Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making

Abstract

1. Introduction

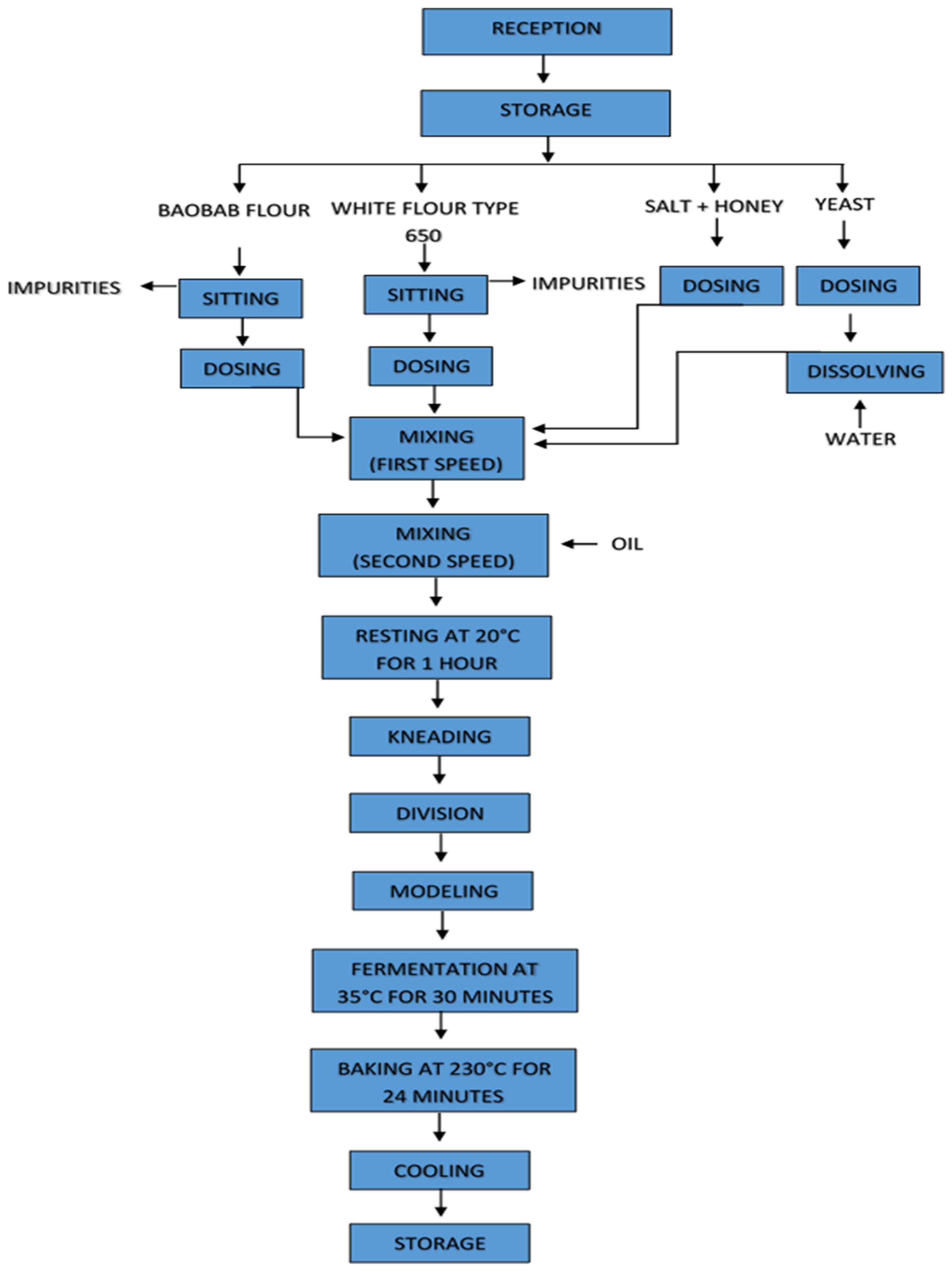

2. Materials and Methods

2.1. Materials, Reagents, and Instruments

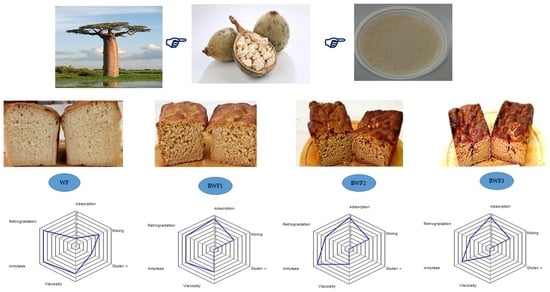

2.2. Preparation of Composite Flours

2.3. Bread Preparation

2.4. Determination of Proximate Composition

2.5. Macro and Microelements

2.6. Physical-Chemical Properties

