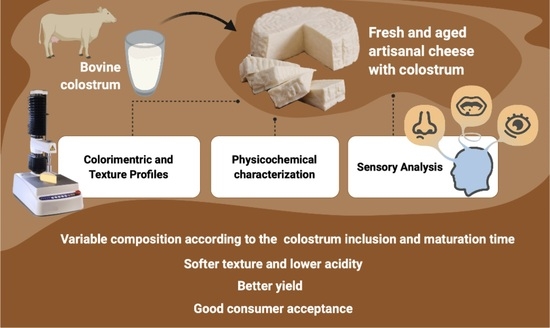

Characterization of Physicochemical and Sensory Properties of Cheeses Added with Bovine Colostrum

Abstract

1. Introduction

2. Materials and Methods

2.1. Milk and Colostrum Sampling and Thermal Processing

2.2. Physical-Chemical Analysis of Milk and Colostrum

2.3. Experimental Treatments and Cheese-Making

2.4. Chemical Composition of Cheese Samples

2.5. Colorimetric Analysis

2.6. Texture Profile Analysis

2.7. Microbiological Analyses

2.8. Sensory Analysis

2.9. Statistical Analyses

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mcgrath, B.A.; Fox, P.F.; Mcsweeney, P.L.H.; Kelly, A.L. Composition and properties of bovine colostrum: A review. Dairy Sci. Technol. 2016, 96, 133–158. [Google Scholar] [CrossRef]

- Foley, J.A.; Otterby, D.E. Availability, storage, treatment, composition, and feeding value of surplus colostrum: A review. J. Dairy Sci. 1978, 61, 1033–1060. [Google Scholar] [CrossRef]

- Silva, E.D.S.; Anaya, K.; Bezerra, M.D.F.; Borba, L.; Barbosa, I.D.M.; De Oliveira, J.P.F.; Urbano, S.A.; Macêdo, C.S.; de Lima Júnior, D.M.; Idiana, D.M.B.; et al. Physicochemical characterization and Brix in Jersey cow colostrum in tropical conditions. Int. J. Agric. Biol. 2021, 26, 139–144. [Google Scholar] [CrossRef]

- Uruakpa, F.O.; Ismond, M.A.H.; Akobundu, E.N.T. Colostro e seus benefícios: Uma revisão. Pesqui. Nutr. 2002, 22, 755–767. [Google Scholar] [CrossRef]

- Adar, T.; Ya’acov, A.B.; Lalazar, G.; Lichtenstein, Y.; Nahman, D.; Mizrahi, M.; Wong, V.; Muller, B.; Rawlin, G.; Ilan, Y. Oral administration of immunoglobulin G-enhanced colostrum alleviates insulin resistance and liver injury and is associated with alterations in natural killer T cells. Clin. Exp. Dermatol. 2012, 167, 252–260. [Google Scholar] [CrossRef]

- Costa, A.; Sneddon, N.W.; Goi, A.; Visentin, G.; Mammi, L.M.E.; Savarino, E.V.; Zingone, F.; Formigoni, A.; Penasa, M.; De Marchi, M. Invited review: Bovine colostrum, a promising ingredient for humans and animals—Properties, processing technologies, and uses. J. Dairy Sci. 2023, 106, 5197–5217. [Google Scholar] [CrossRef]

- Playford, R.J.; Cattell, M.; Marchbank, T. Marked variability in bioactivity between commercially available bovine colostrum for human use; implications for clinical trials. PLoS ONE 2020, 15, e0234719. [Google Scholar]

- Galdino, A.B.d.S.; Rangel, A.H.D.N.; Buttar, H.S.; Nascimento, M.S.L.; Gavioli, E.C.; Oliveira, R.d.P.; Sales, D.C.; Urbano, S.A.; Anaya, K. Bovine colostrum: Benefits for the human respiratory system and potential contributions for clinical management of COVID-19. Food Agric. Immunol. 2021, 32, 143–162. [Google Scholar] [CrossRef]

- Gomes, R.D.; Anaya, K.; Galdino, A.B.; Oliveira, J.P.; Gama, M.A.; Medeiros, C.A.; Gavioli, E.C.; Porto, A.L.F.; Rangel, A.H. Bovine colostrum: A source of bioactive compounds for prevention and treatment of gastrointestinal disorders. NFS J. 2021, 25, 1–11. [Google Scholar] [CrossRef]

