Discrimination of Glutopeak Test and Mixograph Parameters for Evaluation of Wheat Flour Supplemented with Hazelnut Skin, Cross-Linked Starch, and Oxidized Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Dough Quality

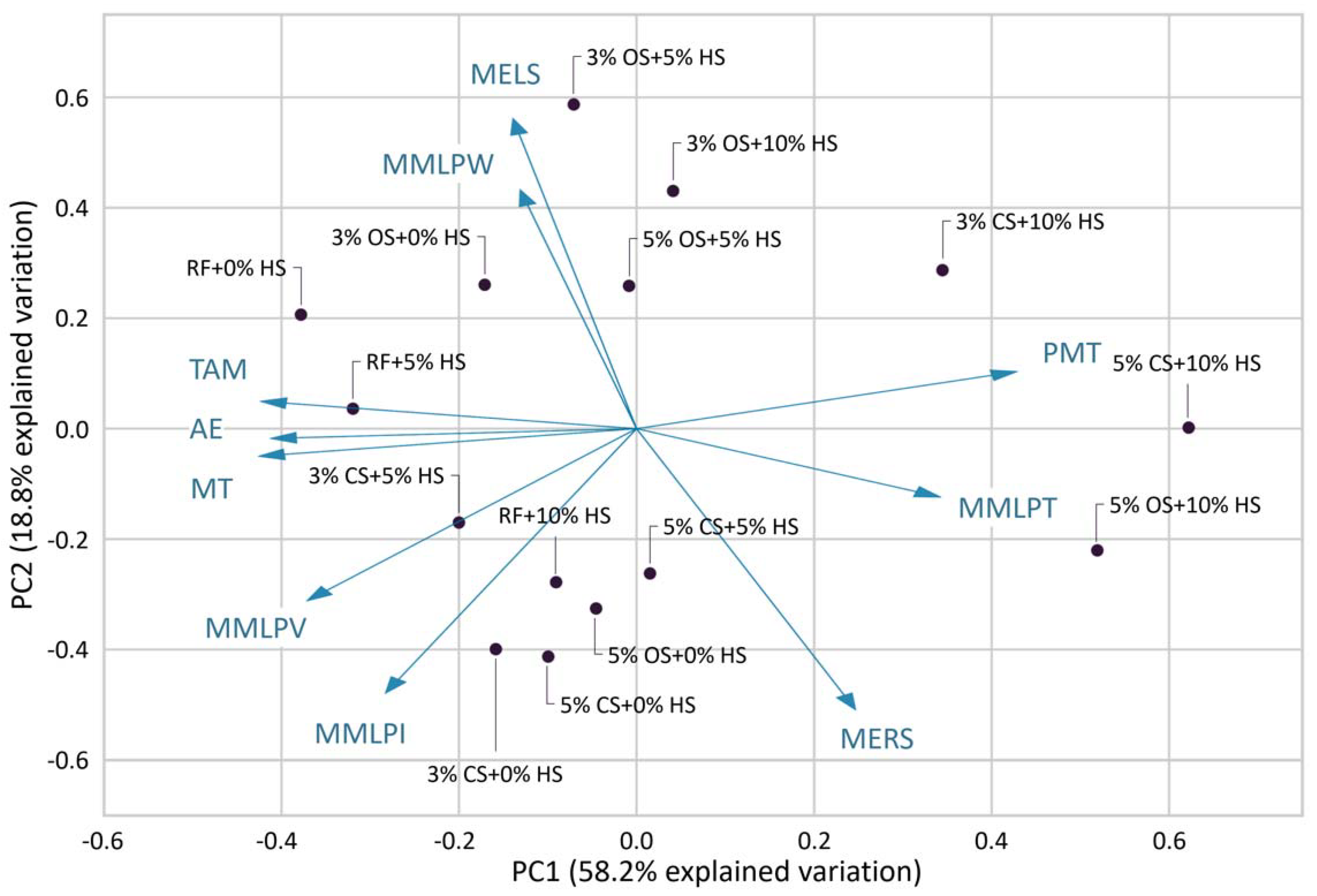

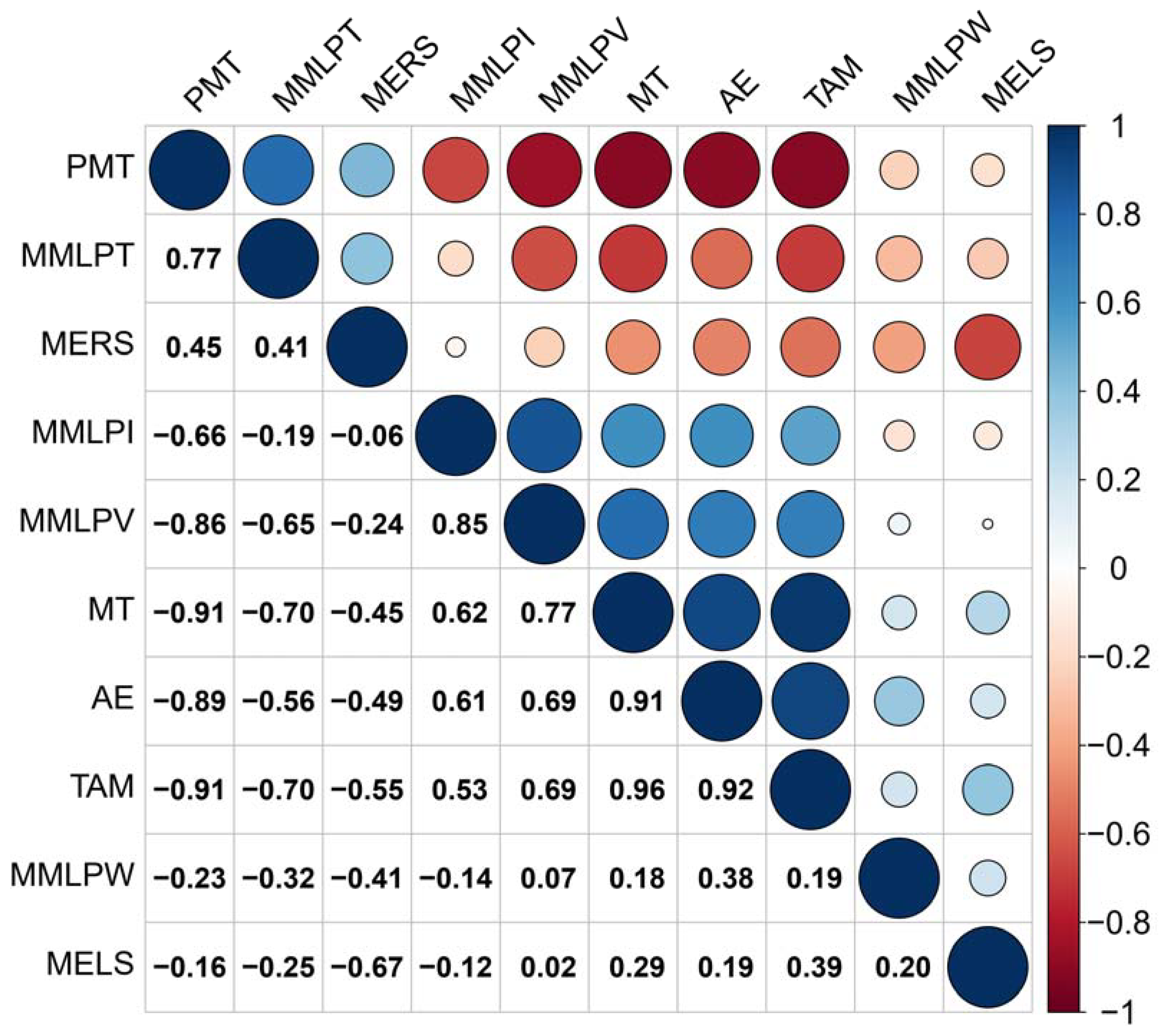

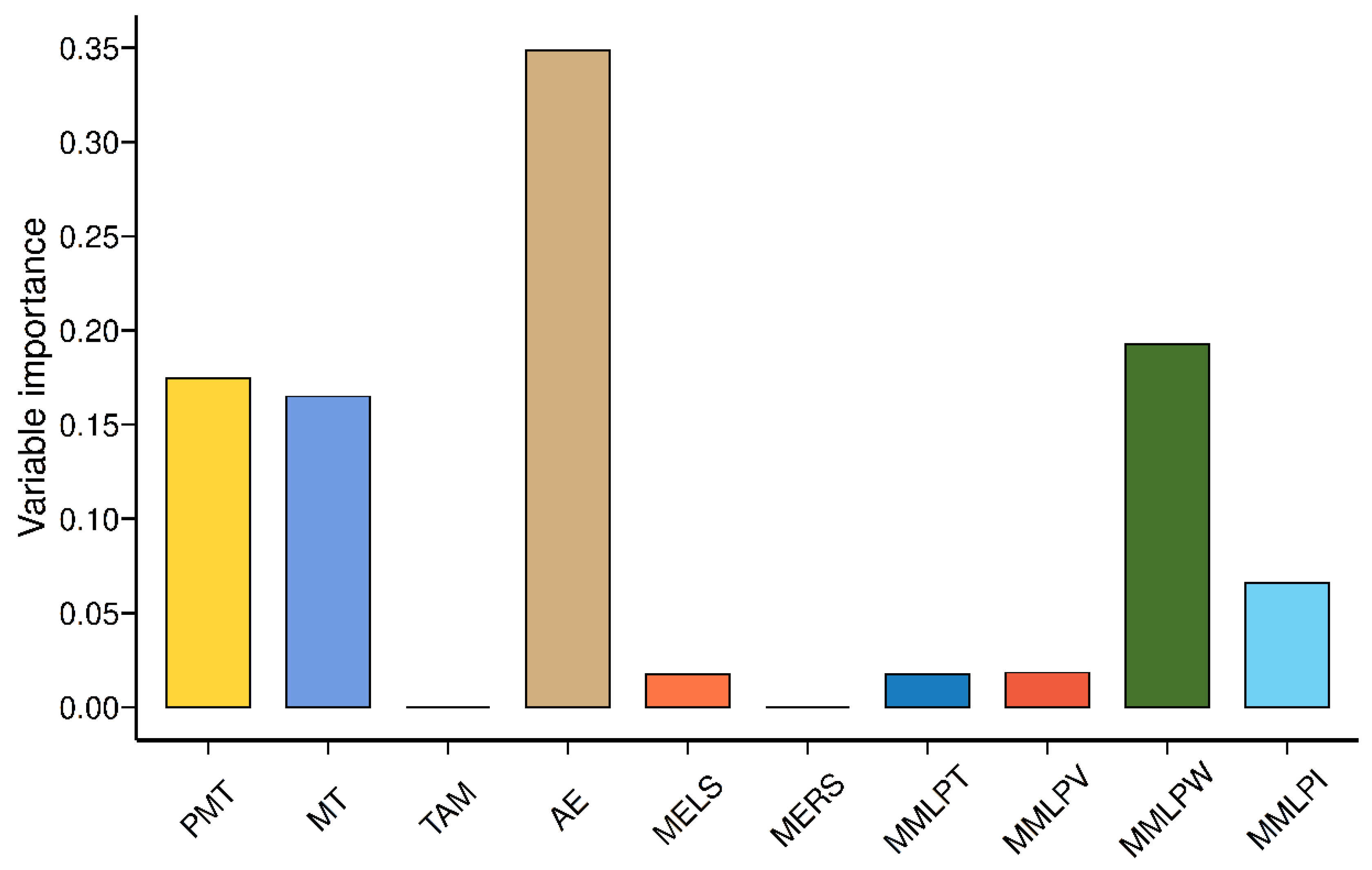

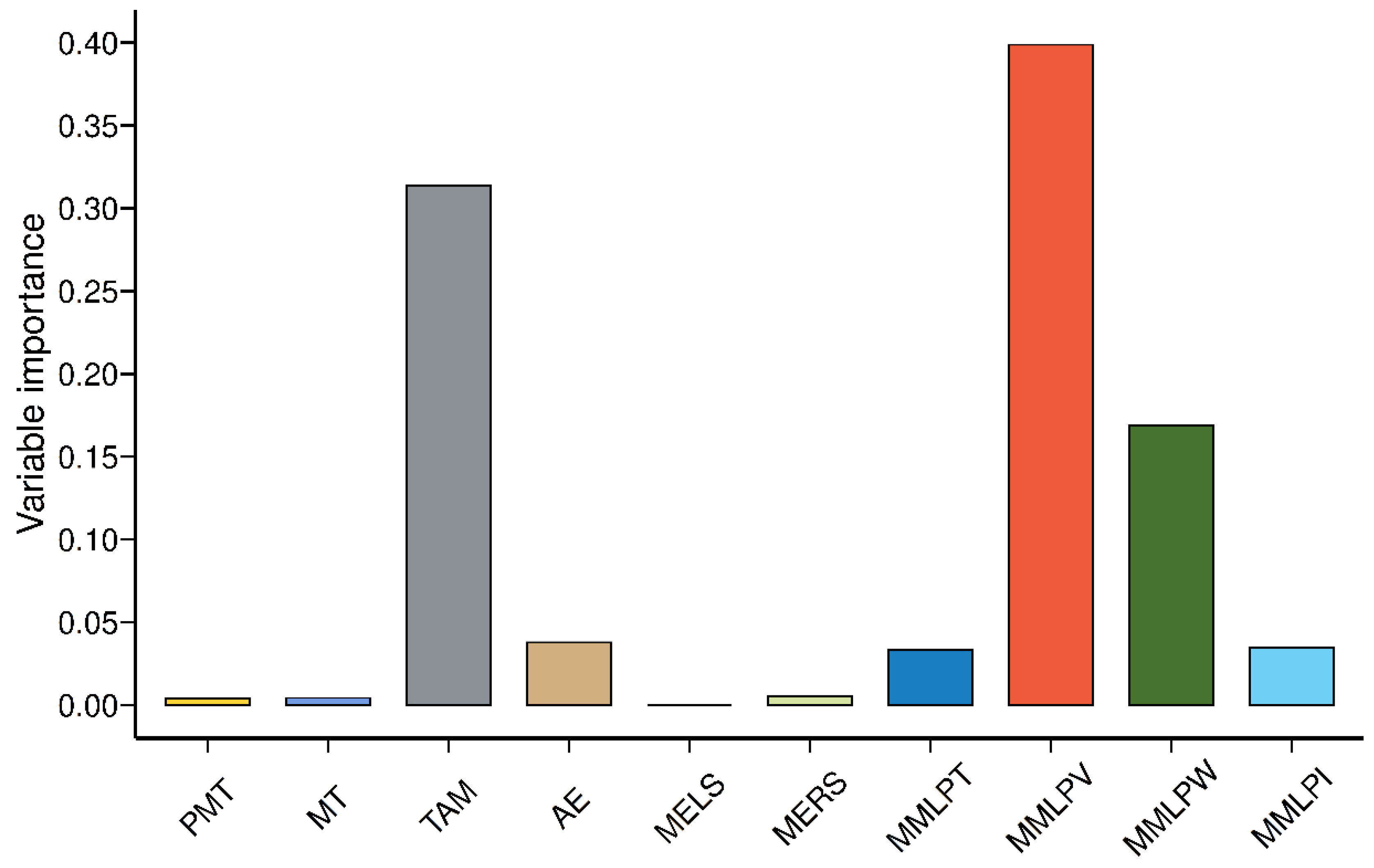

