A New Approach for the Development and Optimization of Gluten-Free Noodles Using Flours from Byproducts of Cold-Pressed Okra and Pumpkin Seeds

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Physicochemical Analysis for Pumpkin and Okra Seed Powders and Noodles

2.3. Development and Optimization of Noodle Formulation

Sensory Analysis

2.4. Quality and Cooking Parameters of Noodles

2.4.1. Determination of Optimum Cooking Time, Swelling Power, Water Holding Capacity, and Cooking Lost

2.4.2. Color

2.4.3. Total Phenolic Content (TPC) and Antioxidant Activity

2.4.4. Texture Analysis

2.4.5. Scanning Electron Microscopy

2.5. Statistics

3. Results and Discussion

3.1. Physicochemical Properties and Proximate Composition of Flours

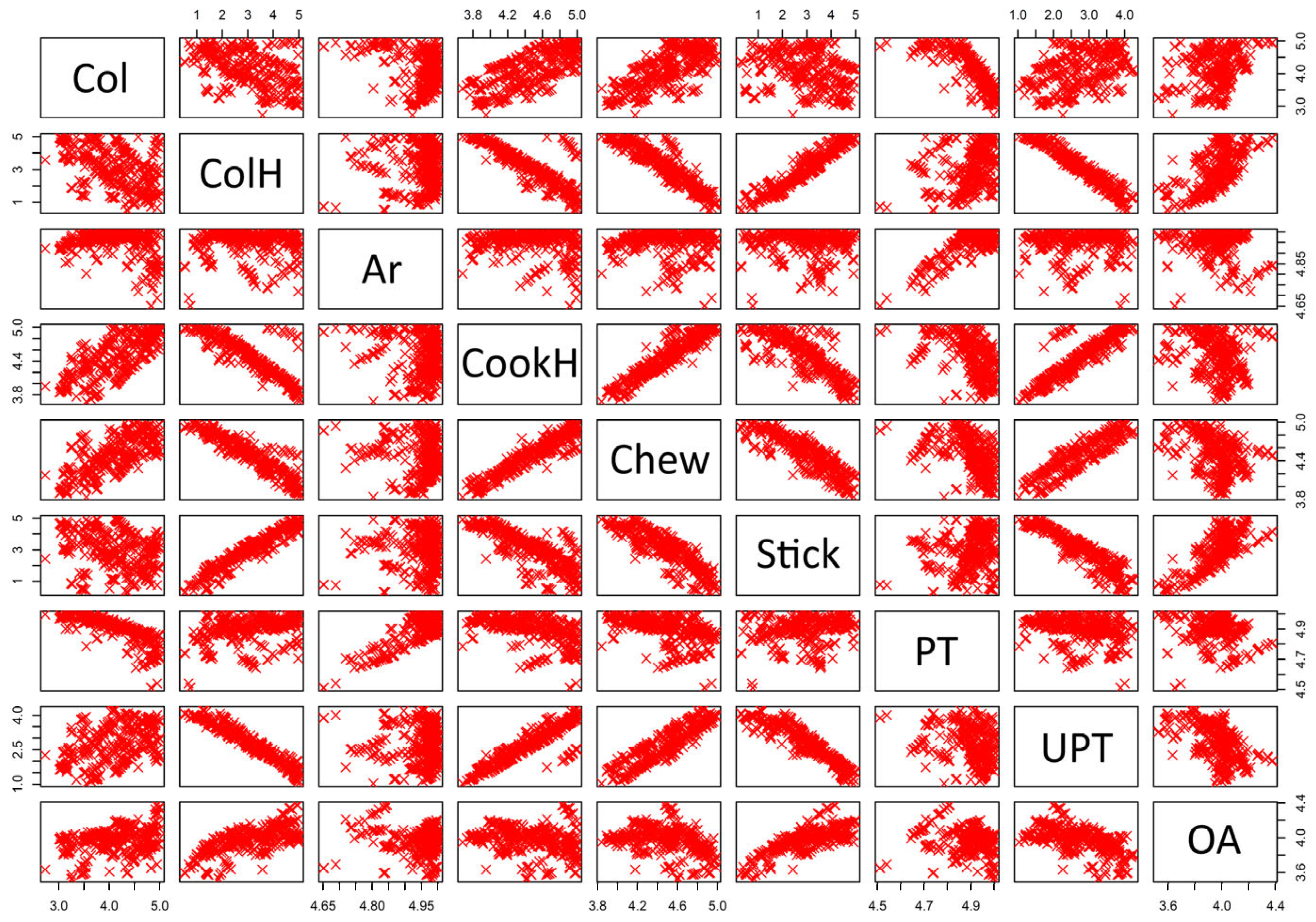

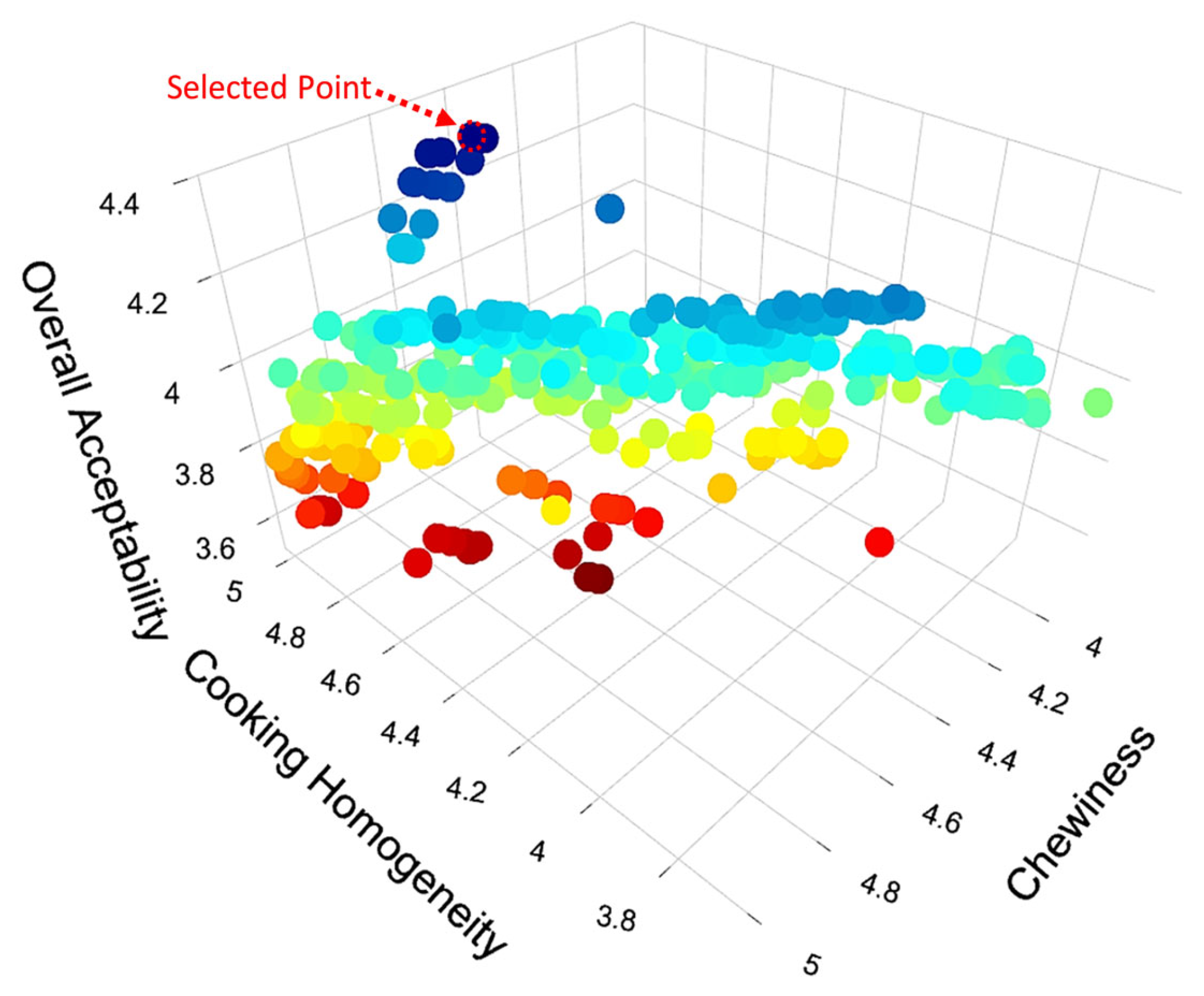

3.2. Development of Noodle Formulation

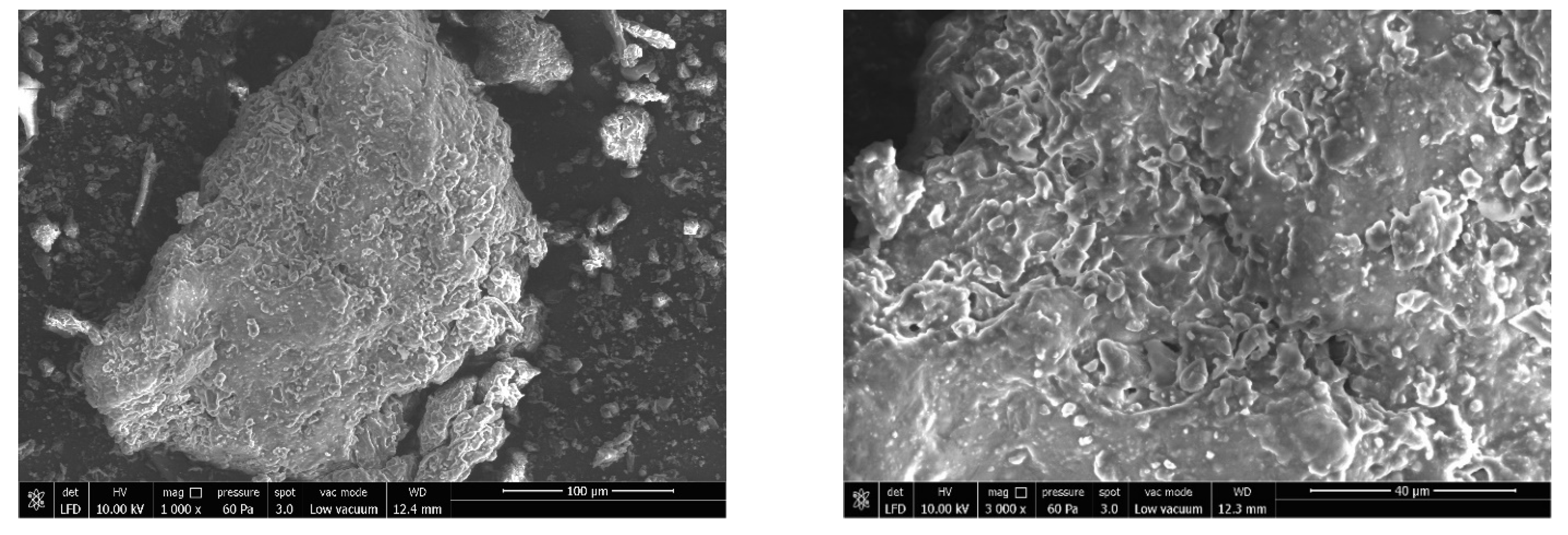

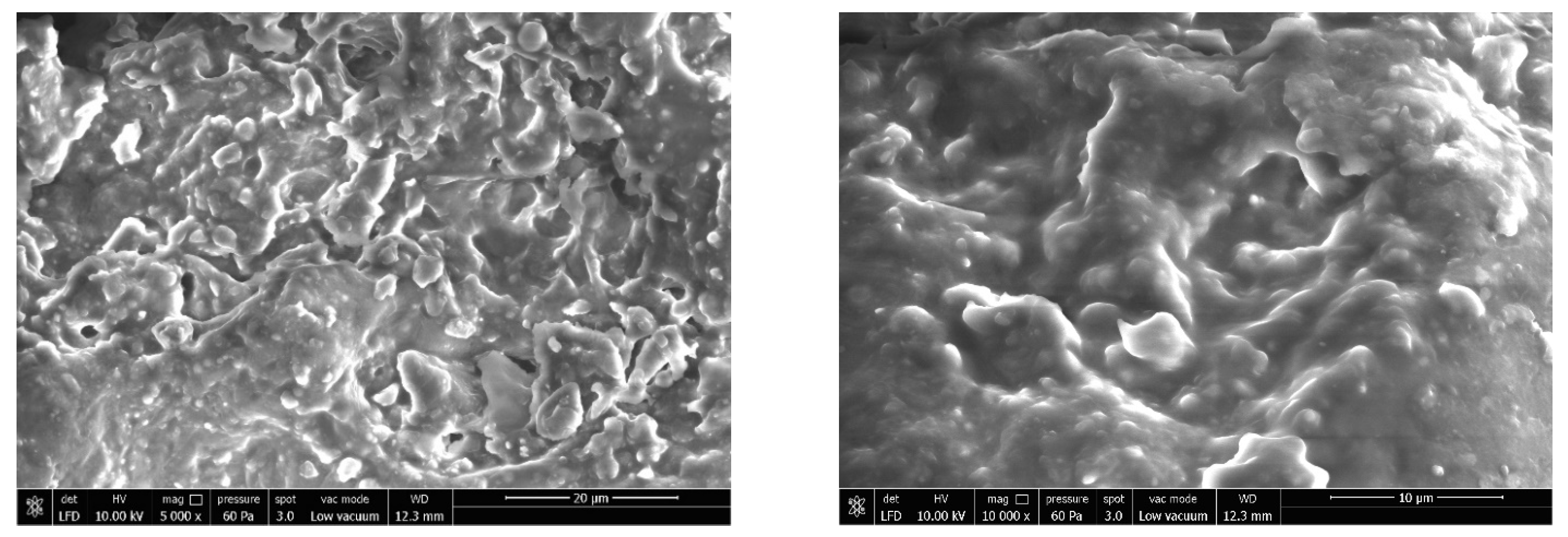

