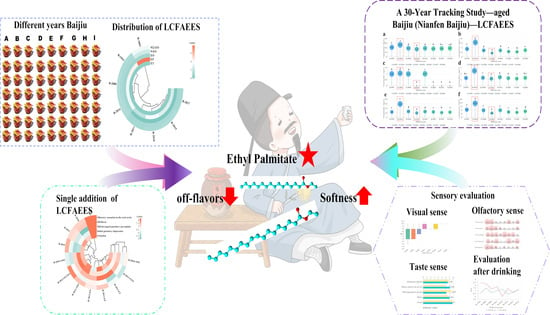

Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Standard Information

2.2. Baijiu Sample Information

2.3. Preprocessing Methods for Baijiu Samples

2.4. Analytical Parameters for GC-MS Detection

2.5. Qualitative Analysis of LCFAEEs

2.6. Quantitative Analysis of LCFAEEs

2.7. Evaluation of Sensomics for Modern Flavor Analysis

2.7.1. Baijiu Evaluation Environment and Conditions

2.7.2. Descriptive Sensory Analysis

Visual Sensory

Olfactory Sensory

Taste Sensory

Evaluation after Drinking

2.8. Statistical Examination and Analysis

3. Results and Discussion

3.1. Description of Parameters

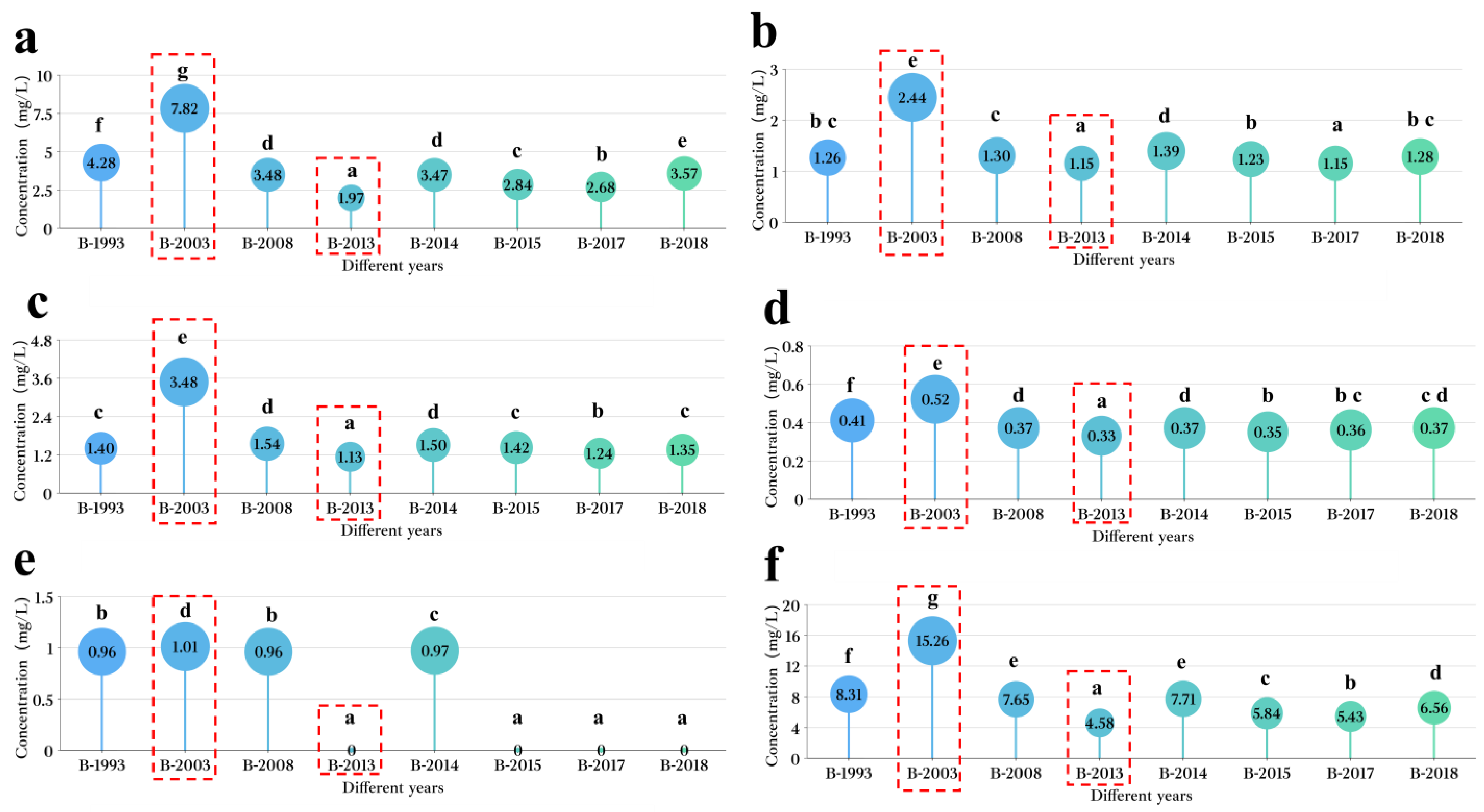

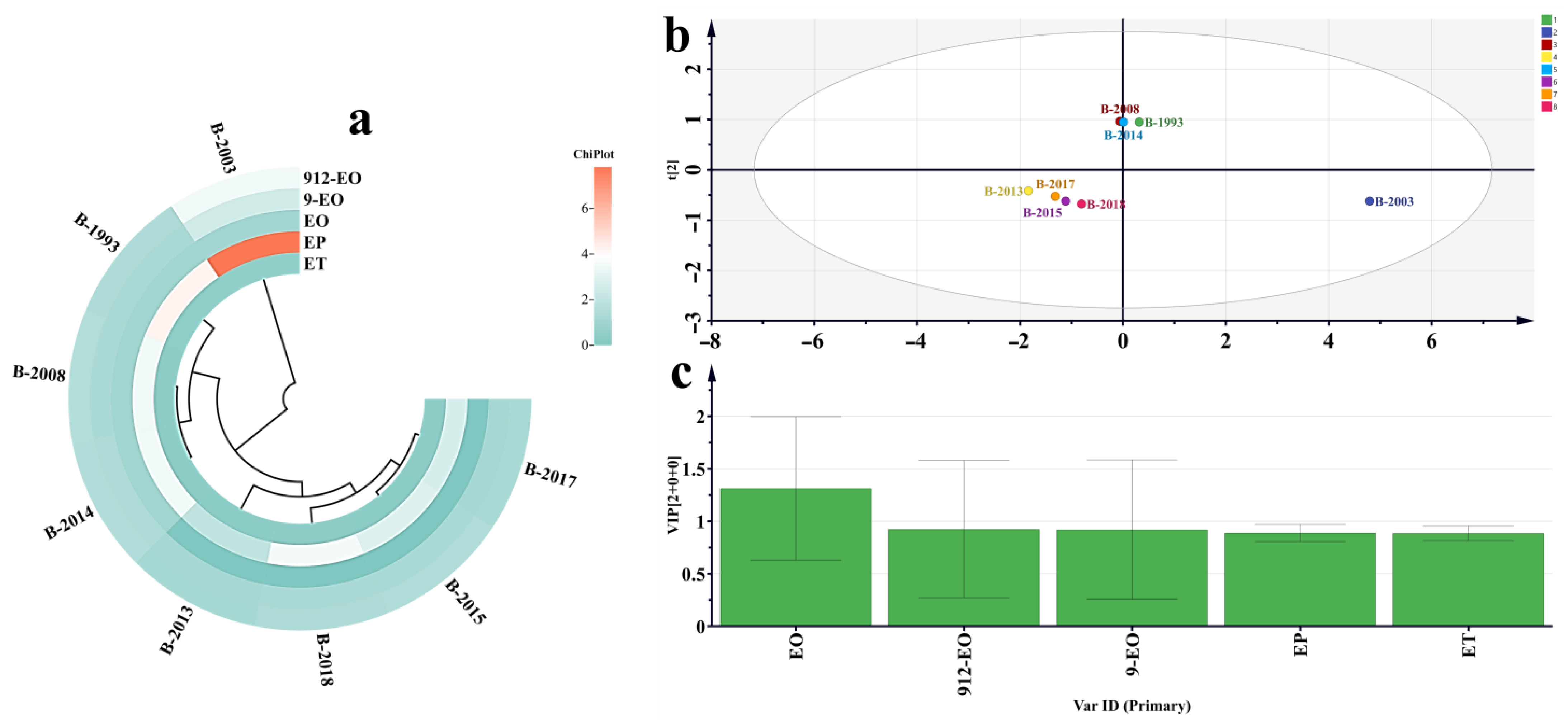

3.2. Distribution of Six LCFAEEs in Baijiu for Different Years

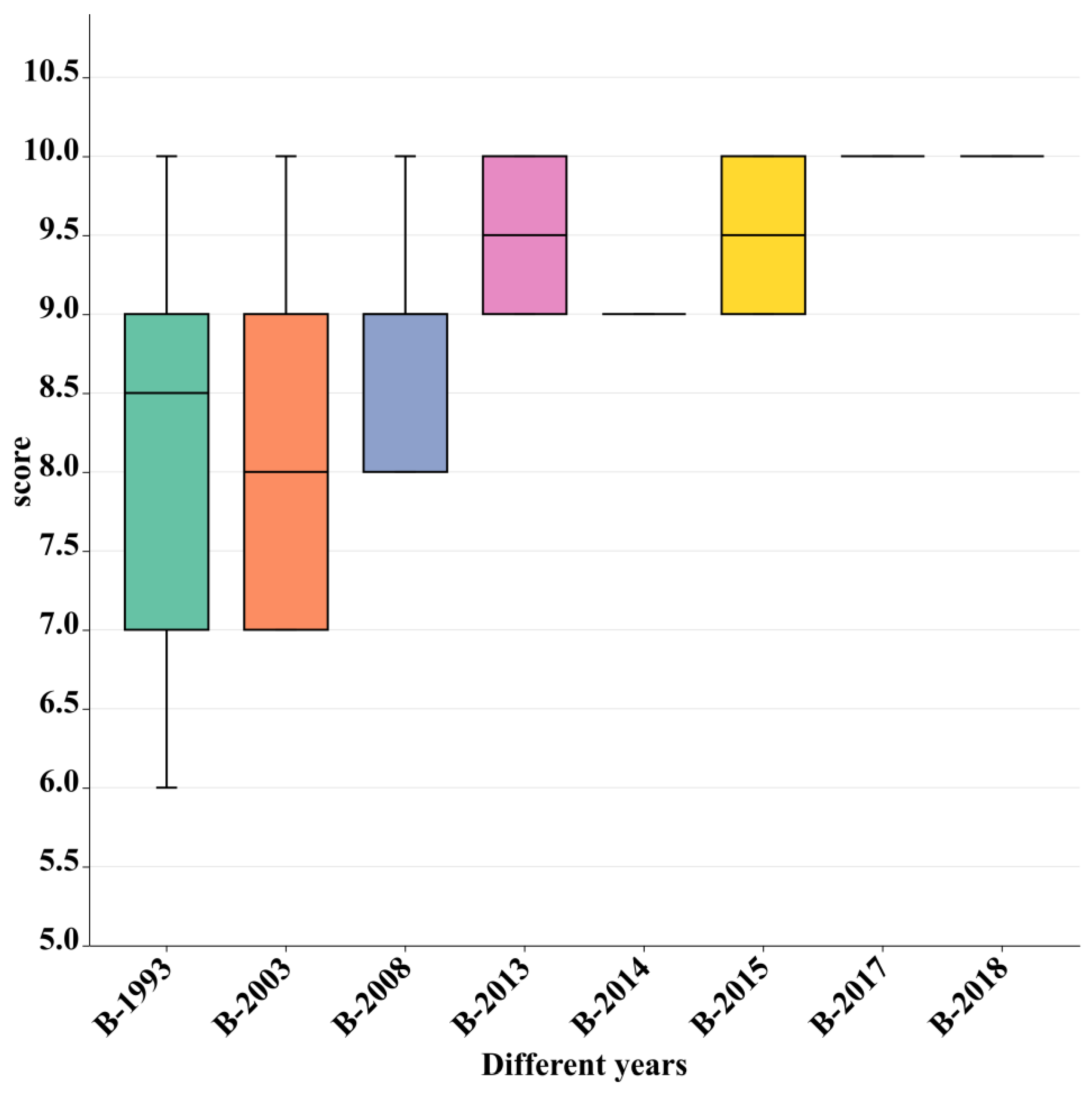

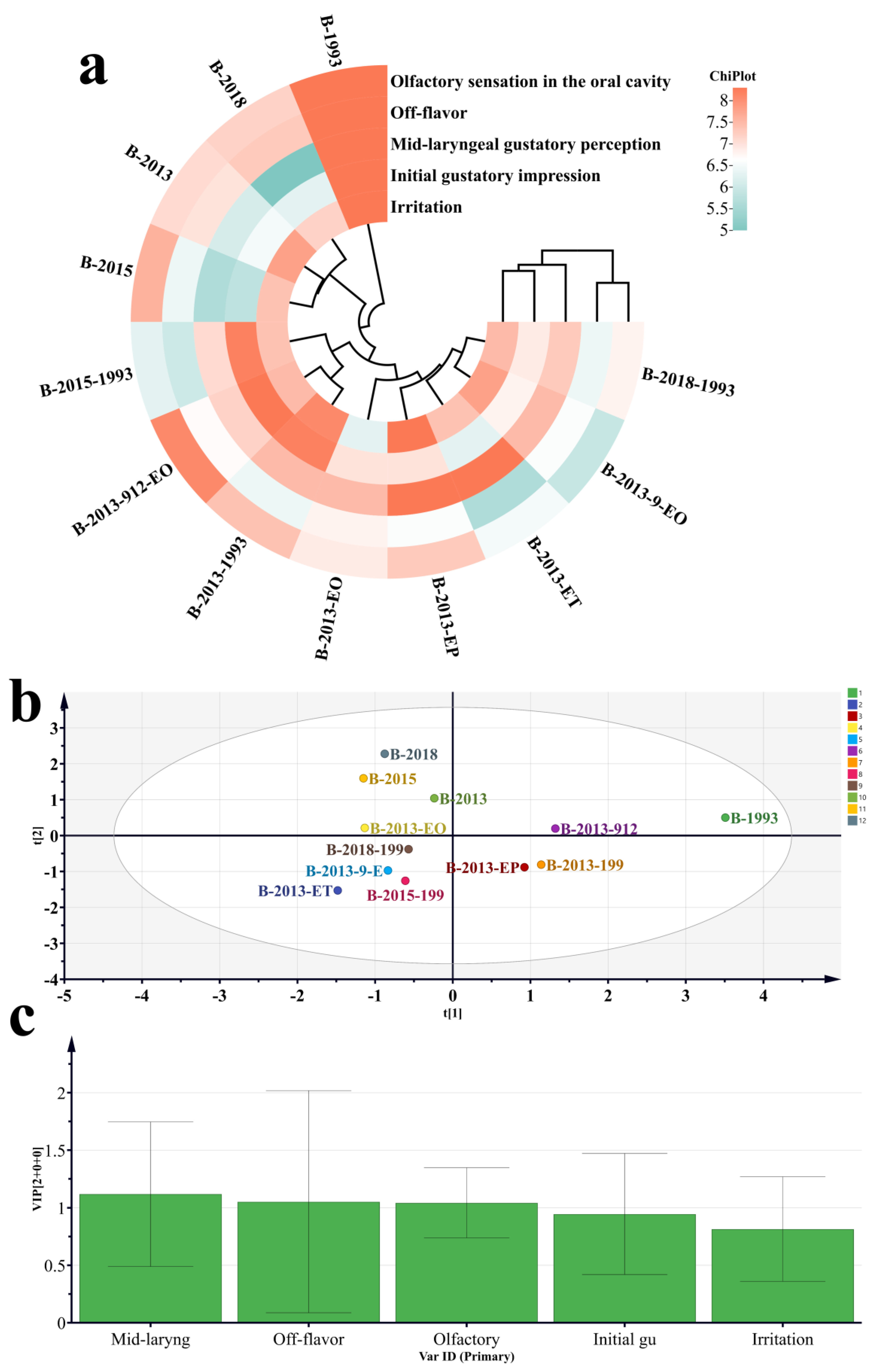

3.3. Analysis of Baijiu Samples Using Modern Flavor Sensomics

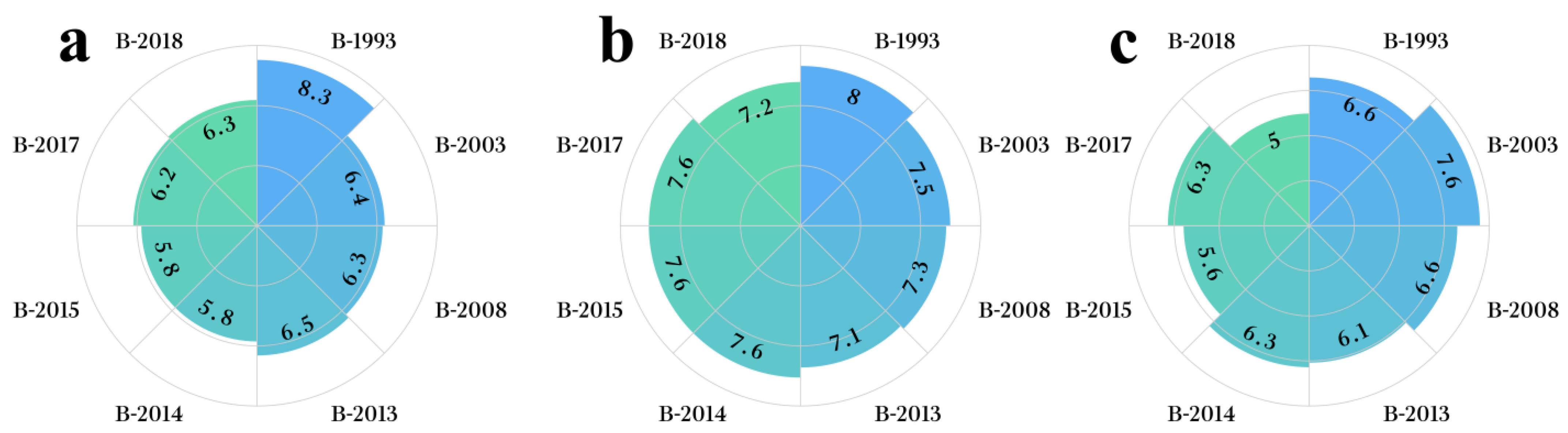

3.3.1. Visual Sense

