Different Characteristics of Annealed Rice Kernels and Flour and Their Effects on the Quality of Rice Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Annealed Rice Kernels and Rice Flour

2.3. Pasting Properties

2.4. Differential Scanning Calorimetry

2.5. X-ray Diffraction (XRD)

2.6. Fourier Transform Infrared Spectroscopy Analysis (FTIR)

2.7. Texture Analysis

2.8. Preparation of Fresh Rice Noodles

2.9. Tensile Properties

2.10. Scanning Electron Microscopy (SEM)

2.11. Low-Field Nuclear Magnetic Resonance (LF-NMR)

2.12. Statistical Analysis

3. Results and Discussion

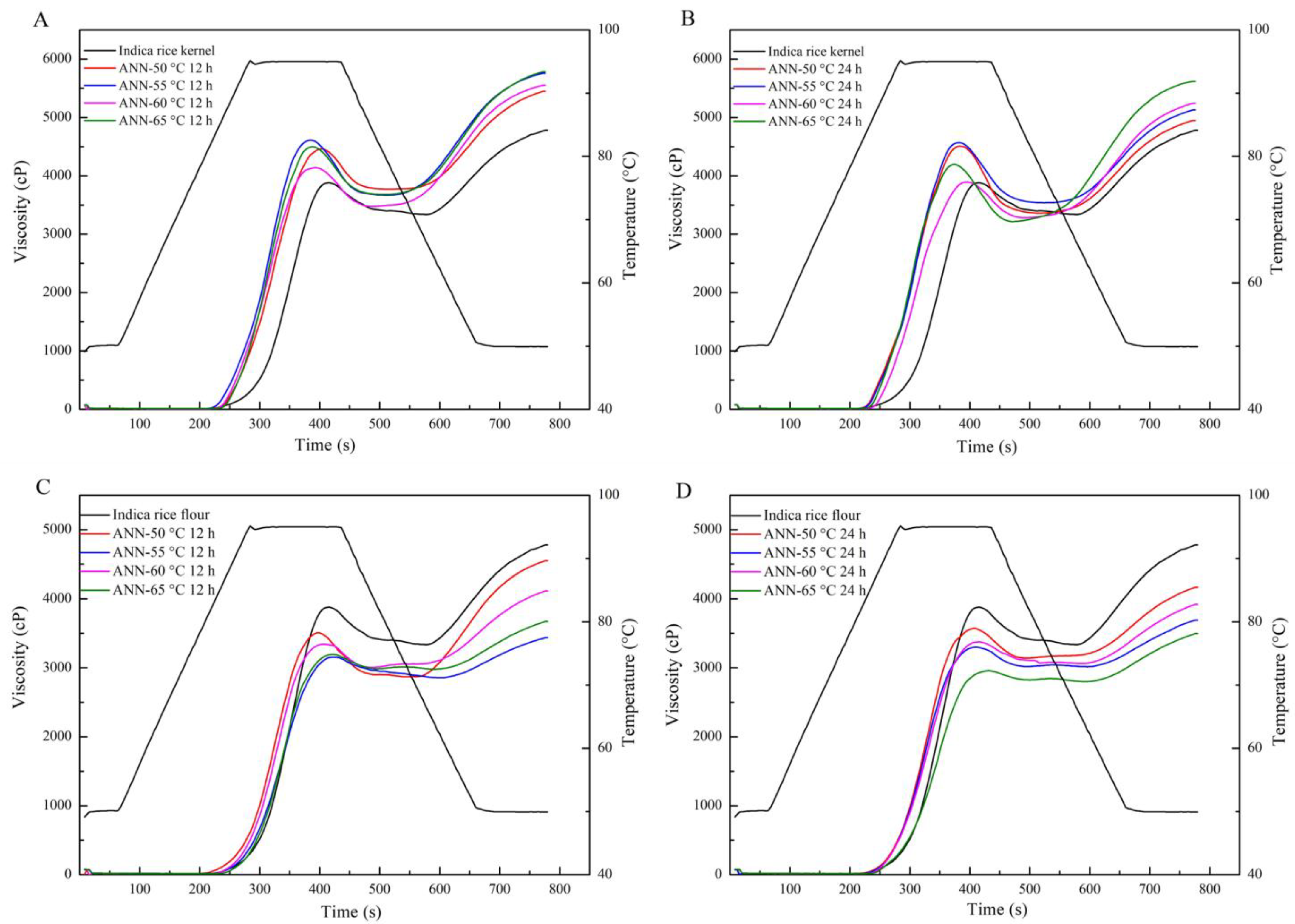

3.1. Pasting Properties of Annealed Rice Kernels and Annealed Rice Flour

3.2. Thermal Properties of Annealed Rice Kernels and Annealed Rice Flour

3.3. X-ray Diffraction Analysis of Annealed Rice Kernels and Annealed Rice Flour

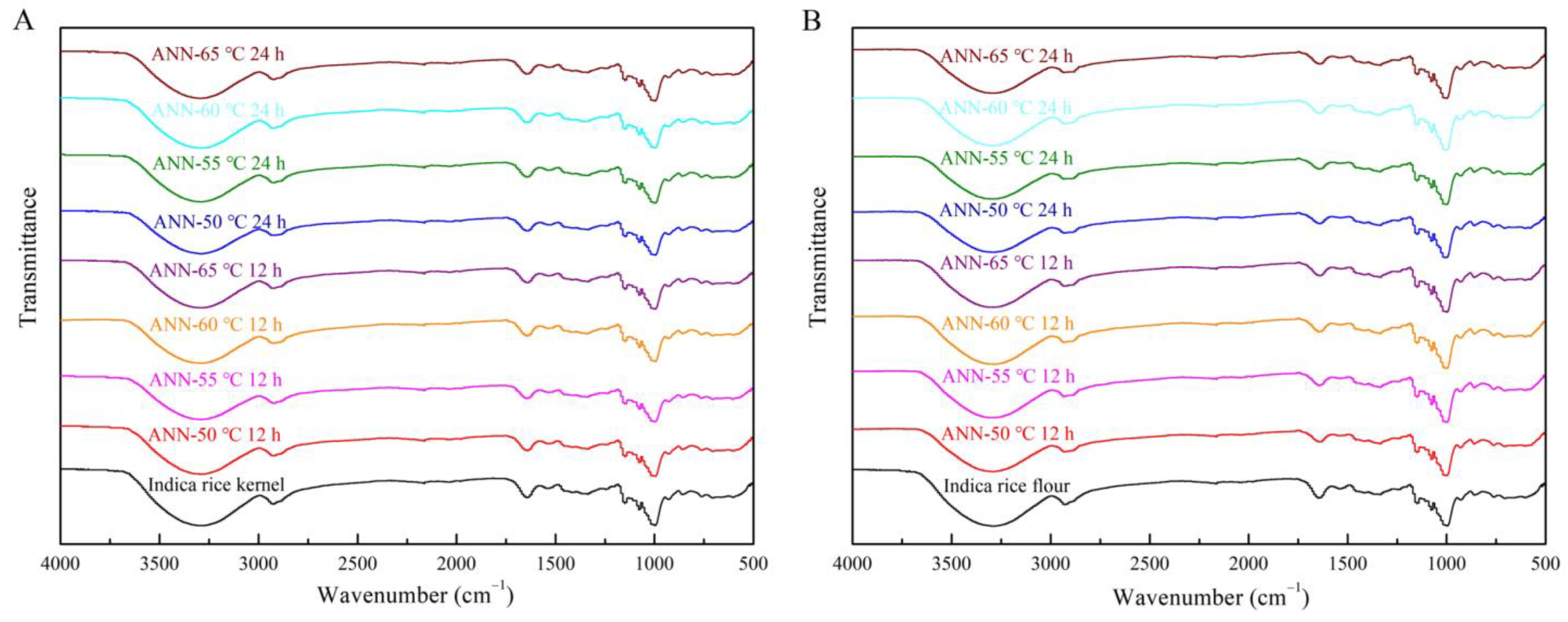

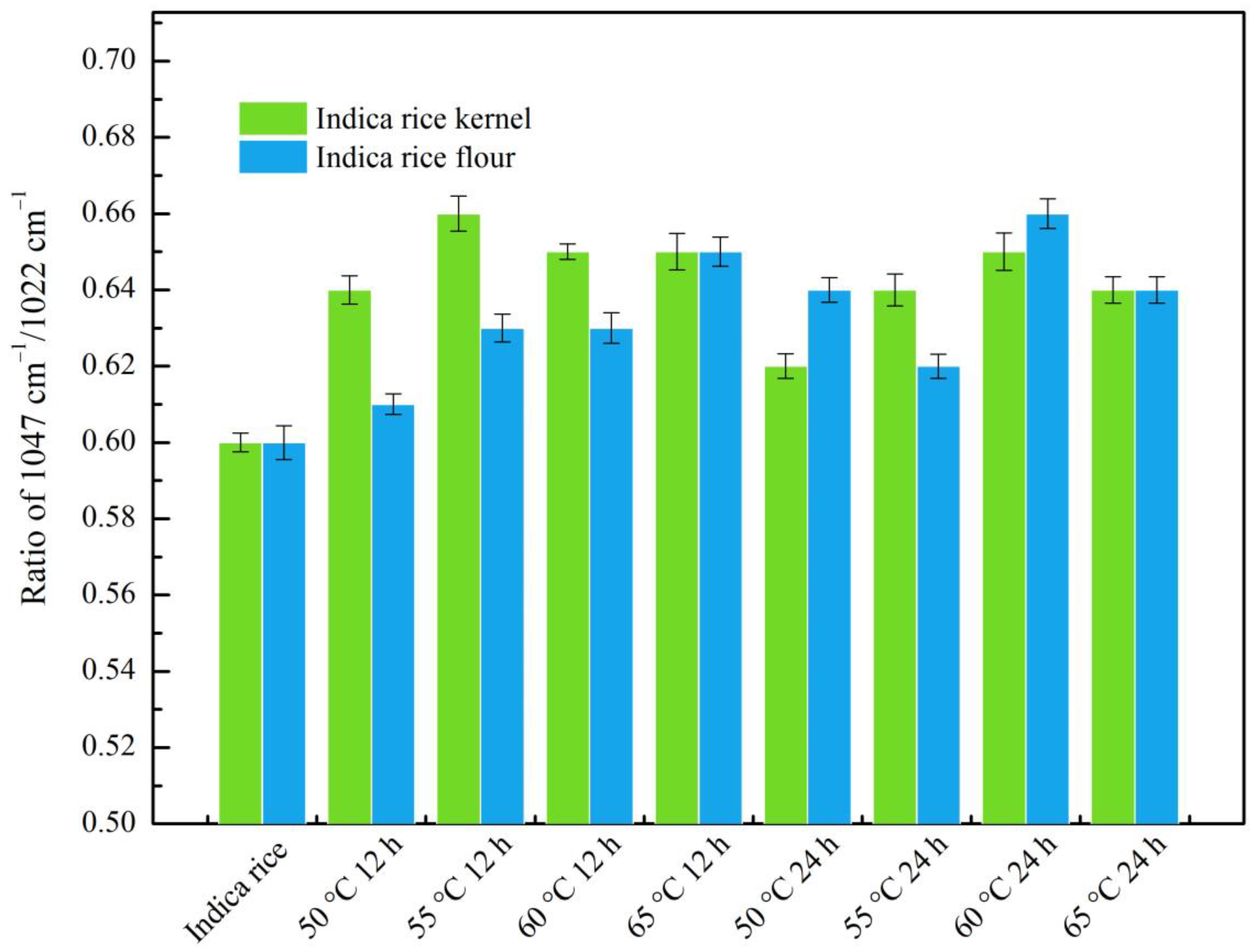

3.4. Infrared Spectroscopy of Annealed Rice Kernels and Annealed Rice Flour

3.5. Texture Analysis of Annealed Rice Kernel Gels and Annealed Rice Flour Gels

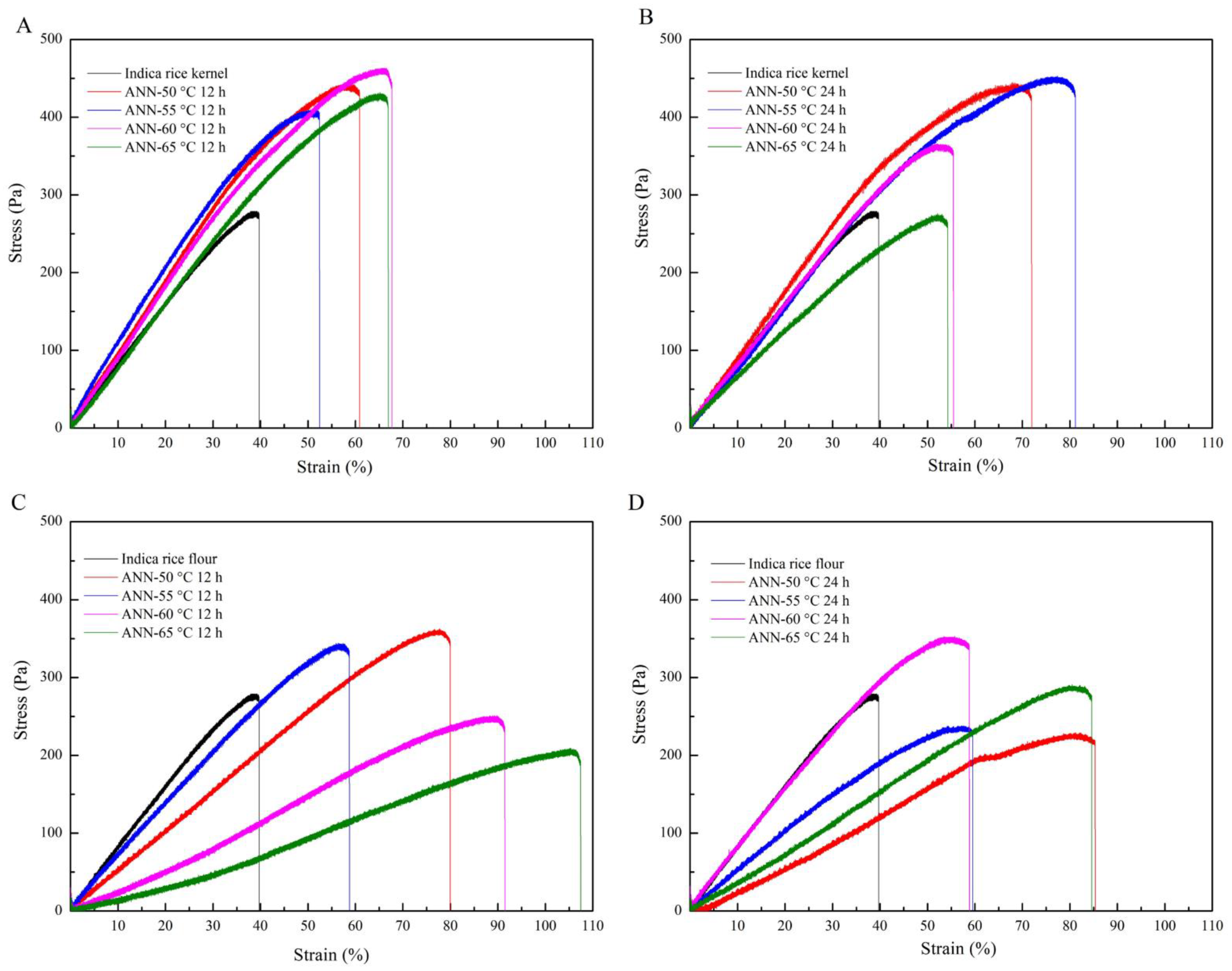

3.6. Tensile Properties of Annealed Rice Kernel Noodles and Annealed Rice Flour Noodles

