Advances in Low-Lactose/Lactose-Free Dairy Products and Their Production

Abstract

1. Introduction

2. Lactose Intolerance

2.1. Epidemiology

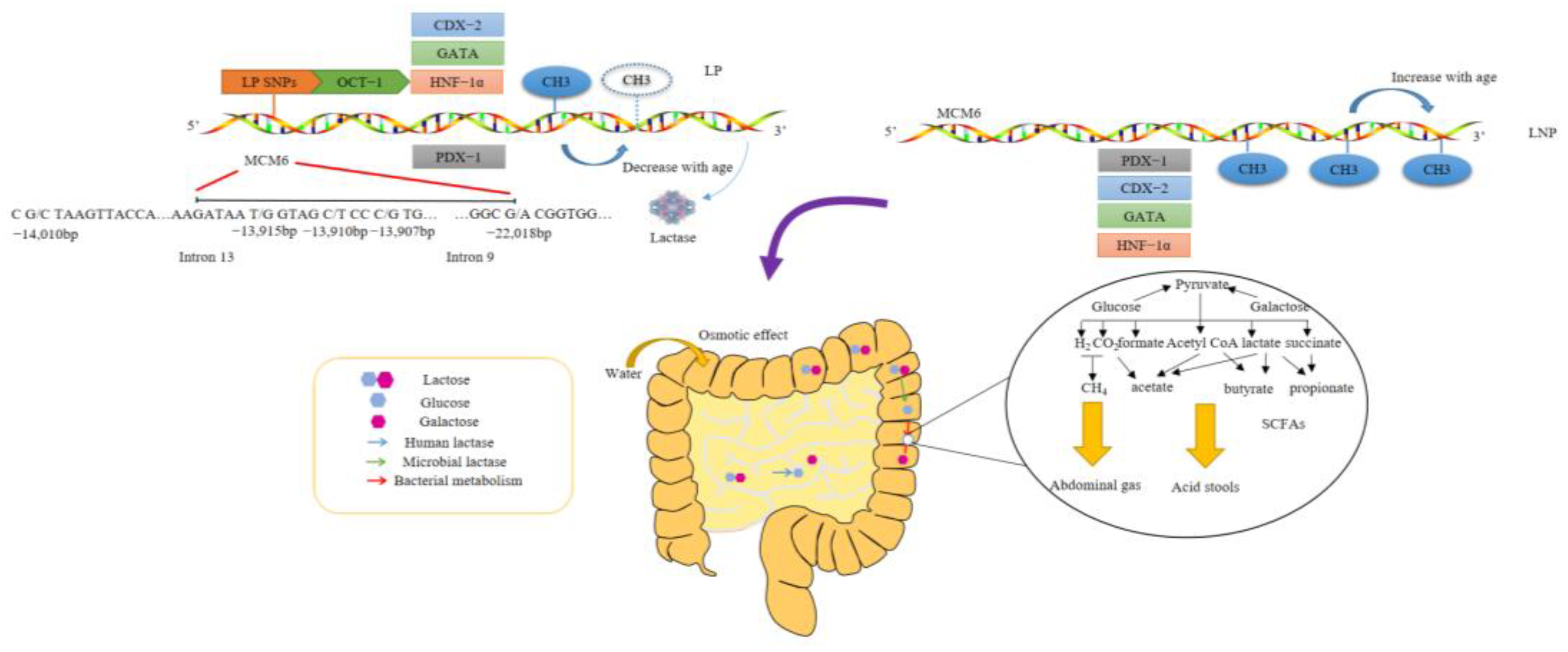

2.2. Lactase Gene and Pathology

3. Lactose-Free Dairy Product Market

4. Production of Lactose-Free Dairy Products

| Threshold | Country/Region | Authorities | References |

|---|---|---|---|

| <1000 mg/L lactose as lactose-free | European countries | EFSA (European Food Safety Authority), 2010 | - |

| <5000 mg/L lactose as lactose-free | China | EFSA (European Food Safety Authority), 2010, | [38] |

| <10,000 mg/L as low-lactose | India | FSSAI (Food Safety and Standards Authority of India), 2019 | [39] |

| <100 mg/L as lactose-free | India | FSSR (Food Safety and Standards Regulation), 2019 | - |

