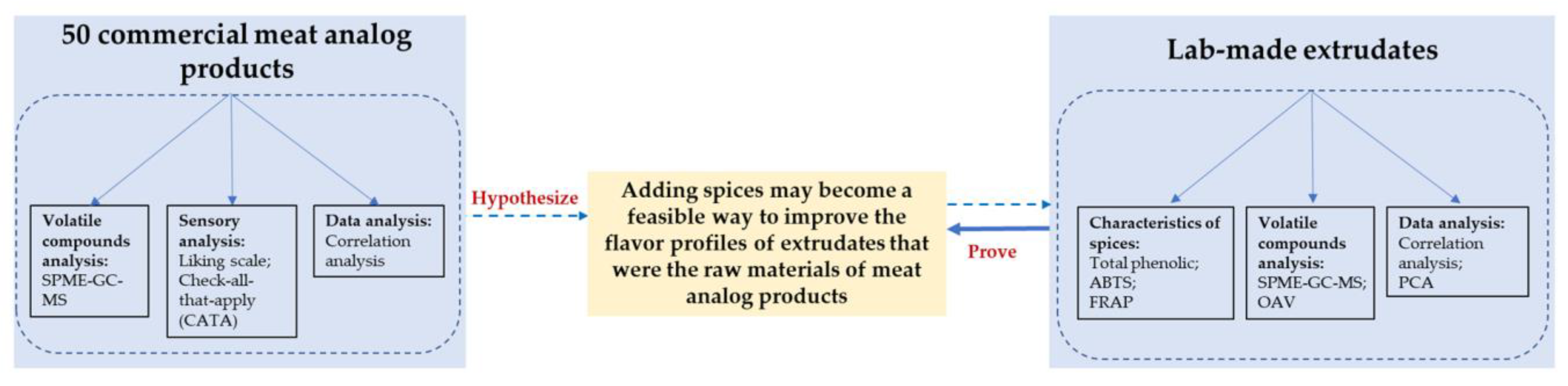

Influences of Spices on the Flavor of Meat Analogs and Their Potential Pathways

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Plant-Based Meat Analog Products

