Branched Chain Amino Acid Content and Antioxidant Activity of Mung Bean Tempeh Powder for Developing Oral Nutrition Supplements

Abstract

1. Introduction

2. Materials and Methods

2.1. Mung Bean Powder and Mung Bean Tempeh Powder Production

2.2. Proximate Analysis

2.3. Amino Acid Analysis

2.4. Fatty Acid Analysis

2.5. ONS Formulation

2.6. Antioxidant Activity Assay

2.7. Sensory Test

2.8. Statistical Analysis

3. Results

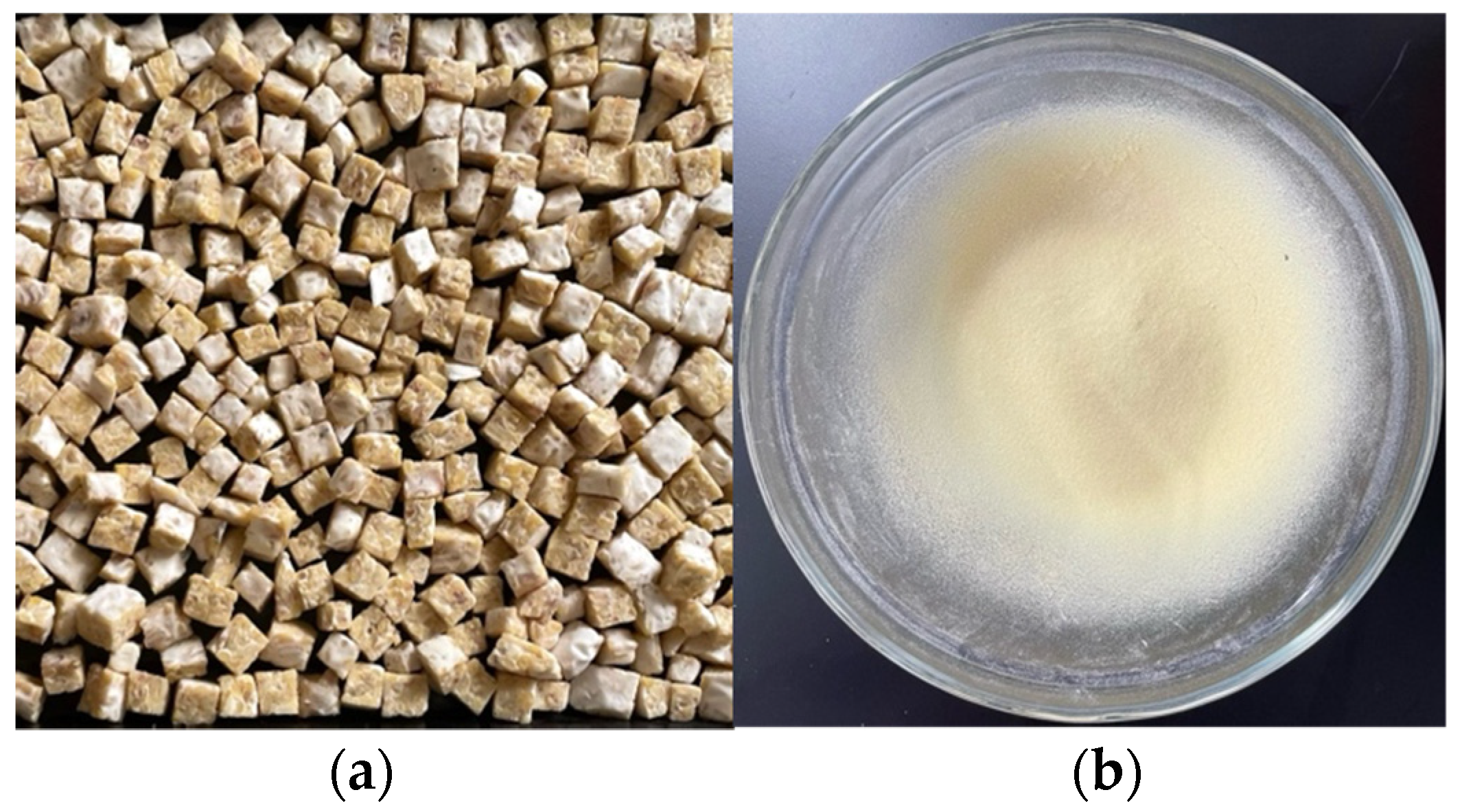

3.1. Mung Bean Tempeh Powder

3.2. Proximate Content of Mung Bean Tempeh Powder

3.3. Amino Acid Profiles of Mung Bean Tempeh Powder

