Changes in Texture Characteristics and Special Requirements of Sichuan-Style Braised Beef for Industrial Production: Based on the Changes in Protein and Lipid of Beef

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Handling

2.3. Texture Properties

2.4. Moisture Content and Moisture State

2.5. Observation of Microstructure

2.6. Sarcoplasmic Protein (SP) and Myofibrillar Protein (MP)

2.7. Carbonyl and Sulfhydryl Content

2.8. Endogenous Fluorescence Intensity

2.9. Thiobarbituric Acid Reactive Substances (TBARS)—Expressed as mg of Malondialdehyde (MDA) per kg of Beef

2.10. Fourier Transform Infrared Spectroscopy (FT-IR)

2.11. Statistical Analysis

3. Results and Discussion

3.1. Texture Properties

3.2. Moisture Content and Moisture State

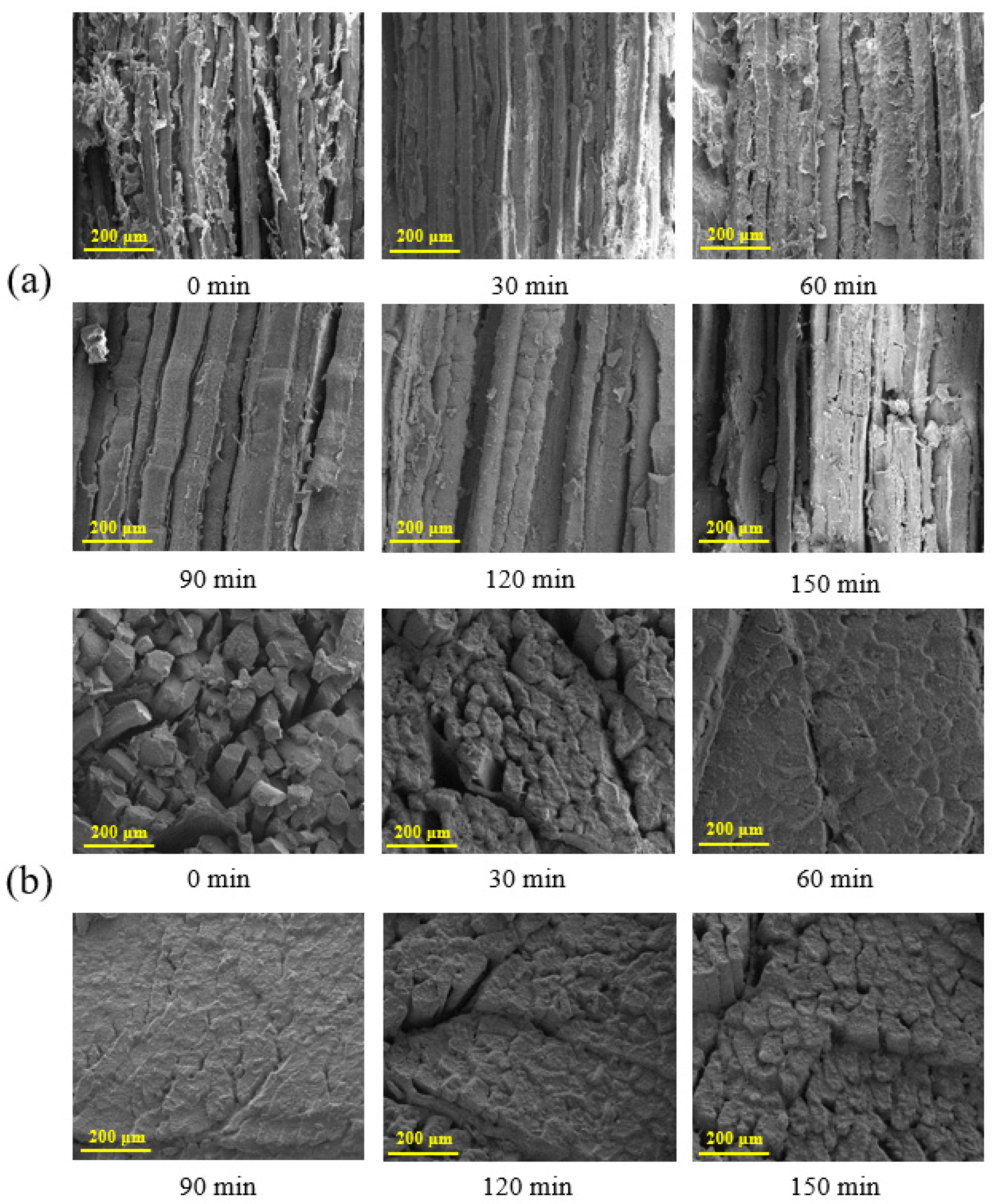

