The Effect of Terminal Freezing and Thawing on the Quality of Frozen Dough: From the View of Water, Starch, and Protein Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and TFT Treatment of Dough

2.3. Texture Properties

2.4. Dynamic Rheological Properties

2.5. The Content of Freezable Water

2.6. Water Distribution

2.7. Pasting Properties

2.8. Protein Parameters

2.8.1. SDS-PAGE

2.8.2. Free Thiol Group (SH) Content

2.8.3. Protein Secondary Structure

2.9. SEM

2.10. Statistical Analysis

3. Results and Discussion

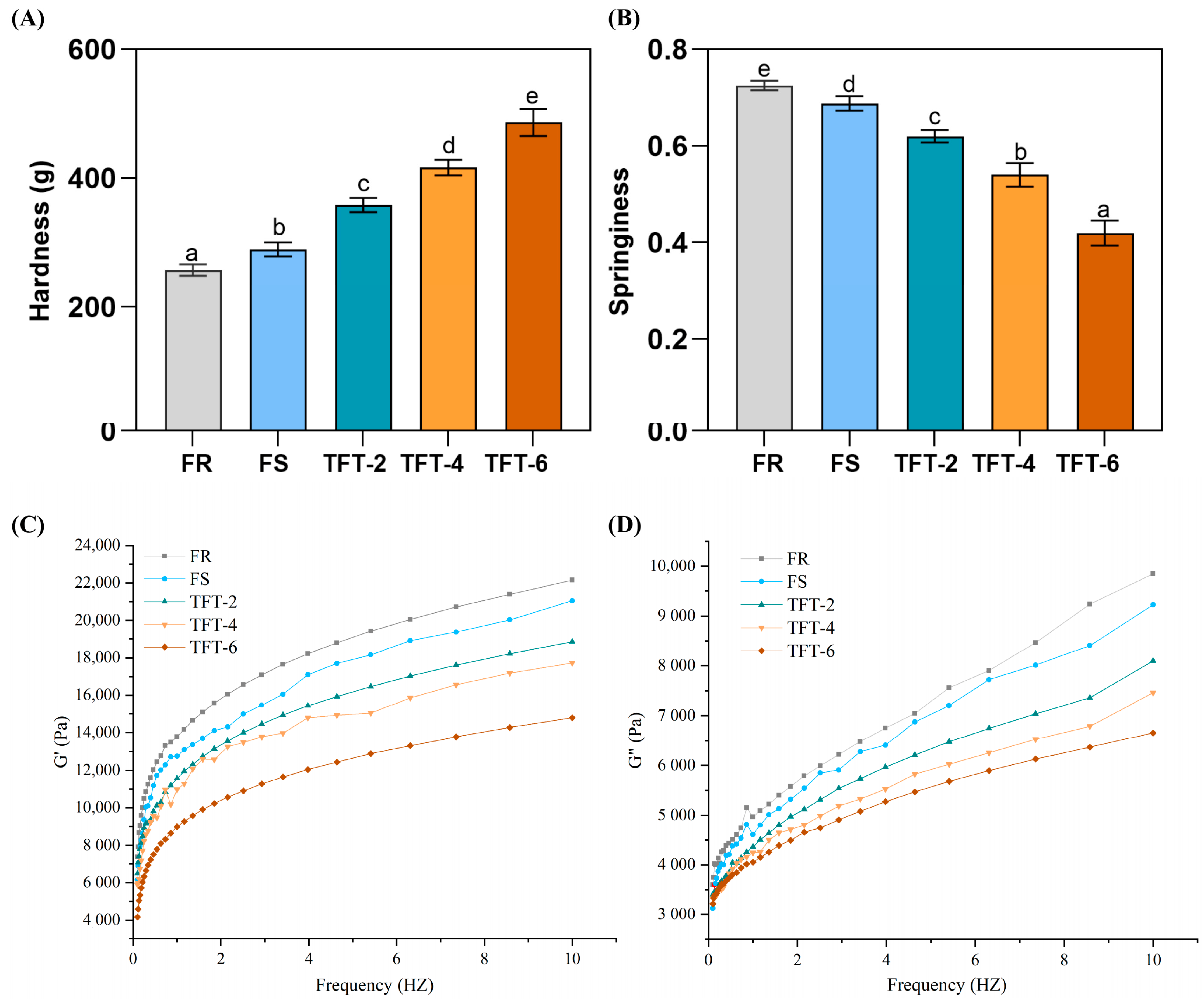

3.1. The Texture Properties of the Dough after TFT Treatment