- Beltrão, F.A.S.; Moura, C.V.R.; Sousa, S.; Andrade, A.E.B.; Souza, W.F.C.; Santos, D.T.P. Caracterização físico química de queijo tipo “chevrotin” simbiótico. Eng. Ambient. 2017, 14, 128–136. [Google Scholar]

- Cao, J.; Wang, X.; Zheng, H. Comparative studies on thermoresistance of protein G-binding region and antigen determinant region of immunoglobulin G in acidic colostral whey. Food Agric. Immunol. 2007, 18, 17–30. [Google Scholar] [CrossRef]

- Sydney, A.C.N.; Ikeda, I.K.; Ribeiro, M.C.d.O.; Sydney, E.B.; Neto, D.P.d.C.; Karp, S.G.; Rodrigues, C.; Soccol, C.R. Colostrum new insights: Products and processes. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2022; pp. 397–422. [Google Scholar]

- Silva, E.G.d.S.O.; Anaya, K.; Bezerra, M.d.F.; Macêdo, C.S.; Urbano, S.A.; Borba, L.H.F.; Barbosa, I.d.M.; Ramalho, H.M.M.; Cipolat-Gotet, C.; Galdino, A.B.d.S.; et al. Physicochemical and sensory evaluation of greek style yoghurt with bovine colostrum. J. Food Sci. Technol. 2021, 42, e22121. [Google Scholar] [CrossRef]

- Gomes, R.D.S.; Barbosa, I.M.; Ribeiro, C.V.D.M.; Anaya, K.; Silva, E.G.S.O.; Oliveira, C.A.A.; da Gama, M.A.S.; Oliveira, J.P.F.; Sale, D.C.; Araújo, E.O.M.; et al. Fatty acid profile of Greek yogurt with colostrum addition. J. Food Sci. Technol. 2023, 43, 26023. [Google Scholar] [CrossRef]

- Galdino, A.B.S.; Anaya, K.; Barbosa, I.M.; Borba, L.H.F.; Silva, E.G.S.O.; Macêdo, C.S.; Ribeiro, C.V.D.M.; Oliveira, J.P.F.; Rangel, A.H.N. Nutritional and physicochemical quality of formulations based on colostrum and bovine whey. PLoS ONE 2022, 17, e0267409. [Google Scholar] [CrossRef]

- Astuti, F.D.; Setyawardani, T.; Santosa, S.S. The physical characteristics of cheese made of milk, colostrum and both during the ripening. J. Indones. Trop. Anim. Agric. 2021, 46, 75–83. [Google Scholar] [CrossRef]

- Herrera-Chávez, B.; Trujillo, A.J.; Calero, P.; Falconí, M.I.; Sánchez-Macías, D. Effects of colostrum in milk on the effectiveness of the pasteurization process and cheese milk quality. J. Appl. Anim. Res. 2022, 50, 246–253. [Google Scholar] [CrossRef]

- Simon, R.; Gennari, A.; Kuhn, D.; Rama, G.R.; Souza, C.F.V.D. Making a fresh cheese using the colostrum surplus of dairy farms: An alternative aiming to minimize the waste of this raw material. Braz. J. Food Technol. 2022, 25, e2021125. [Google Scholar] [CrossRef]

- Mouton, E.; Aryana, K. Influence of Colostrum on the Characteristics of Ice Cream. Food Sci. Nutr. 2015, 6, 480–484. [Google Scholar] [CrossRef][Green Version]

- Playford, R.J.; Weiser, M.J. Bovine colostrum: Its constituents and uses. Nutrients 2021, 13, 265. [Google Scholar] [CrossRef]

- Feeney, E.L.; Lamichhane, P.; Sheehan, J.J. The cheese matrix: Understanding the impact of cheese structure on aspects of cardiovascular health: A food science and a human nutrition perspective. Int. J. Dairy Technol. 2021, 74, 656–670. [Google Scholar] [CrossRef]

- Dzik, S.; Miciński, B.; Aitzhanova, I.; Miciński, J.; Pogorzelska, J.; Beisenov, A.; Kowalski, I.M. Properties of bovine colostrum and the possibilities of use. Pol. Ann. Med. 2017, 24, 295–299. [Google Scholar] [CrossRef]

- Das, A.; Seth, R. Studies on quality attributes of skimmed colostrum powder. Int. J. Chem. Stud. 2017, 5, 17–20. [Google Scholar]