3.3. SEM Analysis

3.4. Protein Oxidation

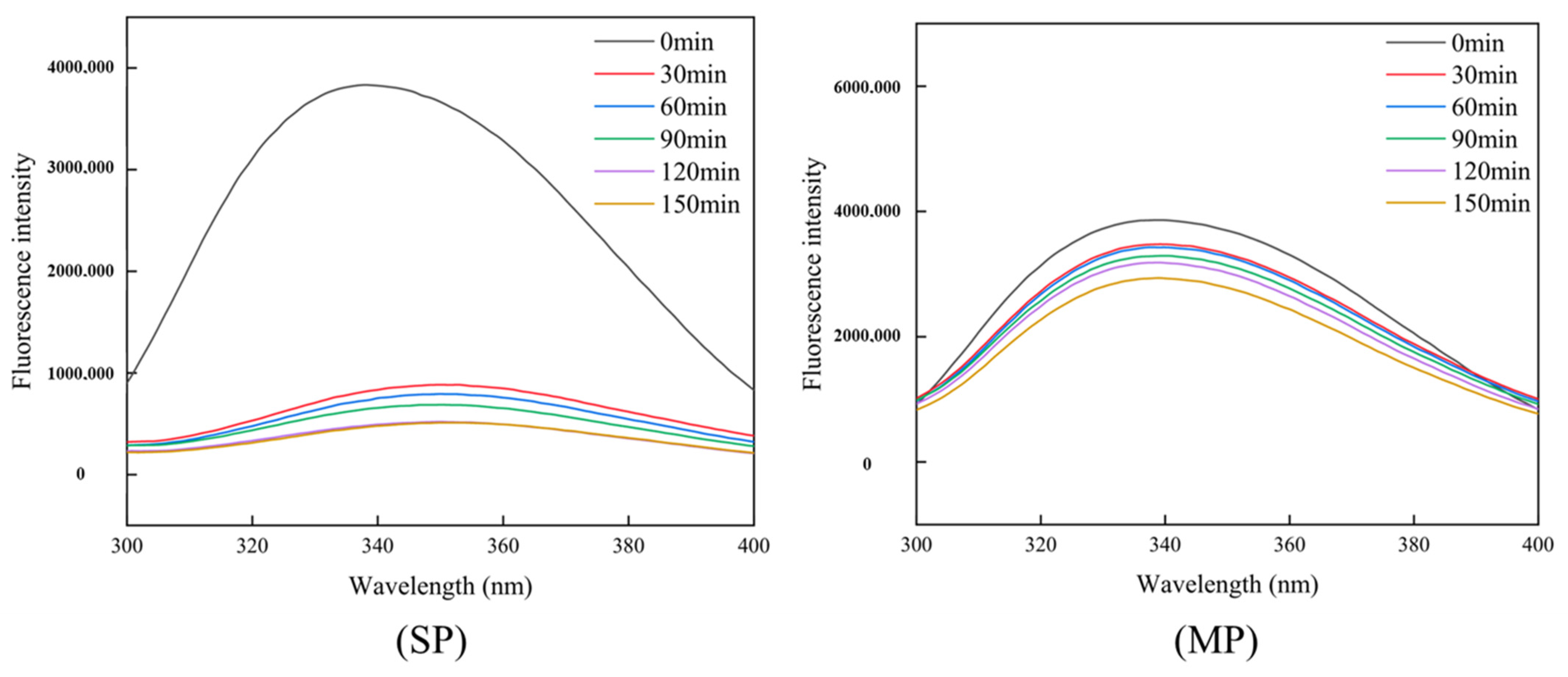

3.5. Endogenous Fluorescence Intensity

3.6. TBARS

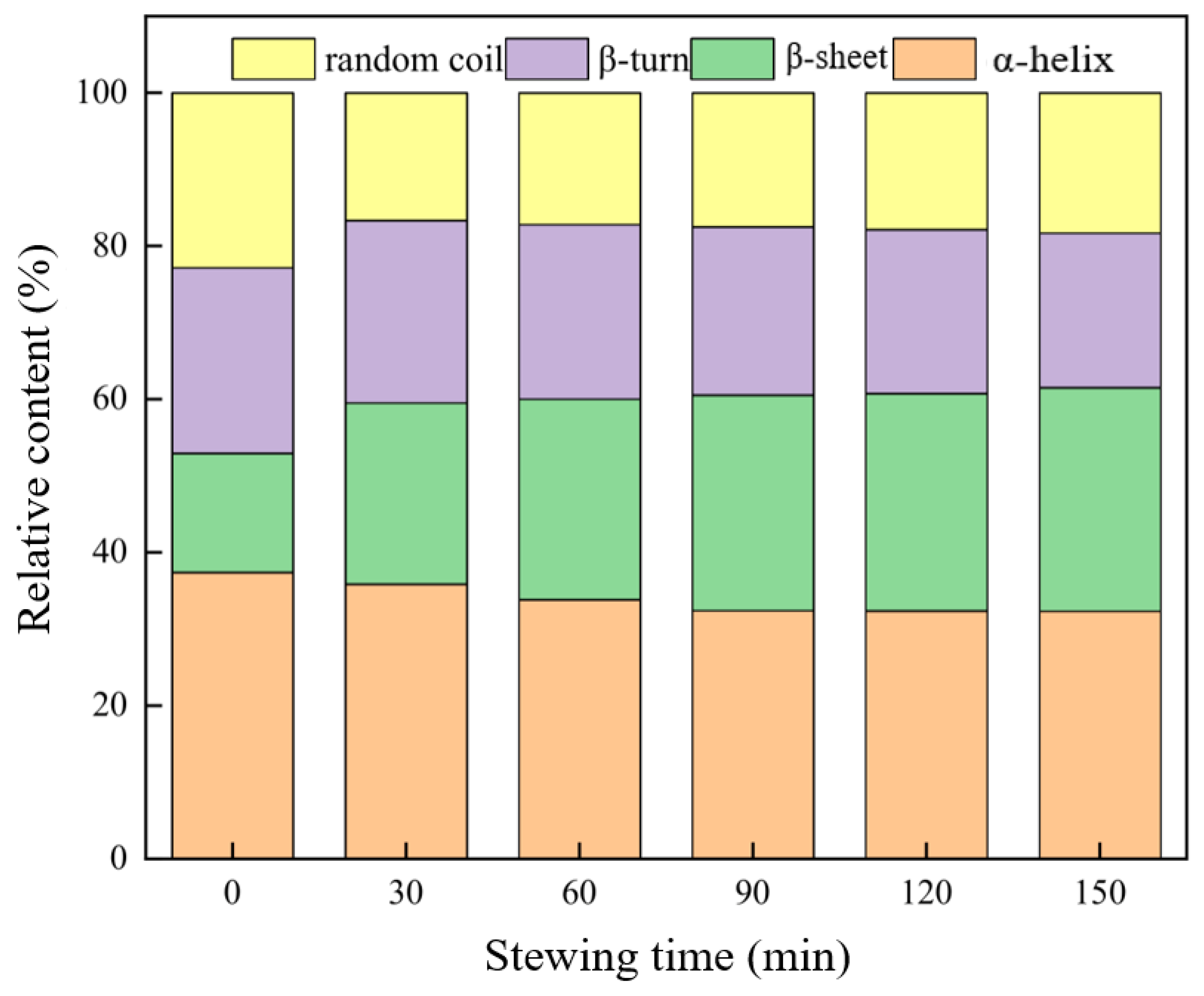

3.7. Protein Secondary Structure

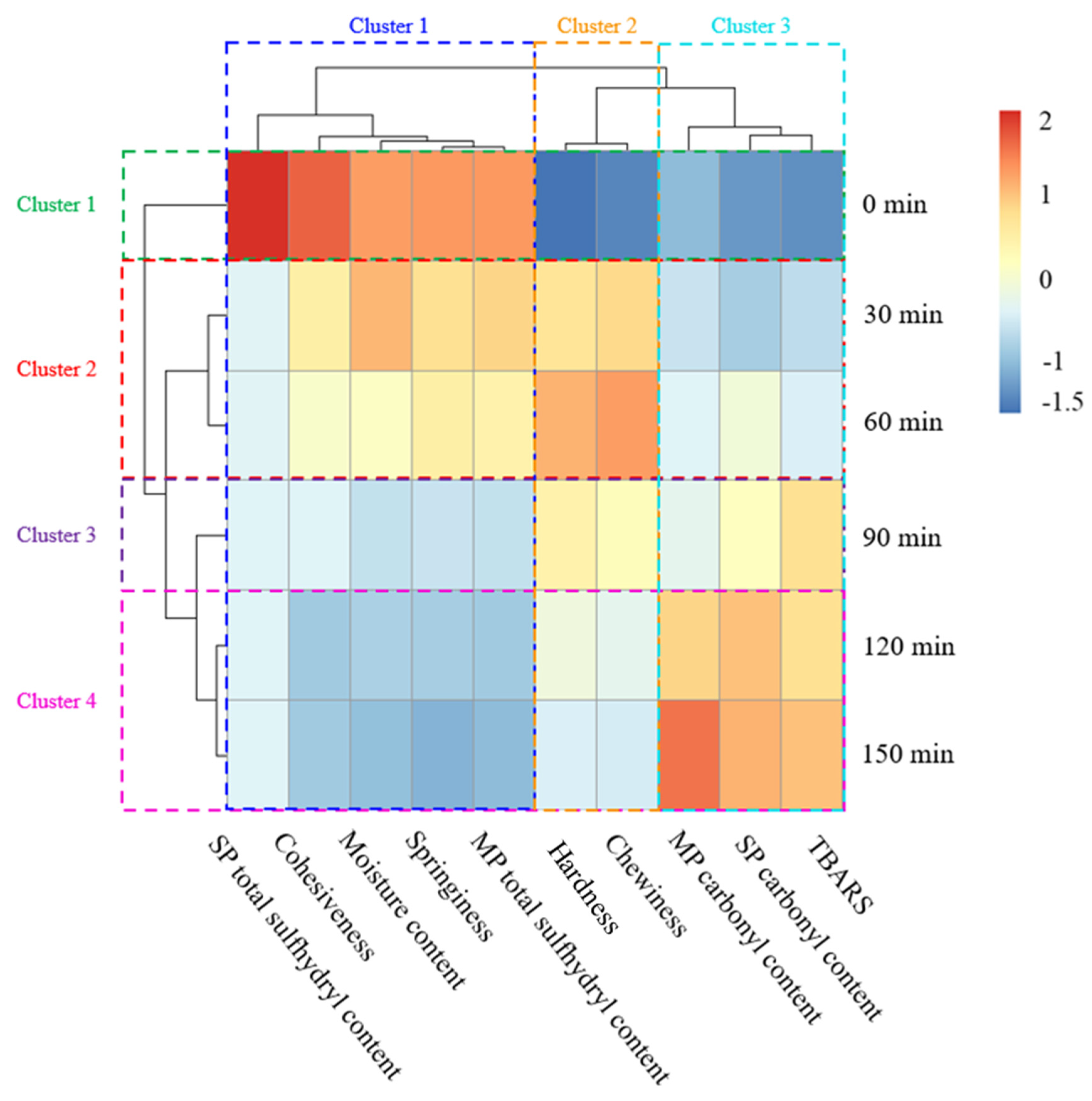

3.8. HCA of Sichuan-Style Braised Beef Treated by Different Stewing Times

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Modzelewska-Kapituła, M.; Tkacz, K.; Nogalski, Z. The influence of muscle, ageing and thermal treatment method on the quality of cooked beef. J. Food Sci. Technol. 2022, 59, 123–132. [Google Scholar] [CrossRef]

- Fabre, R.; Dalzotto, G.; Perlo, F.; Bonato, P.; Teira, G.; Tisocco, O. Cooking method effect on Warner-Bratzler shear force of different beef muscles. Meat Sci. 2018, 138, 10–14. [Google Scholar] [CrossRef]