| 0.1% (w/w) as lactose-free | Italy | Italian Health Ministry | [40] |

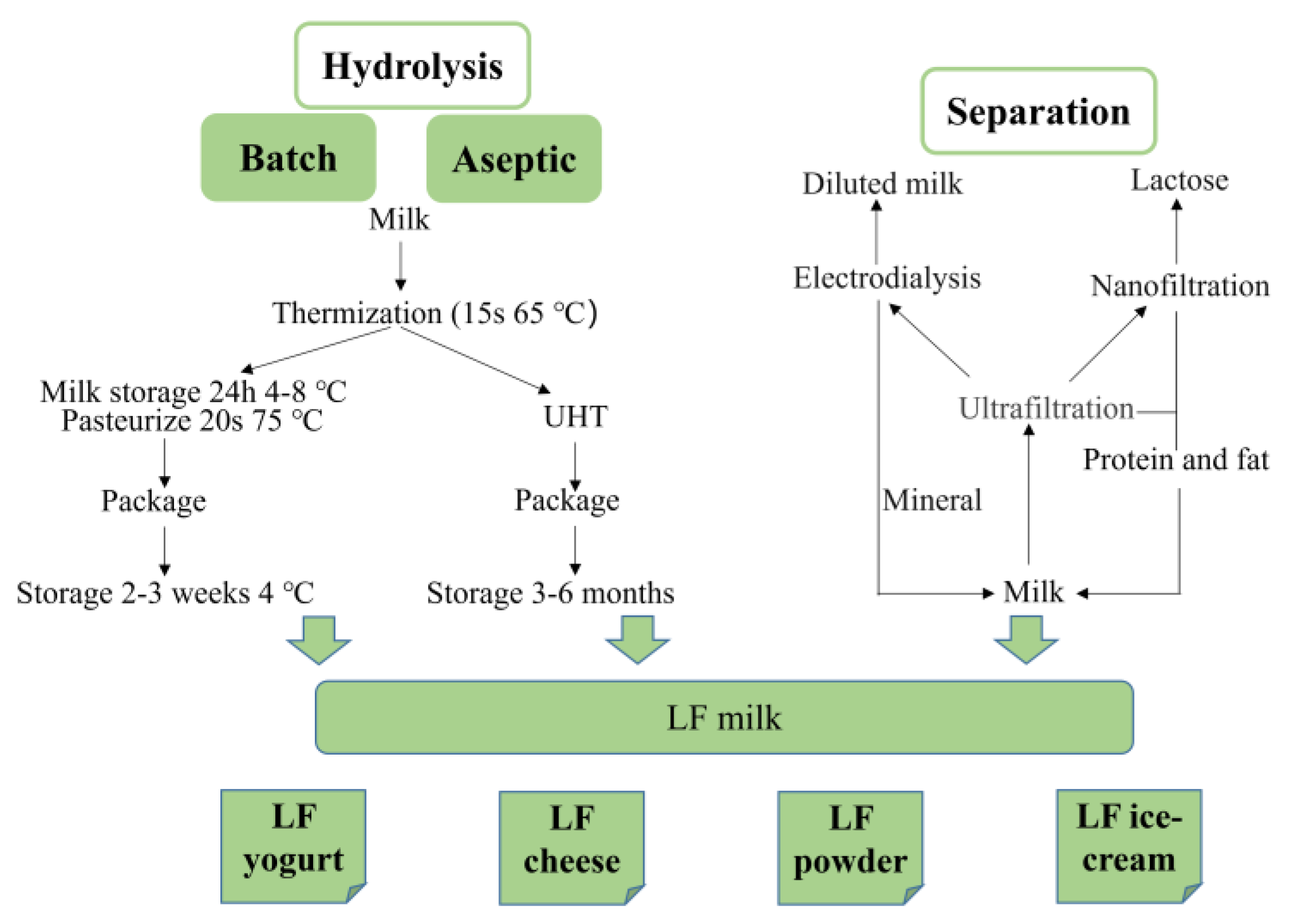

4.1. Separation of Lactose

4.2. Enzymatic Hydrolysis of Lactose

4.2.1. Microorganism Source of Lactase

| Enzyme Source | Process | Advantages | References | |

|---|---|---|---|---|

| Strains resistant to low/high temperature and acid environment | Alteromonas sp.ML117 | Alteromonas sp. ML117. β-galactosidases were heterologously expressed in E. coli and the recombinant lactase was purified. | Recombinant β-galactosidase was a cold-adapted variant and hydrolyzed 86% lactose of milk after 24 h at 10 °C. The enzyme is NaCl-tolerate. | [57] |

| Picrophilus torridus DSM 16176 | The enzyme was purified 110-fold and determined. | This enzyme is thermostable. At 70 °C, it retained 76% and 42% activity after 30 and 120 min. | [58] | |

| Anoxybacillus sp.AH1 | The enzyme was purified 10.2-fold. | The purified enzyme was highly stable and retained at 71% of the original activity at 60 °C and 53% at 70 °C within 120 min. | [59] | |

| Aspergillus niger van Tiegh | Extracellular β-galactosidase was purified to homogeneity using a combination of gel filtration, ion-exchange, chromatography. | The enzyme is highly stable when exposed to simulated gastric conditions in vitro. It retained 68% of original activity. Activity of capsule is some 3.5-fold more than commercial enzyme. | [60] | |

| Strains with lactose affinity and reduction of product inhibition | Bifidobacterium adolescentis | β-galactosidase gene found in Bifidobacterium adolescentis and was expressed in E. coli. | This enzyme had a Km of 3.7 mM. It exhibited low product inhibition by galactose with a Ki of 116 mM and high tolerance for glucose. | [61] |

| Aspergillus candidus | Four amino acid positions (Tyr96, Asn140, Glu142, and Tyr364) were selected for mutation based on their molecular bindings with galactose using site-directed mutagenesis. | β-galactosidase Y364F (Tyr364 mutant) had a galactose inhibition constant (KI) of 282 mM, which is 15.7-fold greater than that of the wild-type enzyme. | [62] | |

| Strains with high transgalactosylation capacity | Klebsiella oxytoca ZJUH1705 | Two β-galactosidase genes were isolated from a novel β-galactosidase-producing Klebsiella oxytoca ZJUH1705. Two β-galactosidase genes were cloned, expressed in E. coli and purified. | β-gal 2 had a high trans-glycosylation capacity. Adding β-gal 2 in lactose with the ratio of 2.5 U/g, a high GOS yield of 45.5%was obtained. | [63] |

| Bacillus sp. D1. BglD1 | A novel β-glucosidase, BglD1 was screened and cloned from the deep-sea bacterium. a mutant BglD1:E224T was generated based on the semi-rational design. | BglD1 hydrolyzed 88.5% lactose and produced 3.3 g/L GOS when using milk as the substrate. The GOS yield of its mutant was 11.5% higher than that of BglD1. | [64] | |

| Paenibacillus barengoltzii | β-galactosidase gene was cloned, expressed in E. coli and purified. | The recombinant β-galactosidase exhibited high trans-glycosylation activity. Maximum yield of GOS was 47.9% at a lactose concentration of 350 g/L. | [65] | |

| Alteromonas sp. ANT48 | β-galactosidase gene was cloned, expressed in E. coli. | 90.6% of the lactose was hydrolyzed at 40 °C within 15 min. GOS yield reached 30.9%. | [66] | |

| Streptococcus thermophilus | Site-directed mutation strategy was attempted to genetically modify β-galactosidase (the enzyme and its mutant were named BagQ and BgaQ-8012 respectively) | The GOS yields increased to 5.8 and 8.3 g/L adding BgaQ or BgaQ-8012. Addition of the β-galactosidases reduced lactose content by 49.3% and 54.4% respectively in yogurt. | [67] |

4.2.2. Immobilized Lactase

4.3. Fermentation

5. Detection and Determination of Lactose

6. Fortification of Lactose-Free Dairy Products

6.1. Function

6.2. Nutrition

7. Improvement in Sensory Properties and Quality of Lactose-Free Dairy Products

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Storhaug, C.L.; Fosse, S.K.; Fadnes, L.T. Country, regional, and global estimates for lactose malabsorption in adults: A systematic review and meta-analysis. Lancet Gastroenterol. Hepatol. 2017, 2, 738–746. [Google Scholar] [CrossRef]

- Li, A.; Zheng, J.; Han, X.; Jiang, Z.; Yang, B.; Yang, S.; Zhou, W.; Li, C.; Sun, M. Health implication of lactose intolerance and updates on its dietary management. Int. Dairy J. 2023, 140, 105608. [Google Scholar] [CrossRef]

- Sharp, E.; D’Cunha, N.M.; Ranadheera, C.S.; Vasiljevic, T.; Panagiotakos, D.B.; Naumovski, N. Effects of lactose-free and low-lactose dairy on symptoms of gastrointestinal health: A systematic review. Int. Dairy J. 2021, 114, 104936. [Google Scholar] [CrossRef]

- Taeger, M.; Thiele, S. Additional costs of lactose-reduced diets: Lactose-free dairy product substitutes are a cost-effective alternative for people with lactose intolerance. Public Health Nutr. 2021, 24, 4043–4053. [Google Scholar] [CrossRef]

- Szabó, E.; Szakos, D.; Kasza, G.; Ózsvári, L. Analysis of the target group of lactose-free functional foods for product development. Acta Aliment. 2021, 50, 153–161. [Google Scholar] [CrossRef]

- Mygdalia, A.; Sfetsas, T.; Dimitropoulou, G.; Zioupou, S.; Mitsopoulos, T.; Lithoxopoulos, P.; Ioannou, C.; Katsantonis, D. Recipe for Brown Rice Milk-based Vegan Ice Cream. Asian Food Sci. J. 2023, 22, 33–39. [Google Scholar] [CrossRef]

- Suri, S.; Kumar, V.; Prasad, R.; Tanwar, B.; Goyal, A.; Kaur, S.; Gat, Y.; Kumar, A.; Kaur, J.; Singh, D. Considerations for development of lactose-free food. J. Nutr. Intermed. Metab. 2019, 15, 27–34. [Google Scholar] [CrossRef]

- Bartuzi, M.; Szamocka, M.; Ukleja-Sokołowska, N. Social and economic difficulties of patients with food intolerances. Adv. Dermatol. Allergol./Postępy Dermatol. I Alergol. 2023, 40, 298–307. [Google Scholar] [CrossRef] [PubMed]

- López Ruiz, Á.L.; Ruiz Morales, F.d.A.; Ruiz Pérez-Cacho, P.; Galán-Soldevilla, H. Effect of Lactose-Reduction in Murciano-Granadina Semi-Hard Goat Cheese on Physicochemical and Sensory Characteristics. Foods 2023, 12, 996. [Google Scholar] [CrossRef]