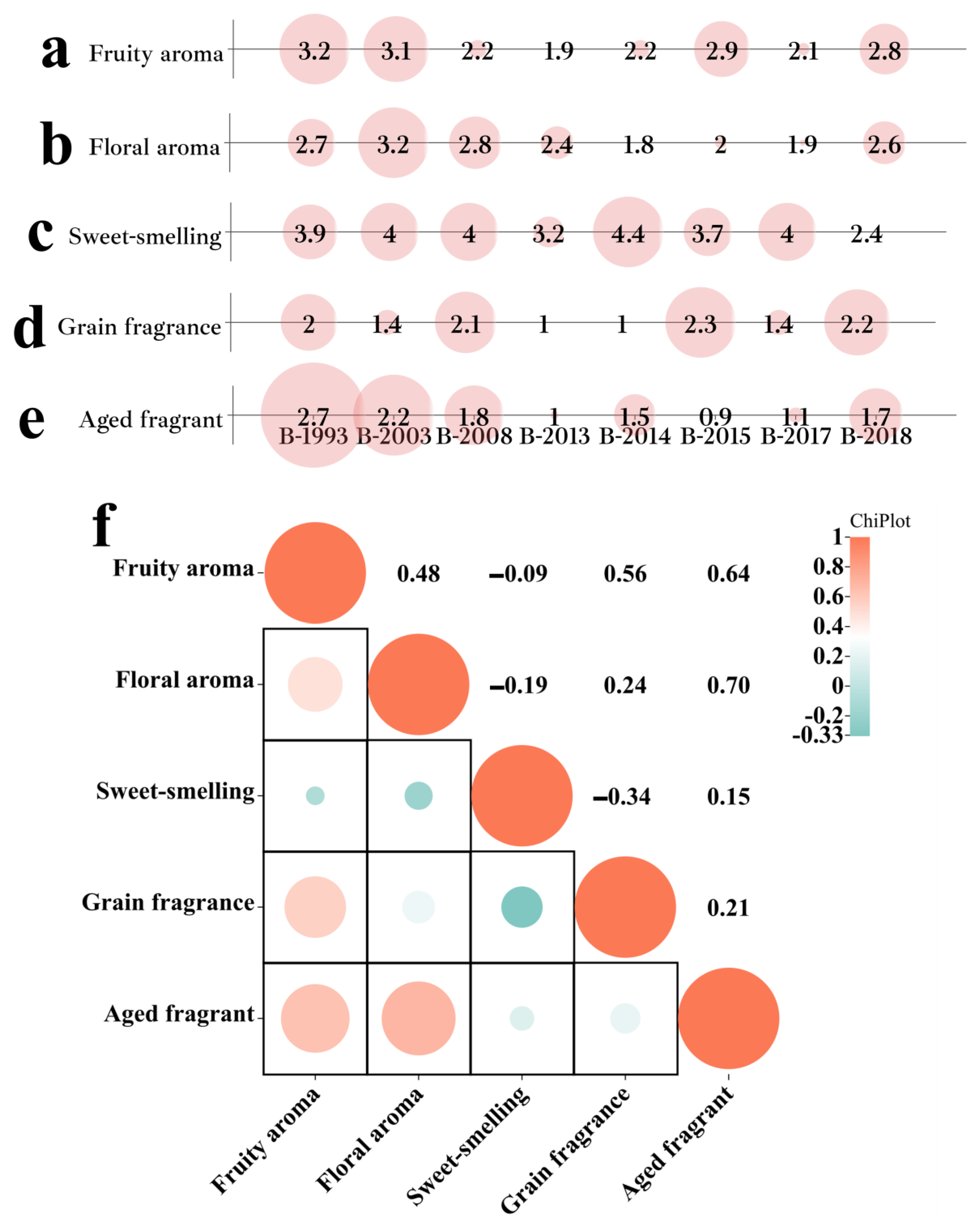

3.3.2. Olfactory Sense

3.3.3. Taste Sense

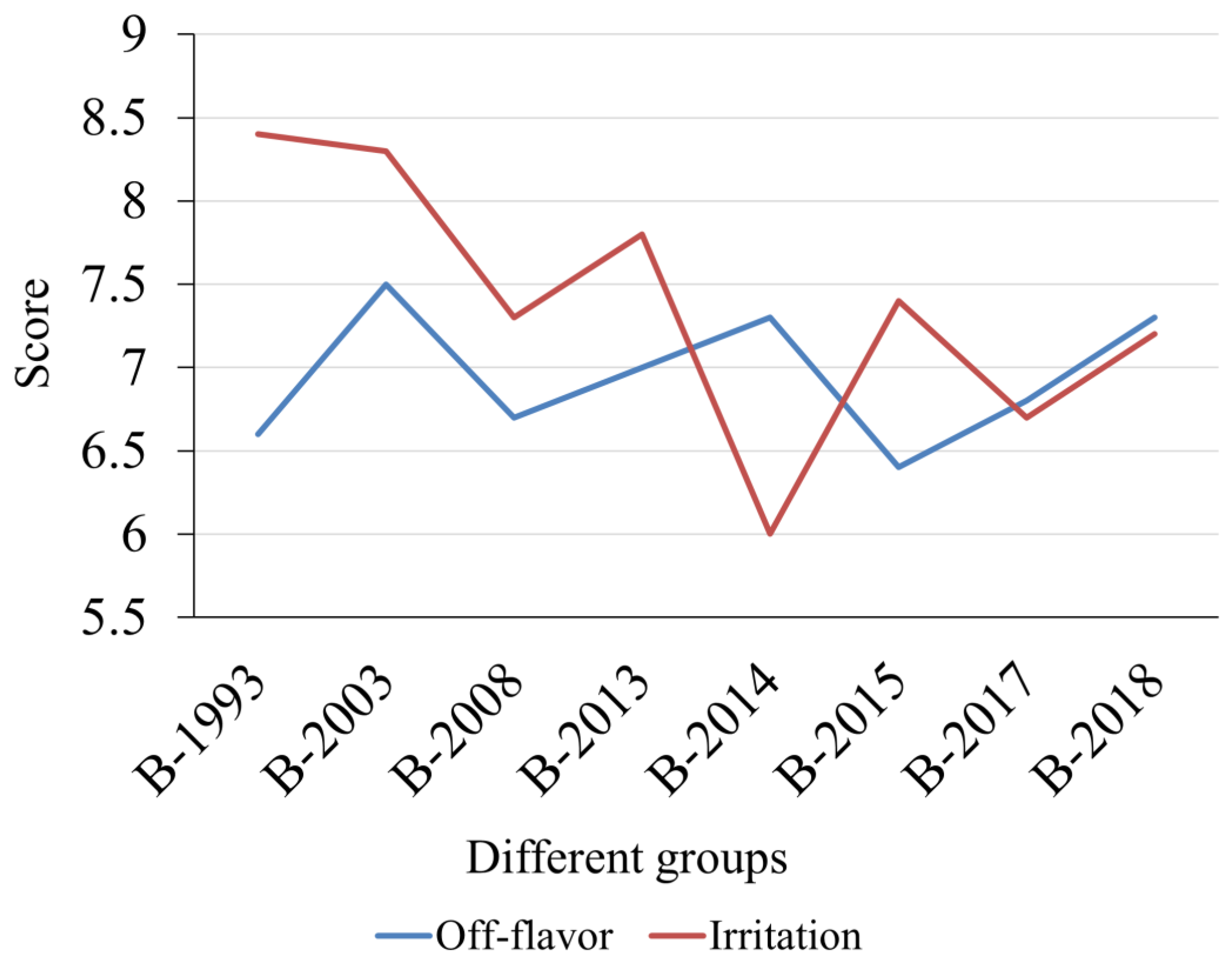

3.3.4. Evaluation after Drinking

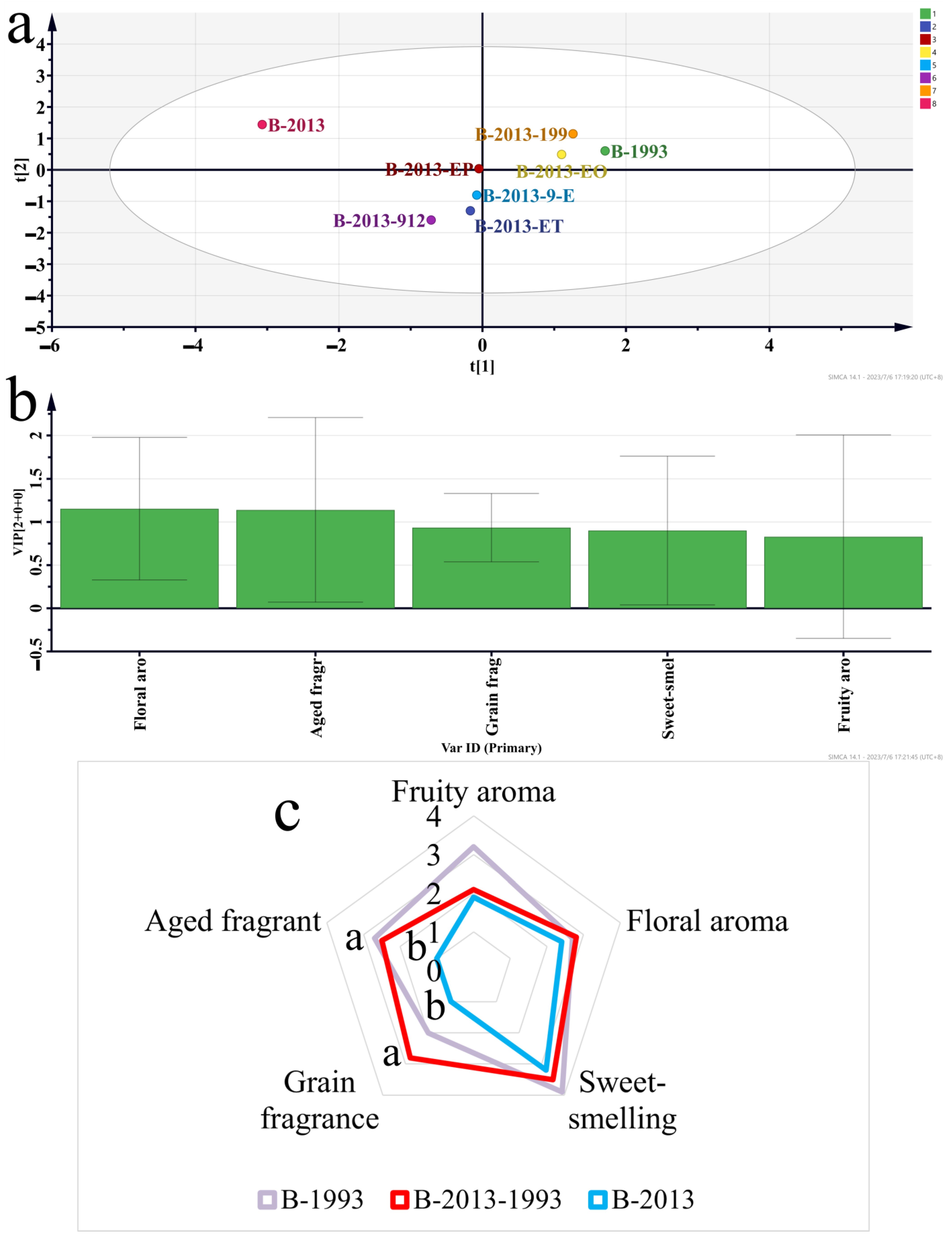

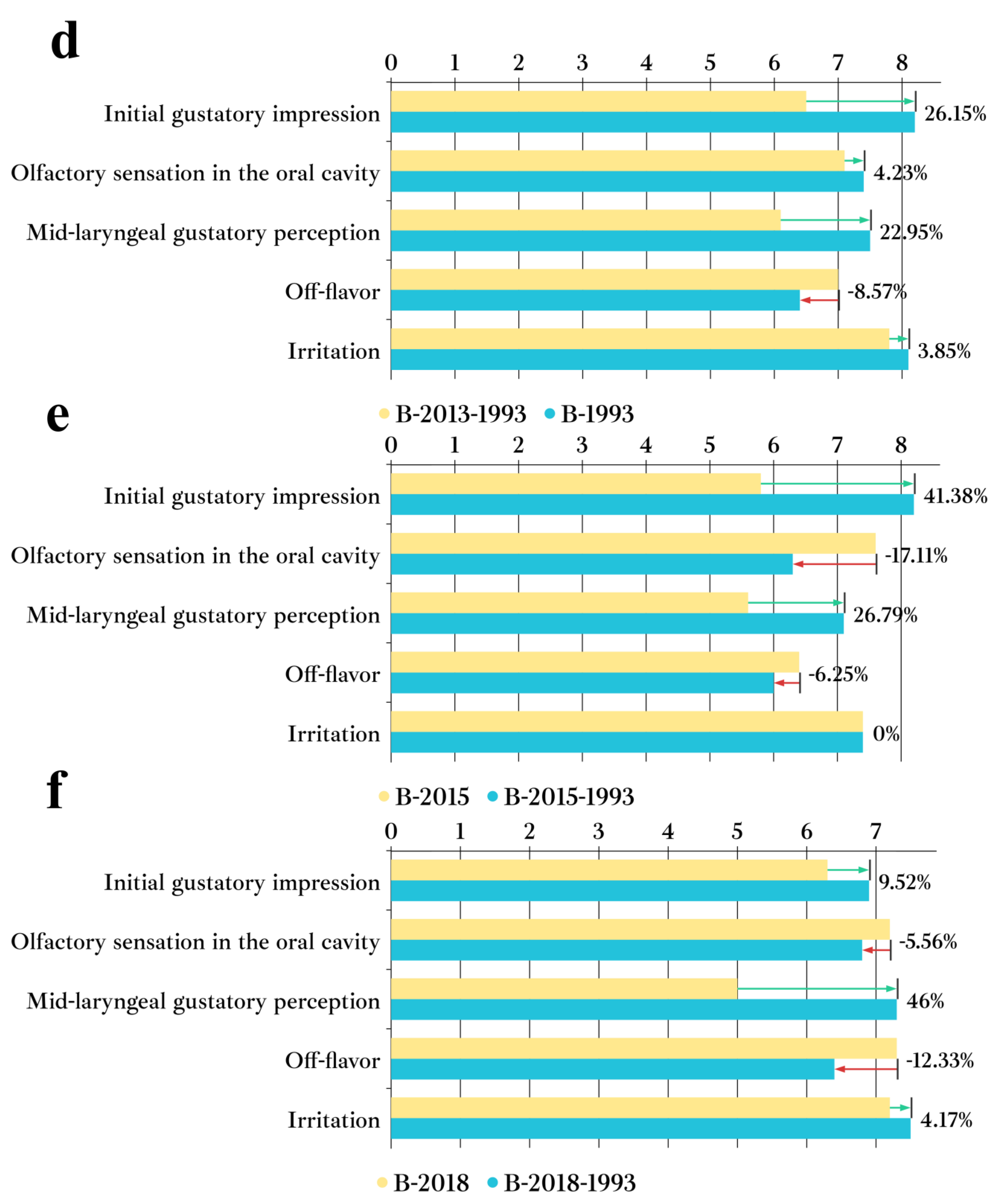

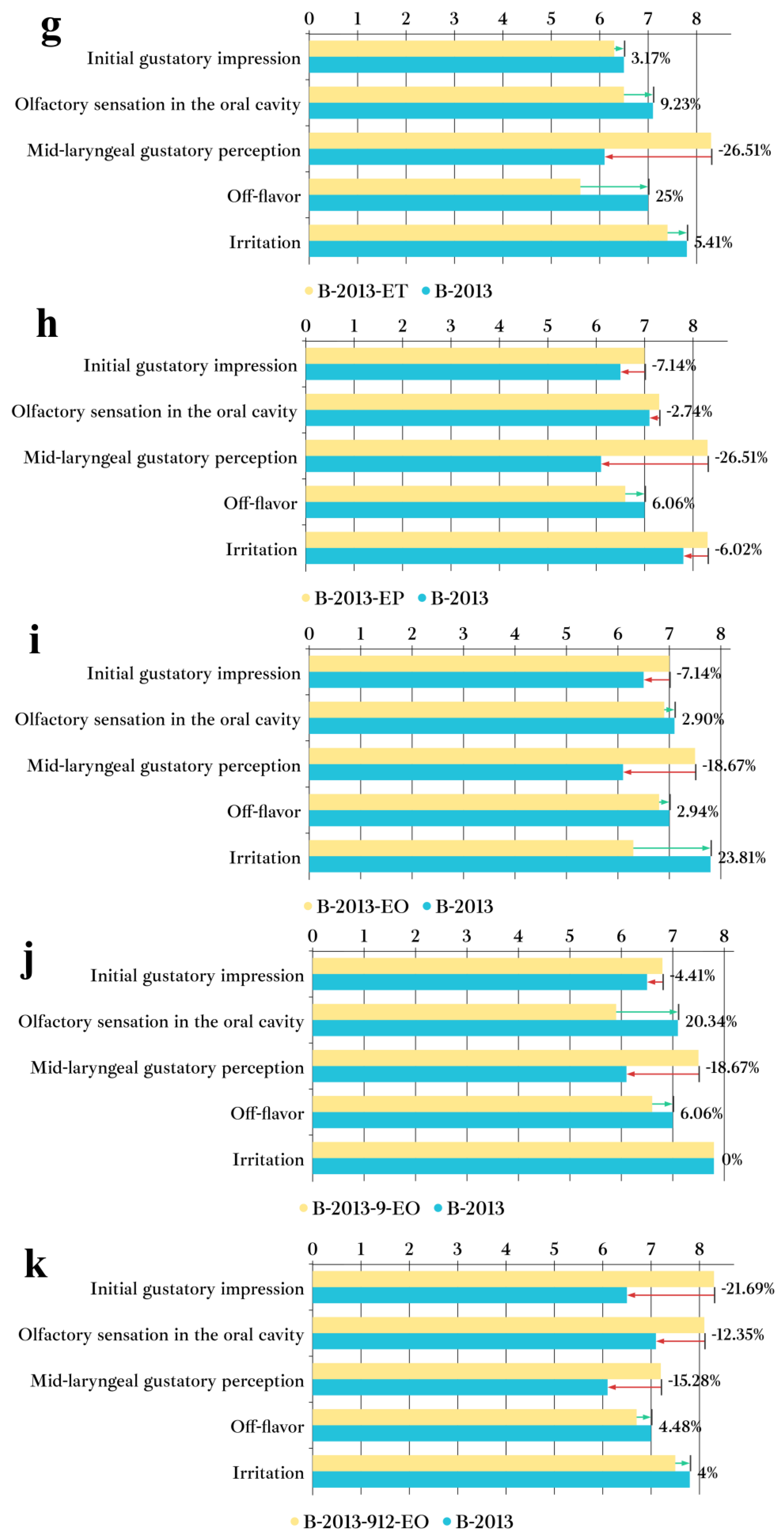

3.4. Baijiu Sample Addition Experiment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Huang, H.; Lu, H.; Wu, M.; Lin, M.; Zhang, C.; Zhao, Z.; Li, W.; Zhang, C.; Li, X.; et al. Characterization of an aspergillus niger for efficient fatty acid ethyl ester synthesis in aqueous phase and the molecular mechanism. Front. Microbiol. 2022, 12, 820380. [Google Scholar] [CrossRef]

- Xiangluan, L.; Qingyi, H.; Yongtao, F.; Wenhong, Z.; Brennan, C.; Weidong, B. The effect of aged pork fat on the quality and volatile compounds of chi-aroma baijiu. Food Sci. Technol./Cienc. E Tecnol. Aliment. 2023, 43, e109922. [Google Scholar]

- Wang, J.; Chen, H.; Wu, Y.; Zhao, D. Uncover the flavor code of strong-aroma baijiu: Research progress on the revelation of aroma compounds in strong-aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499. [Google Scholar] [CrossRef]

- Jia, W.; Ma, R.; Hu, L.; Mo, H. Synergy of physicochemical reactions occurred during aging for harmonizing and improving flavor. Food Chem. X 2023, 17, 100554. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Tian, W.; Zhao, D. Research progress of trace components in sesame-aroma type of baijiu. Food Res. Int. 2020, 137, 109695. [Google Scholar] [CrossRef]