3.3. Physicochemical Properties and Approximate Composition of Noodles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akcicek, A.; Karasu, S. Utilization of cold pressed chia seed oil waste in a low-fat salad dressing as natural fat replacer. J. Food Process. Eng. 2018, 41, e12694. [Google Scholar] [CrossRef]

- Tuna Ağirbaş, H.E.; Yavuz-Düzgün, M.; Özçelik, B. Valorization of fruit seed flours: Rheological characteristics of composite dough and cake quality. J. Food Meas. Charact. 2022, 16, 3117–3129. [Google Scholar] [CrossRef]

- Parry, J.W.; Cheng, Z.; Moore, J.; Yu, L.L. Fatty Acid Composition, Antioxidant Properties, and Antiproliferative Capacity of Selected Cold-Pressed Seed Flours. J. Am. Oil Chem. Soc. 2008, 85, 457–464. [Google Scholar] [CrossRef]

- Pop, C.; Suharoschi, R.; Pop, O.L. Dietary fiber and prebiotic compounds in fruits and vegetables food waste. Sustainability 2021, 13, 7219. [Google Scholar] [CrossRef]

- Koca, I.; Tekguler, B.; Yilmaz, V.A.; Hasbay, I.; Koca, A.F. The use of grape, pomegranate and rosehip seed flours in Turkish noodle (erişte) production. J. Food Process. Preserv. 2018, 42, e13343. [Google Scholar] [CrossRef]

