Combining Native and Malted Triticale Flours in Biscuits: Nutritional and Technological Implications

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials, Recipes, and Baking Conditions

2.2. Physical Characteristics of Doughs and Biscuits

2.3. Chemical Composition of Samples

2.4. Texture Evaluation of Biscuits

2.5. In Vitro Starch Digestion

2.6. Statistical Analyses

3. Results

3.1. Chemical Composition of Native and Malted Grains

3.2. Physical Characteristics of Doughs and Biscuits

3.3. Chemical Composition of Doughs and Biscuits

3.4. Texture Evaluation of Biscuits

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, F. Triticale: Nutritional composition and food uses. Food Chem. 2018, 241, 468–479. [Google Scholar] [CrossRef] [PubMed]

- McGoverin, C.M.; Snyders, F.; Muller, N.; Botes, W.; Fox, G.; Manley, M. A review of triticale uses and the effect of growth environment on grain quality. J. Sci. Food Agric. 2011, 91, 1155–1165. [Google Scholar] [CrossRef] [PubMed]

- Munoz-Insa, A.; Gastl, M.; Becker, T. Influence of Malting on the Protein Composition of Triticale (X Triticosecale Wittmack) ‘Trigold’. Cereal Chem. 2016, 93, 10–19. [Google Scholar] [CrossRef]

- Leon, A.E.; Rubiolo, A.; Anon, M.C. Use of triticale flours in cookies: Quality factors. Cereal Chem. 1996, 73, 779–784. [Google Scholar]

- Fraś, A.; Gołębiewska, K.; Gołębiewski, D.; Mańkowski, D.R.; Boros, D.; Szecówka, P. Variability in the chemical composition of triticale grain, flour and bread. J. Cereal Sci. 2016, 71, 66–72. [Google Scholar] [CrossRef]

- Navarro-Contreras, A.L.; Chaires-González, C.F.; Rosas-Burgos, E.C.; Borboa-Flores, J.; Wong-Corral, F.J.; Cortez-Rocha, M.O.; Cinco-Moroyoqui, F.J. Comparison of Protein and Starch Content of Substituted and Complete Triticales (X Triticosecale Wittmack): Contribution to Functional Properties. Int. J. Food Prop. 2014, 17, 421–432. [Google Scholar] [CrossRef]

- Dennett, A.L.; Wilkes, M.A.; Trethowan, R.M. Characteristics of Modern Triticale Quality: The Relationship between Carbohydrate Properties, α-Amylase Activity, and Falling Number. Cereal Chem. 2013, 90, 594–600. [Google Scholar] [CrossRef]

- Rakha, A.; Åman, P.; Andersson, R. Dietary fiber in triticale grain: Variation in content, composition, and molecular weight distribution of extractable components. J. Cereal Sci. 2011, 54, 324–331. [Google Scholar] [CrossRef]

- Doxastakis, G.; Zafiriadis, I.; Irakli, M.; Marlani, H.; Tananaki, C. Lupin, soya and triticale addition to wheat flour doughs and their effect on rheological properties. Food Chem. 2002, 77, 219–227. [Google Scholar] [CrossRef]

- Dabija, A.; Păiuş, A.M. Study on Flour Quality Assessment Designed to obtain Biscuits. Food Environ. Saf. J. 2016, 14, 218–222. [Google Scholar]

- Saxena, A.K.; Bakhshi, A.K.; Sehgal, K.L.; Sandha, G.S. Effect of grain texture on various milling and end use parameters of newly bred advanced triticale (wheat × rye) lines. J. Food Sci. Technol. 1992, 29, 14–16. [Google Scholar]

- Chauhan, A.; Saxena, D.C.; Singh, S. Physical, textural, and sensory characteristics of wheat and amaranth flour blend cookies. Cogent Food Agric. 2016, 2, 1125773. [Google Scholar] [CrossRef]