2.3. Principal Component Analysis (PCA) and Random Forest (RFT)

2.4. Statistical Analysis

3. Results and Discussion

3.1. Glutopeak Test

3.2. Mixograph Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alasalvar, C.; Karamac, M.; Kosinska, A.; Rybarczyk, A.; Shahidi, F.; Amarowicz, R. Antioxidant activity of hazelnut skin phenolics. J. Agric. Food Chem. 2009, 57, 4645–4650. [Google Scholar] [CrossRef] [PubMed]

- Durmus, Y.; Anil, M.; Simsek, S. Effects of hazelnut skin, cross-linked starch, and oxidized starch on wheat flour and dough quality. J. Food Process. Preserv. 2021, 45, e14919. [Google Scholar] [CrossRef]

- Anil, M. Using of hazelnut testa as a source of dietary fiber in bread-making. J. Food Eng. 2007, 80, 61–67. [Google Scholar] [CrossRef]

- Han, W.; Ma, S.; Li, L.; Zheng, X.; Wang, X. Impact of wheat bran dietary fiber on gluten and gluten-starch microstructure formation in dough. Food Hydrocoll. 2019, 95, 292–297. [Google Scholar] [CrossRef]

- Velioglu, S.D.; Güner, K.G.; Velioğlu, H.M.; Çelikyurt, G. The use of hazelnut testa in bakery products. J. Tekirdag Agric. Fac. 2017, 14, 127–139. [Google Scholar]

