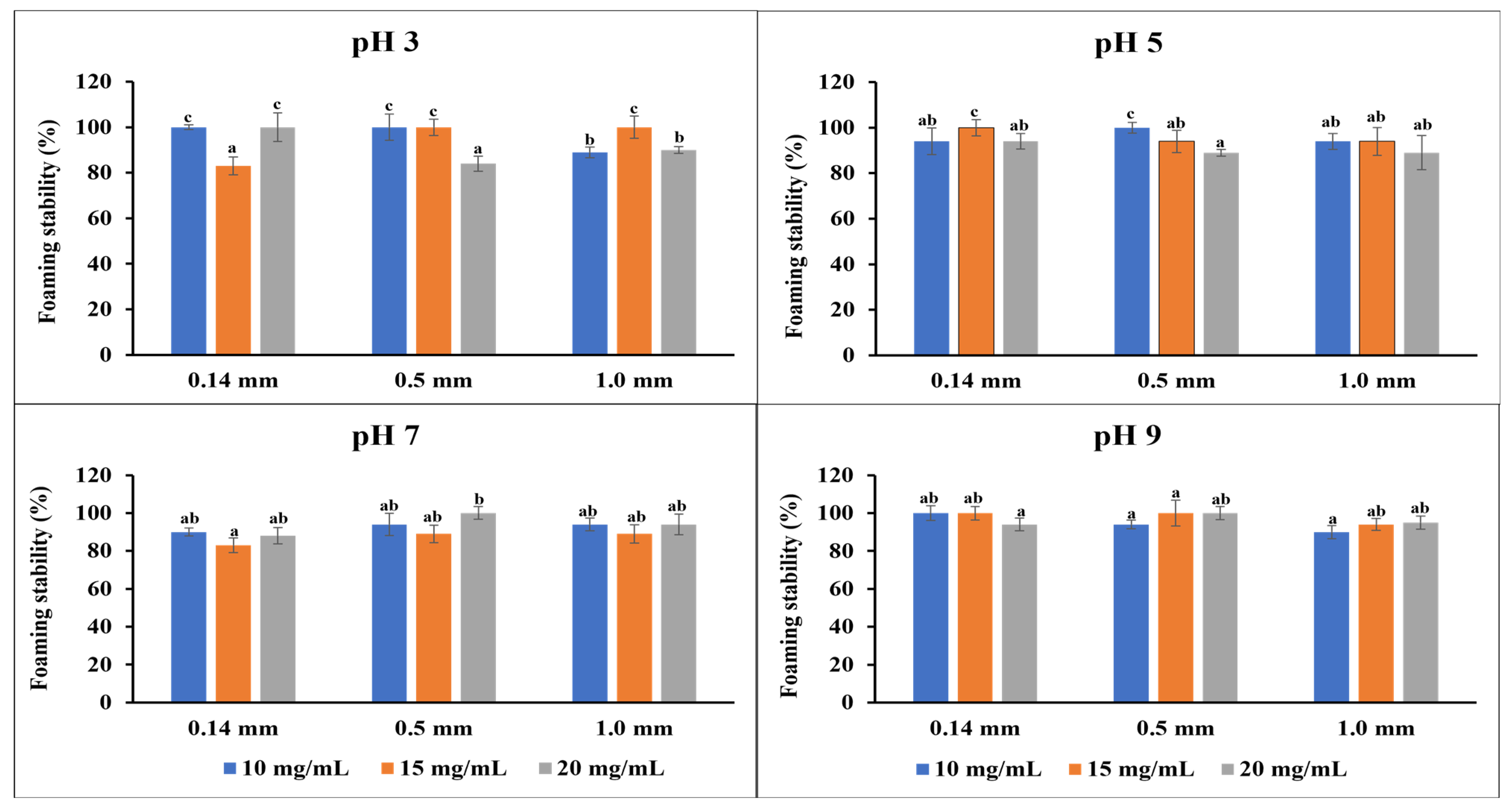

3.5. In Vitro Protein and Starch Digestion

3.6. In Vitro Protein Digestion of Fava Bean-Fortified Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, D.J.; Cheng, F.; Li, D.; Ding, K.; Carlin, J.; Moore, E.; Ai, Y. Important roles of coarse particles in pasting and gelling performance of different pulse flours under high-temperature heating. Food Chem. 2024, 447, 138896. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, S.J.; Jayas, D.S.; Paliwal, J. Implications of blending pulse and wheat flours on rheology and quality characteristics of baked goods: A review. Foods 2022, 11, 3287. [Google Scholar] [CrossRef] [PubMed]

- Rawal, V.; Charrondiere, R.; Xipsiti, M.; Grande, F. Pulses: Nutritional benefits and consumption patterns. In The Global Economy of Pulses; FAO: Rome, Italy, 2019; pp. 9–19. [Google Scholar]

- Semba, R.D.; Ramsing, R.; Rahman, N.; Kraemer, K.; Bloem, M.W. Legumes as a sustainable source of protein in human diets. Glob. Food Secur. 2021, 28, 100520. [Google Scholar] [CrossRef]

- Byars, J.A.; Singh, M.; Kenar, J.A.; Felker, F.C.; Winkler-Moser, J.K. Effect of particle size and processing method on starch and protein digestibility of navy bean flour. Cereal Chem. 2021, 98, 829–839. [Google Scholar] [CrossRef]

- Kumari, B.; Sit, N. Physicochemical, rheological properties, and in-vitro starch digestibility of flours and starches from pigeon pea, cowpea, pinto bean, and navy bean. Starch/Staerke 2024, 2300303. [Google Scholar] [CrossRef]

