Influence of Hulling, Cleaning and Brushing/Polishing of (Pseudo)Cereal Grains on Compositional Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Grain Processing

2.2. Physical and Nutritional Analyses

2.3. Elemental Composition

2.4. Statistical Analyses

3. Results and Discussion

3.1. Variations in Compositional Characteristics

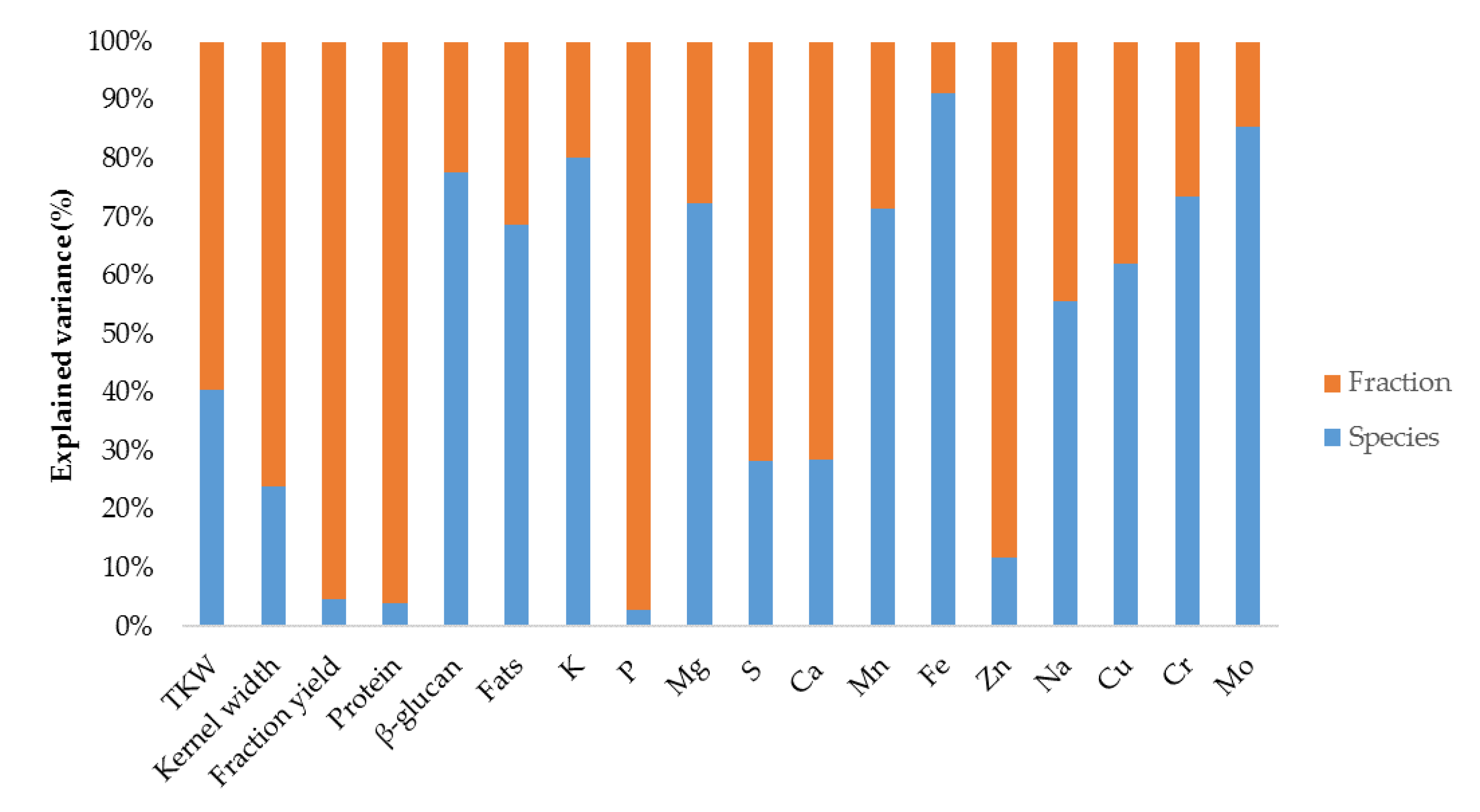

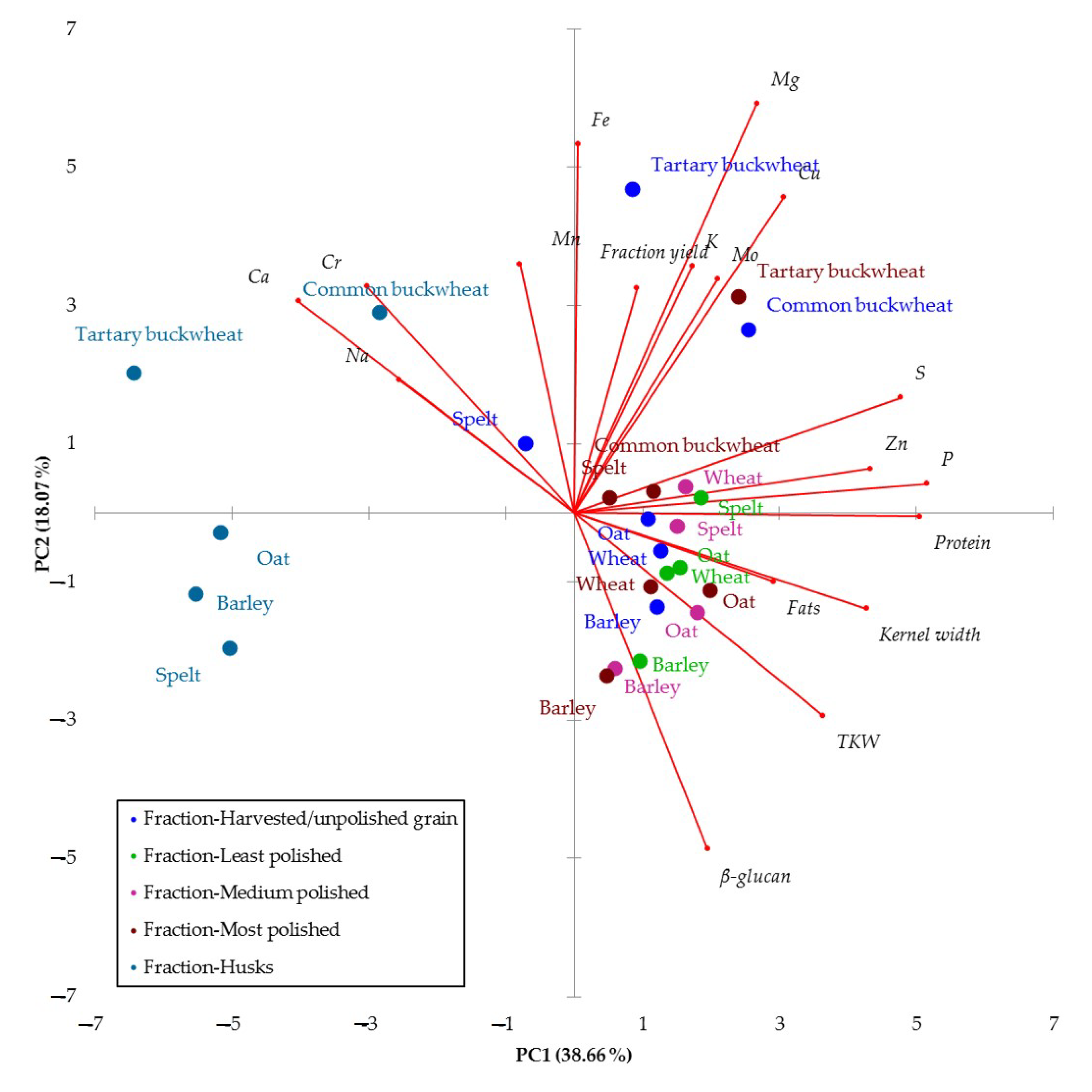

3.2. Analysis of Variance

3.3. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Chatzidimitriou, E.; Wood, L.; Hasanalieva, G.; Markellou, E.; Iversen, P.O.; Seal, C.; Baranski, M.; Vigar, V.; Ernst, L.; et al. Effect of wheat species (Triticum aestivum vs. T. spelta), farming system (organic vs. conventional) and flour type (wholegrain vs. white) on composition of wheat flour—Results of a retail survey in the UK and Germany—2. Antioxidant activity, and phenolic and mineral content. Food Chem. X 2020, 6, 100091. [Google Scholar] [CrossRef]

- Poutanen, K.S.; Kårlund, A.O.; Gómez-Gallego, C.; Johansson, D.P.; Scheers, N.M.; Marklinder, I.M.; Eriksen, A.K.; Silventoinen, P.C.; Nordlund, E.; Sozer, N.; et al. Grains—A major source of sustainable protein for health. Nutr. Rev. 2022, 80, 1648–1663. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Wu, H.; Sajid, A.; Li, Z. Whole grain cereals: The potential roles of functional components in human health. Crit. Rev. Food Sci. Nutr. 2021, 62, 8388–8402. [Google Scholar] [CrossRef] [PubMed]

- Biel, W.; Kazimierska, K.; Bashutska, U. Nutritional value of wheat, triticale, barley and oat grains. Acta Sci. Pol. Zootech. 2020, 19, 19–28. [Google Scholar] [CrossRef]

