Polypropylene/Poly(butylene adipate-co-terephthalate) Breathing Film for Inhibiting Pseudomonas and Maintaining Microbial Communities and Postharvest Quality of Allium mongolicum Regel during Storage

Abstract

:1. Introduction

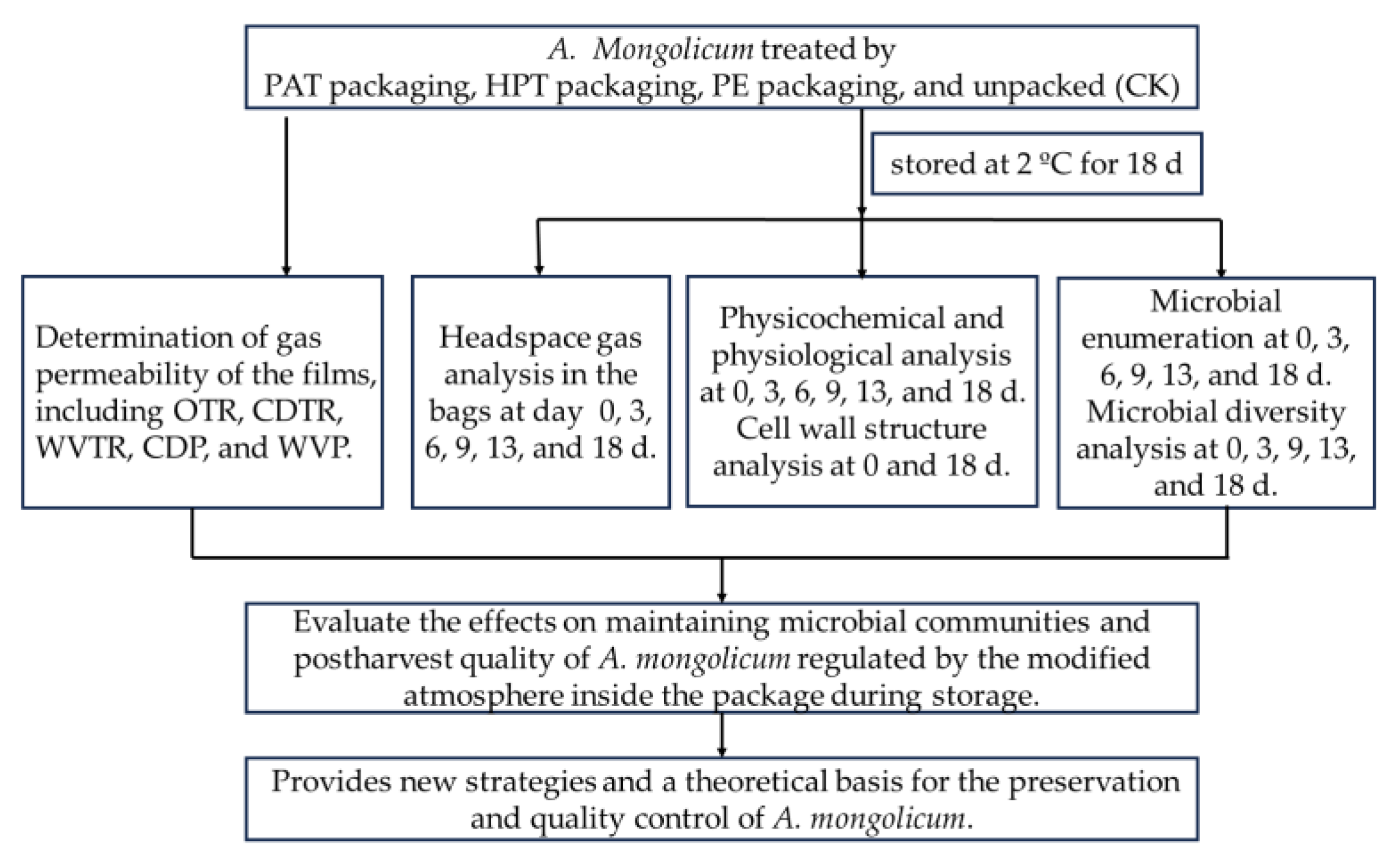

2. Materials and Methods

2.1. Materials Preparation and Sample Storage

2.2. Gas Permeability of the Film

2.3. Headspace Gas Analysis

2.4. Physicochemical and Physiological Analysis