- Summo, C.; De Angelis, D.; Ricciardi, L.; Caponio, F.; Lotti, C.; Pavan, S.; Pasqualone, A. Nutritional, physico-chemical and functional characterization of a global chickpea collection. J. Food Compos. Anal. 2019, 84, 103306. [Google Scholar] [CrossRef]

- Martineau-Côté, D.; Achouri, A.; Karboune, S.; L’Hocine, L. Faba Bean: An untapped source of quality plant proteins and bioactives. Nutrients 2022, 14, 1541. [Google Scholar] [CrossRef]

- Boersch, B.M. Global Economic Outlook for Faba Beans & Soybeans; Mercantile Consulting Venture Inc.: Winnipeg, MB, Canada, 2023. [Google Scholar]

- Dhull, S.B.; Kidwai, M.K.; Noor, R.; Chawla, P.; Rose, P.K. A Review of nutritional profile and processing of faba bean (Vicia faba L.). Legum. Sci. 2022, 4, e129. [Google Scholar] [CrossRef]

- Hood-Niefer, S.D.; Warkentin, T.D.; Chibbar, R.N.; Vandenberg, A.; Tyler, R.T. Effect of genotype and environment on the concentrations of starch and protein in, and the physicochemical properties of starch from, field pea and faba bean. Sci. Food Agric. 2012, 92, 141–150. [Google Scholar] [CrossRef]

- Mayer Labba, I.C.; Frøkiær, H.; Sandberg, A.S. Nutritional and antinutritional composition of fava bean (Vicia faba L) cultivars. Food Res. Int. 2021, 140, 110038. [Google Scholar] [CrossRef]

- Health Canada. Common Food Allergens. Available online: https://www.canada.ca/en/health-canada/services/food-nutrition/food-safety/food-allergies-intolerances/food-allergies.html (accessed on 18 August 2024).