- Singh, J.; Kaur, L.; McCarthy, O. Factors influencing the physico-chemical, morphological, thermal and rheological properties of some chemically modified starches for food applications—A review. Food Hydrocoll. 2007, 21, 1–22. [Google Scholar] [CrossRef]

- Miller, R.A.; Bianchi, E. Effect of RS4 resistant starch on dietary fiber content of white pan bread. Cereal Chem. J. 2017, 94, 185–189. [Google Scholar] [CrossRef]

- Xinwen, Z.; Haizhou, D.; Chuanfu, L.; Yuqiu, G.; Xiao, L. Effects of Potato Oxidized Starch on Dough Characteristics and Quality of Steamed bread. J. Chin. Cereals Oils Assoc. 2014, 29, 6–10. [Google Scholar]

- Chittrakorn, S. Use of Ozone as an Alternative to Chlorine for Treatment of Soft Wheat Flours; Kansas State University: Manhattan, KS, USA, 2008. [Google Scholar]

- Sui, Z.; Yao, T.; Zhong, J.; Li, Y.; Kong, X.; Ai, L. Ozonation treatment improves properties of wheat flour and the baking quality of cake. Philipp. Agric. Sci. 2016, 99, 50–57. [Google Scholar]

- Chandi, G.K.; Seetharaman, K. Optimization of gluten peak tester: A statistical approach. J. Food Qual. 2012, 35, 69–75. [Google Scholar] [CrossRef]

- Cereals and Grains Association. AACC International Approved Methods of Analysis; Updated 8 November 2009; AACC International: St. Paul, MN, USA, 2009; Available online: http://methods.aaccnet.org/ (accessed on 20 February 2019).

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef] [PubMed]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Marti, A.; Augst, E.; Cox, S.; Koehler, P. Correlations between gluten aggregation properties defined by the GlutoPeak test and content of quality-related protein fractions of winter wheat flour. J. Cereal Sci. 2015, 66, 89–95. [Google Scholar] [CrossRef]

- Sissons, M. GlutoPeak: A Breeding Tool for Screening Dough Properties of Durum Wheat Semolina. Cereal Chem. J. 2016, 93, 550–556. [Google Scholar] [CrossRef]

- Wang, K.; Dupuis, B.; Fu, B.X. Gluten Aggregation Behavior in High-Shear-Based GlutoPeak Test: Impact of Flour Water Absorption and Strength. Cereal Chem. 2017, 94, 909–915. [Google Scholar] [CrossRef]

- Marti, A.; Cecchini, C.; D’Egidio, M.G.; Dreisoerner, J.; Pagani, M.A. Characterization of Durum Wheat Semolina by Means of a Rapid Shear-Based Method. Cereal Chem. 2014, 91, 542–547. [Google Scholar] [CrossRef]

- Cardone, G.; D’Incecco, P.; Casiraghi, M.C.; Marti, A. Exploiting milling by-products in bread-making: The case of sprouted wheat. Foods 2020, 9, 260. [Google Scholar] [CrossRef]

- Wang, K.; Sangha, J.; Cuthbert, R.; Fu, B.X. Effectiveness and biochemical basis of wholemeal GlutoPeak test in predicting water absorption and gluten strength of Canadian hard red spring wheat. Cereal Chem. 2021, 98, 878–890. [Google Scholar] [CrossRef]

- Girard, A.L.; Castell-Perez, M.E.; Bean, S.R.; Adrianos, S.L.; Awika, J.M. Effect of condensed tannin profile on wheat flour dough rheology. J. Agric. Food Chem. 2016, 64, 7348–7356. [Google Scholar] [CrossRef]

- Wang, J.; Hou, G.G.; Liu, T.; Wang, N.; Bock, J. GlutoPeak method improvement for gluten aggregation measurement of whole wheat flour. LWT 2018, 90, 8–14. [Google Scholar] [CrossRef]

- Güçbilmez, Ç.M.; Şahin, M.; Akçacık, A.G.; Aydoğan, S.; Demir, B.; Hamzaoğlu, S.; Gür, S.; Yakışır, E. Evaluation of GlutoPeak test for prediction of bread wheat flour quality, rheological properties and baking performance. J. Cereal Sci. 2019, 90, 102827. [Google Scholar] [CrossRef]

- Rakita, S.; Dokić, L.; Dapčević Hadnađev, T.; Hadnađev, M.; Torbica, A. Predicting rheological behavior and baking quality of wheat flour using a GlutoPeak test. J. Texture Stud. 2018, 49, 339–347. [Google Scholar] [CrossRef] [PubMed]