- Li, J.; Han, D.; Huang, F.; Zhang, C. Effect of reheating methods on eating quality, oxidation and flavor characteristics of Braised beef with potatoes dish. Int. J. Gastron. Food Sci. 2023, 31, 100659. [Google Scholar] [CrossRef]

- Saha, J.; Jaroni, D.; Nelson, J.; Willoughby, C.; McDaniel, C.; Jadeja, R. Influences of weight and thickness on cooking time required for various mechanically tenderized beef steaks to reach minimum safe internal temperature without resting. LWT-Food Sci. Technol. 2019, 110, 365–369. [Google Scholar] [CrossRef]

- Anne, D.; Thierry, A.; Keisuke, S.; Michiyo, M. Transformation of highly marbled meats under various cooking processes. Meat Sci. 2022, 189, 108810. [Google Scholar] [CrossRef]

- Isleroglu, H.; Kemerli, T.; Kaymak-Ertekin, F. Effect of steam-assisted hybrid cooking on textural quality characteristics, cooking loss, and free moisture content of beef. Int. J. Food Prop. 2015, 18, 403–414. [Google Scholar] [CrossRef]

- Alirezalu, K.; Pirouzi, S.; Yaghoubi, M.; Karimi-Dehkordi, M.; Jafarzadeh, S.; Mousavi Khaneghah, A. Packaging of beef fillet with active chitosan film incorporated with ε-polylysine: An assessment of quality indices and shelf life. Meat Sci. 2021, 176, 108475. [Google Scholar] [CrossRef]

- Ishiwatari, N.; Fukuoka, M.; Sakai, N. Effect of protein denaturation degree on texture and water state of cooked meat. J. Food Eng. 2013, 117, 361–369. [Google Scholar] [CrossRef]

- Bolumar, T.; Bindrich, U.; Toepfl, S.; Toldrá, F.; Heinz, V. Effect of electrohydraulic shockwave treatment on tenderness, muscle cathepsin and peptidase activities and microstructure of beef loin steaks from Holstein young bulls. Meat Sci. 2014, 98, 759–765. [Google Scholar] [CrossRef]

- Suwandy, V.; Carne, A.; van de Ven, R.; Bekhit, A.E.A.; Hopkins, D.L. Effect of pulsed electric field on the proteolysis of cold boned beef M. Longissimus lumborum and M. Semimembranosus. Meat Sci. 2015, 100, 222–226. [Google Scholar] [CrossRef]

- Guyon, C.; Le Vessel, V.; Meynier, A.; de Lamballerie, M. Modifications of protein-related compounds of beef minced meat treated by high pressure. Meat Sci. 2018, 142, 32–37. [Google Scholar] [CrossRef]

- Zhang, M.; Li, F.; Diao, X.; Kong, B.; Xia, X. Moisture migration, microstructure damage and protein structure changes in porcine longissimus muscle as influenced by multiple freeze-thaw cycles. Meat Sci. 2017, 133, 10–18. [Google Scholar] [CrossRef]