3.7. Scanning Electron Microscopy of Annealed Rice Kernel Noodles and Annealed Rice Flour Noodles

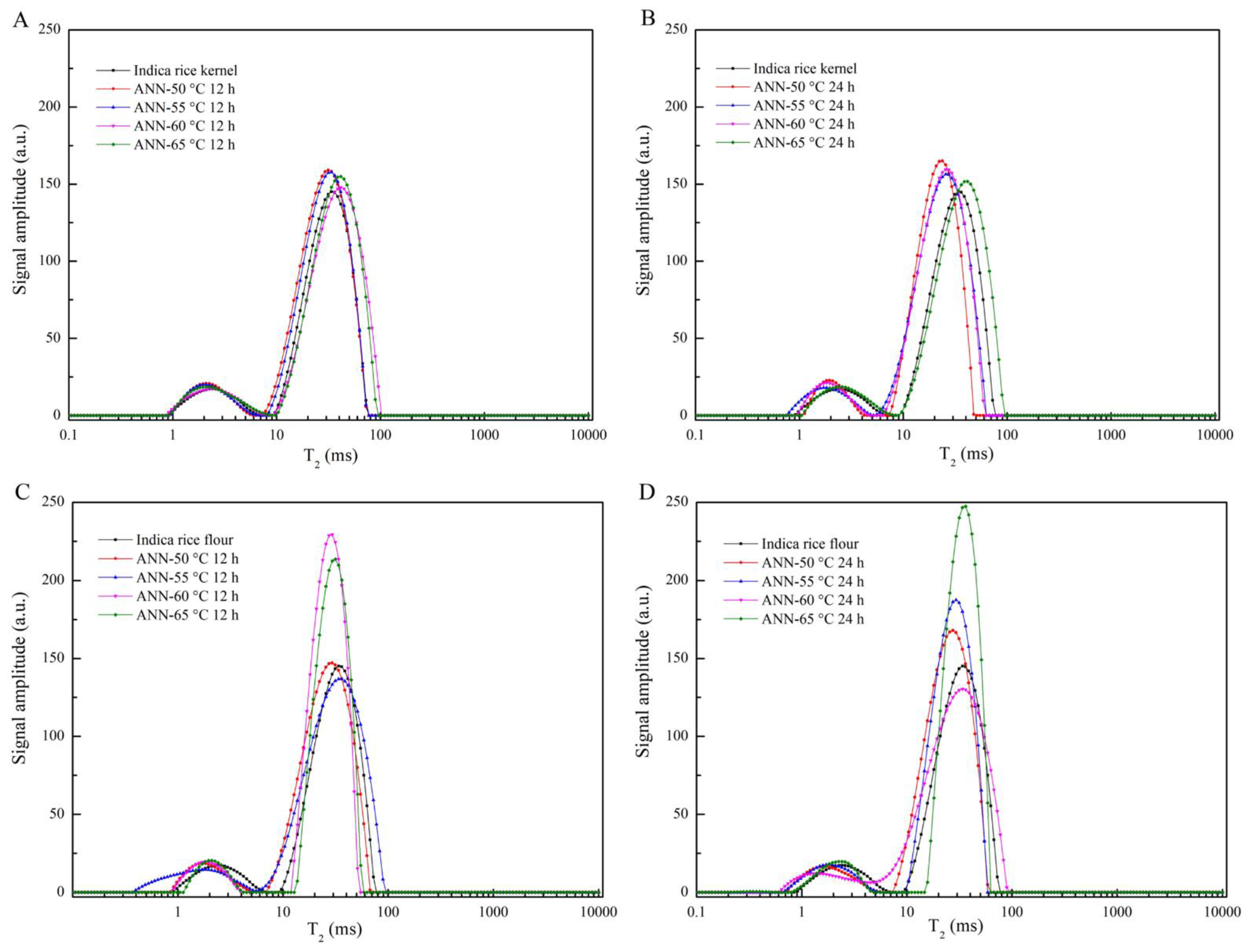

3.8. Water Mobility in Annealed Rice Kernel Noodles and Annealed Rice Flour Noodles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mariotti, M.; Caccialanza, G.; Cappa, C.; Lucisano, M. Rheological behaviour of rice flour gels during formation: Influence of the amylose content and of the hydrothermal and mechanical history. Food Hydrocoll. 2018, 84, 257–266. [Google Scholar] [CrossRef]

- Xie, L.H.; Tang, S.Q.; Luo, J.; Wei, X.J.; Shao, G.N.; Jiao, G.A.; Sheng, Z.H.; Hu, P.S. Physiochemical properties of rice starch for production of vermicelli with premium quality. J. Food Sci. Technol.-Mysore 2017, 54, 3928–3935. [Google Scholar] [CrossRef]

- Lubowa, M.; Yeoh, S.Y.; Easa, A.M. Textural and physical properties of retort processed rice noodles: Influence of chilling and partial substitution of rice flour with pregelatinized high-amylose maize starch. Food Sci. Technol. Int. 2018, 24, 476–486. [Google Scholar] [CrossRef]

- Low, Y.K.; Effarizah, M.E.; Cheng, L.H. Factors Influencing Rice Noodles Qualities. Food Rev. Int. 2020, 36, 781–794. [Google Scholar] [CrossRef]