- Sozer, N.; Cicerelli, L.; Heiniö, R.-L.; Poutanen, K. Effect of wheat bran addition on in vitro starch digestibility, physico-mechanical and sensory properties of biscuits. J. Cereal Sci. 2014, 60, 105–113. [Google Scholar] [CrossRef]

- Barros, F.; Awika, J.; Rooney, L.W. Effect of molecular weight profile of sorghum proanthocyanidins on resistant starch formation. J. Sci. Food Agric. 2014, 94, 1212–1217. [Google Scholar] [CrossRef]

- Demirkesen, I.; Campanella, O.H.; Sumnu, G.; Sahin, S.; Hamaker, B.R. A Study on Staling Characteristics of Gluten-Free Breads Prepared with Chestnut and Rice Flours. Food Bioprocess. Technol. 2013, 7, 806–820. [Google Scholar] [CrossRef]

- Dubat, A.; Rosell, C.M.; Gallagher, E. Mixolab: A New Approach to Rheology; Academic Press: Minneapolis, MN, USA, 2016; p. 117. [Google Scholar]

- Wang, Q.; Li, Y.; Sun, F.; Li, X.; Wang, P.; Sun, J.; Zeng, J.; Wang, C.; Hu, W.; Chang, J.; et al. Tannins improve dough mixing properties through affecting physicochemical and structural properties of wheat gluten proteins. Food Res. Int. 2015, 69, 64–71. [Google Scholar] [CrossRef]

- Al-Foudari, M.; Sidhu, J.S.; Alhazza, A. Effect of psyllium husk and wheat mill bran fractions on the microstructure and mixograph characteristics of Arabic bread. Saudi J. Biol. Sci. 2022, 29, 103479. [Google Scholar] [CrossRef]

- Chen, J.; Fei, M.; Shi, C.; Tian, J.; Sun, C.; Zhang, H.; Ma, Z.; Dong, H. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011, 53, 217–224. [Google Scholar] [CrossRef]

- Chung, O.; Ohm, J.; Caley, M.; Seabourn, B. Prediction of baking characteristics of hard winter wheat flours using computer-analyzed mixograph parameters. Cereal Chem. 2001, 78, 493–497. [Google Scholar] [CrossRef]

- Ma, F.; Baik, B.K. Qualitative effect of added gluten on dough properties and quality of Chinese steamed bread. Cereal Chem. 2017, 94, 827–833. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Blanco, C.A.; Caballero, P.A.; Apesteguía, A. Effect of dietary fibre on dough rheology and bread quality. Eur. Food Res. Technol. 2003, 216, 51–56. [Google Scholar] [CrossRef]

| Modified Starch | Hazelnut Skin | PMT | MT | TAM | AE | |

|---|---|---|---|---|---|---|

| (%) | (%) | (sec.) | (GPU) | (GPU) | (AU) | |

| Refined flour | 0 | 0 | 58.5 h | 75.0 a | 55.5 ab | 1741.6 ab |

| Refined flour | 0 | 5 | 58.5 h | 74.0 ab | 56.0 a | 1748.2 a |

| Refined flour | 0 | 10 | 70.5 cdef | 70.0 cde | 51.5 ef | 1697.9 abc |

| Cross-linked | 3 | 0 | 65.5 efgh | 72.5 abc | 54 abcd | 1676.2 cd |

| Cross-linked | 3 | 5 | 59.5 gh | 72.0 bcd | 54.5 abc | 1696 bcd |

| Cross-linked | 3 | 10 | 95.0 b | 60.5 f | 45.0 g | 1497.1 g |

| Cross-linked | 5 | 0 | 62.5 fgh | 72.5 abc | 52.5 cdef | 1609.9 ef |

| Cross-linked | 5 | 5 | 74.5 cde | 68.5 e | 52.0 def | 1579.4 f |

| Cross-linked | 5 | 10 | 106.0 a | 56.5 g | 42.0 h | 1409.2 h |

| Oxidized | 3 | 0 | 68.5 defg | 69.5 de | 51.5 ef | 1588.1 f |

| Oxidized | 3 | 5 | 79.5 c | 71.5 bcd | 54.5 abc | 1623.0 ef |

| Oxidized | 3 | 10 | 77.5 cd | 69.5 de | 51.5 ef | 1645.1 de |

| Oxidized | 5 | 0 | 78.0 c | 72.0 bcd | 50.5 f | 1599.6 ef |

| Oxidized | 5 | 5 | 79.5 c | 71.0 cde | 53.5 bcde | 1619.6 ef |

| Oxidized | 5 | 10 | 108.5 a | 61.5 f | 44.5 g | 1494.0 g |

| Modified Starch | Hazelnut Skin | MELS | MERS | MMLPT | MMLPV | MMLPW | MMLPI | |

