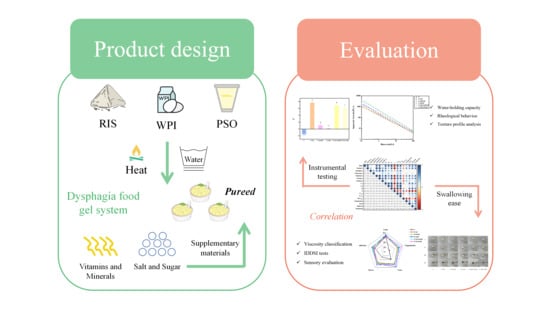

Rheology, Texture and Swallowing Characteristics of a Texture-Modified Dysphagia Food Prepared Using Common Supplementary Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Sample Preparation

2.2.1. The Design of a Simple Dysphagia Food System

2.2.2. The Design of the Dysphagia Food Bolus with Supplementary Materials

2.3. Water-Holding Capacity (WHC)

2.4. IDDSI Test Methods

2.5. Rheological Characterization

2.5.1. Steady-State Viscous Flow Tests

2.5.2. Small Amplitude Oscillatory Shear Tests

2.6. Back Extrusion Test for Swallowing the Food Bolus

2.7. Structural Characteristics Tests

2.7.1. Scanning Electron Microscopy (SEM)

2.7.2. X-ray Diffraction (XRD) Analysis

2.7.3. Confocal Laser Scanning Microscopy (CLSM)

2.8. Color Measurements

2.9. Sensory Evaluation

2.10. Statistical Analysis

3. Results

3.1. Construction of the Dysphagia Food System

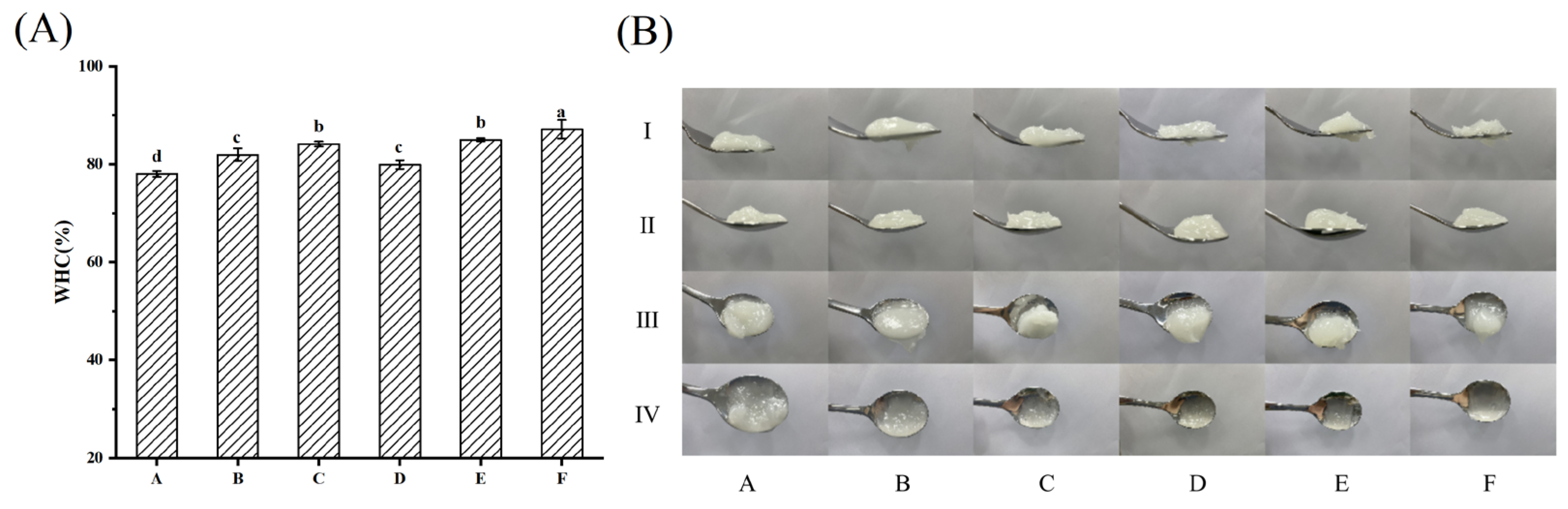

3.1.1. WHC and IDDSI Level of the Dysphagia Food System

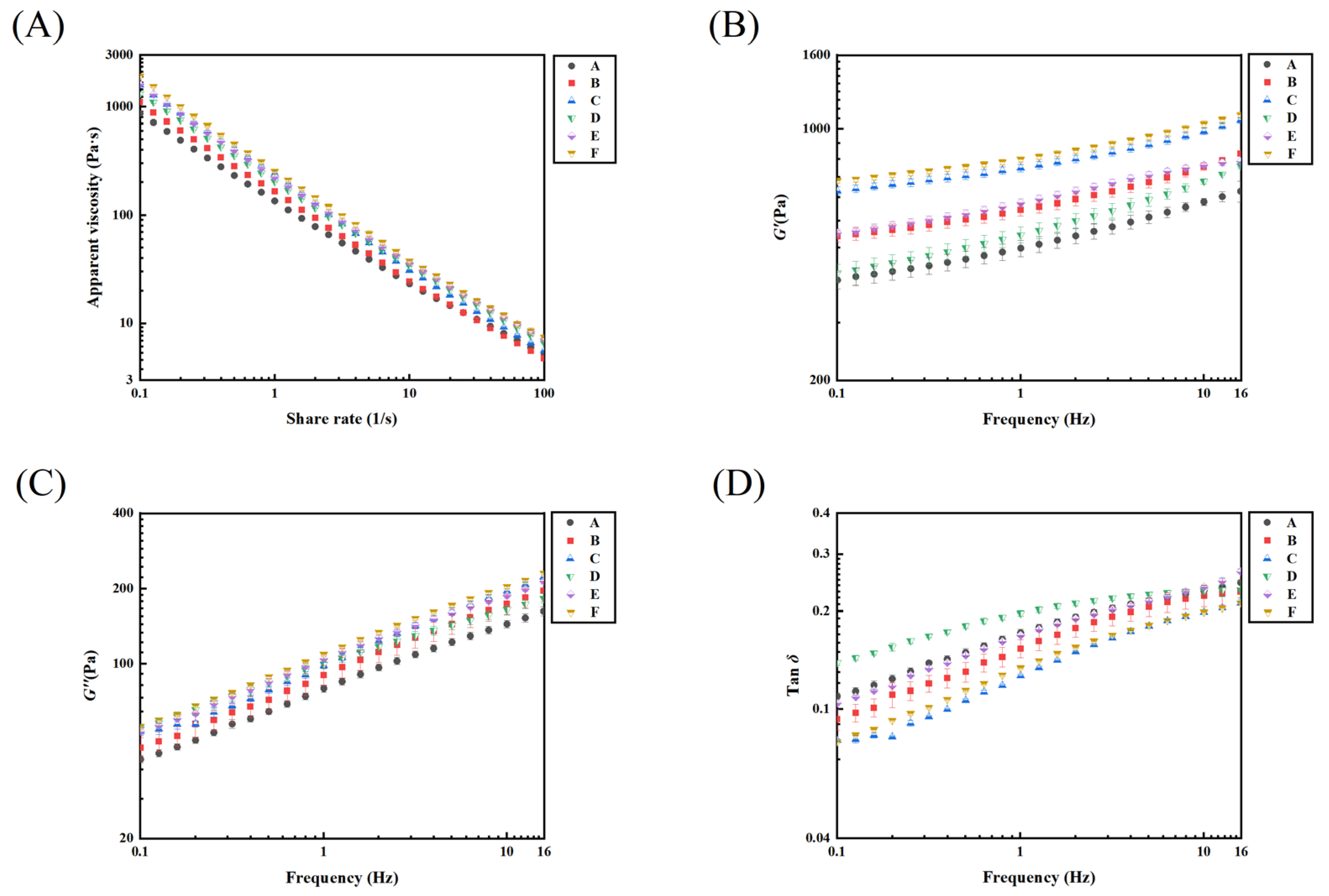

3.1.2. Rheological Properties

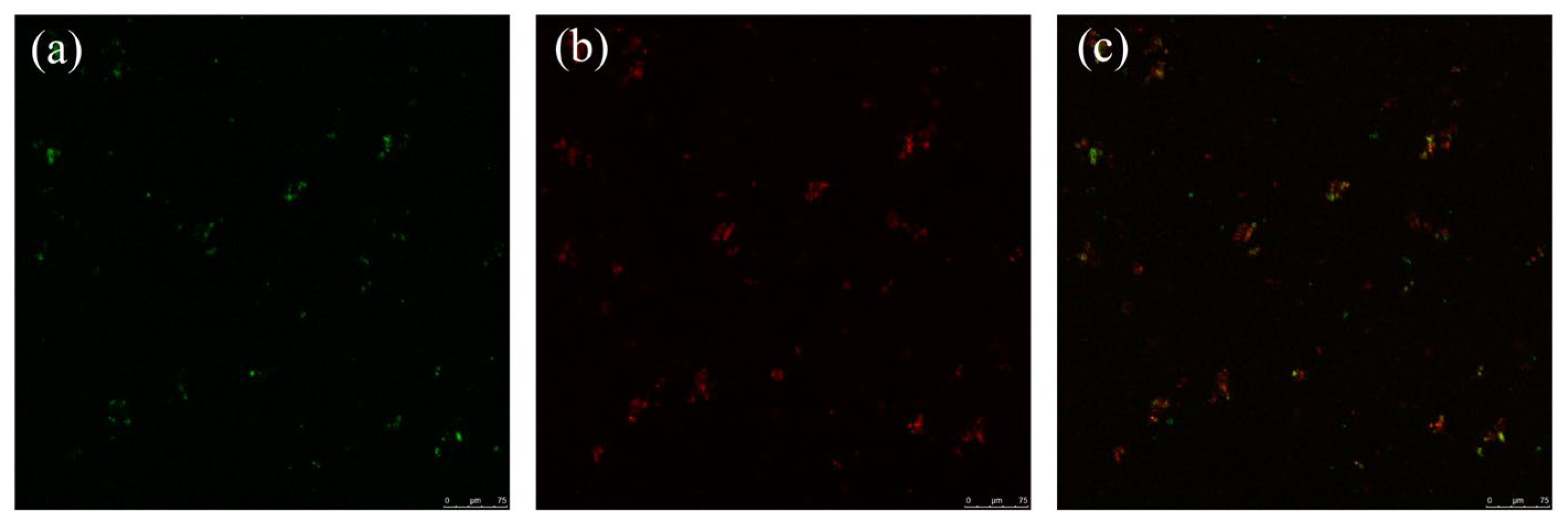

3.1.3. The CLSM of the Food Bolus

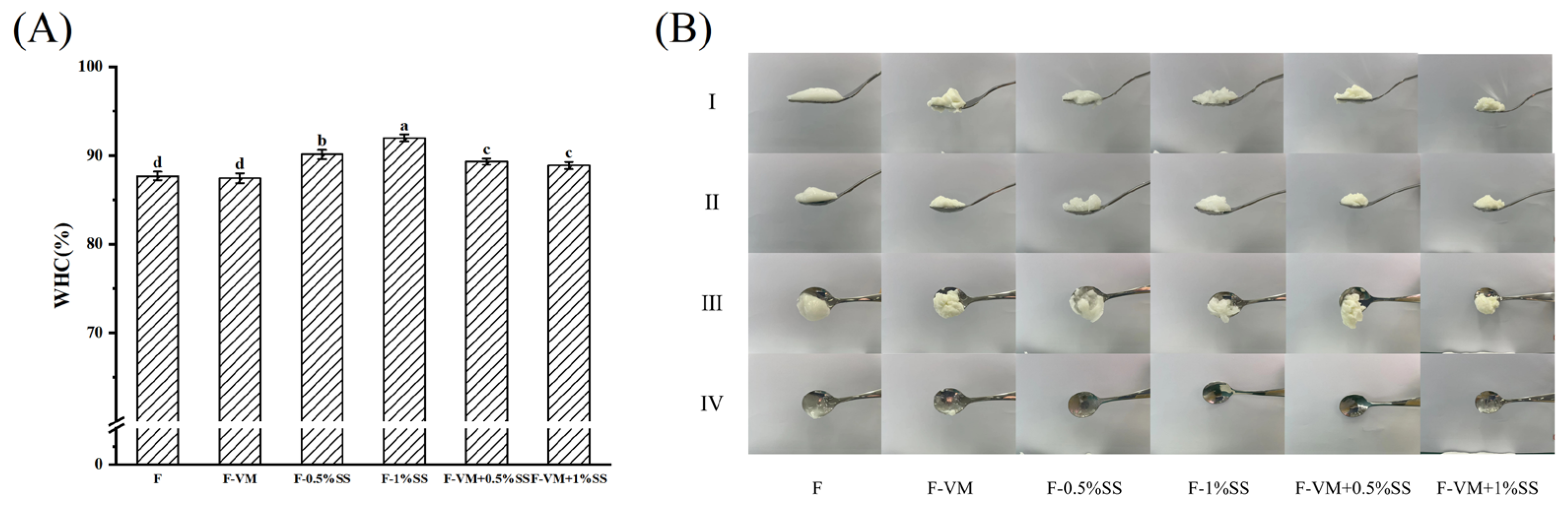

