Exploring the Potential of Wild Andean Blueberries for Powdered Juice Production through Spray Drying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spray-Drying Process

2.3. Charactetization of the Spray-Dried Andean Blueberry Juice Powders

2.3.1. Color Attributes

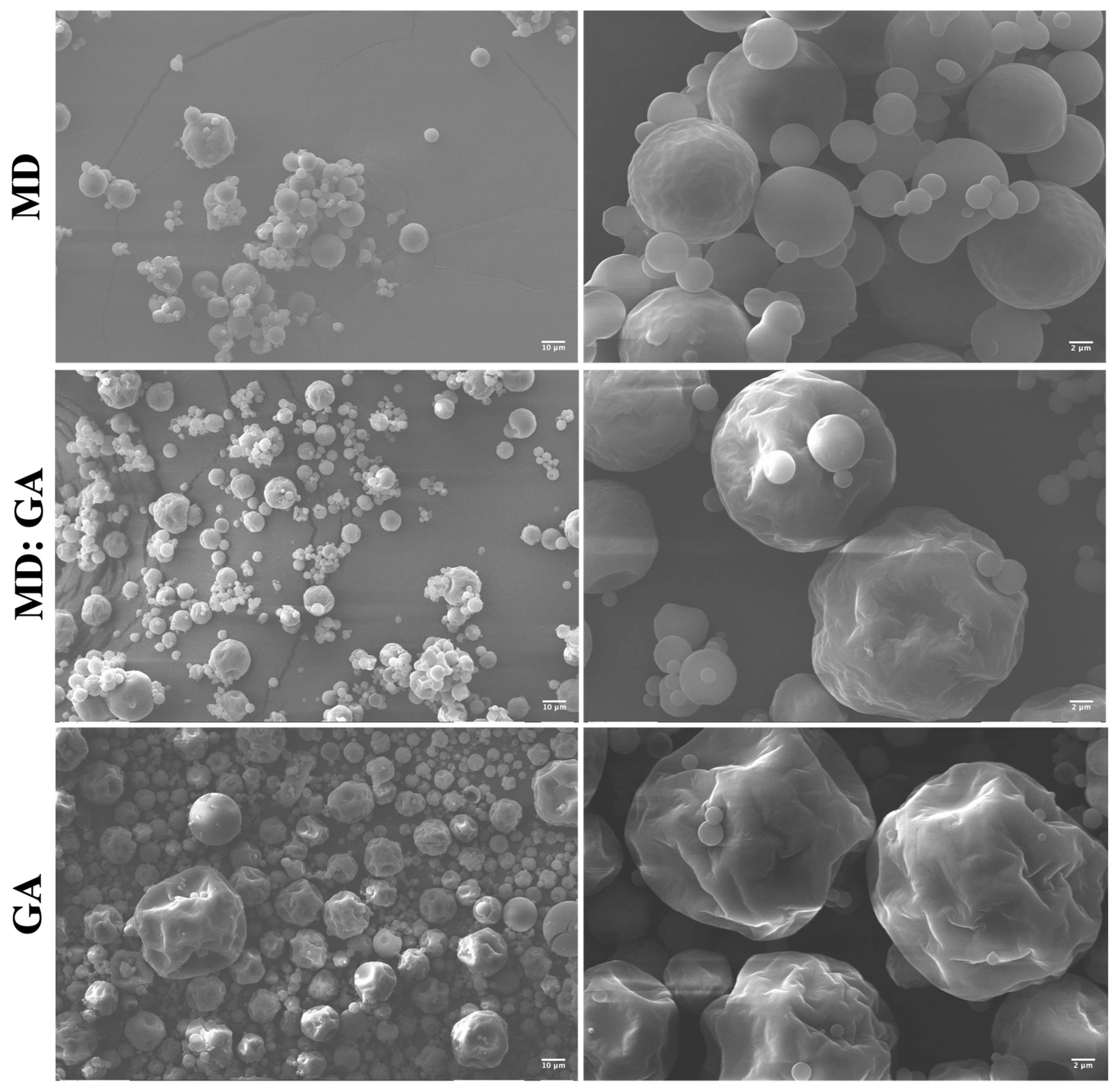

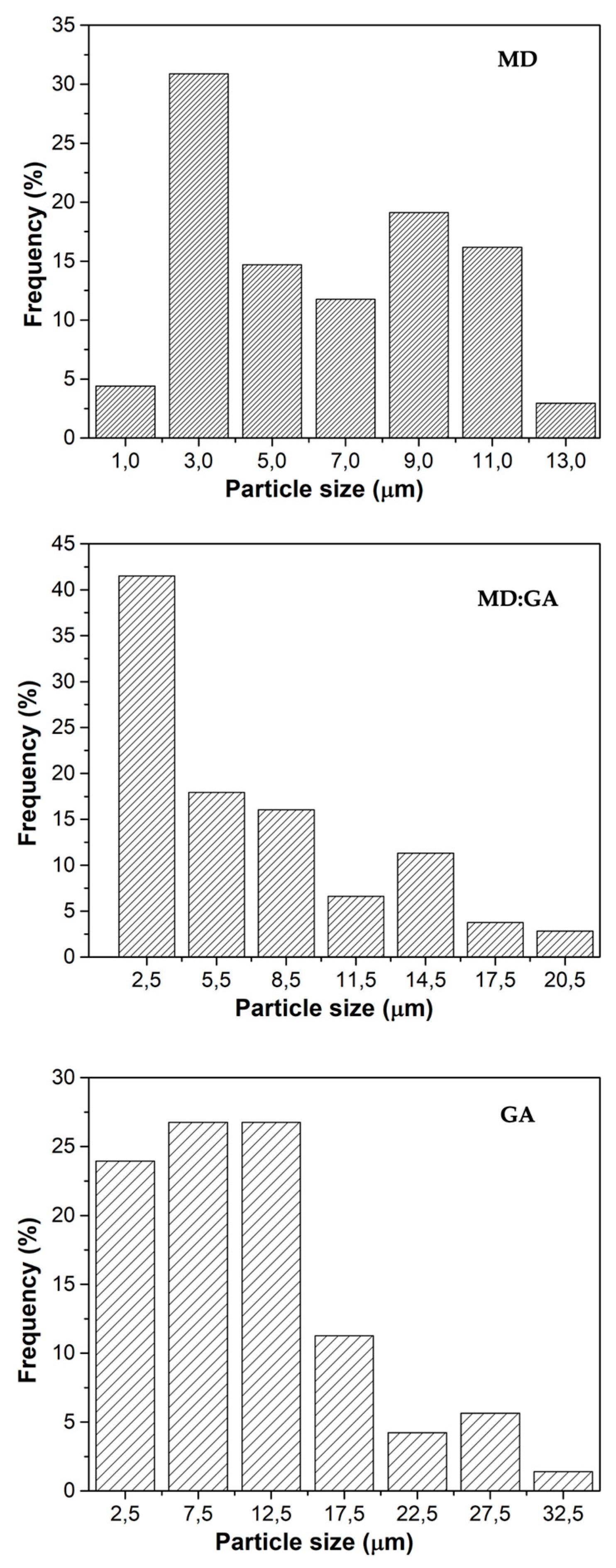

2.3.2. Scanning Electron Microscopy Analysis

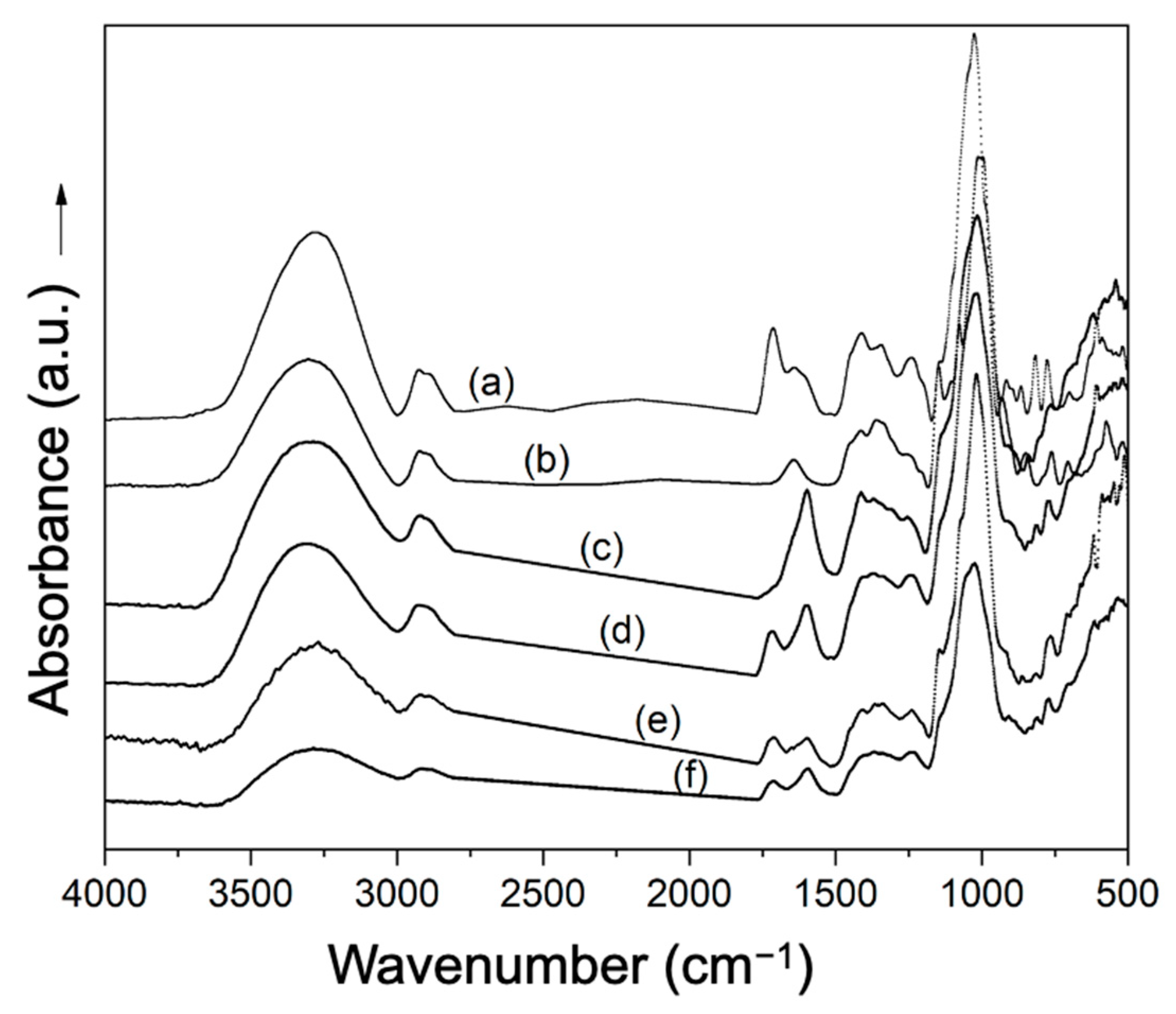

2.3.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.4. Recovery of Total Polyphenolic Compounds and Total Monomeric Anthocyanins

2.3.5. DPPH• Radical Scavenging Activity

2.3.6. Moisture Content and Water Activity

2.3.7. Water Solubility