2.3. Extraction of the Phenolic Fract Ion

2.4. Determination of Total Phenolic Contents

2.5. Determination of the Antioxidant Activity of Phenolics Fractions in Spices

2.6. High-Moisture Extrusion

2.7. Solid-Phase Microextraction (SPME) Extraction

2.8. GC-MS Condition

2.9. Quantitative Analysis of Volatile Compounds

2.9.1. Calculation of Relative Contents of Volatile Compounds

2.9.2. Semi-Quantification of Compounds

2.10. Aroma-Active Compounds in Extrudates

2.11. Consumer Sensory Analysis

2.11.1. Liking Scale

2.11.2. Check-All-That-Apply (CATA)

2.12. Statistical Analysis

3. Results and Discussion

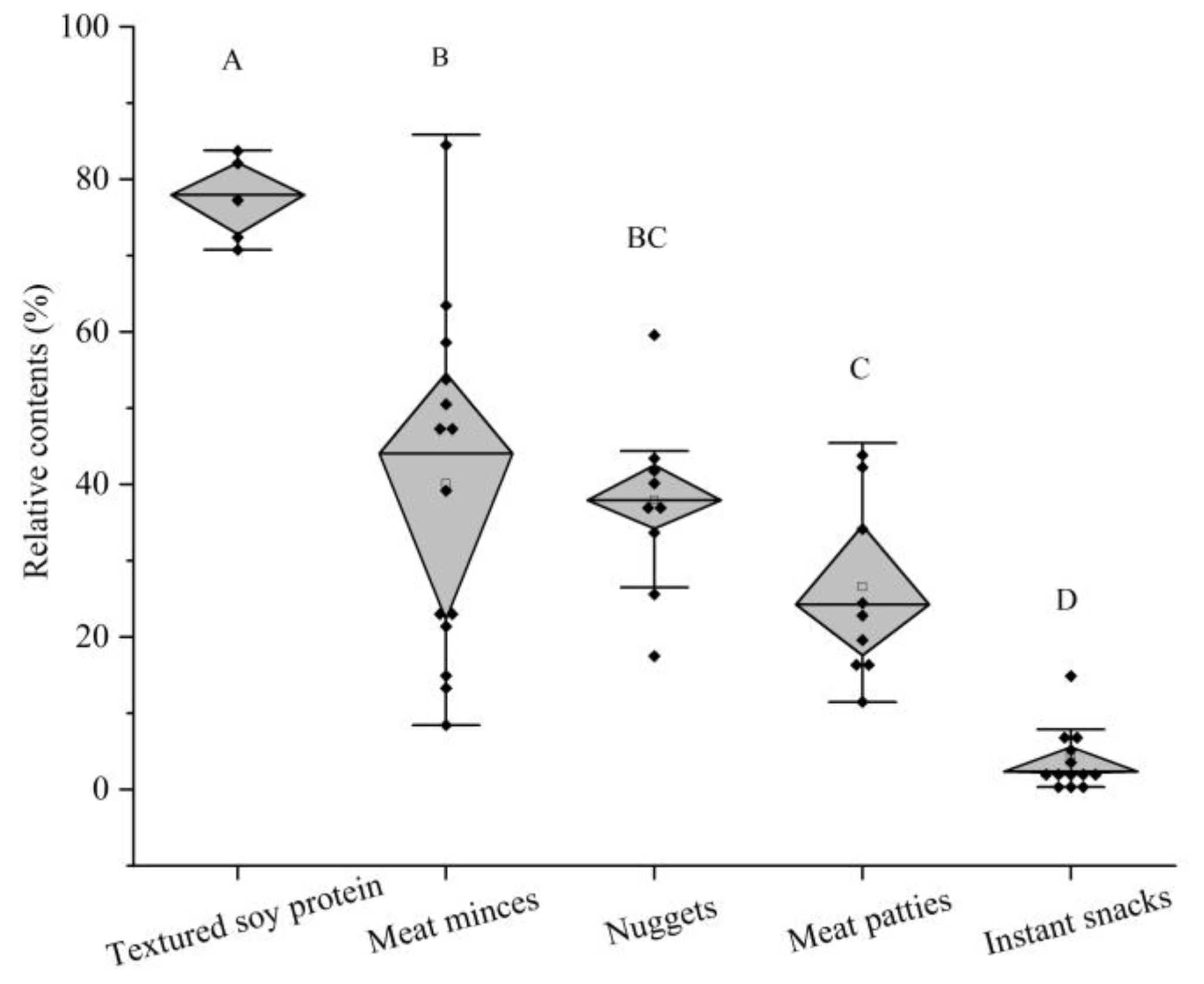

3.1. Analysis of 50 Commercial Plant-Based Meat Analogs

3.1.1. Off-Flavor Compounds in Meat Analogs

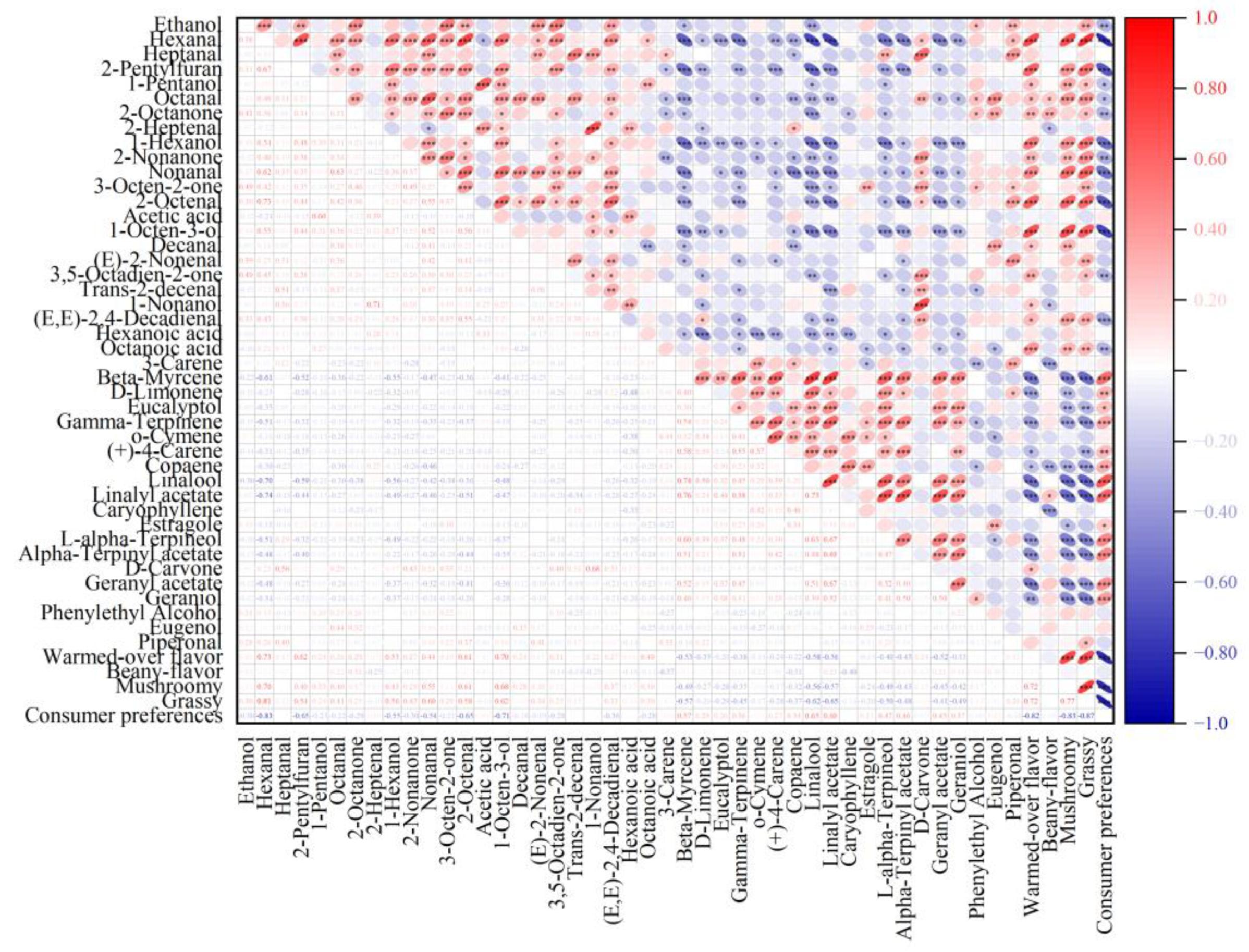

3.1.2. Correlation Analysis

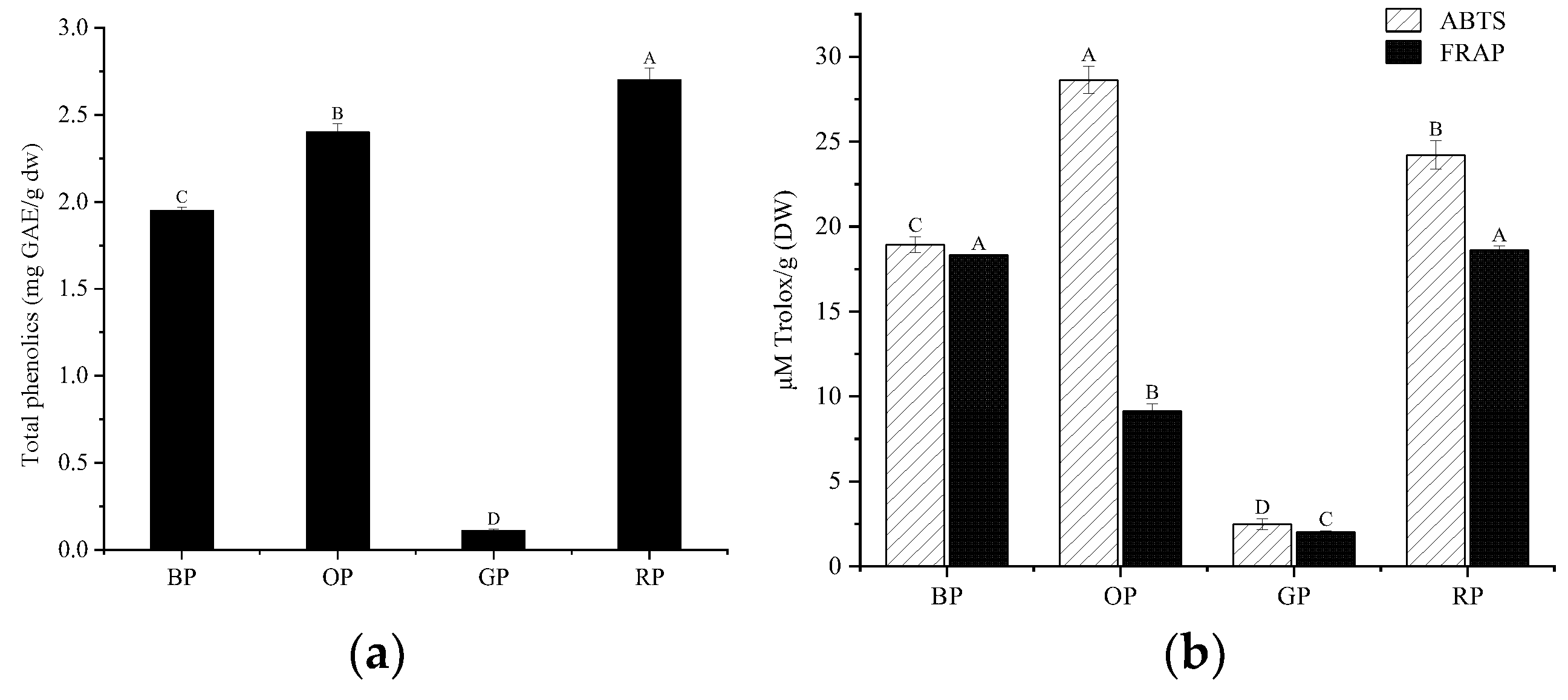

3.2. Determination of Antioxidant Abilities and Total Phenolics of Spices

3.3. Flavor Analysis

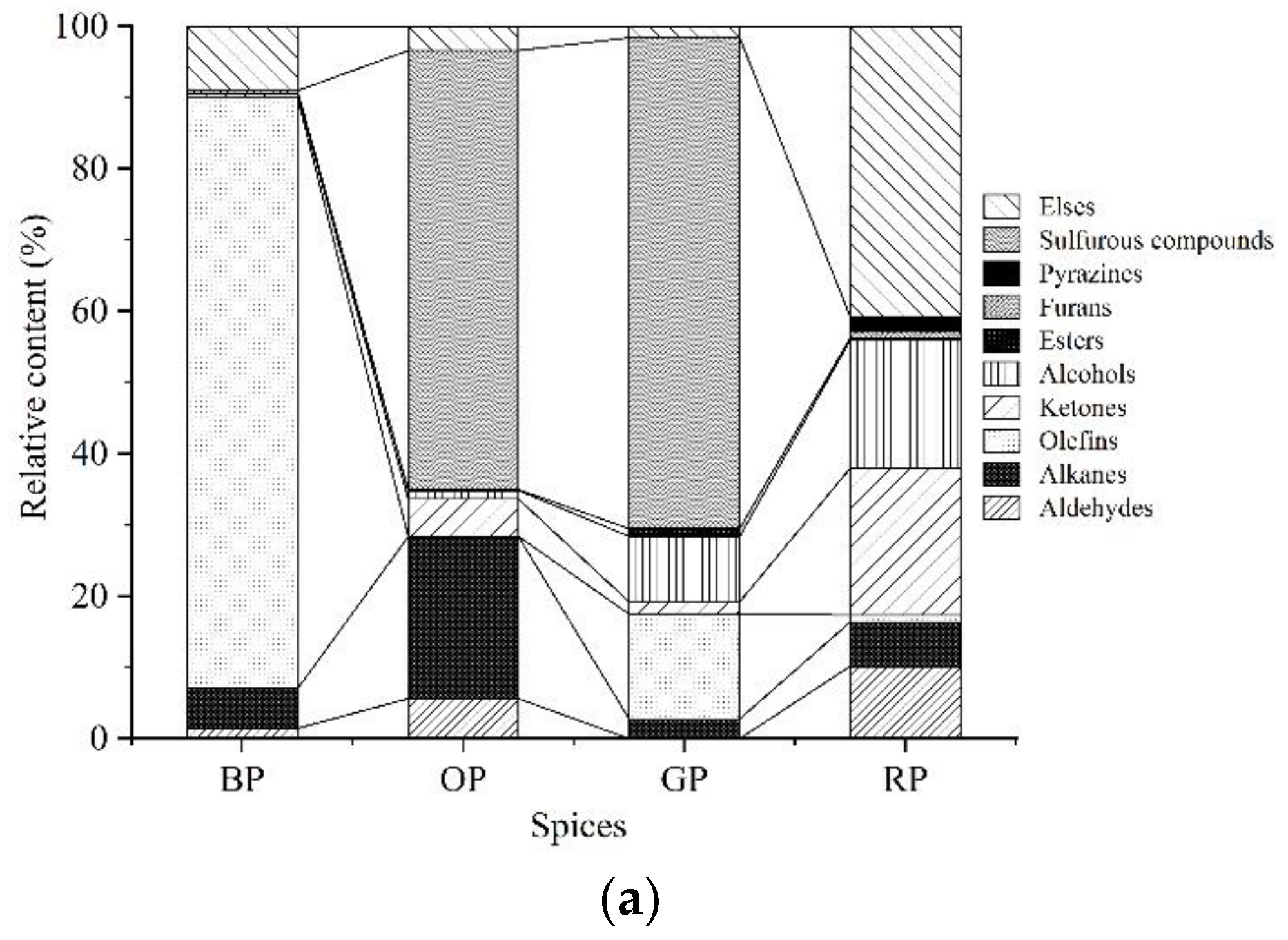