- Martineau-Côté, D.; Achouri, A.; Pitre, M.; Wanasundara, J.; Karboune, S.; L’Hocine, L. Investigation of the nutritional quality of raw and processed Canadian faba bean (Vicia faba L.) flours in comparison to pea and soy using a human in vitro gastrointestinal digestion model. Food Res. Int. 2023, 173, 113264. [Google Scholar] [CrossRef] [PubMed]

- Rahate, K.A.; Madhumita, M.; Prabhakar, P.K. Nutritional composition, anti-nutritional factors, pretreatments-cum-processing impact and food formulation potential of faba bean (Vicia faba L.): A comprehensive review. LWT 2021, 138, 110796. [Google Scholar] [CrossRef]

- Bala, M.; Handa, S.; Mridula, D.; Singh, R.K. Physicochemical, functional and rheological properties of grass pea (Lathyrus sativus L.) flour as influenced by particle size. Heliyon 2020, 6, e05471. [Google Scholar] [CrossRef] [PubMed]

- Bourré, L.; Frohlich, P.; Young, G.; Borsuk, Y.; Sopiwnyk, E.; Sarkar, A.; Nickerson, M.T.; Ai, Y.; Dyck, A.; Malcolmson, L. Influence of particle size on flour and baking properties of yellow pea, navy bean, and red lentil flours. Cereal Chem. 2019, 96, 655–667. [Google Scholar] [CrossRef]

- Cheng, F.; Ding, K.; Yin, H.; Tulbek, M.; Chigwedere, C.M.; Ai, Y. Milling and differential sieving to diversify flour functionality: A comparison between pulses and cereals. Food Res. Int. 2023, 163, 112223. [Google Scholar] [CrossRef]

- Ren, Y.; Setia, R.; Warkentin, T.D.; Ai, Y. Functionality and starch digestibility of wrinkled and round pea flours of two different particle sizes. Food Chem. 2021, 336, 127711. [Google Scholar] [CrossRef]

- Ahmed, J.; Taher, A.; Mulla, M.Z.; Al-Hazza, A.; Luciano, G. Effect of sieve particle size on functional, thermal, rheological and pasting properties of Indian and Turkish lentil flour. J. Food Eng. 2016, 186, 34–41. [Google Scholar] [CrossRef]

- Dhen, N.; Román, L.; Ben Rejeb, I.; Martínez, M.M.; Garogouri, M.; Gómez, M. Particle size distribution of soy flour affecting the quality of enriched gluten-free cakes. LWT 2016, 66, 179–185. [Google Scholar] [CrossRef]

- Rovalino-Córdova, A.M.; Fogliano, V.; Capuano, E. A closer look to cell structural barriers affecting starch digestibility in beans. Carbohydr. Polym. 2018, 181, 994–1002. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Neufeld, J.; Frohlich, P.; Young, G.; Malcolmson, L.; House, J.D. Determination of the protein quality of cooked Canadian pulses. Food Sci. Nutr. 2017, 5, 896–903. [Google Scholar] [CrossRef]

- Nosworthy, M.G.; Medina, G.; Franczyk, A.J.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of processing on the in vitro and in vivo protein quality of beans (Phaseolus vulgaris and Vicia faba). Nutrients 2018, 10, 671. [Google Scholar] [CrossRef] [PubMed]

- Nosworthy, M.G.; Medina, G.; Franczyk, A.J.; Neufeld, J.; Appah, P.; Utioh, A.; Frohlich, P.; House, J.D. Effect of processing on the in vitro and in vivo protein quality of red and green lentils (Lens culinaris). Food Chem. 2018, 240, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Nyende, P. Nutritional Value of Faba Bean Cultivars as Dietary Source of Energy and Protein for Weaned and Growing Pigs. Master’s Thesis, Department of Agricultural, Food and Nutritional Science, University of Alberta, Edmonton, AB, Canada, 2022. [Google Scholar]

- Olakanmi, S.J.; Jayas, D.S.; Paliwal, J.; Chaudhry, M.M.A.; Findlay, C.R.J. Quality Characterization of Fava Bean-Fortified Bread Using Hyperspectral Imaging. Foods 2024, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, S.J.; Jayas, D.S.; Paliwal, J.; Arif Chaudhry, M.M. Effect of particle size on the rheology, baking characteristics, and microstructure of fava bean-fortified bread. LWT 2024, 202, 116286. [Google Scholar] [CrossRef]