2.3.8. Densities and Flow Properties

2.4. Statistical Analysis

3. Results

3.1. Appereance and Chromatic Attributes of the Spray-Dried Powders

3.2. Infrared Spectra of the Spray Dried-Powders

3.3. Content of Bioactive Compounds and Antioxidant Activity of the Spray-Dried Powders

3.4. Water Activity, Moisture Content, and Water Solubility of the Spray-Dried Powders

3.5. Densities and Flow Properties of the Spray-Dried Powders

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muntean, M.V.; Fărcaş, A.C.; Medeleanu, M.; Salanţă, L.C.; Borşa, A. A Sustainable Approach for the Development of Innovative Products from Fruit and Vegetable By-Products. Sustainability 2022, 14, 10862. [Google Scholar] [CrossRef]

- Stavra, K.; Plati, F.; Pavlidou, E.; Paraskevopoulou, A. Characterization of Lemon Juice Powders Produced by Different Drying Techniques and Carrier Materials. Dry Technol. 2022, 40, 1923–1934. [Google Scholar] [CrossRef]

- Mahalakshmi, M.; Meghwal, M. Microencapsulation of Fruit Juices: Techniques, Properties, Application of Fruit Powder. J. Food Process Eng. 2023, 46, e14226. [Google Scholar] [CrossRef]

- Meinhold, K.; Darr, D. Keeping Up with Rising (Quality) Demands? The Transition of a Wild Food Resource to Mass Market, Using the Example of Baobab in Malawi. Front. Sustain. Food Syst. 2022, 6, 840760. [Google Scholar] [CrossRef]