- Pattison, A.L.; Trethowan, R.M.; Pattison, A.L.; Trethowan, R.M. Characteristics of modern triticale quality: Commercially significant flour traits and cookie quality. Crop Pasture Sci. 2013, 64, 874–880. [Google Scholar] [CrossRef]

- Benincasa, P.; Falcinelli, B.; Lutts, S.; Stagnari, F.; Galieni, A. Sprouted Grains: A Comprehensive Review. Nutrients 2019, 17, 421. [Google Scholar] [CrossRef]

- Marti, A.; Cardone, G.; Pagani, M.A.; Casiraghi, M.C. Flour from sprouted wheat as a new ingredient in bread-making. LWT 2018, 89, 237–243. [Google Scholar] [CrossRef]

- Serna-Saldivar, S.O.; Guajardo-Flores, S.; Viesca-Rios, R. Potential of triticale as a substitute for wheat in flour tortilla production. Cereal Chem. 2004, 81, 220–225. [Google Scholar] [CrossRef]

- Gianinetti, A.; Toffoli, F.; Cavallero, A.; Delogu, G.; Stanca, A.M. Improving discrimination for malting quality in barley breeding programmes. Field Crops Res. 2005, 94, 189–200. [Google Scholar] [CrossRef]

- Jukić, M.; Nakov, G.; Komlenić, D.K.; Vasileva, N.; Šumanovac, F.; Lukinac, J. Quality Assessment of cookies made from composite flours containing malted barley flour and wheat flour. Plants 2022, 11, 761. [Google Scholar] [CrossRef]

- Singh, A.k.; Rehal, J.; Kaur, A.; Jyot, G. Enhancement of Attributes of Cereals by Germination and Fermentation: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1575–1589. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis, 17th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Ahure, D.; Ejoha, P.O. Quality evaluation of cookies from malted sorghum (Sorghum bicolor), sprouted soybean (Glycine max) and carrot (Daucus carota) flour blends. Asian J. Biotechnol. Bioresour. Technol. 2020, 6, 14–27. [Google Scholar] [CrossRef][Green Version]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Gallo, A.; Bernardes, T.F.; Copani, G.; Fortunati, P.; Giuberti, G.; Bruschi, S.; Bryan, K.A.; Nielsen, N.G.; Witt, K.L.; Masoero, F. Effect of inoculation with Lactobacillus buchneri LB1819 and Lactococcus lactis O224 on fermentation and mycotoxin production in maize silage compacted at different densities. Anim. Feed Sci. Technol. 2018, 246, 36–45. [Google Scholar] [CrossRef]

- Saleh, S.M.; Ali, S. Physico-functional properties, nutritional quality, and sensory characteristics of pumpkin peel puree fortified biscuit. Egypt. J. Food Sci. 2020, 48, 203–212. [Google Scholar] [CrossRef]

- Duyvejonck, A.E.; Lagrain, B.; Dornez, E.; Delcour, J.A.; Courtin, C.M. Suitability of solvent retention capacity tests to assess the cookie and bread making quality of European wheat flours. LWT-Food Sci. Technol. 2012, 47, 56–63. [Google Scholar] [CrossRef]

- Ikuomola, D.S.; Otutu, O.L.; Oluniran, D.D. Quality assessment of cookies produced from wheat flour and malted barley (Hordeum vulgare) bran blends. Cogent Food Agric. 2017, 3, 1293471. [Google Scholar] [CrossRef]

- Ma, F.; Baik, B.K. Soft wheat quality characteristics required for making baking powder biscuits. J. Cereal Sci. 2018, 79, 127–133. [Google Scholar] [CrossRef]

- Yang, B.; Guo, M.; Zhao, Z. Incorporation of wheat malt into a cookie recipe and its effect on the physicochemical properties of the corresponding dough and cookies. LWT 2020, 117, 108651. [Google Scholar] [CrossRef]