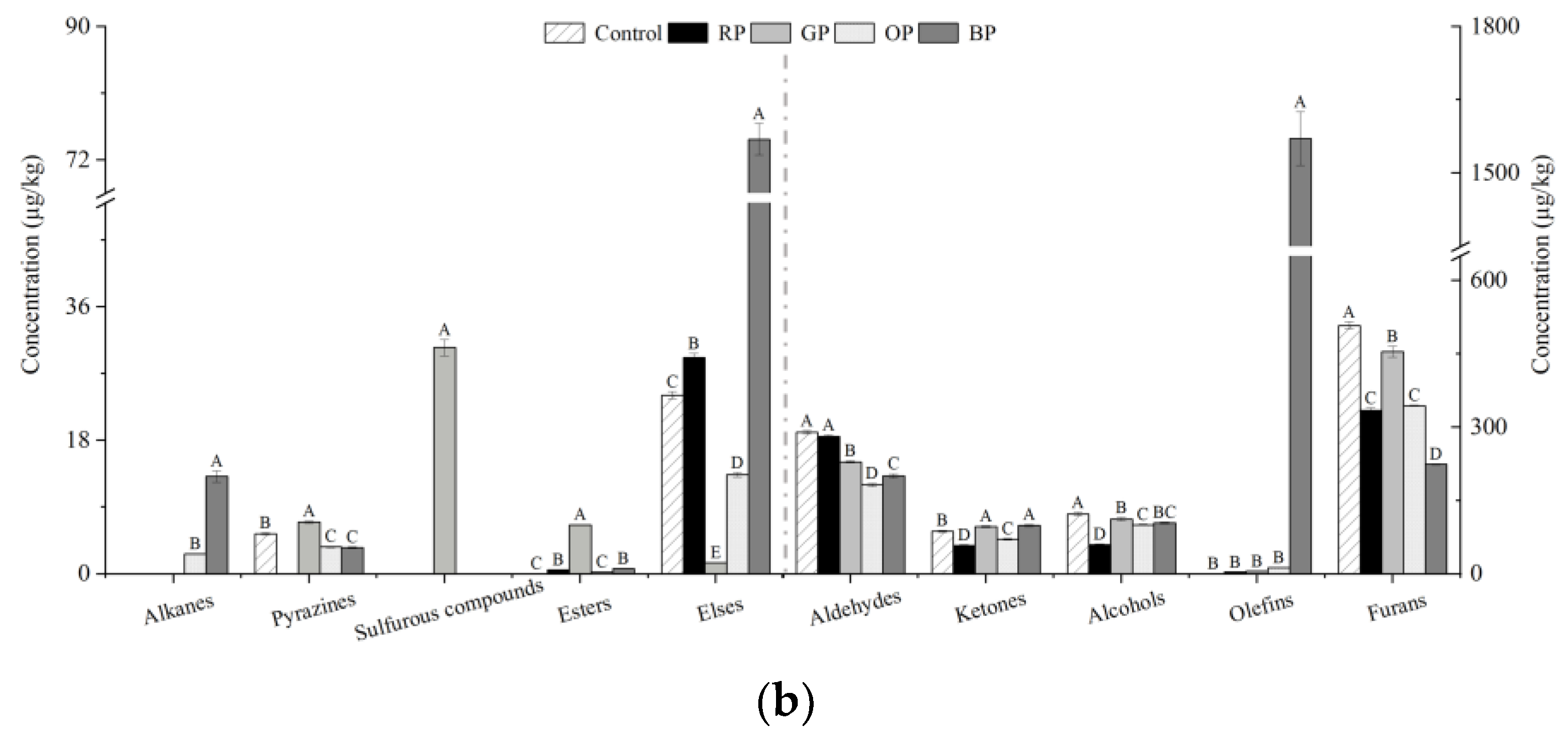

3.3.1. Volatile Compounds of Spices and Extrudates

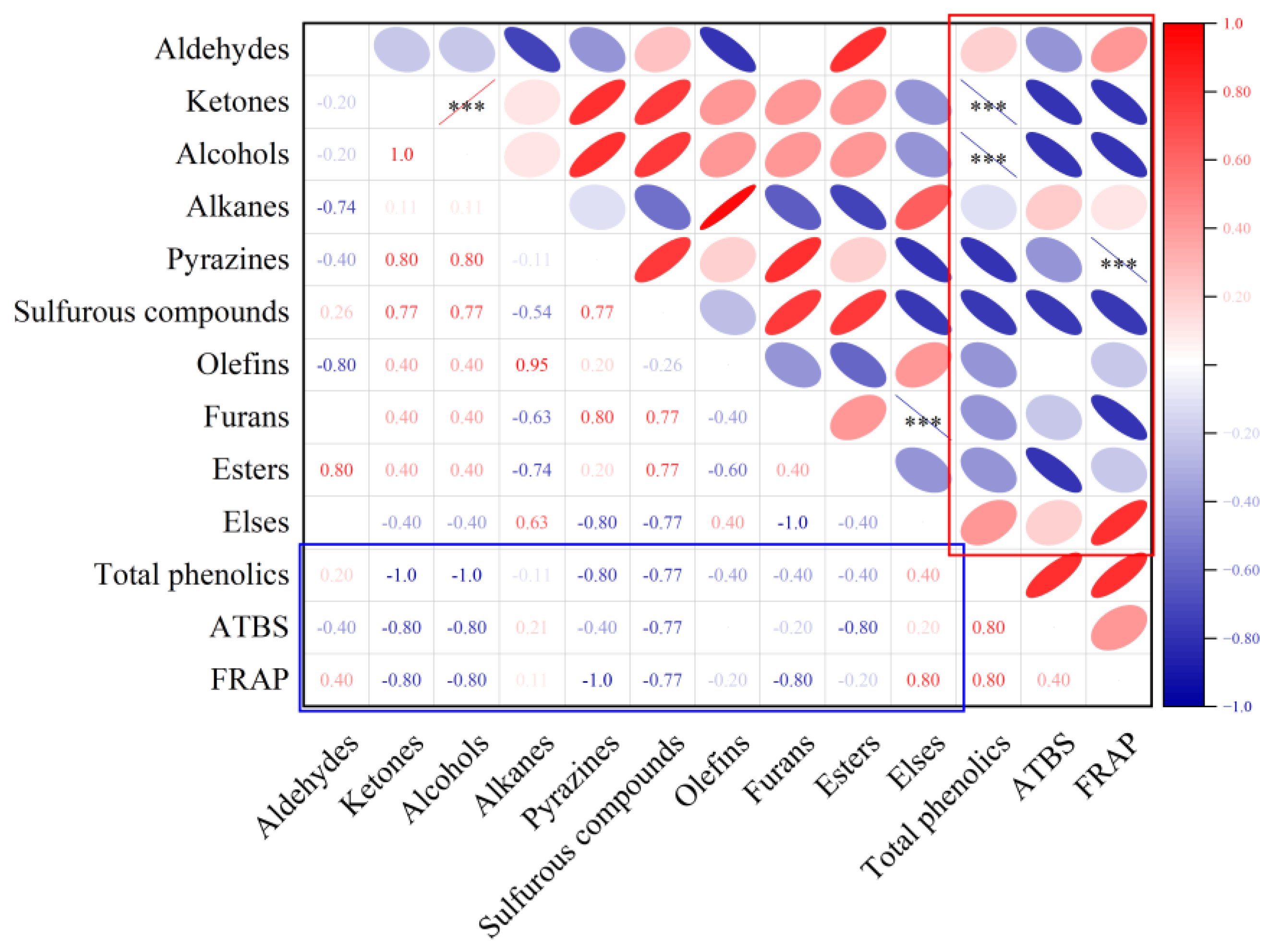

3.3.2. Correlation Analysis

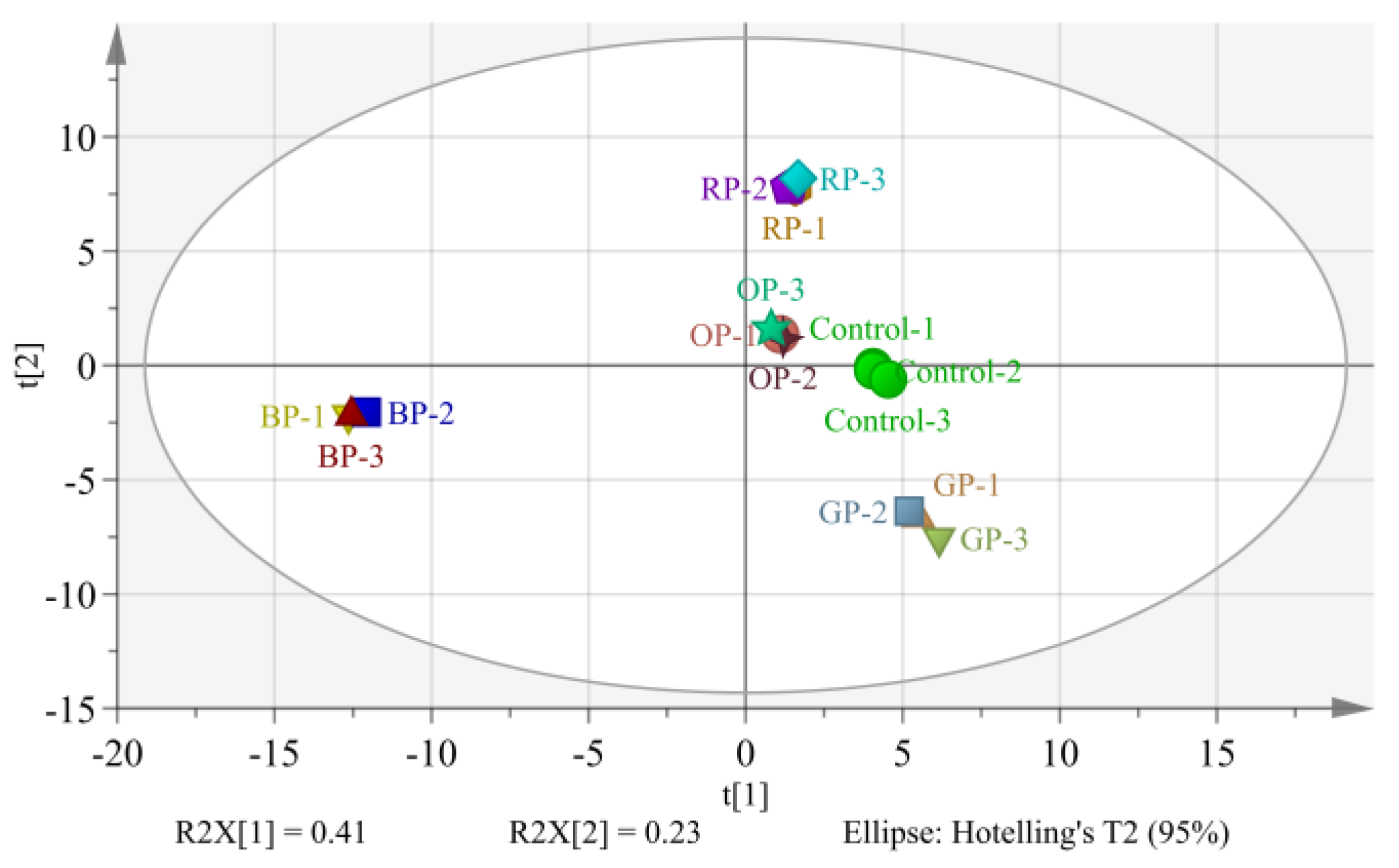

3.3.3. PCA

3.3.4. OAV Analysis of the Sensory Characteristics of Volatile Compounds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shaghaghian, S.; McClements, D.J.; Khalesi, M.; Garcia-Vaquero, M.; Mirzapour-Kouhdasht, A. Digestibility and bioavailability of plant-based proteins intended for use in meat analogues: A review. Trends Food Sci. Technol. 2022, 129, 646–656. [Google Scholar] [CrossRef]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat analogues: Health promising sustainable meat substitutes. Crit. Rev. Food. Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef]

- Guo, Z.; Teng, F.; Huang, Z.; Lv, B.; Lv, X.; Babich, O.; Yu, W.; Li, Y.; Wang, Z.; Jiang, L. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 2020, 105, 105752. [Google Scholar] [CrossRef]

