Understanding the Impact of High-Pressure Treatment on Physico-Chemical, Microstructural, and Microbiological Aspects of Pumpkin Cubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material and HPP Treatments

2.2. pH, TSS, and Moisture

2.3. Histological Analysis

2.4. Colorimetric Analysis

2.5. Texture Analysis

2.6. Extraction of Starch and Pectin

2.7. Total Antioxidant Capacity (TAC)

2.8. Microbiological Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. pH, TSS, and Moisture

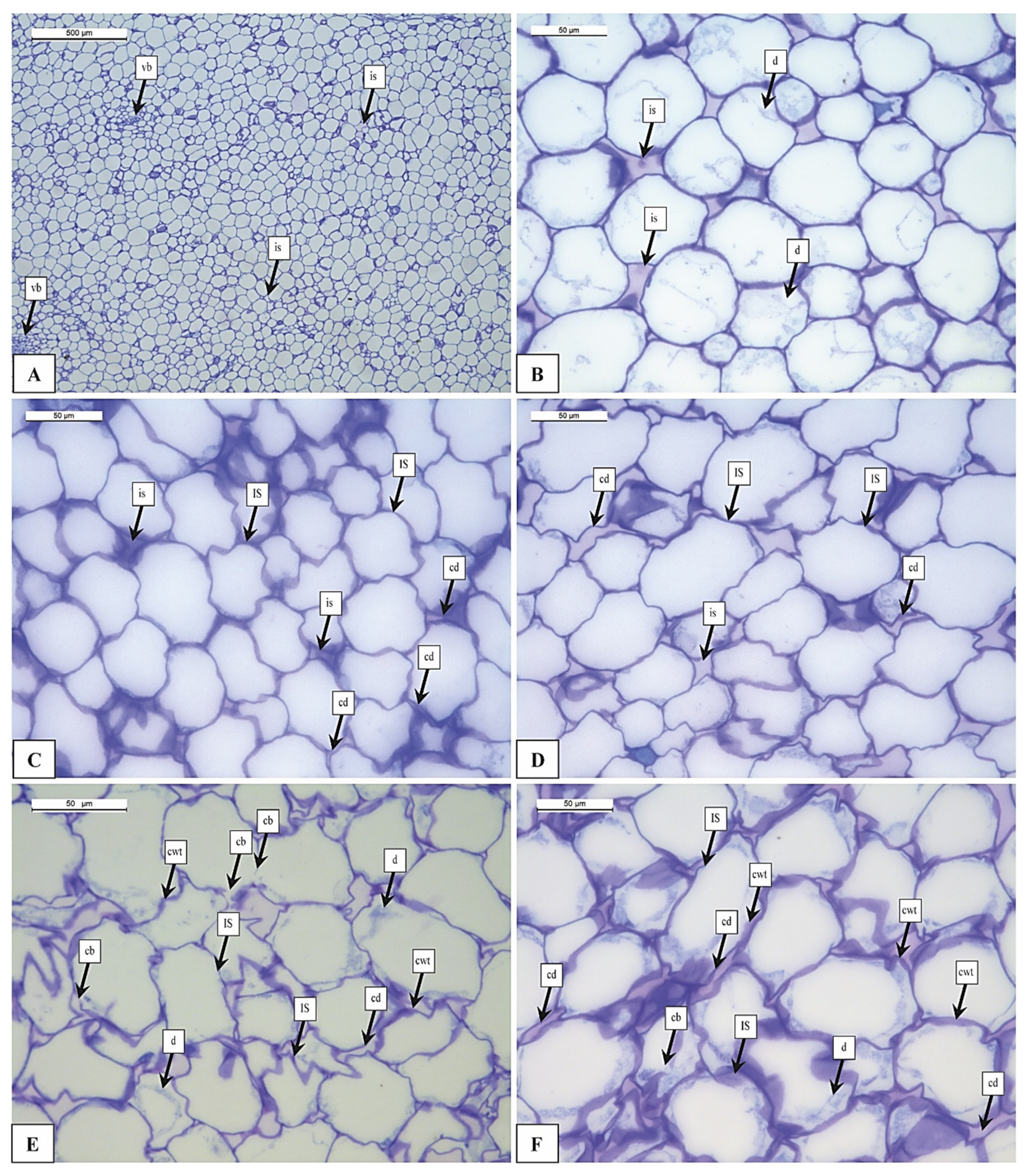

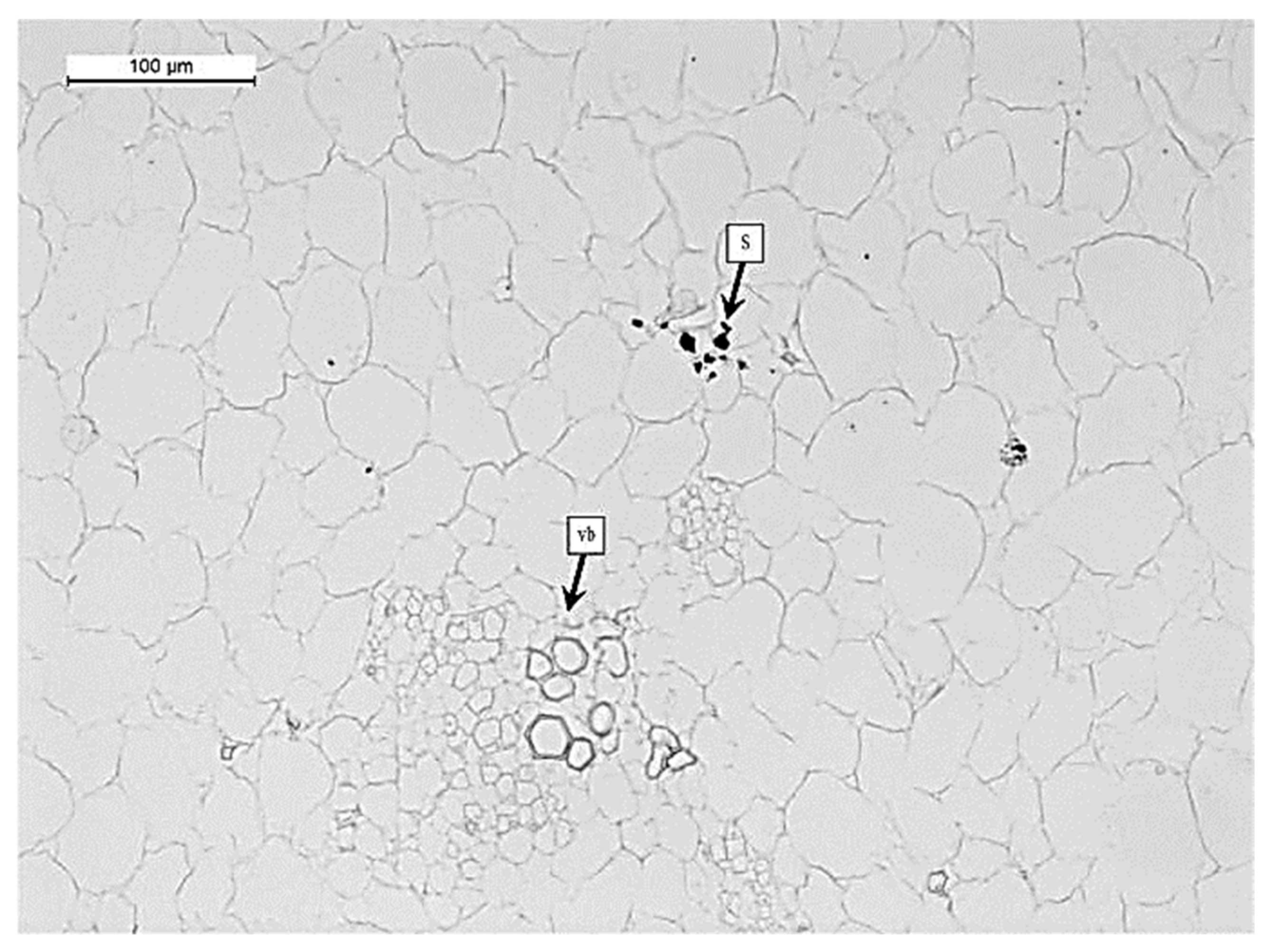