- Wang, A.-X.; Yi, C.; Xiao, T.; Qin, W.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Volatile compounds, bacteria compositions and physicochemical properties of 10 fresh fermented rice noodles from southern China. Food Res. Int. 2021, 150, 110787. [Google Scholar] [CrossRef]

- Tong, L.T.; Gao, X.X.; Lin, L.Z.; Liu, Y.J.; Zhong, K.; Liu, L.Y.; Zhou, X.R.; Wang, L.; Zhou, S.M. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015, 62, 45–49. [Google Scholar] [CrossRef]

- Chen, J.; Yang, S.; Zhang, M.N.; Shan, C.S.; Chen, Z.G. Effects of potato starch on the characteristics, microstructures and quality attributes of indica rice flour and instant rice noodles. Int. J. Food Sci. Technol. 2022, 57, 2285–2297. [Google Scholar] [CrossRef]

- Kim, Y.; Kee, J.I.; Lee, S.; Yoo, S.-H. Quality improvement of rice noodle restructured with rice protein isolate and transglutaminase. Food Chem. 2014, 145, 409–416. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Tao, W.-Y. Effects of lactic acid fermentation on FT-IR and pasting properties of rice flour. Food Res. Int. 2008, 41, 937–940. [Google Scholar] [CrossRef]

- Gujral, H.S.; Guardiola, I.; Carbonell, J.V.; Rosell, C.M. Effect of Cyclodextrinase on Dough Rheology and Bread Quality from Rice Flour. J. Agric. Food Chem. 2003, 51, 3814–3818. [Google Scholar] [CrossRef]