- Kumar, V.; Rani, A.; Rawal, R. First Indian Soybean Variety Free from Off-Flavour Generating Lipoxygenase-2 Gene Identified for Release for Commercial Cultivation. Natl. Acad. Sci. Lett. 2021, 44, 477–480. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, X.; Hua, Y.; Kong, X.; Zhang, C.; Chen, Y.; Wang, S. The absence of lipoxygenase and 7S globulin of soybeans and heating temperatures on the properties of soymilks and soy yogurts. LWT Food Sci. Technol. 2019, 115, 108431. [Google Scholar] [CrossRef]

- Shi, Y.; Singh, A.; Kitts, D.D.; Pratap-Singh, A. Lactic acid fermentation: A novel approach to eliminate unpleasant aroma in pea protein isolates. LWT Food Sci. Technol. 2021, 150, 111927. [Google Scholar] [CrossRef]

- Devanthi, P.V.P.; Gkatzionis, K. Soy sauce fermentation: Microorganisms, aroma formation, and process modification. Food Res. Int. 2019, 120, 364–374. [Google Scholar] [CrossRef]

- Lee, E.J.; Kim, H.; Lee, J.Y.; Ramachandraiah, K.; Hong, G.P. β-Cyclodextrin-Mediated Beany Flavor Masking and Textural Modification of an Isolated Soy Protein-Based Yuba Film. Foods 2020, 9, 818. [Google Scholar] [CrossRef]

- Zhu, D.; Damodaran, S. Removal of off-flavour-causing precursors in soy protein by concurrent treatment with phospholipase A2 and cyclodextrins. Food Chem. 2018, 264, 319–325. [Google Scholar] [CrossRef]

- Damodaran, S.; Kinsella, J.E. Interaction of carbonyls with soy protein: Thermodynamic effects. J. Agric. Food Chem. 1981, 29, 1249–1253. [Google Scholar] [CrossRef]

- Wang, K.; Arntfield, S.D. Effect of protein-flavour binding on flavour delivery and protein functional properties: A special emphasis on plant-based proteins. Flavour. Fragr. J. 2017, 32, 92–101. [Google Scholar] [CrossRef]

- Duppeti, H.; Manjabhatta, S.N.; Kempaiah, B.B. Physicochemical, structural, functional and flavor adsorption properties of white shrimp (Penaeus vannamei) proteins as affected by processing methods. Food Res. Int. 2023, 163, 112296. [Google Scholar] [CrossRef] [PubMed]