2.7. Phytochemical Profile

2.7.1. Preparation of Alcoholic Extracts

2.7.2. Evaluation of the Total Phenolic Content (TPC)

2.7.3. Determination of Total Flavonoid Content (TFC)

2.7.4. Antioxidant Activity

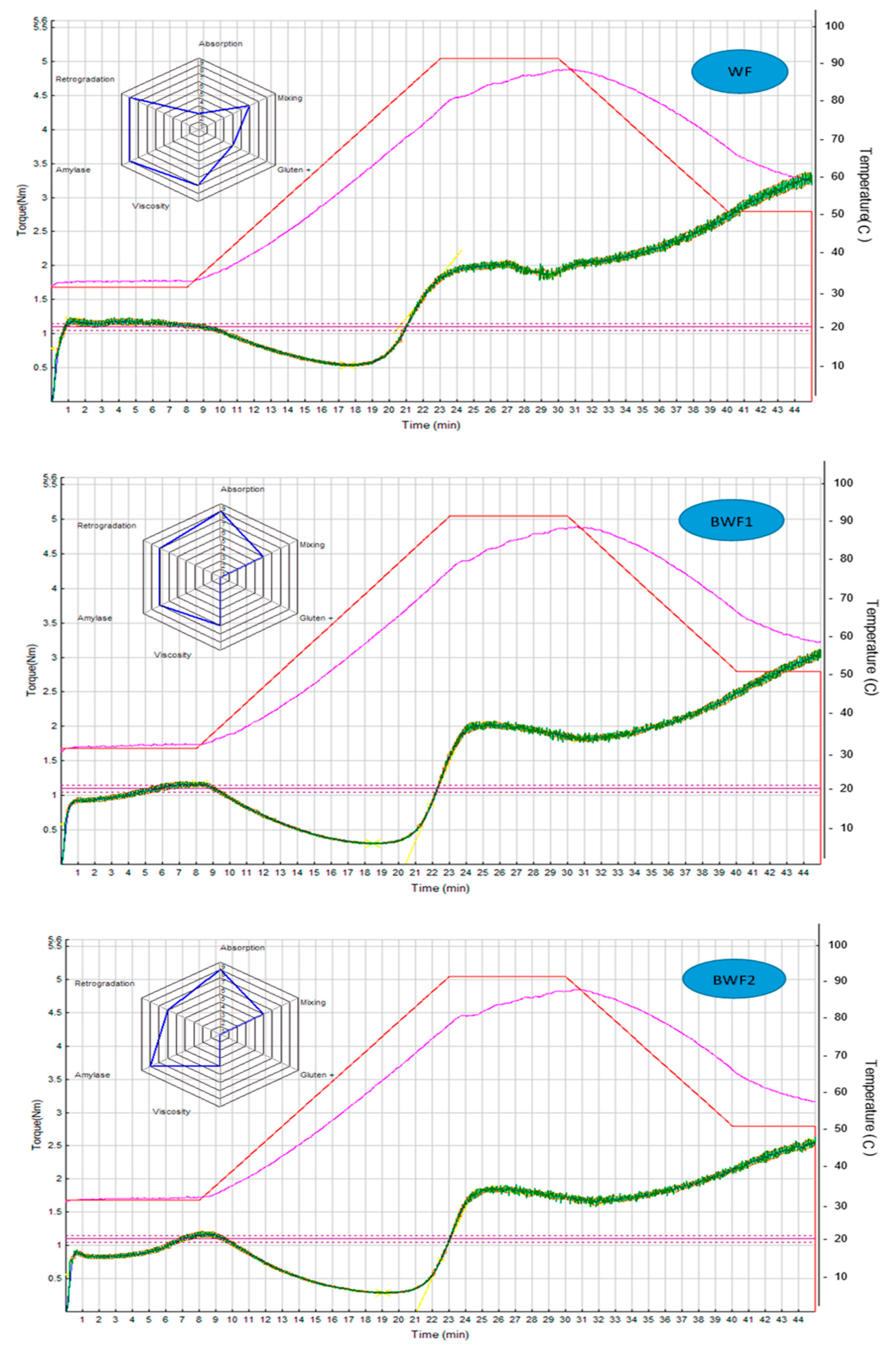

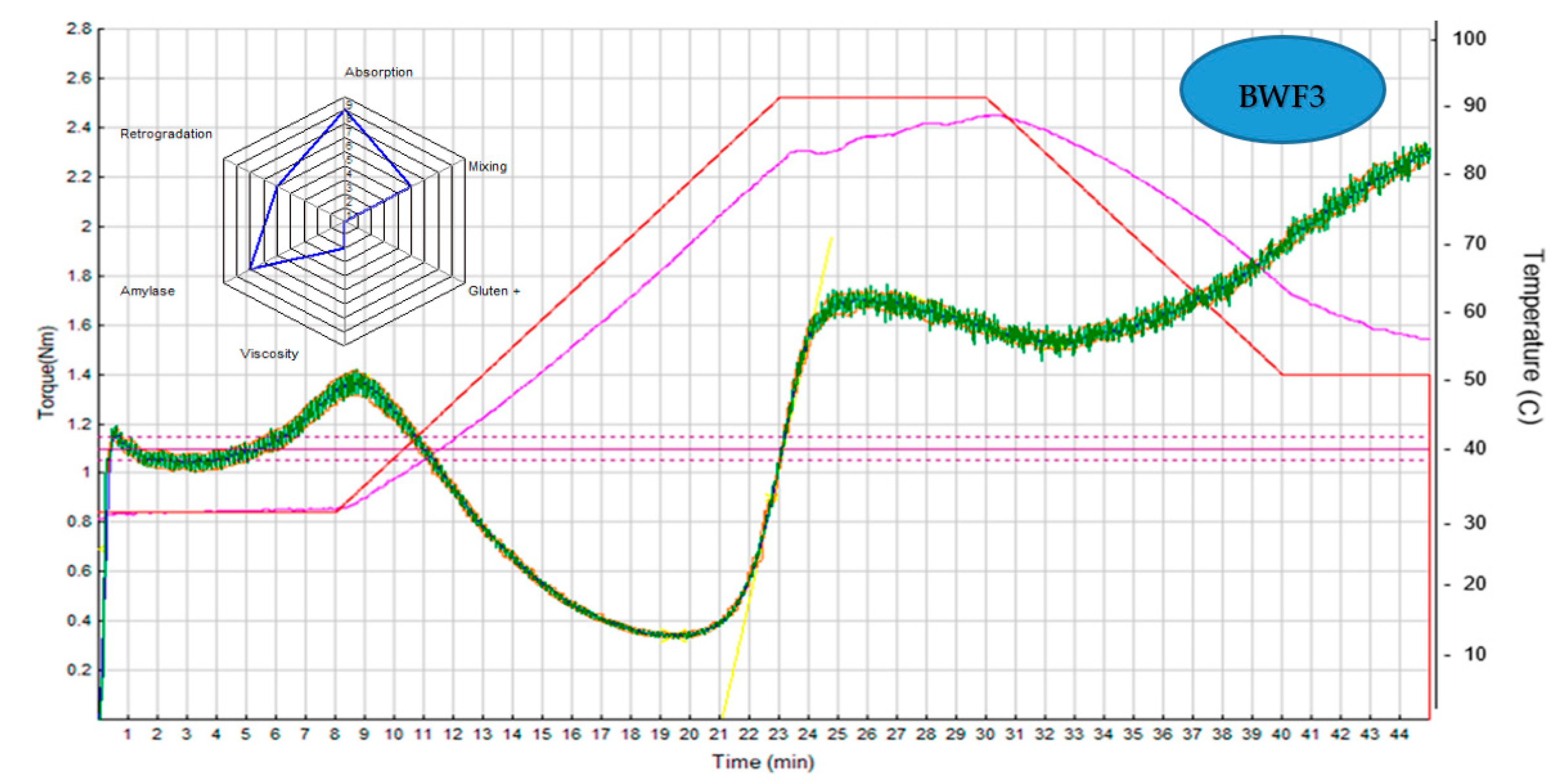

2.8. Rheological Analysis

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Determination of Proximate Composition