3.2. Effects of Supplementary Materials on the WHC of the Food Bolus

3.3. Classification of the Dysphagia Food Bolus with Supplementary Materials

3.4. Rheological Analysis of the Effects of Supplementary Materials on the Food Bolus

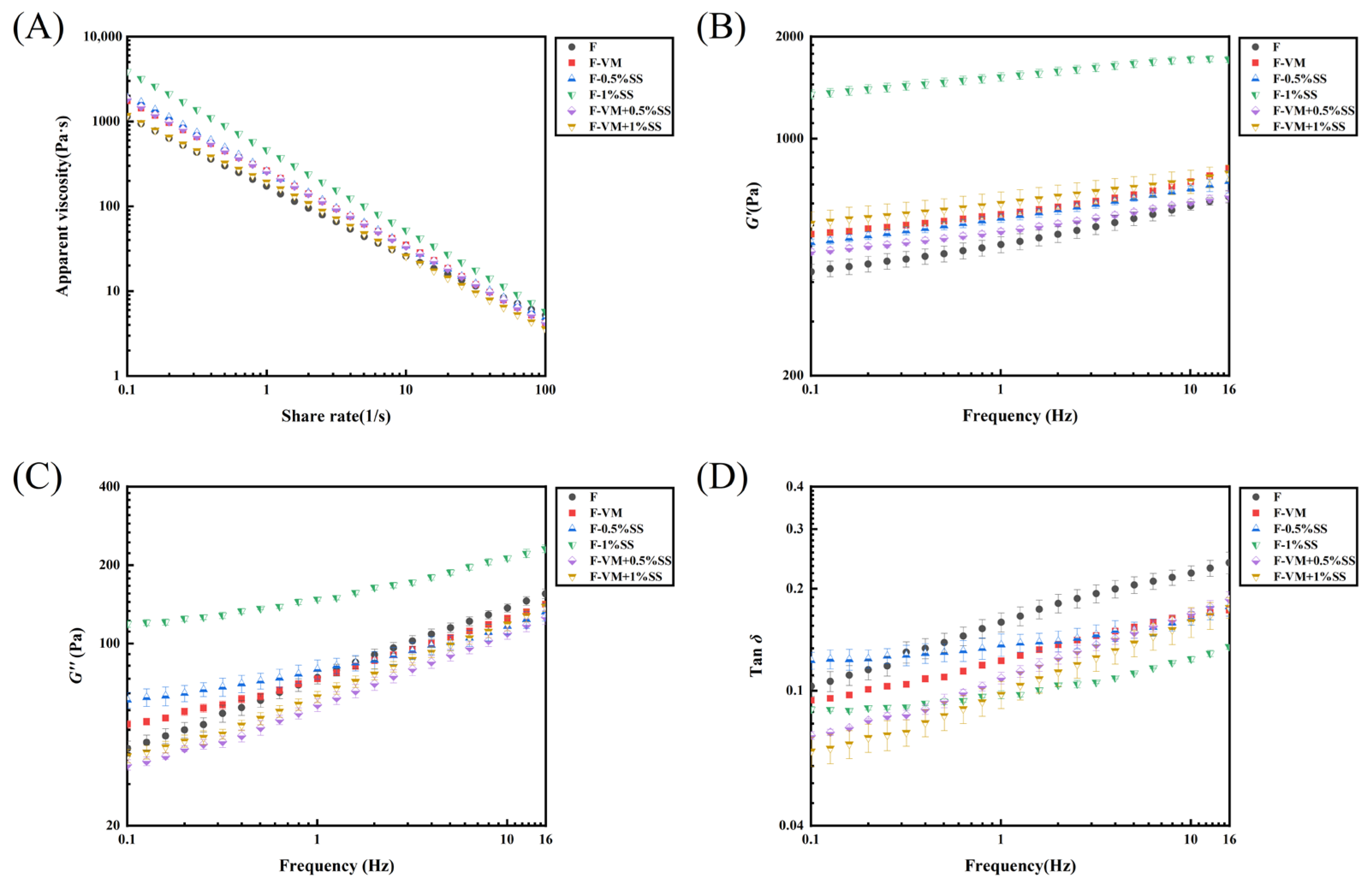

3.4.1. Flow Rheological Properties of the Food Bolus with Supplementary Materials

3.4.2. Viscoelastic Properties of Food Boluses with Supplementary Materials

3.5. Effects of Supplementary Materials on the Mechanical Properties of the Food Bolus

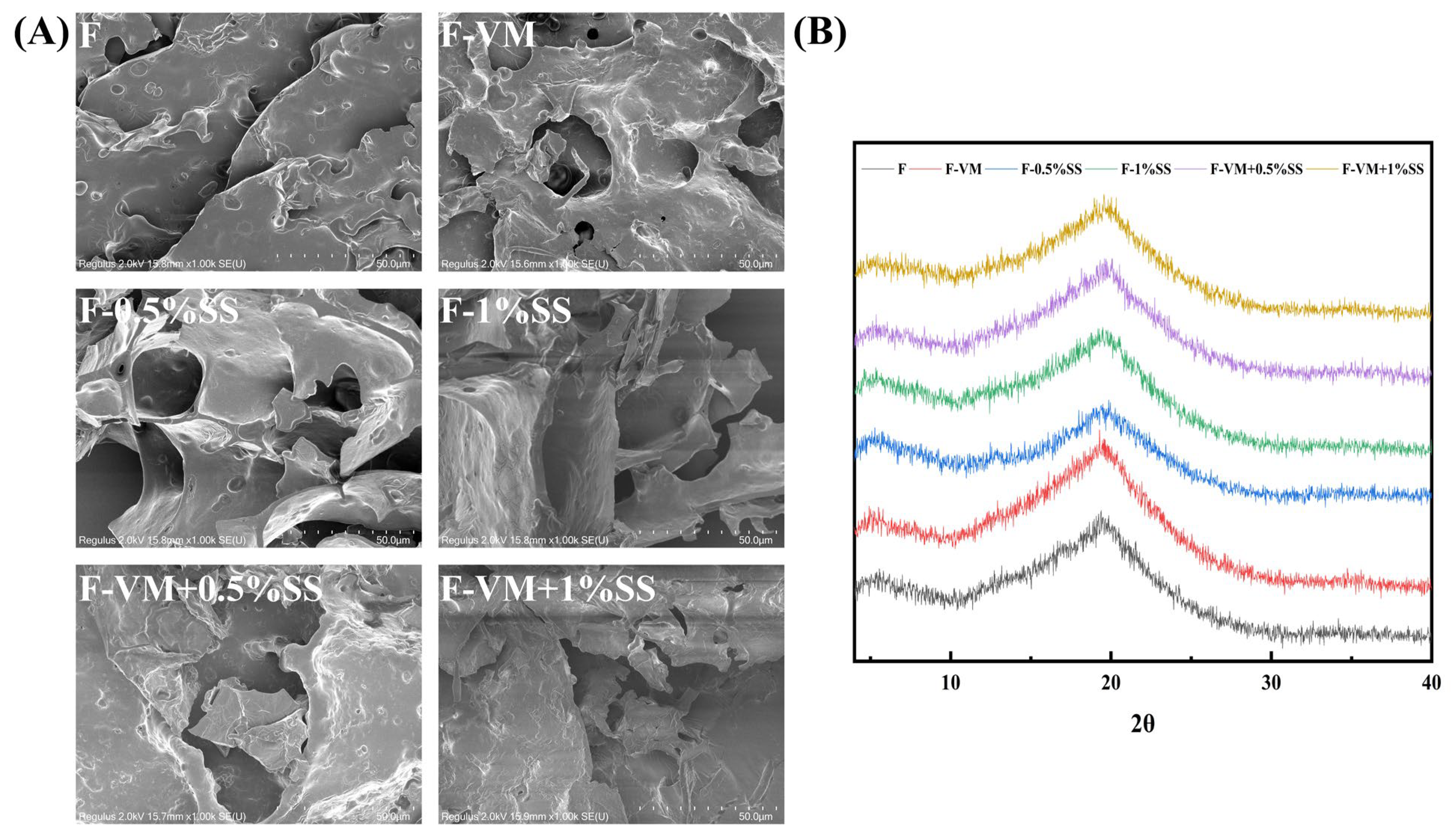

