Co-Delivery System of Vitamin B12 and Vitamin E Using a Binary W/O/W Emulsion Based on Soybean Isolate Protein–Xanthan Gum/Carrageenan: Emulsification Properties, Rheological Properties, Structure, Stability, and Digestive Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of SPI-XG and SPI-CA W/O/W Emulsions

2.2.1. Preparation of W1/O Emulsions

2.2.2. Preparation of W1/O/W2 Emulsions

2.3. Particle Size and Zeta Potential Measurements

2.4. Emulsification Properties

2.5. Absorbed Protein Content

2.6. Rheological Properties

2.7. Microstructure

2.7.1. Optical Microscope

2.7.2. Confocal Laser Scanning Microscopy

2.8. Physicochemical Stability

2.8.1. Storage Stability

2.8.2. pH Stability

2.8.3. Thermal Stability

2.9. Encapsulation Efficiency

2.10. Antioxidant Activity

2.10.1. 1,1-Diphenyl-2-picryl-hydrazyl (DPPH) Radical Scavenging Activity

2.10.2. 2,2′-Azinobis-[3-ethylbenzothiazoline-6-sulfonate acid] (ABTS) Radical Scavenging Activity

2.11. In Vitro Digestion

2.11.1. Release of Free Fatty Acids

2.11.2. Bioaccessibility

2.12. Statistical Analysis

3. Results and Discussion

3.1. Particle Size and Zeta Potential