- Witczak, M.; Korus, J.; Ziobro, R.; Juszczak, L. The effects of maltodextrins on gluten-free dough and quality of bread. J. Food Eng. 2010, 96, 258–265. [Google Scholar] [CrossRef]

- Lai, H.M. Effects of rice properties and emulsifiers on the quality of rice pasta. J. Sci. Food Agric. 2002, 82, 203–216. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Sozer, N. Rheological properties of rice pasta dough supplemented with proteins and gums. Food Hydrocoll. 2009, 23, 849–855. [Google Scholar] [CrossRef]

- Kasunmala, I.G.G.; Navaratne, S.B.; Wickramasinghe, I. Effect of process modifications and binding materials on textural properties of rice noodles. Int. J. Gastron. Food Sci. 2020, 21, 100217. [Google Scholar] [CrossRef]

- Fonseca, L.M.; El Halal, S.L.M.; Dias AR, G.; Zavareze, E.D. Physical modification of starch by heat-moisture treatment and annealing and their applications: A review. Carbohydr. Polym. 2021, 274, 118665. [Google Scholar] [CrossRef]

- Park, S.; Kim, Y.R. Clean label starch: Production, physicochemical characteristics, and industrial applications. Food Sci. Biotechnol. 2021, 30, 1–17. [Google Scholar] [CrossRef]

