Xylooligosaccharides: A Bibliometric Analysis and Current Advances of This Bioactive Food Chemical as a Potential Product in Biorefineries’ Portfolios

Abstract

1. Introduction

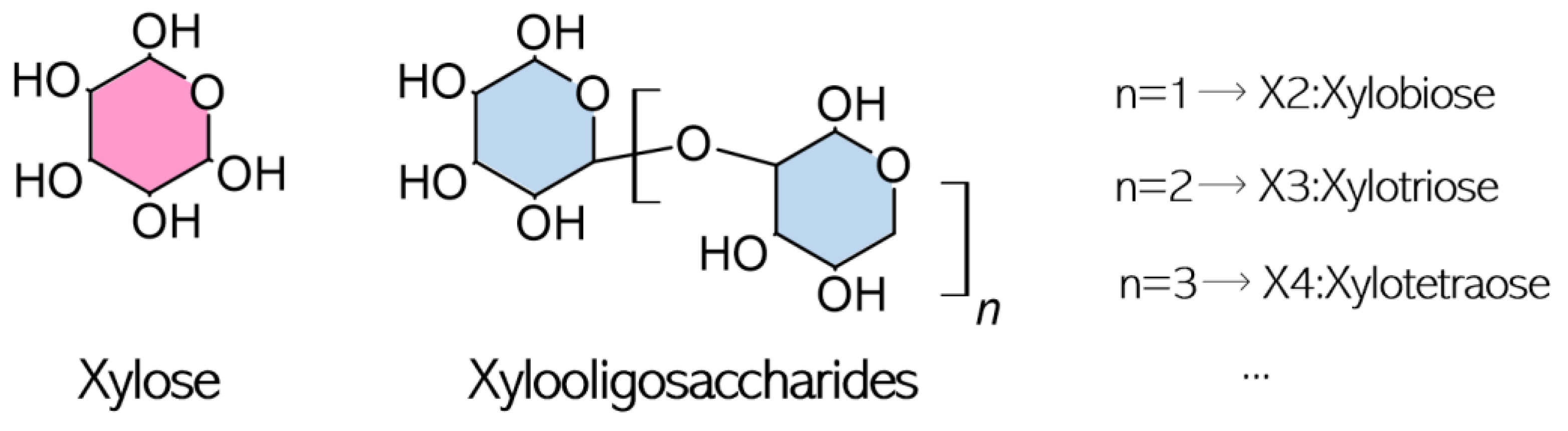

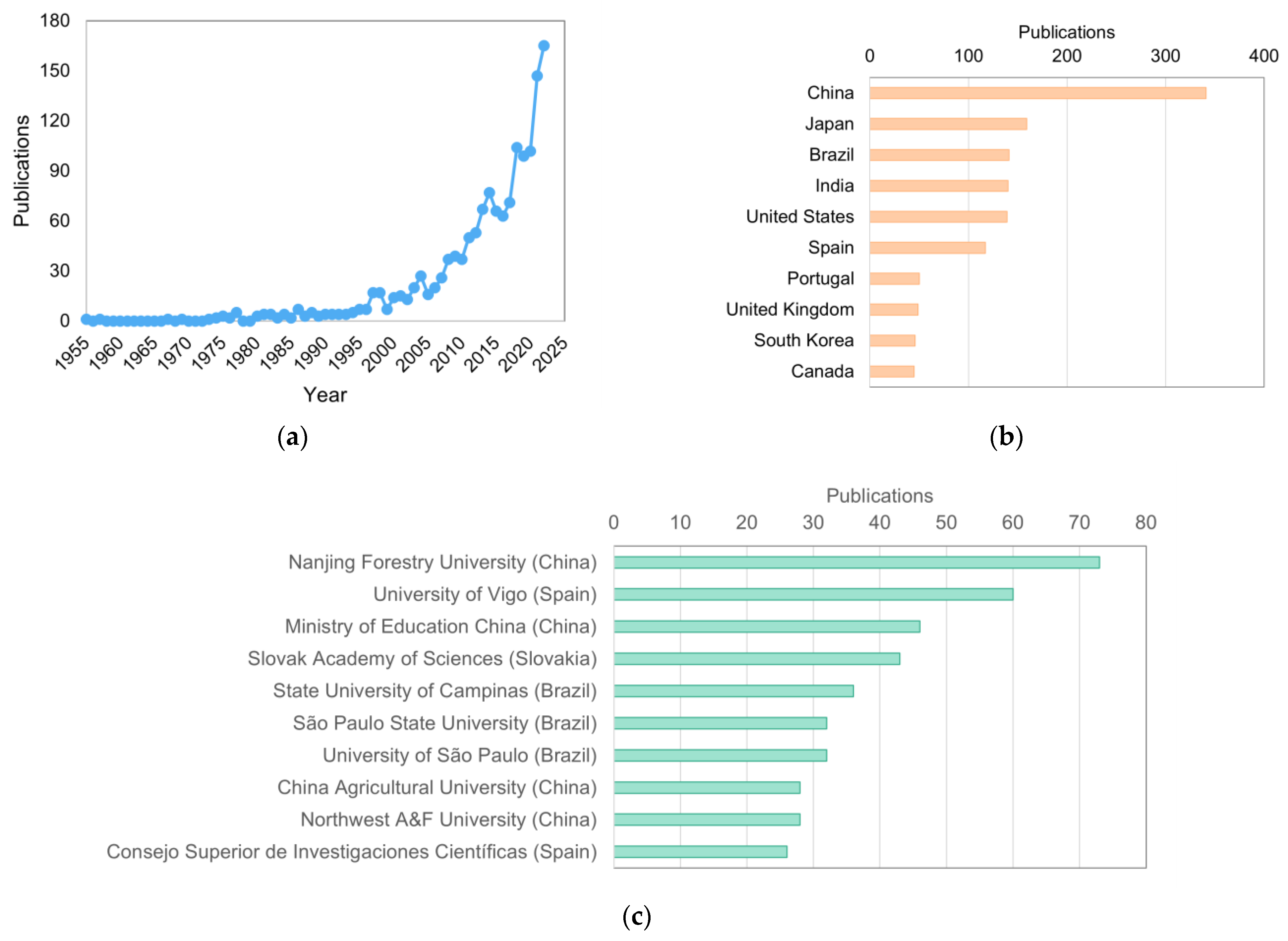

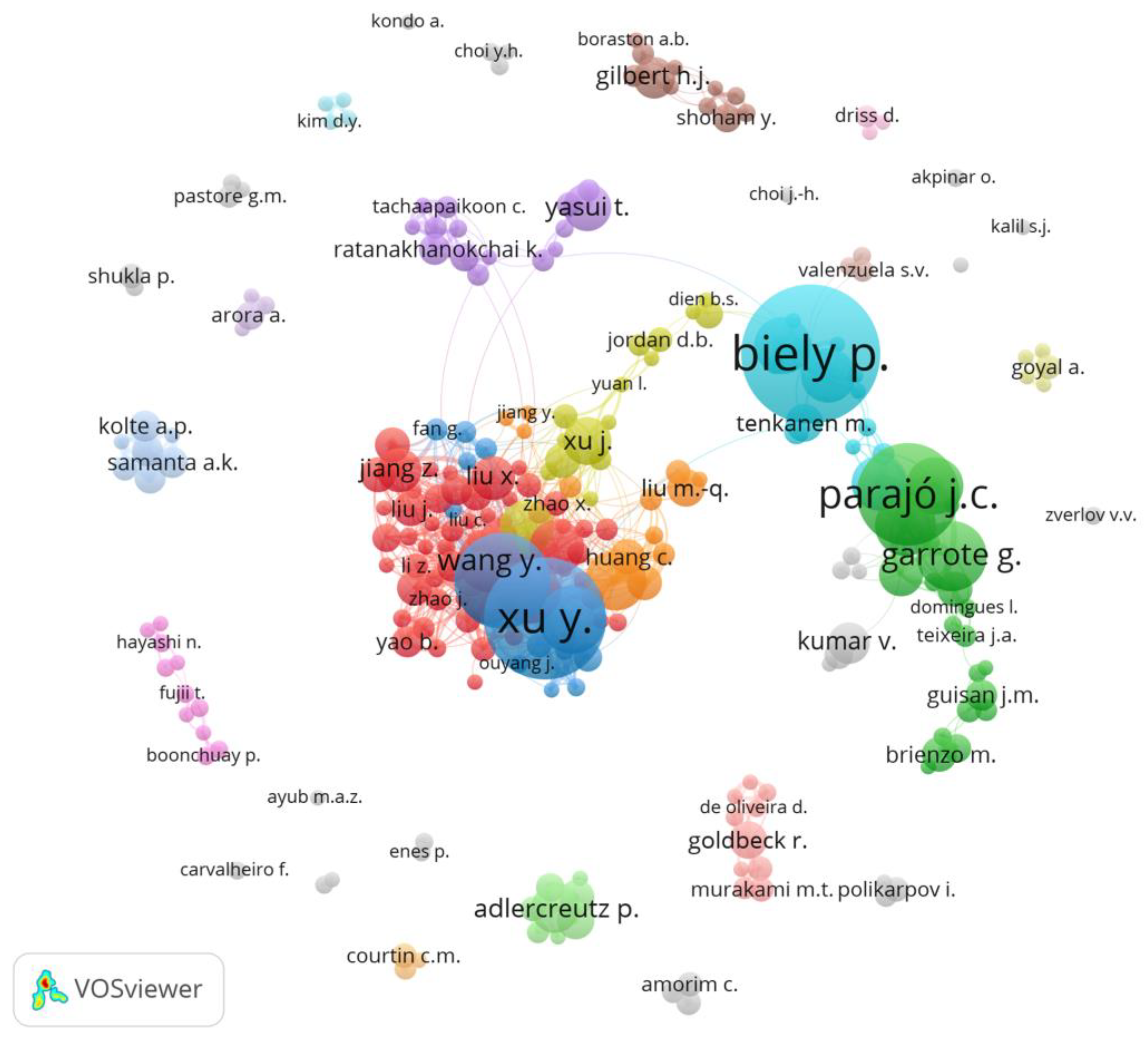

2. Xylooligosaccharides (XOS) Characteristics and Bibliometric Analysis

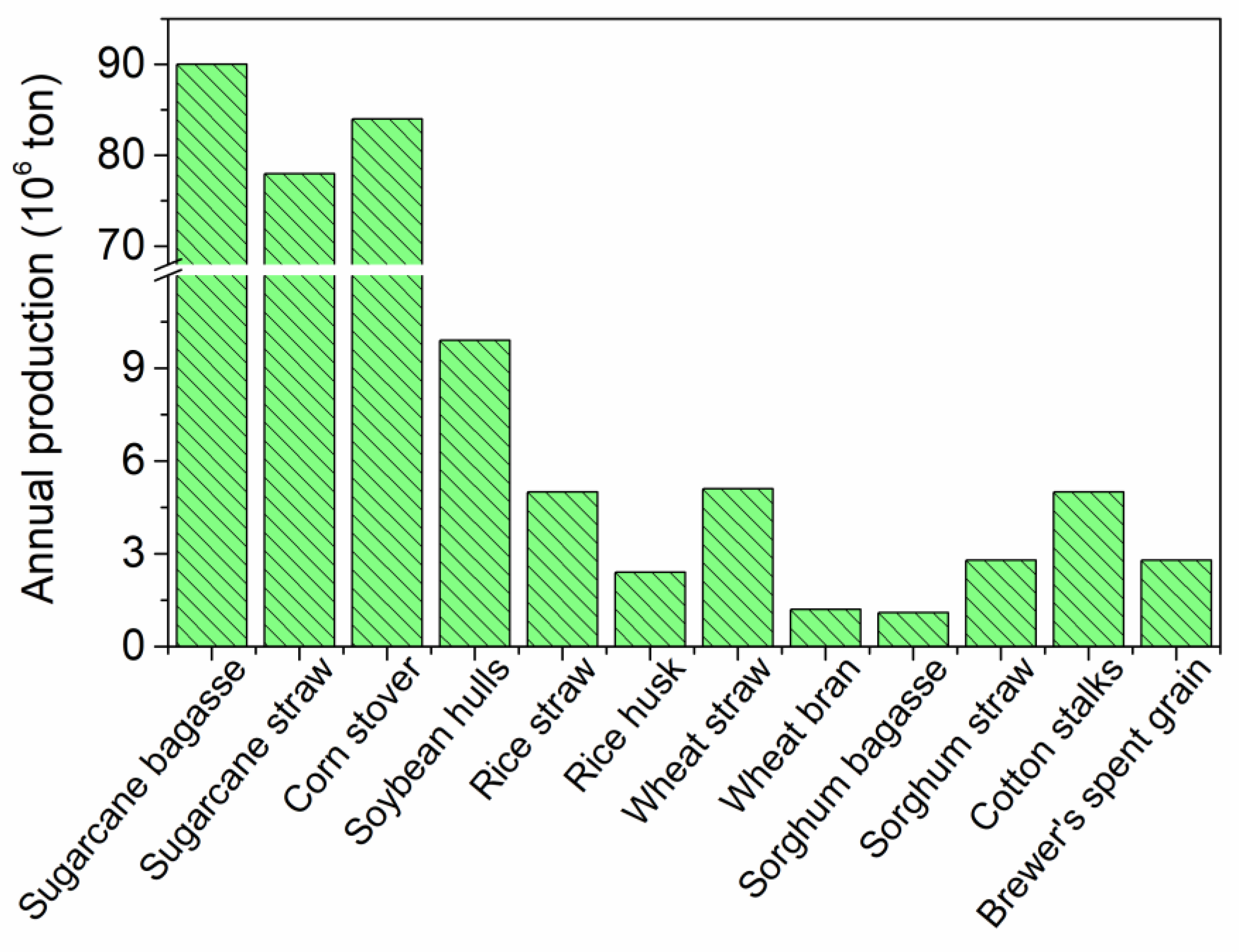

3. Lignocellulosic Biomass Composition and Availability

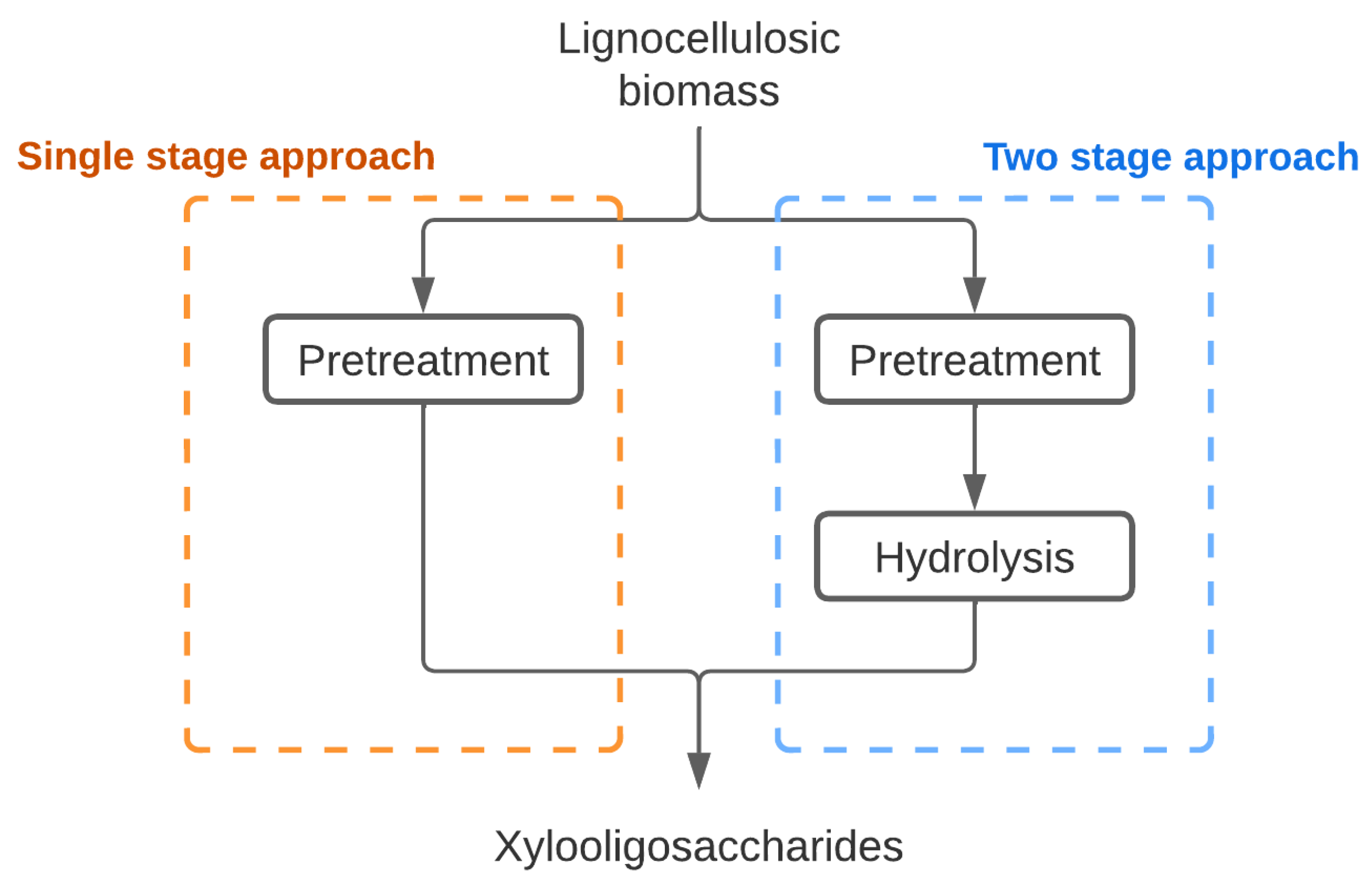

4. XOS Production

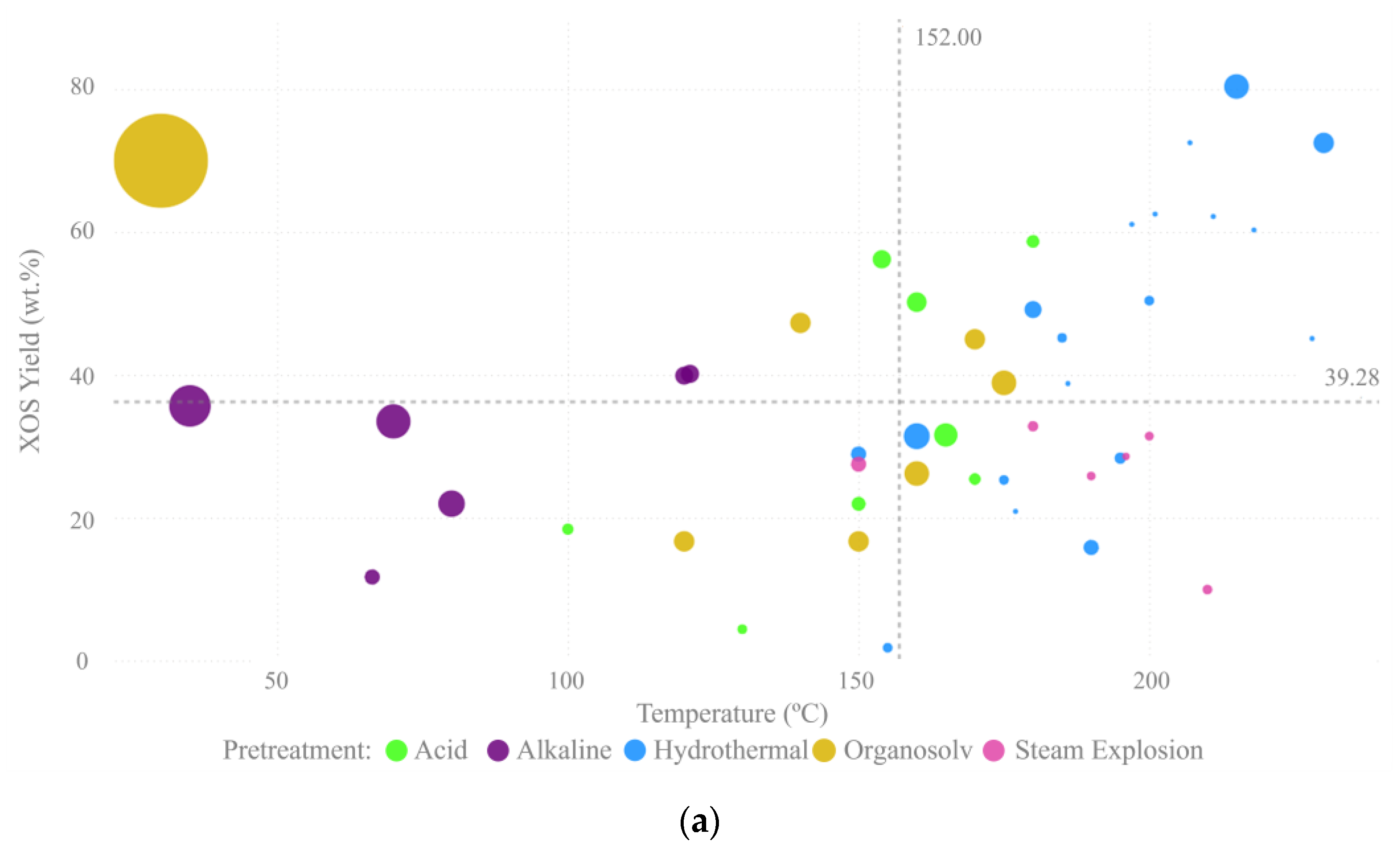

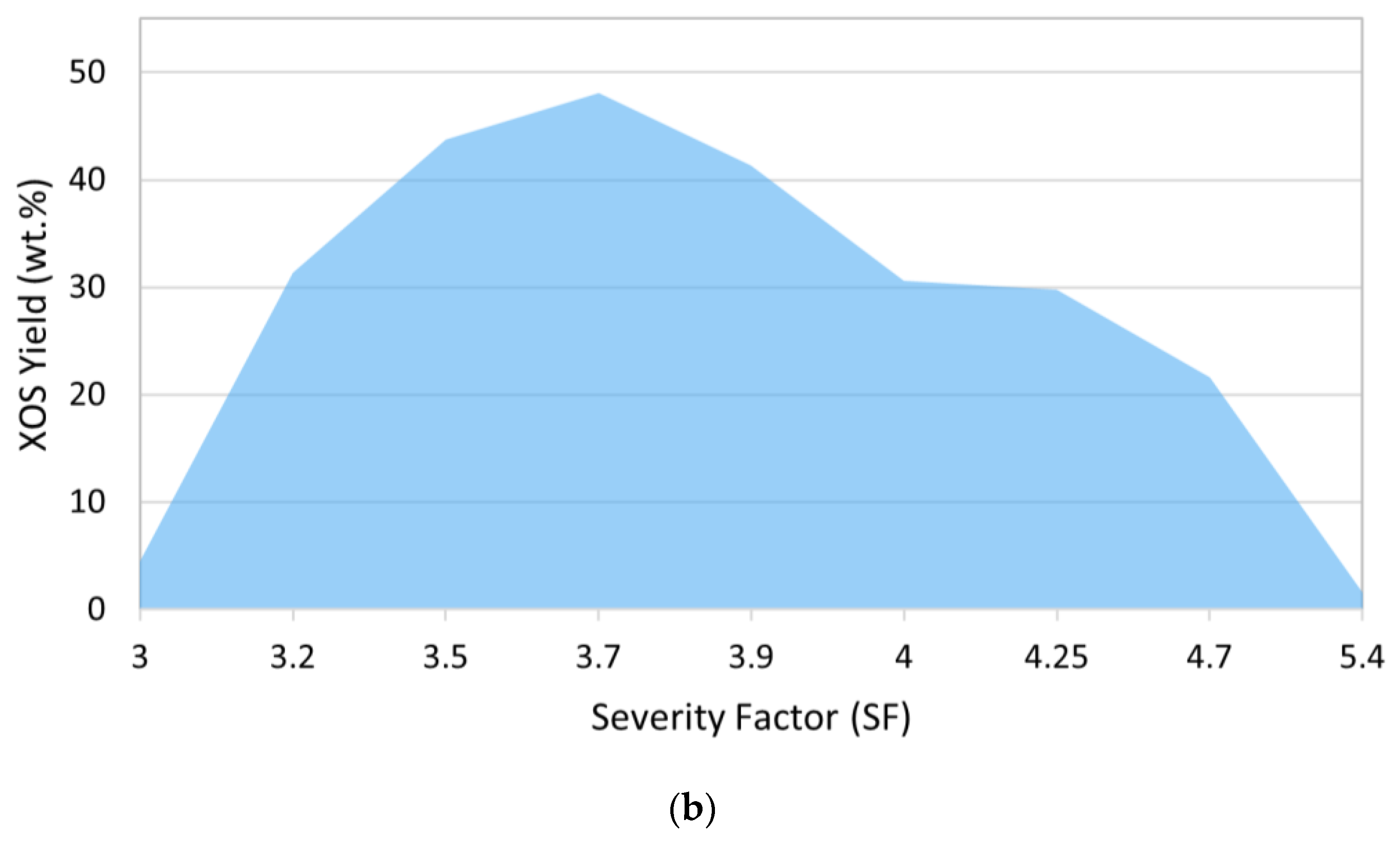

4.1. Biomass Pretreatments

4.2. Enzymatic Hydrolys

4.3. XOS Purification

| XOS Source | Downstream Operations | Observations | Ref. |

|---|---|---|---|

| Brewer spent grain | SE/SP or FDSE or IE | SP with ethanol presented limited yield SP with 2-propanol or acetone presented similar results FDSE presented no significant purification effect | [71] |

| Wheat Flour | MS | Focused on arabinoxylooligosaccharides One or two MS procedures applied to reach different fractionation | [72] |