- Wang, G.; Jing, S.; Song, X.; Zhu, L.; Zheng, F.; Sun, B. Reconstitution of the flavor signature of laobaigan-type baijiu based on the natural concentrations of its odor-active compounds and nonvolatile organic acids. J. Agric. Food. Chem. 2022, 70, 837–846. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Hou, Y.; Chen, H.; Wang, J.; Zhang, C.; Zhao, Z.; Ao, R.; Huang, H.; Hong, J.; Zhao, D.; et al. “Key factor” for baijiu quality: Research progress on acid substances in baijiu. Foods 2022, 11, 2959. [Google Scholar] [CrossRef]

- Du, Y.; Xin, W.; Xia, Y.; Zhu, M.; Qin, J.; Pan, Z.; Wu, R.; Luo, G.; Wu, P.; Wu, Z.; et al. Analysis of fermentation control factors on volatile compounds of primary microorganisms in jiang-flavor daqu. J. Food Biochem. 2022, 46, e14277. [Google Scholar] [CrossRef]

- Sun, X.; Qian, Q.; Xiong, Y.; Xie, Q.; Yue, X.; Liu, J.; Wei, S.; Yang, Q. Characterization of the key aroma compounds in aged chinese xiaoqu baijiu by means of the sensomics approach. Food Chem. 2022, 384, 132452. [Google Scholar] [CrossRef]

- Huang, H.; Wu, Y.; Chen, H.; Hou, Y.; Wang, J.; Hong, J.; Zhao, D.; Sun, J.; Huang, M.; Sun, B. Identification on regional-markers based on the flavor molecular matrix analysis of sauce-aroma style baijiu. J. Sci. Food. Agric. 2023. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, H.; Huang, H.; Chen, F.; Hong, J.; Zhao, D.; Zhang, C.; Zhao, Z.; Wang, S.; Ao, R.; et al. Revelation for the influence mechanism of long-chain fatty acid ethyl esters on the baijiu quality by multicomponent chemometrics combined with modern flavor sensomics. Foods 2023, 12, 1267. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, M.; Zhao, D.; Zheng, J.; Dai, M.; Li, X.; Li, W.; Zhang, C.; Sun, B. Simulated fermentation of strong-flavor baijiu through functional microbial combination to realize the stable synthesis of important flavor chemicals. Foods 2023, 12, 644. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, L.; Lu, Z.; Chai, L.; Wang, S.; Shi, J.; Shen, C.; Xu, Z. Identification of age-markers based on profiling of baijiu volatiles over a two-year maturation period: Case study of lu-flavor baijiu. LWT-Food Sci. Technol. 2021, 141, 110913. [Google Scholar] [CrossRef]

- Hong, J.; Wang, J.; Zhang, C.; Zhao, Z.; Tian, W.; Wu, Y.; Chen, H.; Zhao, D.; Sun, J. Unraveling variation on the profile aroma compounds of strong aroma type of baijiu in different regions by molecular matrix analysis and olfactory analysis. RSC Adv. 2021, 11, 33511–33521. [Google Scholar] [CrossRef]

- Xue, Y.; Tang, F.; Cai, W.; Zhao, X.; Song, W.; Zhong, J.; Liu, Z.; Guo, Z.; Shan, C. Bacterial diversity, organic acid, and flavor analysis of dacha and ercha fermented grains of fen flavor baijiu. Front. Microbiol. 2022, 12, 769290. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yi, X.; Huang, M.; Liu, Y.; Meng, W.; Yang, Q.; Huo, J.; Zhang, Q.; Luo, X.; Wu, J.; et al. Studies on the key odorants in maopu buckwheat finished baijiu and the effect of tartary buckwheat extract on its flavor. LWT-Food Sci. Technol. 2022, 154, 112650. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, J.; Wang, Y.; Zhu, T.; Huang, M.; Wu, J.; Xu, Y.; Zhang, J.; Wang, B. A new method to predict the content changes of aroma compounds during the aging process of niulanshan baijiu using the gm (1,1) gray model. Flavour Frag. J. 2022, 37, 5–19. [Google Scholar] [CrossRef]

- Zhao, D.; Shi, D.; Sun, J.; Li, A.; Sun, B.; Zhao, M.; Chen, F.; Sun, X.; Li, H.; Huang, M.; et al. Characterization of key aroma compounds in gujinggong chinese baijiu by gas chromatography-olfactometry, quantitative measurements, and sensory evaluation. Food Res. Int. 2018, 105, 616–627. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Huang, H.; Zhao, D.; Sun, J.; Huang, M.; Sun, X.; Sun, B. Investigation on the key factors associated with flavor quality in northern strong aroma type of baijiu by flavor matrix. Food Chem. 2023, 426, 136576. [Google Scholar] [CrossRef]

- Zhao, D.; Sun, J.; Sun, B.; Zhao, M.; Zheng, F.; Huang, M.; Sun, X.; Li, H. Intracellular antioxidant effect of vanillin, 4-methylguaiacol and 4-ethylguaiacol: Three components in chinese baijiu. RSC Adv. 2017, 7, 46395–46405. [Google Scholar] [CrossRef]

- Zhao, D.; Jiang, Y.; Sun, J.; Li, H.; Luo, X.; Zhao, M. Anti-inflammatory mechanism involved in 4-ethylguaiacol-mediated inhibition of lps-induced inflammation in thp-1 cells. J. Agric. Food Chem. 2019, 67, 1230–1243. [Google Scholar] [CrossRef]

- Hong, J.; Zhao, D.; Sun, B. Research progress on the profile of trace components in baijiu. Food Rev. Int. 2023, 39, 1666–1693. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, J.; Ma, C.; Wu, Y.; Li, L.; Zhu, C.; Gao, H.; Yang, Z.; Shang, Y.; Wang, C.; et al. Flavor classification and year prediction of chinese baijiu by time-resolved fluorescence. Appl. Opt. 2021, 60, 5480–5487. [Google Scholar] [CrossRef]

- Tu, W.; Cao, X.; Cheng, J.; Li, L.; Zhang, T.; Wu, Q.; Xiang, P.; Shen, C.; Li, Q. Chinese baijiu: The perfect works of microorganisms. Front. Microbiol. 2022, 13, 919044. [Google Scholar] [CrossRef]

- Deng, Y.; Xiong, A.; Zhao, K.; Hu, Y.; Kuang, B.; Xiong, X.; Yang, Z.; Yu, Y.; Zheng, Q. Mechanisms of the regulation of ester balance between oxidation and esterification in aged baijiu. Sci. Rep. 2020, 10, 17169. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhang, X.; Zheng, L.; Meng, L.; Liu, G.; Yang, T.; Lu, Z.; Chai, L.J.; Wang, S.; Shi, J.; et al. Machine learning based age-authentication assisted by chemo-kinetics: Case study of strong-flavor chinese baijiu. Food Res. Int. 2023, 167, 112594. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Zhao, Z.; Li, X.; Sun, B. Flavor mystery of chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2022, 369, 130920. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Y.; Wang, J.; Hong, J.; Tian, W.; Zhao, D.; Sun, J.; Huang, M.; Li, H.; Zheng, F.; et al. Uncover the flavor code of roasted sesame for sesame flavor baijiu: Advance on the revelation of aroma compounds in sesame flavor baijiu by means of modern separation technology and molecular sensory evaluation. Foods 2022, 11, 998. [Google Scholar] [CrossRef]

- Ya, Z.; He, K.; Lu, Z.; Yi, B.; Hou, C.; Shan, S.; Huo, D.; Luo, X. Colorimetric artificial nose for baijiu identification. Flavour Frag. J. 2012, 27, 165–170. [Google Scholar] [CrossRef]