- Normas Analíticas do Instituto Adolfo Lutz. Métodos Químicos e Físicos para Análise de Alimentos, 3rd ed.; IMESP: São Paulo, Brazil, 2008; Volume 1, pp. 233–234. [Google Scholar]

- Gracioli, F.; Lehn, D.N.; Souza, C.F.V. Análise comparativa de custo e rendimento da fabricação de queijo tipo camembert e queijo colonial em pequena escala. Rev. Destaques Acadêmicos 2013, 5, 15–30. [Google Scholar]

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Portaria nº 146 de 7 de Março de 1996. Aprova os Regulamentos Técnicos de Identidade e Qualidade dos Produtos Lácteos; Diário Oficial da União: Brasília, Brazil, 1996. [Google Scholar]

- Official Methods of Analysis of AOAC International, 19th ed.; AOAC International: Gaithersburg, MD, USA, 2012.

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Instrução Normativa 76 de 26 de Novembro de 2018. Dispõe Sobre Regulamentos Técnicos que Fixam a Identidade e as Características de Qualidade que Devem Apresentar o Leite Cru Refrigerado, o leite Pasteurizado e o Leite Pasteurizado Tipo A; Seção 1; Diário Oficial da União: Brasília, Brazil, 2018. [Google Scholar]

- Coimbra, P.T.; Bathazar, C.F.; Guimarães, J.T.; Coutinho, N.M.; Pimentel, T.C.; Neto, R.P.; Esmerino, E.A.; Freitas, M.Q.; Silva, M.C.; Tavares, M.I.; et al. Detection of formaldehyde in raw milk by time domain nuclear magnetic resonance and chemometrics. Food Control 2020, 110, 107006. [Google Scholar] [CrossRef]

- Santurino, C.; Calvo, M.V.; Gómez-Candela, C.; Fontecha, J. Characterization of naturally goat cheese enriched in conjugated linoleic acid and omega-3 fatty acids for human clinical trial in overweight and obese subjects. PharmaNutrition 2017, 5, 8–17. [Google Scholar] [CrossRef]

- Apha, A. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005; p. 953. [Google Scholar]

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Instrução Normativa n° 30, de 26 de Junho de 2001. Aprova os Regulamentos Técnicos de Identidade e Qualidade de Manteiga da terra ou Manteiga de Garrafa; Queijo Coalho e Queijo de Manteiga; Diário Oficial da União: Brasília, Brazil, 2001. [Google Scholar]

- Brasil. Ministério da Agricultura, Pecuária e Abastecimento. Secretaria de Defesa Agropecuária. Instrução Normativa n° 60 de 23 de Dezembro de 2019. Estabelece as Listas de Padrões Microbiológicos para Alimentos Prontos para oferta ao Consumidor; Seção 1; Diário Oficial da União: Brasília, Brazil, 2019; p. 133. [Google Scholar]

- Brasil. Agência Nacional de Vigilância Sanitária. Resolução RDC nº 331, de 23 de Dezembro de 2019. Aprova o Regulamento Técnico sobre Padrões Microbiológicos para Alimentos; Seção 1; Diário Oficial da União: Brasília, Brazil, 2019; p. 96. [Google Scholar]

- Dutcosky, S.D. Análise Sensorial de Alimentos, 4th ed.; Editora Universitária Champagnat: Curitiba, Brazil, 2013; 531p. [Google Scholar]

- Conte, F.; Scarantino, S. A study on the quality of bovine colostrum: Physical, chemical and safety assessment. Int. Food Res. 2013, 20, 925–931. [Google Scholar]

- Sobczuk-Szul, M.; Wielgoz-Groth, Z.; Wronski, M.; Rzemieniewski, A. Changes in the bioactive protein concentrations in the bovine colostrum of Jersey and Polish Holstein–Friesian cows. Turk. J. Vet. Anim. Sci. 2013, 37, 43–49. [Google Scholar] [CrossRef]

- Morrill, N.K.M.; Conrad, E.; Lago, A.; Campbell, J.; Quigley, J.; Tyler, H. Nationwide evaluation of quality and composition of colostrum on dairy farms in the United States. J. Dairy Sci. 2012, 95, 3997–4005. [Google Scholar] [CrossRef]

- Oliveira, E.N.A.; Santos, D.C.; Almeida, F.L.C.; Feitosa, B.F.; Feitosa, R.M. Caracterização de queijos artesanais comercializados em municípios do Ceará. E-xacta 2018, 11, 55–62. [Google Scholar] [CrossRef][Green Version]