3.2. Emulsification Properties

3.3. Absorbed Protein Content

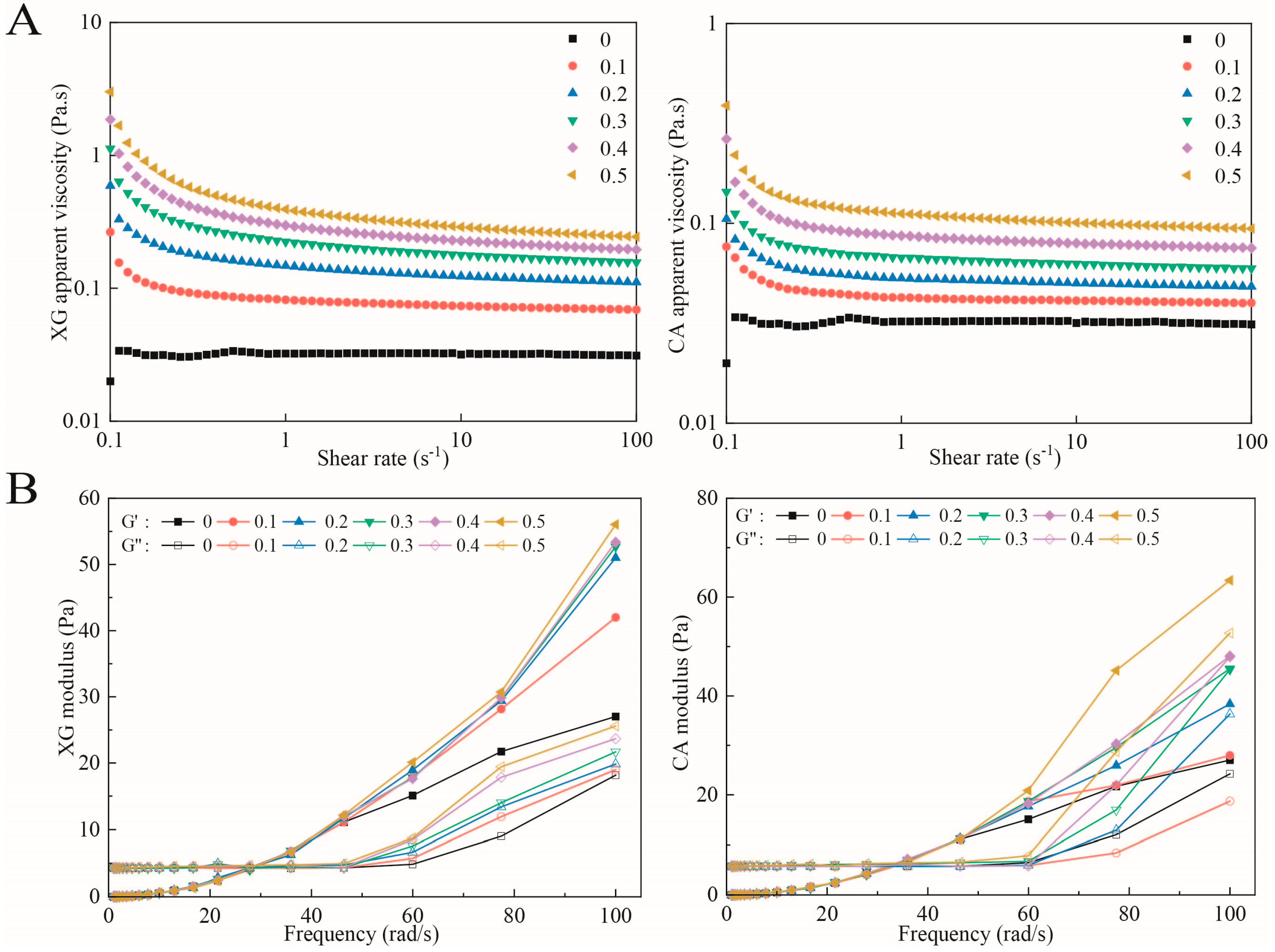

3.4. Rheological Properties

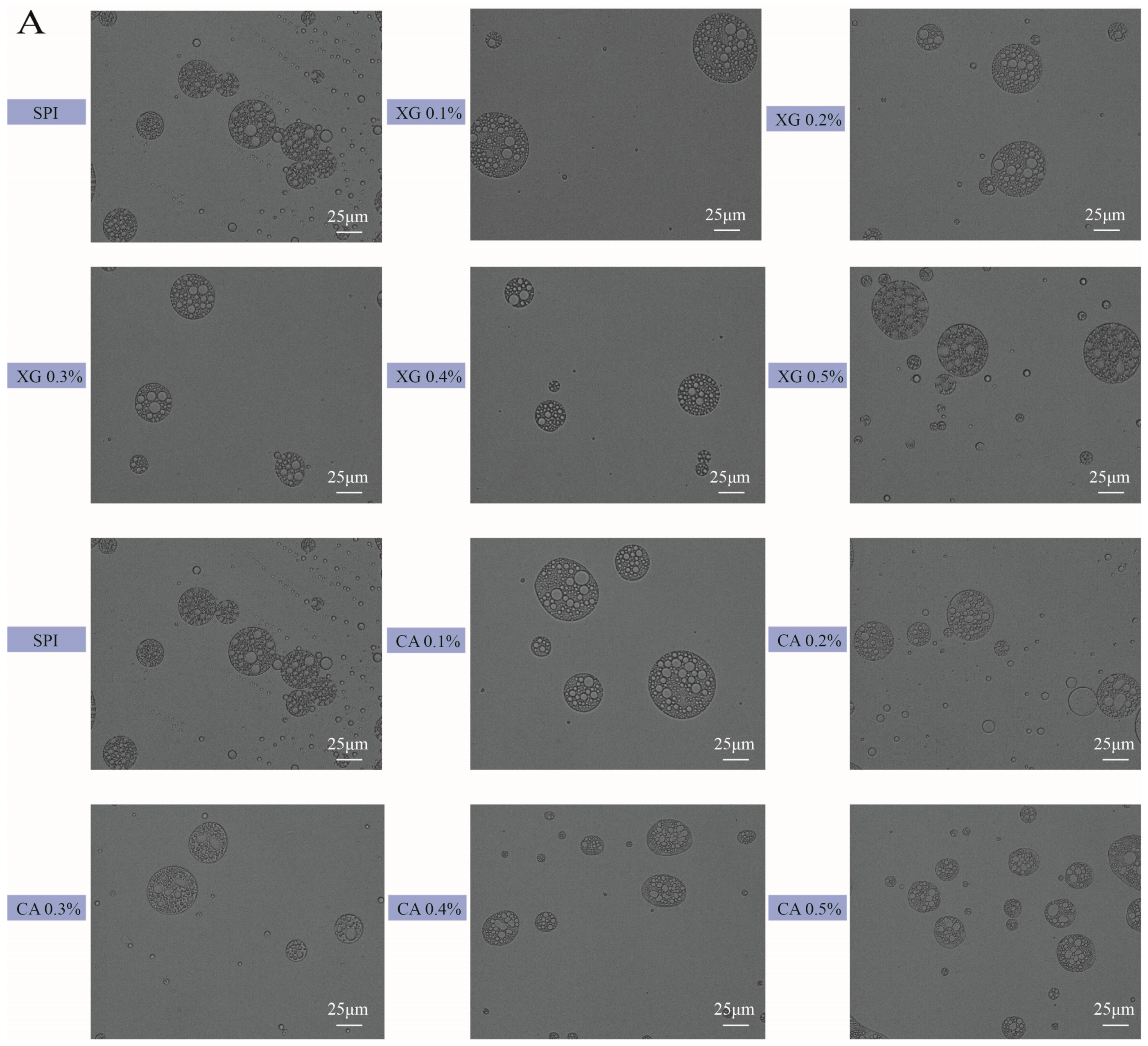

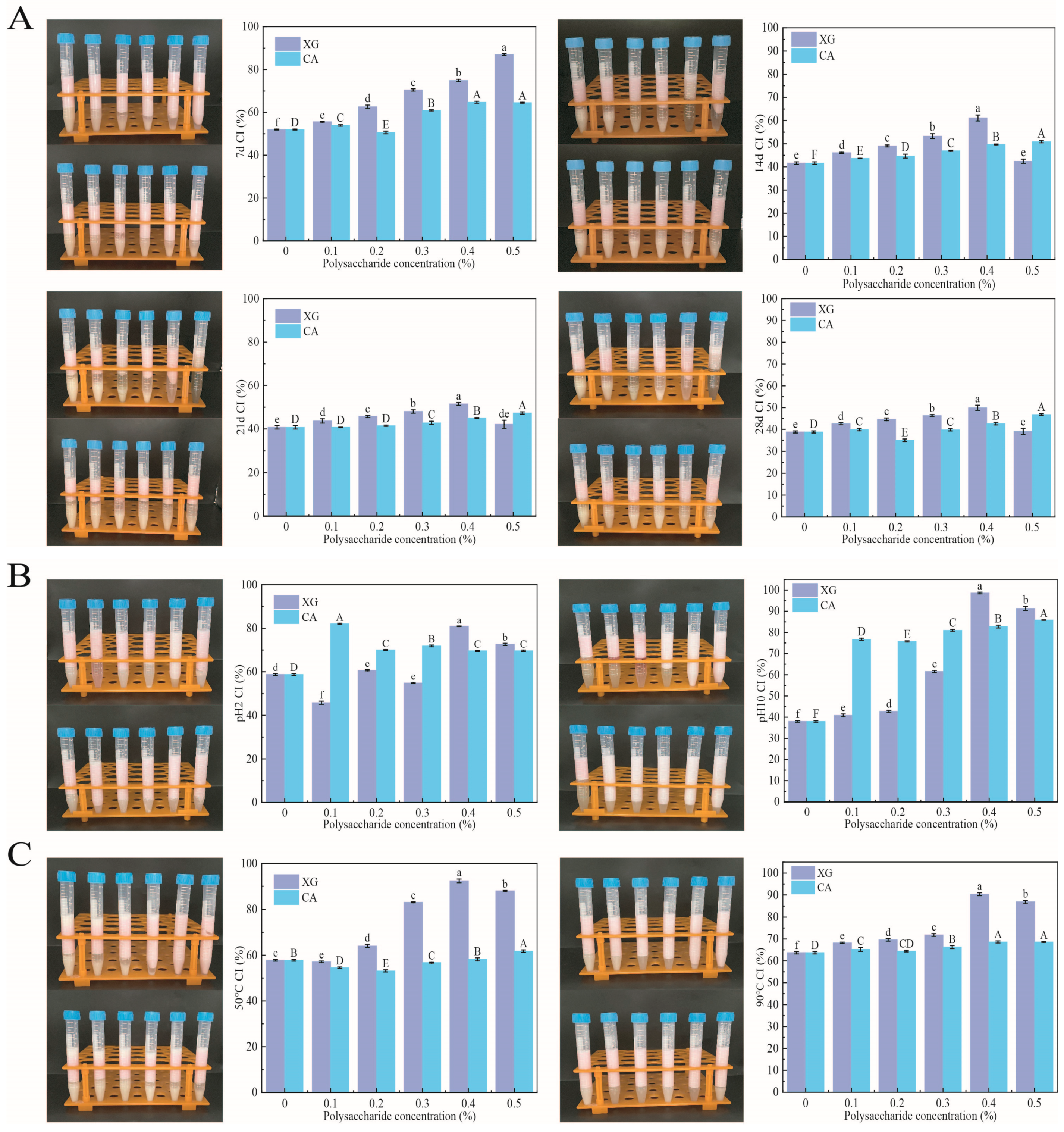

3.5. Microstructure

3.6. Physicochemical Stability

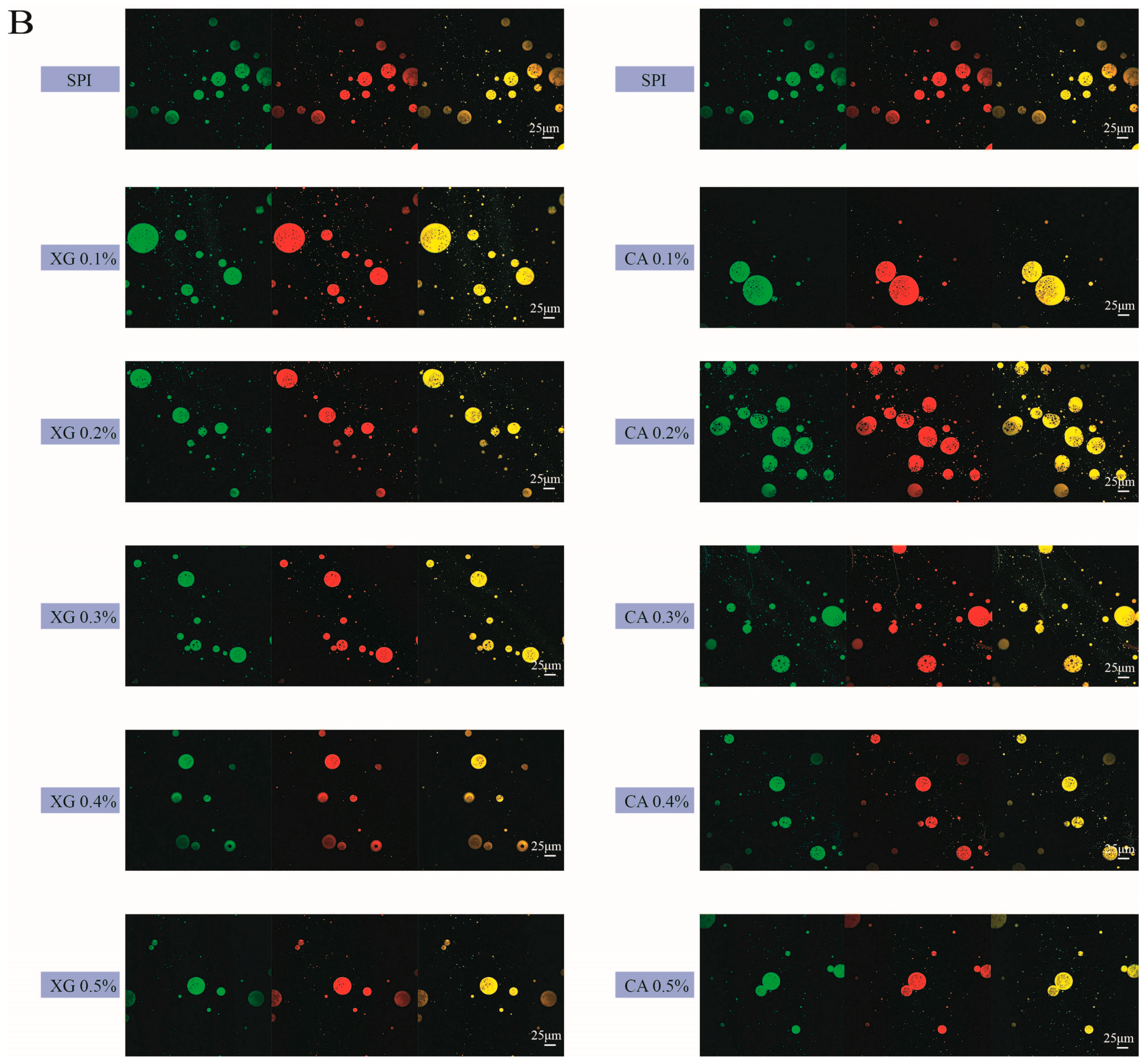

3.6.1. Storage Stability

3.6.2. pH Stability

3.6.3. Thermal Stability