- Song, X.; Zhu, L.; Geng, X.; Li, Q.; Zheng, F.; Zhao, Q.; Ji, J.; Sun, J.; Li, H.; Wu, J.; et al. Analysis, occurrence, and potential sensory significance of tropical fruit aroma thiols, 3-mercaptohexanol and 4-methyl-4-mercapto-2-pentanone, in chinese baijiu. Food Chem. 2021, 363, 130232. [Google Scholar] [CrossRef]

- Han, X.; Yin, X.; Jiang, W.; Xue, X. Style characteristics investigation of quan-xing baijiu by comparing other strong-aroma baijiu brands in china. J. Food Qual. 2022, 2022, 3741199. [Google Scholar] [CrossRef]

- He, Y.; Chen, S.; Tang, K.; Qian, M.; Yu, X.; Xu, Y. Sensory characterization of baijiu pungency by combined time-intensity (ti) and temporal dominance of sensations (tds). Food Res. Int. 2021, 147, 110493. [Google Scholar] [CrossRef]

- Yin, X.; Yoshizaki, Y.; Kurazono, S.; Sugimachi, M.; Takeuchi, H.; Han, X.; Okutsu, K.; Futagami, T.; Tamaki, H.; Takamine, K. Characterization of flavor compounds in rice-flavor baijiu, a traditional chinese distilled liquor, compared with japanese distilled liquors, awamori and kome-shochu. Food Sci. Technol. Res. 2020, 26, 411–422. [Google Scholar] [CrossRef]

- Yan, Q.; Zhang, K.; Zou, W.; Hou, Y. Three main flavour types of chinese baijiu: Characteristics, research, and perspectives. J. Inst. Brew. 2021, 127, 317–326. [Google Scholar] [CrossRef]

- Fan, W.; Xu, Y.; Qian, M. Current practice and future trends of aroma and flavor research in chinese baijiu. In Sex, Smoke, and Spirits: The Role of Chemistry; American Chemical Society: New Orleans, LA, USA, 2019; pp. 145–175. [Google Scholar]

- Li, J.; Liu, X.; Luo, H.; Zhao, D.; Zhang, J.; Qiao, C.; Ma, Y.; Huo, D.; Hou, C. A gold nanorods etching based colorimetric sensor array for the detection of reducing substances and discrimination of chinese baijiu. Food Anal. Methods 2022, 15, 2605–2614. [Google Scholar] [CrossRef]

- An, Y.; Qian, Y.; Chen, S.; Qian, M.C. Aroma comparison of tibetan “qjngke” liquor with other chinese baijiu. In Sex, Smoke, and Spirits: The Role of Chemistry; American Chemical Society: New Orleans, LA, USA, 2019; pp. 225–252. [Google Scholar]

- Liu, H.; Sun, B. Effect of fermentation processing on the flavor of baijiu. J. Agric. Food Chem. 2018, 66, 5425–5432. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, M.; Niu, J.; Lin, M.; Zhu, H.; Wang, K.; Li, X.; Sun, B. Characteristics and correlation of the microbial communities and flavor compounds during the first three rounds of fermentation in chinese sauce-flavor baijiu. Foods 2023, 12, 207. [Google Scholar] [CrossRef]

- Cheng, W.; Chen, X.; Zhou, D.; Xiong, F. Applications and prospects of the automation of compound flavor baijiu production by solid-state fermentation. Int. J. Food Eng. 2022, 18, 737–749. [Google Scholar] [CrossRef]

- Lin, B.; Tang, J.; Yang, Q.; Su, Z.; Zhu, L.; Li, Q.; Jiang, W.; Zhang, L.; Liu, Y.; Chen, S. Microbial succession and its effect on key aroma components during light-aroma-type xiaoqu baijiu brewing process. World J. Microbiol. Biotechnol. 2022, 38, 166. [Google Scholar] [CrossRef]

- Qin, D.; Wu, Z.; Shen, Y.; Cheng, H.; Yang, K.; Li, H.; Ye, X.; Sun, B. Characterization of empty cup aroma in soy sauce aroma type baijiu by vacuum assisted sorbent extraction. J. Food Compos. Anal. 2023, 117, 105147. [Google Scholar] [CrossRef]

- Zheng, Y.; Sun, B.; Zhao, M.; Zheng, F.; Huang, M.; Sun, J.; Sun, X.; Li, H. Characterization of the key odorants in chinese zhima aroma-type baijiu by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agric. Food Chem. 2016, 64, 5367–5374. [Google Scholar] [CrossRef] [PubMed]

- Mu, X.; Lu, J.; Gao, M.; Li, C.; Chen, S. Optimization and validation of a headspace solid-phase microextraction with comprehensive two-dimensional gas chromatography time-of-flight mass spectrometric detection for quantification of trace aroma compounds in chinese liquor (baijiu). Molecules 2021, 26, 6910. [Google Scholar] [CrossRef]

- Cai, W.; Wang, Y.; Wang, W.; Shu, N.; Hou, Q.; Tang, F.; Shan, C.; Yang, X.; Guo, Z. Insights into the aroma profile of sauce-flavor baijiu by gc-ims combined with multivariate statistical analysis. J. Anal. Methods Chem. 2022, 2022, 4614330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Cheng, Y.; Luo, D.; He, J.; Wong, A.K.Y.; Hung, K. Channel attention convolutional neural network for chinese baijiu detection with e-nose. IEEE Sens. J. 2021, 21, 16170–16182. [Google Scholar] [CrossRef]

- Fan, G.; Fu, Z.; Teng, C.; Liu, P.; Wu, Q.; Rahman, M.K.R.; Li, X. Effects of aging on the quality of roasted sesame-like flavor daqu. BMC Microbiol. 2020, 20, 67. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.; Nie, Y.; Xu, Y. Optimization of an intra-oral solid-phase microextraction (spme) combined with comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry (gc × gc-tofms) method for oral aroma compounds monitoring of baijiu. Food Chem. 2022, 385, 132502. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Hu, X.; Li, Y. The impact of environmental factors on the environmental bacterial diversity and composition in the jiang-flavoured baijiu production region. LWT-Food Sci. Technol. 2021, 149, 111784. [Google Scholar] [CrossRef]

- Chen, P.; Liu, Y.; Wu, J.; Yu, B.; Zhao, H.; Huang, M.; Zheng, F. Sensory-directed decoding of key aroma compounds from jiugui-series baijiu, the representative of fuyu-flavor-type baijiu (fftb). J. Food Compos. Anal. 2022, 114, 104799. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Sun, B. Low quantity but critical contribution to flavor: Review of the current understanding of volatile sulfur-containing compounds in baijiu. J. Food Compos. Anal. 2021, 103, 104079. [Google Scholar] [CrossRef]

- Chen, L.; Yan, R.; Zhao, Y.; Sun, J.; Zhang, Y.; Li, H.; Zhao, D.; Wang, B.; Ye, X.; Sun, B. Characterization of the aroma release from retronasal cavity and flavor perception during baijiu consumption by vocus-ptr-ms, gc × gc-ms, and tcata analysis. LWT-Food Sci. Technol. 2023, 174, 114430. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, X.; Zhao, Y.; Zheng, F.; Li, H.; Zhang, F.; Zhang, Y.; Chen, F. Characterization of key aroma compounds in laobaigan chinese baijiu by gcxgc-tof/ms and means of molecular sensory science. Flavour Frag. J. 2019, 34, 514–525. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, Y.; Deng, R.; Wang, Y.; Qiu, Y.; Sun, Q.; Luo, A. An electric-field instrument for accelerated aging to improve flavor of chinese baijiu. LWT-Food Sci. Technol. 2023, 174, 114446. [Google Scholar] [CrossRef]

- Jia, W.; Ma, R. Cross-modal interactions caused by nonvolatile compounds derived from fermentation, distillation and aging to harmonize flavor. Crit. Rev. Food. Sci. Nutr. 2023. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Wang, Z.; Xiong, A.; Hu, Y.; Su, Y.; Zhao, K.; Yu, Y. Elucidating oxidation-based flavour formation mechanism in the aging process of chinese distilled spirits by electrochemistry and uplc-q-orbitrap-ms/ms. Food Chem. 2021, 355, 129596. [Google Scholar] [CrossRef]