- Seal, C.J.; Courtin, C.M.; Venema, K.; de Vries, J. Health benefits of whole grain: Effects on dietary carbohydrate quality, the gut microbiome, and consequences of processing. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2742–2768. [Google Scholar] [CrossRef]

- Călinoiu, L.F.; Vodnar, D.C. Whole grains and phenolic acids: A review on bioactivity, functionality, health benefits and bioavailability. Nutrients 2018, 10, 1615. [Google Scholar] [CrossRef]

- Tieri, M.; Ghelfi, F.; Vitale, M.; Vetrani, C.; Marventano, S.; Lafranconi, A.; Godos, J.; Titta, L.; Gambera, A.; Alonzo, E.; et al. Whole grain consumption and human health: An umbrella review of observational studies. Int. J. Food Sci. Nutr. 2020, 71, 668–677. [Google Scholar] [CrossRef]

- Kulathunga, J.; Reuhs, B.L.; Zwinger, S.; Simsek, S. Comparative study on kernel quality and chemical composition of ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. Foods 2021, 10, 761. [Google Scholar] [CrossRef]

- Heiniö, R.L.; Noort, M.W.J.; Katina, K.; Alam, S.A.; Sozer, N.; De Kock, H.L.; Hersleth, M.; Poutanen, K. Sensory characteristics of wholegrain and bran-rich cereal foods – a review. Trends Food Sci. Technol. 2016, 47, 25–38. [Google Scholar] [CrossRef]

- Klepacka, J.; Najda, A.; Klimek, K. Effect of buckwheat groats processing on the content and bioaccessibility of selected minerals. Foods 2020, 9, 832. [Google Scholar] [CrossRef]

- Jokinen, I.; Sammalisto, S.; Silventoinen-Veijalainen, P.; Sontag-Strohm, T.; Nordlund, E.; Holopainen-Mantila, U. Variation in the physical properties of oat groats, flakes and oat flake flour—Processability of thirty pure cultivar oat batches from Finland. LWT—Food Sci. Technol. 2022, 163, 113595. [Google Scholar] [CrossRef]

- Beloshapka, A.N.; Buff, P.R.; Fahey, G.C., Jr.; Swanson, K.S. Compositional analysis of whole grains, processed grains, grain co-products, and other carbohydrate sources with applicability to pet animal nutrition. Foods 2016, 5, 23. [Google Scholar] [CrossRef]

- Kumar, D.; Kalita, P. Reducing postharvest losses during storage of grain crops to strengthen food security in developing countries. Foods 2017, 6, 8. [Google Scholar] [CrossRef]

- Rathan, N.D.; Krishna, H.; Ellur, R.K.; Sehgal, D.; Govindan, V.; Ahlawat, A.K.; Krishnappa, G.; Jaiswal, J.P.; Singh, J.B.; Sv, S.; et al. Genome-wide association study identifies loci and candidate genes for grain micronutrients and quality traits in wheat (Triticum aestivum L.). Sci. Rep. 2022, 12, 7037. [Google Scholar] [CrossRef] [PubMed]

- Ibba, M.I.; Palacios-Rojas, N.; Rosales-Nolasco, A. Screening and use of nutritional and healthrelated benefits of the main crops. In Developing Sustainable and Health-Promoting Cereals and Pseudocereals: Conventional and Molecular Breeding, 1st ed.; Rakszegi, M., Papageorgiou, M., Rocha, J.M., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 25–55. [Google Scholar]

- Caporaso, N.; Whitworth, M.B.; Fisk, I.D. Protein content prediction in single wheat kernels using hyperspectral imaging. Food Chem. 2018, 240, 32–42. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Baranski, M.; Korkut, R.; Kalee, H.A.; Wood, L.; Bilsborrow, P.; Janovska, D.; Leifert, A.; Winter, S.; Willson, A.; et al. Performance of modern and traditional spelt wheat (Triticum spelta) varieties in rain-fed and irrigated, organic and conventional production systems in a semi-arid environment; results from exploratory field experiments in Crete, Greece. Agronomy 2021, 11, 890. [Google Scholar] [CrossRef]

- Dolijanović, Ž.; Nikolić, S.R.; Subić, J.; Jovović, Z.; Oljača, J.; Bačić, J. Organic spelt production systems: Productive and financial performance in three orographic regions. Ital. J. Agron. 2022, 17, 2025. [Google Scholar] [CrossRef]

- Anders, A.; Kolankowska, E.; Choszcz, D.J.; Konopka, S.; Kaliniewicz, Z. The effect of selected parameters on spelt dehulling in a wire mesh cylinder. Sustainability 2020, 12, 43. [Google Scholar] [CrossRef]