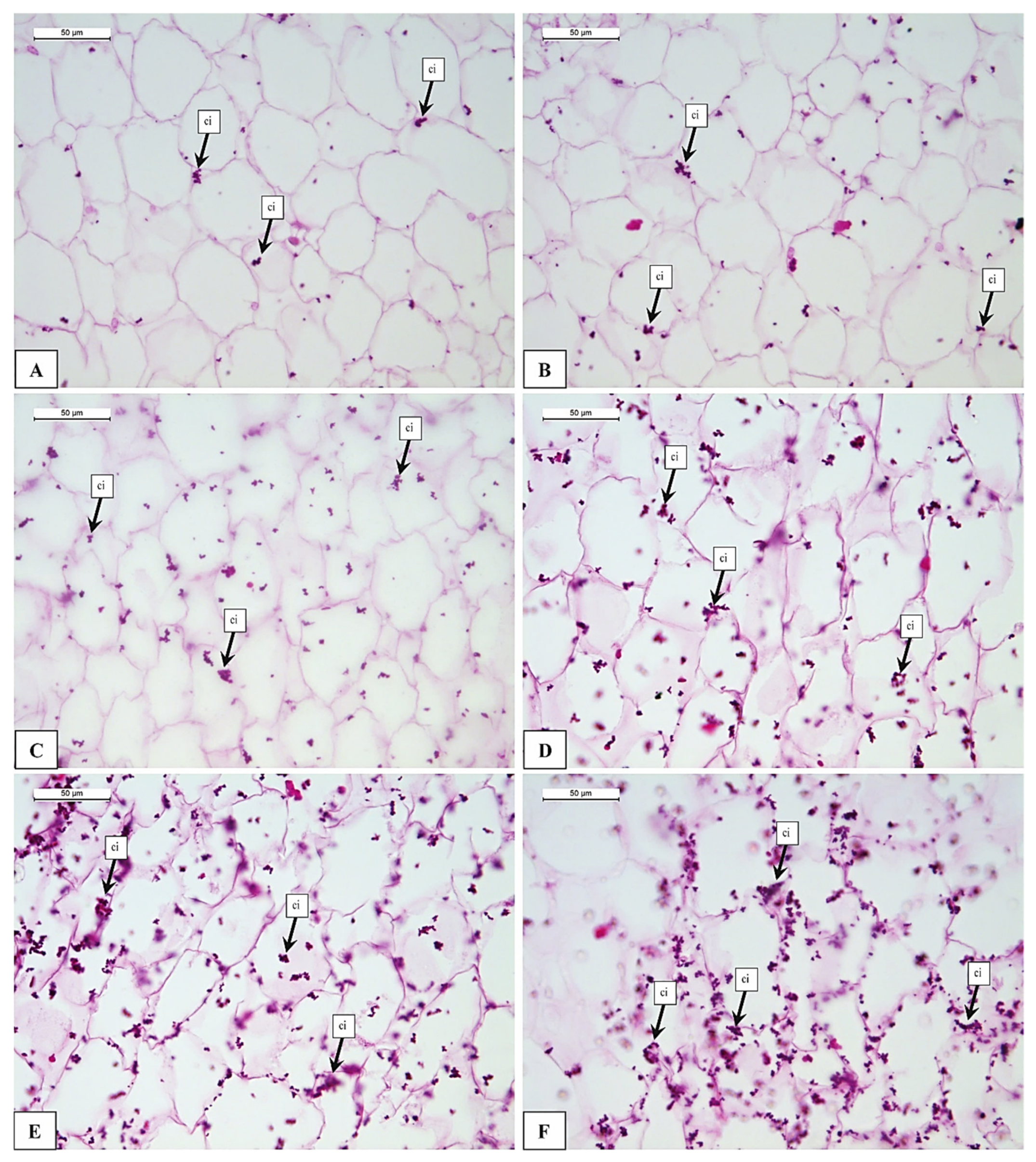

3.2. Histological Analysis

Cell Morphology

3.3. Colorimetric Analysis

3.4. Textural Parameter

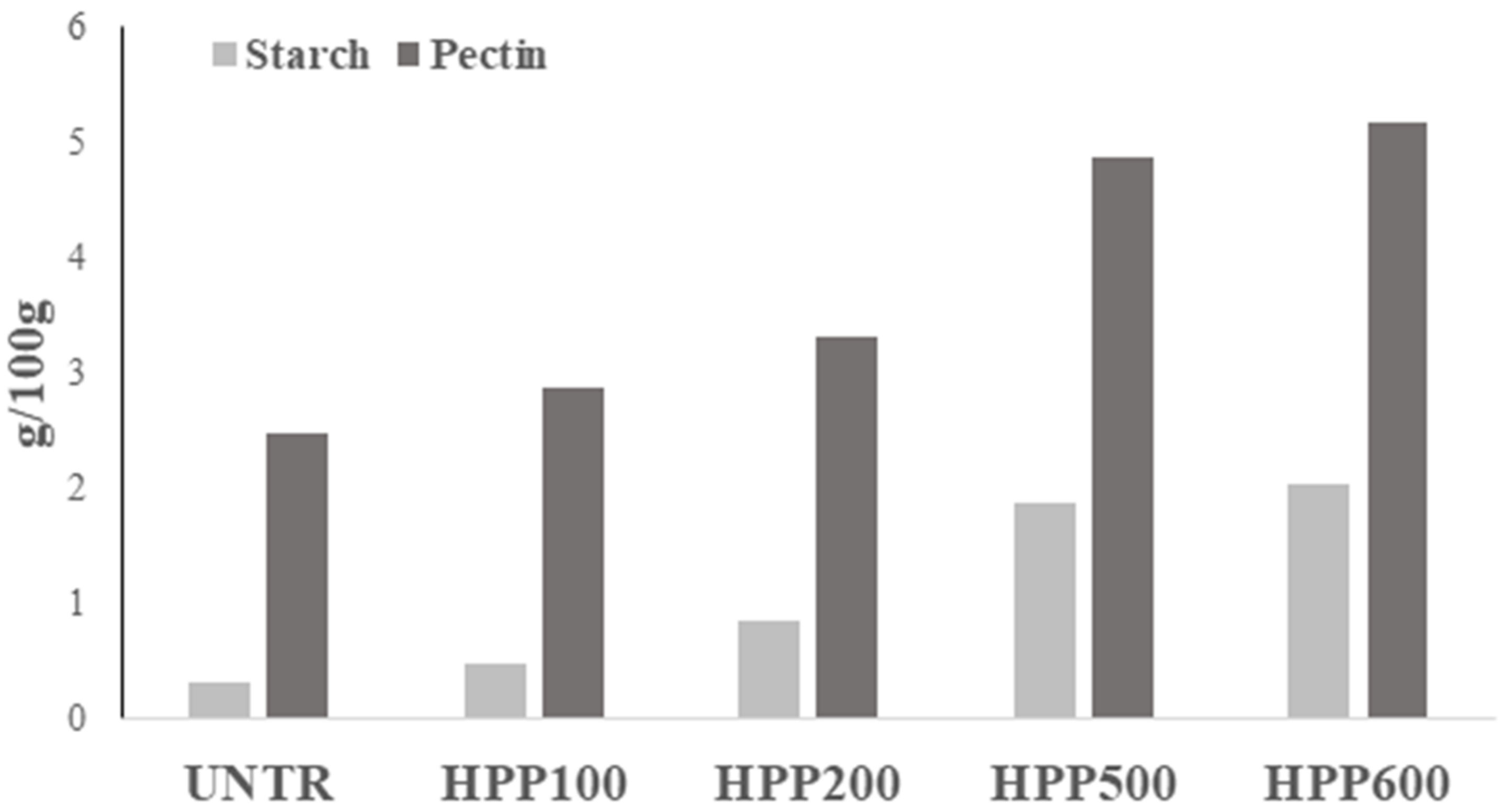

3.5. Starch and Pectin Availability

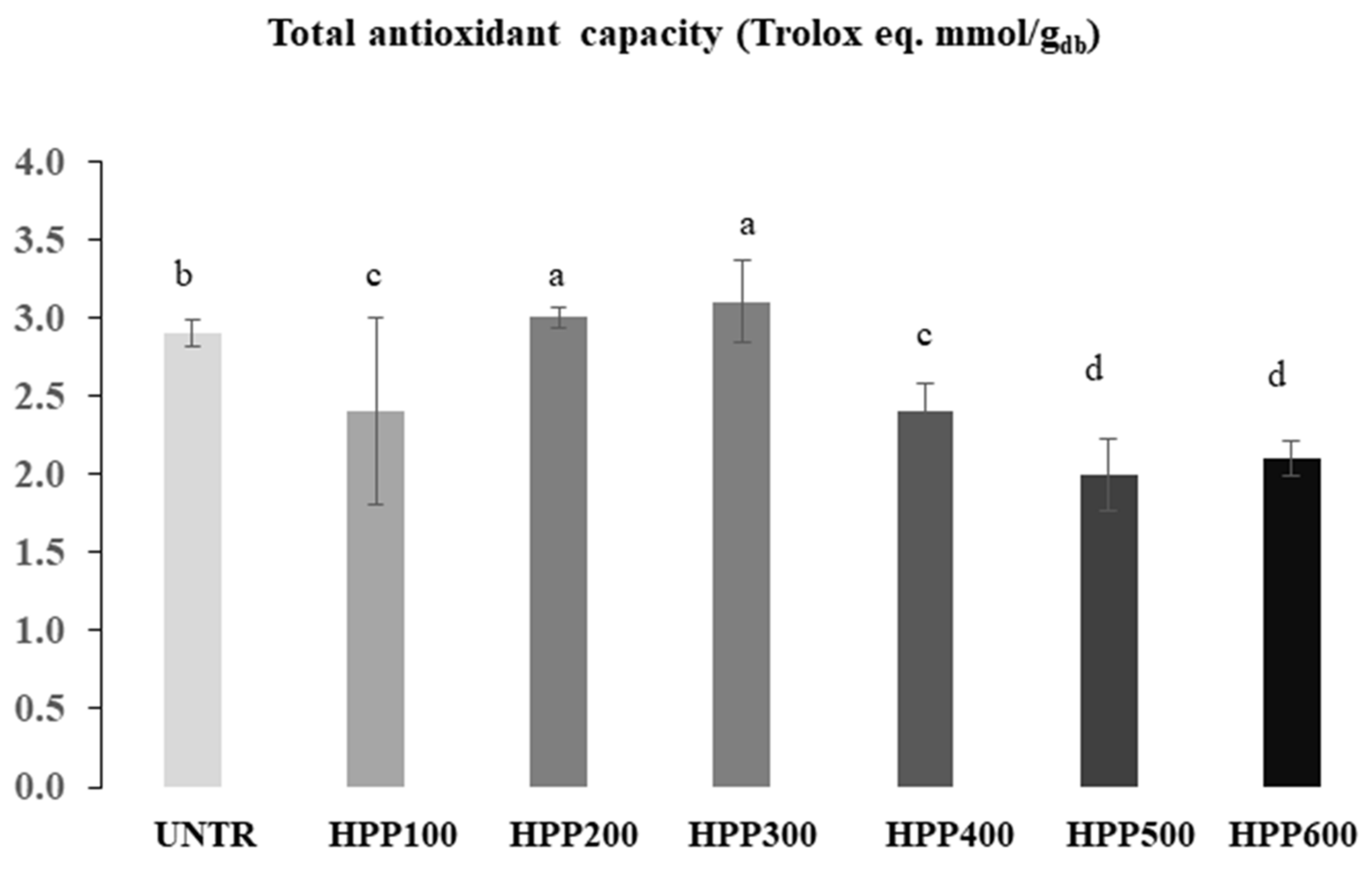

3.6. Total Antioxidant Capacity (TAC)

3.7. Microbiological Determination

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Koung, Y.; Il, W.; Ezura, H. Efficient plant regeneration via organogenesis in winter squash (Cucurbita maxima Duch.). Plant Sci. 2003, 164, 413–418. [Google Scholar] [CrossRef]