- Arora, A.; Damodaran, S. Competitive Binding of Off-Flavor Compounds with Soy Protein and β-Cyclodextrin in a Ternary System: A Model Study. J. Am. Oil Chem. Soc. 2010, 87, 673–679. [Google Scholar] [CrossRef]

- Sjövall, O.; Lapveteläinen, A.; Johansson, A.; Kallio, H.P. Analysis of volatiles formed during oxidation of extruded oats. J. Agric. Food Chem. 1997, 45, 4452–4455. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, X.; Wang, Y.; Pan, D.; Sun, Y.; Cao, J. Study on the volatile compounds generated from lipid oxidation of Chinese bacon (unsmoked) during processing. Eur. J. Lipid Sci. Technol. 2017, 119, 1600512. [Google Scholar] [CrossRef]

- Trujillo-Mayol, I.; Sobral, M.; Viegas, O.; Cunha, S.C.; Ferreira, I.M.P.L.V.O. Incorporation of avocado peel extract to reduce cooking-induced hazards in beef and soy burgers: A clean label ingredient. Food Res. Int. 2021, 4, 110434. [Google Scholar] [CrossRef]

- Cozzolino, R.; Malorni, L.; Martignetti, A.; Picariello, G.; Siano, F.; Forte, G.; De Giulio, B. Comparative analysis of volatile profiles and phenolic compounds of Four Southern Italian onion (Allium cepa L.) Landraces. J. Food Compos. Anal. 2021, 101, 103990. [Google Scholar] [CrossRef]

- Manohar, C.M.; Xue, J.; Murayyan, A.; Neethirajan, S.; Shi, J. Antioxidant activity of polyphenols from Ontario grown onion varieties using pressurized low polarity water technology. J. Funct. Foods 2017, 31, 52–62. [Google Scholar] [CrossRef]

- Naheed, Z.; Cheng, Z.; Wu, C.; Wen, Y.; Ding, H. Total polyphenols, total flavonoids, allicin and antioxidant capacities in garlic scape cultivars during controlled atmosphere storage. Postharvest Biol. Technol. 2017, 131, 39–45. [Google Scholar] [CrossRef]

- Kazeem, M.I.; Akanji, M.A.; Hafizur, R.M.; Choudhary, M.I. Antiglycation, antioxidant and toxicological potential of polyphenol extracts of alligator pepper, ginger and nutmeg from Nigeria. Asian Pac. J. Trop. Biomed. 2012, 2, 727–732. [Google Scholar] [CrossRef]

- Shan, B.; Cai, Y.Z.; Sun, M.; Corke, H. Antioxidant capacity of 26 spice extracts and characterization of their phenolic constituents. J. Agric. Food Chem. 2005, 53, 7749–7759. [Google Scholar] [CrossRef]

- Zhang, Y.; Henning, S.M.; Lee, R.-P.; Huang, J.; Zerlin, A.; Li, Z.; Heber, D. Turmeric and black pepper spices decrease lipid peroxidation in meat patties during cooking. Int. J. Food Sci. Nutr. 2015, 66, 260–265. [Google Scholar] [CrossRef]

- del Amor, F.M.; Serrano-Martínez, A.; Fortea, I.; Núñez-Delicado, E. Differential effect of organic cultivation on the levels of phenolics, peroxidase and capsidiol in sweet peppers. J. Agric. Food Chem. 2008, 88, 770–777. [Google Scholar] [CrossRef]

- Guclu, G.; Keser, D.; Kelebek, H.; Keskin, M.; Emre Sekerli, Y.; Soysal, Y.; Selli, S. Impact of production and drying methods on the volatile and phenolic characteristics of fresh and powdered sweet red peppers. Food Chem. 2021, 338, 128129. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Araújo, L.; Chambers, E.; Adhikari, K.; Hough, G.; Carbonell-Barrachina, A.A. Influence of various traditional seasonings on beef flavor: United States, Spanish, and Argentinian practices. Meat Sci. 2013, 93, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Dwivedi, S.; Vasavada, M.N.; Cornforth, D. Evaluation of Antioxidant Effects and Sensory Attributes of Chinese 5-Spice Ingredients in Cooked Ground Beef. J. Food Sci. 2006, 71, C12–C17. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Shao, Y.; Tang, F.; Huang, Y.; Xu, F.; Chen, Y.; Tong, C.; Chen, H.; Bao, J. Analysis of genotype × environment interactions for polyphenols and antioxidant capacity of rice by association mapping. J. Agric. Food Chem. 2014, 62, 5361–5368. [Google Scholar] [CrossRef] [PubMed]

- Quan, W.; Qie, X.; Chen, Y.; Zeng, M.; Qin, F.; Chen, J.; He, Z. Effect of milk addition and processing on the antioxidant capacity and phenolic bioaccessibility of coffee by using an in vitro gastrointestinal digestion model. Food Chem. 2020, 308, 125598. [Google Scholar] [CrossRef]

- Qie, X.; Chen, Y.; Quan, W.; Wang, Z.; Zeng, M.; Qin, F.; Chen, J.; He, Z. Analysis of β-lactoglobulin–epigallocatechin gallate interactions: The antioxidant capacity and effects of polyphenols under different heating conditions in polyphenolic–protein interactions. Food Funct. 2020, 11, 3867–3878. [Google Scholar] [CrossRef]

- Boatright, W.L.; Lei, Q. Compounds Contributing to the “Beany” Odor of Aqueous Solutions of Soy Protein Isolates. J. Food Sci. 1999, 64, 667–670. [Google Scholar] [CrossRef]

- van Den Dool, H.; Kratz, D.P.A. Generalization of the retention index system including linear temperature programmed gas—Liquid partition chromatography. J. Chromatogr. A 1963, 11, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Surmounting the off-flavor challenge in plant-based foods. Crit. Rev. Food Sci. Nutr. 2022, 23, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, A.; Tsuda, Y.; Hirata, N.; Kubota, K.; Kitamura, K. Aroma Constituents of Soybean [Glycine max (L.) Merril] Milk Lacking Lipoxygenase Isoenzymes. J. Agric. Food Chem. 1995, 43, 2449–2452. [Google Scholar] [CrossRef]

- Yang, L.; Ying, Z.; Li, H.; Li, J.; Zhang, T.; Song, Y.; Liu, X. Extrusion production of textured soybean protein: The effect of energy input on structure and volatile beany flavor substances. Food Chem. 2023, 405, 134728. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, X.; Sun, R.; Jiang, W.; Zhang, D.; Liu, H.; Sun, B. Sensory attributes and characterization of aroma profiles of fermented sausages based on fibrous-like meat substitute from soybean protein and Coprinus comatus. Food Chem. 2022, 373, 131537. [Google Scholar] [CrossRef]