3.6. Effects of Supplementary Materials on the Microstructure the Food Bolus

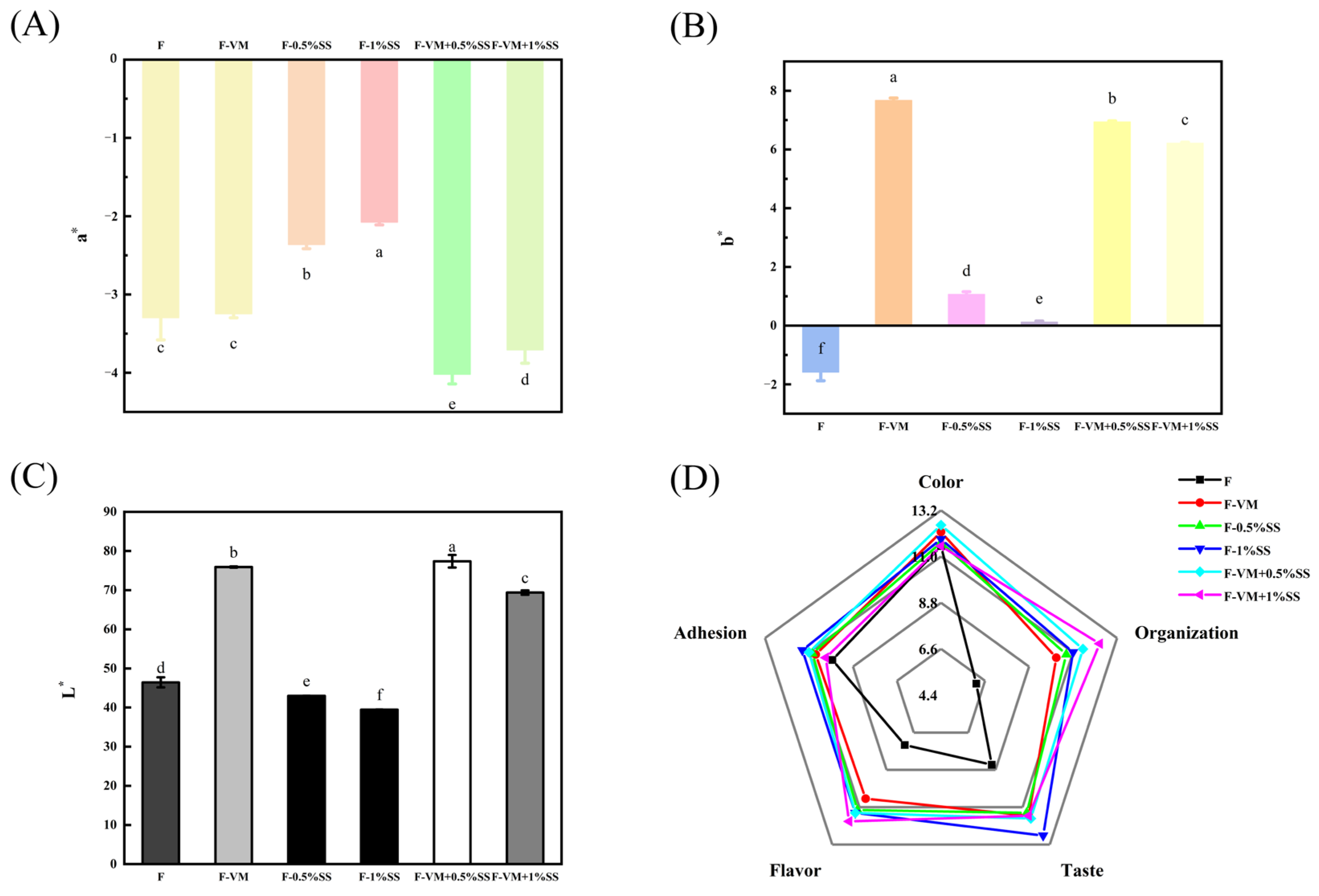

3.7. Effects of Supplementary Materials on the Color Properties of the Food Bolus

3.8. Sensory Evaluation

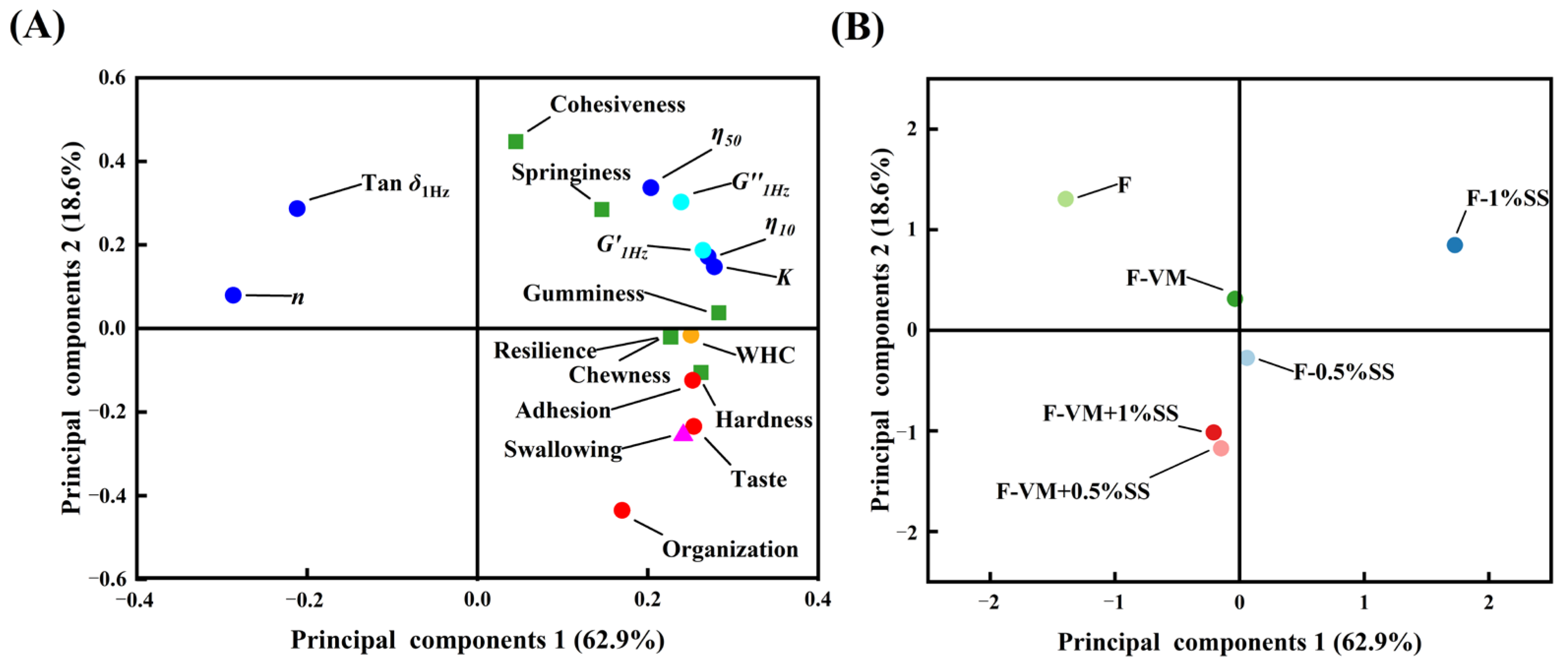

3.9. Relationship between Rheology, Texture and Sense

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Marconati, M.; Engmann, J.; Burbidge, A.S.; Mathieu, V.; Souchon, I.; Ramaioli, M. A review of the approaches to predict the ease of swallowing and post swallow residues. Trends Food Sci. Technol. 2019, 86, 281–297. [Google Scholar] [CrossRef]