2.4.1. Texture Profile Analysis

2.4.2. Weight Loss and Decay Rate

2.4.3. Respiration Rate

2.4.4. Chlorophyll Content, Lipid Peroxidation, and Membrane Permeability

2.5. Morphology of Cell Wall

2.6. Microbial Enumeration

2.7. Microbial Profile Analysis

2.7.1. High-Throughput Illumina Sequencing

2.7.2. Data Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Gas Permeability of the Film

3.2. Headspace Gas Analysis

3.3. Physicochemical Analysis

3.3.1. Maximum Shearing Forces

3.3.2. Weight Loss and Decay Rate

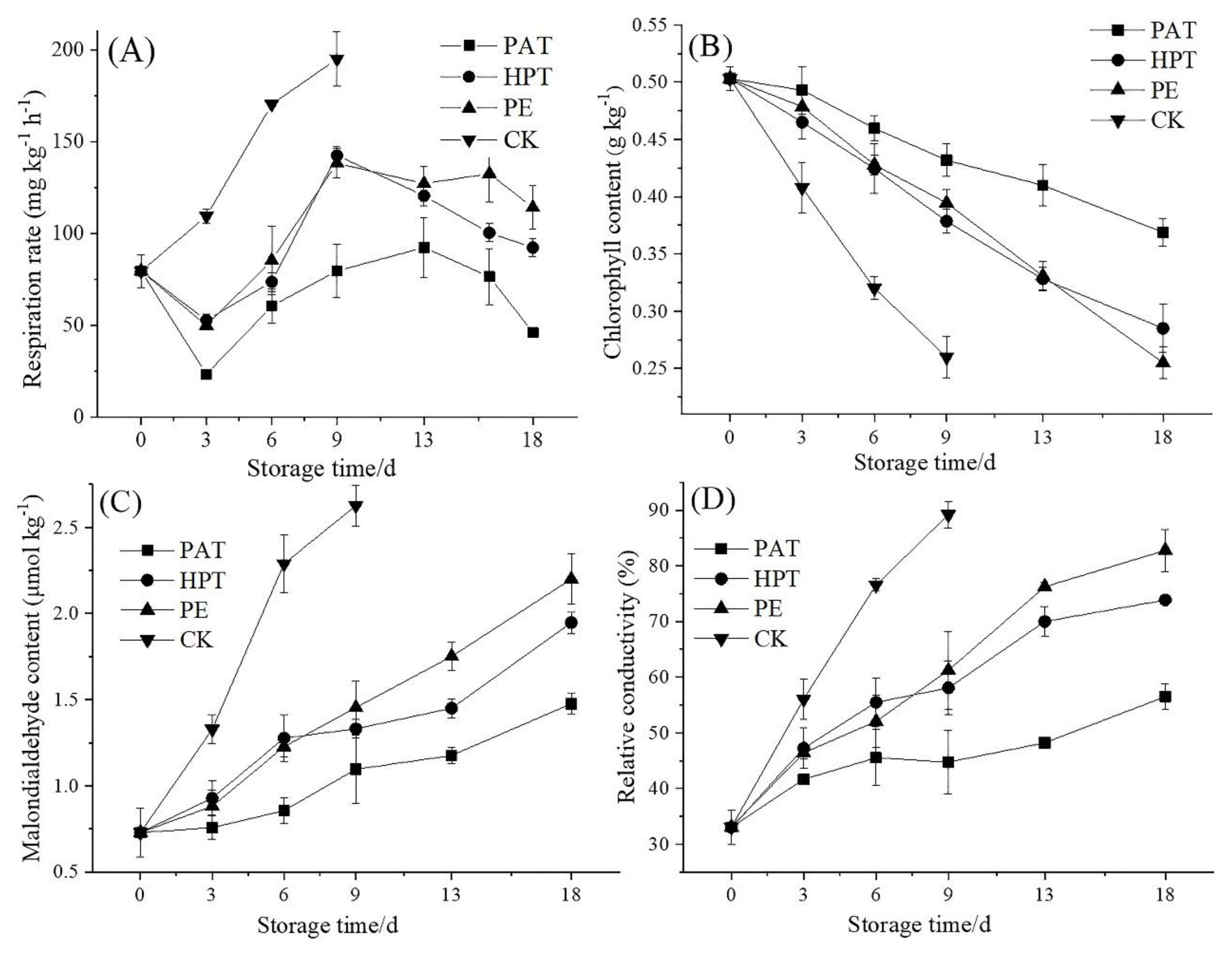

3.3.3. Respiration Rate

3.3.4. Total Chlorophyll Content

3.3.5. Membrane Permeability and Lipid Peroxidation

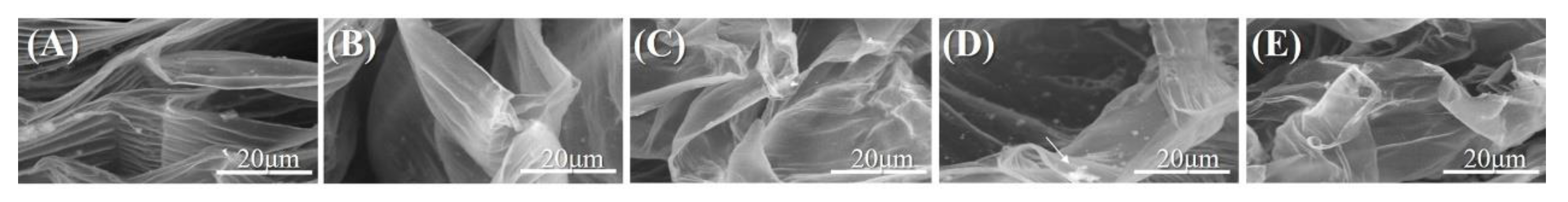

3.4. Morphology of Cell Wall

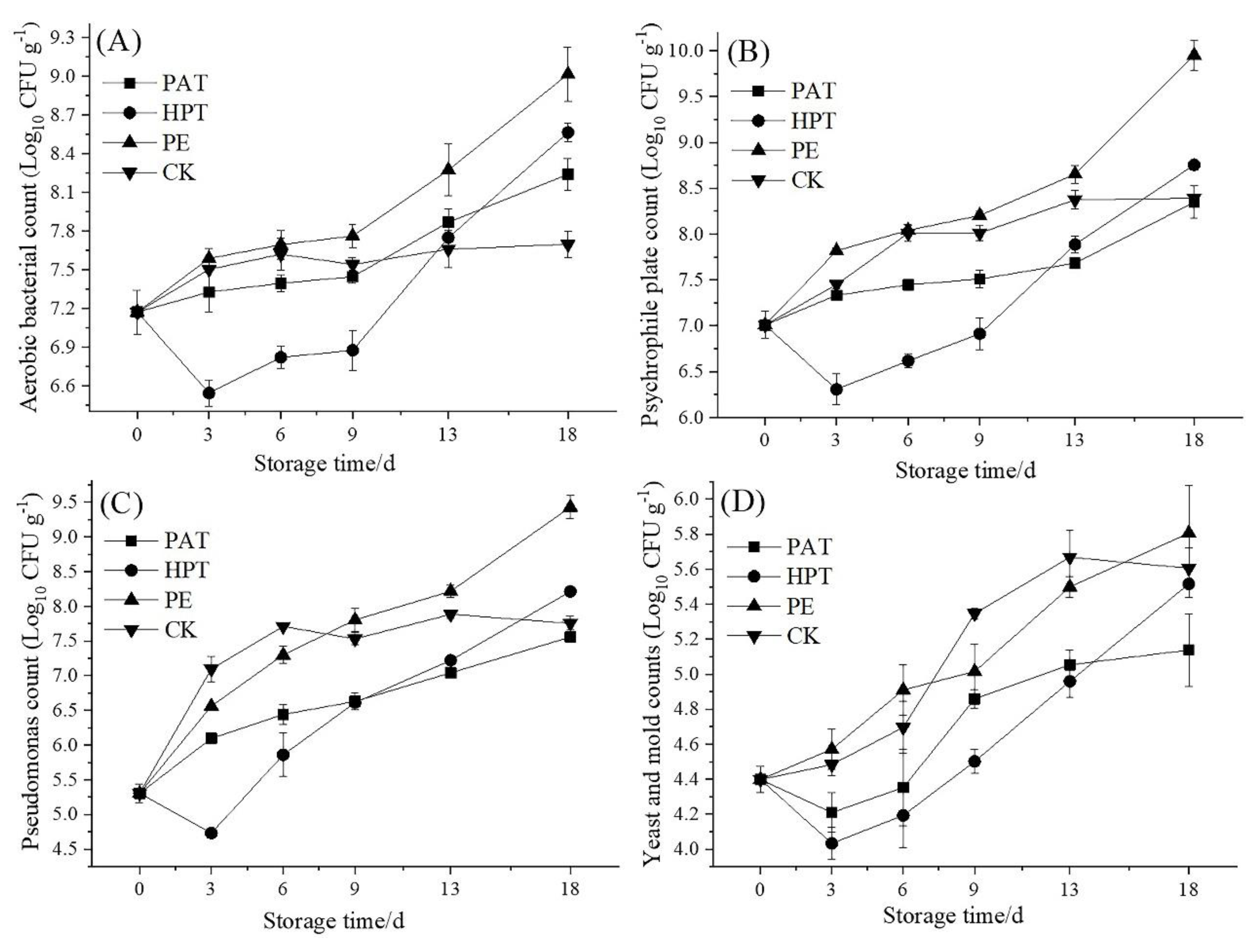

3.5. Microbial Enumeration Analysis

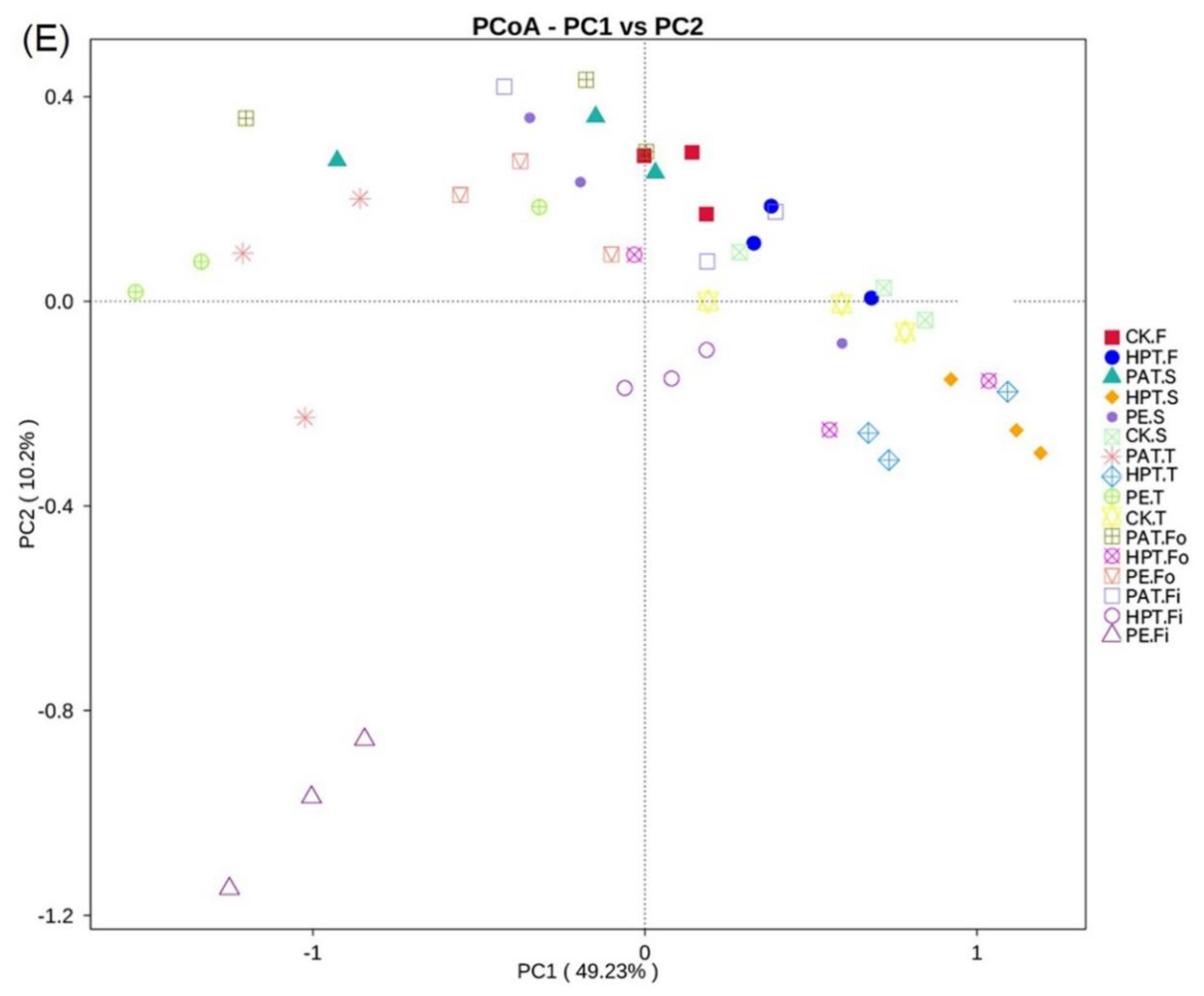