3.2. Macro and Microelements

3.3. Physical-Chemical Proprieties of Baobab Bread

3.4. Rheological Properties of the Different Flours

3.5. Phytochemical Profile of Composite Flours and Bread

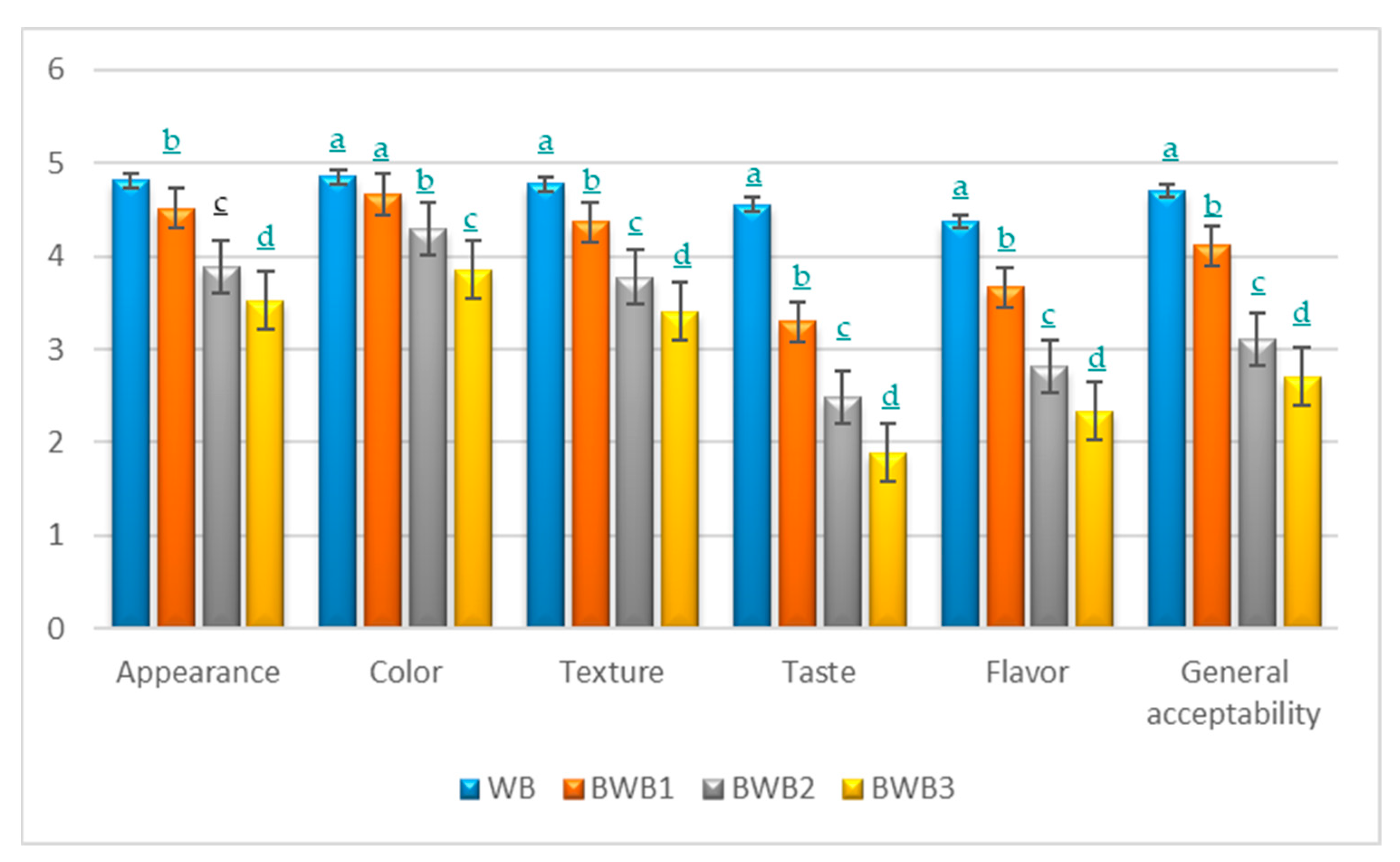

3.6. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cauvain, S.P. Bread and other bakery products. In The Stability and Shelf Life of Food, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 413–459. [Google Scholar]

- Grundas, S.T. Wheat the Crop, Encyclopedia of Food Sciences and Nutrition; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2003; pp. 6130–6137. [Google Scholar]

- Vitali, D.; Dragojević, V.; Šebečić, B. Bio-accessibility of Ca, Mg, Mn and Cu from whole grain tea-biscuits: Impact of proteins, phytic acid, and polyphenols. Food Chem. 2008, 110, 62–68. [Google Scholar] [CrossRef]

- Dooshima, I.B.; Amove, J.; Okoh, A. Quality evaluation of composite bread produced from wheat, defatted soy and banana flours. Int. J. Nutr. Food Sci. 2014, 3, 471–476. [Google Scholar] [CrossRef]

- Agrahar-Murugkar, D. Food to food fortification of bread and biscuits with herbs, spices, millets and oilseeds on bio-accessibility of calcium, iron and zinc and impact of proteins, fat and phenolics. LWT—Food Sci. Technol. 2020, 130, 109703. [Google Scholar] [CrossRef]

- Hedhili, A.; Lubbers, S.; Bou-Maroun, E.; Griffon, F.; Akinyemi, B.E.; Husson, F.; Valentin, D. Moringa Oleifera supplemented biscuits: Nutritional values and consumer segmentation. S. Afr. J. Bot. 2021, 138, 406–414. [Google Scholar] [CrossRef]

- Ibidapo, O.P.; Henshaw Taofik, F.O.; Wasiu, A.S.; Afolabi, A. Quality evaluation of functional bread developed from wheat, malted millet (Pennisetum glaucum) and ‘Okara’ flour blends. Sci. Afr. 2020, 10, e00622. [Google Scholar] [CrossRef]