3.4. Fatty Acid Profiles of Mung Bean Tempeh

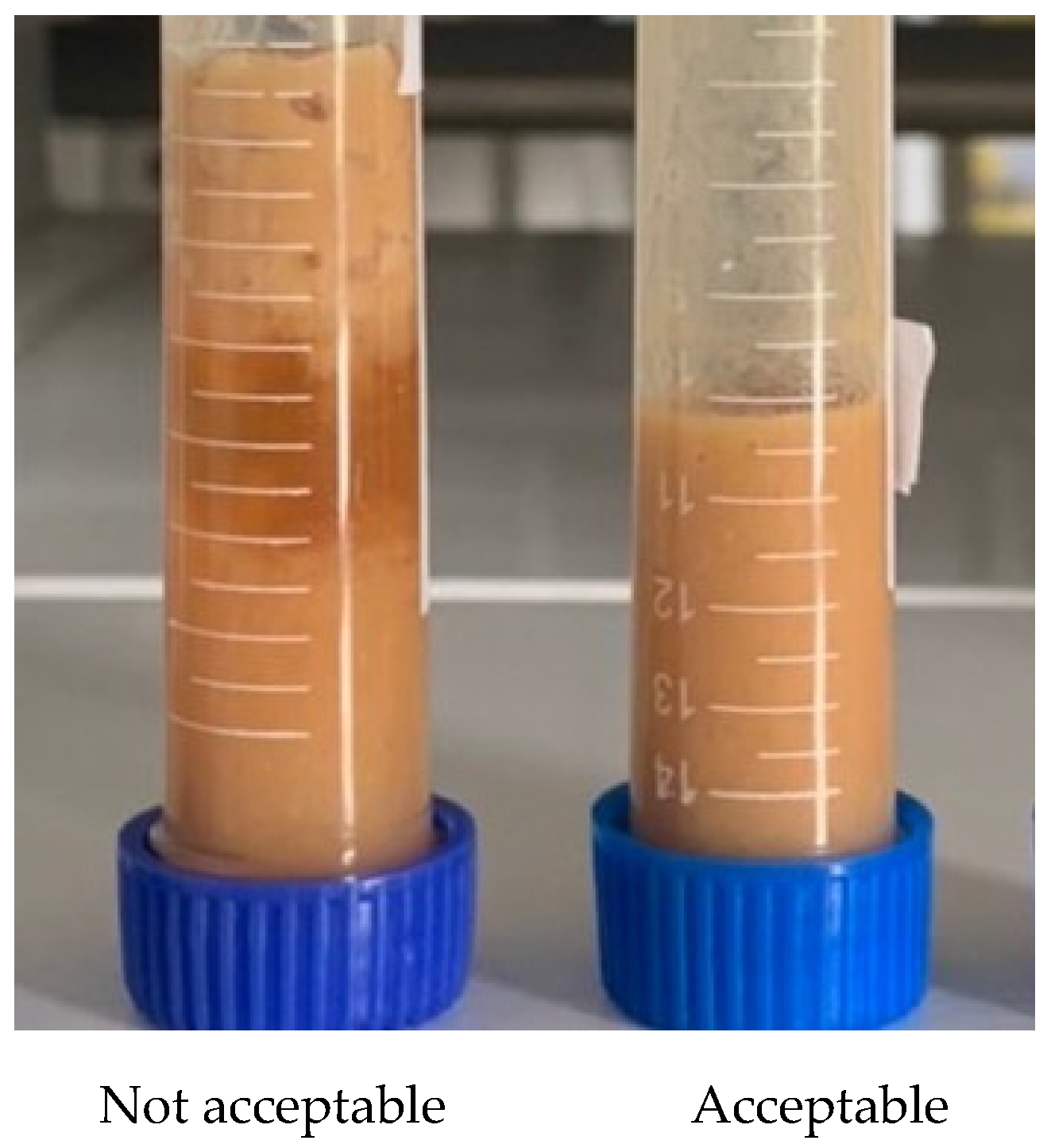

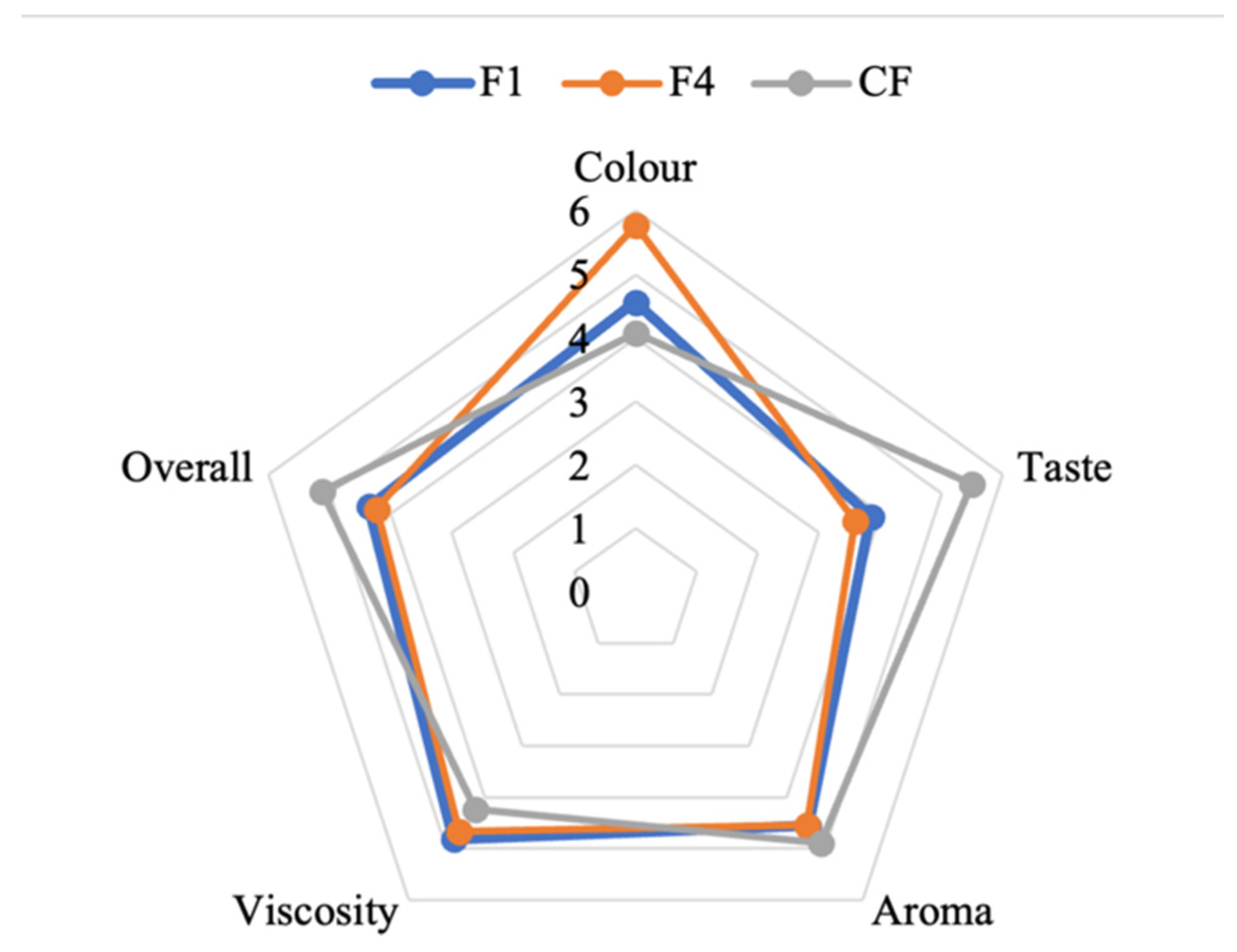

3.5. Sensory Evaluation Results

3.6. ONS Calories and Nutrition

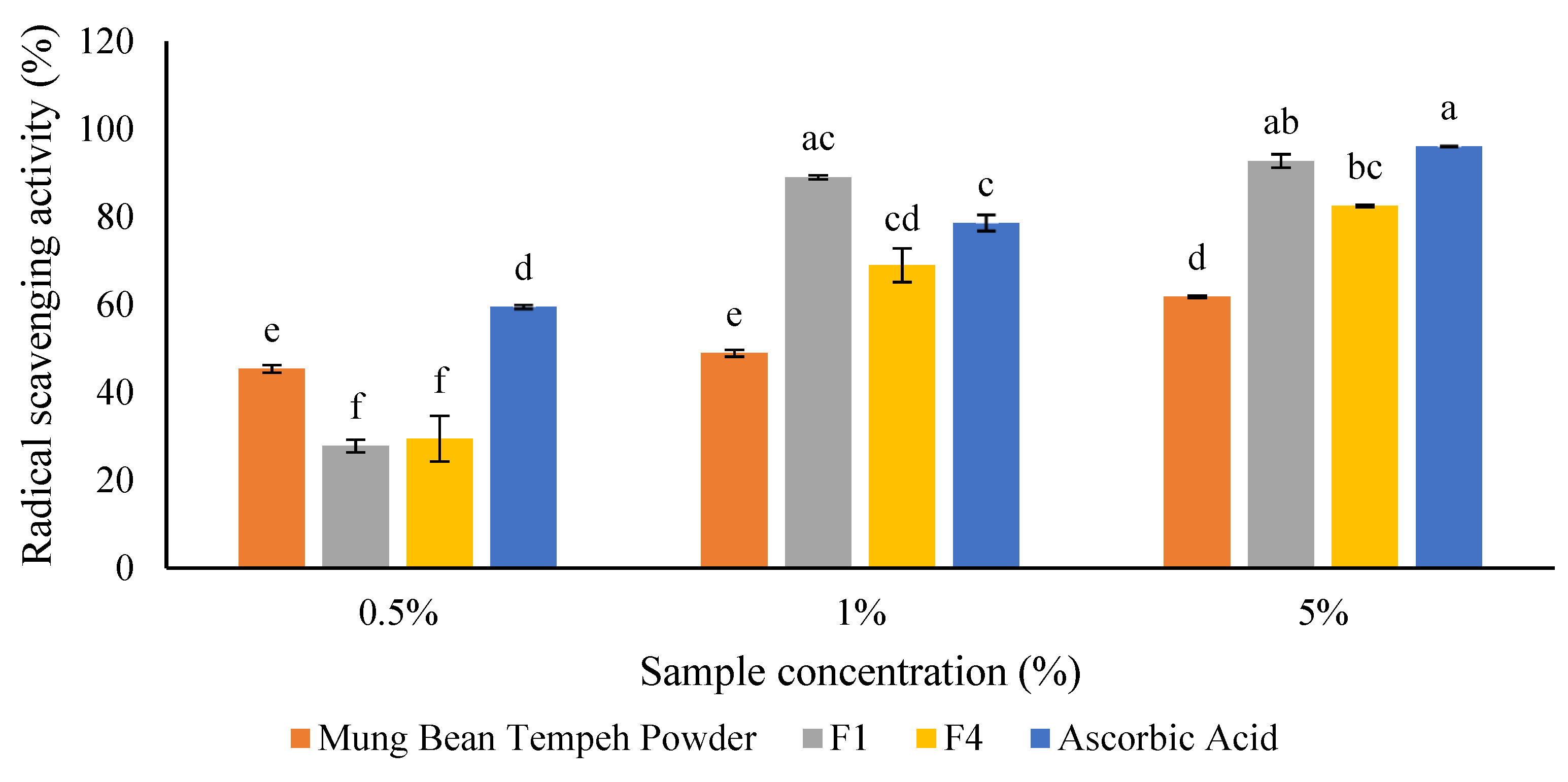

3.7. Antioxidant Activity of Mung Bean Tempeh Powder and ONS

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Radiati, A.; Sumarto. Analysis of physical, organoleptic, and nutritional properties of tempeh from non-soy legumes. JATP 2016, 5, 16–22. [Google Scholar]

