An Evaluation of Food Safety Performance in Wineries

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design

2.2. Sample Selection

2.3. Survey Preparation

3. Results

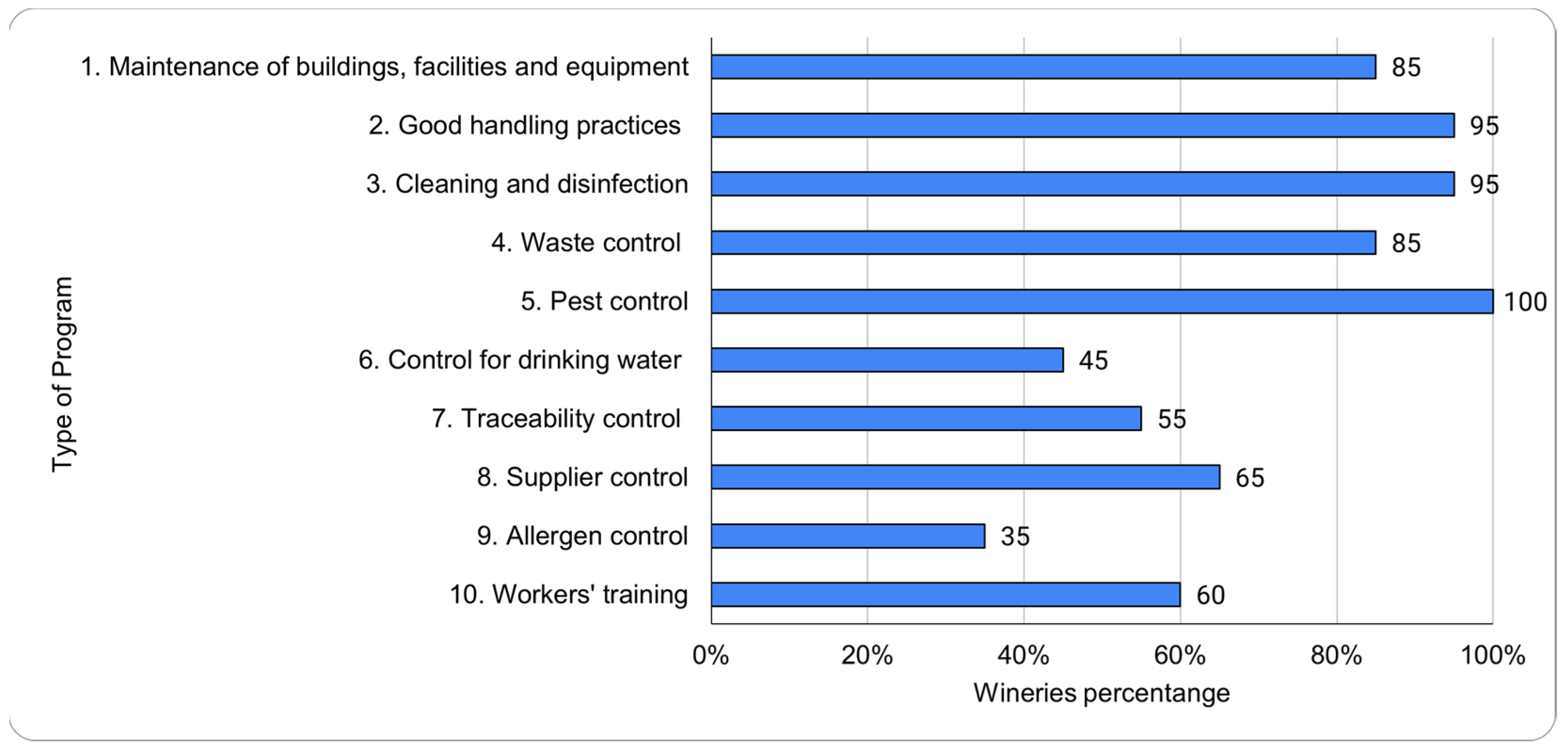

3.1. Prerequisites (PPRs) Implementation

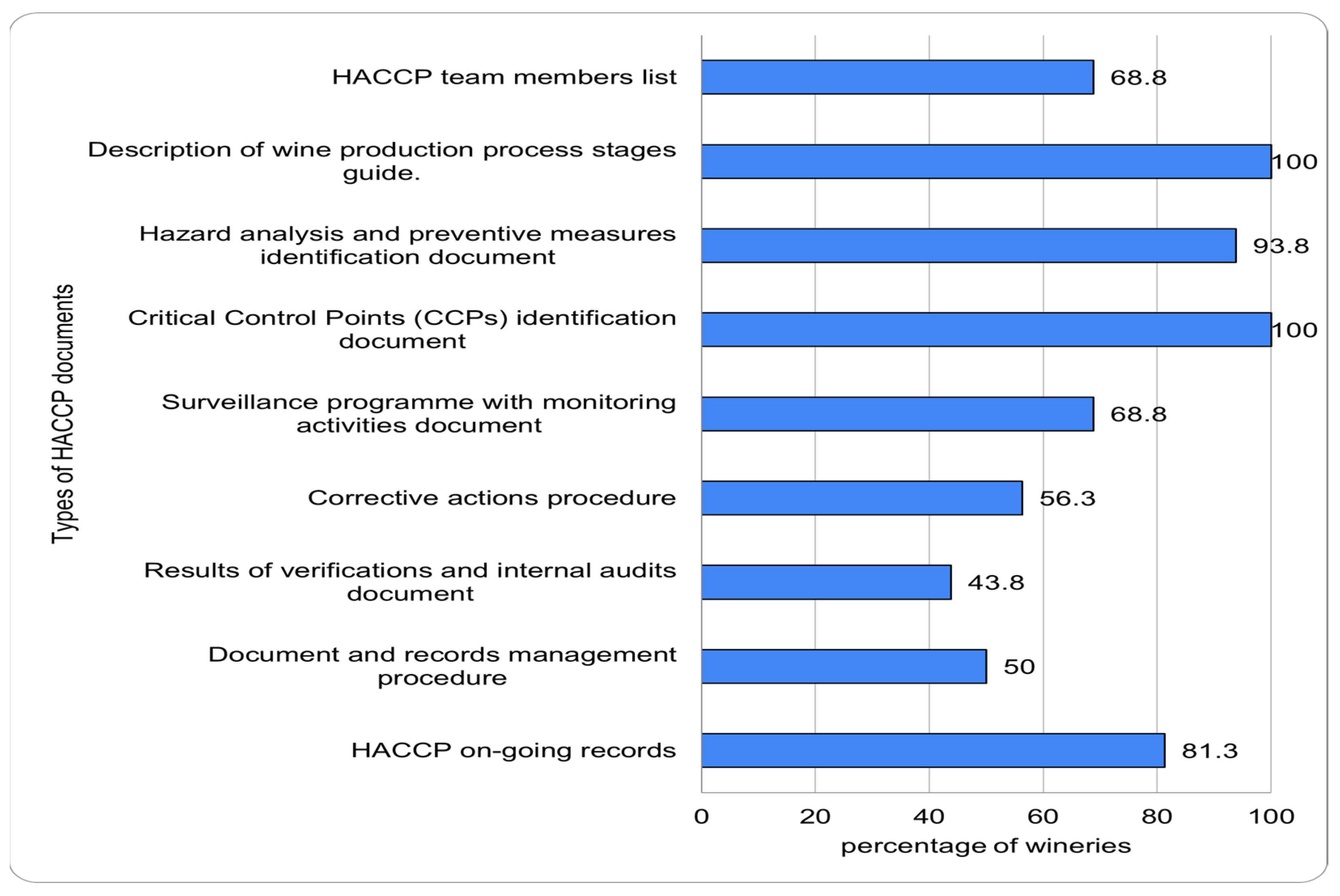

3.2. Critical Control Point Hazard Analysis (HACCP) Implementation

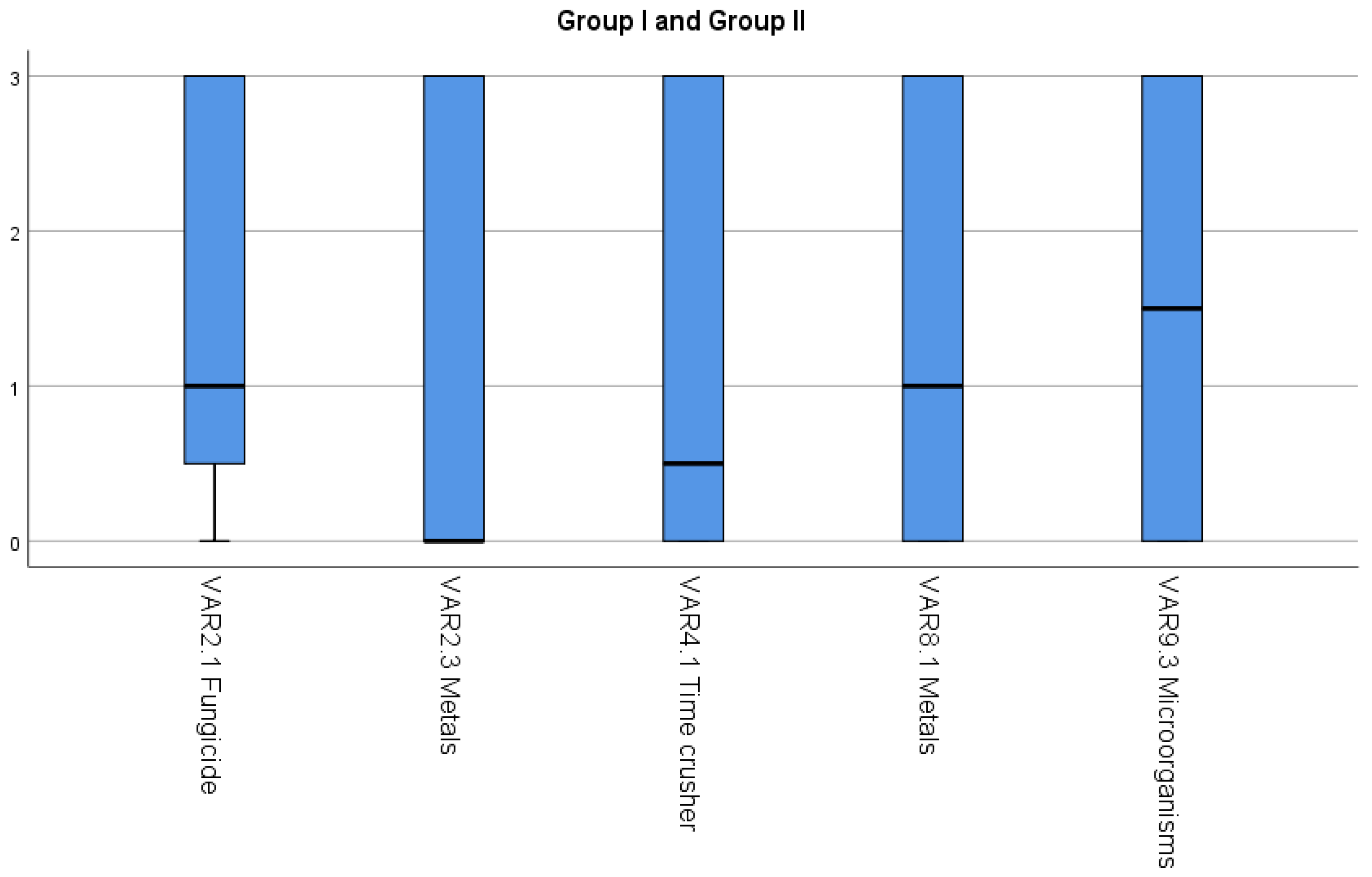

3.2.1. Performance in Principles One and Two: Critical Control Points

3.2.2. Performance in Principles Three to Seven

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robertson, G.L. Chapter In Food Packaging: Principles and Practice; CRC press: Boca Raton, FL, USA, 2005. [Google Scholar]

- European Commission. Commission Regulation (EC) No 606/2009 of 10 July 2009 laying down certain detailed rules for implementing Council Regulation (EC) No 479/2008 as regards the categories of grapevine products, oenological practices and the applicable restrictions. Off. J. Eur. Union L 2009, 193, 1–59. [Google Scholar]