- Vasudha, M.; Gayathri, D. Kinetic and modeling analyses of lactose-hydrolyzing β-galactosidase from Lactiplantibacillus plantarum GV54. World Acad. Sci. J. 2023, 5, 11. [Google Scholar] [CrossRef]

- Kızıldağ, S.; Işık, C.; Teke, M. Milk lactose removal by β-galactosidase immobilized on eggshell membrane. Eur. Food Res. Technol. 2023, 1–12. [Google Scholar] [CrossRef]

- Stouten, K.; Wolfhagen, F.; Castel, R.; van de Werken, M.; Klerks, J.; Verheijen, F.; Vermeer, H.J. Testing for lactase non-persistence in a Dutch population: Genotyping versus the hydrogen breath test. Ann. Clin. Biochem. 2023, 00045632231159288. [Google Scholar] [CrossRef]

- Anguita-Ruiz, A.; Aguilera, C.M.; Gil, Á. Genetics of lactose intolerance: An updated review and online interactive world maps of phenotype and genotype frequencies. Nutrients 2020, 12, 2689. [Google Scholar] [CrossRef] [PubMed]

- Chin, E.L.; Huang, L.; Bouzid, Y.Y.; Kirschke, C.P.; Durbin-Johnson, B.; Baldiviez, L.M.; Bonnel, E.L.; Keim, N.L.; Korf, I.; Stephensen, C.B. Association of lactase persistence genotypes (rs4988235) and ethnicity with dairy intake in a healthy US population. Nutrients 2019, 11, 1860. [Google Scholar] [CrossRef]

- Ingram, C.J.; Elamin, M.F.; Mulcare, C.A.; Weale, M.E.; Tarekegn, A.; Raga, T.O.; Bekele, E.; Elamin, F.M.; Thomas, M.G.; Bradman, N. A novel polymorphism associated with lactose tolerance in Africa: Multiple causes for lactase persistence? Hum. Genet. 2007, 120, 779–788. [Google Scholar] [CrossRef]

- Pinto, J.C.; Oliveira, S.; Teixeira, S.; Martins, D.; Fehn, A.M.; Aço, T.; Gayà-Vidal, M.; Rocha, J. Food and pathogen adaptations in the Angolan Namib desert: Tracing the spread of lactase persistence and human African trypanosomiasis resistance into southwestern Africa. Am. J. Phys. Anthropol. 2016, 161, 436–447. [Google Scholar] [CrossRef] [PubMed]

- Priehodová, E.; Abdelsawy, A.; Heyer, E.; Černý, V. Lactase persistence variants in Arabia and in the African Arabs. Hum. Biol. 2014, 86, 7–18. [Google Scholar] [CrossRef]

- Choi, B.J.; Yoon, J.H.; Choi, Y.J.; Han, L.; Park, Y.G.; Park, W.S. No association of LCT-13910 single nucleotide polymorphism with gastroenteritis in Korean children. Mol. Cell Toxicol. 2013, 9, 23–28. [Google Scholar] [CrossRef]

- Peng, M.-S.; He, J.-D.; Zhu, C.-L.; Wu, S.-F.; Jin, J.-Q.; Zhang, Y.-P. Lactase persistence may have an independent origin in Tibetan populations from Tibet, China. J. Hum. Genet. 2012, 57, 394–397. [Google Scholar] [CrossRef]

- Olds, L.C.; Ahn, J.K.; Sibley, E. 13915*G DNA polymorphism associated with lactase persistence in Africa interacts with Oct-1. Hum. Genet. 2011, 129, 111–113. [Google Scholar] [CrossRef]

- Jensen, T.G.K.; Liebert, A.; Lewinsky, R.; Swallow, D.M.; Olsen, J.; Troelsen, J.T. The −14010*C variant associated with lactase persistence is located between an Oct-1 and HNF1α binding site and increases lactase promoter activity. Hum. Genet. 2011, 130, 483–493. [Google Scholar] [CrossRef]

- Leseva, M.N.; Grand, R.J.; Klett, H.; Boerries, M.; Busch, H.; Binder, A.M.; Michels, K.B. Differences in DNA methylation and functional expression in lactase persistent and non-persistent individuals. Sci. Rep. 2018, 8, 5649. [Google Scholar] [CrossRef] [PubMed]

- Labrie, V.; Buske, O.J.; Oh, E.; Jeremian, R.; Ptak, C.; Gasiūnas, G.; Maleckas, A.; Petereit, R.; Žvirbliene, A.; Adamonis, K. Lactase nonpersistence is directed by DNA-variation-dependent epigenetic aging. Nat. Struct. Mol. Biol. 2016, 23, 566–573. [Google Scholar] [CrossRef]

- Lopera-Maya, E.A.; Kurilshikov, A.; van der Graaf, A.; Hu, S.; Andreu-Sánchez, S.; Chen, L.; Vila, A.V.; Gacesa, R.; Sinha, T.; Collij, V. Effect of host genetics on the gut microbiome in 7738 participants of the Dutch Microbiome Project. Nat. Genet. 2022, 54, 143–151. [Google Scholar] [CrossRef]

- Bonder, M.J.; Kurilshikov, A.; Tigchelaar, E.F.; Mujagic, Z.; Imhann, F.; Vila, A.V.; Deelen, P.; Vatanen, T.; Schirmer, M.; Smeekens, S.P. The effect of host genetics on the gut microbiome. Nat. Genet. 2016, 48, 1407–1412. [Google Scholar] [CrossRef]

- Kurilshikov, A.; Medina-Gomez, C.; Bacigalupe, R.; Radjabzadeh, D.; Wang, J.; Demirkan, A.; Le Roy, C.I.; Raygoza Garay, J.A.; Finnicum, C.T.; Liu, X. Large-scale association analyses identify host factors influencing human gut microbiome composition. Nat. Genet. 2021, 53, 156–165. [Google Scholar] [CrossRef]

- Goodrich, J.K.; Davenport, E.R.; Beaumont, M.; Jackson, M.A.; Knight, R.; Ober, C.; Spector, T.D.; Bell, J.T.; Clark, A.G.; Ley, R.E. Genetic determinants of the gut microbiome in UK twins. Cell Host Microbe 2016, 19, 731–743. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.-Y.; Wang, Z.; Usyk, M.; Vazquez-baeza, Y.; Isasi, C.R.; Mossavar-Rahmani, Y.; McDonald, D.; Sotres-Alvarez, D.; Daviglus, M.L.; Cai, J. Abstract P459: Milk Intake, Host LCT Genotype and Gut Bifidobacteria in Relation to Obesity: Results from the Hispanic Community Health Study/Study of Latinos (HCHS/SOL). Circulation 2020, 141, AP459. [Google Scholar] [CrossRef]

- Dekker, P.J.T.; Koenders, D.; Bruins, M.J. Lactose-free dairy products: Market developments, production, nutrition and health benefits. Nutrients 2019, 11, 551. [Google Scholar] [CrossRef] [PubMed]

- Obermayer-Pietsch, B.M.; Bonelli, C.M.; Walter, D.E.; Kuhn, R.J.; Fahrleitner-Pammer, A.; Berghold, A.; Goessler, W.; Stepan, V.; Dobnig, H.; Leb, G. Genetic predisposition for adult lactose intolerance and relation to diet, bone density, and bone fractures. J. Bone Miner. Res. 2004, 19, 42–47. [Google Scholar] [CrossRef]

- Joslin, S.E.; Durbin-Johnson, B.P.; Britton, M.; Settles, M.L.; Korf, I.; Lemay, D.G. Association of the lactase persistence haplotype block with disease risk in populations of European descent. Front. Genet. 2020, 11, 558762. [Google Scholar] [CrossRef] [PubMed]