- Astawan, M.; Wresdiyati, T.; Maknun, L. Tempeh as Health Source for Food Nutrition and Bioactive Compounds, 1st ed.; Nastiti, D.M., Ed.; IPB University: Bogor, Indonesia, 2017. [Google Scholar]

- Abu-Salem, F.M.; Mohamed, R.K.; Gibriel, A.Y.; Rasmy, N.M. Levels of some antinutritional factors in tempeh produced from some legumes and jojobas seeds. Int. J. Biol. Agric. Biosyst. Life Sci. Eng. 2014, 8, 280–285. [Google Scholar]

- Aryanta, I.W.R. Tempeh for Health. Widya Kesehat. 2020, 2, 44–50. [Google Scholar]

- Junianto, R.; Wanto, H.; Patiung, M. Soybean imports in Indonesia. IJEBD 2022, 5, 1102–1104. [Google Scholar] [CrossRef]

- Zhu, Y.-S.; Sun, S.; Fitzgerald, R. Mung bean proteins and peptides: Nutritional, functional and bioactive properties. Food Nutr. Res. 2018, 62, 1–11. [Google Scholar]

- Aspiyanto; Susilowati, A.; Lotulung, P.D.; Melanie, H.; Maryati, Y. Potency of stirred microfiltration cell in separation of fermented beans as protein isolate for natural source of folic acid. Indones. J. Chem. 2019, 19, 9–18. [Google Scholar] [CrossRef]

- Hubbard, G.P.; Elia, M.; Holdoway, A.; Stratton, R.J. A systematic review of compliance to oral nutritional supplements. J. Clin. Nutr. 2012, 31, 293–312. [Google Scholar] [CrossRef]