- Chadare, F.; Linnemann, A.; Hounhouigan, J.; Nout, M.; Van Boekel, M. Baobab food products: A review on their composition and nutritional value. Crit. Rev. Food Sci. Nutr. 2009, 49, 254–274. [Google Scholar] [CrossRef]

- Gebauer, J.; El Siddig, K.; Ebert, G. Baobab (Adansonia digitata L.): A review on a multipurpose tree with promising future in the Sudan. Gartenbauwissenscha 2002, 67, 155–160. [Google Scholar]

- Wickens, G.; Lowe, P. The Baobabs: Pachycauls of Africa, Madagascar and Australia; Springer: Dordrecht, The Netherlands; London, UK, 2008; p. 500. [Google Scholar]

- Buchmann, C.; Prehsler, S.; Hartl, A.; Vogl, C.R. The importance of baobab (Adansonia digitata L.) in rural West African subsistence–suggestion of a cautionary approach to international market export of baobab fruits. Ecol. Food Nutr. 2010, 49, 145–172. [Google Scholar] [CrossRef]

- De Caluwé, E.; Halamova, K.; Van Damme, P. A review of traditional use, phytochemistry and pharmacology. Afr. Focus 2010, 23, 11–51. [Google Scholar] [CrossRef]

- Kamatou, G.; Vermaak, I.; Viljoen, A. An updated review of Adansonia digitata: A commercially important African tree. S. Afr. J. Bot. 2011, 77, 908–919. [Google Scholar] [CrossRef]

- Codex Alimentarius Commission. Joint FAO/WHO Food Standards Programme, Report of the Thirtieth Session; Codex Alimentarius Commission: Rome, Italy, 2007; pp. 1–184. [Google Scholar]

- Muthai, K.U.; Karori, M.S.; Muchugi, A.; Indieka, A.S.; Dembele, C.; Mng’omba, S.; Jamnadass, R. Nutritional variation in baobab (Adansonia digitata L.) fruit pulp and seeds based on Africa geographical regions. Food Sci. Nutr. 2017, 5, 1116–1129. [Google Scholar] [CrossRef] [PubMed]

- Hyacinthe, T.; Charles, P.; Adama, K.; Diarra, C.S.; Dicko, M.H.; Svejgaard, J.J.; Diawara, B. Variability of vitamins B1, B2 and minerals content in baobab (Adansonia digitata) leavesinEastand West Africa. Food Sci. Nutr. 2015, 3, 17–24. [Google Scholar] [CrossRef]