| Rice Husk | MS/IEC (−)/IEC (+) or MS/SE/IEC (−)/IEC (+) | SE is proper to remove non-saccharide compounds Better purification when applying SE before IEC | [68] |

| Almond shells | Spray drying MS | Membrane performance with different molecular cut-off (1, 2.5, 3.5, and 8 kDa) at pressures between 2.6 and 9 bar Favorable separation from lignin-related products at low fluxes of permeate and with membranes of “low cut-off” Not much irreversible fouling effect after 2 to 4 h of continuous use | [62] |

| Rice straw | GFC | Separation of different byproducts, including di-, and monosaccharides (from oligosaccharides of DP ≥ 3 to high DP oligosaccharides, DP ≥ 23) | [81] |

| Oil palm empty fruit bunches | GFC | Purity higher than 74% and at least 83% consisted of XOS | [82] |

| Corn stalk | Acid precipitation/ ACA (ethanol elution) | Focused on color (chromophore) Highest purity of XOS (97.9%) using 30% ethanol eluate Six different activated carbons tested, purity of XOS increased to 87.28% from 67.31%, and the color value decreased to 1050 from 4682 | [83] |

| Poplar wood chips | Calcium hydroxide treatment followed by ACA | Increase of AC dosage has the tendency to adsorb more XOS with DP > 6 than XOS with DP between 2 and 6 Removal of lignin derivatives (66.9%) and furfural (70.1%) pH during the ACA influences lignin removal Moderate loss of XOS | [84] |

| Bamboo | ACA or UF/IE/NF | Purity of 92.3%, and a total sugar proportion as high as 98.9% Protein removal rate of 77.7%, sugar loss rate of 2.0%, and decolorization rate of 52.3% | [85] |

| Sugarcane bagasse | ACA | Efficient removal of furfural and hydroxymethylfurfuralLow XOS yield obtained (~50% XOS adsorption together with contaminants) | [30] |

| Oil palm empty fruit bunches | Enzymatic polymerization to remove phenolic compounds from crude XOS and MS | 50.2% of the total phenolic compounds polymerized and precipitated, additional 22.6% removed by MS For feasibility, enzymatic polymerization demands research in enzyme reuse technology | [86] |