- Shimomura, Y.; Kitaura, Y. Physiological and pathological roles of branched-chain amino acids in the regulation of protein and energy metabolism and neurological functions. Pharmacol. Res. 2018, 133, 215–217. [Google Scholar] [CrossRef]

- Tamanna, N.; Mahmood, N. Emerging roles of branched-chain amino acid supplementation in human diseases. Int. Sch. Res. Notices 2014, 2014, 235619. [Google Scholar] [CrossRef]

- Maryam, S. The potency of mung bean tempeh fermented from traditional inoculum as a functional food. JST 2015, 4, 635–641. [Google Scholar]

- Faidah, F.H.; Moviana, Y.; Isdiany, N.; Surmita, S.; Hartini, P.W. Formulation of enteral nutrition using tempeh powder as an alternative enteral nutrition product with high protein content. J. Ris. Kesehat. Poltekkes Depkes Bdg. 2019, 11, 67–74. [Google Scholar] [CrossRef]

- Widjajasaputra, A.I.; Widyastuti, T.E.W.; Trisnawati, C.Y. Potency of mung beans with different soaking times as protein source of breastfeeding women in Indonesia. Food Res. 2019, 3, 501–505. [Google Scholar] [CrossRef] [PubMed]

- Dinar, F. Mung bean processing in tempeh production for the economic importance at Tembung village. JPKM 2014, 20, 40–44. [Google Scholar]

- Jauhari, M.; Sulaeman, A.; Riyadi, H.; Ekayanti, I. Development of tempeh based sports beverages for muscles damage recovery. J. Agritech. 2014, 34, 285–290. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis of The Association of Official Analytical Chemists International; AOAC: Washington, DC, USA, 2001. [Google Scholar]

- Waters. Acquity UPLC H-Class PLUS Bio System: Amino Acid Analysis System Guide; Waters Corporation: Wexford, Ireland, 2012; Available online: www.waters.com (accessed on 1 May 2022).

- Dahl-Lassen, R.; van Hecke, J.; Jørgensen, H.; Bukh, C.; Andersen, B.; Schjoerring, J.K. High-throughput analysis of amino acids in plant materials by single quadrupole mass spectrometry. Plant. Methods 2018, 14, 8. [Google Scholar] [CrossRef]

- Nur, N.; Meryandini, A.; Suhartono, M.T.; Suwanto, A. Lipolytic bacteria and the dynamics of flavor production in indonesian tempeh. Biodiversitas 2020, 21, 3818–3825. [Google Scholar] [CrossRef]

- Weimann, A.; Braga, M.; Carli, F.; Higashiguchi, T.; Hübner, M.; Klek, S.; Laviano, A.; Ljungqvist, O.; Lobo, D.N.; Martindale, R.; et al. ESPEN guideline: Clinical nutrition in surgery. Clin. Nutr. 2017, 36, 623–650. [Google Scholar] [CrossRef]

- Ghimeray, A.K.; Jung, U.S.; Lee, H.Y.; Kim, Y.H.; Ryu, E.K.; Chang, M.S. In vitro antioxidant, collagenase inhibition, and in vivo anti-wrinkle effects of combined formulation Punica granatum, Ginkgo biloba, Ficus carica, and Morus alba fruits extract. Clin. Cosmet. Investig. Dermatol. 2015, 8, 389–396. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques, 4th ed.; CRC: Boca Raton, FL, USA, 2006. [Google Scholar]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial fermentation and its role in quality improvement of fermented foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

- Wikandari, R.; Kinanti, D.A.; Permatasari, R.D.; Rahmaningtyas, N.L.; Chairunisa, N.R.; Sardjono; Hellwig, C.; Taherzadeh, M.J. Correlations between the chemical, microbiological characteristics and sensory profile of fungal fermented food. Fermentation 2021, 7, 261. [Google Scholar] [CrossRef]

- Hassanein, T.R.; Prabawati, E.K.; Puspitasari, M.D.; Gunawan-Puteri, T. Analysis of chemical and microbial changes during storage of overripe tempeh powder as seasoning material. Int. J. Sci. Eng. 2015, 8, 131–134. [Google Scholar]

- Syafutri, M.I.; Lidiasari, D.E. The effect of tempeh flour addition concentration on pumpkin tortilla characteristics. JTIHP 2014, 19, 289–296. [Google Scholar]

- Lestari, E.; Kiptiah, M.; Apifah. Characterization and optimization of mung bean powder as the flour substitute for bingka cake. JTAI 2017, 4, 20. [Google Scholar] [CrossRef]