- Hilliard, C.B. High osteoporosis risk among East Africans linked to lactase persistence genotype. BoneKEy Rep. 2016, 5, 803. [Google Scholar] [CrossRef] [PubMed]

- Tolonen, S. Associations of Lactase and Apolipoprotein E Gene Polymorphisms and Physical Activity with Peripheral Bone Traits. Ph.D. Thesis, University of Helsinki, Helsinki, Finland, 2018. [Google Scholar]

- Nguyen, N. An update of the milk market in Vietnam: Lactose-free dairy opportunity. Theseus 2014. [Google Scholar]

- Wang, X.; Wang, Y.H.; Yang, H.X.; Chuang, S.C.; Zhou, C.F.; Yu, X.; Zhang, H. Lysobacter lactosilyticus sp. nov., a Novel beta-Galactosidase Producing Bacterial Strain Isolated from Farmland Soil Applied with Amino Acid Fertilizer. Curr. Microbiol. 2022, 80, 43. [Google Scholar] [CrossRef]

- Rizzo, P.; Harwood, W.; Drake, M. Consumer desires and perceptions of lactose-free milk. J. Dairy Sci. 2020, 103, 6950–6966. [Google Scholar] [CrossRef] [PubMed]

- Świąder, K.; Kulawiak, M.; Chen, Y.-P. Types of lactose-free products and their availability on the Polish market®. Postępy Tech. Przetwórstwa Spożywczego 2020, 1, 39–45. [Google Scholar]

- EFSA Panel on Dietetic Products, Nutrition and Allergies. Scientific opinion on lactose thresholds in lactose intolerance and galactosaemia. EFSA J. 2010, 8, 1777. [Google Scholar]

- Rao, P.S.; Singh, P.; Sharma, V.; Arora, S. Traditional analytical approaches for lactose residues determination in lactose hydrolysed milks: A review. LWT 2021, 151, 112069. [Google Scholar] [CrossRef]

- Facioni, M.S.; Dominici, S.; Marescotti, F.; Covucci, R.; Taglieri, I.; Venturi, F.; Zinnai, A. Lactose Residual Content in PDO Cheeses: Novel Inclusions for Consumers with Lactose Intolerance. Foods 2021, 10, 2236. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, N.; Ranjan, R.; Kumar, S.; Bhat, Z.; Jeong, D.K. Perspective of membrane technology in dairy industry: A review. Asian-Australas. J. Anim. Sci. 2013, 26, 1347. [Google Scholar] [CrossRef]

- Qi, T.; Yang, D.; Chen, X.; Qiu, M.; Fan, Y. Rapid removal of lactose for low-lactose milk by ceramic membranes. Sep. Purif. Technol. 2022, 289, 120601. [Google Scholar] [CrossRef]

- Sanchez-Moya, T.; Hidalgo, A.M.; Ros-Berruezo, G.; Lopez-Nicolas, R. Screening ultrafiltration membranes to separate lactose and protein from sheep whey: Application of simplified model. J. Food Sci. Technol. 2020, 57, 3193–3200. [Google Scholar] [CrossRef] [PubMed]

- Khaire, R.A.; Sunny, A.A.; Gogate, P.R. Ultrasound assisted ultrafiltration of whey using dual frequency ultrasound for intensified recovery of lactose. Chem. Eng. Process.-Process Intensif. 2019, 142, 107581. [Google Scholar] [CrossRef]

- Sofuwani, Z.N.; Aslina, H.S.; Mazlina, M.S. Separation of lactose from raw goat’s milk by cross-flow hollow fiber ultrafiltration membrane. Int. Food Res. J. 2016, 23, S209. [Google Scholar]

- Morelos-Gomez, A.; Terashima, S.; Yamanaka, A.; Cruz-Silva, R.; Ortiz-Medina, J.; Sánchez-Salas, R.; Fajardo-Díaz, J.L.; Muñoz-Sandoval, E.; López-Urías, F.; Takeuchi, K.; et al. Graphene oxide membranes for lactose-free milk. Carbon 2021, 181, 118–129. [Google Scholar] [CrossRef]

- Zhang, H.; Tao, Y.; He, Y.; Pan, J.; Yang, K.; Shen, J.; Gao, C. Preparation of Low-Lactose Milk Powder by Coupling Membrane Technology. ACS Omega 2020, 5, 8543–8550. [Google Scholar] [CrossRef]

- Cordova, A.; Astudillo, C.; Vera, C.; Guerrero, C.; Illanes, A. Performance of an ultrafiltration membrane bioreactor (UF-MBR) as a processing strategy for the synthesis of galacto-oligosaccharides at high substrate concentrations. J. Biotechnol. 2016, 223, 26–35. [Google Scholar] [CrossRef]

- Dantas, A.; Quinteros, G.J.; Darvishvand, S.Y.; Blanco, M.; Hernandez, E.; Prudencio, E.S.; Samsuri, S. The combined use of progressive and block freeze concentration in lactose-free milk: Effect of process parameters and influence on the content of carbohydrates and proteins. J. Food Process Eng. 2021, 44, e13867. [Google Scholar] [CrossRef]

- Batista, K.A.; Silva, C.N.S.; Fernandes, P.M.; Campos, I.T.N.; Fernandes, K.F. Development of a new bioaffinity stationary phase for lactose removal using a lactose-binding lectin immobilized onto polyaniline. Sep. Purif. Technol. 2017, 185, 54–60. [Google Scholar] [CrossRef]

- Zolnere, K.; Ciprovica, I. The comparison of commercially available β-galactosidases for dairy industry. Res. Rural. Dev. 2017, 1, 215–222. [Google Scholar]

- De Albuquerque, T.L.; de Sousa, M.; Gomes, E.S.N.C.; Girao Neto, C.A.C.; Goncalves, L.R.B.; Fernandez-Lafuente, R.; Rocha, M.V.P. Beta-Galactosidase from Kluyveromyces lactis: Characterization, production, immobilization and applications-A review. Int. J. Biol. Macromol. 2021, 191, 881–898. [Google Scholar] [CrossRef] [PubMed]

- Erich, S.; Kuschel, B.; Schwarz, T.; Ewert, J.; Böhmer, N.; Niehaus, F.; Eck, J.; Lutz-Wahl, S.; Stressler, T.; Fischer, L. Novel high-performance metagenome β-galactosidases for lactose hydrolysis in the dairy industry. J. Biotechnol. 2015, 210, 27–37. [Google Scholar] [CrossRef]

- Liu, P.; Xie, J.; Liu, J.; Ouyang, J. A novel thermostable beta-galactosidase from Bacillus coagulans with excellent hydrolysis ability for lactose in whey. J. Dairy Sci. 2019, 102, 9740–9748. [Google Scholar] [CrossRef]

- Ren, G.H.; Cao, L.C.; Kong, W.; Wang, Z.J.; Liu, Y.H. Efficient Secretion of the beta-Galactosidase Bgal1-3 via both Tat-Dependent and Tat-Independent Pathways in Bacillus subtilis. J. Agric. Food Chem. 2016, 64, 5708–5716. [Google Scholar] [CrossRef]

- Mano, M.C.R.; Neri-Numa, I.A.; da Silva, J.B.; Paulino, B.N.; Pessoa, M.G.; Pastore, G.M. Oligosaccharide biotechnology: An approach of prebiotic revolution on the industry. Appl. Microbiol. Biotechnol. 2018, 102, 17–37. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Sun, J.; Wang, W.; Zhuang, Z.; Liu, J.; Hao, J. A novel cold-adapted β-galactosidase from Alteromonas sp. ML117 cleaves milk lactose effectively at low temperature. Process Biochem. 2019, 82, 94–101. [Google Scholar] [CrossRef]