- European Commission. Commission Regulation (EC) No 423/2008 of 8 May 2008 on laying down certain detailed rules for implementing Council Regulation (EC) No 1493/1999 and establishing a community code of oenological practices and processes (Codified version). Off. J. Eur. Union L 2008, 127, 1–45. [Google Scholar]

- European Council. Council Regulation (EC) No 479/2008 of 29 April 2008 on the common organization of the market in wine, amending Regulations (EC) No 1493/1999, (EC) No 1782/2003, (EC) No 1290/2005, (EC) No 3/2008 and repealing Regulations (EEC) No 2392/86 and (EC) No 1493/1999. Off. J. Eur. Union L 2008, 148, 1–61. [Google Scholar]

- European Parliament & European Council. Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on food additives (Text with EEA relevance). Off. J. Eur. Union L 2008, 354, 16–33. [Google Scholar]

- European Commission. Commission Regulation (EU) No 1129/2011 of 11 November 2011 amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council by establishing a Union list of food additives. Off. J. Eur. Union L 2011, 295, 1–177. [Google Scholar]

- European Commission. Amending Annex III to Regulation (EC) No 1333/2008 of the European Parliament and of the Council on food additives by establishing a Union list of food additives approved for use in food additives, food enzymes, food flavourings and nutrients (Text with EEA relevance). Off. J. Eur. Union L 2011, 295, 1–27. [Google Scholar]

- Miller, K.V.; Block, D.E. A review of wine fermentation process modeling. J. Food Eng. 2020, 273, 109783. [Google Scholar] [CrossRef]

- Casassa, L.F.; Harbertson, J.F. Extraction, evolution, and sensory impact of phenolic compounds during red wine maceration. Annu. Rev. Food Sci. Technol. 2014, 5, 83–109. [Google Scholar] [CrossRef]

- Setford, P.C.; Jeffery, D.W.; Grbin, P.R.; Muhlack, R.A. Factors affecting extraction and evolution of phenolic compounds during red wine maceration and the role of process modelling. Trends Food Sci. Technol. 2017, 69, 106–117. [Google Scholar] [CrossRef]