- Molinari, R.; Costantini, L.; Timperio, A.M.; Lelli, V.; Bonafaccia, F.; Bonafaccia, G.; Merendino, N. Tartary buckwheat malt as ingredient of gluten-free cookies. J. Cereal Sci. 2018, 80, 37–43. [Google Scholar] [CrossRef]

- Oliveira, M.E.A.S.; Coimbra, P.P.S.; Galdeano, M.C.; Carvalho, C.W.P.; Takeiti, C.Y. How does germinated rice impact starch structure, products and nutritional evidences?—A review. Trends Food Sci. Technol. 2022, 122, 13–23. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; van Boekel, M.A.J.S. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2000, 11, 364–373. [Google Scholar] [CrossRef]

- Chung, H.-J.; Cho, A.; Lim, S.-T. Utilization of germinated and heat-moisture treated brown rices in sugar-snap cookies. LWT—Food Sci. Technol. 2014, 57, 260–266. [Google Scholar] [CrossRef]

- Karimzadeghan, H.; Mohtarami, F.; Almasi, H. Effect of acorn and triticale flours on physicochemical, textural and sensory properties of biscuit. J. Food Res. 2021, 31, 115–128. [Google Scholar]

- Yang, Q.; Luo, Y.; Wang, H.; Li, J.; Gao, X.; Gao, J.; Feng, B. Effects of germination on the physicochemical, nutritional and in vitro digestion characteristics of flours from waxy and nonwaxy proso millet, common buckwheat and pea. Innov. Food Sci. Emerg. Technol. 2021, 67, 102586. [Google Scholar] [CrossRef]

- Chauhan, A.; Saxena, D.C.; Singh, S. Total dietary fibre and antioxidant activity of gluten free cookies made from raw and germinated amaranth (Amaranthus spp.) flour. LWT—Food Sci. Technol. 2015, 63, 939–945. [Google Scholar] [CrossRef]

- Aluge, O.O.; Akinola, S.A.; Osundahunsi, O.F. Effect of Malted Sorghum on Quality Characteristics of Wheat-Sorghum-Soybean Flour for Potential Use in Confectionaries. Food Nutr. Sci. 2016, 7, 13. [Google Scholar] [CrossRef]

- Baranzelli, J.; Kringel, D.H.; Colussi, R.; Paiva, F.F.; Aranha, B.C.; de Miranda, M.Z.; da Rosa Zavareze, E.; Dias, A.R.G. Changes in enzymatic activity, technological quality and gamma-aminobutyric acid (GABA) content of wheat flour as affected by germination. LWT 2018, 90, 483–490. [Google Scholar] [CrossRef]

- Foster-Powell, K.; Holt, S.H.; Brand-Miller, J.C. International table of glycemic index and glycemic load values: 2002. Am. J. Clin. Nutr. 2002, 76, 5–56. [Google Scholar] [CrossRef]

- Cornejo, F.; Caceres, P.J.; Martínez-Villaluenga, C.; Rosell, C.M.; Frias, J. Effects of germination on the nutritive value and bioactive compounds of brown rice breads. Food Chem. 2015, 173, 298–304. [Google Scholar] [CrossRef]

- Sozer, N.; Cicerelli, L.; Heiniö, R.L.; Poutanen, K. Effect of wheat bran addition on in vitro starch digestibility, physico-mechanical and sensory properties of biscuits. J. Cereal Sci. 2014, 60, 105–113. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No. 1047/2012. Off. J. Eur. Union 2012, L 310/36, 36–37.