- Domínguez, R.; Gómez, M.; Fonseca, S.; Lorenzo, J.M. Effect of different cooking methods on lipid oxidation and formation of volatile compounds in foal meat. Meat Sci. 2014, 97, 223–230. [Google Scholar] [CrossRef]

- Wang, B.; Kong, B.; Li, F.; Liu, Q.; Zhang, H.; Xia, X. Changes in the thermal stability and structure of protein from porcine longissimus dorsi induced by different thawing methods. Food Chem. 2020, 316, 126375. [Google Scholar] [CrossRef]

- Sasaki, K.; Motoyama, M.; Narita, T.; Hagi, T.; Ojima, K.; Oe, M.; Nakajima, I.; Kitsunai, K.; Saito, Y.; Hatori, H.; et al. Characterization and classification of Japanese consumer perceptions for beef tenderness using descriptive texture characteristics assessed by a trained sensory panel. Meat Sci. 2014, 96, 994–1002. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Y.; Pan, D.; Zhou, C.; He, J.; Cao, J. Effect of cooking temperature on texture and flavour binding of braised sauce porcine skin. Int. J. Food Sci. Technol. 2021, 56, 1690–1702. [Google Scholar] [CrossRef]

- Gagaoua, M.; Terlouw, E.M.C.; Mullen, A.M.; Franco, D.; Warner, R.D.; Lorenzo, J.M.; Purslow, P.P.; Gerrard, D.; Hopkins, D.L.; Troy, D.; et al. Molecular signatures of beef tenderness: Underlying mechanisms based on integromics of protein biomarkers from multi-platform proteomics studies. Meat Sci. 2021, 172, 108311. [Google Scholar] [CrossRef]

- Elmas, F.; Bodruk, A.; Köprüalan, Ö.; Arıkaya, Ş.; Koca, N.; Serdaroğlu, F.M.; Kaymak-Ertekin, F.; Koç, M. The effect of pre-drying methods on physicochemical, textural and sensory characteristics on puff dried Turkey breast meat. LWT-Food Sci. Technol. 2021, 145, 111350. [Google Scholar] [CrossRef]

- Zhang, D.; Li, H.; Emara, A.M.; Wang, Z.; Chen, X.; He, Z. Study on the mechanism of KCl replacement of NaCl on the water retention of salted pork. Food Chem. 2020, 332, 127414. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, D.; Tu, J.; Zhong, Y.; Zhang, D.; Wang, Z.; Tao, X. Mechanisms of change in gel water-holding capacity of myofibrillar proteins affected by lipid oxidation: The role of protein unfolding and cross-linking. Food Chem. 2021, 344, 128587. [Google Scholar] [CrossRef]

- Cheng, S.; Wang, X.; Li, R.; Yang, H.; Wang, H.; Wang, H.; Tan, M. Influence of multiple freeze-thaw cycles on quality characteristics of beef semimembranous muscle: With emphasis on water status and distribution by LF-NMR and MRI. Meat Sci. 2019, 147, 44–52. [Google Scholar] [CrossRef]

- Setyabrata, D.; Kim, Y.H.B. Impacts of aging/freezing sequence on microstructure, protein degradation and physico-chemical properties of beef muscles. Meat Sci. 2019, 151, 64–74. [Google Scholar] [CrossRef]

- Pearce, K.L.; Rosenvold, K.; Andersen, H.J.; Hopkins, D.L. Water distribution and mobility in meat during the conversion of muscle to meat and ageing and the impacts on fresh meat quality attributes—A review. Meat Sci. 2011, 89, 111–124. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Liu, Q.; Jiang, H.; Zheng, M.; Qian, M.; Zeng, X.; Bai, W. Monitoring the variations in physicochemical characteristics of squab meat during the braising cooking process. Food Sci. Nutr. 2022, 10, 2727–2735. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.S.; Chin, K.B. Structural changes of meat protein of chicken sausages with various levels of salt and phosphate and their effects on in vitro digestion. Int. J. Food Sci. Technol. 2021, 56, 5250–5258. [Google Scholar] [CrossRef]