- Romero-Román, M.E.; Schoebitz, M.; Fuentealba, J.; García-Viguera, C.; Belchí, M.D.L. Phenolic Compounds in Calafate Berries Encapsulated by Spray Drying: Neuroprotection Potential into the Ingredient. Antioxidants 2021, 10, 1830. [Google Scholar] [CrossRef]

- Gomez Mattson, M.; Sozzi, A.; Corfield, R.; Gagneten, M.; Franceschinis, L.; Schebor, C.; Salvatori, D. Colorant and Antioxidant Properties of Freeze-Dried Extracts from Wild Berries: Use of Ultrasound-Assisted Extraction Method and Drivers of Liking of Colored Yogurts. J. Food Sci. Technol. 2022, 59, 944–955. [Google Scholar] [CrossRef]

- Arango-Varela, S.S.; Luzardo-Ocampo, I.; Maldonado-Celis, M.E. Andean Berry (Vaccinium meridionale Swartz) Juice, in Combination with Aspirin, Displayed Antiproliferative and pro-Apoptotic Mechanisms in Vitro While Exhibiting Protective Effects against AOM-Induced Colorectal Cancer In Vivo. Food Res. Int. 2022, 157, 111244. [Google Scholar] [CrossRef]

- Arango-Varela, S.S.; Luzardo-Ocampo, I.; Maldonado-Celis, M.E.; Campos-Vega, R. Andean Berry (Vaccinium meridionale Swartz) Juice in Combination with Aspirin Modulated Anti-Inflammatory Markers on LPS-Stimulated RAW 264.7 Macrophages. Food Res. Int. 2020, 137, 109541. [Google Scholar] [CrossRef]

- Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. New Freeze-Dried Andean Blueberry Juice Powders for Potential Application as Functional Food Ingredients: Effect of Maltodextrin on Bioactive and Morphological Features. Molecules 2020, 25, 5635. [Google Scholar] [CrossRef]

- Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. Evaluation of Mixtures of Maltodextrin and Gum Arabic for the Encapsulation of Andean Blueberry (Vaccinium meridionale) Juice by Freeze-drying. Int. J. Food Sci. Technol. 2022, 57, 7379–7390. [Google Scholar] [CrossRef]

- Jafari, S.; Jafari, S.M.; Ebrahimi, M.; Kijpatanasilp, I.; Assatarakul, K. A Decade Overview and Prospect of Spray Drying Encapsulation of Bioactives from Fruit Products: Characterization, Food Application and in Vitro Gastrointestinal Digestion. Food Hydrocoll. 2023, 134, 108068. [Google Scholar] [CrossRef]

- Gawałek, J. Spray Drying of Chokeberry Juice—Antioxidant Phytochemicals Retention in the Obtained Powders versus Energy Consumption of the Process. Foods 2022, 11, 2898. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Bansal, M.; Jain, D.; Srivastava, Y. Encapsulation for Efficient Spray Drying of Fruit Juices with Bioactive Retention. J. Food Meas. Charact. 2022, 16, 3792–3814. [Google Scholar] [CrossRef]

- Sobulska, M.; Zbicinski, I. Advances in Spray Drying of Sugar-Rich Products. Dry Technol. 2021, 39, 1774–1799. [Google Scholar] [CrossRef]

- Buljeta, I.; Pichler, A.; Šimunović, J.; Kopjar, M. Polysaccharides as Carriers of Polyphenols: Comparison of Freeze-Drying and Spray-Drying as Encapsulation Techniques. Molecules 2022, 27, 5069. [Google Scholar] [CrossRef]

- Gaćina, N.; Elez Garofulić, I.; Zorić, Z.; Pedisić, S.; Dragović-Uzelac, V. Influence of Encapsulation Parameters on the Retention of Polyphenols in Blackthorn Flower Extract. Processes 2022, 10, 2517. [Google Scholar] [CrossRef]

- Navarro-Flores, M.J.; Ventura-Canseco, L.M.C.; Meza-Gordillo, R.; Ayora-Talavera, T.d.R.; Abud-Archila, M. Spray Drying Encapsulation of a Native Plant Extract Rich in Phenolic Compounds with Combinations of Maltodextrin and Non-Conventional Wall Materials. J. Food Sci. Technol. 2020, 57, 4111–4122. [Google Scholar] [CrossRef]

- Colín-Cruz, M.A.; Pimentel-González, D.J.; Carrillo-Navas, H.; Alvarez-Ramírez, J.; Guadarrama-Lezama, A.Y. Co-Encapsulation of Bioactive Compounds from Blackberry Juice and Probiotic Bacteria in Biopolymeric Matrices. LWT 2019, 110, 94–101. [Google Scholar] [CrossRef]