- Patıroğlu, T.; Kondolot, M. The effect of bovine colostrum on viral upper respiratory tract infections in children with immunoglobulin a deficiency. Clin. Respir. J. 2013, 7, 21–26. [Google Scholar] [CrossRef]

- Saalfeld, M.H.; Ira, K.R.K.; Diniz, G.L.; Kringel, D.H.; Alves, M.I.; Gularte, M.A.; Leite, F.P.L. Colostro: A redescoberta de um alimento saudável, nutritivo e com potencial probiótico. Agroecologia e Desenvolvimento Rural Sustentável 2012, 5, 18–24. [Google Scholar]

- Nardone, A.; Lacetera, N.; Bernabucci, U.; Ronchi, B. Composition of colostrum from dairy heifers exposed to high air temperatures during late pregnancy and the early postpartum period. J. Dairy Sci. 1997, 80, 838–844. [Google Scholar] [CrossRef]

- Louvatel, K.; Degenhardt, R. Caracterização bromatológica de queijos coloniais produzidos no distrito de Santa Lúcia, município de Ouro, SC. In Anais da III Jornada Integrada em Biologia; Universidade do Oeste de Santa Catarina Unoesc: Joaçaba, Brazil, 2016; pp. 37–46. ISSN 2358-0992. [Google Scholar]

- Roig, S.; Narimatsu, A.; Dornelas, J.R.F.; Spadoti, L.M.; Pizaia, P.D.M. Avaliação da proteólise e do derretimento do queijo prato obtido por ultrafiltração. Food Sci. Technol. 2003, 23, 177–182. [Google Scholar]

- Santos, B.M.; Oliveira, M.E.G.; Sousa, Y.R.F.; Madureira, A.R.M.F.M.; Pintado, M.M.E.; Gomes, A.M.P.; de Souza, E.L.; do Egypto, R.D.C.R. Caracterização físico-química e sensorial de queijo de coalho produzido com mistura de leite de cabra e de leite de vaca. Revista do Instituto Adolfo Lutz 2011, 70, 302–310. [Google Scholar]

- Souza, C.H.B.; Saad, S.M.I. Viability of lactobacillus acidophilus La-5 added solely or in co-culture with a yoghurt starter culture and implications on physical-chemical and related properties of Minas fresh cheese during storage. LWT-Food Sci. Technol. 2009, 42, 633–640. [Google Scholar] [CrossRef]

- Assunção, M.V.A.; Andrade, J.A.S.; Santos, T.T.; Lima, J.S.; Talma, S.V.; Machado, A.C.L.O.; Costa, L.P.; Barbosa, J.B. Elaboração e avaliação físico-química de queijo coalho condimentado artesanal no sertão sergipano. Interfaces Científicas Saúde e Ambiente 2018, 7, 79–86. [Google Scholar] [CrossRef]

- Sousa, A.Z.B.; Abrantes, M.R.; Sakamoto, S.M.; Silva, J.B.A.; Lima, P.O.; Lima, R.N.; Rocha, M.O.C.; Sousa, D.B.P. Aspectos físico-químicos e microbiológicos do queijo tipo coalho comercializado em estados do nordeste do Brasil. Arq. Inst. Biol. 2014, 81, 30–35. [Google Scholar] [CrossRef]

- Embrapa. Validação e Transferência da Tecnologia do Queijo Coalho Caprino Maturado e Defumado; Embrapa Agroindústria Tropical: Fortaleza, Brazil, 2018; Volume 152, p. 22. ISSN 1679-6543. [Google Scholar]

- Raimondo, R.F.S.; Saut, P.E.; Souza, R.M.; Nunes, M.T.; Birgel Junior, E.H. Teores de proteína, gordura e sólidos totais no leite de vacas da raça Jersey criadas no Estado de São Paulo durante o primeiro mês de lactação. Rev. Bras. Med. Vet. 2009, 46, 355–362. [Google Scholar] [CrossRef][Green Version]

- Sgarbieri, V.C. Propriedades fisiológicas-funcionais das proteínas do soro de leite. Rev. Nutr. 2004, 17, 397–409. [Google Scholar] [CrossRef]

- Mamede, M.E.D.O.; Viana, A.C.; Souza, A.L.C.; Farias, S.A.O.; Araújo, P.A. Estudo das características sensoriais e da composição química de queijo de Coalho industrializado. Revista do Instituto Adolfo Lutz 2010, 69, 364–370. [Google Scholar]