- Diop, A.; Sakho, M.; Dornier, M.; Cisse, M.; Reynes, M. Le baobab africain (Adansonia digitata L.): Principales caractéristiques et utilisations. Fruits 2005, 61, 55–69. [Google Scholar] [CrossRef]

- Tsetegho Sokeng, A.J.; Sobolev, A.P.; Di Lorenzo, A.; Xiao, J.; Mannina, L.; Capitani, D.; Daglia, M. Metabolite characterization of powdered fruits and leaves from Adansonia digitata L. (baobab): A multi-methodological approach. Food Chem. 2019, 272, 93–108. [Google Scholar] [CrossRef]

- Keding, G.; Kehlenbeck, K.; Kennedy, G.; McMullin, S. Fruit production and consumption: Practices, preferences and attitudes of women in rural western Kenya. Food Secur. 2017, 9, 453–469. [Google Scholar] [CrossRef]

- Ruel, M.T.; Minot, N.; Smith, L. Patterns and Determinants of Fruit and Vegetable Consumption in Sub-Saharan Africa: A Multicounty Comparison; WHO: Geneva, Switzerland, 2005. [Google Scholar]

- Assogbadjo, A.; Chadaré, F.; Kakaï, R.; Fandohan, B.; Baidu-Forason, J. Variation in biochemical composition of baobab (Adansonia digitata) pulp, leaves and seeds in relation to soil types and tree provenances. Agric. Ecosyst. Environ. 2012, 157, 94–99. [Google Scholar] [CrossRef]

- Regulation (EC) No 258/97 of the European Parliament and of the Council, Commission decision-Baobab dried fruit pulp as a novel food ingredient. Document C (2008) 3046. Brussels, Belgium. Off. J. Eur. Union 2008. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2008:183:0038:0039:EN:PDF (accessed on 11 June 2023).

- Górecka, D.; Pachołek, B.; Dziedzic, K.; Górecka, M. Raspberry pomace as a potential fiber source for cookies enrichment. Acta Sci. Pol. Technol. Aliment. 2010, 9, 451–462. [Google Scholar]

- Mounjouenpou, P.; Ngono Eyenga, S.N.N.; Kamsu, E.J.; Kari, P.B.; Ehabe, E.E.; Ndjouenkeu, R. Effect of fortification with baobab (Adansonia digitata L.) pulp flour on sensorial acceptability and nutrient composition of rice cookies. Sci. Afr. 2018, 1, e00002. [Google Scholar] [CrossRef]

- Hernandez-Aguilar, C.; Dominguez-Pacheco, A.; Valderrama-Bravo, C.; Cruz-Orea, A.; Martínez Ortiz, E.; Ivanov, R.; Ordonez-Miranda, J. Photoacoustic characterization of wheat bread mixed with Moringa oleifera. Curr. Res. Food Sci. 2021, 4, 521–531. [Google Scholar] [CrossRef]

- Plustea, L.; Negrea, M.; Cocan, I.; Radulov, I.; Tulcan, C.; Berbecea, A.; Popescu, I.; Obistioiu, D.; Hotea, I.; Suster, G. Lupin (Lupinus s)-Fortified Bread: A Sustainable, Nutritionally, Functionally, and Technologically Valuable Solution for Bakery. Foods 2022, 11, 2067. [Google Scholar] [CrossRef] [PubMed]

- No. 110/1.ICC; ICC Standard Methods of the International Association for Cereal Science and Technology. ICC: Vienna, Austria, 2003.

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- STAS 91/83; Romanian Standard for Bread, Bakery Products and Bakery Specialities—Methods of Analysis. ASRO: București, Romania, 1983.

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Obistioiu, D.; Cocan, I.; Tîrziu, E.; Herman, V.; Negrea, M.; Cucerzan, A.; Neacsu, A.G.; Cozma, A.L.; Nichita, I.; Hulea, A. Phytochemical Profile and Microbiological Activity of Some Plants Belonging to the Fabaceae Family. Antibiotics 2021, 10, 662. [Google Scholar] [CrossRef] [PubMed]

- Cocan, I.; Cadariu, A.-I.; Negrea, M.; Alexa, E.; Obistioiu, D.; Radulov, I.; Poiana, M.-A. Investigating the Antioxidant Potential of Bell Pepper Processing By-Products for the Development of Value-Added Sausage Formulations. Appl. Sci. 2022, 12, 12421. [Google Scholar] [CrossRef]

- Ciulca, S.; Roma, G.; Alexa, E.; Radulov, I.; Cocan, I.; Madosa, E.; Ciulca, A. Variation of Polyphenol Content and Antioxidant Activity in Some Bilberry (Vaccinium myrtillus L.) Populations from Romania. Agronomy 2021, 11, 2557. [Google Scholar] [CrossRef]

- Mixolab Applications Handbook. In Rheological and Enzymatic Analysis; Chopin Applicatios Laboratory: Villeneuve la Garenne, France, 2009.

- ISO 6658:2017; Sensory Analysis—Methodology—Overall Guidelines. ISO: Geneva, Switzerland, 2017.