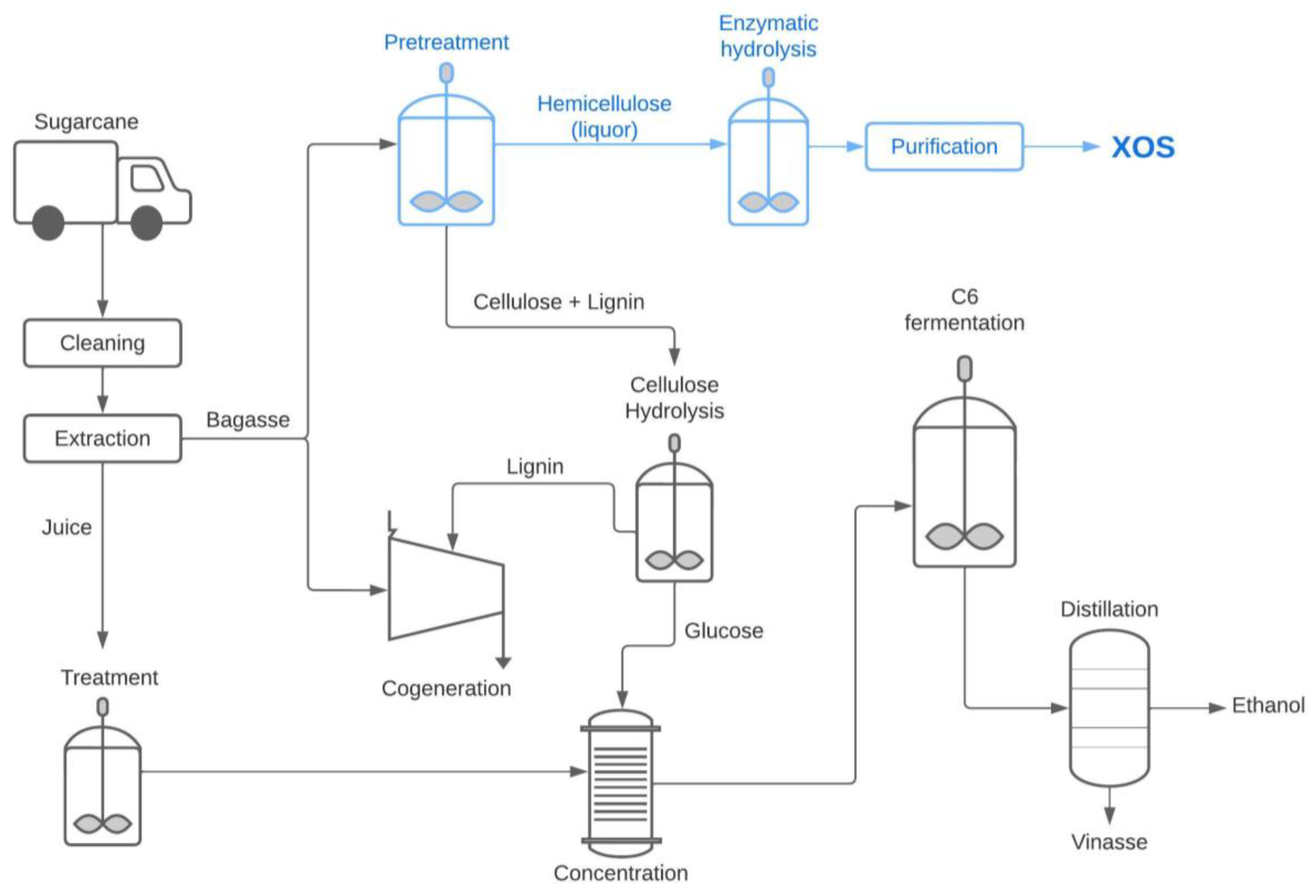

5. XOS in Biorefinery Platforms and Market Opportunities

5.1. XOS Production in Biorefineries

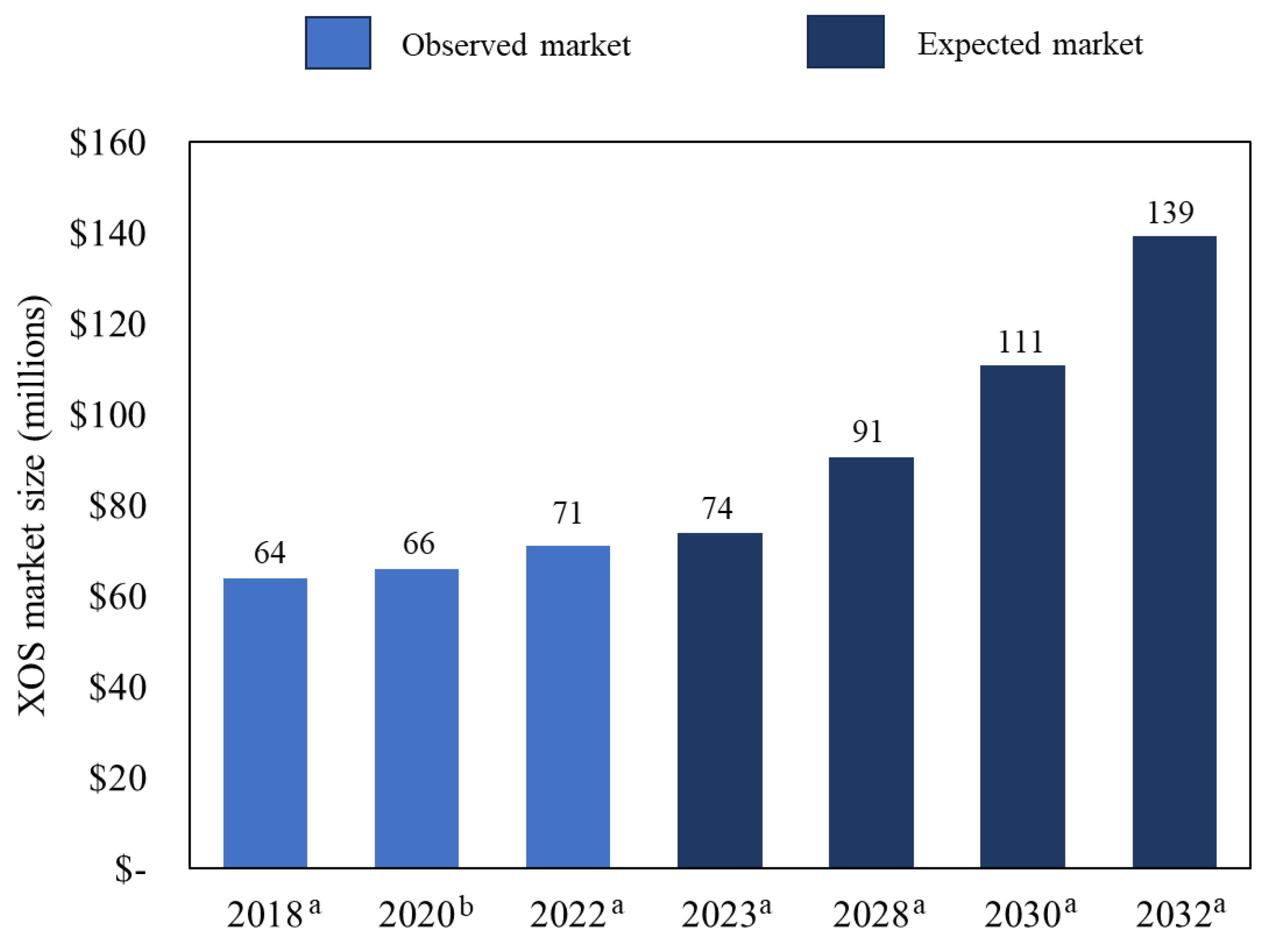

5.2. XOS Global Market and Opportunities

5.3. Techno-Economic and Life Cycle Assessment of XOS Production Integrated into Biorefineries

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Narisetty, V.; Parhi, P.; Mohan, B.; Hazeena, S.H.; Kumar, A.N.; Gullón, B.; Srivastava, A.; Nair, L.M.; Alphy, M.P.; Sindhu, R.; et al. Valorization of renewable resources to functional oligosaccharides: Recent trends and future prospective. Bioresour. Technol. 2022, 346, 126590. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xie, Y.; Ajuwon, K.M.; Zhong, R.; Li, T.; Chen, L.; Zhang, H.; Beckers, Y.; Everaert, N. Xylo-Oligosaccharides, Preparation and Application to Human and Animal Health: A Review. Front. Nutr. 2021, 8, 731930. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, A.F.A.; de OlivaNeto, P.; da Silva, D.F.; Pastore, G.M. Xylo-oligosaccharides from lignocellulosic materials: Chemical structure, health benefits and production by chemical and enzymatic hydrolysis. Food Res. Int. 2013, 51, 75–85. [Google Scholar] [CrossRef]

- Amorim, C.; Silvério, S.C.; Prather, K.L.J.; Rodrigues, L.R. From lignocellulosic residues to market: Production and commercial potential of xylooligosaccharides. Biotechnol. Adv. 2019, 37, 107397. [Google Scholar] [CrossRef]

- FMI. Xylooligosaccharides Market Outlook-2022–2032; Future Market Insights (FMI): Newark, DE, USA, 2022. [Google Scholar]

- Chandel, A.K.; Forte, M.B.S.; Gonçalves, I.S.; Milessi, T.S.; Arruda, P.V.; Carvalho, W.; Mussatto, S.I. Brazilian biorefineries from second generation biomass: Critical insights from industry and future perspectives. Biofuels Bioprod. Biorefin. 2021, 15, 1190–1208. [Google Scholar] [CrossRef]

- Antunes, F.A.F.; Chandel, A.K.; dos Santos, J.C.; Milessi, T.S.S.; Peres, G.F.D.; da Silva, S.S. Hemicellulosic Ethanol Production in Fluidized Bed Reactor from Sugar Cane Bagasse Hydrolysate: Interplay among Carrier Concentration and Aeration Rate. ACS Sustain. Chem. Eng. 2017, 5, 8250–8259. [Google Scholar] [CrossRef]

- del Río, P.G.; Gullón, B.; Wu, J.; Saddler, J.; Garrote, G.; Romaní, A. Current breakthroughs in the hardwood biorefineries: Hydrothermal processing for the co-production of xylooligosaccharides and bioethanol. Bioresour. Technol. 2022, 343, 126100. [Google Scholar] [CrossRef] [PubMed]

- FMI. Xylooligosaccharide Market Outlook (2023 to 2033); FMI: Newark, DE, USA, 2023. [Google Scholar]