- Heshe, G.G.; Haki, G.D.; Woldegiorgis, A.Z.; Gemede, H.F. Effect of conventional milling on the nutritional value and antioxidant capacity of wheat types common in Ethiopia and a recovery attempt with bran supplementation in bread. Food Sci. Nutr. 2016, 4, 534–543. [Google Scholar] [CrossRef]

- Levent, H.; Koyuncu, M.; Bilgiçli, N.; Adıgüzel, E.; Dedeoğlu, M. Improvement of chemical properties of noodle and pasta using dephytinized cereal brans. LWT 2020, 128, 109470. [Google Scholar] [CrossRef]

- Çabuk, B.; Yılmaz, B. Fortification of traditional egg pasta (erişte) with edible insects: Nutritional quality, cooking properties and sensory characteristics evaluation. J. Food Sci. Technol. 2020, 57, 2750–2757. [Google Scholar] [CrossRef]

- Çalışkan Koç, G.; Pandiselvam, R. Evaluation of Physicochemical, Functional, and Sensorial Characteristics of Gluten-Free Turkish Noodle ‘Erişte’ Formulated with Oat and Quinoa Flours. J. Food Qual. 2022, 2022, 8622114. [Google Scholar] [CrossRef]

- Odabas, E.; Cakmak, H. Partial replacement of starch-based flours with quinoa or yellow lentil flour in the production of gluten-free noodles. J. Food Process. Preserv. 2022, 46, e16776. [Google Scholar] [CrossRef]

- Jnawali, P.; Kumar, V.; Tanwar, B. Celiac disease: Overview and considerations for development of gluten-free foods. Food Sci. Hum. Wellness 2016, 5, 169–176. [Google Scholar] [CrossRef]

- Gasparre, N.; Rosell, C.M. Wheat gluten: A functional protein still challenging to replace in gluten-free cereal-based foods. Cereal Chem. 2023, 100, 243–255. [Google Scholar] [CrossRef]

- Bender, D.; Schönlechner, R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Li, Y.; Gao, J.; Lv, J.; Lambo, M.T.; Wang, Y.; Wang, L.; Zhang, Y. Replacing soybean meal with high-oil pumpkin seed cake in the diet of lactating Holstein dairy cows modulated rumen bacteria and milk fatty acid profile. J. Dairy Sci. 2023, 106, 1803–1814. [Google Scholar] [CrossRef] [PubMed]