- Barakat, H. Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes. Foods 2021, 10, 716. [Google Scholar] [CrossRef]

- Cissé, I.; Montet, D.; Reynes, M.; Danthu, P.; Yao, B.; Boulanger, R. Biochemical and nutritional properties of baobab pulp from endemic species of Madagascar and the African mainland. Afr. J. Agric. Res. 2013, 8, 6046–6054. [Google Scholar]

- Nutritional Evaluation of Baobab Dried Fruit Pulp and Its Potential Health Benefits; Leatherhead Food Research for Africa Summary Report; PhytoTrade. 2009. Available online: http://oh.q-sites.com/getattachment/Products/Baobab/PhytoTrade-Baobab-Nutritional-Summary-(1).pdf.aspx (accessed on 10 May 2023).

- Cissé, I. Caractérisation des Propriétés Biochimiques et Nutritionnelles de la Pulpe de Baobab des Espèces Endémiques de Madagascar et d’Afrique Continentale en vue de leur Valorisation. Ph.D. Thesis, Montpellier SupAgro (FRA), Montpellier, France, 2012. [Google Scholar]

- Stadlmayr, B.; Wanangwe, J.; Waruhiu, C.G.; Jamnadass, R.; Kehlenbeck, K. Nutritional composition of baobab (Adansonia digitata L.) fruit pulp sampled at different geographical locations in Kenya. J. Food Compos. Anal. 2020, 94, 103617. [Google Scholar] [CrossRef]

- Lockett, C.; Calvert, C.; Grivetti, L. Energy and micronutrient composition of dietary and medicinal wild plants consumed during drought. Study of rural Fulani, Northeastern Nigeria. Int. J. Food Sci. Nutr. 2000, 51, 195–208. [Google Scholar]

- Murray, S.; Schoeninger, M.; Bunn, H.; Pickering, T.; MarIen, J. Nutritional composition of sorne wild plant foods and honey used by Hadza foragers of Tanzania. Food Compos. Anal. 2001, 14, 3–13. [Google Scholar] [CrossRef]

- Osman, M. Chemical and nutrient analysis of baobab (Adansonia digitata) fruit and seed protein solubility. Plant Foods Hum. Nutr. 2004, 59, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Vidal. FOOD SUPPLEMENT: POTASSIUM. 2014. Available online: https://www.vidal.fr/parapharmacie/complements-alimentaires/potassium.html (accessed on 18 April 2023).

- World Health Organization (WHO). Guidelines: On Potassium Intake in Adults and Children Summary of Guidance. WHO/NMH/NHD/13.1; 2013. Available online: https://apps.who.int/iris/bitstream/handle/10665/85225/WHO_NMH_NHD_13.1_fre.pdf (accessed on 2 May 2023).

- EFSA Panel on Dietetic Products, Nutrition and Allergies. Scientific Opinion on the Tolerable Upper Intake Level of calcium. EFSA J. 2012, 10, 2814. [Google Scholar]

- PassportSanté. Magnesium 2014. Available online: https://www.passeportsante.net/fr/Solutions/PlantesSupplements/Fiche.aspx?doc=magnesium_ps (accessed on 18 April 2023).

- EFSA Panel on Dietetic Products, Nutrition and Allergies. Scientific Opinion on Dietary Reference Values for magnesium. EFSA J. 2015, 13, 4186. [Google Scholar]

- OMS-FAO. Directives Sur L’enrichissement des Aliments en Micronutriments; OMS-FAO: Rome, Italy, 2011; Available online: https://apps.who.int/iris/bitstream/handle/10665/44585/9789242594010_fre.pdf (accessed on 2 May 2023).

- ANSES. Le sel ou Chlorure de Sodium; ANSES: Buenos Aires, Argentina, 2022.

- Antanas, S.; Alexa, E.; Negrea, M.; Guran, E.; Lazureanu, A. Studies regarding rheological properties of triticale, wheat and rye flours. J. Hortic. For. Biotechnol. 2013, 17, 345–349. [Google Scholar]

- Dico, G.M.L.; Ulrici, A.; Pulvirenti, A.; Cammilleri, G.; Macaluso, A.; Vella, A.; Giaccone, V.; Cascio, G.L.; Graci, S.; Scuto, M.; et al. Multivariate statistical analysis of the polyphenols content for the discrimination of honey produced in Sicily (Southern Italy). J. Food Compos. Anal. 2019, 82, 103225. [Google Scholar] [CrossRef]

- Balarabe, B.I.; Yunfeng, P.; Lihua, F.; Munir, A.D.; Mingming, G.; Donghong, L. Characterizing the phenolic constituents of baobab (Adansonia digitata) fruit shell by LC-MS/QTOF and their in vitro biological activities. Sci. Total Environ. 2019, 694, 133387. [Google Scholar]

- Coe, S.A.; Clegg, M.; Armengol, M.; Ryan, L. The polyphenol-rich baobab fruit (Adansonia digitata L.) reduces starch digestion and glycemic response in humans. Nutr. Res. 2013, 33, 888–896. [Google Scholar] [CrossRef]