- Takač, V.; Tóth, V.; Rakszegi, M.; Mikó, P.; Mikić, S.; Mirosavljević, M. The Influence of farming systems, genotype and their interaction on bioactive compound, protein and starch content of bread and spelt wheat. Foods 2022, 11, 4028. [Google Scholar] [CrossRef]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative study on gluten protein composition of ancient (einkorn, emmer and spelt) and modern wheat species (durum and common wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef]

- Sharma, P.; Kotari, S.L. Barley: Impact of processing on physicochemical and thermal properties—A review. Food Rev. Int. 2017, 33, 359–381. [Google Scholar] [CrossRef]

- Tömösközi, S.; Jaksics, E.; Bugyi, Z.; Németh, R.; Schall, E.; Langó, B.; Rakszegi, M. Screening and use of nutritional and health-related benefits of the minor crops. In Developing Sustainable and Health Promoting Cereals and Pseudocereals, 1st ed.; Rakszegi, M., Papageorgiou, M., Rocha, J.M., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 57–85. [Google Scholar]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion processing of raw food materials and by-products: A review Vivian. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef] [PubMed]

- Gamel, T.H. Screening and improving of nutritional and health-related compounds of pseudocereals. In Developing Sustainable and Health Promoting Cereals and Pseudocereals, 1st ed.; Rakszegi, M., Papageorgiou, M., Rocha, J.M., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 87–98. [Google Scholar]

- Luthar, Z.; Zhou, M.; Golob, A.; Germ, M. Breeding buckwheat for increased levels and improved quality of protein. Plants 2021, 10, 14. [Google Scholar] [CrossRef]

- Kreft, I.; Golob, A.; Vombergar, B.; Germ, M. Tartary buckwheat grain as a source of bioactive compounds in husked groats. Plants 2023, 12, 1122. [Google Scholar] [CrossRef]

- Shaveta, H.K.; Kaur, S.; Kaur, S. Hulless barley: A new era of research for food purposes. J. Cereal Res. 2019, 11, 114–124. [Google Scholar] [CrossRef]

- Lukina, K.A.; Kovaleva, O.N.; Loskutov, I.G. Naked barley: Taxonomy, breeding, and prospects of utilization. Vavilov J. Genet. Breed. 2022, 26, 524–536. [Google Scholar] [CrossRef]

- Błażewicz, J.; Kawa-Rygielska, J.; Leszczyńska, D.; Grabiński, J.; Gasiński, A. Influence of variety and nitrogen fertilization on the technological parameters of special malts prepared from naked and hulled oat varieties. Agronomy 2021, 11, 2566. [Google Scholar] [CrossRef]

- Sterna, V.; Zute, S.; Brunava, L. Oat grain composition and its nutrition benefice. Agric. Agric. Sci. Procedia 2016, 8, 252–256. [Google Scholar] [CrossRef]

- Lukinac, J.; Jukić, M. Barley in the production of cereal-based products. Plants 2022, 11, 3519. [Google Scholar] [CrossRef]

- Demirel, F.; Germec, M.; Coban, H.B.; Turhan, I. Optimization of dilute acid pretreatment of barley husk and oat husk and determination of their chemical composition. Cellulose 2018, 25, 6377–6393. [Google Scholar] [CrossRef]

- Lu, L.; Murphy, K.; Baik, B.K. Genotypic variation in nutritional composition of buckwheat groats and husks. Cereal Chem. 2013, 90, 132–137. [Google Scholar] [CrossRef]

- Nogala-Kałucka, M.; Kawka, A.; Dwiecki, K.; Siger, A. Evaluation of bioactive compounds in cereals. Study of wheat, barley, oat and selected grain products. Acta Sci. Pol. Technol. Aliment. 2020, 19, 405–423. [Google Scholar] [CrossRef]

- Gunkova, P.I.; Buchilina, A.S.; Ishevskiy, A.L.; Pchelina, E.A.; Nikolaev, I.A. Chemical composition of buckwheat groats from various Russian manufacturers. IOP Conf. Ser. Earth Environ. Sci. 2021, 852, 012036. [Google Scholar] [CrossRef]

- Marcotuli, I.; Houston, K.; Schwerdt, J.G.; Waugh, R.; Fincher, G.B.; Burton, R.A.; Blanco, A.; Gadaleta, A. Genetic diversity and genome wide association study of β-glucan content in tetraploid wheat grains. PLoS ONE 2016, 11, e0152590. [Google Scholar] [CrossRef]

- Yang, Z.; Xie, C.; Bao, Y.; Liu, F.; Wang, H.; Wang, Y. Oat: Current state and challenges in plant-based food applications. Trends Food Sci. Technol. 2023, 134, 56–71. [Google Scholar] [CrossRef]