3.6. Microbial Profile

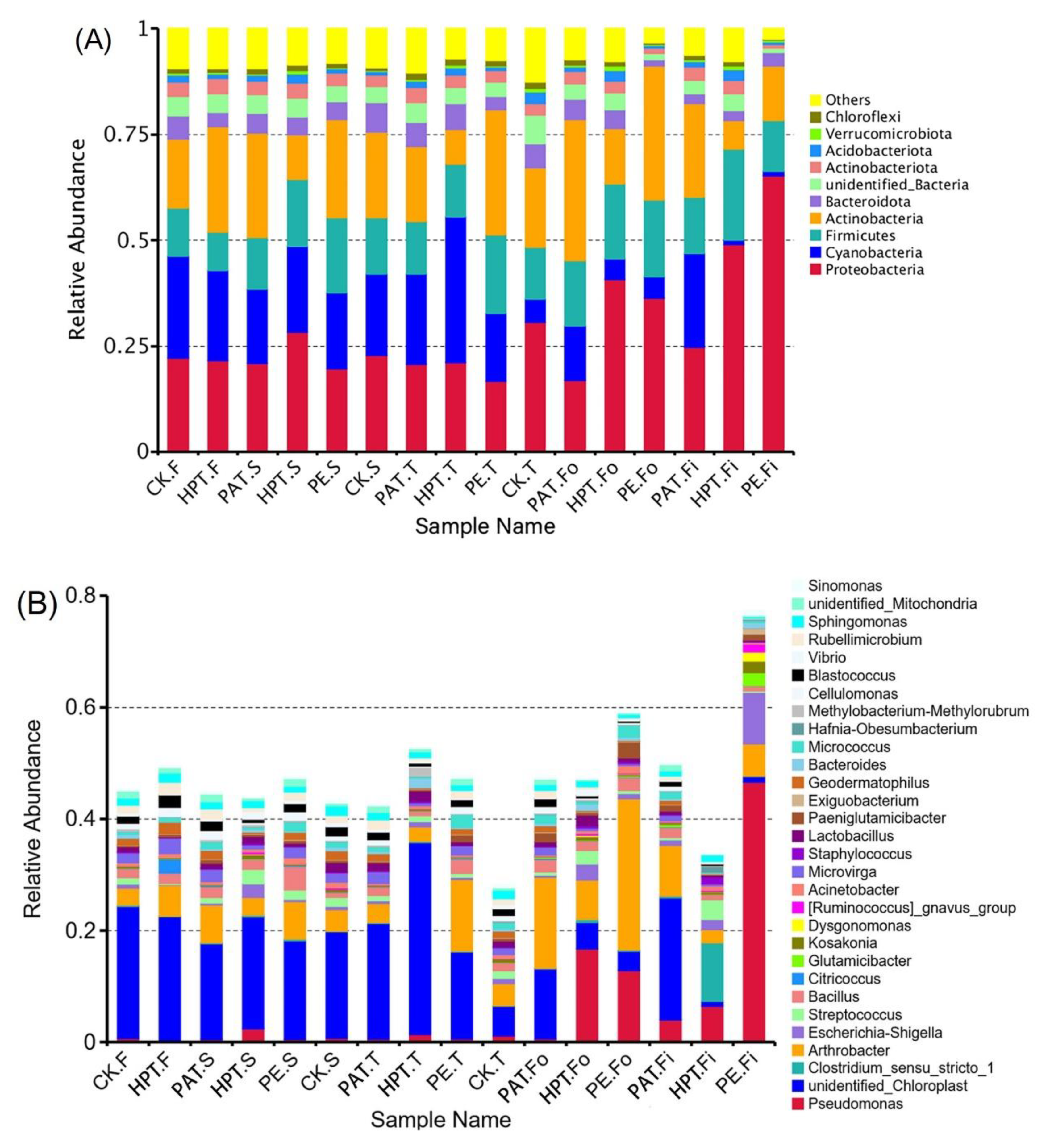

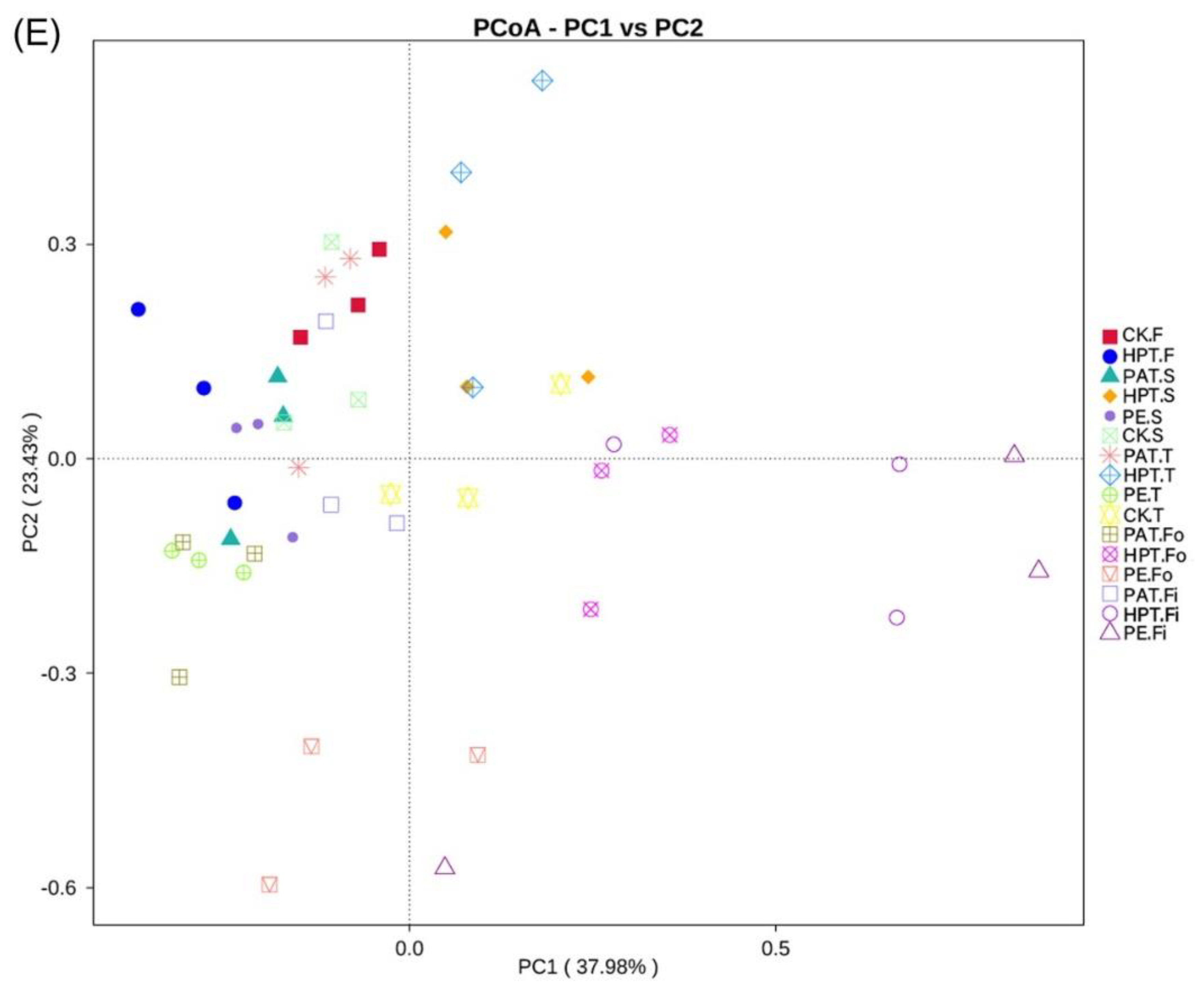

3.6.1. Bacterial Profile

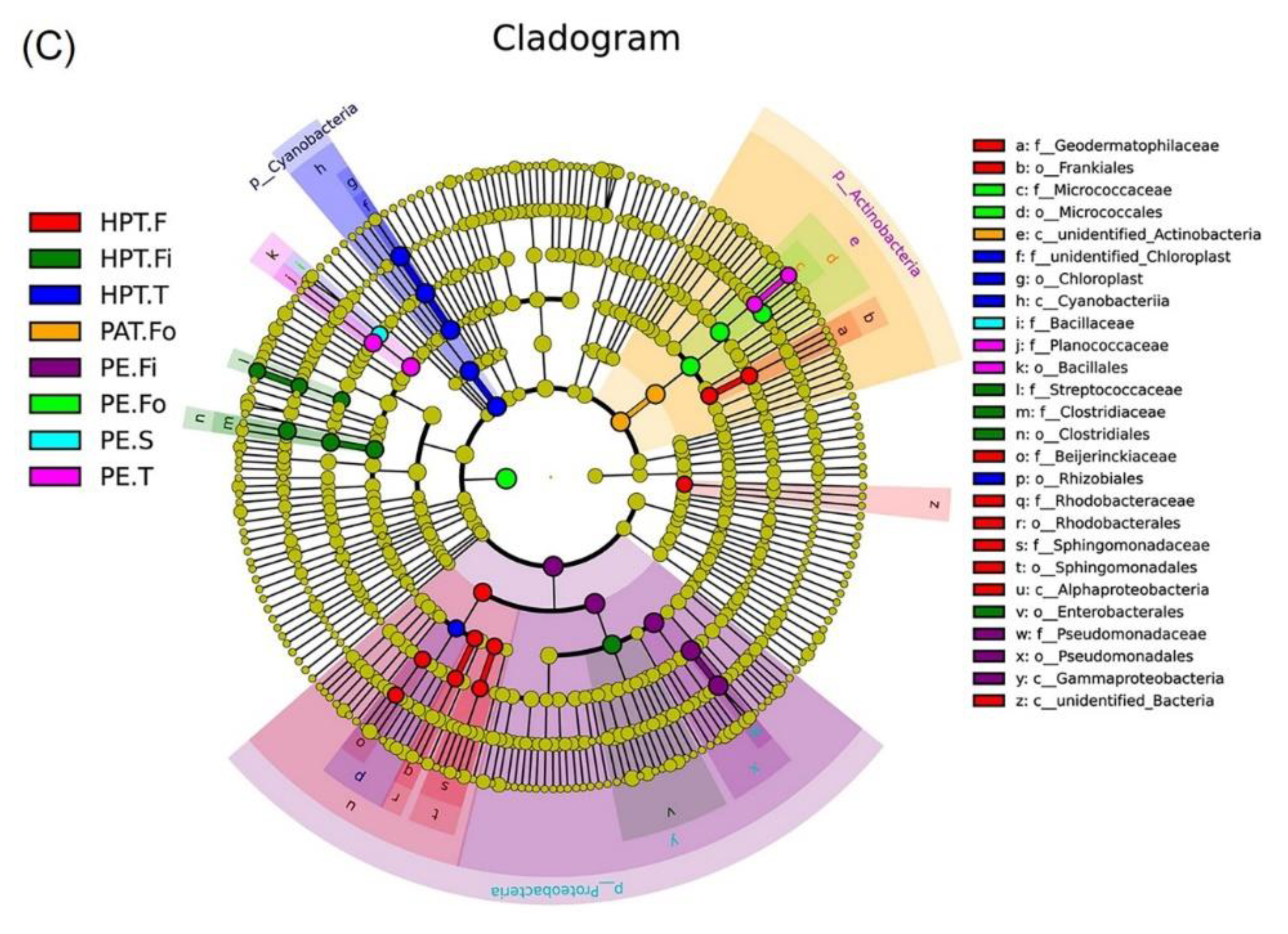

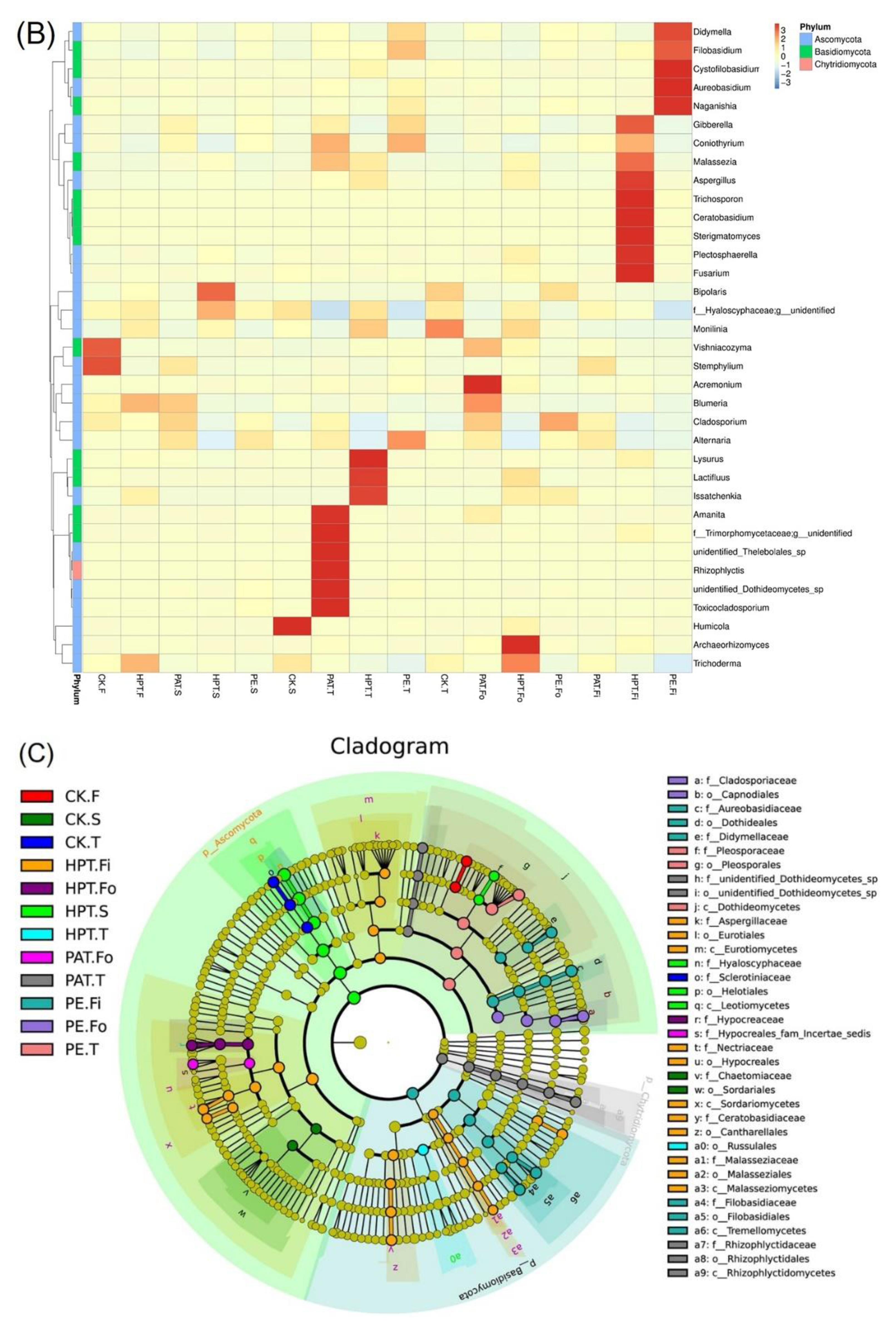

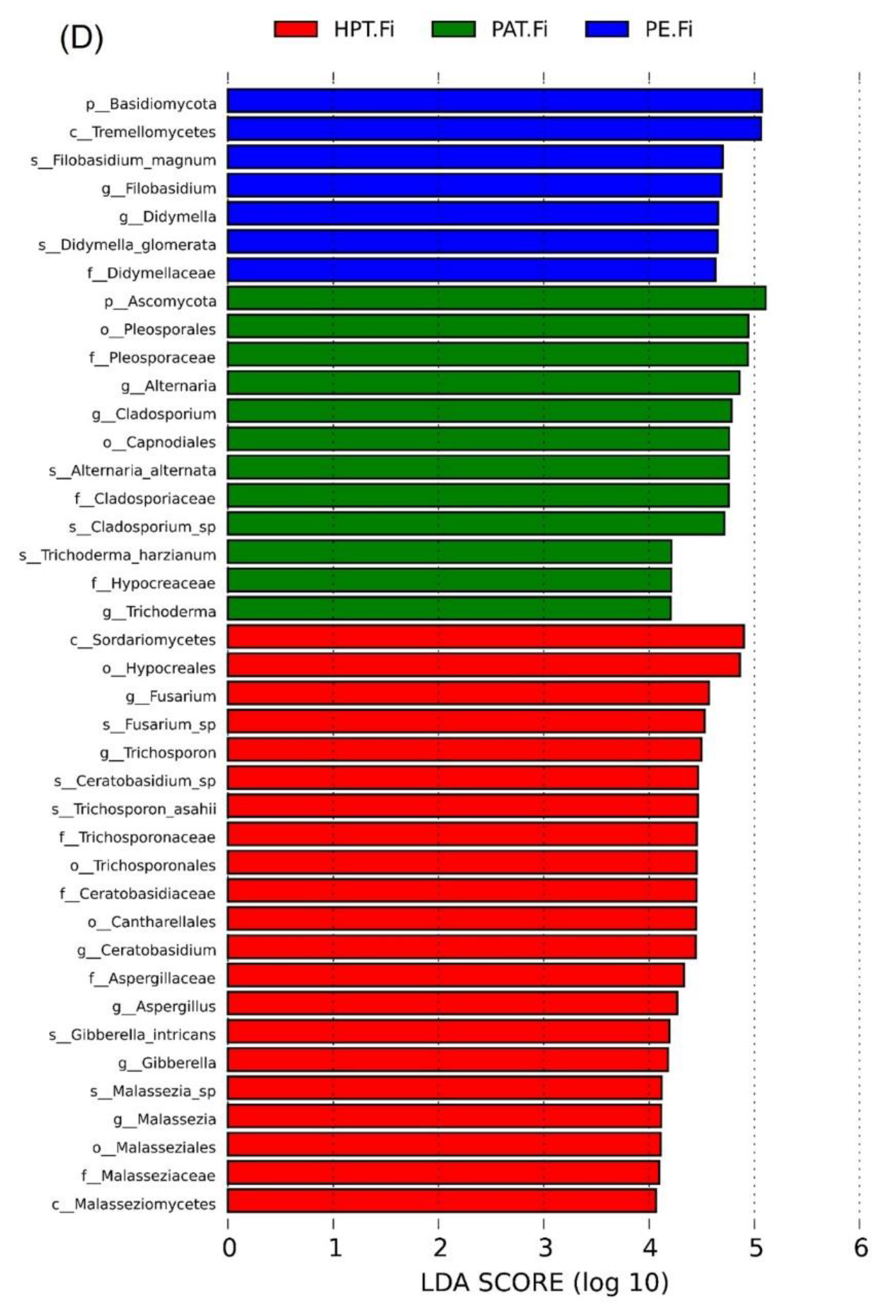

3.6.2. Fungal Profile

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muqier, Q.S.; Wang, T.; Chen, R.; Wang, C.; Ao, C. Effects of flavonoids from Allium mongolicum Regel on growth performance and growth-related hormones in meat sheep. Anim. Nutr. 2017, 3, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Bu, H.; Hu, Y.; Dong, T. Changes in postharvest physiology, biochemistry, sensory properties and microbiological population of Allium mongolicum Regel regulated by adjusting the modified atmosphere inside the package during storage. J. Food Process Preserv. 2022, 46, e16128. [Google Scholar] [CrossRef]