3.7. Encapsulation Efficiency

3.8. Antioxidant Activity

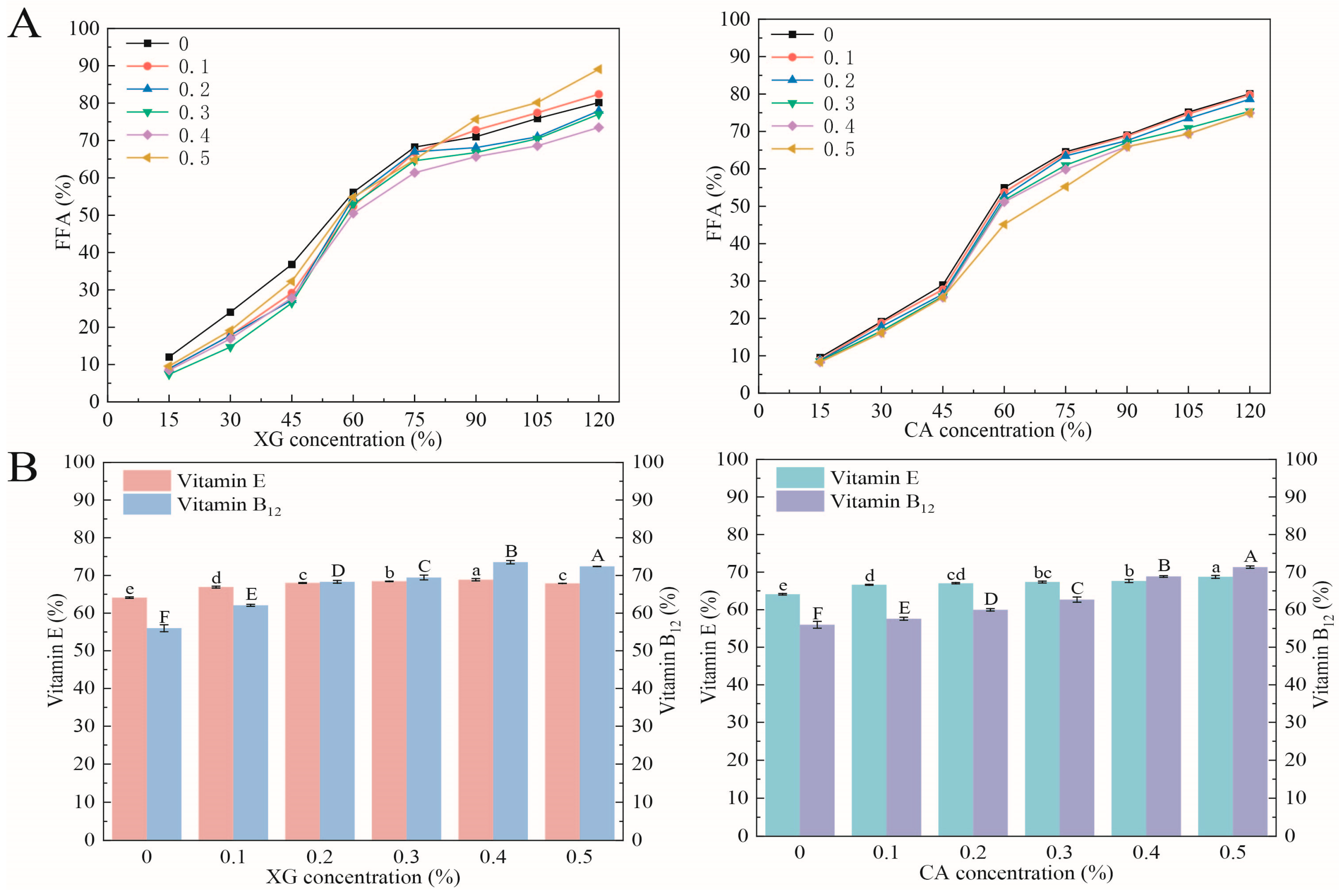

3.9. In Vitro Digestion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mwangi, W.W.; Lim, H.P.; Low, L.E.; Tey, B.T.; Chan, E.S. Food-grade Pickering emulsions for encapsulation and delivery of bioactives. Trends Food Sci. Technol. 2020, 100, 320–332. [Google Scholar] [CrossRef]