- Borad, S.G.; Singh, A.K. Colostrum immunoglobulins: Processing, preservation and application aspects. Int. Dairy J. 2018, 85, 201–210. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A. Medição e análise de cor em alimentos in natura e processados: Uma revisão. Tecnol. Bioprocessos Aliment. 2012, 6, 36–60. [Google Scholar]

- Melo, L.R.B.; Torres, F.R.; Guimarães, J.T.; Cortez, M.A.S. Development of processed low-sodium Maasdam cheese. Arq. Bras. Med. Vet. Zootec. 2022, 74, 1072–1082. [Google Scholar] [CrossRef]

- Fontan, G.C.R. Queijo de Coalho Light: Produção, Caracterização Físico-Química, Sensorial e Reológica. Tese (Programa de Pós-graduação em Ciência e Tecnologia de Alimentos), Universidade Federal de Viçosa, 2013; 86f. Available online: https://www.locus.ufv.br/bitstream/123456789/491/1/texto%20completo.pdf (accessed on 6 October 2023).

- Pereira, R.B.; Bennett, R.J.; Luckman, M.S. Correlation of sensory and instrumental texture evaluation in cheese analogues. Aust. J. Dairy Technol. 2002, 57, 154. [Google Scholar]

- Bourne, M. Food Texture and Viscosity: Concept and Measurement, 2nd ed.; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2002; p. 416. [Google Scholar]

- Andrade, A.S.A.; Rodrigues, M.D.C.P.; Tieko, R.; Nassu, M.A.D.S.N. Medidas instrumentais de cor e textura em queijo de coalho. In Congresso Latino America de Analista de Alimentos; LACEN, Anais: Fortaleza, Brazil, 2007. [Google Scholar]

- Furtado, M.M. Principais Problemas dos Queijos, 3rd ed.; Setembro Editora: Paulo, Brazil, 2017; 225p. [Google Scholar]

- Silva, M.C.D.; Ramos, A.C.S.; Moreno, I.; Moraes, J.d.O. Influência dos procedimentos de fabricação nas características físico-químicas, sensoriais e microbiológicas de queijo de coalho. Revista do Instituto Adolfo Lutz 2010, 69, 214–221. [Google Scholar]

- Dutra, E.R.P. Fundamentos Básicos da Produção de Queijos; Templo: Juiz de Fora, Brazil, 2017; 160p. [Google Scholar]

| Composition | Milk ± SD | Colostrum ± SD |

|---|---|---|

| Fat (g 100 g−1) | 5.40 ± 0.01 a | 4.05 ± 0.01 b |

| Total protein (g 100 g−1) | 3.87 ± 0.01 b | 15.20 ± 0.01 a |

| Lactose (g 100 g−1) | 5.34 ± 0.01 a | 1.48 ± 0.01 b |

| Casein (g 100 g−1) | 3.02 ± 0.01 b | 12.07 ± 0.01 a |

| SNF (g 100 g−1) | 10.02 ± 0.01 b | 17.46 ± 0.14 a |

| TS (g 100 g−1) | 15.42 ± 0.01 a | 21.52 ± 0.01 b |

| Acidity (g lactic acid 100 mL−1) | 0.18 ± 0.01 b | 0.25 ± 0.01 a |

| pH | 6.80 ± 0.01 a | 6.40 ± 0.01 b |

| Treatment | Moisture | Ash | FDM | Protein | Acidity | pH | aw |

|---|---|---|---|---|---|---|---|

| 0—100:0 (milk:colostrum, v:v) | |||||||

| F | 47.52 ± 0.16 g | 2.95 ± 0.00 f | 41.09 ± 5.52 ab | 22.24 ± 0.21 c | 0.04 ± 0.00 b | 5.39 ± 0.02 ef | 0.95 ± 0.01 b |

| A | 46.59 ± 0.29 h | 3.53 ± 0.05 cde | 31.00 ± 1.91 def | 25.48 ± 0.57 abc | 0.04 ± 0.01 b | 5.65 ± 0.08 bc | 0.95 ± 0.01 ab |

| B | 44.77± 0.11 i | 3.34 ± 0.06 ef | 47.36 ± 0.98 a | 23.06 ± 1.32 bc | 0.05 ± 0.00 ab | 5.50 ± 0.02 de | 0.99 ± 0.01 a |