- Fuso, A.; Rosso, F.; Rosso, G.; Risso, D.; Manera, I.; Caligiani, A. Production of xylo-oligosaccharides (XOS) of tailored degree of polymerization from acetylated xylans through modelling of enzymatic hydrolysis. Food Res. Int. 2022, 162, 112019. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Kyung, M.; Jo, I.; Kim, Y.-R.; Ha, N.-C. Structure-based protein engineering of bacterial β-xylosidase to increase the production yield of xylobiose from xylose. Biochem. Biophys. Res. Commun. 2018, 501, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Mensah, R.Q.; Yingkamhaeng, N.; Venkatachalam, P.; Show, P.-L.; Mussatto, S.I.; Sriariyanun, M.; Sukyai, P.; Parakulsuksatid, P.; Rattanaporn, K. Application of green produced xylooligosaccharides from sugarcane residues and their properties–Recent progress towards sustainability. Bioresour. Technol. Rep. 2023, 23, 101537. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.K.; de Souza Vandenberghe, L.P.; Vieira, S.; Goyzueta-Mamani, L.D.; de Mattos, P.B.G.; Manzoki, M.C.; Soccol, V.T.; Soccol, C.R. The Potential of Xylooligosaccharides as Prebiotics and Their Sustainable Production from Agro-Industrial by-Products. Foods 2023, 12, 2681. [Google Scholar] [CrossRef]

- Yan, F.; Tian, S.; Du, K.; Xue, X.; Gao, P.; Chen, Z. Preparation and nutritional properties of xylooligosaccharide from agricultural and forestry byproducts: A comprehensive review. Front. Nutr. 2022, 9, 977548. [Google Scholar] [CrossRef] [PubMed]

- Hughes, S.A.; Shewry, P.R.; Li, L.; Gibson, G.R.; Sanz, M.L.; Rastall, R.A. In Vitro Fermentation by Human Fecal Microflora of Wheat Arabinoxylans. J. Agric. Food Chem. 2007, 55, 4589–4595. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Chen, Y.; Deng, F.; Yan, X.; Zhong, R.; Meng, Q.; Liu, L.; Zhao, Y.; Zhang, S.; Chen, L.; et al. Xylooligosaccharide-mediated gut microbiota enhances gut barrier and modulates gut immunity associated with alterations of biological processes in a pig model. Carbohydr. Polym. 2022, 294, 119776. [Google Scholar] [CrossRef]

- Maeda, R.; Ida, T.; Ihara, H.; Sakamoto, T. Induction of Apoptosis in MCF-7 Cells by β-1,3-Xylooligosaccharides Prepared from Caulerpa lentillifera. Biosci. Biotechnol. Biochem. 2012, 76, 1032–1034. [Google Scholar] [CrossRef]

- Forsan, C.F.; Cedeño, F.R.P.; Masarin, F.; Brienzo, M. Xylooligosaccharides production by optimized autohydrolysis, sulfuric and acetic acid hydrolysis for minimum sugar degradation production. Bioact. Carbohydrates Diet. Fibre 2021, 26, 100268. [Google Scholar] [CrossRef]

- Singh, R.D.; Talekar, S.; Muir, J.; Arora, A. Low degree of polymerization xylooligosaccharides production from almond shell using immobilized nano-biocatalyst. Enzym. Microb. Technol. 2019, 130, 109368. [Google Scholar] [CrossRef] [PubMed]

- Canilha, L.; Kumar Chandel, A.; dos Santos Milessi, T.S.; Fernandes Antunes, F.A.; da Costa Freitas, W.L.; das Gracas Almeida Felipe, M.; da Silva, S.S. Bioconversion of Sugarcane Biomass into Ethanol: An Overview about Composition, Pretreatment Methods, Detoxification of Hydrolysates, Enzymatic Saccharification, and Ethanol Fermentation. J. Biomed. Biotechnol. 2012, 2012, 989572. [Google Scholar] [CrossRef] [PubMed]

- Reis, C.E.R.; Milessi, T.S.; Ramos, M.D.N.; Singh, A.K.; Mohanakrishna, G.; Aminabhavi, T.M.; Kumar, P.S.; Chandel, A.K. Lignocellulosic biomass-based glycoconjugates for diverse biotechnological applications. Biotechnol. Adv. 2023, 68, 108209. [Google Scholar] [CrossRef] [PubMed]

- Jedvert, K.; Heinze, T. Cellulose modification and shaping—A review. J. Polym. Eng. 2017, 37, 845–860. [Google Scholar] [CrossRef]

- Aguiar, A.; Milessi, T.S.; Mulinari, D.R.; Lopes, M.S.; da Costa, S.M.; Candido, R.G. Sugarcane straw as a potential second generation feedstock for biorefinery and white biotechnology applications. Biomass Bioenergy 2021, 144, 105896. [Google Scholar] [CrossRef]

- Menandro, L.M.S.; Cantarella, H.; Franco, H.C.J.; Kölln, O.T.; Pimenta, M.T.B.; Sanches, G.M.; Rabelo, S.C.; Carvalho, J.L.N. Comprehensive assessment of sugarcane straw: Implications for biomass and bioenergy production. Biofuels Bioprod. Biorefin. 2017, 11, 488–504. [Google Scholar] [CrossRef]

- Dias, M.O.S.; Cunha, M.P.; Jesus, C.D.F.; Rocha, G.J.M.; Pradella, J.G.C.; Rossell, C.E.V.; Filho, R.M.; Bonomi, A. Second generation ethanol in Brazil: Can it compete with electricity production? Bioresour. Technol. 2011, 102, 8964–8971. [Google Scholar] [CrossRef] [PubMed]

- Sganzerla, W.G.; Ampese, L.C.; Mussatto, S.I.; Forster-Carneiro, T. A bibliometric analysis on potential uses of brewer's spent grains in a biorefinery for the circular economy transition of the beer industry. Biofuels Bioprod. Biorefin. 2021, 15, 1965–1988. [Google Scholar] [CrossRef]

- Yegin, S. Microbial xylanases in xylooligosaccharide production from lignocellulosic feedstocks. Biomass Convers. Biorefin. 2022, 13, 3619–3658. [Google Scholar] [CrossRef]

- Ahmad, N.; Zakaria, M.R. Oligosaccharide from Hemicellulose. In Lignocellulose for Future Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 135–152. ISBN 978-0-12-816354-2. [Google Scholar]

- Vandenberghe, L.P.S.; Valladares-Diestra, K.K.; Bittencourt, G.A.; Zevallos Torres, L.A.; Vieira, S.; Karp, S.G.; Sydney, E.B.; de Carvalho, J.C.; Soccol, V.T.; Soccol, C.R. Beyond sugar and ethanol: The future of sugarcane biorefineries in Brazil. Renew. Sustain. Energy Rev. 2022, 167, 112721. [Google Scholar] [CrossRef]

- Milessi, T.S.; Corradini, F.A.S.; Marçal, J.V.M.; Baldez, T.O.; Kopp, W.; Giordano, R.C.; Giordano, R.L.C. Xylooligosaccharides production chain in sugarcane biorefineries: From the selection of pretreatment conditions to the evaluation of nutritional properties. Ind. Crops Prod. 2021, 172, 114056. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Lei, F.; Jiang, J. Co-production bioethanol and xylooligosaccharides from sugarcane bagasse via autohydrolysis pretreatment. Renew. Energy 2020, 162, 2297–2305. [Google Scholar] [CrossRef]

- Yang, Q.; Gao, Y.; Huang, Y.; Xu, Q.; Luo, X.-M.; Liu, J.-L.; Feng, J.-X. Identification of three important amino acid residues of xylanase AfxynA from Aspergillus fumigatus for enzyme activity and formation of xylobiose as the major product. Process Biochem. 2015, 50, 571–581. [Google Scholar] [CrossRef]

- Xue, J.-L.; Zhao, S.; Liang, R.-M.; Yin, X.; Jiang, S.-X.; Su, L.-H.; Yang, Q.; Duan, C.-J.; Liu, J.-L.; Feng, J.-X. A biotechnological process efficiently co-produces two high value-added products, glucose and xylooligosaccharides, from sugarcane bagasse. Bioresour. Technol. 2016, 204, 130–138. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.K.; de Souza Vandenberghe, L.P.; Soccol, C.R. Integrated xylooligosaccharides production from imidazole-treated sugarcane bagasse with application of in house produced enzymes. Bioresour. Technol. 2022, 362, 127800. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, A.F.A.; Marcondes, W.F.; de Olivia Neto, P.; Pastore, G.M.; Saddler, J.N.; Arantes, V. The potential of tailoring the conditions of steam explosion to produce xylo-oligosaccharides from sugarcane bagasse. Bioresour. Technol. 2018, 250, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Ávila, P.F.; Martins, M.; Goldbeck, R. Enzymatic Production of Xylooligosaccharides from Alkali-Solubilized Arabinoxylan from Sugarcane Straw and Coffee Husk. Bioenergy Res. 2021, 14, 739–751. [Google Scholar] [CrossRef]

- Brenelli, L.B.; Bhatia, R.; Djajadi, D.T.; Thygesen, L.G.; Rabelo, S.C.; Leak, D.J.; Franco, T.T.; Gallagher, J.A. Xylo-oligosaccharides, fermentable sugars, and bioenergy production from sugarcane straw using steam explosion pretreatment at pilot-scale. Bioresour. Technol. 2022, 357, 127093. [Google Scholar] [CrossRef] [PubMed]

- Wen, P.; Liao, H.; Zhu, J.; Xu, Y.; Zhang, J. Production of xylo-oligosaccharides and ethanol from corncob by combined tartaric acid hydrolysis with simultaneous saccharification and fermentation. Bioresour. Technol. 2022, 363, 127977. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xu, Y.; Yu, S. Co-production of functional xylooligosaccharides and fermentable sugars from corncob with effective acetic acid prehydrolysis. Bioresour. Technol. 2017, 234, 343–349. [Google Scholar] [CrossRef] [PubMed]