- Schuch, A.; Helfenritter, C.; Funck, M.; Schuchmann, H.P. Observations on the influence of different biopolymers on coalescence of inner water droplets in W/O/W (water-in-oil-in-water) double emulsions. Colloids Surf. A-Physicochem. Eng. Asp. 2015, 475, 2–8. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Feng, X.; Yang, H.; Shao, M.; Huang, Y.; Li, Y.; Teng, F. Internal/external aqueous-phase gelation treatment of soybean lipophilic protein W/O/W emulsions: Improvement in microstructure, interfacial properties, physicochemical stability, and digestion characteristics. Food Hydrocoll. 2022, 136, 108257. [Google Scholar] [CrossRef]

- Li, D.; Hu, M.; Hou, L.; Gao, Y.; Tian, Z.; Wen, W.; Fan, B.; Li, S.; Wang, F. The structural and functional properties of soybean protein-polyglutamic acid complex effected the stability of W/O/W emulsion encapsulated Nattokinase. Food Chem. 2023, 414, 135724. [Google Scholar] [CrossRef] [PubMed]

- Tarahi, M.; Ahmed, J. Recent advances in legume protein-based colloidal systems. Legume Sci. 2023, n/a, e185. [Google Scholar] [CrossRef]

- Jiang, M.; Gan, Y.; Li, Y.; Qi, Y.; Zhou, Z.; Fang, X.; Jiao, J.; Han, X.; Gao, W.; Zhao, J. Protein-polysaccharide-based delivery systems for enhancing the bioavailability of curcumin: A review. Int. J. Biol. Macromol. 2023, 250, 126153. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Yue, H.; Li, X.; He, C.; Li, Q.; Cheng, L.; Zhang, J.; Liu, Y.; Wang, S.; Guo, Q. Structural, rheological and functional properties of ultrasonic treated xanthan gums. Int. J. Biol. Macromol. 2023, 246, 125650. [Google Scholar] [CrossRef]

- Liu, F.; Duan, G.; Yang, H. Recent advances in exploiting carrageenans as a versatile functional material for promising biomedical applications. Int. J. Biol. Macromol. 2023, 235, 123787. [Google Scholar] [CrossRef]

- Liang, Z.; Chu, H.; Hou, Z.; Wang, C.; Zhang, G.; Liu, L.; Ma, X.; Li, C.; He, J. W/O/W emulsions stabilized with whey protein concentrate and pectin: Effects on storage, pasteurization, and gastrointestinal viability of Lacticaseibacillus rhamnosus. Int. J. Biol. Macromol. 2023, 232, 123477. [Google Scholar] [CrossRef]

- Brito-Oliveira, T.C.; Bispo, M.; Moraes, I.C.F.; Campanella, O.H.; Pinho, S.C. Stability of curcumin encapsulated in solid lipid microparticles incorporated in cold-set emulsion filled gels of soy protein isolate and xanthan gum. Food Res. Int. 2017, 102, 759–767. [Google Scholar] [CrossRef]

- Liu, Z.; Ha, S.; Guo, C.; Xu, D.; Hu, L.; Li, H.; Hati, S.; Mo, H. 3D printing of curcumin enriched Pickering emulsion gel stablized by pea protein-carrageenan complexes. Food Hydrocoll. 2024, 146, 109170. [Google Scholar] [CrossRef]

- Klojdova, I.; Troshchynska, Y.; Stetina, J. Influence of carrageenan on the preparation and stability of w/o/w double milk emulsions. Int. Dairy J. 2018, 87, 54–59. [Google Scholar] [CrossRef]