| C | 49.11± 0.17 f | 3.96 ± 0.04 bc | 32.60 ± 0.19 cde | 25.85 ± 0.49 ab | 0.08 ± 0.01 a | 5.22 ± 0.02 gh | 0.97 ± 0.00 ab |

| 1—85:15 (milk:colostrum, v:v) | |||||||

| F | 56.98 ± 0.22 b | 3.44 ± 0.01 de | 26.24 ± 1.33 efg | 25.30 ± 0.16 abc | 0.03 ± 0.01 b | 5.61 ± 0.09 bc | 0.96 ± 0.01 b |

| A | 51.00 ± 0.13 e | 3.32 ± 0.08 ef | 32.58 ± 0.08 cde | 23.45 ± 017 abc | 0.02 ± 0.00 b | 5.24 ± 0.03 gh | 0.95 ± 0.02 ab |

| B | 52.41 ± 0.41 d | 3.63 ± 0.01 bcde | 38.40 ± 0.96 bc | 26.07 ± 2.40 ab | 0.03 ± 0.01 b | 5.68 ± 0.00 bc | 0.96 ± 0.01 ab |

| C | 45.99 ± 0.19 h | 4.92 ± 0.02 a | 26.87 ± 1.32 efg | 24.00 ± 0.49 abc | 0.08 ± 0.01 a | 5.30 ± 0.02 fg | 0.94 ± 0.01 b |

| 2—80:20 (milk:colostrum, v:v) | |||||||

| F | 63.22 ± 0.16 a | 3.21 ± 0.02 ef | 31.56 ± 1.52 def | 24.66 ± 0.25 abc | 0.04 ± 0.00 b | 5.73 ± 0.01 b | 0.97 ± 0.01 ab |

| A | 54.58 ± 0.11 c | 4.01 ± 0.09 b | 21.21 ± 0.65 g | 26.65 ± 0.33 a | 0.04 ± 0.02 ab | 5.57 ± 0.03 cd | 0.96 ± 0.00 ab |

| B | 47.48 ± 0.37 g | 3.85 ± 0.03 bcd | 35.65 ± 0.34 bcd | 25.58 ± 0.05 abc | 0.02 ± 0.00 b | 5.48 ± 0.02 de | 0.97 ± 0.02 ab |

| C | 49.42 ± 0.11 f | 3.84 ± 0.09 bcd | 35.13 ± 0.29 bcd | 25.42 ± 0.03 abc | 0.03 ± 0.01 b | 5.03 ± 0.01 ij | 0.95 ± 0.01 ab |

| 3—75:25 (milk:colostrum, v:v) | |||||||

| F | 57.13 ± 0.69 b | 3.23± 0.12 ef | 40.29 ± 3.89 b | 24.73 ± 1.51 abc | 0.02 ± 0.00 b | 6.23 ± 0.01 a | 0.95 ± 0.03 b |

| A | 53.06± 0.12 d | 3.45 ± 0.02 de | 32.68 ± 3.18 cde | 23.83 ± 0.63 abc | 0.04 ± 0.01 b | 5.14 ± 0.01 hi | 0.95 ± 0.01 ab |

| B | 51.49 ± 0.14 e | 4.90 ± 0.55 a | 25.42 ± 3.16 fg | 23.22 ± 0.25 bc | 0.02 ± 0.00 b | 5.46 ± 0.00 de | 0.96 ± 0.00 ab |

| C | 51.31 ± 0.27 e | 3.53 ± 0.01 cde | 29.65 ± 1.18 def | 25.00 ± 0.44 abc | 0.03 ± 0.01 b | 5.02 ± 0.01 j | 0.95 ± 0.01 b |

| Treatments | L* | a* | b* | YI |

|---|---|---|---|---|

| 0—100:0 (milk:colostrum, v:v) | ||||

| F | 65.80 ± 7.87 def | −6.83 ± 8.78 abc | 17.04 ± 5.68 d | 37.24 ± 12.81 bc |

| A | 62.38 ± 1.89 efg | −5.57 ± 5.13 abc | 19.01 ± 4.50 bcd | 43.62 ± 10.71 abc |