- Tóth, V.; Láng, L.; Vida, G.; Mikó, P.; Rakszegi, M. Characterization of the protein and carbohydrate related quality traits of a large set of spelt wheat genotypes. Foods 2022, 11, 2061. [Google Scholar] [CrossRef]

- Giordano, D.; Reyneri, A.; Locatelli, M.; Coïsson, J.D.; Blandino, M. Distribution of bioactive compounds in pearled fractions of tritordeum. Food Chem. 2019, 301, 125228. [Google Scholar] [CrossRef]

- Jordan-Meille, L.; Holland, J.E.; McGrath, S.P.; Glendining, M.J.; Thomas, C.L.; Haefele, S.M. The grain mineral composition of barley, oat and wheat on soils with pH and soil phosphorus gradients. Eur. J. Agron. 2021, 126, 126281. [Google Scholar] [CrossRef]

- Wang, M.; Kong, F.; Liu, R.; Fan, Q.; Zhang, X. Zinc in wheat grain, processing, and food. Front. Nutr. 2020, 7, 124. [Google Scholar] [CrossRef] [PubMed]

- Loskutov, I.G.; Khlestkina, E.K. Wheat, barley, and oat breeding for health benefit components in grain. Plants 2021, 10, 86. [Google Scholar] [CrossRef]

- Gabrovská, D.; Fiedlerová, V.; Holasová, M.; Mašková, E.; Smrčinov, H.; Rysová, J.; Winterová, R.; Michalová, A.; Hutař, M. The nutritional evaluation of underutilized cereals and buckwheat. Food Nutr. Bull. 2002, 23, 246–249. [Google Scholar] [CrossRef] [PubMed]

- Kiewlicz, J.; Rybicka, I. Minerals and their bioavailability in relation to dietary fiber, phytates and tannins from gluten and gluten-free flakes. Food Chem. 2020, 305, 125452. [Google Scholar] [CrossRef] [PubMed]

- Souci, S.W.; Fachmann, W.; Kraut, H. Food Composition and Nutrition Tables, 6th ed.; Medpharm Scientific Publishers: Stuttgart, Germany, 2000; pp. 1–1182. [Google Scholar]

- Angioloni, A.; Collar, C. Nutritional and functional added value of oat, Kamut®, spelt, rye and buckwheat versus common wheat in breadmaking. J. Sci. Food Agric. 2011, 91, 1283–1292. [Google Scholar] [CrossRef] [PubMed]

- Abayomi, O.O.; Gan, C.Y.; Shafie, M.H.; Alenezi, H.; Taiwo, A.E.; Olumide, F.S. Nutritional quality of color cereals and effects of processing on its functional properties. In Functionality and Application of Colored Cereals; Bangar, S.P., Kumar, M., Eds.; Academic Press: Cambridge, MA, USA, 2023; pp. 27–46. [Google Scholar]

| Latin Name | Species | Variety Name | Processing of Harvested Grains |

|---|---|---|---|

| Triticum aestivum L. | Wheat | CCB Ingenio | Winnowing (grain winnowing machine) + brushing/polishing (3×) (adapted traditional stone mill) |

| Triticum aestivum spp. spelta | Spelt | Murska bela | Threshing (LD359 machine) + cleaning (Haldrup DC-20) + brushing/polishing (3×) (adapted traditional stone mill) |

| Hordeum vulgare L. | Barley | Concordia | Winnowing (grain winnowing machine) + brushing/polishing (3×) (adapted traditional stone mill) |

| Avena sativa L. | Oat | Noni | Winnowing (grain winnowing machine) + brushing/polishing (6×) (adapted traditional stone mill) |

| Fagopyrum esculentum Moench | Common buckwheat | Eva | Winnowing (grain winnowing machine) + hulling (Sheller device) |

| Fagopyrum tataricum (L.) Gaertn. | Tartary buckwheat | Doris | Winnowing (grain winnowing machine) + hulling (Sheller device) |

| Species | Fraction | Suitable for Consumption | Physical Parameters | Nutritional Characteristics | Multi-Elemental Profile | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TKW | Kernel Width | FY | Protein | Fats | β-glucan | K | P | Mg | S | Ca | Mn | Fe | Zn | Na | Cu | Cr | Mo | |||

| g | mm | % | mg/g | g/kg | mg/g | |||||||||||||||

| Wheat | Harvested/unpolished grain | Yes | 51.59 | 3.50 | 100.00 | 138.94 | 16.21 | 9.05 | 3.61 | 3.60 | 1.38 | 1.45 | 0.40 | 31.89 | 30.28 | 21.88 | 8.31 | 3.45 | 0.24 | 0.44 |