- Murphy, J.; Ryan, M.P.; Walsh, G. Purification and Characterization of a Novel beta-Galactosidase from the Thermoacidophile Alicyclobacillus vulcanalis. Appl. Biochem. Biotechnol. 2020, 191, 1190–1206. [Google Scholar] [CrossRef]

- Acer, Ö.; Matpan Bekler, F. Characterization of a Thermally Stable β-galactosidase Produced by Thermophilic Anoxybacillus sp. AH1. Türk Doğa Ve Fen Derg. 2021, 10, 130–136. [Google Scholar] [CrossRef]

- O’Connell, S.; Walsh, G. A novel acid-stable, acid-active beta-galactosidase potentially suited to the alleviation of lactose intolerance. Appl. Microbiol. Biotechnol. 2010, 86, 517–524. [Google Scholar] [CrossRef]

- Mulualem, D.M.; Agbavwe, C.; Ogilvie, L.A.; Jones, B.V.; Kilcoyne, M.; O’Byrne, C.; Boyd, A. Metagenomic identification, purification and characterisation of the Bifidobacterium adolescentis BgaC beta-galactosidase. Appl. Microbiol. Biotechnol. 2021, 105, 1063–1078. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, F.; Song, L.; Sun, N.; Guan, W.; Liu, B.; Tian, J.; Zhang, Y.; Zhang, W. Site-directed mutation of beta-galactosidase from Aspergillus candidus to reduce galactose inhibition in lactose hydrolysis. 3 Biotech 2018, 8, 452. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, S.; Zhao, L.; Chen, L.; Du, M.; Zhang, C.; Yang, S.T. A novel beta-galactosidase from Klebsiella oxytoca ZJUH1705 for efficient production of galacto-oligosaccharides from lactose. Appl. Microbiol. Biotechnol. 2020, 104, 6161–6172. [Google Scholar] [CrossRef] [PubMed]

- Deng, P.; Meng, C.; Wu, Y.; Xu, J.; Tang, X.; Zhang, X.; Xiao, Y.; Wang, X.; Fang, Z.; Fang, W. An unusual GH1 beta-glucosidase from marine sediment with beta-galactosidase and transglycosidation activities for superior galacto-oligosaccharide synthesis. Appl. Microbiol. Biotechnol. 2020, 104, 4927–4943. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, Z.; Jiang, Z.; Yan, Q.; Yang, S. Biochemical characterization of a novel beta-galactosidase from Paenibacillus barengoltzii suitable for lactose hydrolysis and galactooligosaccharides synthesis. Int. J. Biol. Macromol. 2017, 104, 1055–1063. [Google Scholar] [CrossRef]

- Li, S.; Zhu, X.; Xing, M. A New beta-Galactosidase from the Antarctic Bacterium Alteromonas sp. ANT48 and Its Potential in Formation of Prebiotic Galacto-Oligosaccharides. Mar. Drugs 2019, 17, 599. [Google Scholar] [CrossRef]

- Zhao, J.C.; Mu, Y.L.; Gu, X.Y.; Xu, X.N.; Guo, T.T.; Kong, J. Site-directed mutation of beta-galactosidase from Streptococcus thermophilus for galactooligosaccharide-enriched yogurt making. J. Dairy Sci. 2022, 105, 940–949. [Google Scholar] [CrossRef]

- Damin, B.; Kovalski, F.; Fischer, J.; Piccin, J.; Dettmer, A. Challenges and perspectives of the β-galactosidase enzyme. Appl. Microbiol. Biotechnol. 2021, 105, 5281–5298. [Google Scholar] [CrossRef] [PubMed]

- Ureta, M.M.; Martins, G.N.; Figueira, O.; Pires, P.F.; Castilho, P.C.; Gomez-Zavaglia, A. Recent advances in beta-galactosidase and fructosyltransferase immobilization technology. Crit. Rev. Food Sci. Nutr. 2021, 61, 2659–2690. [Google Scholar] [CrossRef]

- Zdarta, J.; Meyer, A.S.; Jesionowski, T.; Pinelo, M. A general overview of support materials for enzyme immobilization: Characteristics, properties, practical utility. Catalysts 2018, 8, 92. [Google Scholar] [CrossRef]

- Aslan, Y.; Taher, A.Y.; Cavidoğlu, İ. Improved catalytic activity of Aspergillus oryzae β-Galactosidase by covalent immobilization on Eupergit CM. JAPS: J. Anim. Plant Sci. 2018, 28, 1648–1655. [Google Scholar]

- Wolf, M.; Gasparin, B.C.; Paulino, A.T. Hydrolysis of lactose using beta-d-galactosidase immobilized in a modified Arabic gum-based hydrogel for the production of lactose-free/low-lactose milk. Int. J. Biol. Macromol. 2018, 115, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Inanan, T. Cryogel disks for lactase immobilization and lactose-free milk production. LWT 2022, 154, 112608. [Google Scholar] [CrossRef]

- Ricardi, N.C.; Arenas, L.T.; Benvenutti, E.V.; Hinrichs, R.; Flores, E.E.E.; Hertz, P.F.; Costa, T.M.H. High performance biocatalyst based on beta-d-galactosidase immobilized on mesoporous silica/titania/chitosan material. Food Chem. 2021, 359, 129890. [Google Scholar] [CrossRef] [PubMed]

- Tizchang, S.; Khiabani, M.S.; Mokarram, R.R.; Hamishehkar, H. Bacterial cellulose nano crystal as hydrocolloid matrix in immobilized β-galactosidase onto silicon dioxide nanoparticles. LWT 2020, 123, 109091. [Google Scholar] [CrossRef]

- Ansari, S.A.; Alshanberi, A.M. Stability studies of β-galactosidase immobilized on gluconic acid coated fullerenes. Braz. J. Chem. Eng. 2021, 39, 361–367. [Google Scholar] [CrossRef]

- Tizchang, S.; Khiabani, M.S.; Mokarram, R.R.; Hamishehkar, H.; Mohammadi, N.S.; Chisti, Y. Immobilization of beta-galactosidase by halloysite-adsorption and entrapment in a cellulose nanocrystals matrix. Biochim. Biophys Acta Gen. Subj. 2021, 1865, 129896. [Google Scholar] [CrossRef]

- Alshanberi, A.M.; Satar, R.; Ansari, S.A. Stabilization of beta-Galactosidase on Modified Gold Nanoparticles: A Preliminary Biochemical Study to Obtain Lactose-Free Dairy Products for Lactose-Intolerant Individuals. Molecules 2021, 26, 1226. [Google Scholar] [CrossRef]

- Savaiano, D.A.; Hutkins, R.W. Yogurt, cultured fermented milk, and health: A systematic review. Nutr. Rev. 2021, 79, 599–614. [Google Scholar] [CrossRef]

- Li, S.; Ye, A.; Singh, H. Effects of seasonal variations on the quality of set yogurt, stirred yogurt, and Greek-style yogurt. J. Dairy Sci. 2021, 104, 1424–1432. [Google Scholar] [CrossRef] [PubMed]

- Dertli, E.; Çon, A.H. Microbial diversity of traditional kefir grains and their role on kefir aroma. LWT-Food Sci. Technol. 2017, 85, 151–157. [Google Scholar] [CrossRef]