- De Mello Capetti, C.C.; Pellegrini, V.O.A.; Santo, M.C.E.; Cortez, A.A.; Falvo, M.; de Silva Curvelo, A.A.; Campos, E.; Filgueiras, J.G.; Guimaraes, F.E.G.; de Azevedo, E.R.; et al. Enzymatic production of xylooligosaccharides from corn cobs: Assessment of two different pretreatment strategies. Carbohydr. Polym. 2023, 299, 120174. [Google Scholar] [CrossRef]

- Samanta, A.K.; Jayapal, N.; Kolte, A.P.; Senani, S.; Sridhar, M.; Dhali, A.; Suresh, K.P.; Jayaram, C.; Prasad, C.S. Process for Enzymatic Production of Xylooligosaccharides from the Xylan of Corn Cobs. J. Food Process. Preserv. 2015, 39, 729–736. [Google Scholar] [CrossRef]

- Teng, C.; Yan, Q.; Jiang, Z.; Fan, G.; Shi, B. Production of xylooligosaccharides from the steam explosion liquor of corncobs coupled with enzymatic hydrolysis using a thermostable xylanase. Bioresour. Technol. 2010, 101, 7679–7682. [Google Scholar] [CrossRef]

- Swart, L.J.; Bedzo, O.K.K.; van Rensburg, E.; Görgens, J.F. Pilot-scale xylooligosaccharide production through steam explosion of screw press–dried brewers’ spent grains. Biomass Convers. Biorefin. 2022, 12, 1295–1309. [Google Scholar] [CrossRef]

- Khat-udomkiri, N.; Sivamaruthi, B.S.; Sirilun, S.; Lailerd, N.; Peerajan, S.; Chaiyasut, C. Optimization of alkaline pretreatment and enzymatic hydrolysis for the extraction of xylooligosaccharide from rice husk. AMB Express 2018, 8, 115. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Conrad, M.; Sun, S.N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef] [PubMed]

- Scapini, T.; dos Santos, M.S.N.; Bonatto, C.; Wancura, J.H.C.; Mulinari, J.; Camargo, A.F.; Klanovicz, N.; Zabot, G.L.; Tres, M.V.; Fongaro, G.; et al. Hydrothermal pretreatment of lignocellulosic biomass for hemicellulose recovery. Bioresour. Technol. 2021, 342, 126033. [Google Scholar] [CrossRef] [PubMed]

- Rabelo, S.C.; Nakasu, P.Y.S.; Scopel, E.; Araújo, M.F.; Cardoso, L.H.; da Costa, A.C. Organosolv pretreatment for biorefineries: Current status, perspectives, and challenges. Bioresour. Technol. 2023, 369, 128331. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Wen, Y.; Kapu, N.S.; Beatson, R. Evaluation of an organosolv-based biorefinery process to fractionate wheat straw into ethanol and co-products. Ind. Crops Prod. 2018, 121, 294–302. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel ethanol production from lignocellulosic biomass: An overview on feedstocks and technological approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Karnaouri, A.; Asimakopoulou, G.; Kalogiannis, K.G.; Lappas, A.A.; Topakas, E. Efficient production of nutraceuticals and lactic acid from lignocellulosic biomass by combining organosolv fractionation with enzymatic/fermentative routes. Bioresour. Technol. 2021, 341, 125846. [Google Scholar] [CrossRef]

- Bergrath, J.; Rumpf, J.; Burger, R.; Do, X.T.; Wirtz, M.; Schulze, M. Beyond Yield Optimization: The Impact of Organosolv Process Parameters on Lignin Structure. Macromol. Mater. Eng. 2023, 2300093. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, L.; Zhang, F.; Li, P.; Ji, L.; Wang, K.; Jiang, J. Coproduction of xylooligosaccharides, glucose, and less-condensed lignin from sugarcane bagasse using syringic acid pretreatment. Bioresour. Technol. 2023, 386, 129527. [Google Scholar] [CrossRef]

- Heitz, M.; Carrasco, F.; Rubio, M.; Brown, A.; Chornet, E.; Overend, R.P. Physico-chemical characterization of lignocellulosic substrates pretreated via autohydrolysis: An application to tropical woods. Biomass 1987, 13, 255–273. [Google Scholar] [CrossRef]

- Ramos, M.D.N.; Milessi, T.S.; Candido, R.G.; Mendes, A.A.; Aguiar, A. Enzymatic catalysis as a tool in biofuels production in Brazil: Current status and perspectives. Energy Sustain. Dev. 2022, 68, 103–119. [Google Scholar] [CrossRef]

- Collins, T.; Gerday, C.; Feller, G. Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol. Rev. 2005, 29, 3–23. [Google Scholar] [CrossRef] [PubMed]

- Dodd, D.; Cann, I.K.O. Enzymatic deconstruction of xylan for biofuel production. GCB Bioenergy 2009, 1, 2–17. [Google Scholar] [CrossRef]

- Kharazmi, S.; Taheri-Kafrani, A.; Soozanipour, A.; Nasrollahzadeh, M.; Varma, R.S. Xylanase immobilization onto trichlorotriazine-functionalized polyethylene glycol grafted magnetic nanoparticles: A thermostable and robust nanobiocatalyst for fruit juice clarification. Int. J. Biol. Macromol. 2020, 163, 402–413. [Google Scholar] [CrossRef]

- Alagöz, D.; Varan, N.E.; Yildirim, D.; Fernandéz-Lafuente, R. Optimization of the immobilization of xylanase from Thermomyces lanuginosus to produce xylooligosaccharides in a batch type reactor. Mol. Catal. 2022, 531, 112647. [Google Scholar] [CrossRef]

- Nascimento, A.G.L.C.; Zuppa, É.S.; Zonin, M.; de Sousa, G.F.S.; de Andrades, D.; Ayub, M.A.Z.; Maller, A.; da Conceição Silva, J.L.; de Cássia Garcia Simão, R.; Kadowaki, M.K. Prebiotic effect of sorghum biomass xylooligosaccharides employing immobilized endoxylanase from Thermomyces lanuginosus PC7S1T. Braz. J. Microbiol. 2022, 53, 1167–1174. [Google Scholar] [CrossRef] [PubMed]

- Milessi, T.S.S.; Kopp, W.; Rojas, M.J.; Manrich, A.; Baptista-Neto, A.; Tardioli, P.W.; Giordano, R.C.; Fernandez-Lafuente, R.; Guisan, J.M.; Giordano, R.L.C. Immobilization and stabilization of an endoxylanase from Bacillus subtilis (XynA) for xylooligosaccharides (XOs) production. Catal. Today 2016, 259, 130–139. [Google Scholar] [CrossRef]

- Vázquez, M.J.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Xylooligosaccharides: Manufacture and applications. Trends Food Sci. Technol. 2000, 11, 387–393. [Google Scholar] [CrossRef]

- Nabarlatz, D.; Torras, C.; Garciavalls, R.; Montané, D. Purification of xylo-oligosaccharides from almond shells by ultrafiltration. Sep. Purif. Technol. 2007, 53, 235–243. [Google Scholar] [CrossRef]

- Aachary, A.A.; Prapulla, S.G. Xylooligosaccharides (XOS) as an Emerging Prebiotic: Microbial Synthesis, Utilization, Structural Characterization, Bioactive Properties, and Applications. Compr. Rev. Food Sci. Food Saf. 2011, 10, 2–16. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- Huang, C.; Wang, X.; Liang, C.; Jiang, X.; Yang, G.; Xu, J.; Yong, Q. A sustainable process for procuring biologically active fractions of high-purity xylooligosaccharides and water-soluble lignin from Moso bamboo prehydrolyzate. Biotechnol. Biofuels 2019, 12, 189. [Google Scholar] [CrossRef]

- Hong, C.; Corbett, D.; Venditti, R.; Jameel, H.; Park, S. Xylooligosaccharides as prebiotics from biomass autohydrolyzate. LWT 2019, 111, 703–710. [Google Scholar] [CrossRef]

- Santibáñez, L.; Henríquez, C.; Corro-Tejeda, R.; Bernal, S.; Armijo, B.; Salazar, O. Xylooligosaccharides from lignocellulosic biomass: A comprehensive review. Carbohydr. Polym. 2021, 251, 117118. [Google Scholar] [CrossRef] [PubMed]

- Vegas, R.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Manufacture and Refining of Oligosaccharides from Industrial Solid Wastes. Ind. Eng. Chem. Res. 2005, 44, 614–620. [Google Scholar] [CrossRef]

- Swennen, K.; Courtin, C.M.; Vanderbruggen, B.; Vandecasteele, C.; Delcour, J.A. Ultrafiltration and ethanol precipitation for isolation of arabinoxylooligosaccharides with different structures. Carbohydr. Polym. 2005, 62, 283–292. [Google Scholar] [CrossRef]

- Vegas, R.; Luque, S.; Alvarez, J.R.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Membrane-Assisted Processing of Xylooligosaccharide-Containing Liquors. J. Agric. Food Chem. 2006, 54, 5430–5436. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, M.J.; Garrote, G.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Refining of autohydrolysis liquors for manufacturing xylooligosaccharides: Evaluation of operational strategies. Bioresour. Technol. 2005, 96, 889–896. [Google Scholar] [CrossRef]

- Vegas, R.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Processing of Rice Husk Autohydrolysis Liquors for Obtaining Food Ingredients. J. Agric. Food Chem. 2004, 52, 7311–7317. [Google Scholar] [CrossRef] [PubMed]