- Andersen, U.T.; Beck, A.M.; Kjaersgaard, A.; Hansen, T.; Poulsen, I. Systematic review and evidence based recommendations on texture modified foods and thickened fluids for adults (≥18 years) with oropharyngeal dysphagia. e-SPEN J. 2013, 8, e127–e134. [Google Scholar] [CrossRef]

- Kou, W.; Pandolfino, J.E.; Kahrilas, P.J.; Patankar, N.A. Simulation studies of the role of esophageal mucosa in bolus transport. Biomech. Model. Mechanobiol. 2017, 16, 1001–1009. [Google Scholar] [CrossRef] [PubMed]

- Pant, A.; Lee, A.Y.; Karyappa, R.; Lee, C.P.; An, J.; Hashimoto, M.; Tan, U.-X.; Wong, G.; Chua, C.K.; Zhang, Y. 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Cosentino, G.; Todisco, M.; Giudice, C.; Tassorelli, C.; Alfonsi, E. Anodal transcranial direct current stimulation and intermittent theta-burst stimulation improve deglutition and swallowing reproducibility in elderly patients with dysphagia. Neurogastroenterol. Motil. 2020, 32, e13791. [Google Scholar] [CrossRef] [PubMed]

- Herranz, B.; Criado, C.; Pozo-Bayon, M.A.; Alvarez, M.D. Effect of addition of human saliva on steady and viscoelastic rheological properties of some commercial dysphagia-oriented products. Food Hydrocoll. 2021, 111, 106403. [Google Scholar] [CrossRef]

- Ueshima, J.; Momosaki, R.; Shimizu, A.; Motokawa, K.; Sonoi, M.; Shirai, Y.; Uno, C.; Kokura, Y.; Shimizu, M.; Nishiyama, A.; et al. Nutritional assessment in adult patients with dysphagia: A scoping review. Nutrients 2021, 13, 778. [Google Scholar] [CrossRef]

- Cichero, J.A.Y. Adjustment of food textural properties for elderly patients. J. Texture Stud. 2016, 47, 277–283. [Google Scholar] [CrossRef] [Green Version]

- Dietsch, A.M.; Pelletier, C.A.; Solomon, N.P. Saliva production and enjoyment of real-food flavors in people with and without dysphagia and/or xerostomia. Dysphagia 2018, 33, 803–808. [Google Scholar] [CrossRef] [Green Version]

- Tokifuji, A.; Matsushima, Y.; Hachisuka, K.; Yoshioka, K. Texture, sensory and swallowing characteristics of high-pressure-heat-treated pork meat gel as a dysphagia diet. Meat Sci. 2013, 93, 843–848. [Google Scholar] [CrossRef]

- Pematilleke, N.; Kaur, M.; Adhikari, B.; Torley, P.J. Investigation of the effects of addition of carboxy methyl cellulose (CMC) and tapioca starch (TS) on the beef patties targeted to the needs of people with dysphagia: A mixture design approach. Meat Sci. 2022, 191, 108868. [Google Scholar] [CrossRef] [PubMed]

- Strother, H.; Moss, R.; McSweeney, M.B. Comparison of 3D printed and molded carrots produced with gelatin, guar gum and xanthan gum. J. Texture Stud. 2020, 51, 852–860. [Google Scholar] [CrossRef] [PubMed]

- Cichero, J.A.Y.; Lam, P.T.; Chen, J.; Dantas, R.O.; Duivestein, J.; Hanson, B.; Kayashita, J.; Pillay, M.; Riquelme, L.F.; Steele, C.M.; et al. Release of updated International Dysphagia Diet Standardisation Initiative Framework (IDDSI 2.0). J. Texture Stud. 2020, 51, 195–196. [Google Scholar] [CrossRef] [PubMed]

- Cichero, J.A.Y.; Lam, P.; Steele, C.M.; Hanson, B.; Chen, J.; Dantas, R.O.; Duivestein, J.; Kayashita, J.; Lecko, C.; Murray, J.; et al. Development of international terminology and definitions for texture-modified foods and thickened fluids used in dysphagia management: The IDDSI Framework. Dysphagia 2017, 32, 293–314. [Google Scholar] [CrossRef] [Green Version]

- Min, C.; Yang, Q.; Pu, H.; Cao, Y.; Ma, W.; Kuang, J.; Huang, J.; Xiong, Y.L. Textural characterization of calcium salts-induced mung bean starch-flaxseed protein composite gels as dysphagia food. Food Res. Int. 2023, 164, 112355. [Google Scholar] [CrossRef]

- Xie, Y.S.; Zhao, W.Y.; Yu, W.Y.; Lin, X.Y.; Tao, S.F.; Prakash, S.; Dong, X.P. Validating the textural characteristics of soft fish-based paste through International Dysphagia Diet Standardisation Initiative recommended tests. J. Texture Stud. 2021, 52, 240–250. [Google Scholar] [CrossRef]

- Xing, X.; Chitrakar, B.; Hati, S.; Xie, S.; Li, H.; Li, C.; Liu, Z.; Mo, H. Development of black fungus-based 3D printed foods as dysphagia diet: Effect of gums incorporation. Food Hydrocoll. 2022, 123, 107173. [Google Scholar] [CrossRef]

- Shimizu, A.; Maeda, K.; Tanaka, K.; Ogawa, M.; Kayashita, J. Texture-modified diets are associated with decreased muscle mass in older adults admitted to a rehabilitation ward. Geriatr. Gerontol. Int. 2018, 18, 698–704. [Google Scholar] [CrossRef]

- Shimizu, A.; Momosaki, R.; Kayashita, J.; Fujishima, I. Impact of multiple texture-modified diets on oral intake and nutritional status in older patients with pneumonia: A retrospective cohort study. Dysphagia 2020, 35, 574–582. [Google Scholar] [CrossRef]

- Serra-Prat, M.; Palomera, M.; Gomez, C.; Sar-Shalom, D.; Saiz, A.; Montoya, J.G.; Navajas, M.; Palomera, E.; Clave, P. Oropharyngeal dysphagia as a risk factor for malnutrition and lower respiratory tract infection in independently living older persons: A population-based prospective study. Age Ageing 2012, 41, 376–381. [Google Scholar] [CrossRef] [Green Version]

- Wright, L.; Cotter, D.; Hickson, M.; Frost, G. Comparison of energy and protein intakes of older people consuming a texture modified diet with a normal hospital diet. J. Hum. Nutr. Diet. 2005, 18, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Dhillon, B.; Sodhi, N.S.; Singh, D.; Kaur, A. Analyses of functional diets formulated for dysphagia patients under international dysphagia diet standardization initiative (IDDSI) level 3 to level 7. J. Food Meas. Charact. 2022, 16, 3537–3546. [Google Scholar] [CrossRef]

- Rodd, B.G.; Tas, A.A.; Taylor, K.D.A. Dysphagia, texture modification, the elderly and micronutrient deficiency: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 7354–7369. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Lv, C.; Cui, X.; Yi, F.; Su, C. Study on biological activity of perilla seed oil extracted by supercritical carbon dioxide. LWT-Food Sci. Technol. 2021, 146, 111457. [Google Scholar] [CrossRef]