- Li, M.Y.; Zhu, X.M.; Niu, X.T.; Chen, X.M.; Tian, J.X.; Kong, Y.D. Effects of dietary Allium mongolicum Regel polysaccharide on growth, lipopolysaccharide induced antioxidant responses and immune responses in Channa argus. Mol. Biol. Rep. 2019, 46, 2221–2230. [Google Scholar] [CrossRef] [PubMed]

- Li, M.Y.; Guo, W.Q.; Guo, G.L.; Zhu, X.M.; Niu, X.T.; Shan, X.F. Effect of sub-chronic exposure to selenium and Allium mongolicum Regel flavonoids on Channa argus: Bioaccumulation, oxidative stress, immune responses and immune-related signaling molecules. Fish Shellfish Immunol. 2019, 91, 122–129. [Google Scholar] [CrossRef]

- Sang, Y.; Yang, W.; Liu, Y.; Zhang, W.; Guo, T.; Shen, P. Influences of low temperature on the postharvest quality and antioxidant capacity of winter jujube (Zizyphus jujuba Mill. cv. Dongzao). LWT-Food Sci. Technol. 2022, 154, 112876. [Google Scholar] [CrossRef]

- Salmas, C.E.; Giannakas, A.E.; Baikousi, M.; Kollia, E.; Tsigkou, V.; Proestos, C. Effect of Copper and Titanium-Exchanged Montmorillonite Nanostructures on the Packaging Performance of Chitosan/Poly-Vinyl-Alcohol-Based Active Packaging Nanocomposite Films. Foods 2021, 10, 3038. [Google Scholar] [CrossRef]

- Asgarian, Z.S.; Palou, L.; Souza, R.F.; Quintanilla, P.G.; Taberner, V.; Karimi, R.; Pérez-Gago, M.B. Hydroxypropyl Methylcellulose and Gum Arabic Composite Edible Coatings Amended with Geraniol to Control Postharvest Brown Rot and Maintain Quality of Cold-Stored Plums. Foods 2023, 12, 2978. [Google Scholar] [CrossRef]

- Saleh, I.; Abu-Dieyeh, M. Novel Prosopis juliflora leaf ethanolic extract coating for extending postharvest shelf-life of strawberries. Food Control 2022, 133, 108641. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Ukuku, D.O.; Olanya, O.M.; Sokorai, K.; Fan, X. Effects of pulsed light and aerosolized formic acid treatments on inactivation of Salmonella enterica on cherry tomato, reduction of microbial loads, and preservation of fruit quality. Food Control 2021, 136, 108667. [Google Scholar] [CrossRef]

- Treesuwan, K.; Jirapakkul, W.; Tongchitpakdee, S.; Chonhenchob, V.; Mahakarnchanakul, W.; Tongkhao, K. Sulfite-free treatment combined with modified atmosphere packaging to extend trimmed young coconut shelf life during cold storage. Food Control 2022, 139, 109099. [Google Scholar] [CrossRef]

- Li, J.; Wei, Q.; Huang, L.; Fang, T.; Chen, B.; Jiang, Y. Mathematical modeling Pseudomonas spp. growth and microflora composition variation in Agaricus bisporus fruiting bodies during chilled storage. Postharvest Biol. Technol. 2020, 163, 111144. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.; Zhang, X.; Dong, C.; Xue, W.; Xu, W. The effect of different doses of ozone treatments on the postharvest quality and biodiversity of cantaloupes. Postharvest Biol. Technol. 2020, 163, 111124. [Google Scholar] [CrossRef]

- Badiche-El Hilali, F.; Valverde, J.M.; García-Pastor, M.E.; Serrano, M.; Castillo, S.; Valero, D. Melatonin Postharvest Treatment in Leafy ‘Fino’ Lemon Maintains Quality and Bioactive Compounds. Foods 2023, 12, 2979. [Google Scholar] [CrossRef]

- Balanon, D.A.G.; Sane, A.; Jariyasakoolroj, P.; Leelaphiwat, P. Application of biodegradable film as modified atmosphere packaging for red chili (Capsicum annuum cv. Jinda). Packag. Technol. Sci. 2023, 36, 379–388. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, H.; Chen, X.; Huang, L.; Fan, J.; Zhou, J. Modified-atmosphere packaging maintains the quality of postharvest whole lettuce (Lactuca sativa L. Grand Rapid) by mediating the dynamic equilibrium of the electron transport chain and protecting mitochondrial structure and function. Postharvest Biol. Technol. 2019, 147, 206–213. [Google Scholar] [CrossRef]

- Meng, X.; Lv, Z.; Jiang, T.; Tan, Y.; Sun, S.; Feng, J. Preparation and Characterization of a Novel Artemisia Oil Packaging Film and Its Application in Mango Preservation. Foods 2023, 12, 2969. [Google Scholar] [CrossRef]

- Hotchkiss, J.H.; Banco, M.J. Influence of new packaging technologies on the growth of microorganisms in produce. J. Food Prot. 1992, 55, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Radziejewska-Kubzdela, E.; Czaczyk, K. Effect of Pretreatment and Modified Atmosphere Packaging on Quality of dry Coleslaw mix. Packag. Technol. Sci. 2015, 28, 1011–1026. [Google Scholar] [CrossRef]

- Ibaraki, T.; Ishii, T.; Ikematsu, E.; Ikeda, H.; Ohta, H. Modilied atmosphere packaging of cut welsh onion: Effect of micro-perforated polypropylene film packaging on chemical components and quality stability of the vegetable. Food Sci. Technol. Res. 2000, 6, 126–129. [Google Scholar] [CrossRef]

- Lashkari, E. Effect of Modified Atmosphere Packaging (MAP) on the Stability of Anthocyanins and Degradation of Phenolic Compounds during Postharvest Storage of Pomegranate Fruit. Food Nutr. Sci. 2022, 13, 316–335. [Google Scholar] [CrossRef]

- Paulsen, E.; Barrios, S.; Lema, P. Ready-to-eat cherry tomatoes: Passive modified atmosphere packaging conditions for shelf life extension. Food Packag. Shelf Life 2019, 22, 100407. [Google Scholar] [CrossRef]

- Juikar, S.K.; Warkar, S.G. Biopolymers for packaging applications: An overview. Packag. Technol. Sci. 2023, 36, 229–251. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Maniglia, B.C.; Tadini, C.C. Biodegradable polymers: A review about biodegradation and its implications and applications. Packag. Technol. Sci. 2023, 36, 81–95. [Google Scholar] [CrossRef]

- Oliveira, T.A.; Oliveira, R.R.; Barbosa, R.; Azevedo, J.B.; Alves, T.S. Effect of reprocessing cycles on the degradation of PP/PBAT-thermoplastic starch blends. Carbohydr. Polym. 2017, 168, 52–60. [Google Scholar] [CrossRef] [PubMed]