- Chandla, N.K.; Saxena, D.C.; Singh, S. Processing and evaluation of heat moisture treated (HMT) amaranth starch noodles; An inclusive comparison with corn starch noodles. J. Cereal Sci. 2017, 75, 306–313. [Google Scholar] [CrossRef]

- Purwani, E.Y.; Widaningrum, W.; Thahir, R.; Muslich, M. Effect of heat moisture treatment of sago starch on its noodle quality. Indones. J. Agric. Sci. 2016, 7, 8–14. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. A review of the hydrothermal treatments impact on starch based systems properties. Crit. Rev. Food Sci. Nutr. 2020, 60, 3890–3915. [Google Scholar] [CrossRef]

- Iftikhar, S.A.; Dutta, H. Status of polymorphism, physicochemical properties and in vitro digestibility of dual retrogradation-annealing modified rice starches. Int. J. Biol. Macromol. 2019, 132, 330–339. [Google Scholar] [CrossRef] [PubMed]

- Song, H.Y.; Lee, S.Y.; Choi, S.J.; Kim, K.M.; Kim, J.S.; Han, G.J.; Moon, T.W. Digestibility and physicochemical properties of granular sweet potato starch as affected by annealing. Food Sci. Biotechnol. 2014, 23, 23–31. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.N.; Chen, Z.X.; Wang, X.P.; Wang, K.; Li, Y.F.; Wang, R.; Luo, X.H.; Li, Y.A.; Li, J. Effect of annealing on the physico-chemical properties of rice starch and the quality of rice noodles. J. Cereal Sci. 2018, 84, 125–131. [Google Scholar] [CrossRef]

- Dutta, D.; Sit, N. Comparison of Properties of Films Prepared from Potato Starch Modified by Annealing and Heat-Moisture Treatment. Starch-Starke 2022, 74, 2200110. [Google Scholar] [CrossRef]

- Yadav, B.S.; Guleria, P.; Yadav, R.B. Hydrothermal modification of Indian water chestnut starch: Influence of heat-moisture treatment and annealing on the physicochemical, gelatinization and pasting characteristics. LWT-Food Sci. Technol. 2013, 53, 211–217. [Google Scholar] [CrossRef]

- Heo, S.; Lee, S.M.; Shim, J.H.; Yoo, S.H.; Lee, S. Effect of dry- and wet-milled rice flours on the quality attributes of gluten-free dough and noodles. J. Food Eng. 2013, 116, 213–217. [Google Scholar] [CrossRef]

- Sun, Y.J.; Li, F.; Luan, Y.J.; Li, P.; Dong, X.Y.; Chen, M.; Dai, L.; Sun, Q.J. Gelatinization, pasting, and rheological properties of pea starch in alcohol solution. Food Hydrocoll. 2021, 112, 106331. [Google Scholar] [CrossRef]

- Lu, H.; Xiong, L.; Li, M.; Chen, H.H.; Xiao, J.X.; Wang, S.Q.; Qiu, L.Z.; Bian, X.L.; Sun, C.R.; Sun, Q.J. Separation and characterization of linear glucans debranched from normal corn, potato and sweet potato starches. Food Hydrocoll. 2019, 89, 196–206. [Google Scholar] [CrossRef]

- Sun, Q.; Li, P.; Li, Y.; Ji, N.; Dai, L.; Xiong, L.; Sun, Q.J. Rapid production of corn starch gels with high mechanical properties through alcohol soaking. Int. J. Biol. Macromol. 2020, 163, 1557–1564. [Google Scholar] [CrossRef]

- Liu, M.X.; Huang, J.D.; Luo, B.H.; Zhou, C.R. Tough and highly stretchable polyacrylamide nanocomposite hydrogels with chitin nanocrystals. Int. J. Biol. Macromol. 2015, 78, 23–31. [Google Scholar] [CrossRef]

- Ge, S.J.; Li, M.; Ji, N.; Liu, J.; Mu, H.Y.; Xiong, L.; Sun, Q.J. Preparation of a Strong Gelatin-Short Linear Glucan Nanocomposite Hydrogel by an in Situ Self-Assembly Process. J. Agric. Food Chem. 2018, 66, 177–186. [Google Scholar] [CrossRef]

- Jia, Y.Z.; Zhang, Z.; Li, M.; Ji, N.; Qin, Y.; Wang, Y.F.; Shi, R.; Wang, T.; Xiong, L.; Sun, Q.J. The effect of hydroxypropyl starch on the improvement of mechanical and cooking properties of rice noodles. Food Res. Int. 2022, 162, 111922. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.X.; Xu, H.M.; Tang, S.; Gu, Z.Y. Study on the Thermal and Water Migration of Chinese steamed buns during cooling process after steam cooking. LWT-Food Sci. Technol. 2021, 145, 111377. [Google Scholar] [CrossRef]

- Siwatch, M.; Yadav, R.B.; Yadav, B.S. Annealing and heat-moisture treatment of amaranth starch: Effect on structural, pasting, and rheological properties. J. Food Meas. Charact. 2022, 16, 2323–2334. [Google Scholar] [CrossRef]

- Adebowale, K.O.; Lawal, O.S. Foaming, gelation and electrophoretic characteristics of mucuna bean (Mucuna pruriens) protein concentrates. Food Chem. 2003, 83, 237–246. [Google Scholar] [CrossRef]

- Cai, J.W.; Chiang, J.H.; Tan MY, P.; Saw, L.K.; Xu, Y.Y.; Ngan-Loong, M.N. Physicochemical properties of hydrothermally treated glutinous rice flour and xanthan gum mixture and its application in gluten-free noodles. J. Food Eng. 2016, 186, 1–9. [Google Scholar] [CrossRef]

- Guo, B.Z.; Wang, Y.T.; Pang, M.; Wu, J.Y.; Hu, X.T.; Huang, Z.H.; Wang, H.Q.; Xu, S.Q.; Luo, S.J.; Liu, C.M. Annealing treatment of amylose and amylopectin extracted from rice starch. Int. J. Biol. Macromol. 2020, 164, 3496–3500. [Google Scholar] [CrossRef]