3.2. Dynamic Rheology Property

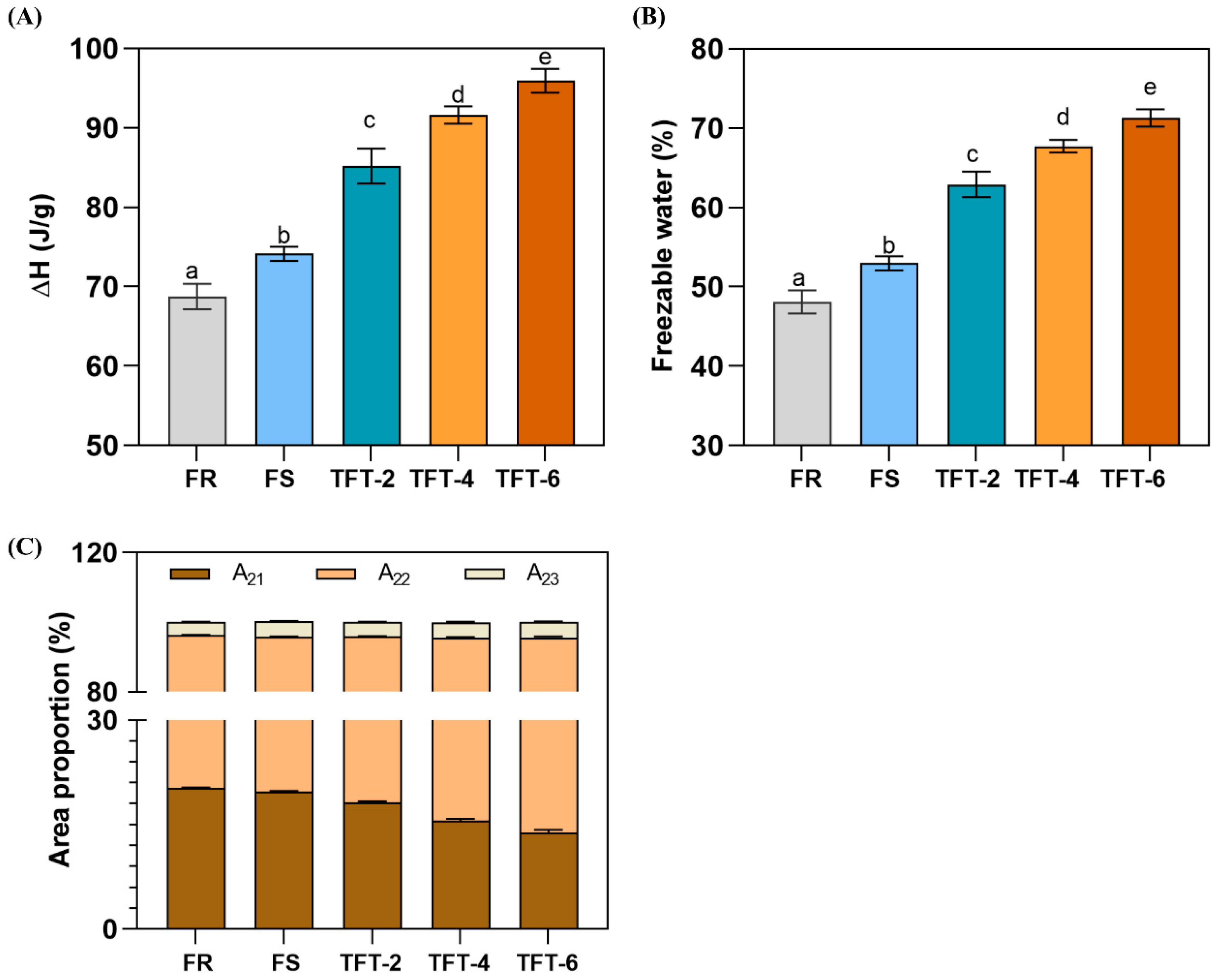

3.3. Freezable Water

3.4. The Water Migration of the Dough after TFT Treatment

3.5. Pasting Properties

3.6. SDS-PAGE

3.7. SH Content

3.8. Secondary Structure of Gluten

3.9. SEM

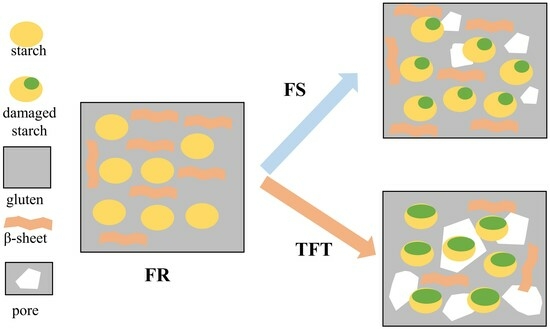

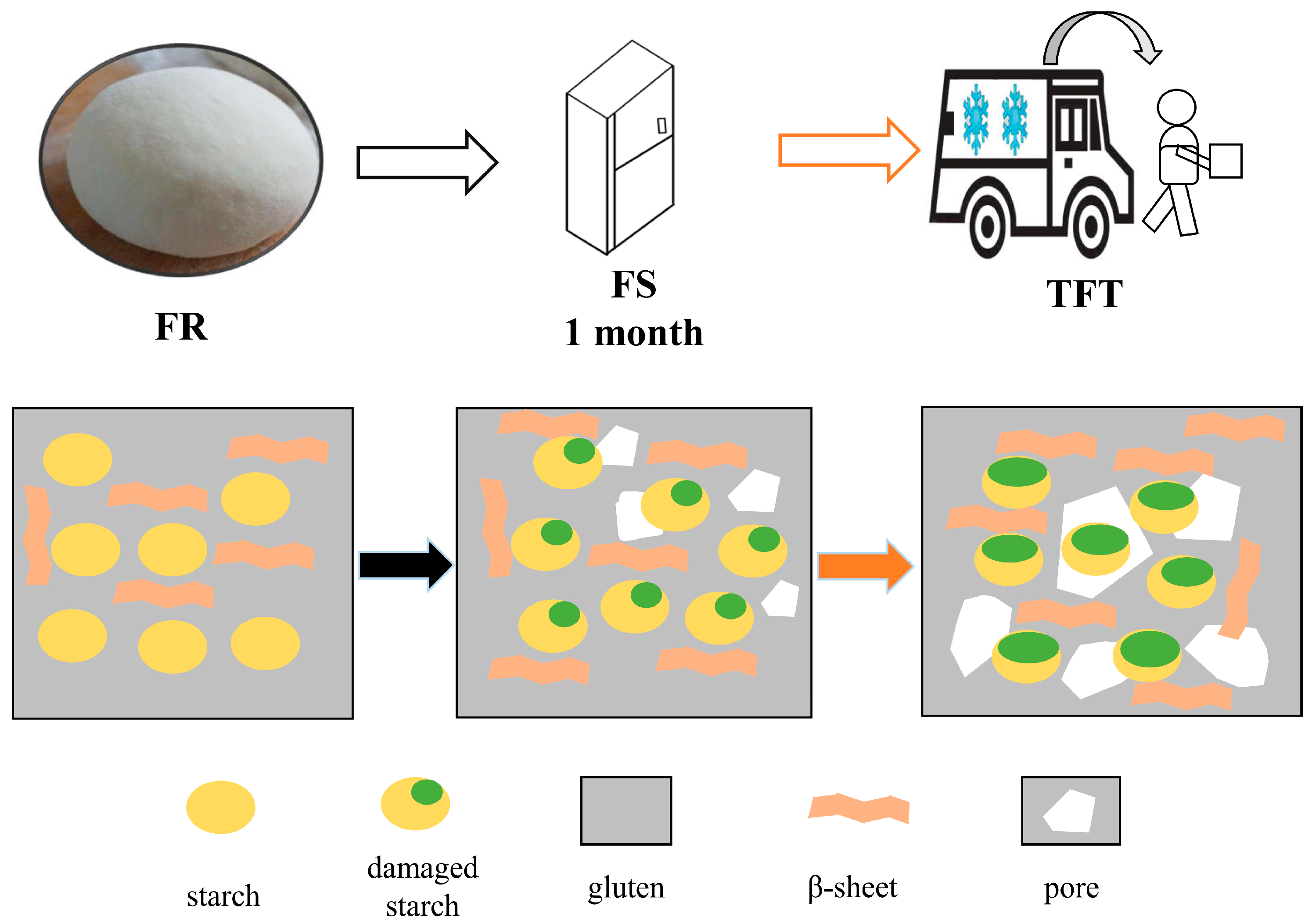

3.10. Schematic Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, Y.; Liu, X.; Xie, Q.; Chen, L.; Chang, C.; Wu, W.; Xiao, S.; Wang, X. Effects of Laminaria japonica polysaccharides on the texture, retrogradation, and structure performances in frozen dough bread. LWT-Food Sci. Technol. 2021, 151, 112239. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, Q.; Sun, D. Measuring and controlling ice crystallization in frozen foods: A review of recent developments. Trends Food Sci. Technol. 2019, 90, 13–25. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Ding, B.; Ding, W.; Xiao, S.; Song, J.; Lyu, Q.; Ke, Y.; Wang, X.; Fu, Y. Effect of hydrocolloids on physical, thermal and microstructure properties of par-baked baguette during frozen storage. Int. J. Biol. Macromol. 2020, 163, 1866–1874. [Google Scholar] [CrossRef]