- AACC. Rheological behaviour of flour by farinograph: Constant flour weight procedure. In Approved Methods Analysis, 11th ed.; Method 54-21.02; AACC: Washington, DC, USA, 2011; pp. 1–8. [Google Scholar] [CrossRef]

- AOAC. Official methods of analysis of the association of official analytical chemists international Arlington. AOAC Int. 2005, 11, 6–7. [Google Scholar]

- Williams, P.; Sobering, D.; Antoniszyn, J. Protein testing methods at the Canadian Grain Commission. In Wheat Protein, Production and Marketing, Proceedings of the Wheat Protein Sym-Posium; University of Saskatchewan Press: Saskatoon, SK, Canada, 1998; pp. 37–47. [Google Scholar]

- Beuchat, L.R. Functional and Electrophoretic Characteristics of Succinylated Peanut Flour Protein. J. Agric. Food Chem. 1977, 25, 258–261. [Google Scholar] [CrossRef]

- Maskus, H.; Bourré, L.; Fraser, S.; Sarkar, A.; Malcolmson, L. Effects of grinding method on the compositional, physical, and functional properties of whole and split yellow pea flours. Cereal Foods World 2016, 61, 59–64. [Google Scholar] [CrossRef]

- Osemwota, E.C.; Alashi, A.M.; Aluko, R.E. Physicochemical and functional properties of albumin, globulin and glutelin fractions of green lentil seed. Int. J. Food Sci. Technol. 2022, 57, 3967–3981. [Google Scholar] [CrossRef]

- Gani, A.; Hussain, A.; Ahmad, M.; Baba, W.N.; Gani, A.; Masoodi, F.A.; Wani, S.M.; Shah, A.; Wani, I.A.; Maqsood, S. Engineering and functional properties of four varieties of pulses and their correlative study. J. Food Meas. Charact. 2015, 9, 347–358. [Google Scholar] [CrossRef]

- Hsu, H.W.; Vavak, D.L.; Satterlee, L.D.; Miller, G.A. A multienzyme technique for estimating protein digestibility. J. Food Sci. 1977, 42, 1269–1273. [Google Scholar] [CrossRef]

- Englyst, H.N.; Veenstra, J.; Hudson, G.J. Measurement of Rapidly Available Glucose (RAG) in plant foods: A potential in vitro predictor of the glycaemic response. Br. J. Nutr. 1996, 75, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Gu, Z.; Jiang, H.; Zha, F.; Manthey, F.; Rao, J.; Chen, B. Toward a Comprehensive understanding of ultracentrifugal milling on the physicochemical properties and aromatic profile of yellow pea flour. Food Chem. 2021, 345, 128760. [Google Scholar] [CrossRef] [PubMed]

- Ng, S.H.; Robert, S.D.; Wan Ahmad, W.A.N.; Wan Ishak, W.R. Incorporation of Dietary Fibre-Rich Oyster Mushroom (Pleurotus Sajor-Caju) Powder Improves Postprandial Glycaemic Response by Interfering with Starch Granule Structure and Starch Digestibility of Biscuit. Food Chem. 2017, 227, 358–368. [Google Scholar] [CrossRef] [PubMed]

- Sinaki, N.Y.; Paliwal, J.; Koksel, F. Enhancing the techno-functionality of pea flour by air injection-assisted extrusion at different temperatures and flour particle sizes. Foods 2023, 12, 889. [Google Scholar] [CrossRef] [PubMed]

- Eze, C.; Ekaette, I.; Ngadi, M. Impact of ultracentrifugal milling on the thermo-rheological, functional, and physicochemical properties of yellow and green pea flour. LWT 2024, 198, 115959. [Google Scholar] [CrossRef]