- Dotto, J.M.; Chacha, J.S. The potential of pumpkin seeds as a functional food ingredient: A review. Sci. Afr. 2020, 10, e00575. [Google Scholar] [CrossRef]

- Budžaki, S.; Strelec, I.; Krnić, M.; Alilović, K.; Tišma, M.; Zelić, B. Proximate analysis of cold-press oil cakes after biological treatment with Trametes versicolor and Humicola grisea. Eng. Life Sci. 2018, 18, 924–931. [Google Scholar] [CrossRef]

- Sobczak, P.; Zawiślak, K.; Starek, A.; Żukiewicz-Sobczak, W.; Sagan, A.; Zdybel, B.; Andrejko, D. Compaction process as a concept of press-cake production from organic waste. Sustainability 2020, 12, 1567. [Google Scholar] [CrossRef]

- Charaya, A.; Chawla, N.; Dhatt, A.S.; Sharma, M.; Sharma, S.; Kaur, I. Evaluation of biochemical composition of hulled and hull-less genotypes of pumpkin seeds grown in subtropical India. Heliyon 2023, 9, e12995. [Google Scholar] [CrossRef]

- Xu, K.; Guo, M.; Roman, L.; Pico, J.; Martinez, M.M. Okra seed and seedless pod: Comparative study of their phenolics and carbohydrate fractions and their impact on bread-making. Food Chem. 2020, 317, 126387. [Google Scholar] [CrossRef]

- Oyelade, O.J.; Ade-Omowaye, B.I.O.; Adeomi, V.F. Influence of variety on protein, fat contents and some physical characteristics of okra seeds. J. Food Eng. 2003, 57, 111–114. [Google Scholar] [CrossRef]

- Hu, L.; Guo, J.; Zhu, X.; Liu, R.; Wu, T.; Sui, W.; Zhang, M. Effect of steam explosion on nutritional composition and antioxidative activities of okra seed and its application in gluten-free cookies. Food Sci. Nutr. 2020, 8, 4409–4421. [Google Scholar] [CrossRef] [PubMed]

- Marti, A.; Seetharaman, K.; Pagani, M.A. Rheological Approaches Suitable for Investigating Starch and Protein Properties Related to Cooking Quality of Durum Wheat Pasta. J. Food Qual. 2013, 36, 133–138. [Google Scholar] [CrossRef]

- Schoenlechner, R.; Mandala, I.; Kiskini, A.; Kostaropoulos, A.; Berghofer, E. Effect of water, albumen and fat on the quality of gluten-free bread containing amaranth. Int. J. Food Sci. Technol. 2010, 45, 661–669. [Google Scholar] [CrossRef]

- Padalino, L.; Mastromatteo, M.; Sepielli, G.; Del Nobile, M.A. Formulation optimization of gluten-free functional spaghetti based on maize flour and oat bran enriched in β-glucans. Materials 2011, 4, 2119–2135. [Google Scholar] [CrossRef] [PubMed]

- Giménez, M.A.; González, R.J.; Wagner, J.; Torres, R.; Lobo, M.O.; Samman, N.C. Effect of extrusion conditions on physicochemical and sensorial properties of corn-broad beans (Vicia faba) spaghetti type pasta. Food Chem. 2013, 136, 538–545. [Google Scholar] [CrossRef] [PubMed]

- Padalino, L.; Conte, A.; Del Nobile, M.A. Overview on the general approaches to improve gluten-free pasta and bread. Foods 2016, 5, 87. [Google Scholar] [CrossRef]

- Deb, K. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 2, 182–197. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Garcia-Amezquita, L.E.; Serna-Saldívar, S.O.; Welti-Chanes, J. Advances in the functional characterization and extraction processes of dietary fiber. Food Eng. Rev. 2016, 8, 251–271. [Google Scholar] [CrossRef]

- Süfer, Ö. Gluten-free traditional Turkish noodle with Macrolepiota procera mushroom: Functional, textural, thermal and sensory characteristics. Cereal Chem. 2022, 99, 1074–1085. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer: Berlin/Heidelberg, Germany, 2010; Volume 2. [Google Scholar]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An Introduction to Statistical Learning; Springer: Berlin/Heidelberg, Germany, 2013; Volume 112. [Google Scholar]

- Weisberg, S. alr3: Data to Accompany Applied Linear Regression 3rd Edition; Wiley: Minneapolis, MN, USA, 2018; Volume 2. [Google Scholar]

- Barton, K. MuMIn: Multi-Model Inference. 2009. Available online: http://r-forge.r-project.org/projects/mumin/ (accessed on 1 April 2023).