- Laird, E.J.; O’Halloran, A.M.; Carey, D.; O’Connor, D.; Kenny, R.A.; Molloy, A.M. Voluntary fortification is ineffective to maintain the vitamin B-12 and folate status of older Irish adults: Evidence from the Irish Longitudinal Study on Ageing (TILDA). Br. J. Nutr. 2018, 120, 111–120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wirth, R.; Smoliner, C.; Jager, M.; Warnecke, T.; Leischker, A.H.; Dziewas, R.; Committee, D.S. Guideline clinical nutrition in patients with stroke. Exp. Trans. Stroke Med. 2013, 5, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- The National Health and Family Planning Commission of China. Chinese General Guidelines for Special Medical Use Formulas GB29922-2013. In The National Food Safety Standard Determination; Standards Press of China: Beijing, China, 2013. [Google Scholar]

- Cheng, Y.Y. Introduction to Chinese Dietary Reference Intakes (2013 resived). Nutr. Sci. 2014, 36, 313–317. [Google Scholar]

- Jiang, L.; Ren, Y.M.; Shen, M.Y.; Zhang, J.H.; Yu, Q.; Chen, Y.; Zhang, H.D.; Xie, J.H. Effect of acid/alkali shifting on function, gelation properties, and microstructure of Mesona chinensis polysaccharide-whey protein isolate gels. Food Hydrocoll. 2021, 117, 106699. [Google Scholar] [CrossRef]

- Pematilleke, N.; Kaur, M.; Wai, C.T.R.; Adhikari, B.; Torley, P.J. Effect of the addition of hydrocolloids on beef texture: Targeted to the needs of people with dysphagia. Food Hydrocoll. 2021, 113, 106413. [Google Scholar] [CrossRef]

- Ren, Y.M.; Rong, L.Y.; Shen, M.Y.; Liu, W.M.; Xiao, W.H.; Luo, Y.; Xie, J.H. Interaction between rice starch and Mesona chinensis Benth polysaccharide gels: Pasting and gelling properties. Carbohydr. Polym. 2020, 240, 116316. [Google Scholar] [CrossRef]

- Ren, Y.M.; Wu, Z.H.; Shen, M.Y.; Rong, L.Y.; Liu, W.M.; Xiao, W.H.; Xie, J.H. Improve properties of sweet potato starch film using dual effects: Combination Mesona chinensis Benth polysaccharide and sodium carbonate. LWT-Food Sci. Technol. 2021, 140, 110679. [Google Scholar] [CrossRef]

- Cui, T.; Wu, Y.; Ni, C.; Sun, Y.; Cheng, J. Rheology and texture analysis of gelatin/dialdehyde starch hydrogel carriers for curcumin controlled release. Carbohydr. Polym. 2022, 283, 119154. [Google Scholar] [CrossRef] [PubMed]

- Ribes, S.; Estarriaga, R.; Grau, R.; Talens, P. Physical, sensory, and simulated mastication properties of texture-modified Spanish sauce using different texturing agents. Food Funct. 2021, 12, 8181–8195. [Google Scholar] [CrossRef]

- Zhang, J.H.; Jiang, L.; Yang, J.; Chen, X.X.; Shen, M.Y.; Yu, Q.; Chen, Y.; Xie, J.H. Effect of calcium chloride on heat-induced Mesona chinensis polysaccharide-whey protein isolation gels: Gel properties and interactions. LWT-Food Sci. Technol. 2022, 155, 112907. [Google Scholar] [CrossRef]

- Huang, S.X.; Chi, C.D.; Li, X.X.; Zhang, Y.P.; Chen, L. Understanding the structure, digestibility, texture and flavor attributes of rice noodles complexation with xanthan and dodecyl gallate. Food Hydrocoll. 2022, 127, 107538. [Google Scholar] [CrossRef]

- Ribes, S.; Gallego, M.; Barat, J.M.; Grau, R.; Talens, P. Impact of chia seed mucilage on technological, sensory, and in vitro digestibility properties of a texture-modified puree. J. Funct. Food. 2022, 89, 104943. [Google Scholar] [CrossRef]

- The National Standardization Administration of China. Sensory evaluation GB/T 10220-2012. In National Standards of the People’s Republic of China; Standards Press of China: Beijing, China, 2012. [Google Scholar]

- Min, C.; Ma, W.H.; Kuang, J.W.; Huang, J.R.; Xiong, Y.L.L. Textural properties, microstructure and digestibility of mungbean starch-flaxseed protein composite gels. Food Hydrocoll. 2022, 126, 107482. [Google Scholar] [CrossRef]

- Guan, Y.; Zhao, G.; Thaiudom, S. Evaluation of the physico-chemical properties of potato starch-based foods and their interactions with milk protein and soybean oil. Food Chem. X 2022, 16, 110495. [Google Scholar] [CrossRef]

- Ong, J.J.X.; Steele, C.M.; Duizer, L.M. Challenges to assumptions regarding oral shear rate during oral processing and swallowing based on sensory testing with thickened liquids. Food Hydrocoll. 2018, 84, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Zhang, M.; Mujumdar, A.S.; Li, J. Feasibility of hydrocolloid addition for 3D printing of Qingtuan with red bean filling as a dysphagia food. Food Res. Int. 2023, 165, 112469. [Google Scholar] [CrossRef]

- Dafiah, P.M.; Swapna, N. Variations in the amplitude and duration of hyolaryngeal elevation during swallow: Effect of sour and carbonated liquid bolus. Physiol. Behav. 2020, 224, 113028. [Google Scholar] [CrossRef] [PubMed]

- Li, J.H.; Li, X.; Wang, C.Y.; Zhang, M.Q.; Xu, Y.L.; Zhou, B.; Su, Y.J.; Yang, Y.J. Characteristics of gelling and water holding properties of hen egg white/yolk gel with NaCl addition. Food Hydrocoll. 2018, 77, 887–893. [Google Scholar] [CrossRef]

- Khemakhem, M.; Attia, H.; Ayadi, M.A. The effect of pH, sucrose, salt and hydrocolloid gums on the gelling properties and water holding capacity of egg white gel. Food Hydrocoll. 2019, 87, 11–19. [Google Scholar] [CrossRef]

- Cutler, A.N.; Morris, E.R.; Taylor, L.J. Oral perception of viscosity in fluid foods and model systems. J. Texture Stud. 1983, 14, 377–395. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Y.; Xu, Z.; Pan, W.; Shen, M.; Han, J.; Sun, X.; Zhang, Y.; Xie, J.; Zhang, X.; et al. Cross-linked corn bran arabinoxylan improves the pasting, rheological, gelling properties of corn starch and reduces its in vitro digestibility. Food Hydrocoll. 2022, 126, 107440. [Google Scholar] [CrossRef]

- Gallegos, C.; Quinchia, L.; Ascanio, G.; Salinas-Vázquez, M.; Brito-de la Fuente, E. Rheology and dysphagia: An overview. Annu. Trans. Nord. Rheol. Soc. 2012, 20, 3–10. [Google Scholar]

- National Dysphagia Diet Task Force and American Dietetic Association. National Dysphagia Diet: Standardization for Optimal Care; American Dietetic Association: Chicago, IL, USA, 2002. [Google Scholar]

- Contreras-Jimenez, B.; Vazquez-Contreras, G.; Cornejo-Villegas, M.D.; del Real-Lopez, A.; Rodriguez-Garcia, M.E. Structural, morphological, chemical, vibrational, pasting, rheological, and thermal characterization of isolated jicama (Pachyrhizus spp.) starch and jicama starch added with Ca(OH)(2). Food Chem. 2019, 283, 83–91. [Google Scholar] [CrossRef]