- Rosa, D.D.; Dias, M.M.; Grześkowiak, Ł.M.; Reis, S.A.; Conceição, L.L.; Maria do Carmo, G.P. Milk kefir: Nutritional, microbiological and health benefits. Nutr. Res. Rev. 2017, 30, 82–96. [Google Scholar] [CrossRef]

- Malaguarnera, G.; Leggio, F.; Vacante, M.; Motta, M.; Giordano, M.; Biondi, A.; Basile, F.; Mastrojeni, S.; Mistretta, A.; Malaguarnera, M. Probiotics in the gastrointestinal diseases of the elderly. J. Nutr. Health Aging 2012, 16, 402–410. [Google Scholar] [CrossRef]

- Panseri, S.; Pavlovic, R.; Castrica, M.; Nobile, M.; Di Cesare, F.; Chiesa, L.M. Determination of Carbohydrates in Lactose-Free Dairy Products to Support Food Labelling. Foods 2021, 10, 1219. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, E.; Watanabe, R.; Ichimura, T.; Ishida, T.; Kimura, K. Effect of lactose hydrolysis on the milk-fermenting properties of Lactobacillus delbrueckii ssp. bulgaricus 2038 and Streptococcus thermophilus 1131. J. Dairy Sci. 2021, 104, 1454–1464. [Google Scholar] [CrossRef]

- Martins, A.R.; Monteiro, R.L.; Burkert, J.F.d.M.; Burkert, C.A.V. Simultaneous enzymatic hydrolysis and lactic fermentation to obtain a yogurt with low lactose content. Ciência E Agrotecnologia 2012, 36, 551–559. [Google Scholar] [CrossRef]

- Raza, A.; Iqbal, S.; Shah, F.-u.-H.; Ahmad, Z.; Rehman, M.A.; Waseem, M.; Usman, M. Conversion of milk lactose to galacto-oligosaccharides by enzymes to produce prebiotic enriched cheese. Future Foods 2021, 4, 100097. [Google Scholar] [CrossRef]

- Rutkowska, J.; Antoniewska-Krzeska, A.; Żbikowska, A.; Cazón, P.; Vázquez, M. Volatile composition and sensory profile of lactose-free kefir, and its acceptability by elderly consumers. Molecules 2022, 27, 5386. [Google Scholar] [CrossRef] [PubMed]

- Popescu, L.; Bulgaru, V.; Siminiuc, R. Effects of lactose hydrolysis and milk type on the quality of lactose-free yoghurt. J. Eng. Sci. 2022, 29, 164–175. [Google Scholar] [CrossRef]

- Ibrahim, A.H. Impact of hydrolyzed lactose by β-galactosidase enzyme on the physicochemical and organoleptic properties of fermented camel milk. Emir. J. Food Agric. 2018, 30, 778–790. [Google Scholar] [CrossRef]

- Schmidt, C.; Mende, S.; Jaros, D.; Rohm, H. Fermented milk products: Effects of lactose hydrolysis and fermentation conditions on the rheological properties. Dairy Sci. Technol. 2016, 96, 199–211. [Google Scholar] [CrossRef]

- Mangan, D.; McCleary, B.V.; Culleton, H.; Cornaggia, C.; Ivory, R.; McKie, V.A.; Delaney, E.; Kargelis, T. A novel enzymatic method for the measurement of lactose in lactose-free products. J. Sci. Food Agric. 2019, 99, 947–956. [Google Scholar] [CrossRef] [PubMed]

- Idda, I.; Spano, N.; Ciulu, M.; Nurchi, V.M.; Panzanelli, A.; Pilo, M.I.; Sanna, G. Gas chromatography analysis of major free mono-and disaccharides in milk: Method assessment, validation, and application to real samples. J. Sep. Sci. 2016, 39, 4577–4584. [Google Scholar] [CrossRef] [PubMed]

- Garballo-Rubio, A.; Soto-Chinchilla, J.; Moreno, A.; Zafra-Gómez, A. Determination of residual lactose in lactose-free cow milk by hydrophilic interaction liquid chromatography (HILIC) coupled to tandem mass spectrometry. J. Food Compos. Anal. 2018, 66, 39–45. [Google Scholar] [CrossRef]

- Morlock, G.E.; Morlock, L.P.; Lemo, C. Streamlined analysis of lactose-free dairy products. J. Chromatogr. A 2014, 1324, 215–223. [Google Scholar] [CrossRef]

- Monti, L.; Negri, S.; Meucci, A.; Stroppa, A.; Galli, A.; Contarini, G. Lactose, galactose and glucose determination in naturally "lactose free" hard cheese: HPAEC-PAD method validation. Food Chem. 2017, 220, 18–24. [Google Scholar] [CrossRef] [PubMed]

- Da Cunha, D.A.; Valim, T.C.; Filgueiras, P.R.; Junior, V.L.; Neto, A.C. Lactose quantification in bovine milk by nuclear magnetic resonance without deuterated solvent (No-D qNMR). Anal. Methods 2020, 12, 4892–4898. [Google Scholar] [CrossRef]

- De Oliveira Neves, L.N.; de Oliveira, M.A.L. Quantification of lactose and lactulose in hydrolysed-lactose UHT milk using capillary zone electrophoresis. Int. Dairy J. 2020, 106, 104710. [Google Scholar] [CrossRef]

- Churakova, E.; Peri, K.; Vis, J.S.; Smith, D.W.; Beam, J.M.; Vijverberg, M.P.; Stor, M.C.; Winter, R.T. Accurate analysis of residual lactose in low-lactose milk: Comparing a variety of analytical techniques. Int. Dairy J. 2019, 96, 126–131. [Google Scholar] [CrossRef]

- Cano-Contreras, A.D.; Minero Alfaro, I.J.; Medina López, V.M.; Amieva Balmori, M.; Remes Troche, J.M.; Espadaler Mazo, J.; Perez Lopez, N. Efficacy of i3. 1 probiotic on improvement of lactose intolerance symptoms: A randomized, placebo-controlled clinical trial. J. Clin. Gastroenterol. 2022, 56, 141–147. [Google Scholar] [CrossRef]

- Masoumi, S.J.; Mehrabani, D.; Saberifiroozi, M.; Fattahi, M.R.; Moradi, F.; Najafi, M. The effect of yogurt fortified with Lactobacillus acidophilus and Bifidobacterium sp. probiotic in patients with lactose intolerance. Food Sci. Nutr. 2021, 9, 1704–1711. [Google Scholar] [CrossRef]

- Gingold-Belfer, R.; Levy, S.; Layfer, O.; Pakanaev, L.; Niv, Y.; Dickman, R.; Perets, T.T. Use of a novel probiotic formulation to alleviate lactose intolerance symptoms—A pilot study. Probiotics Antimicrob. Proteins 2020, 12, 112–118. [Google Scholar] [CrossRef]

- Catanzaro, R.; Sciuto, M.; Marotta, F. Lactose Intolerance—Old and New Knowledge on Pathophysiological Mechanisms, Diagnosis, and Treatment. SN Compr. Clin. Med. 2021, 3, 499–509. [Google Scholar] [CrossRef]

- Oak, S.J.; Jha, R. The effects of probiotics in lactose intolerance: A systematic review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1675–1683. [Google Scholar] [CrossRef]

- Vitellio, P.; Celano, G.; Bonfrate, L.; Gobbetti, M.; Portincasa, P.; De Angelis, M. Effects of Bifidobacterium longum and Lactobacillus rhamnosus on gut microbiota in patients with lactose intolerance and persisting functional gastrointestinal symptoms: A randomised, double-blind, cross-over study. Nutrients 2019, 11, 886. [Google Scholar] [CrossRef] [PubMed]