- Gagneten, M.; Corfield, R.; Mattson, M.G.; Sozzi, A.; Leiva, G.; Salvatori, D.; Schebor, C. Spray-Dried Powders from Berries Extracts Obtained upon Several Processing Steps to Improve the Bioactive Components Content. Powder Technol. 2019, 342, 1008–1015. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, C.C.; Germer, S.P.M.; Alvim, I.D.; Vissotto, F.Z.; de Aguirre, J.M. Influence of Carrier Agents on the Physicochemical Properties of Blackberry Powder Produced by Spray Drying. Int. J. Food Sci. Technol. 2012, 47, 1237–1245. [Google Scholar] [CrossRef]

- Gawałek, J.; Domian, E. Tapioca Dextrin as an Alternative Carrier in the Spray Drying of Fruit Juices—A Case Study of Chokeberry Powder. Foods 2020, 9, 1125. [Google Scholar] [CrossRef] [PubMed]

- Halahlah, A.; Piironen, V.; Mikkonen, K.S.; Ho, T.M. Wood Hemicelluloses as Innovative Wall Materials for Spray-Dried Microencapsulation of Berry Juice: Part 1—Effect of Homogenization Techniques on Their Feed Solution Properties. Food Bioprocess Technol. 2023, 16, 909–929. [Google Scholar] [CrossRef]

- Bastías-Montes, J.M.; Choque-Chávez, M.C.; Alarcón-Enos, J.; Quevedo-León, R.; Muñoz-Fariña, O.; Vidal-San-martín, C. Effect of Spray Drying at 150, 160, and 170 °C on the Physical and Chemical Properties of Maqui Extract (Aristotelia chilensis (Molina) Stuntz). Chil. J. Agric. Res. 2019, 79, 144–152. [Google Scholar] [CrossRef] [Green Version]

- Franceschinis, L.; Salvatori, D.M.; Sosa, N.; Schebor, C. Physical and Functional Properties of Blackberry Freeze- and Spray-Dried Powders. Dry Technol. 2014, 32, 197–207. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Lee, J.; Durst, R.W.; Wrolstad, R.E. Determination of Total Monomeric Anthocyanin Pigment Content of Fruit Juices, Beverages, Natural Colorants, and Wines by the PH Differential Method: Collaborative Study. J. AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef] [Green Version]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a Free Radical Method to Evaluate Antioxidant Activity. Lebensm. Wiss. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Yu, Y.; Lv, Y. Degradation Kinetic of Anthocyanins from Rose (Rosa rugosa) as Prepared by Microencapsulation in Freeze-Drying and Spray-Drying. Int. J. Food Prop. 2019, 22, 2009–2021. [Google Scholar] [CrossRef] [Green Version]

- Pieczykolan, E.; Kurek, M.A. Use of Guar Gum, Gum Arabic, Pectin, Beta-Glucan and Inulin for Microencapsulation of Anthocyanins from Chokeberry. Int. J. Biol. Macromol. 2019, 129, 665–671. [Google Scholar] [CrossRef]

- Silva, P.I.; Stringheta, P.C.; Teófilo, R.F.; de Oliveira, I.R.N. Parameter Optimization for Spray-Drying Microencapsulation of Jaboticaba (Myrciaria jaboticaba) Peel Extracts Using Simultaneous Analysis of Responses. J. Food Eng. 2013, 117, 538–544. [Google Scholar] [CrossRef] [Green Version]

- Loksuwan, J. Characteristics of Microencapsulated β-Carotene Formed by Spray Drying with Modified Tapioca Starch, Native Tapioca Starch and Maltodextrin. Food Hydrocoll. 2007, 21, 928–935. [Google Scholar] [CrossRef]

- Pang, S.F.; Yusoff, M.M.; Gimbun, J. Assessment on Bioavailability of Flavonoids from Orthosiphon Stamineus during Spray Drying. In Developments in Sustainable Chemical and Bioprocess Technology; Springer: New York, NY, USA, 2013; pp. 137–144. ISBN 9781461462088. [Google Scholar]

- Kurozawa, L.E.; Morassi, A.G.; Vanzo, A.A.; Park, K.J.; Hubinger, M.D. Influence of Spray Drying Conditions on Physicochemical Properties of Chicken Meat Powder. Dry Technol. 2009, 27, 1248–1257. [Google Scholar] [CrossRef]