- Donglu, F.; Wenjian, Y.; Kimatu, B.M.; Xinxin, A.; Qiuhui, H.; Liyan, Z. Effect of nanocomposite packaging on postharvest quality and ROS metabolism of mushrooms (Flammulina velutipes). Postharvest Biol. Technol. 2016, 119, 49–57. [Google Scholar] [CrossRef]

- Xiao, Z.; Luo, Y.; Lester, G.E.; Kou, L.; Yang, T.; Wang, Q. Postharvest quality and shelf life of radish microgreens as impacted by storage temperature, packaging film, and chlorine wash treatment. LWT-Food Sci. Technol. 2014, 55, 551–558. [Google Scholar] [CrossRef]

- Cheng, P.; Yun, X.; Xu, C.; Yang, Y.; Han, Y.; Dong, T. Use of poly(epsilon-caprolactone)-based films for equilibrium-modified atmosphere packaging to extend the postharvest shelf life of garland chrysanthemum. Food Sci. Nutr. 2019, 7, 1946–1956. [Google Scholar] [CrossRef]

- Kaya, C.; Kirnak, H.; Higgs, D.; Saltali, K. Supplementary calcium enhances plant growth and fruit yield in strawberry cultivars grown at high (NaCl) salinity. Sci. Hortic. 2002, 93, 65–74. [Google Scholar] [CrossRef]

- Ge, L.; Lai, H.; Huang, Y.; Wang, Y.; Li, Y.; Zhu, S. Comparative evaluation of package types in alleviating textural softening and package-swelling of Paocai during storage: Insight into microbial invasion, cell wall pectinolysis and alteration in sugar and organic acid profiles. Food Chem. 2021, 365, 130489. [Google Scholar] [CrossRef]

- Yahya, H.N.; Lignou, S.; Wagstaff, C.; Bell, L. Changes in bacterial loads, gas composition, volatile organic compounds, and glucosinolates of fresh bagged Ready-To-Eat rocket under different shelf life treatment scenarios. Postharvest Biol. Technol. 2019, 148, 107–119. [Google Scholar] [CrossRef]

- Ehsani, A.; Naghibi, S.S.; Aminzare, M.; Keykhosravi, K.; Hashemi, M. Extraction of specific egg yolk antibodies and application in chitosan coating: Effect on microbial and sensory properties of rainbow trout fillet during chilled storage. J. Sci. Food Agric. 2019, 99, 2356–2364. [Google Scholar] [CrossRef] [PubMed]

- Quast, C.; Pruesse, E.; Yilmaz, P.; Gerken, J.; Schweer, T.; Yarza, P. The SILVA ribosomal RNA gene database project: Improved data processing and web-based tools. Nucleic Acids Res. 2013, 41, 590–596. [Google Scholar] [CrossRef] [PubMed]

- Kõljalg, U.; Nilsson, R.H.; Abarenkov, K.; Tedersoo, L.; Taylor, A.F.S.; Larsson, K.H. Towards a unified paradigm for sequence-based identification of fungi. Mol. Ecol. 2013, 22, 5271–5277. [Google Scholar] [CrossRef]

- Beaudry, R.M. Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biol. Technol. 1999, 15, 293–303. [Google Scholar] [CrossRef]

- Chandra, D.; Kim, J.G.; Kim, Y.P. Changes in microbial population and quality of microgreens treated with different sanitizers and packaging films. Hortic. Environ. Biotechnol. 2012, 53, 32–40. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Oliveira, F.A.R.; Montanez, J.C.; Frias, J. Development of user-friendly software for design of modified atmosphere packaging for fresh and fresh-cut produce. Innov. Food Sci. Emerg. Technol. 2007, 8, 84–92. [Google Scholar] [CrossRef]

- Hodges, D.M.; Forney, C.F.; Wismer, W. Processing line effects on storage attributes of fresh-cut spinach leaves. Hortscience 2000, 35, 1308–1311. [Google Scholar] [CrossRef]

- Xu, D.; Shi, M.; Jia, B.; Yan, Z.; Gao, L.; Guan, W. Effect of ozone on the activity of antioxidant and chlorophyll-degrading enzymes during postharvest storage of coriander (Coriandrum sativum L.). J. Food Process Preserv. 2019, 43, 14020. [Google Scholar] [CrossRef]

- Garrido, Y.; Tudela, J.A.; Hernández, J.A.; Gil, M.I. Modified atmosphere generated during storage under light conditions is the main factor responsible for the quality changes of baby spinach. Postharvest Biol. Technol. 2016, 114, 45–53. [Google Scholar] [CrossRef]

- Lin, S.; Chen, C.; Luo, H.; Xu, W.; Zhang, H.; Tian, J.J. The combined effect of ozone treatment and polyethylene packaging on postharvest quality and biodiversity of Toona sinensis (A. Juss.) M. Roem. Postharvest Biol. Technol. 2019, 154, 1–10. [Google Scholar] [CrossRef]

- Li, X.; Bao, Z.; Chen, Y.; Lan, Q.; Song, C.; Shi, L.; Chen, W.; Cao, S.; Yang, Z.; Zheng, Q. Exogenous glutathione modulates redox homeostasis in okra (Abelmoschus esculentus) during storage. Postharvest Biol. Technol. 2023, 195, 112145. [Google Scholar] [CrossRef]

- Li, X.Y.; Xiong, T.T.; Zhu, Q.N.; Zhou, Y.W.; Lei, Q.M.; Lu, H.Y.; Chen, W.X.; Li, X.P.; Zhu, X.Y. Combination of 1-MCP and modified atmosphere packaging (MAP) maintains banana fruit quality under high temperature storage by improving antioxidant system and cell wall structure. Postharvest Biol. Technol. 2023, 198, 112265. [Google Scholar] [CrossRef]

- Chitravathi, K.; Chauhan, O.P.; Raju, P.S.; Madhukar, N. Efficacy of Aqueous Ozone and Chlorine in Combination with Passive Modified Atmosphere Packaging on the Postharvest Shelf-Life Extension of Green Chillies (Capsicum annuum L.). Food Bioprocess Technol. 2015, 8, 1386–1392. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, Y.; Li, T.; Yang, Y.; Zeng, F.; Wang, H. Microbial composition and correlation between microbiota and quality-related physiochemical characteristics in Chongqing radish paocai. Food Chem. 2022, 369, 130897. [Google Scholar] [CrossRef]

- Jiang, K.; Li, L.; Yang, Z.H.; Chen, H.Y.; Qin, Y.Y.; Brennan, C. Variable characteristics of microbial communities and volatile organic compounds during post-harvest storage of wild morel mushrooms. Postharvest Biol. Technol. 2023, 203, 112401. [Google Scholar] [CrossRef]

- Shinde, S.P.; Chaudhari, S.R.; Matche, R.S. A way forward for a sustainable active packaging solution for prolonging the freshness and shelf life of Rosa hybrida L. cut flowers. Postharvest Biol. Technol. 2023, 204, 112475. [Google Scholar] [CrossRef]

- Pinto, L.; Ippolito, A.; Baruzzi, F. Control of spoiler Pseudomonas spp. on fresh cut vegetables by neutral electrolyzed water. Food Microbiol. 2015, 50, 102–108. [Google Scholar] [CrossRef]

- Liu, D.J.; Wang, F.; Brennan, C.; Benjakul, S.; Xiao, G.S.; Ying, X.G.; Ma, L.K. Combined melatonin and UV-C treatment maintains the quality of fresh-cut bamboo shoots during storage by altering microbial diversity and metabolites. Postharvest Biol. Technol. 2023, 200, 112327. [Google Scholar] [CrossRef]