|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%/min) | (%/min) | (min) | (%) | (%) | (% torque·min) | |

| Refined flour | 0 | 0 | 23.0 a | −10.3 a | 3.7 cd | 68.9 a | 24.4 ab | 196.1 ab |

| Refined flour | 0 | 5 | 30.4 a | −10.0 a | 4.7 abcd | 63.9 ab | 17.0 abcde | 240.8 a |

| Refined flour | 0 | 10 | 13.8 a | −5.6 a | 4.5 abcd | 60.7 bc | 22.8 abcd | 221.2 a |

| Cross-linked | 3 | 0 | 20.0 a | −5.1 a | 4.2 bcd | 65.0 ab | 14.4 de | 224.3 a |

| Cross-linked | 3 | 5 | 17.0 a | −6.5 a | 4.0 bcd | 61.2 bc | 19.9 abcde | 197.2 ab |

| Cross-linked | 3 | 10 | 21.6 a | −9.0 a | 4.9 abc | 39.3 ef | 18.4 abcde | 136.4 bcd |

| Cross-linked | 5 | 0 | 13.6 a | −5.3 a | 3.6 d | 62.8 abc | 12.9 e | 182.8 abc |

| Cross-linked | 5 | 5 | 22.8 a | −6.9 a | 4.9 abc | 57.1 c | 12.9 e | 225.6 a |

| Cross-linked | 5 | 10 | 19.5 a | −3.5 a | 5.2 ab | 33.9 f | 15.5 cde | 111.7 d |

| Oxidized | 3 | 0 | 30.4 a | −8.0 a | 3.6 d | 68.5 a | 23.5 abc | 187.1 abc |

| Oxidized | 3 | 5 | 33.2 a | −10.5 a | 4.0 bcd | 43.6 de | 17.8 abcde | 127.20 cd |

| Oxidized | 3 | 10 | 25.4 a | −7.2 a | 4.6 abcd | 39.0 ef | 25.7 a | 133.0 cd |

| Oxidized | 5 | 0 | 23.2 a | −5.8 a | 4.7 abcd | 65.8 ab | 15.4 cde | 239.0 a |

| Oxidized | 5 | 5 | 31.3 a | −6.4 a | 4.2 bcd | 46.2 d | 17.3 abcde | 147.7 bcd |

| Oxidized | 5 | 10 | 13.7 a | −3.7 a | 5.5 a | 35.5 f | 15.9 bcde | 151.7 bcd |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durmus, Y.; Anil, M.; Simsek, S. Discrimination of Glutopeak Test and Mixograph Parameters for Evaluation of Wheat Flour Supplemented with Hazelnut Skin, Cross-Linked Starch, and Oxidized Starch. Foods 2023, 12, 328. https://doi.org/10.3390/foods12020328

Durmus Y, Anil M, Simsek S. Discrimination of Glutopeak Test and Mixograph Parameters for Evaluation of Wheat Flour Supplemented with Hazelnut Skin, Cross-Linked Starch, and Oxidized Starch. Foods. 2023; 12(2):328. https://doi.org/10.3390/foods12020328

Chicago/Turabian StyleDurmus, Yusuf, Munir Anil, and Senay Simsek. 2023. "Discrimination of Glutopeak Test and Mixograph Parameters for Evaluation of Wheat Flour Supplemented with Hazelnut Skin, Cross-Linked Starch, and Oxidized Starch" Foods 12, no. 2: 328. https://doi.org/10.3390/foods12020328

APA StyleDurmus, Y., Anil, M., & Simsek, S. (2023). Discrimination of Glutopeak Test and Mixograph Parameters for Evaluation of Wheat Flour Supplemented with Hazelnut Skin, Cross-Linked Starch, and Oxidized Starch. Foods, 12(2), 328. https://doi.org/10.3390/foods12020328