- Balarabe, B.I.; Hauwa, L.Y.; Yunfeng, P.; Huanhuan, Z.; Mingming, G.; Donghong, L. Ultrasound-assisted adsorption/desorption for the enrichment and purification of flavonoids from baobab (Adansonia digitata) fruit pulp. Ultrason. Sonochem. 2020, 65, 104980. [Google Scholar] [CrossRef]

| Samples | Ingredients | ||||||

|---|---|---|---|---|---|---|---|

| Baobab Flour (g) | Wheat Flour Type 650 (g) | Yeast (g) | Salt (g) | Honey (g) | Oil (mL) | Water (mL) | |

| WB | - | 1000 | 50 | 20 | 30 | 80 | 800 |

| BWB1 | 100 | 900 | 50 | 20 | 30 | 80 | 800 |

| BWB2 | 200 | 800 | 50 | 20 | 30 | 80 | 800 |

| BWB3 | 300 | 700 | 50 | 20 | 30 | 80 | 800 |

| Samples | Nutritional Characteristics | |||||

|---|---|---|---|---|---|---|

| Moisture | Mineral Content | Proteins | Lipids | Carbohydrates | Energy Values | |

| (%) | (%) | (%) | (%) | (g/100 g) | (kcal/100 g) | |

| Composite flours | ||||||

| WF | 10.80 ± 0.04 d | 0.33 ± 0.03 c | 11.26 ± 0.02 a | 1.33 ± 0.03 c | 76.28 ± 0.04 | 362.13 ± 0.16 |

| BF | 13.79 ± 0.01 a | 4.00 ± 0.02 a | 4.31 ± 0.05 d | 1.56 ± 0.02 a | 76.34 ± 0.06 | 336.62 ± 0.16 |

| BWF1 | 11.39 ± 0.24 c,d | 0.66 ± 0.02 c | 11.05 ± 0.06 a | 1.40 ± 0.05 b | 75.50 ± 0.13 | 358.80 ± 0.22 |

| BWF2 | 11.59 ± 0.01 b,c | 1.10 ± 0.18 b | 10.16 ± 0.05 b | 1.42 ± 0.03 b | 75.73 ± 0.17 | 356.35 ± 0.69 |

| BWF3 | 11.80 ± 0.03 b | 1.21 ± 0.04 b | 9.80 ± 0.02 c | 1.45 ± 0.01 b | 75.74 ± 0.07 | 355.21 ± 0.23 |

| Breads | ||||||

| BW | 35.20 ± 0.02 a | 0.96 ± 0.02 d | 10.67 ± 0.01 a | 5.19 ± 0.03 c | 47.98 ± 0.02 | 281.31 ± 0.2 |

| BWB1 | 34.60 ± 0.04 b | 1.69 ± 0.01 c | 8.90 ± 0.01 b | 5.20 ± 0.05 c | 49.60 ± 0.36 | 280.84 ± 9.5 |

| BWB2 | 34.66 ± 0.05 b | 1.95 ± 0.03 b | 8.51 ± 0.01 c | 5.26 ± 0.02 b | 49.63 ± 0.03 | 279.84 ± 0.11 |

| BWB3 | 34.73 ± 0.04 b | 2.17 ± 0.05 a | 8.02 ± 0.04 d | 5.30 ± 0.02 a | 49.79 ± 0.8 | 278.93 ± 0.41 |

| Samples | Macro- and Microelements Contents (mg/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Ni | Zn | Fe | Mn | Ca | Mg | K | Na | |

| Composite flours | |||||||||

| BF | 8.04 ± 0.05 a | 0.598 ± 0.002 a | 14.90 ± 0.01 a | 155.14 ± 2.95 a | 4.84 ± 0.05 d | 1570.67 ± 29.67 a | 1066.73 ± 9.97 a | 13,276.47 ± 174 a | 143.19 ± 5.22 a |

| WF | 2.4 ± 0.002 c | nd | 11.40 ± 0.01 b | 12.13 ± 0.03 e | 8.69 ± 0.02 a | 166.22 ± 0.99 d | 273.15 ± 1.28 e | 1188.68 ± 101 e | 60.38 ± 0.76 d |

| BWF1 | 2.88 ± 0.03 c | 0.22 ± 0.026 c | 11.79 ± 0.01 b | 17.89 ± 0.20 d | 6.84 ± 0.05 b | 246.12 ± 2.62 c | 431.81 ± 7.5 d | 1589.59 ± 164 d | 83.86 ± 2.04 c |

| BWF2 | 3.4 ± 0.17 b | 0.267 ± 0.001 c | 12.21 ± 0.04 c | 33.37 ± 0.44 c | 6.61 ± 0.29 b | 307.95 ± 2.05 b | 553.78 ± 3.41 c | 3640.07 ± 135 c | 87.66 ± 1.95 c |

| BWF3 | 3.96 ± 0.02 b | 0.526 ± 0.037 b | 12.35 ± 0.09 c | 47.14 ± 0.4 b | 5.86 ± 0.15 c | 329.15 ± 6.40 b | 573.33 ± 0.75 b | 4155.47 ± 147 b | 96.57 ± 0.62 b |

| Composite breads | |||||||||

| WB | 1.96 ± 0.03 c | 0.152 ± 0.002 c | 12.20 ± 0.09 a | 11.15 ± 0.03 d | 7.14 ± 0.17 a | 327.49 ± 1.05 d | 264.47 ± 2.91 d | 984.53 ± 13.42 d | 40.44 ± 0.57 b |

| BWB1 | 2.19 ± 0.02 b,c | 0.164 ± 0.002 c | 12.21 ± 0.04 a | 19.83 ± 0.11 c | 6.57 ± 0.25 b | 343.13 ± 8.61 c | 343.13 ± 5.26 c | 1392.13 ± 127 c | 45.39 ± 1.41 b |