- Marboh, V.; Gayary, M.A.; Gautam, G.; Mahanta, C.L. Comparative Study of Heat-Moisture Treatment and Annealing on Morphology, Crystallinity, Pasting, and Thermal Properties of Sohphlang (Flemingia vestita) Starch. Starch-Starke 2022, 74, 2100294. [Google Scholar] [CrossRef]

- Xu, M.J.; Saleh, A.S.M.; Gong, B.; Li, B.; Jing, L.Z.; Gou, M.; Jiang, H.; Li, W.H. The effect of repeated versus continuous annealing on structural, physicochemical, and digestive properties of potato starch. Food Res. Int. 2018, 111, 324–333. [Google Scholar] [CrossRef] [PubMed]

- Vandeputte, G.E.; Vermeylen, R.; Geeroms, J.; Delcour, J.A. Rice starches. I. Structural aspects provide insight into crystallinity characteristics and gelatinisation behaviour of granular starch. J. Cereal Sci. 2003, 38, 43–52. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Wei, T.; Shen, J.; Wang, M. Differences in physicochemical properties and in vitro digestibility between tartary buckwheat flour and starch modified by heat-moisture treatment. LWT-Food Sci. Technol. 2017, 86, 285–292. [Google Scholar] [CrossRef]

- Sun, L.T.; Xu, Z.K.; Song, L.L.; Ma, M.T.; Zhang, C.C.; Chen, X.J.; Xu, X.M.; Sui, Z.Q.; Corke, H. Removal of starch granule associated proteins alters the physicochemical properties of annealed rice starches. Int. J. Biol. Macromol. 2021, 185, 412–418. [Google Scholar] [CrossRef]

- Bian, L.; Chung, H.J. Molecular structure and physicochemical properties of starch isolated from hydrothermally treated brown rice flour. Food Hydrocoll. 2016, 60, 345–352. [Google Scholar] [CrossRef]

- Shi, Y.-C. Two- and Multi-Step Annealing of Cereal Starches in Relation to Gelatinization. J. Agric. Food Chem. 2008, 56, 1097–1104. [Google Scholar] [CrossRef]

- Zhu, F.; Liu, P.Z. Starch gelatinization, retrogradation, and enzyme susceptibility of retrograded starch: Effect of amylopectin internal molecular structure. Food Chem. 2020, 316, 126036. [Google Scholar] [CrossRef]

- Li, M.-j.; Wang, H.-r.; Tong, L.-T.; Fan, B.; Yang, X.-j.; Sun, R.-q.; Liu, L.-y.; Wang, F.-z.; Wang, L.-l. A comparison study of three heating assisted enzyme inactivation pretreatments on the physicochemical properties and edible quality of highland barley grain and flour. J. Cereal Sci. 2022, 104, 103404. [Google Scholar] [CrossRef]

- Liu, R.; Xing, Y.N.; Zhang, Y.Q.; Zhang, B.; Jiang, X.J.; Wei, Y.M. Effect of mixing time on the structural characteristics of noodle dough under vacuum. Food Chem. 2015, 188, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.Y.; Koh, B.K. Effects of Annealing and Removal of the Water-Soluble Fraction of Dry-Milled Rice Flour on the Texture of Cooked Rice Noodles. Food Nutr. Sci. 2017, 8, 889–900. [Google Scholar]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT-Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Li, H.Y.; Wen, Y.Y.; Wang, J.; Sun, B.G. The molecular structures of leached starch during rice cooking are controlled by thermodynamic effects, rather than kinetic effects. Food Hydrocoll. 2017, 73, 295–299. [Google Scholar] [CrossRef]

- Xu, K.; She, Z.Y.; Wang, H.W.; Liu, X.L.; Zhang, Y.Y.; Chi, C.D.; Zhang, H. Textural quality of sweet dumpling: Effect of germination of waxy rice. Int. J. Food Sci. Technol. 2021, 56, 4081–4090. [Google Scholar] [CrossRef]

- Wei, P.; Fang, F.; Liu, G.M.; Zhang, Y.Y.; Wei, L.Y.; Zhou, K.; You, X.R.; Li, M.J.; Wang, Y.; Sun, J.; et al. Effects of composition, thermal, and theological properties of rice raw material on rice noodle quality. Front. Nutr. 2022, 9, 1003657. [Google Scholar] [CrossRef] [PubMed]

- Cham, S.; Suwannaporn, P. Effect of hydrothermal treatment of rice flour on various rice noodles quality. J. Cereal Sci. 2010, 51, 284–291. [Google Scholar] [CrossRef]

- Li, C.M.; You, Y.X.; Chen, D.; Gu, Z.B.; Zhang, Y.Z.; Holler, T.P.; Ban, X.F.; Hong, Y.; Cheng, L.; Li, Z.F. A systematic review of rice noodles: Raw material, processing method and quality improvement. Trends Food Sci. Technol. 2021, 107, 389–400. [Google Scholar] [CrossRef]

- Koh, L.W.; Kasapis, S.; Lim, K.M.; Foo, C.W. Structural enhancement leading to retardation of in vitro digestion of rice dough in the presence of alginate. Food Hydrocoll. 2009, 23, 1458–1464. [Google Scholar] [CrossRef]

- Sittipod, S.; Shi, Y.C. Changes in physicochemical properties of rice starch during steeping in the parboiling process. J. Cereal Sci. 2016, 69, 398–405. [Google Scholar] [CrossRef]

- Zhou, Z.; Robards, K.; Helliwell, S.; Blanchard, C. Effect of storage temperature on rice thermal properties. Food Res. Int. 2010, 43, 709–715. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.Q.; Tong, Q.Y.; Zhang, Z.P.; Jin, Z.Y. Effect of pullulan on the water distribution, microstructure and textural properties of rice starch gels during cold storage. Food Chem. 2017, 214, 702–709. [Google Scholar] [CrossRef]