| B | 64.65 ± 3.13 def | 7.21 ± 8.62 a | 17.83 ± 12.65 cd | 39.35 ± 27.94 bc |

| C | 75.66 ± 0.66 b | −7.76 ± 1.91 abc | 30.73 ± 0.65 abc | 58.01 ± 0.72 abc |

| 1—85:15 (milk:colostrum, v:v) | ||||

| F | 62.76 ± 0.86 defg | 1.49 ± 5.22 ab | 20.09 ± 1.88 bcd | 45.69 ± 3.63 abc |

| A | 59.77 ± 0.86 fg | −7.53 ± 1.36 abc | 23.69 ± 0.27 abcd | 56.62 ± 0.34 abc |

| B | 63.26 ± 3.30 def | −10.28 ± 3.60 bc | 15.30 ± 1.54 d | 34.51 ± 1.88 c |

| C | 64.48 ± 0.40 def | 2.16 ± 1.49 ab | 31.49 ± 1.80 ab | 69.78 ± 4.40 a |

| 2—80:20 (milk:colostrum, v:v) | ||||

| F | 63.53 ± 1.84 def | −15.06 ± 6.09 c | 16.70 ± 3.26 d | 37.54 ± 7.03 bc |

| A | 83.44 ± 1.03 a | −5.39 ± 4.22 abc | 26.99 ± 3.92 abcd | 46.16 ± 6.18 abc |

| B | 66.51 ± 2.52 cdef | −8.60 ± 0.92 abc | 25.25 ± 4.38 abcd | 54.06 ± 7.47 abc |