- Pinelo, M.; Jonsson, G.; Meyer, A.S. Membrane technology for purification of enzymatically produced oligosaccharides: Molecular and operational features affecting performance. Sep. Purif. Technol. 2009, 70, 1–11. [Google Scholar] [CrossRef]

- Patil, N.V.; Janssen, A.E.M.; Boom, R.M. The potential impact of membrane cascading on downstream processing of oligosaccharides. Chem. Eng. Sci. 2014, 106, 86–98. [Google Scholar] [CrossRef]

- Akpinar, O.; Ak, O.; Kavas, A.; Bakir, U.; Yilmaz, L. Enzymatic Production of Xylooligosaccharides from Cotton Stalks. J. Agric. Food Chem. 2007, 55, 5544–5551. [Google Scholar] [CrossRef]

- Córdova, A.; Astudillo, C.; Illanes, A. Membrane Technology for the Purification of Enzymatically Produced Oligosaccharides. In Separation of Functional Molecules in Food by Membrane Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 113–153. ISBN 978-0-12-815056-6. [Google Scholar]

- Singh, R.D.; Nadar, C.G.; Muir, J.; Arora, A. Green and clean process to obtain low degree of polymerisation xylooligosaccharides from almond shell. J. Clean. Prod. 2019, 241, 118237. [Google Scholar] [CrossRef]

- Kumar, V.; Satyanarayana, T. Generation of xylooligosaccharides from microwave irradiated agroresidues using recombinant thermo-alkali-stable endoxylanase of the polyextremophilic bacterium Bacillus halodurans expressed in Pichia pastoris. Bioresour. Technol. 2015, 179, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Wijaya, H.; Sasaki, K.; Kahar, P.; Rahmani, N.; Hermiati, E.; Yopi, Y.; Ogino, C.; Prasetya, B.; Kondo, A. High Enzymatic Recovery and Purification of Xylooligosaccharides from Empty Fruit Bunch via Nanofiltration. Processes 2020, 8, 619. [Google Scholar] [CrossRef]

- Chen, M.-H.; Bowman, M.J.; Cotta, M.A.; Dien, B.S.; Iten, L.B.; Whitehead, T.R.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Miscanthus × giganteus xylooligosaccharides: Purification and fermentation. Carbohydr. Polym. 2016, 140, 96–103. [Google Scholar] [CrossRef]

- Moniz, P.; Pereira, H.; Duarte, L.C.; Carvalheiro, F. Hydrothermal production and gel filtration purification of xylo-oligosaccharides from rice straw. Ind. Crops Prod. 2014, 62, 460–465. [Google Scholar] [CrossRef]

- Ho, A.L.; Carvalheiro, F.; Duarte, L.C.; Roseiro, L.B.; Charalampopoulos, D.; Rastall, R.A. Production and purification of xylooligosaccharides from oil palm empty fruit bunch fibre by a non-isothermal process. Bioresour. Technol. 2014, 152, 526–529. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Zhang, J.; Qu, Y.-S.; Li, H.-Q. Removal of chromophore in enzymatic hydrolysis by acid precipitation to improve the quality of xylo-oligosaccharides from corn stalk. Bioresour. Technol. 2018, 249, 751–757. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Chen, J.; Yang, G.; Ji, X.; Wang, Q.; Liu, S.; Ni, Y. Combined Treatments Consisting of Calcium Hydroxide and Activate Carbon for Purification of Xylo-Oligosaccharides of Pre-Hydrolysis Liquor. Polymers 2019, 11, 1558. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, X.; Wu, Z.; Xu, J.; Hu, L.; Lin, L. Purification of Xylooligosaccharides from bamboo with non-organic solvent to prepare food grade functional sugars. Results Chem. 2021, 3, 100153. [Google Scholar] [CrossRef]

- Kim, D.; Yu, J.-H.; Hong, K.-S.; Jung, C.-D.; Kim, H.; Kim, J.; Myung, S. Green production of low-molecular-weight xylooligosaccharides from oil palm empty fruit bunch via integrated enzymatic polymerization and membrane separation for purification. Sep. Purif. Technol. 2022, 293, 121084. [Google Scholar] [CrossRef]

- Wang, L.; Li, Z.; Liu, Y. Ultrasonic-assisted extraction and purification of xylo-oligosaccharides from wheat bran. J. Food Process. Eng. 2022, 45, e14152. [Google Scholar] [CrossRef]

- Álvarez, C.; González, A.; Ballesteros, I.; Gullón, B.; Negro, M.J. In Vitro Assessment of the Prebiotic Potential of Xylooligosaccharides from Barley Straw. Foods 2022, 12, 83. [Google Scholar] [CrossRef] [PubMed]

- IEA Bioenergy. Biorefineries: Adding Value to the Sustainable Utilisation of Biomass; IEA Bioenergy: Paris, France, 2009. [Google Scholar]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Budzianowski, W.M. High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew. Sustain. Energy Rev. 2017, 70, 793–804. [Google Scholar] [CrossRef]

- Pinales-Márquez, C.D.; Rodríguez-Jasso, R.M.; Araújo, R.G.; Loredo-Treviño, A.; Nabarlatz, D.; Gullón, B.; Ruiz, H.A. Circular bioeconomy and integrated biorefinery in the production of xylooligosaccharides from lignocellulosic biomass: A review. Ind. Crops Prod. 2021, 162, 113274. [Google Scholar] [CrossRef]

- Pereira, B.; Marcondes, W.F.; Carvalho, W.; Arantes, V. High yield biorefinery products from sugarcane bagasse: Prebiotic xylooligosaccharides, cellulosic ethanol, cellulose nanofibrils and lignin nanoparticles. Bioresour. Technol. 2021, 342, 125970. [Google Scholar] [CrossRef]

- Valladares-Diestra, K.K.; de Souza Vandenberghe, L.P.; Soccol, C.R. A biorefinery approach for enzymatic complex production for the synthesis of xylooligosaccharides from sugarcane bagasse. Bioresour. Technol. 2021, 333, 125174. [Google Scholar] [CrossRef]

- AR. Global Xylooligosaccharides (XOS) Sales Market Report; Absoloute Reports: Pune, India, 2021. [Google Scholar]

- Alibaba. Kosher HALAL Xylo-Oligosaccharide Powder Xos Xylooligosaccharide 95% 80% 70%. 2023. Available online: https://www.alibaba.com/product-detail/Kosher-HALAL-Xylo-oligosaccharide-powder-xos_60794536009.html (accessed on 21 July 2023).

- Jain, I.; Kumar, V.; Satyanarayana, T. Xylooligosaccharides: An economical prebiotic from agroresidues and their health benefits. Experiment 2015, 53, 131–142. [Google Scholar]

- Zhao, J.; Zhang, X.; Zhou, X.; Xu, Y. Selective Production of Xylooligosaccharides by Xylan Hydrolysis Using a Novel Recyclable and Separable Furoic Acid. Front. Bioeng. Biotechnol. 2021, 9, 660266. [Google Scholar] [CrossRef] [PubMed]

- Amazon NOW Supplements, Prebiotic Bifido Boost with PreticXTM Xylooligosaccharide (XOS) Prebiotic, Powder, 3-Ounce. 2023. Available online: https://www.amazon.com/NOW-Prebiotic-Bifido-Powder-3-Ounce/dp/B07BRVN4XV/ref=sr_1_1?crid=29M14F4V5BYJV&keywords=xylooligosaccharides+xos+prebiotic&qid=1688031800&sprefix=xylooligosaccharide%2Caps%2C215&sr=8-1 (accessed on 21 July 2023).

- Pharma, U. XOS-XILOOLIGOSSACARÍDEOS 60CAPS. 2023. Available online: https://www.unicpharma.com.br/xos-xilooligossacarideos-/p (accessed on 21 July 2023).

- Megazyme XOS Price. 2023. Available online: www.megazyme.com (accessed on 20 July 2023).

- FactMR. Xylooligosaccharides Market; FactMR: Leinster, Ireland, 2023; Available online: https://www.factmr.com/report/4396/xylooligosaccharide-market (accessed on 20 July 2023).

- CMI. Xylooligosaccharides Market Analysis; CMI: Pune, India, 2023; Available online: https://www.coherentmarketinsights.com/market-insight/xylo-oligosaccharides-market-2150 (accessed on 20 July 2023).

- Lan, K.; Xu, Y.; Kim, H.; Ham, C.; Kelley, S.S.; Park, S. Techno-economic analysis of producing xylo-oligosaccharides and cellulose microfibers from lignocellulosic biomass. Bioresour. Technol. 2021, 340, 125726. [Google Scholar] [CrossRef] [PubMed]

- Swart, L.J.; Petersen, A.M.; Bedzo, O.K.; Görgens, J.F. Techno-economic analysis of the valorization of brewers spent grains: Production of xylitol and xylo-oligosaccharides. J. Chem. Technol. Biotechnol. 2021, 96, 1632–1644. [Google Scholar] [CrossRef]

- Cao, R.; Liu, X.; Guo, J.; Xu, Y. Comparison of various organic acids for xylo-oligosaccharide productions in terms of pKa values and combined severity. Biotechnol. Biofuels 2021, 14, 69. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; da Silva, M.F.; Zabot, G.L.; Goldbeck, R.; Mussatto, S.I.; Forster-Carneiro, T. Techno-economic assessment of subcritical water hydrolysis of brewer’s spent grains to recover xylo-oligosaccharides. J. Supercrit. Fluids 2023, 196, 105895. [Google Scholar] [CrossRef]

- van Heerden, C. Techno-Economic Analysis of 1,3-Propanediol, Sorbitol, Itaconic Acid, and Xylooligosaccharides Production from Sugarcane-Based Feedstocks. Master’s Thesis, Faculty of Engineering at Stellenbosch University, Stellenbosch, South Africa, 2023. [Google Scholar]