- Lu, L.; Yang, Z.; Guo, X.; Xing, J.; Zhu, K. Effect of NaHCO3 and freeze–thaw cycles on frozen dough: From water state, gluten polymerization and microstructure. Food Chem. 2021, 358, 129869. [Google Scholar] [CrossRef]

- Luo, W.; Sun, D.; Zhu, Z.; Wang, Q. Improving freeze tolerance of yeast and dough properties for enhancing frozen dough quality—A review of effective methods. Trends Food Sci. Tech. 2018, 72, 25–33. [Google Scholar] [CrossRef]

- Zheng, K.; Chen, Z.; Fu, Y.; Chen, L.; Zhu, X.; Chen, X.; Ding, W. Effect of tea polyphenols on the storage stability of non-fermented frozen dough: Protein structures and state of water. Foods 2023, 12, 80. [Google Scholar] [CrossRef]

- He, N.; Pan, Z.; Li, L.; Zhang, X.; Yuan, Y.; Yang, Y.; Han, S.; Li, B. Improving the microstructural and rheological properties of frozen unfermented wheat dough with laccase and ferulic acid. Foods 2023, 12, 2772. [Google Scholar] [CrossRef]

- Yaqoob, S.; Liu, H.; Zhao, C.; Liu, M.; Cai, D.; Liu, J. Influence of multiple freezing/thawing cycles on a structural, rheological, and textural profile of fermented and unfermented corn dough. Food Sci. Nutr. 2019, 7, 3471–3479. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, S.; Tian, C.; Yan, G.; Wang, D. An overview of current status of cold chain in China. Int. J. Refrig. 2018, 88, 483–495. [Google Scholar] [CrossRef]

- Ndraha, N.; Hsiao, H.; Vlajic, J.; Yang, M.; Lin, H. Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. Food Control 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, H.; Wang, L.; Qian, H.; Qi, X.; Xiao, J. Effect of barley antifreeze protein on thermal properties and water state of dough during freezing and freeze-thaw cycles. Food Hydrocoll. 2015, 47, 32–40. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, B.; Zhang, Y.; Rasheed, M.; Gu, S.; Guo, B. Effect of freezing rate and frozen storage on the rheological properties and protein structure of non-fermented doughs. J. Food Eng. 2021, 293, 110377. [Google Scholar] [CrossRef]

- Fujii, K.; Usui, M.; Ohsuga, A.; Tsuji, M. Effect of Thermoresponsive Xyloglucan on the Bread-Making Properties and Preservation of Gluten-Free Rice-Flour Bread. Foods 2023, 12, 2761. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, P.; Zhang, T.; Wang, Z.; Cai, D.; Chen, X.; Shen, Y.; Xu, J.; Song, C.; Goff, D. Effect of carboxymethyl chitosan on the storage stability of frozen dough: State of water, protein structures and quality attributes. Food Res. Int. 2022, 151, 110863. [Google Scholar] [CrossRef]

- Jia, Z.; Luo, Y.; Barba, F.; Wu, Y.; Ding, W.; Xiao, S.; Lyu, Q.; Wang, X.; Fu, Y. Effect of β-cyclodextrins on the physical properties and anti-staling mechanisms of corn starch gels during storage. Carbohyd. Polym. 2022, 284, 119187. [Google Scholar] [CrossRef]

- Liu, Y.; Leng, Y.; Xiao, S.; Zhang, Y.; Ding, W.; Ding, B.; Wu, Y.; Wang, X.; Fu, Y. Effect of inulin with different degrees of polymerization on dough rheology, gelatinization, texture and protein composition properties of extruded flour products. LWT-Food Sci. Technol. 2022, 159, 113225. [Google Scholar] [CrossRef]