- Zhao, D.R.; Jiang, Y.S.; Sun, J.Y.; Li, H.H.; Sun, X.T.; Zhao, M.M. Amelioration of 4-methylguaiacol on lps-induced inflammation in thp-1 cells through nf-kappa b/i kappa b alpha/ap-1 and nrf2/ho-1 signaling pathway. J. Funct. Foods 2019, 55, 95–103. [Google Scholar] [CrossRef]

- Zhao, D.; Shi, D.; Sun, J.; Li, H.; Zhao, M.; Sun, B. Quantification and cytoprotection by vanillin, 4methylguaiacol and 4-ethylguaiacol against aaphinduced abnormal oxidative stress in hepg2 cells+. RSC Adv. 2018, 8, 35474–35484. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Y.; Fu, G.; Chen, Y.; Wan, Y.; Deng, M.; Cai, W.; Li, M. Improvement of the flavor of major ethyl ester compounds during chinese te-flavor baijiu brewing by wickerhamomyces anomalus. Food Biosci. 2022, 50, 102022. [Google Scholar] [CrossRef]

- Guo, X.; Cheng, Y.; Huang, Y. Study on the drunkenness of chinese baijiu with representative flavor based on behavioral characteristics. Front. Nutr. 2022, 9, 1014813. [Google Scholar] [CrossRef]

- Sun, Y.; Ma, Y.; Chen, S.; Xu, Y.; Tang, K. Exploring the mystery of the sweetness of baijiu by sensory evaluation, compositional analysis and multivariate data analysis. Foods 2021, 10, 2843. [Google Scholar] [CrossRef]

| Name | Abbreviation of Chart Name | CAS | Fineness | Sources |

|---|---|---|---|---|

| Ethyl tetradecanoate | ET | 124-06-1 | GC ≥ 98.0% | Beijing InnoChem Science and Technology Co., Ltd. |

| Ethyl palmitate | EP | 628-97-7 | GC ≥ 98.0% | |

| Ethyl octadecanoate | EO | 111-61-5 | GC ≥ 99.0% | |

| Ethyl 9-octadecenoate | 9-EO | 111-62-6 | GC ≥ 98.5% | |

| Ethyl 9,12-octadecadienoate | 912-EO | 544-35-4 | GC ≥ 97.0% | |

| Ethyl 9,12,15-octadecatrienoate | 91215-EO | 1191-41-9 | GC ≥ 98.0% |

| Numbering of Baijiu Sample Groups | Descriptive Information about Baijiu | Alcohol/° |

|---|---|---|

| B-1993 | A certain Baijiu produced in 1993 | 56 |

| B-2003 | A certain Baijiu produced in 2003 | 58 |

| B-2008 | A certain Baijiu produced in 2008 | 54 |

| B-2013 | A certain Baijiu produced in 2013 | 55 |

| B-2014 | A certain Baijiu produced in 2014 | 59 |

| B-2015 | A certain Baijiu produced in 2015 | 59 |

| B-2017 | A certain Baijiu produced in 2017 | 58 |

| B-2018 | A certain Baijiu produced in 2018 | 60 |

| One-Level Indicators | Two-Level Indicators | Specific Description | Rating Score (Points) |

|---|---|---|---|

| Visual sense | Clear and transparent with an absence of impurities | Optically pure with no suspension or precipitation. | 0–10 |

| Olfactory sense | Fruity aroma | The aroma profile of Baijiu showcases a diverse range of fruity notes, encompassing fragrances reminiscent of various fruits such as banana, apple, pineapple, and more. These fruity aromas yield a pleasant olfactory experience, evoking a sense of comfort and enjoyment. | 0–5 |

| Floral aroma | The sensory attribute referred to as “sweet flower fragrance” encompasses a delightful and appealing floral aroma. This aroma specifically includes the scents of flowers such as roses, chrysanthemums, and others. | 0–5 | |

| Sweet-smelling | The mellow aroma of Baijiu is characterized by its smooth, nuanced, and lingering fragrance that evokes a harmonious blend of distinct and complex notes. | 0–5 | |

| Grain fragrance | Pleasing aroma of cooked cereal grains. | 0–5 | |

| Aged fragrant | Distinct from Baijiu, this aroma can be characterized as an evident oak barrel aroma. | 0–5 | |

| Taste sense | Initial gustatory impression | The intricate trace constituents in Baijiu may elicit transient, mild irritation. | 0–10 |

| Olfactory sensation in the oral cavity | The profound Baijiu aroma resembles an exhilarating volcanic eruption enveloping the oral cavity. | 0–10 | |

| Mid-laryngeal gustatory perception | Absence of throat irritation and Baijiu’s subtle softness. | 0–10 | |

| Evaluation after drinking | Off-flavor | The off-flavor of Baijiu is characterized by unpleasant and atypical sensory attributes that deviate from the desired qualities, often exhibiting notes of mustiness, earthiness, or pungency. | 0–10 |

| Irritation | The characteristics of Baijiu’s irritation can manifest as a transient, mild sensation that momentarily stimulates the throat without inducing significant discomfort. | 0–10 |

| Compounds | Qualitative Ion | Quantitative Ion | LOD/(μg/L) | LOQ/(μg/L) | Intra-Day Precision/(%) | Inter-Day Precision/(%) | Recovery Rate/(%) | Regression Equation | R2 |

|---|---|---|---|---|---|---|---|---|---|

| ET | 88, 101, 157, 211, 256 | 88, 256 | 0.24 | 0.76 | 1.1 | 2.57 | 95–103 | y = 307,753x − 80,514 | 0.9989 |

| EP | 88, 101, 157, 239, 284 | 88, 284 | 0.32 | 1.91 | 1.15 | 1.73 | 105–108 | y = 308,141x − 217,577 | 0.9976 |

| EO | 88, 101, 157, 269, 312 | 88, 312 | 0.11 | 1.13 | 2.11 | 3.79 | 95–101 | y = 1,000,000x − 929,800 | 0.9896 |

| 9-EO | 55, 180, 222, 264, 310 | 55, 310 | 0.18 | 1.18 | 1.13 | 1.15 | 96–106 | y = 968,421x − 943,401 | 0.9958 |

| 912-EO | 67, 81, 109, 263, 308 | 67, 308 | 0.24 | 3.32 | 2.14 | 8.62 | 98–107 | y = 1,000,000x − 1,000,000 | 0.9950 |

| 91215-EO | 79, 95, 108, 121, 306 | 79, 306 | 0.44 | 1.15 | 2.35 | 0.85 | 102–103 | y = 1,000,000x − 1,000,000 | 0.9799 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Chen, H.; Sun, Y.; Huang, H.; Chen, Y.; Hong, J.; Liu, X.; Wei, H.; Tian, W.; Zhao, D.; et al. Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters. Foods 2023, 12, 3087. https://doi.org/10.3390/foods12163087

Wu Y, Chen H, Sun Y, Huang H, Chen Y, Hong J, Liu X, Wei H, Tian W, Zhao D, et al. Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters. Foods. 2023; 12(16):3087. https://doi.org/10.3390/foods12163087

Chicago/Turabian StyleWu, Yashuai, Hao Chen, Yue Sun, He Huang, Yiyuan Chen, Jiaxin Hong, Xinxin Liu, Huayang Wei, Wenjing Tian, Dongrui Zhao, and et al. 2023. "Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters" Foods 12, no. 16: 3087. https://doi.org/10.3390/foods12163087

APA StyleWu, Y., Chen, H., Sun, Y., Huang, H., Chen, Y., Hong, J., Liu, X., Wei, H., Tian, W., Zhao, D., Sun, J., Huang, M., & Sun, B. (2023). Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters. Foods, 12(16), 3087. https://doi.org/10.3390/foods12163087