- Lee, Y.G.; Bark, S.W.; Kim, H.S. Physicochemical properties of the mung bean (Phaseolus aureus L.) as biohealth functional substance. Korean J. Appl. Sci. Technol. 2019, 36, 1096–1107. [Google Scholar]

- Pal, M.M. Glutamate: The master neurotransmitter and its implications in chronic stress and mood disorders. Front. Hum. Neurosci. 2021, 15, 722323. [Google Scholar] [CrossRef]

- Pathak, A.; Vajpai, K.; Vajpai, S.K. Phytochemical investigation of plant seeds of chhattisgarh: Amino acid composition of seeds of Butea monosperma and Ocimum gratissium. Biomed. Pharmacol. 2012, 5, 45–49. [Google Scholar] [CrossRef]

- Świąder, K.; Marczewska, M. Trends of using sensory evaluation in new product development in the food industry in countries that belong to the EIT regional innovation scheme. Foods 2021, 10, 446. [Google Scholar] [CrossRef]

- Stippler, D.; Bode, V.; Fischer, M.; Kollex, K.; Rohde, E.; Tisowsky, B.; Künstner, J.; Pahne, N. Proposal for a new practicable categorization system for food for special medical purposes—Enteral nutritional products. Clin. Nutr. ESPEN 2015, 10, e219–e223. [Google Scholar] [CrossRef]

- Matemu, A.; Nakamura, S.; Katayama, S. Health benefits of antioxidative peptides derived from legume proteins with a high amino acid score. Antioxidants 2021, 10, 316. [Google Scholar] [CrossRef]

- Xu, N.; Chen, G.; Liu, H. Antioxidative categorization of twenty amino acids based on experimental evaluation. Molecules 2017, 22, 2066. [Google Scholar] [CrossRef]

- Barus, T.; Titarsole, N.N.; Mulyono, N.; Prasasty, V.D. Tempeh antioxidant activity using DPPH method: Effects of fermentation, processing, and microorganisms. IJFET 2019, 8, 75–80. [Google Scholar] [CrossRef]

- Dullius, A.; Fassina, P.; Giroldi, M.; Goettert, M.I.; de Souza, C.F.V. A biotechnological approach for the production of branched chain amino acid containing bioactive peptides to improve human health: A review. Food Res. Int. 2020, 131, 109002. [Google Scholar] [CrossRef] [PubMed]

- Ghone, R.A.; Suryakar, A.N.; Kulhalli, P.M.; Bhagat, S.S.; Padalkar, R.K.; Karnik, A.C.; Hundekar, P.S.; Sangle, D.A. A study of oxidative stress biomarkers and effect of oral antioxidant supplementation in severe acute malnutrition. J. Clin. Diagn. Res. 2013, 7, 2146–2148. [Google Scholar] [CrossRef]

- The European Commission. Commission Regulation (EU) 2016/1413 of 24 August 2016 amending Regulation (EU) No. 432/2012 establishing a list of permitted health claims made on foods other than those referring to the reduction of disease risk and to children’s development and health. J. Eur. Commun. 2016, 230, 8–15. [Google Scholar]

| Ingredients | Content (%) | |||||

|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F5 | F6 | |

| Mung bean tempeh powder | 10.40 | 7.60 | 6.00 | 10.40 | 7.60 | 6.00 |

| Palm sugar | 10.40 | 7.60 | 6.00 | - | - | - |

| Honey | - | - | - | 10.40 | 7.60 | 6.00 |

| Olive oil | 3.70 | 2.70 | 2.10 | 3.70 | 2.70 | 2.10 |

| Emulsifier SP | 1.50 | 1.10 | 0.90 | 1.50 | 1.10 | 0.90 |

| Water | 74.00 | 81.00 | 85.00 | 74.00 | 81.00 | 85.00 |

| Parameter | Unit | Mung Bean Tempeh Powder | Mung Bean Powder |

|---|---|---|---|

| Ash content | % | 2.76 ± 0.06 | 3.21 ± 0.01 |

| Moisture content | % | 7.73 ± 0.18 | 7.29 ± 0.01 |

| Protein content | % | 39.19 ± 0.50 | 23.60 ± 0.47 |

| Carbohydrate (by difference) | % | 47.06 ± 0.28 | 65.00 ± 0.48 |

| Total fat | % | 3.28 ± 0.11 | 0.91 ± 0.01 |

| Calorie from fat | Kcal/100 g | 29.48 ± 0.95 | 8.15 ± 0.06 |

| Total calories | Kcal/100 g | 374.46 ± 0.08 | 362.55 ± 0.01 |

| Levels | Amino Acids | Mung Bean Tempeh Powder (mg/g) | Mung Bean Powder (mg/g) |