- BeMiller, J.N. Pasting, paste, and gel properties of starch–hydrocolloid combinations. Carbohydr. Polym. 2011, 86, 386–423. [Google Scholar] [CrossRef]

- Xu, X.N.; Yan, W.L.; Yang, Z.K.; Wang, X.N.; Xiao, Y.; Du, X.F. Effect of ultra-high pressure on quality characteristics of parboiled rice. J. Cereal Sci. 2019, 87, 117–123. [Google Scholar] [CrossRef]

| Sample | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| Indica rice kernel | 73.00 ± 0.12 a | 77.96 ± 0.11 c | 82.92± 0.28 ab | 7.69 ± 0.11 a |

| ANN-50 °C 12 h | 73.04 ± 0.14 ab | 77.41 ± 0.24 ab | 82.24 ± 0.28 a | 10.21 ± 0.41 b |

| ANN-55 °C 12 h | 73.33 ± 0.19 ab | 77.56 ± 0.21 ab | 82.12 ± 0.23 a | 10.75 ± 0.11 b |

| ANN-60 °C 12 h | 76.24 ± 0.05 c | 79.38 ± 0.09 d | 83.35 ± 0.04 b | 10.89 ± 0.38 b |

| ANN-65 °C 12 h | 76.71 ± 0.03 cd | 79.78 ± 0.10 e | 83.43 ± 0.14 b | 10.71 ± 1.75 b |

| Sample | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| Indica rice kernel | 73.00 ± 0.12 a | 77.96 ± 0.11 c | 82.92 ± 0.28 ab | 7.69 ± 0.11 a |

| ANN-50 °C 24 h | 73.06 ± 0.12 ab | 77.25 ± 0.18 a | 82.00 ± 0.06 a | 11.25 ± 0.08 b |

| ANN-55 °C 24 h | 73.59 ± 0.20 b | 77.69 ± 0.03 bc | 82.21 ± 0.04 a | 10.62 ± 0.04 b |

| ANN-60 °C 24 h | 76.96 ± 0.18 c | 79.91 ± 0.23 d | 83.44 ± 0.48 b | 9.82 ± 0.14 ab |

| ANN-65 °C 24 h | 77.54 ± 0.23 d | 80.53 ± 0.18 e | 84.50 ± 0.32 c | 9.83 ± 0.67 ab |

| Sample | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| Indica rice flour | 73.00 ± 0.12 b | 77.96 ± 0.11 c | 82.92 ± 0.28 bc | 7.69 ± 0.11 a |

| ANN-50 °C 12 h | 72.37 ± 0.02 a | 76.92 ± 0.18 ab | 81.77 ± 0.33 a | 10.91 ± 0.11 b |

| ANN-55 °C 12 h | 73.10 ± 0.11 bc | 77.24 ± 0.16 b | 81.75 ± 0.35 a | 11.26 ± 0.36 b |

| ANN-60 °C 12 h | 75.77 ± 0.01 c | 78.91 ± 0.08 d | 82.46 ± 0.24 b | 10.60 ± 0.66 b |

| ANN-65 °C 12 h | 76.82 ± 0.21 d | 79.85 ± 0.26 e | 83.31 ± 0.44 cd | 10.92 ± 0.50 b |

| Sample | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|

| Indica rice flour | 73.00 ± 0.12 b | 77.96 ± 0.11 c | 82.92 ± 0.28 bc | 7.69 ± 0.11 a |

| ANN-50 °C 24 h | 72.46 ± 0.24 a | 76.76 ± 0.34 a | 81.41 ± 0.49 a | 10.80 ± 0.40 c |

| ANN-55 °C 24 h | 73.43 ± 0.04 c | 77.23 ± 0.04 b | 81.44 ± 0.15 a | 11.21 ± 0.82 c |

| ANN-60 °C 24 h | 76.26 ± 0.03 d | 79.51 ± 0.08 d | 83.13 ± 0.18 bcd | 10.83 ± 0.08 c |

| ANN-65 °C 24 h | 77.38 ± 0.33 e | 80.25 ± 0.30 e | 83.57 ± 0.30 d | 9.75 ± 1.00 b |

| Sample | Relative Intensity (%) | Sample | Relative Intensity (%) |

|---|---|---|---|

| Indica rice kernel | 34.73 ± 0.12 a | Indica rice kernel | 34.73 ± 0.12 a |

| ANN-50 °C 12 h | 45.27 ± 0.02 b | ANN-50 °C 24 h | 39.67 ± 0.28 b |

| ANN-55 °C 12 h | 46.03 ± 0.11 c | ANN-55 °C 24 h | 44.52 ± 0.06 d |

| ANN-60 °C 12 h | 44.92 ± 0.33 b | ANN-60 °C 24 h | 40.50 ± 0.04 c |

| ANN-65 °C 12 h | 45.61 ± 0.04 b | ANN-65 °C 24 h | 41.58 ± 0.32 c |

| Sample | Relative Intensity (%) | Sample | Relative Intensity (%) |

|---|---|---|---|

| Indica rice flour | 34.73 ± 0.12 a | Indica rice flour | 34.73 ± 0.12 a |

| ANN-50 °C 12 h | 36.98 ± 0.34 b | ANN-50 °C 24 h | 37.70 ± 0.24 b |

| ANN-55 °C 12 h | 45.36 ± 0.08 d | ANN-55 °C 24 h | 44.61 ± 0.21 e |

| ANN-60 °C 12 h | 43.31 ± 0.15 c | ANN-60 °C 24 h | 42.16 ± 0.09 d |

| ANN-65 °C 12 h | 42.23 ± 0.11 c | ANN-65 °C 24 h | 39.49 ± 0.03 c |

| Sample | Hardness (g) | Springiness (g) | Cohesiveness (g) | Chewiness (g) | Resilience (g) |

|---|---|---|---|---|---|

| Indica rice kernel | 77.06 ± 5.63 a | 0.868 ± 0.004 a | 0.593 ± 0.033 a | 39.60 ± 0.91 a | 0.268 ± 0.024 a |