- Leis, R.; de Castro, M.-J.; de Lamas, C.; Picáns, R.; Couce, M.L. Effects of prebiotic and probiotic supplementation on lactase deficiency and lactose intolerance: A systematic review of controlled trials. Nutrients 2020, 12, 1487. [Google Scholar] [CrossRef] [PubMed]

- Savaiano, D.A.; Ritter, A.J.; Klaenhammer, T.R.; James, G.M.; Longcore, A.T.; Chandler, J.R.; Walker, W.A.; Foyt, H.L. Improving lactose digestion and symptoms of lactose intolerance with a novel galacto-oligosaccharide (RP-G28): A randomized, double-blind clinical trial. Nutr. J. 2013, 12, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Chey, W.; Sandborn, W.; Ritter, A.J.; Foyt, H.; Azcarate-Peril, M.A.; Savaiano, D.A. Galacto-oligosaccharide RP-G28 improves multiple clinical outcomes in lactose-intolerant patients. Nutrients 2020, 12, 1058. [Google Scholar] [CrossRef]

- Pereira, J.A.; Pinto, S.S.; Dias, C.O.; Vieira, M.P.; Ribeiro, D.H.; Amboni, R.D.; Fritzen-Freire, C.B. Potentially symbiotic fermented milk: A preliminary approach using lactose-free milk. LWT 2020, 118, 108847. [Google Scholar] [CrossRef]

- Pawlos, M.; Znamirowska, A.; Kluz, M.; Szajnar, K.; Kowalczyk, M. Low-lactose fermented goat milks with Bifidobacterium animalis ssp. lactis Bb-12. J. Microbiol. Biotechnol. Food Sci. 2021, 2021, 751–755. [Google Scholar]

- Pachekrepapol, U.; Somboonchai, N.; Krimjai, W. Physicochemical, rheological, and microbiological properties of lactose-free functional yogurt supplemented with fructooligosaccharides. J. Food Process. Preserv. 2021, 45, e15017. [Google Scholar] [CrossRef]

- Dantas, A.; Verruck, S.; Canella, M.H.M.; Hernandez, E.; Prudencio, E.S. Encapsulated Bifidobacterium BB-12 addition in a concentrated lactose-free yogurt: Its survival during storage and effects on the product’s properties. Food Res. Int. 2021, 150, 110742. [Google Scholar] [CrossRef] [PubMed]

- Pinto, S.S.; Fritzen-Freire, C.B.; Dias, C.O.; Amboni, R.D. A potential technological application of probiotic microcapsules in lactose-free Greek-style yoghurt. Int. Dairy J. 2019, 97, 131–138. [Google Scholar] [CrossRef]

- Sabikhi, L.; Kumar, M.; Mathur, B. Bifidobacterium bifidum in probiotic Edam cheese: Influence on cheese ripening. J. Food Sci. Technol. 2014, 51, 3902–3909. [Google Scholar] [CrossRef] [PubMed]

- Garcia, S.L.A.; da Silva, G.M.; Medeiros, J.M.S.; de Queiroga, A.P.R.; de Queiroz, B.B.; de Farias, D.R.B.; Correia, J.O.; Florentino, E.R.; Buriti, F.C.A. Influence of co-cultures of Streptococcus thermophilus and probiotic lactobacilli on quality and antioxidant capacity parameters of lactose-free fermented dairy beverages containing Syzygium cumini (L.) Skeels pulp. RSC Adv. 2020, 10, 10297–10308. [Google Scholar] [CrossRef]

- Kwak, H.-S.; Lee, W.-J.; Lee, M.-R. Revisiting lactose as an enhancer of calcium absorption. Int. Dairy J. 2012, 22, 147–151. [Google Scholar] [CrossRef]

- Jääskeläinen, T.; Itkonen, S.T.; Lundqvist, A.; Erkkola, M.; Koskela, T.; Lakkala, K.; Dowling, K.G.; Hull, G.L.; Kröger, H.; Karppinen, J. The positive impact of general vitamin D food fortification policy on vitamin D status in a representative adult Finnish population: Evidence from an 11-y follow-up based on standardized 25-hydroxyvitamin D data. Am. J. Clin. Nutr. 2017, 105, 1512–1520. [Google Scholar] [CrossRef]

- Chalupa-Krebzdak, S.; Long, C.J.; Bohrer, B.M. Nutrient density and nutritional value of milk and plant-based milk alternatives. Int. Dairy J. 2018, 87, 84–92. [Google Scholar] [CrossRef]

- Heaney, R.P.; Rafferty, K. The settling problem in calcium-fortified soybean drinks. J. Am. Diet. Assoc. 2006, 106, 1753. [Google Scholar] [CrossRef]

- Dantas, A.; Orellana-Palma, P.; Kumar, D.; Hernandez, E.; Prudencio, E.S. Block freeze concentration by centrifugation and vacuum increases the content of lactose-free milk macronutrients. J. Food Sci. 2022, 87, 5317–5329. [Google Scholar] [CrossRef]

- Da Silva, A.T.; de Lima, J.J.; Reis, P.; Passos, M.; Baumgartner, C.G.; Sereno, A.B.; Krüger, C.C.H.; Cândido, L.M.B. Application of Lactose-Free Whey Protein to Greek Yogurts: Potential Health Benefits and Impact on Rheological Aspects and Sensory Attributes. Foods 2022, 11, 3861. [Google Scholar] [CrossRef]

- Troise, A.D.; Bandini, E.; De Donno, R.; Meijer, G.; Trezzi, M.; Fogliano, V. The quality of low lactose milk is affected by the side proteolytic activity of the lactase used in the production process. Food Res Int 2016, 89, 514–525. [Google Scholar] [CrossRef]

- Nielsen, S.D.; Zhao, D.; Le, T.T.; Rauh, V.; Sørensen, J.; Andersen, H.J.; Larsen, L.B. Proteolytic side-activity of lactase preparations. Int. Dairy J. 2018, 78, 159–168. [Google Scholar] [CrossRef]

- Milkovska-Stamenova, S.; Hoffmann, R. Influence of storage and heating on protein glycation levels of processed lactose-free and regular bovine milk products. Food Chem 2017, 221, 489–495. [Google Scholar] [CrossRef]

- Jo, Y.; Benoist, D.; Barbano, D.; Drake, M. Flavor and flavor chemistry differences among milks processed by high-temperature, short-time pasteurization or ultra-pasteurization. J. Dairy Sci. 2018, 101, 3812–3828. [Google Scholar] [CrossRef]

- Tossavainen, O.; Kallioinen, H. Proteolytic changes in lactose hydrolysed UHT milks during storage. Milchwiss.-Milk Sci. Int. 2007, 62, 410–414. [Google Scholar]

- Ghosh, K.; Maity, C.; Adak, A.; Halder, S.K.; Jana, A.; Das, A.; Parua, S.; Das Mohapatra, P.K.; Pati, B.R.; Mondal, K.C. Ethnic preparation of haria, a rice-based fermented beverage, in the province of lateritic West Bengal, India. Ethnobot. Res. Appl. 2014, 12, 39–50. [Google Scholar]

- Moreira, T.C.; da Silva, A.T.; Fagundes, C.; Ferreira, S.M.R.; Cândido, L.M.B.; Passos, M.; Krüger, C.C.H. Elaboration of yogurt with reduced level of lactose added of carob (Ceratonia siliqua L.). LWT-Food Sci. Technol. 2017, 76, 326–329. [Google Scholar] [CrossRef]