- Caili, F.; Huan, S.; Quanhong, L. A review on pharmacological activities and utilization technologies of pumpkin. Plant Foods Hum. Nutr. 2006, 61, 73–80. [Google Scholar] [CrossRef] [PubMed]

- Azevedo-Meleiro, C.H.; Rodriguez-Amaya, D.B. Qualitative and quantitative differences in carotenoid composition among Cucurbita moschata, Cucurbita maxima, and Cucurbita pepo. J. Agric. Food Chem. 2007, 55, 4027–4033. [Google Scholar] [CrossRef] [PubMed]

- Dini, I.; Tenore, G.C.; Dini, A. Effect of industrial and domestic processing on antioxidant properties of pumpkin pulp. LWT Food Sci. Technol. 2013, 53, 382–385. [Google Scholar] [CrossRef]

- Stevenson, D.G.; Yoo, S.H.; Hurst, P.L.; Jane, J.L. Structural and physicochemical characteristics of winter squash (Cucurbita maxima D.) fruit starches at harvest. Carbohydr. Polym. 2005, 59, 153–163. [Google Scholar] [CrossRef]

- Yuan, T.; Ye, F.; Chen, T.; Li, M.; Zhao, G. Structural characteristics and physicochemical properties of starches from winter squash (Cucurbita maxima Duch.) and pumpkin (Cucurbita moschata Duch. ex Poir.). Food Hydrocoll. 2022, 122, 107115. [Google Scholar] [CrossRef]

- Evageliou, V.; Ptitchkina, N.M.; Morris, E.R. Solution viscosity and structural modification of pumpkin biopectin. Food Hydrocoll. 2005, 19, 1032–1036. [Google Scholar] [CrossRef]

- Nguyen-the, C.; Carlin, F. The microbiology of minimally processed fresh fruits and vegetables. Crit. Rev. Food Sci. Nutr. 1994, 34, 371–401. [Google Scholar] [CrossRef]

- Wachtel, M.R.; Charkowski, A.O. Cross-contamination of lettuce with Escherichia coli O157: H7. J. Food Prot. 2002, 65, 465–470. [Google Scholar] [CrossRef]

- Knockaert, G.; De Roeck, A.; Lemmens, L.; Van Buggenhout, S.; Hendrickx, M.; Van Loey, A. Effect of thermal and high pressure processes on structural and health-related properties of carrots (Daucus carota). Food Chem. 2011, 125, 903–912. [Google Scholar] [CrossRef]

- Contador, R.; González-Cebrino, F.; García-Parra, J.; Lozano, M.; Ramírez, R. Effect of Hydrostatic High Pressure and Thermal Treatments on Two Types of Pumpkin Purée and Changes during Refrigerated Storage. J. Food Process. Preserv. 2014, 38, 704–712. [Google Scholar] [CrossRef]

- Gao, G.; Ren, P.; Cao, X.; Yan, B.; Liao, X.; Sun, Z.; Wang, Y. Comparing quality changes of cupped strawberry treated by high hydrostatic pressure and thermal processing during storage. Food Bioprod. Process. 2016, 100, 221–229. [Google Scholar] [CrossRef]

- Paciulli, M.; Medina-Meza, I.G.; Chiavaro, E.; Barbosa-Cánovas, G.V. Impact of thermal and high pressure processing on quality parameters of beetroot (Beta vulgaris L.). LWT Food Sci. Technol. 2016, 68, 98–104. [Google Scholar] [CrossRef]

- Paciulli, M.; Ganino, T.; Meza, I.G.M.; Rinaldi, M.; Rodolfi, M.; Morbarigazzi, M.; Chiavaro, E. High pressure and thermal processing on the quality of zucchini slices. Eur. Food Res. Technol. 2021, 247, 475–484. [Google Scholar] [CrossRef]

- Cardello, A.V.; Schutz, H.G.; Lesher, L.L. Consumer perceptions of foods processed by innovative and emerging technologies: A conjoint analytic study. Innov. Food Sci. Emerg. Technol. 2007, 8, 73–83. [Google Scholar] [CrossRef]

- Chauhan, O.P. (Ed.) Non-Thermal Processing of Foods; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Basak, S.; Ramaswamy, H.S. Effect of high-pressure processing on the texture of selected fruits and vegetables. J. Texture Stud. 1998, 29, 587–601. [Google Scholar] [CrossRef]

- Zhou, C.L.; Liu, W.; Zhao, J.; Yuan, C.; Song, Y.; Chen, D.; Ni, Y.Y.; Li, Q.H. The effect of high hydrostatic pressure on the microbiological quality and physical-chemical characteristics of Pumpkin (Cucurbita maxima Duch.) during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2014, 21, 24–34. [Google Scholar] [CrossRef]