- López-Córdoba, A.; Goyanes, S. Food Powder Properties. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Premi, M.; Sharma, H.K. Effect of Different Combinations of Maltodextrin, Gum Arabic and Whey Protein Concentrate on the Encapsulation Behavior and Oxidative Stability of Spray Dried Drumstick (Moringa oleifera) Oil. Int. J. Biol. Macromol. 2017, 105, 1232–1240. [Google Scholar] [CrossRef] [PubMed]

- Comunian, T.A.; Monterrey-Quintero, E.S.; Thomazini, M.; Balieiro, J.C.C.; Piccone, P.; Pittia, P.; Favaro-Trindade, C.S. Assessment of Production Efficiency, Physicochemical Properties and Storage Stability of Spray-Dried Chlorophyllide, a Natural Food Colourant, Using Gum Arabic, Maltodextrin and Soy Protein Isolate-Based Carrier Systems. Int. J. Food Sci. Technol. 2011, 46, 1259–1265. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Ramirez, M.J.; Orrego, C.E.; Teixeira, J.A.; Mussatto, S.I. Encapsulation of Antioxidant Phenolic Compounds Extracted from Spent Coffee Grounds by Freeze-Drying and Spray-Drying Using Different Coating Materials. Food Chem. 2017, 237, 623–631. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, Y.; Wang, P.; Wang, J.; Wu, Y.; Han, Y.; Zhou, J. Combining Various Wall Materials for Encapsulation of Blueberry Anthocyanin Extracts: Optimization by Artificial Neural Network and Genetic Algorithm and a Comprehensive Analysis of Anthocyanin Powder Properties. Powder Technol. 2017, 311, 77–87. [Google Scholar] [CrossRef]

- Mansour, M.; Salah, M.; Xu, X. Effect of Microencapsulation Using Soy Protein Isolate and Gum Arabic as Wall Material on Red Raspberry Anthocyanin Stability, Characterization, and Simulated Gastrointestinal Conditions. Ultrason. Sonochem. 2020, 63, 104927. [Google Scholar] [CrossRef]

- Xue, J.; Su, F.; Meng, Y.; Guo, Y. Enhanced Stability of Red-Fleshed Apple Anthocyanins by Copigmentation and Encapsulation. J. Sci. Food Agric. 2019, 99, 3381–3390. [Google Scholar] [CrossRef]

- Alzate-Arbeláez, A.F.; Dorta, E.; López-Alarcón, C.; Cortés, F.B.; Rojano, B.A. Immobilization of Andean Berry (Vaccinium meridionale) Polyphenols on Nanocellulose Isolated from Banana Residues: A Natural Food Additive with Antioxidant Properties. Food Chem. 2019, 294, 503–517. [Google Scholar] [CrossRef]

- Mahdavee Khazaei, K.; Jafari, S.M.; Ghorbani, M.; Hemmati Kakhki, A. Application of Maltodextrin and Gum Arabic in Microencapsulation of Saffron Petal’s Anthocyanins and Evaluating Their Storage Stability and Color. Carbohydr. Polym. 2014, 105, 57–62. [Google Scholar] [CrossRef]

- Nogueira, G.F.; Fakhouri, F.M.; Velasco, J.I.; de Oliveira, R.A. Active Edible Films Based on Arrowroot Starch with Microparticles of Blackberry Pulp Obtained by Freeze-Drying for Food Packaging. Polymers 2019, 11, 1382. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarabandi, K.H.; Peighambardoust, S.H.; Sadeghi Mahoonak, A.R.; Samaei, S.P. Effect of Different Carriers on Microstructure and Physical Characteristics of Spray Dried Apple Juice Concentrate. J. Food Sci. Technol. 2018, 55, 3098–3109. [Google Scholar] [CrossRef] [PubMed]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of Process Conditions on the Physicochemical Properties of Açai (Euterpe oleraceae Mart.) Powder Produced by Spray Drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Zhang, L.L.; Ma, C.C. Influence of Operating Parameters on Physicochemical Properties of Fruit Juice Powders Produced by Spray Drying. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; Volume 941–944, pp. 1196–1200. [Google Scholar]

- Caliskan, G.; Dirim, S.N. The Effect of Different Drying Processes and the Amounts of Maltodextrin Addition on the Powder Properties of Sumac Extract Powders. Powder Technol. 2016, 287, 308–314. [Google Scholar] [CrossRef]