| ANN-50 °C 12 h | 104.25 ± 1.48 c | 0.878 ± 0.000 ab | 0.597 ± 0.003 a | 54.62 ± 0.52 c | 0.295 ± 0.008 a |

| ANN-55 °C 12 h | 102.16 ± 2.52 c | 0.899 ± 0.013 c | 0.619 ± 0.013 ab | 56.82 ± 1.68 cd | 0.306 ± 0.002 ab |

| ANN-60 °C 12 h | 107.18 ± 0.40 d | 0.868 ± 0.011 a | 0.594 ± 0.016 a | 55.17 ± 0.57 c | 0.293 ± 0.006 a |

| ANN-65 °C 12 h | 94.01 ± 4.34 b | 0.889 ± 0.000 ab | 0.602 ± 0.004 a | 50.27 ± 1.94 b | 0.280 ± 0.004 a |

| Sample | Hardness (g) | Springiness (g) | Cohesiveness (g) | Chewiness (g) | Resilience (g) |

|---|---|---|---|---|---|

| Indica rice kernel | 77.06 ± 5.63 a | 0.868 ± 0.004 a | 0.593 ± 0.033 a | 39.60 ± 0.91 a | 0.268 ± 0.024 a |

| ANN-50 °C 24 h | 103.79 ± 3.29 c | 0.888 ± 0.007 bc | 0.633 ± 0.008 ab | 58.27 ± 2.12 c | 0.348 ± 0.042 b |

| ANN-55 °C 24 h | 104.47 ± 0.36 c | 0.892 ± 0.007 bcd | 0.637 ± 0.013 ab | 59.35 ± 1.54 d | 0.366 ± 0.004 bc |

| ANN-60 °C 24 h | 85.73 ± 1.90 b | 0.909 ± 0.010 d | 0.681 ± 0.006 b | 53.04 ± 0.15 bc | 0.478 ± 0.025 d |

| ANN-65 °C 24 h | 107.84 ± 2.45 cd | 0.885 ± 0.002 abc | 0.612 ± 0.037 ab | 58.34 ± 2.01 c | 0.299 ± 0.027 a |

| Sample | Hardness (g) | Springiness (g) | Cohesiveness (g) | Chewiness (g) | Resilience (g) |

|---|---|---|---|---|---|

| Indica rice flour | 77.06 ± 5.63 a | 0.868 ± 0.004 a | 0.593 ± 0.033 a | 39.60 ± 0.91 a | 0.268 ± 0.023 a |

| ANN-50 °C 12 h | 82.99 ± 1.98 b | 0.915 ± 0.002 c | 0.644 ± 0.058 b | 48.92 ± 5.67 b | 0.414 ± 0.116 d |

| ANN-55 °C 12 h | 95.54 ± 5.50 c | 0.928 ± 0.008 c | 0.626 ± 0.040 b | 55.34 ± 0.84 bc | 0.316 ± 0.047 ab |

| ANN-60 °C 12 h | 99.60 ± 2.64 cd | 0.883 ± 0.015 ab | 0.629 ± 0.003 b | 55.29 ± 2.10 bc | 0.375 ± 0.003 c |

| ANN-65 °C 12 h | 104.62 ± 0.96 d | 0.884 ± 0.008 ab | 0.612 ± 0.023 ab | 56.49 ± 2.13 c | 0.304 ± 0.005 ab |

| Sample | Hardness (g) | Springiness (g) | Cohesiveness (g) | Chewiness (g) | Resilience (g) |

|---|---|---|---|---|---|

| Indica rice flour | 77.06 ± 5.63 a | 0.868 ± 0.004 a | 0.593 ± 0.033 a | 39.60 ± 0.91 a | 0.268 ± 0.023 a |

| ANN-50 °C 24 h | 111.64 ± 1.03 c | 0.916 ± 0.001 c | 0.688 ± 0.022 b | 70.31 ± 3.00 d | 0.491 ± 0.032 d |

| ANN-55 °C 24 h | 107.72 ± 4.96 bc | 0.891 ± 0.009 b | 0.628 ± 0.025 b | 60.24 ± 0.28 bc | 0.364 ± 0.007 c |

| ANN-60 °C 24 h | 104.65 ± 2.06 bc | 0.881 ± 0.003 ab | 0.619 ± 0.028 a | 57.00 ± 3.90 b | 0.304 ± 0.021 b |

| ANN-65 °C 24 h | 103.35 ± 1.06 b | 0.937 ± 0.004 d | 0.683 ± 0.018 b | 66.10 ± 1.36 c | 0.346 ± 0.055 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Shang, M.; Chen, X.; Dai, L.; Ji, N.; Qin, Y.; Wang, Y.; Xiong, L.; Sun, Q.; Xie, F. Different Characteristics of Annealed Rice Kernels and Flour and Their Effects on the Quality of Rice Noodles. Foods 2023, 12, 1914. https://doi.org/10.3390/foods12091914

Zhang Z, Shang M, Chen X, Dai L, Ji N, Qin Y, Wang Y, Xiong L, Sun Q, Xie F. Different Characteristics of Annealed Rice Kernels and Flour and Their Effects on the Quality of Rice Noodles. Foods. 2023; 12(9):1914. https://doi.org/10.3390/foods12091914

Chicago/Turabian StyleZhang, Ziwen, Mengshan Shang, Xiaoyu Chen, Lei Dai, Na Ji, Yang Qin, Yanfei Wang, Liu Xiong, Qingjie Sun, and Fengwei Xie. 2023. "Different Characteristics of Annealed Rice Kernels and Flour and Their Effects on the Quality of Rice Noodles" Foods 12, no. 9: 1914. https://doi.org/10.3390/foods12091914

APA StyleZhang, Z., Shang, M., Chen, X., Dai, L., Ji, N., Qin, Y., Wang, Y., Xiong, L., Sun, Q., & Xie, F. (2023). Different Characteristics of Annealed Rice Kernels and Flour and Their Effects on the Quality of Rice Noodles. Foods, 12(9), 1914. https://doi.org/10.3390/foods12091914