- Hite, B.H.; Giddings, N.J. 1914. The effect of pressure on certain micro-organisms encountered in the preservation of fruits and vegetables. West Va. Agric. For. Exp. Stn. Bull. 1914, 146, 1–67. [Google Scholar]

- Oey, I.; Lille, M.; Van Loey, A.; Hendrickx, M. Effect of high-pressure processing on colour, texture and flavour of fruit- and vegetable-based food products: A review. Trends Food Sci. Technol. 2008, 19, 320–328. [Google Scholar] [CrossRef]

- Trejo Araya, X.I.; Hendrickx, M.; Verlinden, B.E.; Van Buggenhout, S.; Smale, N.J.; Stewart, C.; John Mawson, A. Understanding texture changes of high pressure processed fresh carrots: A microstructural and biochemical approach. J. Food Eng. 2007, 80, 873–884. [Google Scholar] [CrossRef]

- Oey, I.; Van der Plancken, I.; Van Loey, A.; Hendrickx, M. Does high pressure processing influence nutritional aspects of plant based food systems? Trends Food Sci. Technol. 2008, 19, 300–308. [Google Scholar] [CrossRef]

- Xu, S.; Han, I. Influence of high-pressure processing on carrot texture and tissue. Biotechnology 2006, 5, 134–136. [Google Scholar] [CrossRef]

- Kato, N.; Teramoto, A.; Fuchigami, M. Pectic substance degradation and texture of carrots as affected by pressurization. J. Food Sci. 1997, 62, 359–362. [Google Scholar] [CrossRef]

- Préstamo, G.; Arroyo, G. High hydrostatic pressure effects on vegetable structure. J. Food Sci. 1998, 63, 878–881. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Lille, M.; Messagie, I.; Von Loey, A.; Autio, K.; Hendrickx, M. Impact of pretreatment and freezing conditions on the microstructure of frozen carrots: Quantification and relation to texture loss. Eur. Food Res. Technol. 2006, 222, 543–553. [Google Scholar] [CrossRef]

- Sun, Y.; Yao, J.; Zhang, L.; Chen, F.; Hu, X.; Zhang, Y. New evidence on pectin-related instantaneous pressure softening mechanism of asparagus lettuce under high pressure processing. Food Sci. Technol. Int. 2019, 25, 337–346. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Sila, D.N.; Duvetter, T.; Van Loey, A.; Hendrickx, M. Pectins in processed fruits and vegetables: Part III—Texture engineering. Compr. Rev. Food Sci. Food Saf. 2009, 8, 105–117. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2005. [Google Scholar]

- Ruzin, S.E. Plant Microtechnique and Microscopy; Oxford University Press: New York, NY, USA, 1999; Volume 198, p. 322. [Google Scholar]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–66. [Google Scholar]

- Syahariza, Z.A.; Li, E.; Hasjim, J. Extraction and dissolution of starch from rice and sorghum grains for accurate structural analysis. Carbohydr. Polym. 2010, 82, 14–20. [Google Scholar] [CrossRef]

- Ptitchkina, N.M.; Danilova, I.A.; Doxastakis, G.; Kasapis, S.; Morris, E.R. Pumpkin pectin: Gel formation at unusually low concentration. Carbohydr. Polym. 1994, 23, 265–273. [Google Scholar] [CrossRef]

- Vázquez-Gutiérrez, J.L.; Hernández-Carrión, M.; Quiles, A.; Hernando, I. Influence of Storage at 4 °C on the Stability of High Hydrostatic Pressure Treated Onion. Czech J. Food Sci. 2014, 32, 96–101. [Google Scholar] [CrossRef]

- Oliveira, M.M.; De Tribst, A.A.L.; Leite Júnior, B.R.D.C.; Oliveira, R.A.; De Cristianini, M. Effects of high pressure processing on cocoyam, Peruvian carrot, and sweet potato: Changes in microstructure, physical characteristics, starch, and drying rate. Innov. Food Sci. Emerg. Technol. 2015, 31, 45–53. [Google Scholar] [CrossRef]

- Yi, J.; Feng, H.; Bi, J.; Zhou, L.; Zhou, M.; Cao, J.; Li, J. High hydrostatic pressure induced physiological changes and physical damages in asparagus spears. Postharvest Biol. Technol. 2016, 118, 1–10. [Google Scholar] [CrossRef]

- Hu, X.; Ma, T.; Ao, L.; Kang, H.; Hu, X.; Song, Y.; Liao, X. Effect of high hydrostatic pressure processing on textural properties and microstructural characterization of fresh-cut pumpkin (Cucurbita pepo). J. Food Process Eng. 2020, 43, e13379. [Google Scholar] [CrossRef]

- Sila, D.N.; Doungla, E.; Smout, C.; Van Loey, A.; Hendrickx, M. Pectin fraction interconversions: Insight into understanding texture evolution of thermally processed carrots. J. Agric. Food Chem. 2006, 54, 8471–8479. [Google Scholar] [CrossRef]