- American Association of Cereal Chemists. 66-50.01 Pasta and noodle cooking quality-firmness. In Approved Methods of Analysis, 11th ed.; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Toor, R.K.; Savage, G.P. Effect of semi-drying on the antioxidant components of tomatoes. Food Chem. 2006, 94, 90–97. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Improvement of the texture and quality of cooked gluten-free pasta. LWT 2016, 70, 96–103. [Google Scholar] [CrossRef]

- Akinoso, R.; Adegoroye, E.O.; Sanusi, M.S. Effects of roasting on physicochemical properties and fatty acids composition of okra seed oil. Meas. Food 2023, 9, 100076. [Google Scholar] [CrossRef]

- Omoniyi, S.A.; Idowu, A.A.A.; Adeola, A. Potential Domestic and Industrial Utilizations of Okra Seed: A Review. Ann. Food Sci. Technol. 2018, 19, 722–730. [Google Scholar]

- Monica, S.J.; John, S.; Madhanagopal, R.; Sivaraj, C.; Khusro, A.; Arumugam, P.; Gajdacs, M.; Lydia, D.E.; Sahibzada, M.U.K.; Alghamdi, S.; et al. Chemical composition of pumpkin (Cucurbita maxima) seeds and its supplemental effect on Indian women with metabolic syndrome. Arab. J. Chem. 2022, 15, 103985. [Google Scholar] [CrossRef]

- Saykova, I.; Tylkowski, B.; Popovici, C.; Peev, G. Extraction of Phenolic and Flavonoid Compounds from Solid Wastes of Grape Seed Oil Production by Cold Pressing. J. Chem. Technol. Metall. 2018, 53, 177–190. [Google Scholar]

- Çakaloğlu, B.; Özyurt, V.H.; Ötleş, S. Cold press in oil extraction. A review. Ukr. Food J. 2018, 7, 640–654. [Google Scholar] [CrossRef]

- Deb, K. Multi-objective Optimisation Using Evolutionary Algorithms: An Introduction. In Multi-Objective Evolutionary Optimisation for Product Design and Manufacturing; Wang, L., Ng, A.H.C., Deb, K., Eds.; Springer: London, UK, 2011; pp. 3–34. [Google Scholar] [CrossRef]

- Cakmak, H.; Mama, M.; Yilmaz, S.M. Determination of the effects of flaxseed (Linum usitatissimum L.) sprouts powder on the gluten-free cupcake quality. J. Food Process. Preserv. 2021, 45, e15435. [Google Scholar] [CrossRef]

- Joshi, M.; Aldred, P.; Panozzo, J.F.; Kasapis, S.; Adhikari, B. Rheological and microstructural characteristics of lentil starch–lentil protein composite pastes and gels. Food Hydrocoll. 2014, 35, 226–237. [Google Scholar] [CrossRef]

- Chandla, N.K.; Saxena, D.C.; Singh, S. Processing and evaluation of heat moisture treated (HMT) amaranth starch noodles; An inclusive comparison with corn starch noodles. J. Cereal Sci. 2017, 75, 306–313. [Google Scholar] [CrossRef]

- Chauhan, A.; Saxena, D.C.; Singh, S. Effect of hydrocolloids on microstructure, texture and quality characteristics of gluten-free pasta. J. Food Meas. Charact. 2017, 11, 1188–1195. [Google Scholar] [CrossRef]

- Bresciani, A.; Giuberti, G.; Cervini, M.; Marti, A. Pasta from yellow lentils: How process affects starch features and pasta quality. Food Chem. 2021, 364, 130387. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Liu, S.X. Evaluation of amaranth flour processing for noodle making. J. Food Process. Preserv. 2021, 45, e15270. [Google Scholar] [CrossRef]

- Del Nobile, M.A.; Baiano, A.; Conte, A.; Mocci, G. Influence of protein content on spaghetti cooking quality. J. Cereal Sci. 2005, 41, 347–356. [Google Scholar] [CrossRef]

- Yao, M.; Li, M.; Dhital, S.; Tian, Y.; Guo, B. Texture and digestion of noodles with varied gluten contents and cooking time: The view from protein matrix and inner structure. Food Chem. 2020, 315, 126230. [Google Scholar] [CrossRef]