- Guldiken, B.; Franczyk, A.; Boyd, L.; Wang, N.; Choo, K.; Sopiwnyk, E.; House, J.D.; Paliwal, J.; Nickerson, M. Impact of milling on the functional and physicochemical properties of green lentil and yellow pea flours. Cereal Chem. 2022, 99, 218–229. [Google Scholar] [CrossRef]

- Guldiken, B.; Franczyk, A.; Boyd, L.; Wang, N.; Choo, K.; Sopiwnyk, E.; House, J.; Paliwal, J.; Nickerson, M. Physicochemical, nutritional and functional properties of chickpea (Cicer arietinum) and navy bean (Phaseolus vulgaris) flours from different mills. Eur. Food Res. Technol. 2022, 248, 1847–1858. [Google Scholar] [CrossRef]

- Shevkani, K.; Kaur, M.; Singh, N. Composition, pasting, functional, and microstructural properties of flours from different split dehulled pulses (Dhals). J. Food Process. Preserv. 2021, 45, e15485. [Google Scholar] [CrossRef]

- Raikos, V.; Neacsu, M.; Russell, W.; Duthie, G. Comparative study of the functional properties of lupin, green pea, fava bean, hemp, and buckwheat flours as affected by pH. Food Sci. Nutr. 2014, 2, 802–810. [Google Scholar] [CrossRef]

- Keivaninahr, F.; Gadkari, P.; Zoroufchi Benis, K.; Tulbek, M.; Ghosh, S. Prediction of emulsification behaviour of pea and faba bean protein concentrates and isolates from structure-functionality analysis. RSC Adv. 2021, 11, 12117–12135. [Google Scholar] [CrossRef]

- Krstonošić, V.S.; Kalić, M.D.; Dapčević-Hadnađev, T.R.; Lončarević, I.S.; Hadnađev, M.S. Physico-chemical characterization of protein stabilized oil-in-water emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2020, 602, 125045. [Google Scholar] [CrossRef]

- Zhang, M.; Fan, L.; Liu, Y.; Huang, S.; Li, J. Effects of proteins on emulsion stability: The role of proteins at the oil-water interface. Food Chem. 2022, 397, 133726. [Google Scholar] [CrossRef] [PubMed]

- Shevkani, K.; Kaur, A.; Kumar, S.; Singh, N. Cowpea protein isolates: Functional properties and application in gluten-free rice muffins. LWT 2015, 63, 927–933. [Google Scholar] [CrossRef]

- Aluko, R.E.; Mofolasayo, O.A.; Watts, B.M. Emulsifying and foaming properties of commercial yellow pea (Pisum sativum L.) seed flours. J. Agric. Food Chem. 2009, 57, 9793–9800. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Kaushal, P.; Sandhu, K.S. Studies on physicochemical and pasting properties of taro (Colocasia esculenta L.) flour in comparison with a cereal, tuber and legume flour. J. Food Sci. Technol. 2013, 50, 94–100. [Google Scholar] [CrossRef] [PubMed]

- Tinus, T.; Damour, M.; Van Riel, V.; Sopade, P.A. Particle size-starch-protein digestibility relationships in cowpea (Vigna unguiculata). J. Food Eng. 2012, 113, 254–264. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, Q.; Hoover, R.; Warkentin, T.D.; Vandenberg, B. In vitro starch digestibility, expected glycemic index, and thermal and pasting properties of flours from pea, lentil and chickpea cultivars. Food Chem. 2008, 111, 316–321. [Google Scholar] [CrossRef] [PubMed]

- Abebe, W.; Collar, C.; Ronda, F. Impact of variety type and particle size distribution on starch enzymatic hydrolysis and functional properties of tef flours. Carbohydr. Polym. 2015, 115, 260–268. [Google Scholar] [CrossRef]