- Lopes, T.F.; Carvalheiro, F.; Duarte, L.C.; Gírio, F.; Quintero, J.A.; Aroca, G. Techno-economic and life-cycle assessments of small-scale biorefineries for isobutene and xylo-oligosaccharides production: A comparative study in Portugal and Chile. Biofuels Bioprod. Biorefin. 2019, 13, 1321–1332. [Google Scholar] [CrossRef]

- Barbosa, F.C.; Nogueira, G.P.; Kendrick, E.; Franco, T.T.; Leak, D.; Dias, M.O.S.; Cavaliero, C.K.N.; Goldbeck, R. Production of cello-oligosaccharides through the biorefinery concept: A technical-economic and life-cycle assessment. Biofuels Bioprod. Biorefin. 2021, 15, 1763–1774. [Google Scholar] [CrossRef]

- González-García, S.; Morales, P.C.; Gullón, B. Estimating the environmental impacts of a brewery waste–based biorefinery: Bio-ethanol and xylooligosaccharides joint production case study. Ind. Crops Prod. 2018, 123, 331–340. [Google Scholar] [CrossRef]

| Pretreatment | Approach | Conditions | Xylanase in the 2nd Stage | XOS Yield (%) | XOS (g/L) | Ref. |

|---|---|---|---|---|---|---|

| Sugarcane Bagasse | ||||||

| Hydrothermal | SS | 195 °C 10 min 10% solid load | -- | 45.2 | 9.2 | [30] |

| Hydrothermal | TS | 195 °C 10 min 10% solid load | Xylanase Novozymes NS22036 | 90.8 | 32.5 | [30] |

| Hydrothermal | SS | 160 °C 100 min 10% solid load | -- | 50.5 | 12.4 | [31] |

| Acid | SS | Acetic acid 1% 100 °C 15 min 10% solid load | -- | 18.4 | 5.0 | [18] |

| Alkaline | TS | KOH 10% 25 °C 20 h 10% solid load | Xylanase AfxynA from Aspergillus fumigatus FC-2-2 | 70.0 | 4.0 | [32] |

| Alkaline | TS | NaOH 8% 40 °C 24 h 10% solid load | Endo-β-1,4-xylanase from Pichia pastoris | 57.4 | -- | [33] |

| Organosolv | TS | Imidazole 160 °C 1 h 10% solid load | Xylanase from Aspergillus niger | 30.0 | 6.1 | [34] |

| Organosolv | TS | Ethanol 50% 170 °C 1 h 10% solid load | Xylanase Novozymes NS22036 | 89.5 | 33.3 | [30] |

| Steam Explosion | SS | 0.5% H2SO4 1905 min | -- | 38.2 | NR | [35] |

| Sugarcane Straw | ||||||

| Alkaline | TS | KOH 24% + NaBH2 1% 35 °C, 3 h 8% solid load | Endoxylanase, α-L-arabinofuranosidase, and feruloyl esterase | 40.4 | NR | [36] |

| Steam Explosion | SS | Straw 80% moisture 200°, 10 min 10% solid load | -- | 35.2 | 8.0 | [37] |

| Corncob | ||||||

| Acid | SS | Tartaric acid 60 mM 170 °C 10 min 10% solid load | -- | 56.4 | NR | [38] |

| Acid | SS | Acetic acid 60 mM 170 °C 10 min 10% solid load | -- | 6.2 | NR | [38] |

| Acid | SS | HCl pH 2.7150 °C 30 min 20% solid load | -- | 22.5 | 13.71 | [39] |

| Alkaline | TS | NaOH 1% 121 °C 40 min 10% solid load | Paenibacillus xylanivorans GH10 and GH11 xylanases and metatranscriptomic GH11 xylosidase | 22.8 | NR | [40] |

| Alkaline | TS | NaOH 16% 120 °C 45 min 10% solid load | Endoxylanase from Trichoderma viride | 9.0 | NR | [41] |

| Steam Explosion | TS | Corncobs~100 mm 196 °C 5 min | Thermostable xylanase from P. thermophila J18 | 28.6 | 8.5 | [42] |

| Brewers’ spent grain | ||||||

| Steam Explosion | SS | 180 °C 10 min 25% solid load | -- | 75.1 | NR | [43] |

| Rice husk | ||||||

| Alkaline | SS | NaOH 6% 120 °C 45 min 10% solid load | -- | 44.4 | 17.4 | [44] |

| Coffee husk | ||||||

| Alkaline | SS | KOH 24% 35 °C 6 h 8% solid load | -- | 31.8 | NR | [36] |

| Value | Information/Observation | Reference |

|---|---|---|

| Prices of XOS in the market | ||

| USD 20.00/kg–USD 45.00/kg | Depending on its purity level and on its amount | Alibaba [96] |

| USD 22.50/kg | Depending on its purity level | Jain et al. [97] |

| USD 25.00/kg–USD 50.00/kg | Depending on its purity level | Santibáñez et al. [67] |

| USD 25.00/kg–USD 50.00/kg | Depending on its purity level | Zhao et al. [98] |

| USD 25.00/kg–USD 50.00/kg | Depending on its purity level | Brenelli et al. [37] |

| USD 28.00/kg | Depending on its purity level | Amorim et al. [4] |

| USD 235.00/kg | Powder, 70% XOS and 26% maltodextrin, sold in pills | Amazon [99] |

| USD 632.30/kg | Powder, 95% XOS, sold in pills of 500 mg/pill | Unic Pharma [100] |

| USD 3680.00/kg–USD 20,000.00/kg | Analytical uses—high purity of xylohexaose, xylopentaose, xylotetraose, xylotriose, and xyloniose for use in research | Megazyme [101] |

| Economic Performance | Information | Pretreatment Conditions | Reference |

|---|---|---|---|

| Minimum XOS selling price | |||

| 3.43 USD/kg–7.50 USD/kg | 80% XOS from Miscanthus | Extrusion and autohydrolysis 190 °C for 10 min with 1:3 solid/liquid ratio | Lan et al. [104] |

| 4.03 USD/kg–8.97 USD/kg | 90% XOS from Miscanthus | Lan et al. [104] | |

| 4.84 USD/kg–10.64 USD/kg | 95% XOS from Miscanthus | Lan et al. [104] | |

| 2.51 USD/kg | Dedicated XOS production from brewers’ spent grains | Steam explosion (180 °C/10 min) followed by enzymatic hydrolysis | Swart et al. [105] |

| 2.18 USD/kg | Xylitol and XOS co-production from brewers’ spent grains | Hydrothermal pretreatment (120 °C/15 min) followed by enzymatic hydrolysis | Swart et al. [105] |

| 5.50 USD/kg | Annexed XOS production from sugarcane | SO2-catalyzed steam explosion (195 °C/5 min) | Heerden [108] |

| Production costs | |||

| 1.18 USD/kg | XOS from corn stover in the Portuguese case study | Hydrothermal pretreatment (210 °C, 1:8 solid/liquid ratio) | Lopes et al. [109] |

| 1.56 USD/kg | XOS from wheat straw in Chilean case study | Lopes et al. [109] | |

| USD 18.36/kg | XOS from brewers’ spent grains | Subcritical water hydrolysis in two sequential reactors | Sganzerla et al. [107] |

| CO2 Emissions per Kg of XOS | Scenario | Reference |

|---|---|---|

| 9.21 kg CO2eq/kg | Annexed XOS production from sugarcane | Heerden [108] |

| 11.39 kg CO2eq/kg | Annexed XOS and PDO co-production from sugarcane | Heerden [108] |

| 4.21 kg CO2eq/kg | bioethanol and XOS co-production from the lignocellulosic residue barley straw from cereal cultivation and BSG | González-García et al. [111] |

| 3.8 kg CO2eq/kg–5.5 kg CO2eq/kg | Co-production of cello-oligosaccharides and XOS using cellulosic substrates from sugarcane straw | Barbosa et al. [110] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manicardi, T.; Baioni e Silva, G.; Longati, A.A.; Paiva, T.D.; Souza, J.P.M.; Pádua, T.F.; Furlan, F.F.; Giordano, R.L.C.; Giordano, R.C.; Milessi, T.S. Xylooligosaccharides: A Bibliometric Analysis and Current Advances of This Bioactive Food Chemical as a Potential Product in Biorefineries’ Portfolios. Foods 2023, 12, 3007. https://doi.org/10.3390/foods12163007

Manicardi T, Baioni e Silva G, Longati AA, Paiva TD, Souza JPM, Pádua TF, Furlan FF, Giordano RLC, Giordano RC, Milessi TS. Xylooligosaccharides: A Bibliometric Analysis and Current Advances of This Bioactive Food Chemical as a Potential Product in Biorefineries’ Portfolios. Foods. 2023; 12(16):3007. https://doi.org/10.3390/foods12163007

Chicago/Turabian StyleManicardi, Tainá, Gabriel Baioni e Silva, Andreza A. Longati, Thiago D. Paiva, João P. M. Souza, Thiago F. Pádua, Felipe F. Furlan, Raquel L. C. Giordano, Roberto C. Giordano, and Thais S. Milessi. 2023. "Xylooligosaccharides: A Bibliometric Analysis and Current Advances of This Bioactive Food Chemical as a Potential Product in Biorefineries’ Portfolios" Foods 12, no. 16: 3007. https://doi.org/10.3390/foods12163007

APA StyleManicardi, T., Baioni e Silva, G., Longati, A. A., Paiva, T. D., Souza, J. P. M., Pádua, T. F., Furlan, F. F., Giordano, R. L. C., Giordano, R. C., & Milessi, T. S. (2023). Xylooligosaccharides: A Bibliometric Analysis and Current Advances of This Bioactive Food Chemical as a Potential Product in Biorefineries’ Portfolios. Foods, 12(16), 3007. https://doi.org/10.3390/foods12163007