- Yuan, X.; Jiang, W.; Zhang, D.; Liu, H.; Sun, B. Textural, Sensory and Volatile Compounds Analyses in Formulations of Sausages Analogue Elaborated with Edible Mushrooms and Soy Protein Isolate as Meat Substitute. Foods 2021, 11, 52. [Google Scholar] [CrossRef]

- Lungu, N.S.; Afolayan, A.J. Warmed-over flavour profiles, microbial changes, shelf-life and check-all-that-apply sensory analysis of cooked minced pork treated with varying levels of Moringa oleifera leaf and root powder. Heliyon 2022, 8, e10616. [Google Scholar] [CrossRef]

- Lee, J.-G.; Kim, D.-W.; Shin, Y.; Kim, Y.-J. Comparative study of the bioactive compounds, flavours and minerals present in black pepper before and after removing the outer skin. LWT Food Sci. Technol. 2020, 125, 109356. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Bhandari, B.; Yang, P. Intelligent detection of flavor changes in ginger during microwave vacuum drying based on LF-NMR. Food Res. Int. 2019, 119, 417–425. [Google Scholar] [CrossRef]

- Lee, B.J.; Hendricks, D.G.; Cornforth, D.P. A comparison of carnosine and ascorbic acid on color and lipid stability in a ground beef pattie model system. Meat Sci. 1999, 51, 245–253. [Google Scholar] [CrossRef]

- Bi, K.H.; Zhang, L.; Qiao, X.G.; Xu, Z.X. Tea Polyphenols as Inhibitors of Furan Formed in the Maillard Model System and Canned Coffee Model. J. Food Sci. 2017, 82, 1271–1277. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.S.; Lee, E.J.; Moon, S.H.; Paik, H.D.; Ahn, D.U. Addition of garlic or onion before irradiation on lipid oxidation, volatiles and sensory characteristics of cooked ground beef. Meat Sci. 2011, 88, 286–291. [Google Scholar] [CrossRef]

- Hertog, M.G.L.; Hollman, P.C.; Katan, M.B. Content of potentially anticarcinogenic flavonoids of 28 vegetables and 9 fruits commonly consumed in the Netherlands. J. Agric. Food Chem. 1992, 40, 2379–2383. [Google Scholar] [CrossRef]

- Martini, S.; Cattivelli, A.; Conte, A.; Tagliazucchi, D. Black, green, and pink pepper affect differently lipid oxidation during cooking and in vitro digestion of meat. Food Chem. 2021, 350, 129246. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Xu, B.; Xu, Y.; Yao, Z.; Zhu, B.; Li, X.; Sun, Y. Effects of different thermal treatment temperatures on volatile flavour compounds of water-boiled salted duck after packaging. LWT Food Sci. Technol. 2022, 154, 112625. [Google Scholar] [CrossRef]

- Liu, D.; Bai, L.; Feng, X.; Chen, Y.P.; Zhang, D.; Yao, W.; Zhang, H.; Chen, G.; Liu, Y. Characterization of Jinhua ham aroma profiles in specific to aging time by gas chromatography-ion mobility spectrometry (GC-IMS). Meat Sci. 2020, 168, 108178. [Google Scholar] [CrossRef] [PubMed]

- Jeleń, H.H.; Gracka, A. Analysis of black pepper volatiles by solid phase microextraction–gas chromatography: A comparison of terpenes profiles with hydrodistillation. J. Chromatogr. A 2015, 1418, 200–209. [Google Scholar] [CrossRef]

- Iglesias, J.; Medina, I.; Bianchi, F.; Careri, M.; Mangia, A.; Musci, M. Study of the volatile compounds useful for the characterisation of fresh and frozen-thawed cultured gilthead sea bream fish by solid-phase microextraction gas chromatography–mass spectrometry. Food Chem. 2009, 115, 1473–1478. [Google Scholar] [CrossRef]

- Moon, S.-Y.; Cliff, M.A.; Li-Chan, E.C.Y. Odour-active components of simulated beef flavour analysed by solid phase microextraction and gas chromatography–mass spectrometry and –olfactometry. Food Res. Int. 2006, 39, 294–308. [Google Scholar] [CrossRef]

- Zha, F.; Yang, Z.; Rao, J.; Chen, B. Gum Arabic-Mediated Synthesis of Glyco-pea Protein Hydrolysate via Maillard Reaction Improves Solubility, Flavor Profile, and Functionality of Plant Protein. J. Agric. Food Chem. 2019, 67, 10195–10206. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Chong, Y.; Ding, Y.; Gu, S.; Liu, L. Determination of the effects of different washing processes on aroma characteristics in silver carp mince by MMSE–GC–MS, e-nose and sensory evaluation. Food Chem. 2016, 207, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Chen, X.; Hayat, K.; Duhoranimana, E.; Zhang, X.; Xia, S.; Yu, J.; Xing, F. Characterization of odor-active compounds of chicken broth and improved flavor by thermal modulation in electrical stewpots. Food Res. Int. 2018, 109, 72–81. [Google Scholar] [CrossRef]

- Toldra, F. Proteolysis and lipolysis in flavour development of dry-cured meat products. Meat Sci. 1998, 49, S101–S110. [Google Scholar] [CrossRef]

- Kim, C.-H.; Maga, J.A. Chain Length and Functional Group Impact on Flavor Retention during Extrusion; Colorado State University: Fort Collins, CO, USA, 1994. [Google Scholar]

- Lee, J.; Min, D.B. Analysis of volatile compounds from chlorophyll photosensitized linoleic acid by headspace solid-phase microextraction (HS-SPME). Food Sci. Biotechnol. 2010, 19, 611–616. [Google Scholar] [CrossRef]

- Kang, K.-M.; Baek, H.-H. Aroma quality assessment of Korean fermented red pepper paste (gochujang) by aroma extract dilution analysis and headspace solid-phase microextraction–gas chromatography–olfactometry. Food Chem. 2014, 145, 488–495. [Google Scholar] [CrossRef]

- Zhang, S.-S.; Guo, S.; Zheng, Z.-J.; Liu, S.-J.; Hou, Y.-F.; Ho, C.-T.; Bai, N.-S. Characterization of volatiles in Allium tenuissimum L. flower by headspace-gas chromatography-olfactometry-mass spectrometry, odor activity values, and the omission and recombination experiments. LWT Food Sci. Technol. 2021, 151, 112144. [Google Scholar] [CrossRef]

- Feng, Y.; Su, G.; Zhao, H.; Cai, Y.; Cui, C.; Sun-Waterhouse, D.; Zhao, M. Characterisation of aroma profiles of commercial soy sauce by odour activity value and omission test. Food Chem. 2015, 167, 220–228. [Google Scholar] [CrossRef]