- Cui, F.; Han, S.; Wang, J.; McClements, D.J.; Liu, X.; Liu, F. Co-delivery of curcumin and epigallocatechin gallate in W/O/W emulsions stabilized by protein fibril-cellulose complexes. Colloids Surf. B-Biointerfaces 2023, 222, 113072. [Google Scholar] [CrossRef] [PubMed]

- Aewsiri, T.; Benjakul, S.; Visessanguan, W. Functional properties of gelatin from cuttlefish (Sepia pharaonis) skin as affected by bleaching using hydrogen peroxide. Food Chem. 2009, 115, 243–249. [Google Scholar] [CrossRef]

- Glusac, J.; Isaschar-Ovdat, S.; Fishman, A. Transglutaminase modifies the physical stability and digestibility of chickpea protein-stabilized oil-in-water emulsions. Food Chem. 2020, 315, 126301. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.-J.; Choi, D.; Lee, J.; Jo, Y.-J. Encapsulation of a bioactive peptide in a formulation of W-1/O/W-2-type double emulsions: Formation and stability. Food Struct.-Neth. 2020, 25, 100145. [Google Scholar] [CrossRef]

- Arancibia, C.; Miranda, M.; Matiacevich, S.; Troncoso, E. Physical properties and lipid bioavailability of nanoemulsion-based matrices with different thickening agents. Food Hydrocoll. 2017, 73, 243–254. [Google Scholar] [CrossRef]

- Huang, K.; Liu, R.; Zhang, Y.; Guan, X. Characteristics of two cedarwood essential oil emulsions and their antioxidant and antibacterial activities. Food Chem. 2021, 346, 128970. [Google Scholar] [CrossRef]

- Yi, F.; Wu, K.; Yu, G.; Su, C. Preparation of Pickering emulsion based on soy protein isolate-gallic acid with outstanding antioxidation and antimicrobial. Colloids Surf. B-Biointerfaces 2021, 206, 111954. [Google Scholar] [CrossRef]

- Chen, M.; Li, W.; Wang, W.; Cao, Y.; Lan, Y.; Huang, Q.; Xiao, J. Effects of gelation on the stability, tribological properties and time-delayed release profile of double emulsions. Food Hydrocoll. 2022, 131, 107753. [Google Scholar] [CrossRef]

- Gharehbeglou, P.; Jafari, S.M.; Hamishekar, H.; Homayouni, A.; Mirzaei, H. Pectin-whey protein complexes vs. small molecule surfactants for stabilization of double nano-emulsions as novel bioactive delivery systems. J. Food Eng. 2019, 245, 139–148. [Google Scholar] [CrossRef]

- Tamnak, S.; Mirhosseini, H.; Tan, C.P.; Amid, B.T.; Kazemi, M.; Hedayatnia, S. Encapsulation properties, release behavior and physicochemical characteristics of water-in-oil-in-water (W/O/W) emulsion stabilized with pectin-pea protein isolate conjugate and Tween 80. Food Hydrocoll. 2016, 61, 599–608. [Google Scholar] [CrossRef]

- Peng, W.; Kong, X.; Chen, Y.; Zhang, C.; Yang, Y.; Hua, Y. Effects of heat treatment on the emulsifying properties of pea proteins. Food Hydrocoll. 2016, 52, 301–310. [Google Scholar] [CrossRef]

- Murillo-Martinez, M.M.; Pedroza-Islas, R.; Lobato-Calleros, C.; Martinez-Ferez, A.; Vernon-Carter, E.J. Designing W-1/O/W-2 double emulsions stabilized by protein-polysaccharide complexes for producing edible films: Rheological, mechanical and water vapour properties. Food Hydrocoll. 2011, 25, 577–585. [Google Scholar] [CrossRef]

- Matos, M.; Gutierrez, G.; Iglesias, O.; Coca, J.; Pazos, C. Enhancing encapsulation efficiency of food-grade double emulsions containing resveratrol or vitamin B-12 by membrane emulsification. J. Food Eng. 2015, 166, 212–220. [Google Scholar] [CrossRef]

- Huang, H.; Belwal, T.; Aalim, H.; Li, L.; Lin, X.; Liu, S.; Ma, C.; Li, Q.; Zou, Y.; Luo, Z. Protein-polysaccharide complex coated W/O/W emulsion as secondary microcapsule for hydrophilic arbutin and hydrophobic coumaric acid. Food Chem. 2019, 300, 125171. [Google Scholar] [CrossRef]