- Hadde, E.K.; Nicholson, T.M.; Cichero, J.A.Y.; Deblauwe, C. Rheological characterisation of thickened milk components (protein, lactose and minerals). J. Food Eng. 2015, 166, 263–267. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, M.Y.; Han, X.Y.; Wen, H.L.; Xie, J.H. Gelation characteristics of Mesona chinensis polysaccharide-maize starches gels: Influences of KCl and NaCl. J. Cereal Sci. 2020, 96, 103108. [Google Scholar] [CrossRef]

- Cornejo-Villegas, M.D.; Rincon-Londono, N.; Del Real-Lopez, A.; Rodriguez-Garcia, M.E. The effect of Ca2+ ions on the pasting, morphological, structural, vibrational, and mechanical properties of corn starch-water system. J. Cereal Sci. 2018, 79, 174–182. [Google Scholar] [CrossRef]

- Hayakawa, F.; Kazami, Y.; Ishihara, S.; Nakao, S.; Nakauma, M.; Funami, T.; Nishinari, K.; Kohyama, K. Characterization of eating difficulty by sensory evaluation of hydrocolloid gels. Food Hydrocoll. 2014, 38, 95–103. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, M.Q.; Chang, C.H.; Gu, L.P.; Peng, N.; Su, Y.J.; Yang, Y.J. Molecular forces and gelling properties of heat-set whole chicken egg protein gel as affected by NaCl or pH. Food Chem. 2018, 261, 36–41. [Google Scholar] [CrossRef] [PubMed]

- Mirzaaghaei, M.; Nasirpour, A.; Keramat, J.; Goli, S.A.H.; Dinari, M.; Desobry, S.; Durand, A. Chemical modification of waxy maize starch by esterification with saturated fatty acid chlorides: Synthesis, physicochemical and emulsifying properties. Food Chem. 2022, 393, 133293. [Google Scholar] [CrossRef]

- Luan, H. Exploration of the Characterization Method of Starch Crystal Structure by XRD. Master’s Thesis, Tianjin University of Science and Technology, Tianjin, China, 2020. [Google Scholar]

- Geng, M.; Feng, X.; Wu, X.; Tan, X.; Liu, Z.; Li, L.; Huang, Y.; Teng, F.; Li, Y. Encapsulating vitamins C and E using food-grade soy protein isolate and pectin particles as carrier: Insights on the vitamin additive antioxidant effects. Food Chem. 2023, 418, 135955. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M.; Vieira, J. Particle size distribution and compositional effects on textural properties and appearance of dark chocolates. J. Food Eng. 2008, 87, 181–190. [Google Scholar] [CrossRef]

- Belorio, M.; Marcondes, G.; Gomez, M. Influence of psyllium versus xanthan gum in starch properties. Food Hydrocoll. 2020, 105, 105843. [Google Scholar] [CrossRef]

- Bai, J.; Dong, M.X.; Li, J.Y.; Tian, L.J.; Xiong, D.D.; Jia, J.; Yang, L.; Liu, X.B.; Duan, X. Effects of egg white on physicochemical and functional characteristics of steamed cold noodles (a wheat starch gel food). LWT-Food Sci. Technol. 2022, 169, 114057. [Google Scholar] [CrossRef]

- Ribes, S.; Grau, R.; Talens, P. Use of chia seed mucilage as a texturing agent: Effect on instrumental and sensory properties of texture-modified soups. Food Hydrocoll. 2022, 123, 107171. [Google Scholar] [CrossRef]

| Dysphagia Food | PSO | RIS | WPI |

|---|---|---|---|

| A | 15% | 60% | 25% |

| B | 65% | 20% | |

| C | 70% | 15% | |

| D | 10% | 60% | 30% |

| E | 65% | 25% | |

| F | 70% | 20% |

| Supplementary Materials | GB 29922-2013 for People over 10 Years of Age Special Medical Food Requirements for Nutrients/100 kJ | Nutrient Contents in Mixed Vitamins and Mixed Minerals/g | Additional Contents in Food Bolus | |

|---|---|---|---|---|

| Mixed minerals | Mg (mg) | ≥4.4 | 130 | 1% |

| Fe (mg) | 0.20–0.55 | 9.5 | ||

| Zn (mg) | 0.1–0.5 | 6 | ||

| Ca (mg) | ≥13 | 260 | ||

| P (mg) | ≥9.6 | 189 | ||

| Mixed vitamins | VA (μg) | 9.3–53.8 | 3376 | 0.20% |

| VB1 (mg) | ≥0.02 | 3.906 | ||

| VB2 (mg) | ≥0.02 | 3.9 | ||

| VB6 (mg) | ≥0.02 | 3.91 | ||

| VB12 (μg) | ≥0.03 | 9.8 | ||

| VC (mg) | ≥1.3 | 525 | ||

| VD (μg) | 0.19–0.75 | 4.075 | ||

| VE (mg) | ≥0.19 | 36 | ||

| Nicotinic acid (mg) | ≥0.05 | 62.5 | ||

| Folic acid (μg) | ≥5.3 | 1300 | ||

| Pantothenic acid (mg) | ≥0.07 | 12.512 | ||

| Salt | ≤5.0 g/d | 0.5%, 1% | ||

| Sugar | ≤10.0 g/d | 0.5%, 1% | ||

| Dysphagia Food | RIS:WPI:PSO | Mixed Minerals | Mixed Vitamins | Salt | Sugar |

|---|---|---|---|---|---|

| F | 70%:20%:10% | - | - | - | - |

| F-VM | 1% | 0.2% | - | - | |

| F-0.5%SS | - | - | 0.5% | 0.5% | |

| F-1%SS | - | - | 1% | 1% | |

| F-VM + 0.5%SS | 1% | 0.2% | 0.5% | 0.5% | |

| F-VM + 1%SS | 1% | 0.2% | 1% | 1% |

| Criteria | Standard for Evaluation | Score |

|---|---|---|

| Color | Not uniform | 0–6 |

| Generally uniform | 7–11 | |

| Very uniform | 12–16 | |

| Organization | Loose structure, poor elasticity and chewiness. | 0–6 |

| Tight structure, normal elasticity and chewiness | 7–11 | |

| Tight structure, good elasticity and chewiness | 12–16 | |

| Taste | Poor taste and hard texture | 0–6 |

| Average taste and soft texture | 7–11 | |

| Good taste and soft texture | 12–16 | |

| Flavor | Strange smell and unacceptable | 0–6 |

| Light smell and acceptable | 7–11 | |

| Good smell and very acceptable | 12–16 | |

| Adhesion | More oral residue after swallowing | 0–6 |

| Less oral residue after swallowing | 7–11 | |

| No residue in oral after swallowing | 12–16 | |

| Swallowing | Hard to swallow | 0–7 |

| Normal to swallow | 8–13 | |

| Easy to swallow | 14–20 |

| Sample | F | F-VM | F-0.5%SS | F-1%SS | F-VM + 0.5%SS | F-VM + 1%SS |

|---|---|---|---|---|---|---|

| Flow Sweep | ||||||

| η0.1 (Pa·s) | 1124 ± 50 c | 1740 ± 45 b | 1857 ± 85 b | 3863 ± 151 a | 1850 ± 53 b | 1155 ± 16 c |