- Kaneko, S.; Kumazawa, K.; Nishimura, O. Studies on the key aroma compounds in raw (unheated) and heated Japanese soy sauce. J. Agric. Food Chem. 2013, 61, 3396–3402. [Google Scholar] [CrossRef]

| Retention Time | Compounds | CAS | Odor Description |

|---|---|---|---|

| 3.531 | Ethanol | 64-17-5 | alcohol |

| 6.032 | Hexanal | 66-25-1 | grassy, fishy |

| 8.058 | Heptanal | 111-71-7 | fatty, oily |

| 9.067 | 2-Pentylfuran | 3777-69-3 | fragrant, waxy, mushroom |

| 9.313 | 1-Pentanol | 71-41-0 | spicy |

| 9.956 | Octanal | 124-13-0 | fatty, spicy |

| 9.987 | 2-Octanone | 111-13-7 | soapy, fruity |

| 10.598 | 2-Heptenal | 2463-63-0 | fatty |

| 11.165 | 1-Hexanol | 111-27-3 | salty, beany, potato |

| 11.821 | 2-Nonanone | 821-55-6 | fatty |

| 11.86 | Nonanal | 124-9-6 | waxy, fatty |

| 12.114 | 3-Octen-2-one | 1669-44-9 | earthy, pungency |

| 12.437 | 2-Octenal | 2363-89-5 | vegetable, cucumber, fatty |

| 12.691 | Acetic acid | 64-19-7 | acid |

| 12.841 | 1-Octen-3-ol | 3391-86-4 | mushroom, grassy |

| 13.628 | Decanal | 112-31-2 | oily |

| 14.181 | (E)-2-Nonenal | 18829-56-6 | cucumber, woody |

| 14.721 | 3,5-Octadien-2-one | 30086-02-3 | grassy, green |

| 15.849 | Trans-2-decenal | 3913-81-3 | Rosin, grassy |

| 16.129 | 1-Nonanol | 143-08-8 | fatty, citrus |

| 18.216 | (E, E)-2,4-Decadienal | 25152-84-5 | spicy, fatty |

| 18.608 | Hexanoic acid | 142-62-1 | cheesy, pungency |

| 21.368 | Octanoic acid | 124-07-2 | stringency |

| Compounds | OAV | |||||

|---|---|---|---|---|---|---|

| Control | OP | RP | BP | GP | ||

| Off-flavor compounds in extrudates | Hexanal | 24.51 | 24.56 | 27.39 | 19.8 | 24.28 |

| Octanal | 17.5 | 17.02 | 12.78 | N.D. | 12.44 | |

| Nonanal | 26.6 | 16.26 | 18.32 | 15.86 | 19.89 | |

| Decanal | 68.5 | 85.2 | 51.9 | N.D. | 47.2 | |

| 2-Octenal | 1.75 | 1.69 | 1.09 | 1.12 | 1.21 | |

| 3-Octen-2-one | 5.47 | N.D. | 3.63 | 2.65 | 3.81 | |

| Indole | 1.77 | N.D. | 1.67 | N.D. | N.D. | |

| 2-Butylfuran | 1.7 | N.D. | 2.73 | N.D. | 1.93 | |

| 2-Pentlyfuran | 84.87 | 58.75 | 53.79 | 38.46 | 65.8 | |

| 2-Ethylfuran | N.D. | N.D. | 5.93 | N.D. | N.D. | |

| 1-Octen-3-ol | 31.81 | 31.06 | 25.21 | 15.41 | 25 | |

| 1-Heptanol | 2.22 | 2.56 | N.D. | 1.12 | 1.74 | |

| 1-Nonanol | 1.23 | 1.33 | N.D. | N.D. | N.D. | |

| 1-Hexanol | 18.07 | 19.73 | N.D. | 9.75 | 15.46 | |

| Sum | 286 | 258.16 | 204.44 | 104.17 | 218.76 | |

| Pleasant-flavor compounds in extrudates | Terpineol | N.D. | 5.51 | N.D. | N.D. | N.D. |

| Linalool | N.D. | N.D. | N.D. | 7.39 | N.D. | |

| 2-Nonanone | 1.83 | 3.33 | 1.06 | N.D. | 1.12 | |

| 1-Caryophyllene | 14.06 | 68.59 | N.D. | 14,997.34 | 43.13 | |

| 3-Carene | N.D. | N.D. | N.D. | 3389.09 | N.D. | |

| D-Limonene | N.D. | N.D. | N.D. | 8.21 | N.D. | |

| (+)-4- Carene | N.D. | N.D. | N.D. | 124.55 | N.D. | |

| Pinene | N.D. | N.D. | N.D. | 11.04 | N.D. | |

| 2,4-Di-tert-butylphenol | N.D. | N.D. | N.D. | 4.1 | N.D. | |

| Diallyl sulfide | N.D. | N.D. | N.D. | N.D. | 501.8 | |

| Diallyl disulfide | N.D. | N.D. | N.D. | N.D. | 1.02 | |

| Benzaldehyde | 1.54 | 1.01 | N.D. | N.D. | 1.14 | |

| Pentanal | N.D. | N.D. | 2.23 | N.D. | N.D. | |

| (E, E)-2,4-Decadienal | 12.87 | 10.57 | N.D. | N.D. | 8.8 | |

| 1-Octanol | N.D. | 45.82 | N.D. | 36.27 | N.D. | |

| Sum | 30.3 | 134.83 | 3.29 | 18,577.99 | 557.01 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Qin, F.; He, Z.; Zeng, M.; Wang, Z.; Chen, J. Influences of Spices on the Flavor of Meat Analogs and Their Potential Pathways. Foods 2023, 12, 1650. https://doi.org/10.3390/foods12081650

Yuan J, Qin F, He Z, Zeng M, Wang Z, Chen J. Influences of Spices on the Flavor of Meat Analogs and Their Potential Pathways. Foods. 2023; 12(8):1650. https://doi.org/10.3390/foods12081650

Chicago/Turabian StyleYuan, Jingyao, Fang Qin, Zhiyong He, Maomao Zeng, Zhaojun Wang, and Jie Chen. 2023. "Influences of Spices on the Flavor of Meat Analogs and Their Potential Pathways" Foods 12, no. 8: 1650. https://doi.org/10.3390/foods12081650

APA StyleYuan, J., Qin, F., He, Z., Zeng, M., Wang, Z., & Chen, J. (2023). Influences of Spices on the Flavor of Meat Analogs and Their Potential Pathways. Foods, 12(8), 1650. https://doi.org/10.3390/foods12081650