- Gatellier, P.; Kondjoyan, A.; Portanguen, S.; Santé-Lhoutellier, V. Effect of cooking on protein oxidation in n-3 polyunsaturated fatty acids enriched beef. Implication on nutritional quality. Meat Sci. 2010, 85, 645–650. [Google Scholar] [CrossRef]

- Utrera, M.; Morcuende, D.; Estévez, M. Temperature of frozen storage affects the nature and consequences of protein oxidation in beef patties. Meat Sci. 2014, 96, 1250–1257. [Google Scholar] [CrossRef]

- Wang, Z.; He, Z.; Emara, A.M.; Gan, X.; Li, H. Effects of malondialdehyde as a byproduct of lipid oxidation on protein oxidation in rabbit meat. Food Chem. 2019, 288, 405–412. [Google Scholar] [CrossRef]

- Estévez, M. Protein carbonyls in meat systems: A review. Meat Sci. 2011, 89, 259–279. [Google Scholar] [CrossRef]

- Turgut, S.S.; Işıkçı, F.; Soyer, A. Antioxidant activity of pomegranate peel extract on lipid and protein oxidation in beef meatballs during frozen storage. Meat Sci. 2017, 129, 111–119. [Google Scholar] [CrossRef]

- Rysman, T.; Van Hecke, T.; Van Poucke, C.; De Smet, S.; Van Royen, G. Protein oxidation and proteolysis during storage and in vitro digestion of pork and beef patties. Food Chem. 2016, 209, 177–184. [Google Scholar] [CrossRef]

- Hellwig, M. Analysis of protein oxidation in food and feed products. J. Agric. Food Chem. 2020, 68, 12870–12885. [Google Scholar] [CrossRef]

- Mitra, B.; Lametsch, R.; Akcan, T.; Ruiz-Carrascal, J. Pork proteins oxidative modifications under the influence of varied time-temperature thermal treatments: A chemical and redox proteomics assessment. Meat Sci. 2018, 140, 134–144. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Liu, X.; Wu, D.; Ding, Y.; Li, G.; Wu, Y. Typical reactive carbonyl compounds in food products: Formation, influence on food quality, and detection methods. Compr. Rev. Food Sci. Saf. 2020, 19, 503–529. [Google Scholar] [CrossRef]

- Du, X.; Zhao, M.; Pan, N.; Wang, S.; Xia, X.; Zhang, D. Tracking aggregation behaviour and gel properties induced by structural alterations in myofibrillar protein in mirror carp (Cyprinus carpio) under the synergistic effects of pH and heating. Food Chem. 2021, 362, 130222. [Google Scholar] [CrossRef]

- Vaskoska, R.; Vénien, A.; Ha, M.; White, J.D.; Unnithan, R.R.; Astruc, T.; Warner, R.D. Thermal denaturation of proteins in the muscle fibre and connective tissue from bovine muscles composed of type I (masseter) or type II (cutaneous trunci) fibres: DSC and FTIR microspectroscopy study. Food Chem. 2021, 343, 128544. [Google Scholar] [CrossRef]

- Zhang, D.; Li, H.; Wang, Z.; Emara, A.M.; Hu, Y.; He, Z. Effects of in vitro oxidation on myofibrillar protein charge, aggregation, and structural characteristics. Food Chem. 2020, 332, 127396. [Google Scholar] [CrossRef]

| Stewing Time (min) | Hardness (g) | Springiness (Ratio) | Cohesiveness (Ratio) | Chewiness (g) |

|---|---|---|---|---|

| 0 | 203.94 ± 21.02 a | 0.77 ± 0.01 a | 0.55 ± 0.01 a | 81.50 ± 4.08 a |

| 30 | 1896.23 ± 478.87 bc | 0.75 ± 0.02 a | 0.50 ± 0.04 a | 651.34 ± 132.05 cd |