- Zhou, J.; Jia, Z.; Wang, M.; Wang, Q.; Barba, F.; Wan, L.; Wang, X.; Fu, Y. Effects of Laminaria japonica polysaccharides on gelatinization properties and long-term retrogradation of wheat starch. Food Hydrocoll. 2022, 133, 107908. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, D.; Guo, L.; Zhou, H.; Wu, F.; Xu, X. The contribution of particle-size distribution to the physiochemical properties of total wheat starch during freezing. Cereal Chem. 2021, 98, 604–615. [Google Scholar] [CrossRef]

- Wang, P.; Yang, R.; Gu, Z.; Xu, X.; Jin, Z. Comparative study on the freeze stability of yeast and chemical leavened steamed bread dough. Food Chem. 2017, 221, 482–488. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Liu, Y.; Zhang, H. Effects of multiple freeze–thaw cycles on the quality of frozen dough. Cereal Chem. 2018, 95, 499–507. [Google Scholar] [CrossRef]

- Liu, H.; Wan, L.; Xiao, S.; Fu, Y.; Wang, X. Changes in the physicochemical and protein distribution properties of dough with the wheat oligopeptide incorporation. Food Biosci. 2023, 52, 102354. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Li, M.; Liu, C.; Zheng, X.; Hong, J.; Bian, K.; Li, L. Interaction between A-type/B-type starch granules and gluten in dough during mixing. Food Chem. 2021, 358, 129870. [Google Scholar] [CrossRef]

- Zhu, J.; Li, L.; Zhao, L.; Song, L.; Li, X. Effects of freeze–thaw cycles on the structural and thermal properties of wheat gluten with variations in the high molecular weight glutenin subunit at the Glu-B1 locus. J. Cereal Sci. 2019, 87, 266–272. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Ren, G.; Cui, G.; Han, S.; Liu, J. Effects of konjac glucomannan on the water distribution of frozen dough and corresponding steamed bread quality. Food Chem. 2020, 330, 127243. [Google Scholar] [CrossRef]

- Gaikwad, S.; Arya, S. Influence of frozen storage on quality of multigrain dough, par baked and ready to eat thalipeeth with additives. LWT-Food Sci. Technol. 2018, 96, 350–356. [Google Scholar] [CrossRef]

- Guo, L.; Fang, F.; Zhang, Y.; Xu, D.; Jin, Z.; Xu, X. Glutathione affects rheology and water distribution of wheat dough by changing gluten conformation and protein depolymerisation. Int. J. Food Sci. Technol. 2021, 56, 3157–3165. [Google Scholar] [CrossRef]

- Kontogiorgos, V. Microstructure of hydrated gluten network. Food Res. Int. 2011, 44, 2582–2586. [Google Scholar] [CrossRef]

- Ma, S.; Li, L.; Wang, X.; Zheng, X.; Bian, K.; Bao, Q. Effect of mechanically damaged starch from wheat flour on the quality of frozen dough and steamed bread. Food Chem. 2016, 202, 120–124. [Google Scholar] [CrossRef]

- Xie, Q.; Liu, X.; Xiao, S.; Pan, W.; Wu, Y.; Ding, W.; Lyu, Q.; Wang, X.; Fu, Y. Effect of mulberry leaf polysaccharides on the baking and staling properties of frozen dough bread. J. Sci. Food Agric. 2022, 102, 6071–6079. [Google Scholar] [CrossRef]

- Qian, X.; Gu, Y.; Sun, B.; Wang, X. Changes of aggregation and structural properties of heat-denatured gluten proteins in fast-frozen steamed bread during frozen storage. Food Chem. 2021, 365, 130492. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, X.; Liu, X.; Liu, W.; Liu, Q.; Huang, J.; Zhang, L.; Hu, H. Effect of salt ions on mixed gels of wheat gluten protein and potato isolate protein. LWT-Food Sci. Technol. 2022, 154, 112564. [Google Scholar] [CrossRef]

- Koh, B.; Lee, G.; Lim, S. Effect of Amino Acids and Peptides on Mixing and Frozen Dough Properties of Wheat Flour. J. Food Sci. 2005, 70, s359–s364. [Google Scholar] [CrossRef]

- Lu, L.; Zhu, K. Physicochemical and fermentation properties of pre-fermented frozen dough: Comparative study of frozen storage and freeze–thaw cycles. Food Hydrocoll. 2023, 136, 108253. [Google Scholar] [CrossRef]

- Wang, P.; Jin, Z.; Xu, X. Physicochemical alterations of wheat gluten proteins upon dough formation and frozen storage—A review from gluten, glutenin and gliadin perspectives. Trends Food Sci. Technol. 2015, 46, 189–198. [Google Scholar] [CrossRef]