| C | 68.79 ± 1.07 bcde | 7.04 ± 0.79 a | 34.04 ± 2.71 a | 70.64 ± 4.64 a |

| 3—75:25 (milk:colostrum, v:v) | ||||

| F | 55.43 ± 0.87 g | −4.10 ± 6.24 abc | 14.07 ± 3.81 d | 36.19 ± 9.30 c |

| A | 74.16 ± 0.51 bc | 0.02 ± 4.00 abc | 33.66 ± 0.01 a | 64.84 ± 0.44 ab |

| B | 64.68 ± 1.88 def | 3.69 ± 6.07 ab | 24.82 ± 1.04 abcd | 54.79 ± 0.92 abc |

| C | 70.41 ± 0.51 bcd | 1.89 ± 9.43 ab | 26.06 ± 1.29 abcd | 52.88 ± 2.65 abc |

| Treatments | Firmness | Cohesivity | Chewability | Resilience |

|---|---|---|---|---|

| 0—100:0 (milk:colostrum, v:v) | ||||

| F | 58.99 ± 6.51 ab | 0.60 ± 0.05 a | 35.89 ± 6.96 ab | 0.28 ± 0.03 b |

| A | 65.20 ± 8.64 a | 0.61 ± 0.05 a | 40.09 ± 6.56 a | 0.29 ± 0.04 b |

| B | 50.03 ± 8.08 bc | 0.55 ± 0.03 ab | 27.41 ± 5.00 bcd | 0.22 ± 0.03 b |

| C | 46.31 ± 4.53 bcd | 0.61 ± 0.05 a | 28.14 ± 3.69 bc | 0.20 ± 0.02 b |

| 1—85:15 (milk:colostrum, v:v) | ||||

| F | 33.44 ± 3.25 def | 0.56 ± 0.03 ab | 18.62 ± 1.15 def | 0.31 ± 0.06 b |

| A | 42.87 ± 4.82 cd | 0.53 ± 0.05 ab | 22.76 ± 3.82 cde | 0.32 ± 0.08 b |

| B | 26.37 ± 1.20 efg | 0.50 ± 0.02 abc | 13.22 ± 0.81 fg | 0.44 ± 0.27 b |

| C | 39.21 ± 6.91 cde | 0.34 ± 0.06 d | 13.39 ± 4.37 fg | 0.39 ± 0.13 b |

| 2—80:20 (milk:colostrum, v:v) | ||||

| F | 11.75 ± 1.26 h | 0.40 ± 0.08 cd | 4.68 ± 0.80 g | 0.39 ± 0.18 b |

| A | 51.07 ± 4.5 bc | 0.51 ± 0.04 abc | 25.68 ± 3.72 cd | 0.45 ± 0.18 b |

| B | 45.34 ± 7.08 cd | 0.57 ± 0.04 ab | 25.64 ± 2.79 cd | 0.22 ± 0.02 b |

| C | 27.58 ± 2.26 efg | 0.45 ± 0.03 bcd | 12.56 ± 1.57 fg | 0.40 ± 0.53 b |

| 3—75:25 (milk:colostrum, v:v) | ||||

| F | 16.46 ± 1.86 gh | 0.55 ± 0.03 ab | 8.99 ± 1.03 g | 0.23 ± 0.04 b |

| A | 23.51 ± 1.69 fgh | 0.55± 0.06 ab | 12.93 ± 2.22 fg | 0.25 ± 0.11 b |

| B | 24.24 ± 4.96 fgh | 0.57 ± 0.04 ab | 13.84 ± 3.53 efg | 0.22 ± 0.03 b |

| C | 23.34 ± 3.24 fgh | 0.41 ± 0.05 cd | 9.46 ± 0.69 fg | 1.14 ± 0.23 a |

| Attributes | 0F | 1F | 2F | 3F |

|---|---|---|---|---|

| Appearance | 8.10 ± 0.99 a | 7.67 ± 1.34 a | 7.86 ± 1.09 a | 7.75 ± 1.22 a |

| Color | 7.81 ± 1.31 a | 7.54 ± 1.26 a | 7.73 ± 1.17 a | 7.64 ± 1.38 a |

| Aroma | 7.52 ± 1.40 a | 6.76 ± 1.63 b | 7.07 ± 1.46 b | 7.12 ± 1.62 b |

| Texture | 7.83 ± 1.16 a | 6.98 ± 1.97 b | 6.98 ± 1.74 b | 7.36 ± 1.61 b |

| Flavor | 7.90 ± 1.32 a | 6.63 ± 1.96 b | 6.47 ± 1.93 b | 7.07 ± 1.80 b |

| Overall evaluation | 7.72 ± 1.02 a | 7.08 ± 1.52 b | 6.94 ± 1.56 b | 7.41 ± 1.40 b |

| Purchase intent | 4.38 ± 0.94 a | 3.49 ± 1.16 b | 3.50 ± 1.17 b | 3.79 ± 1.28 b |

| Attributes | AI (%) | |||

|---|---|---|---|---|

| 0F | 1F | 2F | 3F | |

| Appearance | 90.08 | 85.30 | 87.33 | 86.14 |

| Color | 86.85 | 83.87 | 85.90 | 84.94 |

| Aroma | 83.63 | 75.14 | 78.49 | 79.21 |

| Texture | 87.09 | 75.12 | 77.65 | 81.83 |

| Flavor | 87.81 | 73.71 | 71.92 | 78.61 |

| Overall evaluation | 86.97 | 78.73 | 77.18 | 82.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbosa, I.d.M.; Anaya, K.; Macêdo, C.S.; Coelho, R.R.P.; Cipolat-Gotet, C.; Silva, E.G.d.S.O.; Araújo, N.G.; Chagas, B.M.E.d.; Oliveira, J.P.F.d.; Boari, C.A.; et al. Characterization of Physicochemical and Sensory Properties of Cheeses Added with Bovine Colostrum. Foods 2023, 12, 4474. https://doi.org/10.3390/foods12244474

Barbosa IdM, Anaya K, Macêdo CS, Coelho RRP, Cipolat-Gotet C, Silva EGdSO, Araújo NG, Chagas BMEd, Oliveira JPFd, Boari CA, et al. Characterization of Physicochemical and Sensory Properties of Cheeses Added with Bovine Colostrum. Foods. 2023; 12(24):4474. https://doi.org/10.3390/foods12244474

Chicago/Turabian StyleBarbosa, Idiana de Macêdo, Katya Anaya, Cláudia Souza Macêdo, Robson Rogério Pessoa Coelho, Claudio Cipolat-Gotet, Emerson Gabriel dos Santos Oliveira Silva, Nkarthe Guerra Araújo, Bruna Maria Emerenciano das Chagas, Juliana Paula Felipe de Oliveira, Cleube Andrade Boari, and et al. 2023. "Characterization of Physicochemical and Sensory Properties of Cheeses Added with Bovine Colostrum" Foods 12, no. 24: 4474. https://doi.org/10.3390/foods12244474

APA StyleBarbosa, I. d. M., Anaya, K., Macêdo, C. S., Coelho, R. R. P., Cipolat-Gotet, C., Silva, E. G. d. S. O., Araújo, N. G., Chagas, B. M. E. d., Oliveira, J. P. F. d., Boari, C. A., Sales, D. C., Araújo, E. d. O. M., Neves, J. A., & Rangel, A. H. d. N. (2023). Characterization of Physicochemical and Sensory Properties of Cheeses Added with Bovine Colostrum. Foods, 12(24), 4474. https://doi.org/10.3390/foods12244474