- Susanna, S.; Prabhasankar, P. A study on development of Gluten free pasta and its biochemical and immunological validation. LWT-Food Sci. Technol. 2013, 50, 613–621. [Google Scholar] [CrossRef]

- Linares-García, L.; Repo-Carrasco-Valencia, R.; Paulet, P.G.; Schoenlechner, R. Development of gluten-free and egg-free pasta based on quinoa (Chenopdium quinoa Willd) with addition of lupine flour, vegetable proteins and the oxidizing enzyme POx. Eur. Food Res. Technol. 2019, 245, 2147–2156. [Google Scholar] [CrossRef]

- Göksel Saraç, M. Evaluation of non-starch polysaccharide addition in Turkish noodles: ELECTRE techniques approach. J. Texture Stud. 2021, 52, 368–379. [Google Scholar] [CrossRef]

- Rachman, A.; Brennan, M.A.; Morton, J.; Brennan, C.S. Gluten-free pasta production from banana and cassava flours with egg white protein and soy protein addition. Int. J. Food Sci. Technol. 2020, 55, 3053–3060. [Google Scholar] [CrossRef]

| zCol | zColH | zAr | zCookH. | zChew | zStick | zPT. | zUPT | zOA | |

|---|---|---|---|---|---|---|---|---|---|

| β0 | −3529.37 | 4478.85 | −674.27 | −2446.59 | −2139.56 | 3180.06 | −415.33 | −4613.85 | −769.94 |

| βOSF | 204.09 | −248.84 | 39.67 | 139.93 | 121.95 | −167.89 | 24.67 | 261.73 | 46.90 |

| βPSF | 204.28 | −249.06 | 39.74 | 140.04 | 122.05 | −167.94 | 24.74 | 262.06 | 46.97 |

| βs | 24.64 | 8.40 | 11.96 | 12.67 | 8.93 | 6.91 | 17.21 | 11.30 | |

| βw | 17.84 | −55.93 | 1.24 | 18.13 | 16.75 | −68.01 | 39.81 | −3.73 | |

| βgff | −92.53 | 113.07 | −17.84 | −63.48 | −55.27 | 76.57 | −11.05 | −118.62 | −21.14 |

| (βOSF)2 | −2.72 | 3.32 | −0.53 | −1.86 | −1.63 | 2.24 | −0.33 | −3.49 | −0.62 |

| (βPSF)2 | −2.72 | 3.33 | −0.53 | −1.87 | −1.63 | 2.24 | −0.33 | −3.50 | −0.63 |

| (βw)2 | −0.62 | 2.33 | −0.70 | −0.63 | 2.95 | 0.04 | −1.56 | 0.23 | |

| (βgff)2 | 3.21 | −3.92 | 0.62 | 2.20 | 1.92 | −2.65 | 0.38 | 4.12 | 0.74 |

| βOSFβPSF | −5.44 | 6.64 | −1.06 | −3.73 | −3.25 | 4.48 | −0.66 | −6.98 | −1.25 |

| Moisture | TP | TF | TC | TDF | Salt | Ash | TPC | ABTS | |

|---|---|---|---|---|---|---|---|---|---|

| PSF | 5.36 ± 0.12 | 39.35 ± 0.31 | 16.68 ± 0.20 | 7.55 ± 0.17 | 17.97 ± 0.02 | n.a | 3.55 ± 0.39 | 19.1 ± 4.00 | 296.18 ± 15.16 |

| OSF | 5.20 ± 0.34 | 32.68 ± 0.14 | 8.46 ± 2.05 | 21.3 ± 0.24 | 32.39 ± 0.17 | n.a | 4.90 ± 0.03 | 16.5 ± 3.00 | 218.20 ± 15.51 |

| Statistics of Objective Space | Optimization Results | Validation Scores | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Var | Fit. Val. | Pred. Int. | Conf. Int. | Trial 1 | Trial 2 | Trial 3 | |

| Col | 2.73 | 4.99 | 0.32 | 4.95 | 4.70–5.20 | 4.44–5.47 | 4.64 ± 0.11 | 4.76 ± 0.22 | 4.70 ± 0.14 |

| ColH | 0.51 | 4.99 | 1.63 | 4.92 | 4.82–5.02 | 4.66–5.18 | 4.79 ± 0.20 | 4.81 ± 0.15 | 4.77 ± 0.13 |