| Malting Stage | Hours | Minutes | Ti | Tf |

|---|---|---|---|---|

| Cleaning | 15 | |||

| Steeping 1 | 7 | 15 | 15 | 15 |

| Germination 1 | 8 | 19 | 19 | |

| Steeping 2 | 9 | 15 | 15 | |

| Germination 2 | 6 | 19 | 19 | |

| Steeping 3 | 30 | 15 | 15 | |

| Germination 3 | 39 | 30 | 15 | 15 |

| Germination 4 | 24 | 15 | 15 | |

| Germination 5 | 25 | 15 | 15 | |

| Kilning 1 | 7 | 30 | 40 | |

| Kilning 2 | 6 | 40 | 60 | |

| Kilning 3 | 6 | 30 | 60 | 70 |

| Kilning 4 | 4 | 30 | 70 | 80 |

| Kilning 5 | 30 | 25 | 25 |

| Triticale | Crude Protein | Total Starch | Ash | TDF |

|---|---|---|---|---|

| Native | 12.3 ± 0.49 a | 58.4 ± 4.04 a | 2.6 ± 0.02 a | 11.1 ± 2.21 b |

| Malted | 13.7 ± 0.18 a | 52.1 ± 1.92 b | 1.7 ± 0.01 a | 18.3 ± 3.01 a |

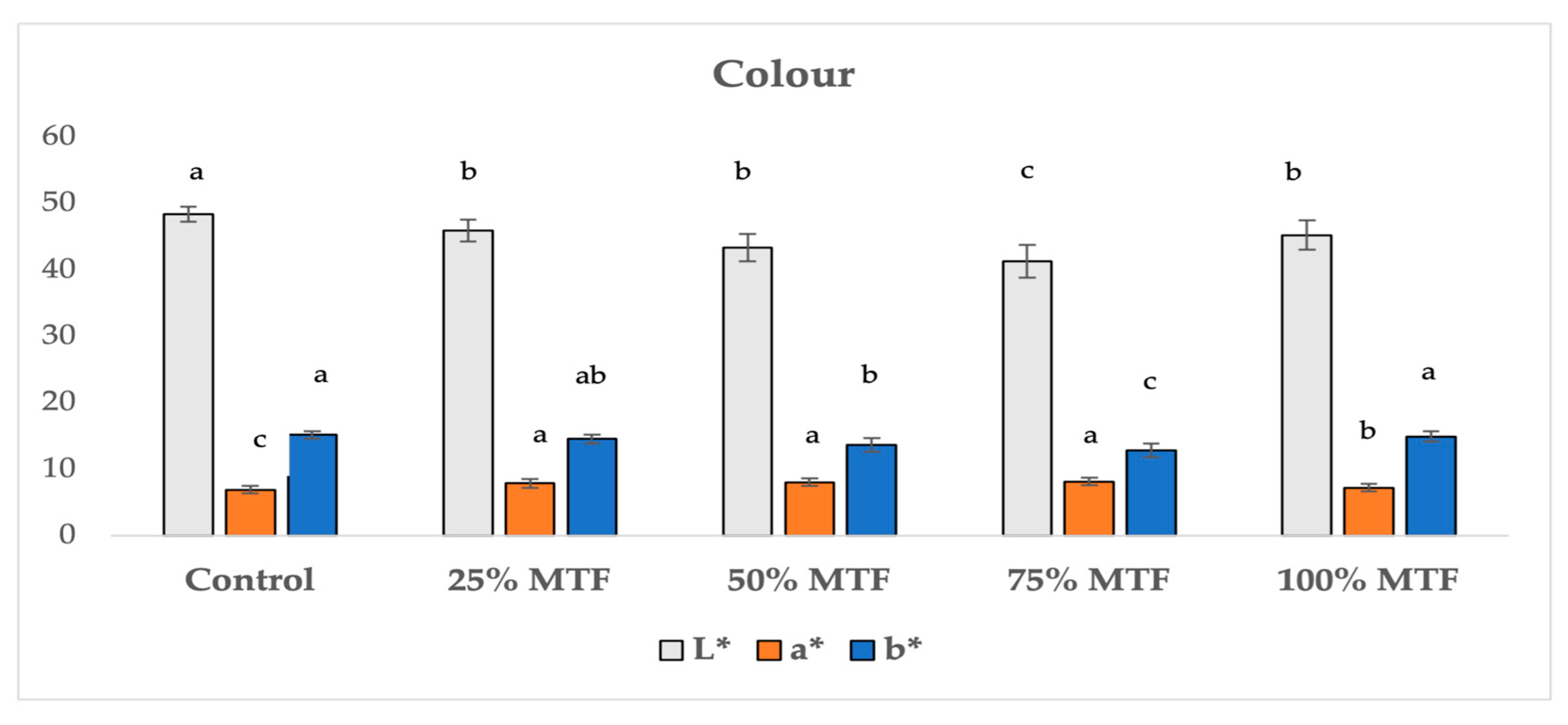

| Control | 25% MTF | 50% MTF | 75% MTF | 100% MTF | |

|---|---|---|---|---|---|

| L* | 44.82 ± 0.63 a | 45.43 ± 0.75 a | 43.22 ± 0.93 b | 42.38 ± 0.89 b | 41.01 ± 1.02 c |

| a* | 6.66 ± 0.25 b | 7.16 ± 0.29 a | 6.93 ± 0.24 b | 6.81 ± 0.19 b | 6.60 ± 0.18 b |

| b* | 14.36 ± 0.62 a | 14.04 ± 0.48 a | 13.37 ± 0.51 b | 13.38 ± 0.45 b | 12.37 ± 0.63 c |

| Moisture 1 | 44.76 ± 0.01 a | 43.78 ± 0.01 a | 44.68 ± 0.02 a | 44.99 ± 0.02 a | 41.22 ± 0.02 b |