| 60 | 2227.07 ± 87.96 c | 0.73 ± 0.09 a | 0.48 ± 0.03 a | 756.00 ± 100.15 d |

| 90 | 1721.12 ± 81.06 bc | 0.69 ± 0.06 a | 0.46 ± 0.10 a | 507.64 ± 45.81 bc |

| 120 | 1298.48 ± 439.08 b | 0.68 ± 0.08 a | 0.45 ± 0.03 a | 372.38 ± 52.75 b |

| 150 | 1065.95 ± 47.77 b | 0.67 ± 0.07 a | 0.44 ± 0.03 a | 327.27 ± 17.87 ab |

| Stewing Time (min) | ||||||

|---|---|---|---|---|---|---|

| 0 | 30 | 60 | 90 | 120 | 150 | |

| Moisture content (%) | 70.27 ± 1.03 c | 69.19 ± 1.23 c | 63.93 ± 0.52 b | 59.76 ± 0.01 a | 58.89 ± 0.15 a | 57.81 ± 0.99 a |

| MP carbonyl content (nmol/mg) | 0.60 ± 0.01 a | 1.45 ± 0.004 b | 1.84 ± 0.010 c | 2.04 ± 0.01 d | 4.40 ± 0.004 e | 5.79 ± 0.01 f |

| SP carbonyl content (nmol/mg) | 0.04 ± 0.00 a | 0.51 ± 0.01 b | 1.27 ± 0.01 c | 1.50 ± 0.004 d | 2.31 ± 0.05 e | 2.44 ± 0.02 f |

| MP total sulfhydryl content (nmol/mg) | 68.10 ± 2.88 c | 63.11 ± 4.08 bc | 57.84 ± 1.85 b | 45.83 ± 0.87 a | 42.93 ± 0.71 a | 40.89 ± 1.88 a |

| SP total sulfhydryl content (nmol/mg) | 165.20 ± 2.55 c | 12.99 ± 0.17 b | 11.030 ± 0.30 ab | 10.54 ± 0.92 ab | 10.21 ± 0.32 ab | 8.82 ± 0.30 a |

| TBARS (mg/kg) | 0.02 ± 0.001 a | 0.05 ± 0.001 b | 0.06 ± 0.002 c | 0.11 ± 0.01 d | 0.11 ± 0.001 d | 0.12 ± 0.001 d |

| Stewing Time (min) | T21 (%) | T22 (%) | T23 (%) |

|---|---|---|---|

| 30 | 1.08 | 94.84 | 4.09 |

| 60 | 1.12 | 87.64 | 11.24 |

| 90 | 1.86 | 85.18 | 12.96 |

| 120 | 1.08 | 81.68 | 17.24 |

| 150 | 0.52 | 81.08 | 18.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, X.; Ruan, J.; Wu, Z.; Tang, Y.; Liu, P.; Zhang, D.; Li, H. Changes in Texture Characteristics and Special Requirements of Sichuan-Style Braised Beef for Industrial Production: Based on the Changes in Protein and Lipid of Beef. Foods 2023, 12, 1386. https://doi.org/10.3390/foods12071386

Pu X, Ruan J, Wu Z, Tang Y, Liu P, Zhang D, Li H. Changes in Texture Characteristics and Special Requirements of Sichuan-Style Braised Beef for Industrial Production: Based on the Changes in Protein and Lipid of Beef. Foods. 2023; 12(7):1386. https://doi.org/10.3390/foods12071386

Chicago/Turabian StylePu, Xiaoli, Jinggang Ruan, Zhicheng Wu, Yong Tang, Ping Liu, Dong Zhang, and Hongjun Li. 2023. "Changes in Texture Characteristics and Special Requirements of Sichuan-Style Braised Beef for Industrial Production: Based on the Changes in Protein and Lipid of Beef" Foods 12, no. 7: 1386. https://doi.org/10.3390/foods12071386

APA StylePu, X., Ruan, J., Wu, Z., Tang, Y., Liu, P., Zhang, D., & Li, H. (2023). Changes in Texture Characteristics and Special Requirements of Sichuan-Style Braised Beef for Industrial Production: Based on the Changes in Protein and Lipid of Beef. Foods, 12(7), 1386. https://doi.org/10.3390/foods12071386