- Le, D.; Audenaert, K.; Haesaert, G. Fusarium basal rot: Profile of an increasingly important disease in Allium spp. Trop. Plant Pathol. 2021, 46, 241–253. [Google Scholar] [CrossRef]

- Tonti, S.; Mandrioli, M.; Nipoti, P.; Pisi, A. Toschi TG and Prodi A, Detection of fumonisins in fresh and dehydrated commercial garlic. J. Agric. Food Chem. 2017, 65, 7000–7005. [Google Scholar] [CrossRef]

- Tirado-Ramírez, M.A.; López-Orona, C.A.; Velázquez-Alcaraz, T.J.; Díaz-Valdés, T.; Velarde-Félix, S.; Martínez-Campos, A.R. First report of onion basal rot caused by Fusarium falciforme in Mexico. Plant Dis. 2018, 102, 2646. [Google Scholar] [CrossRef]

| Sample | Thickness (μm) | OTR (cm3 m−2 d−1) | CDTR (cm3 m−2 d−1) | CDP (10−6 cm3 m m−2 d−1 Pa−1) | WVTR (g m−2 d−1) | WVP (10−8 g m m−2 d−1 Pa−1) |

|---|---|---|---|---|---|---|

| PP | 25.0 | 4119 ± 35 | 12,451 ± 468 | 3.08 ± 0.12 | 2.45 ± 0.30 | 2.97 ± 0.36 |

| PBAT | 25.1 | 4059 ± 60 | 38,333 ± 586 | 9.53 ± 0.15 | 27.49 ± 0.95 | 33.5 ± 1.16 |

| PAT | 34.2 | 2990 ± 115 | 13,867 ± 29 | 4.70 ± 0.01 | 4.42 ± 0.15 | 7.34 ± 0.25 |

| PE | 8.0 | 35,663 ± 182 | 152,500 ± 534 | 1.21 ± 0.02 | 13.77 ± 0.75 | 0.54 ± 0.05 |

| Treatment | Storage Time (d) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 13 | 18 | |

| O2 (%) | ||||||

| PAT | 20.5 | 0.47 ± 0.01 b | 0.57 ± 0.10 b | 0.54 ± 0.08 b | 0.63 ± 0.05 b | 0.51 ± 0.01 b |

| HPT | 20.5 | 0.07 ± 0.01 c | 0.06 ± 0.02 c | 0.09 ± 0.02 c | 0.07 ± 0.01 c | 0.05 ± 0.01 c |

| PE | 20.5 | 19.63 ± 0.21 a | 19.87 ± 0.21 a | 20.33 ± 0.12 a | 19.83 ± 0.12 a | 19.53 ± 0.29 a |

| CO2 (%) | ||||||

| PAT | 0 | 8.03 ± 0.40 b | 7.07 ± 0.38 b | 6.27 ± 0.25 b | 6.53 ± 0.25 b | 6.20 ± 0.20 a |

| HPT | 0 | 10.73 ± 0.68 a | 8.77 ± 0.32 a | 9.20 ± 1.27 a | 7.35 ± 0.78 a | 6.40 ± 0.79 a |

| PE | 0 | 0.37 ± 0.09 c | 0.20 ± 0.10 c | 0.23 ± 0.06 c | 0.23 ± 0.06 c | 0.27 ± 0.06 b |

| Treatment | Storage Time (d) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 13 | 18 | |

| Maximum shearing forces (N) | ||||||

| PAT | 2.84 ± 0.49 | 2.97 ± 0.45 c | 3.05 ± 0.56 c | 3.29 ± 0.24 b | 3.28 ± 0.28 a | 2.99 ± 0.32 a |

| HPT | 2.84 ± 0.49 | 3.88 ± 0.55 b | 3.94 ± 0.59 b | 3.07 ± 0.62 bc | 2.74 ± 0.63 b | 2.59 ± 0.44 b |

| PE | 2.84 ± 0.49 | 2.89 ± 0.38 c | 3.11 ± 0.53 c | 2.95 ± 0.21 c | 2.63 ± 0.40 b | 2.55 ± 0.35 b |

| CK | 2.84 ± 0.49 | 4.68 ± 0.82 a | 4.55 ± 0.33 a | 4.22 ± 0.20 a | ||

| Weight loss rate (%) | ||||||

| PAT | 0 | 2.53 ± 0.20 c | 2.95 ± 0.24 c | 3.03 ± 0.22 c | 3.56 ± 0.83 c | 4.64 ± 0.76 c |

| HPT | 1.64 ± 0.9 | 3.60 ± 1.07 b | 3.81 ± 0.41 b | 5.57 ± 0.85 b | 6.92 ± 0.92 b | 9.89 ± 1.72 b |

| PE | 0 | 2.46 ± 0.33 c | 2.85 ± 0.07 c | 5.68 ± 0.90 b | 7.17 ± 0.55 b | 10.03 ± 1.33 b |

| CK | 0 | 29.12 ± 3.34 a | 54.00 ± 0.57 a | 70.37 ± 1.53 a | ||

| decay rate (%) | ||||||

| PAT | 0 | 0 | 0 | 0.96 ± 0.16 c | 1.92 ± 0.38 c | 4.95 ± 1.02 d |

| HPT | 0 | 0 | 2.67 ± 0.40 b | 6.39 ± 0.96 b | 11.83 ± 2.02 b | 23.28 ± 1.21 c |

| PE | 0 | 0 | 0 | 6.39 ± 1.23 b | 15.28 ± 2.41 b | 30.78 ± 1.92 b |

| CK | 0 | 12.86 ± 1.18 a | 26.33 ± 1.53 a | 31.67 ± 2.89 a | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, H.; Hu, J.; Han, F.; Wang, L.; Chen, Q.; Cheng, P.; Yue, H.; Dong, T.; Yun, X. Polypropylene/Poly(butylene adipate-co-terephthalate) Breathing Film for Inhibiting Pseudomonas and Maintaining Microbial Communities and Postharvest Quality of Allium mongolicum Regel during Storage. Foods 2023, 12, 3370. https://doi.org/10.3390/foods12183370

Bu H, Hu J, Han F, Wang L, Chen Q, Cheng P, Yue H, Dong T, Yun X. Polypropylene/Poly(butylene adipate-co-terephthalate) Breathing Film for Inhibiting Pseudomonas and Maintaining Microbial Communities and Postharvest Quality of Allium mongolicum Regel during Storage. Foods. 2023; 12(18):3370. https://doi.org/10.3390/foods12183370

Chicago/Turabian StyleBu, Hongyu, Jian Hu, Feng Han, Limei Wang, Qianru Chen, Peifang Cheng, Hai Yue, Tungalag Dong, and Xueyan Yun. 2023. "Polypropylene/Poly(butylene adipate-co-terephthalate) Breathing Film for Inhibiting Pseudomonas and Maintaining Microbial Communities and Postharvest Quality of Allium mongolicum Regel during Storage" Foods 12, no. 18: 3370. https://doi.org/10.3390/foods12183370

APA StyleBu, H., Hu, J., Han, F., Wang, L., Chen, Q., Cheng, P., Yue, H., Dong, T., & Yun, X. (2023). Polypropylene/Poly(butylene adipate-co-terephthalate) Breathing Film for Inhibiting Pseudomonas and Maintaining Microbial Communities and Postharvest Quality of Allium mongolicum Regel during Storage. Foods, 12(18), 3370. https://doi.org/10.3390/foods12183370