| aw | 0.973 ± 0.002 a | 0.959± 0.001 b | 0.946 ± 0.004 b | 0.944 ± 0.001 b | 0.925 ± 0.005 c |

| Control | 25% MTF | 50% MTF | 75% MTF | 100% MTF | |

|---|---|---|---|---|---|

| Diameter (mm) | 3.28 ± 0.10 a | 3.45 ± 0.09 a | 3.47 ± 0.08 a | 3.56 ± 0.06 a | 3.54 ± 0.07 a |

| Thickness (mm) | 1.38 ± 0.11 c | 1.47 ± 0.11 b | 1.51 ± 0.08 b | 1.48 ± 0.11 b | 1.55 ± 0.16 a |

| Spread ratio (D/T) | 2.46 ± 0.20 a | 2.36 ± 0.19 b | 2.29 ± 0.12 c | 2.39 ± 0.17 b | 2.31 ± 0.21 c |

| Control | 25% MTF | 50% MTF | 75% MTF | 100% MTF | |

|---|---|---|---|---|---|

| Moisture 1 | 14.22 ± 0.02 c | 14.23 ± 0.01 c | 18.35 ± 0.04 a | 17.03 ± 0.00 b | 18.89 ± 0.04 a |

| aw | 0.859 ± 0.012 a | 0.859 ± 0.006 a | 0.806 ± 0.012 b | 0.801 ± 0.022 b | 0.759 ± 0.003 c |

| Crude protein | 12.44 ± 0.47 b | 13.09 ± 1.02 a | 13.56 ± 0.37 a | 13.53 ± 0.58 a | 13.84 ± 0.42 a |

| Crude lipid ns | 16.72 ± 0.06 | 16.11 ± 0.17 | 16.47 ± 0.15 | 16.53 ± 0.02 | 15.74 ± 0.05 |

| Total starch | 49.51 ± 1.64 a | 46.52 ± 1.25 b | 40.45 ± 1.94 c | 37.28 ± 2.14 d | 36.15 ± 1.87 d |

| Glucose | 0.31 ± 0.00 d | 1.05 ± 0.01 c | 1.23 ± 0.02 c | 1.72 ± 0.03 b | 2.80 ± 0.07 a |

| Fructose | 0.24 ± 0.00 d | 0.51 ± 0.00 c | 0.59 ± 0.01 c | 0.87 ± 0.01 b | 1.29 ± 0.01 a |