- Shrestha, A.K.; Howes, T.; Adhikari, B.P.; Bhandari, B.R. Water sorption and glass transition properties of spray dried lactose hydrolysed skim milk powder. LWT-Food Sci. Technol. 2007, 40, 1593–1600. [Google Scholar] [CrossRef]

- Torres, J.K.F.; Stephani, R.; Tavares, G.M.; De Carvalho, A.F.; Costa, R.G.B.; de Almeida, C.E.R.; Almeida, M.R.; de Oliveira, L.F.C.; Schuck, P.; Perrone, Í.T. Technological aspects of lactose-hydrolyzed milk powder. Food Res. Int. 2017, 101, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Queiroz, E.S.; Rezende, A.L.L.; Perrone, Í.T.; Francisquini, J.d.A.; de Carvalho, A.F.; Alves, N.M.G.; de Oliveira, L.F.C.; Stephani, R. Spray drying and characterization of lactose-free goat milk. LWT 2021, 147, 111516. [Google Scholar] [CrossRef]

- Naranjo, G.B.; Gonzales, A.S.P.; Leiva, G.E.; Malec, L.S. The kinetics of Maillard reaction in lactose-hydrolysed milk powder and related systems containing carbohydrate mixtures. Food Chem. 2013, 141, 3790–3795. [Google Scholar] [CrossRef] [PubMed]

- Tossavainen, O.; Sahlstein, J. Process for Producing a Lactose-Free Milk Product. U.S. Patent 7,829,130, 9 November 2010. [Google Scholar]

- McCain, H.R.; Kaliappan, S.; Drake, M.A. Invited review: Sugar reduction in dairy products. J. Dairy Sci. 2018, 101, 8619–8640. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, S.; Saeedabadian, A. Influences of lactose hydrolysis of milk and sugar reduction on some physical properties of ice cream. J. Food Sci. Technol. 2013, 52, 367–374. [Google Scholar] [CrossRef]

| Method | Support Material | Activity of Enzyme and Ability of Hydrolysis | Other Advantages | References |

|---|---|---|---|---|

| Covalent binding | Eupergit CM | The activity of immobilized enzyme decreased after 20 times of repeated use, and reached 99.3% after 15 days of storage. Lactose was completely hydrolyzed within 4 h. | Storage stability and activity of enzyme increase. | [71] |

| Cross-linking and adsorption | Modified arabic gum-based hydrogel | After 3 cycles, activity of immobilized β-D-galactosidase was 52.79% of the initial enzyme. | Improve the efficiency of lactose hydrolysis and lower costs. | [72] |

| Adsorption | Fe-chelated cryogel disk | The immobilized lactase lost 29.2% after 70 days and preserved 64.9% of initial activity after 25-runs. | The optimum temperature of immobilized lactase increase. | [73] |

| Covalent binding | Mesoporous silica/titania with a chitosan coating | Lactase retained approximately 90% of initial activity and achieved full conversion of lactose even after 15 cycles in batch system. | Enzyme is hard to deform and demonstrates high operational stability for application and manufacturing. | [74] |

| Entrapment | Bacterial cellulose nano crystal | β-galactosidase retained 80% activity after 12 cycles of use. | β-galactosidase showed higher stability to various range of pH and temperature. | [75] |

| Covalent binding | Gluconic acid coated fullerenes | β-galactosidase was able to be recovered easily and retained 89% activity after 6 repeated uses. | Obvious improvement in lactose hydrolysis was observed at high temperature. | [76] |

| Entrapment and adsorption | Halloysite nanotubes and cellulose nanocrystals | Enzyme retained 76% activity after 12 cycles. | Enzyme was more thermostable at 55 °C than the free enzyme. | [77] |

| Covalent binding | Modified gold nanoparticles | β-galactosidase exhibited greater operational activity after 6 reuses. | Stability was significantly enhanced at wider temperature, pH and higher galactose concentrations. | [78] |

| Product | Study | Conclusion | References |

|---|---|---|---|

| Low-lactose fermented goat milk | Development of low-lactose fermented goat milks with Bifidobacterium animalis ssp. lactis Bb-12 and evaluate the effect of prior lactose hydrolysis on the viability of Bifidobacterium animalis ssp lactis Bb-12. | The lactose hydrolysis of milk resulted a higher hardness in probiotic fermented goat milk. Moreover, the lactose-free probiotic fermented milk had a more distinct sweet taste than the control one and was characterized by a less sour flavor. | [110] |

| Lactose-free functional yogurt | Physicochemical, rheological, and microbiological properties of lactose-free functional yogurt supplemented with FOS. | Lactose hydrolysis and FOS supplementation increased acidification rate during fermentation of yogurts. FOS helped to improve syneresis. | [111] |

| Concentrated lactose-free yogurt | Effect of encapsulated Bifidobacterium Bb-12 on the lactose-free yogurt. | Viability of Bifidobacterium Bb-12 was found for all spray-dried powders produced with lactose-free skim milk powder, lactose-free skim milk powder and inulin, and lactose-free skim milk powder and oligofructose to be higher than recommended to exert health benefits. | [112] |

| Lactose-free Greek-style yogurt | Evaluation of potential of lactose-free Greek-style yogurt as probiotic matrix. | Three different microcapsule formulations were produced using gum arabic, inulin and maltodextrin as wall materials. All formulations showed encapsulation yield above 96% and good probiotic viability (>8 log cfu/g) throughout 30 days of storage (4 °C). | [113] |

| Probiotic Edam cheese | Influence of Bifidobacterium bifidum on cheese. | Lactose in control as well as in experimental cheeses (107 viable cell) was depleted within 15 days. The free fatty acids increased from 2.23% and 2.31% on 0-day to 2.78% and 2.83% after 3 months, in control and probiotic cheeses, respectively. | [114] |

| Lactose-free fermented dairy beverages | Influence of co-cultures of Streptococcus thermophilus and probiotic lactobacilli on quality and antioxidant capacity parameters of lactose-free fermented dairy beverages containing Syzygium cumini (L.) skeels pulp. | Viability of bacteria are above 7 log CFU/g and total phenolic content around 40 mg GAE/100 g. The dairy beverages are good options for functional foods due to its nutritional value, viability of probiotic lactobacilli, phenolic content, and antioxidant capacity, also serving lactose-intolerant people. | [115] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, A.; Zheng, J.; Han, X.; Yang, S.; Cheng, S.; Zhao, J.; Zhou, W.; Lu, Y. Advances in Low-Lactose/Lactose-Free Dairy Products and Their Production. Foods 2023, 12, 2553. https://doi.org/10.3390/foods12132553

Li A, Zheng J, Han X, Yang S, Cheng S, Zhao J, Zhou W, Lu Y. Advances in Low-Lactose/Lactose-Free Dairy Products and Their Production. Foods. 2023; 12(13):2553. https://doi.org/10.3390/foods12132553

Chicago/Turabian StyleLi, Aili, Jie Zheng, Xueting Han, Sijia Yang, Shihui Cheng, Jingwen Zhao, Wenjia Zhou, and Yan Lu. 2023. "Advances in Low-Lactose/Lactose-Free Dairy Products and Their Production" Foods 12, no. 13: 2553. https://doi.org/10.3390/foods12132553

APA StyleLi, A., Zheng, J., Han, X., Yang, S., Cheng, S., Zhao, J., Zhou, W., & Lu, Y. (2023). Advances in Low-Lactose/Lactose-Free Dairy Products and Their Production. Foods, 12(13), 2553. https://doi.org/10.3390/foods12132553