- Sun, W.; Tribuzi, G.; Bornhorst, G.M. Particle size and water content impact breakdown and starch digestibility of chickpea snacks during in vitro gastrointestinal digestion. Food Res. Int. 2023, 173, 113201. [Google Scholar] [CrossRef]

- Xu, X.; Bean, S.; Wu, X.; Shi, Y.C. Effects of protein digestion on in vitro digestibility of starch in sorghum differing in endosperm hardness and flour particle size. Food Chem. 2022, 383, 132635. [Google Scholar] [CrossRef]

- Drulyte, D.; Orlien, V. The effect of processing on digestion of legume proteins. Foods 2019, 8, 224. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Aal, E.S.M. Effects of baking on protein digestibility of organic spelt products determined by two in vitro digestion methods. LWT 2008, 41, 1282–1288. [Google Scholar] [CrossRef]

- Joye, I. Protein digestibility of cereal products. Foods 2019, 8, 199. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Wang, S.; Zhang, H.; Du, C.; Li, S.; Yang, J. Effects of black soybean powder particle size on the characteristics of mixed powder and wheat flour dough. LWT 2022, 167, 113834. [Google Scholar] [CrossRef]

- Korese, J.K.; Chikpah, S.K.; Hensel, O.; Pawelzik, E.; Sturm, B. Effect of orange-fleshed sweet potato flour particle size and degree of wheat flour substitution on physical, nutritional, textural and sensory properties of cookies. Eur. Food Res. Technol. 2021, 247, 889–905. [Google Scholar] [CrossRef]

| Flour Description | Moisture (%) | Protein (%) | Total Starch db. (%) | Starch Damage db. (%) | Fats (%) | Color Properties | |||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | WI | ||||||

| 0.14 mm fava bean | 9.9 ± 0.0 a | 30.8 ± 0.1 b | 46.1 ± 1.1 a | 1.3 ± 0.03 b | 1.74 ± 0.28 a | 74.5 ± 0.1 a | 0.6 ± 0.01 a | 27.5 ± 0.2 a | 62.49 ± 0.21 a |

| 0.50 mm fava bean | 10.3 ± 0.1 b | 30.5 ± 0.1 ab | 48.8 ± 0.9 a | 1.3 ± 0.03 b | 1.51 ± 0.11 a | 74.6 ± 0.1 a | 0.6 ± 0.05 a | 27.7 ± 0.1 a | 62.41 ± 0.14 a |

| 1.0 mm fava bean | 11.1 ± 0.1 c | 30.4 ± 0.0 a | 45.2 ± 0.4 a | 1.0 ± 0.02 a | 1.44 ± 0.12 a | 75.2 ± 0.0 b | 0.5 ± 0.04 a | 27.4 ± 0.1 a | 63.00 ± 0.04 a |

| Flour Description | Peak Viscosity (cP) | Hot Paste Viscosity (cP) | Breakdown (cP) | Final Viscosity (cP) | Setback (cP) | Peak Time (min) | Pasting Temp. (°C) |

|---|---|---|---|---|---|---|---|

| 0.14 mm fava bean | 1713 ± 54 b | 1720 ± 53 b | −8 ± 0.5 ab | 3452 ± 29 b | 1732 ± 24 b | 7 ± 0.0 a | 78.3 ± 0.1 a |

| 0.50 mm fava bean | 2040 ± 15 c | 2041 ± 14 c | −1 ± 1.0 b | 3816 ± 20 c | 1775 ± 6 b | 7 ± 0.1 a | 76.7 ± 0.1 a |

| 1.0 mm fava bean | 1299 ± 23 a | 1311 ± 26 a | −12 ± 3.0 a | 2970 ± 37 a | 1659 ± 11 a | 7 ± 0.0 a | 77.4 ± 0.9 a |

| Flour Description | d(0.1) | d(0.5) | d(0.9) | D[4,3] | Span | Uniformity |

|---|---|---|---|---|---|---|

| 0.14 mm fava bean | 8.0 ± 0.5 a | 25.0 ± 0 a | 289.0 ± 8 b | 110.0 ± 3 b | 12.0 ± 0.4 c | 3.8 ± 0.14 c |