| Ash | 1.59 ± 0.07 b | 1.59 ± 0.00 b | 1.60 ± 0.01 ab | 1.61 ± 0.00 a | 1.62 ± 0.00 a |

| Total dietary fiber | 3.49 ± 0.57 e | 5.09 ± 1.11 d | 7.21 ± 0.98 c | 9.54 ± 1.02 b | 9.92 ± 1.16 a |

| Starch HI 2 | 59.50 ± 2.56 d | 62.51 ± 2.45 d | 78.89 ± 2.04 c | 88.31 ± 3.01 b | 104.43 ± 3.33 a |

| pGI | 59.49 ± 2.99 d | 62.08 ± 2.54 d | 76.20 ± 2.33 c | 84.32 ± 1.44 b | 98.22 ± 2.23 a |

| Control | 25% MTF | 50% MTF | 75% MTF | 100% MTF | |

|---|---|---|---|---|---|

| Firmness | 21,483.87 ± 3987.87 a | 20,913.87 ± 2119.96 a | 16,309.29 ± 1991.21 b | 16,068.56 ± 1863.12 b | 15,543.27 ± 1835.50 c |

| Force B | 18,700.20 ± 3606.08 a | 17,995.66 ± 1876.98 b | 13,899.94 ± 1695.89 c | 13,611.72 ± 1591.88 c | 13,337.45 ± 1596.17 c |

| Springiness | 0.89 ± 0.16 a | 0.97 ± 0.06 c | 0.91 ± 0.11 b | 0.87 ± 0.14 a | 0.94 ± 0.08 b |

| Cohesiveness ns | 0.5 ± 0.04 a | 0.5 ± 0.02 a | 0.5 ± 0.01 a | 0.5 ± 0.01 a | 0.5 ± 0.03 a |

| Chewiness | 10,741.60 ± 2458.83 a | 10,672.80 ± 1193.46 a | 8010.70 ± 1142.59 b | 7965.28 ± 1112.44 b | 7921.18 ± 1147.62 c |

| Gumminess | 10,750.13 ± 2460.51 a | 10,671.20 ± 1192.92 a | 8008.00 ± 1138.10 b | 7962.56 ± 1111.79 b | 7914.36 ± 1146.52 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piazza, I.; Carnevali, P.; Faccini, N.; Baronchelli, M.; Terzi, V.; Morcia, C.; Ghizzoni, R.; Patrone, V.; Morelli, L.; Cervini, M.; et al. Combining Native and Malted Triticale Flours in Biscuits: Nutritional and Technological Implications. Foods 2023, 12, 3418. https://doi.org/10.3390/foods12183418

Piazza I, Carnevali P, Faccini N, Baronchelli M, Terzi V, Morcia C, Ghizzoni R, Patrone V, Morelli L, Cervini M, et al. Combining Native and Malted Triticale Flours in Biscuits: Nutritional and Technological Implications. Foods. 2023; 12(18):3418. https://doi.org/10.3390/foods12183418

Chicago/Turabian StylePiazza, Isabella, Paola Carnevali, Nadia Faccini, Marina Baronchelli, Valeria Terzi, Caterina Morcia, Roberta Ghizzoni, Vania Patrone, Lorenzo Morelli, Mariasole Cervini, and et al. 2023. "Combining Native and Malted Triticale Flours in Biscuits: Nutritional and Technological Implications" Foods 12, no. 18: 3418. https://doi.org/10.3390/foods12183418

APA StylePiazza, I., Carnevali, P., Faccini, N., Baronchelli, M., Terzi, V., Morcia, C., Ghizzoni, R., Patrone, V., Morelli, L., Cervini, M., & Giuberti, G. (2023). Combining Native and Malted Triticale Flours in Biscuits: Nutritional and Technological Implications. Foods, 12(18), 3418. https://doi.org/10.3390/foods12183418