- Sarabandi, K.; Jafari, S.M.; Mahoonak, A.S.; Mohammadi, A. Application of Gum Arabic and Maltodextrin for Encapsulation of Eggplant Peel Extract as a Natural Antioxidant and Color Source. Int. J. Biol. Macromol. 2019, 140, 59–68. [Google Scholar] [CrossRef] [PubMed]

| Samples | a* | b* | L* | h | Chroma |

|---|---|---|---|---|---|

| GA | 42.2 ± 1.6 a | 2.6 ± 0.2 a | 55.0 ± 1.8 b | 3.6 ± 0.2 a | 42.3 ± 1.6 a |

| MD:GA | 45.9 ± 0.4 b | 3.8 ± 0.3 b | 52.7 ± 2.5 b | 4.7 ± 0.3 b | 46.0 ± 0.4 b |

| MD | 45.6 ± 0.5 b | 6.1 ± 0.1 c | 47.5 ± 0.2 a | 7.6 ± 0.1 c | 46.0 ± 0.5 b |

| Samples | Total Polyphenols Content (mg GAE.g−1) | Total Polyphenols Recovery (%) | Total Monomeric Anthocyanins (mg C3G.g−1) | Total Monomeric Anthocyanins Recovery (%) | DPPH Scavenging Activity (mg GAE.g−1) |

|---|---|---|---|---|---|

| GA | 5.17 ± 0.04 c | 81.5 ± 2.8 a | 0.70 ± 0.05 c | 80.8 ± 3.2 b | 2.14 ± 0.02 c |

| MD:GA | 5.70 ± 0.09 b | 87.2 ± 1.1 b | 0.78 ± 0.03 b | 83.6 ± 3.6 b | 2.49 ± 0.02 b |

| MD | 5.40 ± 0.03 a | 81.5 ± 0.5 a | 0.88 ± 0.02 a | 96.3 ± 1.7 a | 2.41 ± 0.02 a |

| Samples | Water Activity (aw) | Moisture Content (%) | Water Solubility (%) |

|---|---|---|---|

| GA | 0.30 ± 0.01 a | 4.7 ± 0.3 b | 96.4 ± 1.0 a,b |

| MD:GA | 0.29 ± 0.01 a | 5.1 ± 0.2 a,b | 96.7 ± 1.0 b |

| MD | 0.28 ± 0.02 a | 5.4 ± 0.3 a | 95.0 ± 0.3 a |

| Samples | Bulk Density (kg.m−3) | Tapped Density (kg.m−3) | Hausner Index | Carr Index (%) | Angle of Repose (°) |

|---|---|---|---|---|---|

| GA | 329 ± 5.2 a | 404 ± 23 b | 1.2 ± 0.06 a | 16.3 ± 4.5 a | 34.5 ± 2.7 c |

| MD:GA | 323 ± 15 a | 389 ± 11 ab | 1.1 ± 0.04 a | 13.6 ± 2.9 a | 29.2 ± 3.3 b |

| MD | 302 ± 24 a | 353 ± 17 a | 1.2 ± 0.10 a | 17.6 ± 3.0 a | 22.9 ± 0.4 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estupiñan-Amaya, M.; Fuenmayor, C.A.; López-Córdoba, A. Exploring the Potential of Wild Andean Blueberries for Powdered Juice Production through Spray Drying. Foods 2023, 12, 2348. https://doi.org/10.3390/foods12122348

Estupiñan-Amaya M, Fuenmayor CA, López-Córdoba A. Exploring the Potential of Wild Andean Blueberries for Powdered Juice Production through Spray Drying. Foods. 2023; 12(12):2348. https://doi.org/10.3390/foods12122348

Chicago/Turabian StyleEstupiñan-Amaya, Mauren, Carlos Alberto Fuenmayor, and Alex López-Córdoba. 2023. "Exploring the Potential of Wild Andean Blueberries for Powdered Juice Production through Spray Drying" Foods 12, no. 12: 2348. https://doi.org/10.3390/foods12122348

APA StyleEstupiñan-Amaya, M., Fuenmayor, C. A., & López-Córdoba, A. (2023). Exploring the Potential of Wild Andean Blueberries for Powdered Juice Production through Spray Drying. Foods, 12(12), 2348. https://doi.org/10.3390/foods12122348