| 0.50 mm fava bean | 9.0 ± 0.0 b | 34.0 ± 1 b | 247.0 ± 3 a | 88.0 ± 2 a | 7.0 ± 0.1 b | 2.1 ± 0.03 b |

| 1.0 mm fava bean | 16.0 ± 0.0 c | 285.0 ± 1 c | 713.0 ± 8 c | 320.0 ± 3 c | 3.0 ± 0.02 a | 0.8 ± 0.01 a |

| Flour Description | Swelling Power | WSI | LGC (%) | OAC (g/g) | WAC g/g | Bulk Density (g/mL3) |

|---|---|---|---|---|---|---|

| 0.14 mm fava bean | 4.52 ± 0.06 a | 37.69 ± 0.38 b | 14 a | 3.66 ± 0.21 a | 0.86 ± 0.01 a | 0.54 ± 0.01 a |

| 0.5 mm fava bean | 4.59 ± 0.13 a | 38.51 ± 1.45 b | 14 a | 3.86 ± 0.18 a | 0.91 ± 0.02 ab | 0.55 ± 0.01 a |

| 1.0 mm fava bean | 4.41 ± 0.04 a | 31.26 ± 0.88 a | 20 b | 3.72 ± 0.12 a | 0.96 ± 0.02 b | 0.76 ± 0.01 b |

| Flour Description | IVPD (%) | RDS (%) | SDS (%) | TDS (%) | RS (%) |

|---|---|---|---|---|---|

| 0.14 mm fava bean | 75.95 ± 0.63 a | 6.03 ± 0.42 b | 31.10 ± 0.30 c | 38.43 ± 1.72 c | 7.68 ± 0.09 a |

| 0.5 mm fava bean | 75.77 ± 0.09 a | 5.35 ± 0.47 b | 29.22 ± 0.34 b | 36.57 ± 1.01 b | 11.24 ± 0.31 b |

| 1.0 mm fava bean | 75.59 ± 0.09 a | 3.20 ± 0.40 a | 27.15 ± 0.16 a | 30.35 ± 0.17 a | 14.80 ± 0.38 c |

| Flour Description | Substitution Level | IVPD (%) † |

|---|---|---|

| Control | 0 | 86.66 ± 1.09 b |

| 0.14 mm | 10 | 82.22 ± 0.09 a |

| 20 | 84.31 ± 1.26 ab | |

| 30 | 84.67 ± 1.27 ab | |

| 0.50 mm | 10 | 83.21 ± 2.18 ab |

| 20 | 84.22 ± 0.63 ab | |

| 30 | 84.94 ± 0.09 ab | |

| 1.00 mm | 10 | 85.48 ± 0.09 ab |

| 20 | 84.31 ± 0.37 ab | |

| 30 | 84.94 ± 1.00 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olakanmi, S.J.; Jayas, D.S.; Paliwal, J.; Aluko, R.E. Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread. Foods 2024, 13, 2862. https://doi.org/10.3390/foods13182862

Olakanmi SJ, Jayas DS, Paliwal J, Aluko RE. Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread. Foods. 2024; 13(18):2862. https://doi.org/10.3390/foods13182862

Chicago/Turabian StyleOlakanmi, Sunday J., Digvir S. Jayas, Jitendra Paliwal, and Rotimi E. Aluko. 2024. "Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread" Foods 13, no. 18: 2862. https://doi.org/10.3390/foods13182862

APA StyleOlakanmi, S. J., Jayas, D. S., Paliwal, J., & Aluko, R. E. (2024). Impact of Particle Size on the Physicochemical, Functional, and In Vitro Digestibility Properties of Fava Bean Flour and Bread. Foods, 13(18), 2862. https://doi.org/10.3390/foods13182862