|---|---|---|---|

| Overview | Total amino acids | 286.21 ± 0.58 | 152.25 ± 0.36 |

| Total essential amino acids | 117.97 ± 0.22 | 65.94 ± 0.13 | |

| Total BCAAs | 54.14 ± 0.05 | 27.62 ± 0.05 | |

| Higher levels | Glutamic acid | 48.76 ± 0.11 a | 29.22 ± 0.10 a |

| Alanine | 37.39 ± 0.14 b | 7.61 ± 0.02 b | |

| Aspartic acid | 23.37 ± 0.04 c | 18.44 ± 0.05 c | |

| Leucine * | 22.97 ± 0.03 d | 13.04 ± 0.04 d | |

| Phenylalanine * | 19.99 ± 0.05 e | 10.60 ± 0.03 e | |

| Lysine * | 17.81 ± 0.06 f | 12.03 ± 0.02 f | |

| Valine * | 17.21 ± 0.03 g | 7.99 ± 0.01 g | |

| Isoleucine * | 13.96 ± 0.01 h | 6.58 ± 0.01 h | |

| Arginine | 13.50 ± 0.01 i | 1.07 ± 0.01 i | |

| Threonine * | 13.50 ± 0.02 i | 5.93 ± 0.01 j | |

| Glycine | 12.48 ± 0.05 j | 6.71 ± 0.01 h | |

| Histidine * | 12.37 ± 0.00 j | 4.68 ± 0.02 k | |

| Tyrosine | 11.92 ± 0.04 k | 3.93 ± 0.00 l | |

| Serine | 11.67 ± 0.01 l | 9.24 ± 0.03 m | |

| Proline | 9.14 ± 0.01 m | 7.13 ± 0.01 n | |

| Lower levels | Tryptophan * | 0.17 ± 0.03 n | 1.68 ± 0.01 o |

| Methionine | 0.01 ± 0.00 n | 3.39 ± 0.00 p | |

| Cystine | ND | 2.90 ± 0.00 q |

| Parameters | Chemical Structure | Fatty Acids (%) |

|---|---|---|

| Individual fatty acids | ||

| Linolenic acid | C18:3 | 0.39 ± 0.01 a |

| Linolenic acid | C18:3 ω3 | 0.23 ± 0.00 b |

| Linolenic acid | C18:3 ω6 | 0.16 ± 0.00 c |

| Linoleic acid | C18:2 | 1.48 ± 0.00 d |

| Linoleic acid | C18:2 ω6 | 1.48 ± 0.00 d |

| Oleic acid | C18:1 ω9 C | 1.01 ± 0.00 e |

| Stearic acid | C18:0 | 0.12 ± 0.00 f |

| Heptadecanoic acid | C17:0 | 0.02 ± 0.00 g |

| Palmitoleic acid | C16:1 Ω7 | 0.02 ± 0.00 g |

| Palmitic acid | C16:0 | 0.73 ± 0.00 h |

| Myristic acid | C14:0 | 0.02 ± 0.00 g |

| Sums of fatty acids | ||

| SFA | 0.87 ± 0.00 | |

| MUFA | 1.05 ± 0.00 | |

| PUFA | 1.87 ± 0.00 | |

| UFA | 2.92 ± 0.00 | |

| Omega-3 | 0.23 ± 0.00 | |

| Omega-6 | 1.64 ± 0.00 | |

| Omega-9 Omega-7 | 1.01 ± 0.00 0.02 ± 0.00 |

| Formulation | Day | Parameter | ||||

|---|---|---|---|---|---|---|

| Color | Viscosity | Taste | Scent | Overall | ||

| F1 | H0 | Dark brown | Slightly thick, smooth | Moderate sweet, tempeh | Strong tempeh and palm sugar | Acceptable |

| H1 | Dark brown | Slightly thick, smooth | Moderate sweet, tempeh | Strong tempeh and palm sugar | ||

| H2 | Dark brown | Slightly thick, smooth | Moderate sweet, tempeh | Strong tempeh and palm sugar | ||

| H3 | Dark brown | Slightly thick, smooth | Moderate sweet, tempeh | Strong tempeh and palm sugar | ||

| F2 | H0 | Dark brown | Slightly runny, smooth | Fairly sweet, tempeh | Moderate tempeh and palm sugar | Not acceptable |

| H1 | Light brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and palm sugar | ||

| H2 | Light brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and palm sugar | ||

| H3 | Light brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and palm sugar | ||

| F3 | H0 | Dark brown | Runny smooth | Fairly sweet, tempeh | Slightly tempeh and palm sugar | Not acceptable |