- Paximada, P.; Tsouko, E.; Kopsahelis, N.; Koutinas, A.A.; Mandala, I. Bacterial cellulose as stabilizer of o/w emulsions. Food Hydrocoll. 2016, 53, 225–232. [Google Scholar] [CrossRef]

- Lutz, R.; Aserin, A.; Wicker, L.; Garti, N. Double emulsions stabilized by a charged complex of modified pectin and whey protein isolate. Colloids Surf. B Biointerfaces 2009, 72, 121–127. [Google Scholar] [CrossRef]

- Gao, Z.-M.; Wang, J.-M.; Wu, N.-N.; Wan, Z.-L.; Guo, J.; Yang, X.-Q.; Yin, S.-W. Formation of Complex Interface and Stability of Oil-in-Water (O/W) Emulsion Prepared by Soy Lipophilic Protein Nanoparticles. J. Agric. Food Chem. 2013, 61, 7838–7847. [Google Scholar] [CrossRef]

- Jiang, Z.; Tian, J.; Bai, X.; McClements, D.J.; Ma, C.; Liu, X.; Liu, F. Improving probiotic survival using water-in-oil-in-water (W1/O/W2) emulsions: Role of fish oil in inner phase and sodium alginate in outer phase. Food Chem. 2023, 417, 135889. [Google Scholar] [CrossRef]

- He, J.; Wu, X.; Xie, Y.; Gao, Y.; McClements, D.J.; Zhang, L.; Zou, L.; Liu, W. Capsaicin encapsulated in W/O/W double emulsions fabricated via ethanol-induced pectin gelling: Improvement of bioaccessibility and reduction of irritation. Int. J. Biol. Macromol. 2023, 235, 123899. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Decker, E.A.; Xiao, H.; McClements, D.J. Nanoemulsion delivery systems: Influence of carrier oil on beta-carotene bioaccessibility. Food Chem. 2012, 135, 1440–1447. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Liang, X.; Ma, C.; McClements, D.J.; Liu, X.; Liu, F. Design and characterization of double-cross-linked emulsion gels using mixed biopolymers: Zein and sodium alginate. Food Hydrocoll. 2021, 113, 106473. [Google Scholar] [CrossRef]

- Dima, C.; Dima, S. Bioaccessibility study of calcium and vitamin D-3 co-microencapsulated in water-in-oil-in-water double emulsions. Food Chem. 2020, 303, 125416. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, T.; Wu, X.; Gao, Y.; Teng, F.; Li, Y. Co-Delivery System of Vitamin B12 and Vitamin E Using a Binary W/O/W Emulsion Based on Soybean Isolate Protein–Xanthan Gum/Carrageenan: Emulsification Properties, Rheological Properties, Structure, Stability, and Digestive Characteristics. Foods 2023, 12, 4361. https://doi.org/10.3390/foods12234361

Gao T, Wu X, Gao Y, Teng F, Li Y. Co-Delivery System of Vitamin B12 and Vitamin E Using a Binary W/O/W Emulsion Based on Soybean Isolate Protein–Xanthan Gum/Carrageenan: Emulsification Properties, Rheological Properties, Structure, Stability, and Digestive Characteristics. Foods. 2023; 12(23):4361. https://doi.org/10.3390/foods12234361

Chicago/Turabian StyleGao, Tian, Xixi Wu, Yiting Gao, Fei Teng, and Yang Li. 2023. "Co-Delivery System of Vitamin B12 and Vitamin E Using a Binary W/O/W Emulsion Based on Soybean Isolate Protein–Xanthan Gum/Carrageenan: Emulsification Properties, Rheological Properties, Structure, Stability, and Digestive Characteristics" Foods 12, no. 23: 4361. https://doi.org/10.3390/foods12234361

APA StyleGao, T., Wu, X., Gao, Y., Teng, F., & Li, Y. (2023). Co-Delivery System of Vitamin B12 and Vitamin E Using a Binary W/O/W Emulsion Based on Soybean Isolate Protein–Xanthan Gum/Carrageenan: Emulsification Properties, Rheological Properties, Structure, Stability, and Digestive Characteristics. Foods, 12(23), 4361. https://doi.org/10.3390/foods12234361