| η1 (Pa·s) | 167.2 ± 10.3 d | 263.6 ± 6.2 b | 257.2 ± 5.2 b | 462.7 ± 14.1 a | 258.2 ± 3.3 b | 192.0 ± 0.8 c |

| η10 (Pa·s) | 26.70 ± 2.02 c | 35.17 ± 0.77 b | 33.87 ± 1.15 b | 52.20 ± 1.47 a | 33.74 ± 0.50 b | 25.75 ± 0.14 c |

| η50 (Pa·s) | 8.437 ± 0.434 b | 7.842 ± 0.238 b | 8.220 ± 0.450 b | 11.39 ± 0.28 a | 7.894 ± 0.155 b | 6.443 ± 0.025 c |

| K (Pa·sn) | 168.9 ± 10.2 c | 247.7 ± 3.5 b | 258.8 ± 9.9 b | 459.2 ± 13.7 a | 249.3 ± 4.8 b | 179.1 ± 2.5 c |

| n (-) | 0.225 ± 0.008 a | 0.130 ± 0.009 c | 0.122 ± 0.005 c | 0.055 ± 0.002 d | 0.125 ± 0.004 c | 0.159 ± 0.005 b |

| R2 (Power law) | 0.988 | 0.981 | 0.992 | 0.970 | 0.962 | 0.982 |

| Frequency Sweep | ||||||

| G′1Hz (Pa) | 487.3 ± 26.7 d | 598.1 ± 12.6 b c | 582.9 ± 4.5 b c | 1521 ± 44 a | 533.1 ± 10.0 c d | 643.7 ± 52.4 b |

| G″1Hz (Pa) | 74.13 ± 4.13 b | 73.31 ± 2.08 b | 79.72 ± 6.72 b | 148.0 ± 2.3 a | 58.20 ± 3.33 c | 62.40 ± 3.06 c |

| Tan δ1Hz (-) | 0.159 ± 0.010 a | 0.123 ± 0.002 b c | 0.137 ± 0.010 b | 0.097 ± 0.003 d | 0.109 ± 0.004 c d | 0.098 ± 0.009 d |

| G′0 | 498.7 ± 22.2 d | 613.2 ± 11.6 b | 587.3 ± 10.5 b c | 1517 ± 41 a | 541.4 ± 9.3 c d | 648.3 ± 50.8 b |

| n′ | 0.094 ± 0.005 a | 0.075 ± 0.001 c | 0.082 ± 0.004 b | 0.055 ± 0.002 e | 0.072 ± 0.003 c | 0.065 ± 0.002 d |

| R2 (Power law) | 0.990 | 0.976 | 0.992 | 0.985 | 0.991 | 0.995 |

| G″0 | 74.80 ± 3.83 b | 75.31 ± 2.16 b | 81.00 ± 5.94 b | 152.0 ± 3.5 a | 58.94 ± 2.88 c | 63.83 ± 3.31 c |

| n″ | 0.251 ± 0.002 b | 0.212 ± 0.002 c | 0.148 ± 0.010 d | 0.134 ± 0.002 e | 0.264 ± 0.007 a | 0.267 ± 0.001 a |

| R2 (Power law) | 0.988 | 0.994 | 0.982 | 0.980 | 0.996 | 0.976 |

| Sample | Hardness (g) | Springiness | Cohesiveness | Gumminess | Chewiness | Resilience |

|---|---|---|---|---|---|---|

| F | 200.9 ± 18.0 c | 0.884 ± 0.010 ab | 0.672 ± 0.053 ab | 134.8 ± 13.1 d | 119.0 ± 10.5 d | 0.136 ± 0.008 c |

| F-VM | 395.7 ± 19.2 b | 0.940 ± 0.010 a | 0.647 ± 0.059 abc | 275.0 ± 18.3 b | 241.3 ± 31.6 bc | 0.261 ± 0.069 ab |

| F-0.5%SS | 534.4 ± 10.8 a | 0.911 ± 0.027 a | 0.556 ± 0.038 c | 308.8 ± 21.0 b | 271.5 ± 31.4 b | 0.204 ± 0.040 abc |

| F-1%SS | 563.5 ± 71.5 a | 0.929 ± 0.032 a | 0.683 ± 0.040 a | 382.0 ± 29.0 a | 354.7 ± 28.5 a | 0.281 ± 0.033 a |

| F-VM + 0.5%SS | 377.0 ± 21.3 b | 0.850 ± 0.037 b | 0.571 ± 0.028 bc | 217.7 ± 2.4 c | 182.5 ± 7.0 c | 0.165 ± 0.035 bc |

| F-VM + 1%SS | 392.4 ± 76.1 b | 0.884 ± 0.026 ab | 0.608 ± 0.033 abc | 206.1 ± 5.3 c | 211.3 ± 44.1 bc | 0.254 ± 0.070 ab |

| Sample | Chroma | Sensory Test | |||

|---|---|---|---|---|---|

| Cab* | hab* | ΔE* | Swallowing | Total Score | |

| F | 4.300 ± 0.654 c | 0.422 ± 0.055 a | - | 11.17 ± 2.27 c | 54.50 ± 3.04 c |

| F-0VM | 8.335 ± 0.068 a | −1.169 ± 0.010 e | 29.84 ± 0.32 b | 11.33 ± 1.11 c | 66.33 ± 4.64 b |

| F-0.5%SS | 2.465 ± 0.052 d | −0.371 ± 0.080 c | 5.325 ± 0.324 e | 13.00 ± 1.41 ab | 68.67 ± 3.77 ab |

| F-1%SS | 2.079 ± 0.033 e | −0.057 ± 0.031 b | 8.364 ± 0.140 d | 15.00 ± 1.63 a | 73.17 ± 2.48 a |

| F-VM + 0.5%SS | 7.999 ± 0.115 a | −1.048 ± 0.015 d | 31.18 ± 1.58 a | 14.17 ± 1.67 a | 72.17 ± 4.74 a |

| F-VM + 1%SS | 7.174 ± 0.065 b | −1.043 ± 0.020 d | 23.11 ± 1.05 c | 13.00 ± 1.15 ab | 70.33 ± 3.59 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Rong, L.; Shen, M.; Yu, Q.; Chen, Y.; Li, J.; Xie, J. Rheology, Texture and Swallowing Characteristics of a Texture-Modified Dysphagia Food Prepared Using Common Supplementary Materials. Foods 2023, 12, 2287. https://doi.org/10.3390/foods12122287

Wang X, Rong L, Shen M, Yu Q, Chen Y, Li J, Xie J. Rheology, Texture and Swallowing Characteristics of a Texture-Modified Dysphagia Food Prepared Using Common Supplementary Materials. Foods. 2023; 12(12):2287. https://doi.org/10.3390/foods12122287

Chicago/Turabian StyleWang, Xin, Liyuan Rong, Mingyue Shen, Qiang Yu, Yi Chen, Jinwang Li, and Jianhua Xie. 2023. "Rheology, Texture and Swallowing Characteristics of a Texture-Modified Dysphagia Food Prepared Using Common Supplementary Materials" Foods 12, no. 12: 2287. https://doi.org/10.3390/foods12122287

APA StyleWang, X., Rong, L., Shen, M., Yu, Q., Chen, Y., Li, J., & Xie, J. (2023). Rheology, Texture and Swallowing Characteristics of a Texture-Modified Dysphagia Food Prepared Using Common Supplementary Materials. Foods, 12(12), 2287. https://doi.org/10.3390/foods12122287