| BWB2 | 2.52 ± 0.03 a,b | 0.265 ± 0.002 b | 12.28 ± 0.02 a | 24.48 ± 0.36 b | 5.16 ± 0.15 c | 366.05 ± 3.55 b | 436.89 ± 5.34 b | 1686.30 ± 185 b | 55.79 ± 0.57 a |

| BWB3 | 2.65 ± 0.02 a | 0.366 ± 0.007 a | 12.3 ± 0.05 a | 37.54 ± 0.64 a | 4.67 ± 0.06 d | 395.05 ± 2.85 a | 464.78 ± 1.94 a | 2059.74 ± 75 a | 56.57 ± 0.98 a |

| Indicator | MU | WB | BWB1 | BWB2 | BWB3 |

|---|---|---|---|---|---|

| Volume | cm3/100 g | 190.97 ± 1.05 a | 155.04 ± 0.95 b | 152.34 ± 1.02 b | 121.88 ± 1.16 c |

| Porosity | % | 78.84 ± 0.56 a | 73.50 ± 0.67 b | 70.53 ± 0.85 c | 66.22 ± 0.45 d |

| Elasticity | % | 90 ± 0.15 a | 85 ± 0.27 b | 75 ± 0.33 c | 72 ± 0.19 c |

| H/D | - | 0.62 ± 0.01 a | 0.58 ± 0.02 b | 0.57 ± 0.01 c | 0.55 ± 0.03 d |

| Acidity | grade | 2.4 ± 0.05 d | 5.4 ± 0.08 c | 10.8 ± 0.05 b | 15 ± 0.06 a |

| Samples | WA (%) | ST (min) | C1 | C2 | C3 | C4 | C5 | α (Nm/min) | β (Nm/min) | γ (Nm/min) |

|---|---|---|---|---|---|---|---|---|---|---|

| WF | 55.8 | 9.52 | 1.189 | 0.538 | 2.027 | 1.860 | 3.289 | −0.074 | 0.306 | −0.046 |

| BF | 76.7 | 0.30 | 1.255 | 0.731 | 1.170 | 0.266 | 0.487 | nd | 0.158 | −0.064 |

| BWF 1 | 62.1 | 5.82 | 1.165 | 0.304 | 2.030 | 1.819 | 3.054 | −0.094 | 0.568 | −0.028 |

| BWF 2 | 63.5 | 3.97 | 1.172 | 0.287 | 1.852 | 1.658 | 2.565 | −0.090 | 0.532 | −0.012 |

| BWF 3 | 63.8 | 3.82 | 1.372 | 0.342 | 1.706 | 1.524 | 2.306 | −0.110 | 0.530 | −0.056 |

| Samples | WAI | MI | GI | VI | AI | RI |

|---|---|---|---|---|---|---|

| WF | 2 | 6 | 4 | 7 | 8 | 8 |

| BWF 1 | 8 | 5 | 0 | 6 | 7 | 7 |

| BWF 2 | 8 | 5 | 0 | 4 | 8 | 6 |

| BWF 3 | 8 | 5 | 0 | 2 | 7 | 5 |

| Samples | Total Polyphenols Content (mg/100 g) | Total Flavonoids Content (mg/100 g) | Antioxidant Activity, DPPH (%) |

|---|---|---|---|

| Flours | |||

| WF | 176.7 ± 0.69 d | 1.72 ± 0.08 e | 31.77 ± 0.43 d |

| BF | 629.7 ± 0.35 a | 213.13 ± 0.08 a | 86.62 ± 0.04 a |

| BWF1 | 157.97 ± 1.53 e | 70.53 ± 0.08 d | 82.08 ± 0.04 c |

| BWF2 | 231.78 ± 1.97 c | 119.01 ± 0.1 c | 82.86 ± 0.56 c |

| BWF3 | 296.1 ± 3.29 b | 138.97 ± 0.81 b | 84.86 ± 0.01 b |

| Breads | |||

| WB | 183.8 ± 6.06 d | 2.90 ± 0.05 d | 31.003 ± 0.09 d |

| BWB1 | 193.3 ± 2.1 c | 44.05 ± 0.81 c | 58.86 ± 0.01 c |

| BWB2 | 232.1 ± 0.6 b | 111.68 ± 8.135 b | 61.66 ± 0.02 b |

| BWB3 | 297.63 ± 1.75 a | 208.06 ± 0.002 a | 66.72 ± 0.07 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dossa, S.; Negrea, M.; Cocan, I.; Berbecea, A.; Obistioiu, D.; Dragomir, C.; Alexa, E.; Rivis, A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods 2023, 12, 2697. https://doi.org/10.3390/foods12142697

Dossa S, Negrea M, Cocan I, Berbecea A, Obistioiu D, Dragomir C, Alexa E, Rivis A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods. 2023; 12(14):2697. https://doi.org/10.3390/foods12142697

Chicago/Turabian StyleDossa, Sylvestre, Monica Negrea, Ileana Cocan, Adina Berbecea, Diana Obistioiu, Christine Dragomir, Ersilia Alexa, and Adrian Rivis. 2023. "Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making" Foods 12, no. 14: 2697. https://doi.org/10.3390/foods12142697

APA StyleDossa, S., Negrea, M., Cocan, I., Berbecea, A., Obistioiu, D., Dragomir, C., Alexa, E., & Rivis, A. (2023). Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods, 12(14), 2697. https://doi.org/10.3390/foods12142697