| Least polished | Yes (groats) | 50.77 | 3.40 | 38.00 | 139.74 | 19.63 | 9.04 | 3.71 | 3.60 | 1.41 | 1.65 | 0.39 | 33.87 | 30.28 | 21.10 | 7.80 | 3.41 | 0.14 | 0.45 | |

| Medium polished | Yes (groats) | 49.84 | 3.40 | 59.00 | 139.11 | 18.55 | 8.32 | 4.39 | 3.85 | 1.66 | 1.63 | 0.44 | 39.39 | 36.66 | 26.42 | 17.82 | 4.03 | 0.14 | 0.55 | |

| Most polished | Yes | 39.81 | 3.10 | 1.00 | 144.89 | 18.55 | 8.52 | 3.75 | 3.54 | 1.35 | 1.64 | 0.45 | 32.34 | 31.57 | 22.76 | 7.00 | 3.38 | 0.09 | 0.41 | |

| Husks | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | |

| Spelt | Harvested/unpolished grain | No | n.a. | n.a. | 100.00 | 108.00 | 18.58 | 6.15 | 3.68 | 3.11 | 1.26 | 1.08 | 0.54 | 40.22 | 39.31 | 22.43 | 8.56 | 4.24 | 0.33 | 0.96 |

| Least polished | Yes (groats) | 42.61 | 3.20 | 51.00 | 142.25 | 17.63 | 8.29 | 3.91 | 4.07 | 1.42 | 1.27 | 0.28 | 37.21 | 38.65 | 27.94 | 8.54 | 4.88 | 0.29 | 0.97 | |

| Medium polished | Yes | 32.75 | 3.00 | 8.00 | 138.71 | 15.15 | 8.60 | 3.81 | 3.82 | 1.36 | 1.47 | 0.31 | 33.42 | 36.80 | 25.66 | 7.47 | 4.64 | 0.19 | 0.99 | |

| Most polished | Yes | n.a. | n.a. | 3.00 | 134.98 | 13.96 | 8.24 | 3.71 | 3.53 | 1.29 | 1.40 | 0.33 | 30.92 | 46.92 | 35.92 | 8.39 | 4.49 | 0.29 | 0.86 | |

| Husks | No | n.a. | n.a. | 38.00 | 24.92 | 4.53 | 2.70 | 2.14 | 0.66 | 0.50 | 0.29 | 0.64 | 28.04 | 20.55 | 6.44 | 7.46 | 1.35 | 0.61 | 0.62 | |

| Barley | Harvested/unpolished grain | No | 52.24 | 3.60 | 100.00 | 118.95 | 21.94 | 48.86 | 4.06 | 3.54 | 1.25 | 1.24 | 0.53 | 18.71 | 35.69 | 24.83 | 14.30 | 4.85 | 0.23 | 0.05 |

| Least polished | Yes | 51.40 | 3.60 | 5.00 | 118.59 | 21.98 | 48.48 | 3.95 | 3.43 | 1.21 | 1.14 | 0.48 | 15.72 | 33.90 | 23.01 | 12.81 | 4.65 | 0.19 | 0.24 | |

| Medium polished | Yes | 49.23 | 3.57 | 15.00 | 116.00 | 16.86 | 54.40 | 3.90 | 3.34 | 1.18 | 0.96 | 0.39 | 14.05 | 31.75 | 22.79 | 13.29 | 4.68 | 0.54 | 0.15 | |

| Most polished | Yes (groats) | 46.70 | 3.50 | 58.00 | 113.09 | 17.49 | 52.58 | 3.68 | 3.15 | 1.10 | 1.00 | 0.41 | 13.49 | 28.61 | 20.50 | 12.07 | 4.38 | 0.17 | 0.07 | |

| Husks | No | n.a. | n.a. | 20.00 | 34.72 | 5.79 | 0.96 | 2.76 | 0.84 | 0.84 | 0.41 | 1.10 | 27.39 | 23.98 | 10.55 | 23.11 | 1.71 | 0.90 | 0.04 | |

| Oat | Harvested/unpolished grain | No | 30.12 | 2.70 | 100.00 | 111.84 | 51.89 | 33.62 | 4.93 | 3.49 | 1.04 | 1.54 | 0.52 | 47.28 | 36.37 | 24.51 | 13.76 | 3.46 | 0.13 | 0.49 |

| Least polished | Yes | 27.69 | 2.60 | 8.00 | 129.23 | 58.84 | 44.92 | 4.22 | 4.03 | 1.23 | 1.68 | 0.61 | 41.19 | 34.13 | 24.77 | 9.99 | 4.01 | 0.41 | 0.59 | |

| Medium polished | Yes | 27.11 | 2.50 | 17.00 | 136.78 | 67.23 | 53.03 | 3.81 | 3.87 | 1.15 | 1.66 | 0.43 | 36.74 | 31.68 | 24.81 | 9.56 | 3.92 | 0.19 | 0.55 | |