- Wang, P.; Zou, M.; Li, D.; Zhou, Y.; Jiang, D.; Yang, R.; Gu, Z. Conformational rearrangement and polymerization behavior of frozen-stored gluten during thermal treatment. Food Hydrocoll. 2020, 101, 105502. [Google Scholar] [CrossRef]

- Wang, P.; Wu, F.; Rasoamandrary, N.; Jin, Z.; Xu, X. Frozen-induced depolymerization of glutenin macropolymers: Effect of the frozen storage time and gliadin content. J. Cereal Sci. 2015, 62, 159–162. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Mujumdar, A. Application of physical field-assisted freezing and thawing to mitigate damage to frozen food. J. Sci. Food Agric. 2023, 103, 2223–2238. [Google Scholar] [CrossRef]

- Liu, H.; Guo, X.; Zhu, K. Effects of freeze-thaw cycles on the quality of frozen raw noodles. Food Chem. 2022, 387, 132940. [Google Scholar] [CrossRef]

- Zhao, B.; Fu, S.; Li, H.; Li, H.; Liu, C.; Chen, Z. Effect of storage conditions on the quality of frozen steamed bread. Int. J. Food Sci. Technol. 2022, 57, 695–704. [Google Scholar] [CrossRef]

| Samples | PV (cP) | BD (cP) | ST (cP) | PT (°C) |

|---|---|---|---|---|

| FR | 857 ± 12 a | 305 ± 6 a | 545 ± 5 a | 95.35 ± 0.05 d |

| FS | 919 ± 9 b | 320 ± 7 b | 574 ± 4 b | 95.25 ± 0.06 d |

| TFT-2 | 960 ± 15 c | 332 ± 8 c | 644 ± 8 c | 95.00 ± 0.02 c |

| TFT-4 | 991 ± 11 d | 394 ± 6 d | 665 ± 9 d | 94.50 ± 0.05 b |

| TFT-6 | 1134 ± 12 e | 423 ± 8 e | 718 ± 7 e | 93.50 ± 0.04 a |

| Samples | Secondary Structure (%) | |||

|---|---|---|---|---|

| α-Helix | β-Sheet | β-Turn | Random Coil | |

| FR | 17.53 ± 0.06 d | 26.50 ± 0.10 a | 40.37 ± 0.21 d | 15.60 ± 0.12 a |

| FS | 17.42 ± 0.09 d | 26.87 ± 0.13 b | 39.96 ± 0.12 c | 15.75 ± 0.11 a |

| TFT-2 | 17.37 ± 0.08 c | 27.27 ± 0.09 c | 39.02 ± 0.13 b | 16.34 ± 0.13 b |

| TFT-4 | 17.16 ± 0.13 b | 27.79 ± 0.18 d | 38.57 ± 0.19 a | 16.48 ± 0.09 b |

| TFT-6 | 16.95 ± 0.08 a | 28.17 ± 0.13 e | 38.23 ± 0.15 a | 16.65 ± 0.10 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, L.; Chen, L.; Liu, D.; Liu, H.; Jiang, D.; Fu, Y.; Wang, X. The Effect of Terminal Freezing and Thawing on the Quality of Frozen Dough: From the View of Water, Starch, and Protein Properties. Foods 2023, 12, 3888. https://doi.org/10.3390/foods12213888

Liu X, Chen L, Chen L, Liu D, Liu H, Jiang D, Fu Y, Wang X. The Effect of Terminal Freezing and Thawing on the Quality of Frozen Dough: From the View of Water, Starch, and Protein Properties. Foods. 2023; 12(21):3888. https://doi.org/10.3390/foods12213888

Chicago/Turabian StyleLiu, Xiaorong, Luncai Chen, Lei Chen, Dezheng Liu, Hongyan Liu, Dengyue Jiang, Yang Fu, and Xuedong Wang. 2023. "The Effect of Terminal Freezing and Thawing on the Quality of Frozen Dough: From the View of Water, Starch, and Protein Properties" Foods 12, no. 21: 3888. https://doi.org/10.3390/foods12213888

APA StyleLiu, X., Chen, L., Chen, L., Liu, D., Liu, H., Jiang, D., Fu, Y., & Wang, X. (2023). The Effect of Terminal Freezing and Thawing on the Quality of Frozen Dough: From the View of Water, Starch, and Protein Properties. Foods, 12(21), 3888. https://doi.org/10.3390/foods12213888