| Ar | 4.65 | 4.99 | 0.01 | 4.84 | 4.68–5.01 | 4.49–5.20 | 4.71 ± 0.13 | 4.69 ± 0.16 | 4.73 ± 0.14 |

| CookH | 3.68 | 4.99 | 0.14 | 4.85 | 4.66–5.03 | 4.47–5.22 | 4.79 ± 0.09 | 4.74 ± 0.11 | 4.70 ± 0.22 |

| Chew | 3.84 | 4.99 | 0.09 | 4.49 | 4.28–4.69 | 4.07–4.91 | 4.53 ± 0.15 | 4.57 ± 0.22 | 4.54 ± 0.14 |

| Stick | 0.29 | 4.99 | 1.57 | 4.13 | 3.91–4.35 | 3.67–4.59 | 4.04 ± 0.13 | 4.11 ± 0.27 | 4.09 ± 0.20 |

| PT | 4.51 | 4.99 | 0.01 | 4.81 | 4.61–5.01 | 4.37–5.24 | 4.89 ± 0.12 | 4.86 ± 0.11 | 4.87 ± 0.11 |

| UPT | 1.03 | 4.25 | 0.69 | 2.02 | 1.64–2.41 | 1.22–2.83 | 2.13 ± 0.11 | 2.16 ± 0.21 | 2.14 ± 0.18 |

| OA | 3.53 | 4.38 | 0.02 | 4.38 | 4.27–4.48 | 4.17–4.59 | 4.56 ± 0.26 | 4.49 ± 0.26 | 4.46 ± 0.31 |

| Properties | Optimized Noodles |

|---|---|

| Optimum cooking time (min) | 35.00 |

| Swelling power (g/g) | 1.87 ± 0.02 |

| Cooking lost (%) | 6.68 ± 0.04 |

| Water-holding capacity (%) | 107.60 ± 1.35 |

| Properties | Uncooked Noodles | Cooked Noodles | PSF | OSF |

|---|---|---|---|---|

| L* | 63.64 ± 0.33 | 58.63 ± 0.91 | 70.64 ± 2.60 | 63.28 ± 0.40 |

| a* | 0.54 ± 0.02 | 0.71 ± 0.01 | −2.49 ± 0.04 | 2.41 ± 0.06 |

| b* | 17.61 ± 0.22 | 19.32 ± 0.46 | 20.86 ± 0.11 | 13.56 ± 0.14 |

| Hardness (g) | Adhesiveness (g.sec) | Springiness | Cohesiveness | Gumminess | Chewiness | Resilience | |

|---|---|---|---|---|---|---|---|

| Noodle | 2534 ± 15.8 | −0.058 ± 0.01 | 2621.66 ± 12.5 | 0.880 ± 0.02 | 1624.038 ± 18.7 | 4261.5 ± 33.0 | 0.646 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aydin, E.; Turgut, S.S.; Aydin, S.; Cevik, S.; Ozcelik, A.; Aksu, M.; Ozcelik, M.M.; Ozkan, G. A New Approach for the Development and Optimization of Gluten-Free Noodles Using Flours from Byproducts of Cold-Pressed Okra and Pumpkin Seeds. Foods 2023, 12, 2018. https://doi.org/10.3390/foods12102018

Aydin E, Turgut SS, Aydin S, Cevik S, Ozcelik A, Aksu M, Ozcelik MM, Ozkan G. A New Approach for the Development and Optimization of Gluten-Free Noodles Using Flours from Byproducts of Cold-Pressed Okra and Pumpkin Seeds. Foods. 2023; 12(10):2018. https://doi.org/10.3390/foods12102018

Chicago/Turabian StyleAydin, Ebru, Sebahattin Serhat Turgut, Sedef Aydin, Serife Cevik, Ayse Ozcelik, Mehmet Aksu, Muhammed Mustafa Ozcelik, and Gulcan Ozkan. 2023. "A New Approach for the Development and Optimization of Gluten-Free Noodles Using Flours from Byproducts of Cold-Pressed Okra and Pumpkin Seeds" Foods 12, no. 10: 2018. https://doi.org/10.3390/foods12102018

APA StyleAydin, E., Turgut, S. S., Aydin, S., Cevik, S., Ozcelik, A., Aksu, M., Ozcelik, M. M., & Ozkan, G. (2023). A New Approach for the Development and Optimization of Gluten-Free Noodles Using Flours from Byproducts of Cold-Pressed Okra and Pumpkin Seeds. Foods, 12(10), 2018. https://doi.org/10.3390/foods12102018