| Most polished | Yes (groats) | 24.56 | 2.40 | 34.00 | 136.84 | 69.58 | 50.67 | 3.98 | 4.01 | 1.18 | 1.69 | 0.36 | 36.86 | 33.26 | 25.07 | 9.65 | 4.00 | 0.19 | 0.62 | |

| Husks | No | n.a. | n.a. | 41.00 | 22.69 | 5.67 | 1.16 | 5.43 | 0.81 | 0.39 | 0.75 | 0.94 | 34.15 | 25.14 | 12.27 | 24.98 | 1.22 | 1.28 | 0.11 | |

| Common buckwheat | Harvested/unpolished grain | No | 34.71 | 3.80 | 100.00 | 122.00 | 21.00 | 0.82 | 5.07 | 3.84 | 2.36 | 1.70 | 0.68 | 32.96 | 36.19 | 20.53 | 4.42 | 7.66 | 0.36 | 1.08 |

| Least polished | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | |

| Medium polished | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | |

| Most polished | Yes (groats) | 23.79 | 3.30 | 70.00 | 105.27 | 14.13 | 0.53 | 3.42 | 3.07 | 1.69 | 1.53 | 0.23 | 14.83 | 35.50 | 16.88 | 4.19 | 6.70 | 0.22 | 0.84 | |

| Husks | No | n.a. | n.a. | 30.00 | 52.00 | 6.00 | 0.45 | 5.78 | 1.29 | 1.80 | 0.98 | 1.28 | 60.73 | 37.81 | 9.77 | 15.03 | 6.18 | 0.33 | 0.73 | |

| Tartary buckwheat | Harvested/unpolished grain | No | 22.74 | 2.90 | 100.00 | 125.00 | 26.00 | 0.28 | 4.59 | 3.83 | 2.29 | 1.58 | 0.89 | 38.93 | 414.96 | 27.47 | 29.36 | 6.26 | 0.84 | 0.49 |

| Least polished | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | |

| Medium polished | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | |

| Most polished | Yes (groats) | 13.31 | 2.40 | 60.00 | 148.48 | 32.03 | 0.16 | 4.95 | 4.85 | 2.46 | 1.74 | 0.42 | 21.07 | 148.31 | 31.41 | 8.61 | 6.80 | 1.92 | 0.69 | |

| Husks | No | n.a. | n.a. | 40.00 | 38.00 | 3.00 | 0.26 | 2.59 | 0.55 | 1.40 | 0.45 | 2.24 | 38.29 | 144.17 | 9.15 | 17.76 | 3.67 | 3.00 | 0.20 | |

| Species | Fraction | |||

|---|---|---|---|---|

| MSS | p | MSS | p | |

| TKW | 523.836 | 0.006 | 961.378 | 0.000 |

| Kernel width | 1.943 | 0.046 | 7.665 | 0.000 |

| FY | 194.563 | 0.830 | 4985.117 | 0.000 |

| Protein | 263.033 | 0.155 | 7978.262 | <0.0001 |

| β-glucan | 1319.126 | 0.000 | 473.717 | 0.030 |

| Fats | 973.720 | 0.000 | 553.781 | 0.005 |

| K | 1.045 | 0.246 | 0.321 | 0.762 |

| P | 0.189 | 0.362 | 7.872 | <0.0001 |

| Mg | 0.800 | <0.0001 | 0.383 | 0.000 |

| S | 0.231 | 0.000 | 0.733 | <0.0001 |

| Ca | 0.171 | 0.046 | 0.535 | 0.001 |

| Mn | 276.429 | 0.020 | 137.314 | 0.165 |

| Fe | 20687.415 | 0.001 | 2513.799 | 0.450 |

| Zn | 22.995 | 0.224 | 216.684 | <0.0001 |

| Na | 62.018 | 0.082 | 62.085 | 0.092 |

| Cu | 8.218 | <0.0001 | 6.273 | <0.0001 |

| Cr | 1.131 | 0.000 | 0.507 | 0.015 |

| Mo | 0.410 | <0.0001 | 0.087 | 0.001 |

| TKW | Kernel Width | FY | Protein | Fats | β-Glucan | K | P | Mg | S | Ca | Mn | Fe | Zn | Na | Cu | Cr | Mo | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| g | mm | % | mg/g | g/kg | mg/kg | ||||||||||||||

| Species | Wheat | 48.00 a | 3.35 a | 49.50 a | 140.67 a | 18.23 b | 8.73 b | 3.86 a | 3.65 a | 1.45 b | 1.59 a | 0.42 b | 34.37 ab | 32.20 b | 23.04 a | 10.23 a | 3.57 c | 0.15 b | 0.46 b |