| H1 | Light brown | Runny smooth, separated water | Fairly sweet, tempeh | Slightly tempeh and palm sugar | ||

| H2 | Light brown | Runny smooth, separated water | Fairly sweet, tempeh | Slightly tempeh and palm sugar | ||

| H3 | Light brown | Runny smooth, separated water | Fairly sweet, tempeh | Slightly tempeh and palm sugar | ||

| F4 | H0 | Yellowish brown | Slightly thick, smooth | Mildly sweet, tempeh | Strong tempeh and honey | Acceptable |

| H1 | Yellowish brown | Slightly thick, smooth | Mildly sweet, tempeh | Strong tempeh and honey | ||

| H2 | Yellowish brown | Slightly thick, smooth | Mildly sweet, tempeh | Strong tempeh and honey | ||

| H3 | Yellowish brown | Slightly thick, smooth | Mildly sweet, tempeh | Strong tempeh and honey | ||

| F5 | H0 | Yellowish brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and honey | Not acceptable |

| H1 | Yellowish brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and honey | ||

| H2 | Yellowish brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and honey | ||

| H3 | Yellowish brown | Slightly runny, smooth, separated water | Fairly sweet, tempeh | Moderate tempeh and honey | ||

| F6 | H0 | Yellowish brown | Runny, smooth | Fairly sweet, tempeh | Slight tempeh and honey | Not acceptable |

| H1 | Yellowish brown | Runny, smooth, separated water | Fairly sweet, tempeh | Slight tempeh and honey | ||

| H2 | Yellowish brown | Runny, smooth, separated water | Fairly sweet, tempeh | Slight tempeh and honey | ||

| H3 | Yellowish brown | Runny, smooth, separated water | Fairly sweet, tempeh | Slight tempeh and honey | ||

| Formulation | Color | Taste | Aroma | Viscosity | Overall |

|---|---|---|---|---|---|

| F1 | 4.56 ± 0.21 b | 3.79 ± 0.24 b | 4.56 ± 0.22 a | 4.82 ± 0.20 a | 4.36 ± 0.21 b |

| F4 | 5.77 ± 0.15 a | 3.55 ± 0.22 b | 4.54 ± 0.22 a | 4.67 ± 0.22 a | 4.23 ± 0.19 b |

| CF | 4.08 ± 0.21 b | 5.61 ± 0.20 a | 4.90 ± 0.21 a | 4.23 ± 0.26 a | 5.13 ± 0.18 a |

| Ingredients | F1 | F4 | Nutrition | ||

|---|---|---|---|---|---|

| Amount | Calorie | Amount | Calorie | ||

| Mung bean tempeh powder | 5.20 | 19 | 5.20 | 19 | 2.04 g protein 2.45 g carbohydrate 0.17 g fat |

| Palm sugar | 5.20 | 20 | - | - | 5.20 g carbohydrate |

| Honey | - | - | 5.20 | 16 | 3.97 g carbohydrate |

| Olive oil | 1.90 | 17 | 1.90 | 17 | 1.90 fat |

| Total | 12.30 | 56 | 12.30 | 52 | - |

| Content | F1 (% kcal) | F4 (% kcal) | ESPEN Guidelines (% kcal) |

|---|---|---|---|

| Protein | 14.30 | 15.60 | 8–30 |

| Carbohydrate | 53.60 | 49.20 | 30–65 |

| Fat | 32.10 | 35.20 | 25–40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yanti; Violina, V.; Putri, C.E.; Lay, B.W. Branched Chain Amino Acid Content and Antioxidant Activity of Mung Bean Tempeh Powder for Developing Oral Nutrition Supplements. Foods 2023, 12, 2789. https://doi.org/10.3390/foods12142789

Yanti, Violina V, Putri CE, Lay BW. Branched Chain Amino Acid Content and Antioxidant Activity of Mung Bean Tempeh Powder for Developing Oral Nutrition Supplements. Foods. 2023; 12(14):2789. https://doi.org/10.3390/foods12142789

Chicago/Turabian StyleYanti, Vanessa Violina, Caecilia Eka Putri, and Bibiana Widiyati Lay. 2023. "Branched Chain Amino Acid Content and Antioxidant Activity of Mung Bean Tempeh Powder for Developing Oral Nutrition Supplements" Foods 12, no. 14: 2789. https://doi.org/10.3390/foods12142789

APA StyleYanti, Violina, V., Putri, C. E., & Lay, B. W. (2023). Branched Chain Amino Acid Content and Antioxidant Activity of Mung Bean Tempeh Powder for Developing Oral Nutrition Supplements. Foods, 12(14), 2789. https://doi.org/10.3390/foods12142789