- Paciulli, M.; Rinaldi, M.; Rodolfi, M.; Ganino, T.; Morbarigazzi, M.; Chiavaro, E. Effects of high hydrostatic pressure on physico-chemical and structural properties of two pumpkin species. Food Chem. 2019, 274, 281–290. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, J.; Zhang, Y.; Liao, X.; Chen, F.; Hu, X. Microstructural and morphological behaviors of asparagus lettuce cells subject to high pressure processing. Food Res. Int. 2015, 71, 174–183. [Google Scholar] [CrossRef]

- Gosavi, N.S.; Polunas, M.; Martin, D.; Karwe, M.V. Effect of Food Microstructure on Calcium Infusion under High Pressure. Food Eng. Rev. 2021, 13, 36–53. [Google Scholar] [CrossRef]

- Michel, M.; Autio, K. Effects of high pressure on protein-and polysaccharide-based structures. In Ultra High-Pressure Treatments of Foods; Springer: Boston, MA, USA, 2001; pp. 189–214. [Google Scholar]

- Tangwongchai, R.; Ledward, D.A.; Ames, J.M. Effect of high-pressure treatment on the texture of cherry tomato. J. Agric. Food Chem. 2000, 48, 1434–1441. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, X.; Chen, F.; Liao, X.; Hu, X. Mechanisms of carrot texture alteration induced by pure effect of high pressure processing. Innov. Food Sci. Emerg. Technol. 2019, 54, 260–269. [Google Scholar] [CrossRef]

- Moelants, K.R.N.; Jolie, R.P.; Palmers, S.K.J.; Cardinaels, R.; Christiaens, S.; Van Buggenhout, S.; Van Loey, A.M.; Moldenaers, P.; Hendrickx, M.E. The Effects of Process-Induced Pectin Changes on the Viscosity of Carrot and Tomato Sera. Food Bioprocess Technol. 2013, 6, 2870–2883. [Google Scholar] [CrossRef]

- Sila, D.N.; Van Buggenhout, S.; Duvetter, T.; Fraeye, I.; De Roeck, A.; Van Loey, A.; Hendrickx, M. Pectins in processed fruits and vegetables: Part II—Structure–function relationships. Compr. Rev. Food Sci. Food Saf. 2009, 8, 86–104. [Google Scholar] [CrossRef]

- Bartlett, D.H. Pressure effects on in vivo microbial processes. Biochim. Biophys. Acta Protein Struct. Mol. Enzymol. 2002, 1595, 367–381. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Xi, H.; Guo, X.; Qin, Z.; Pang, X.; Hu, X.; Liao, X.; Wu, J. Comparative study of quality of cloudy pomegranate juice treated by high hydrostatic pressure and high temperature short time. Innov. Food Sci. Emerg. Technol. 2013, 19, 85–94. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Cao, X.; Chen, F.; Hu, X.; Liao, X. Comparison of high hydrostatic pressure and high temperature short time processing on quality of purple sweet potato nectar. Innov. Food Sci. Emerg. Technol. 2012, 16, 326–334. [Google Scholar] [CrossRef]

- Houška, M.; Strohalm, J.; Kocurová, K.; Totušek, J.; Lefnerová, D.; Tříska, J.; Vrchotová, N.; Fiedrleová, V.; Holasova, M.; Gabrovská, D.; et al. High pressure and foods-fruit/vegetable juices. J. Food Eng. 2006, 77, 386–398. [Google Scholar] [CrossRef]

| Maximum Elongation (μm) | Minimum Elongation (μm) | Perimetral Segment (μm) | Thickness (μm) | |