| Spelt | 37.68 ab | 3.10 a | 40.00 a | 109.77 b | 13.97 b | 6.80 b | 3.45 a | 3.04 a | 1.17 bc | 1.10 bc | 0.42 b | 33.96 ab | 36.45 b | 23.68 a | 8.09 a | 3.92 c | 0.34 b | 0.88 a | |

| Barley | 49.89 a | 3.57 a | 39.60 a | 100.27 b | 16.81 b | 41.06 a | 3.67 a | 2.86 a | 1.12 bc | 0.95 c | 0.58 b | 17.87 b | 30.79 b | 20.34 a | 15.12 a | 4.05 c | 0.41 b | 0.11 c | |

| Oat | 27.37 b | 2.55 b | 40.00 a | 107.48 b | 50.64 a | 36.68 a | 4.47 a | 3.24 a | 1.00 c | 1.46 a | 0.57 b | 39.24 a | 32.12 b | 22.29 a | 13.59 a | 3.32 c | 0.44 b | 0.47 b | |

| Common buckwheat | 29.25 b | 3.55 a | 66.67 a | 93.09 b | 13.71 b | 0.60 b | 4.76 a | 2.73 a | 1.95 a | 1.40 ab | 0.73 ab | 36.17 ab | 36.50 b | 15.73 a | 7.88 a | 6.84 a | 0.30 b | 0.89 a | |

| Tartary buckwheat | 18.03 c | 2.65 b | 66.67 a | 103.83 b | 20.34 b | 0.23 b | 4.04 a | 3.08 a | 2.05 a | 1.26 abc | 1.18 a | 32.76 ab | 235.81 a | 22.67 a | 18.58 a | 5.58 b | 1.92 a | 0.46 b | |

| Fractions | Harvested/unpolished grain | 38.28 a | 3.30 a | 100.00 a | 120.79 a | 25.94 a | 16.46 ab | 4.32 a | 3.57 a | 1.60 a | 1.43 a | 0.59 b | 35.00 a | 98.80 a | 23.60 a | 13.12 a | 4.99 a | 0.36 b | 0.59 a |

| Least polished | 43.12 a | 3.20 a | 25.50 b | 132.45 a | 29.52 a | 27.68 a | 3.95 a | 3.78 a | 1.32 ab | 1.44 a | 0.44 b | 32.00 a | 34.24 a | 24.20 a | 9.79 a | 4.24 a | 0.26 b | 0.56 a | |

| Medium polished | 39.73 a | 3.12 a | 24.75 b | 132.65 a | 29.45 a | 31.09 a | 3.98 a | 3.72 a | 1.34 ab | 1.43 a | 0.39 b | 30.90 a | 34.22 a | 24.92 a | 12.03 a | 4.32 a | 0.26 b | 0.56 a | |

| Most polished | 29.63 b | 2.94 b | 37.67 b | 130.59 a | 27.62 a | 20.12 ab | 3.91 a | 3.69 a | 1.51 a | 1.50 a | 0.37 b | 24.92 a | 54.03 a | 25.42 a | 8.32 a | 4.96 a | 0.48 b | 0.58 a | |

| Husks | n.a. | n.a | 33.80 b | 34.47 b | 5.00 b | 1.11 b | 3.74 a | 0.83 b | 0.99 b | 0.58 b | 1.24 a | 37.72 a | 50.33 a | 9.63 b | 17.67 a | 2.83 b | 1.22 a | 0.34 b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinkovič, L.; Pipan, B.; Neji, M.; Rakszegi, M.; Meglič, V. Influence of Hulling, Cleaning and Brushing/Polishing of (Pseudo)Cereal Grains on Compositional Characteristics. Foods 2023, 12, 2452. https://doi.org/10.3390/foods12132452

Sinkovič L, Pipan B, Neji M, Rakszegi M, Meglič V. Influence of Hulling, Cleaning and Brushing/Polishing of (Pseudo)Cereal Grains on Compositional Characteristics. Foods. 2023; 12(13):2452. https://doi.org/10.3390/foods12132452

Chicago/Turabian StyleSinkovič, Lovro, Barbara Pipan, Mohamed Neji, Marianna Rakszegi, and Vladimir Meglič. 2023. "Influence of Hulling, Cleaning and Brushing/Polishing of (Pseudo)Cereal Grains on Compositional Characteristics" Foods 12, no. 13: 2452. https://doi.org/10.3390/foods12132452

APA StyleSinkovič, L., Pipan, B., Neji, M., Rakszegi, M., & Meglič, V. (2023). Influence of Hulling, Cleaning and Brushing/Polishing of (Pseudo)Cereal Grains on Compositional Characteristics. Foods, 12(13), 2452. https://doi.org/10.3390/foods12132452