|---|---|---|---|---|

| UNTR | 88.9 ± 2.5 a | 72.2 ± 2.6 a | 267.8 ± 6.4 a | 1.51 ± 0.12 c |

| HPP100 | 83.0 ± 4.1 ab | 65.2 ± 3.6 abc | 236.4 ± 10.9 abcd | 1.72 ± 0.14 c |

| HPP200 | 73.3 ± 3.0 c | 60.7 ± 3.2 bcd | 229.2 ± 6.6 bcd | 1.62 ± 0.20 c |

| HPP300 | 76.2 ± 4.8 bc | 65.5 ± 4.5 abc | 246.6 ± 9.3 abc | 1.52 ± 0.21 c |

| HPP400 | 74.2 ± 3.6 c | 59.2 ± 5.4 cd | 210.7 ± 25.6 d | 2.39 ± 0.12 b |

| HPP500 | 68.8 ± 4.3 c | 69.0 ± 3.6 ab | 258.3 ± 18.5 ab | 2.58 ± 0.26 b |

| HPP600 | 73.9 ± 3.7 c | 54.7 ± 3.5 d | 223.6 ± 11.8 cd | 3.35 ± 0.36 a |

| L* | a* | b* | ΔE | |

|---|---|---|---|---|

| UNTR | 60.5 ± 4.3 a | 32.5 ± 3.7 a | 43.2 ± 6.8 b | - |

| HPP100 | 53.9 ± 2.8 b | 25.0 ± 3.5 bc | 29.6 ± 5.9 c | 17.3 ± 7.3 a |

| HPP200 | 51.4 ± 1.7 c | 25.5 ± 3.8 bc | 30.4 ± 11.2 c | 17.9 ± 10.6 a |

| HPP300 | 53.3 ± 0.6 bc | 22.4 ± 2.3 c | 30.1 ± 3.1 c | 18.1 ± 3.4 a |

| HPP400 | 53.6 ± 1.1 bc | 24.4 ± 2.4 bc | 33.6 ± 3.1 c | 14.7 ± 2.4 b |

| HPP500 | 53.2 ± 1.5 bc | 23.5 ± 3.3 bc | 31.9 ± 6.3 c | 16.6 ± 6.2 ab |

| HPP600 | 53.4 ± 0.8 bc | 26.9 ± 1.1 b | 36.8 ± 2.8 bc | 11.3 ± 1.9 b |

| Hardness (N) | Resilience (%) | Cohesiveness (-) | Springiness (%) | Chewiness (N) | |

|---|---|---|---|---|---|

| UNTR | 194.9 ± 37.9 a | 37.6 ± 8.1 a | 0.65 ± 0.09 a | 61.6 ± 11.1 a | 69.1 ± 16.4 a |

| HPP100 | 167.5 ± 49.5 ab | 33.0 ± 2.9 ab | 0.56 ± 0.04 ab | 53.0 ± 5.3 ab | 46.7 ± 13.46 b |

| HPP200 | 156.9 ± 41.0 b | 29.9 ± 6.6 bc | 0.48 ± 0.09 bcd | 48.1 ± 7.3 cd | 33.7 ± 10.5 c |

| HPP300 | 136.6 ± 27.0 bc | 27.0 ± 7.4 bc | 0.43 ± 0.12 cd | 45.4 ± 7.2 cd | 26.1 ± 8.9 cd |

| HPP400 | 107.1 ± 26.5 cd | 22.9 ± 7.6 cd | 0.37 ± 0.12 bcd | 42.7 ± 5.8 d | 18.5 ± 5.2 de |

| HPP500 | 93.9 ± 31.6 d | 21.7 ± 6.2 d | 0.35 ± 0.11 d | 40.8 ± 10.3 d | 15.8 ± 5.6 de |

| HPP600 | 87.4 ± 27.8 d | 21.6 ± 8.6 d | 0.38 ± 0.12 d | 42.4 ± 10.4 d | 14.6 ± 4.5 e |

| Log CFU/g | ||

|---|---|---|

| UNTR | PCA | 3.24 ± 0.23 |

| MRS | 2.64 ± 0.19 | |

| YEDC | 3.04 ± 0.19 | |

| HPP100 | PCA | 3.34 ± 0.18 |

| MRS | 2.51 ± 0.56 | |

| YEDC | 3.06 ± 0.27 | |

| HPP200 | PCA | 2.74 ± 0.37 |

| MRS | 1.89 ± 0.27 | |

| YEDC | 2.11 ± 0.25 | |

| HPP300 | PCA | 2.01 ± 0.01 |

| MRS | 1.00 ± 0.00 | |

| YEDC | 1.00 ± 0.00 | |

| HPP400 | PCA | <1 |

| MRS | <1 | |

| YEDC | <1 | |

| HPP500 | PCA | <1 |

| MRS | <1 | |

| YEDC | <1 | |

| HPP600 | PCA | <1 |

| MRS | <1 | |

| YEDC | <1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rinaldi, M.; Dhenge, R.; Rodolfi, M.; Bertani, G.; Bernini, V.; Dall’Acqua, S.; Ganino, T. Understanding the Impact of High-Pressure Treatment on Physico-Chemical, Microstructural, and Microbiological Aspects of Pumpkin Cubes. Foods 2023, 12, 1280. https://doi.org/10.3390/foods12061280

Rinaldi M, Dhenge R, Rodolfi M, Bertani G, Bernini V, Dall’Acqua S, Ganino T. Understanding the Impact of High-Pressure Treatment on Physico-Chemical, Microstructural, and Microbiological Aspects of Pumpkin Cubes. Foods. 2023; 12(6):1280. https://doi.org/10.3390/foods12061280

Chicago/Turabian StyleRinaldi, Massimiliano, Rohini Dhenge, Margherita Rodolfi, Gaia Bertani, Valentina Bernini, Stefano Dall’Acqua, and Tommaso Ganino. 2023. "Understanding the Impact of High-Pressure Treatment on Physico-Chemical, Microstructural, and Microbiological Aspects of Pumpkin Cubes" Foods 12, no. 6: 1280. https://doi.org/10.3390/foods12061280

APA StyleRinaldi, M., Dhenge, R., Rodolfi, M., Bertani, G., Bernini, V., Dall’Acqua, S., & Ganino, T. (2023). Understanding the Impact of High-Pressure Treatment on Physico-Chemical, Microstructural, and Microbiological Aspects of Pumpkin Cubes. Foods, 12(6), 1280. https://doi.org/10.3390/foods12061280