- Metivier, R.P.; Francis, F.J.; Clydesdale, F.M. Solvent extraction of anthocyanins from wine pomace. J. Food Sci. 1980, 45, 1099–1100. [Google Scholar] [CrossRef]

- He, F.; Liang, N.; Mu, L.; Pan, Q.; Wang, J.; Reeves, M.J.; Duan, C. Anthocyanins and their variation in red wines I. Monomeric anthocyanins and their color expression. Molecules 2012, 17, 1571–1601. [Google Scholar]

- Romero-Cascales, I.; Fernández-Fernández, J.I.; López-Roca, J.M.; Gómez-Plaza, E. The maceration process during winemaking extraction of anthocyanins from grape skins into wine. Eur. Food Res. Technol. 2005, 221, 163–167. [Google Scholar] [CrossRef]

- Sablayrolles, J.M. Control of alcoholic fermentation in winemaking: Current situation and prospect. Food Res. Int. 2009, 42, 418–424. [Google Scholar] [CrossRef]

- Davis, C.R.; Wibowo, D.; Eschenbruch, R.; Lee, T.H.; Fleet, G.H. Practical implications of malolactic fermentation: A review. Am. J. Enol. Vitic. 1985, 36, 290–301. [Google Scholar]

- Lonvaud-Funel, A. Lactic acid bacteria in the quality improvement and depreciation of wine. Lactic Acid Bacteria: Genetics, Metabolism and Applications; Springer: Dordrecht, The Netherlands, 1999; pp. 317–331. [Google Scholar]

- Vernhet, A. Red wine clarification and stabilization. In Red Wine Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 237–251. [Google Scholar]

- Mierczynska-Vasilev, A.; Smith, P.A. Current state of knowledge and challenges in wine clarification. Aust. J. Grape Wine Res. 2015, 21, 615–626. [Google Scholar] [CrossRef]

- Oliva, J.; Payá, P.; Cámara, M.Á.; Barba, A. Removal of famoxadone, fluquinconazole and trifloxystrobin residues in red wines: Effects of clarification and filtration processes. J. Environ. Sci. Health Part B 2007, 42, 775–781. [Google Scholar] [CrossRef]

- McRae, J.M.; Mierczynska-Vasilev, A.; Soden, A.; Barker, A.M.; Day, M.P.; Smith, P.A. Effect of commercial-scale filtration on sensory and colloidal properties of red wines over 18 months bottle aging. Am. J. Enol. Vitic. 2017, 68, 263–274. [Google Scholar] [CrossRef]

- Petronilho, S.; Rudnitskaya, A.; Coimbra, M.A.; Rocha, S.M. Comprehensive study of variety oenological potential using statistic tools for the efficient use of non-renewable resources. Appl. Sci. 2021, 11, 4003. [Google Scholar] [CrossRef]

- Petronilho, S.; Lopez, R.; Ferreira, V.; Coimbra, M.A.; Rocha, S.M. Revealing the usefulness of aroma networks to explain wine aroma properties: A case study of Portuguese wines. Molecules 2020, 25, 272. [Google Scholar] [CrossRef] [Green Version]

- Christaki, T.; Tzia, C. Quality and safety assurance in winemaking. Food Control 2002, 13, 503–517. [Google Scholar] [CrossRef]

- Lee, J.C.; Daraba, A.; Voidarou, C.; Rozos, G.; El Enshasy, H.A.; Varzakas, T. Implementation of Food Safety Management Systems along with Other Management Tools (HAZOP, FMEA, Ishikawa, Pareto). The Case Study of Listeria monocytogenes and Correlation with Microbiological Criteria. Foods 2021, 10, 2169. [Google Scholar]

- European Parliament & European Council (2002) Regulation (EC) No 178/2002 of the European Parliament and of The Council of 28 January2002 laying down the general principles and requirements of food law, establishing the European Food SafetyAuthorityand laying down procedures in matters of food safety. Off. J. Eur. Union L 2002, 31, 1–24.

- Food and Agriculture Organization. La Seguridad Alimentaria: Información Para La Toma De Decisiones; FAO: Roma, Italy, 2011. [Google Scholar]

- Bauman, H.E. The origin and concept of HACCP. In HACCP in Meat, Poultry, and Fish Processing; Springer: Berlin/Heidelberg, Germany, 1995; pp. 1–7. [Google Scholar]

- Sperber, W.H. Determining Critical Control Points; Pierson, M.D., Corlett, D.A., Eds.; HACCP: Principles and Applications; Springer: Boston, MA, USA, 1992; pp. 39–49. [Google Scholar]

- European Commission. Commission Notice on the implementation of food safety management systems covering prerequisite programs (PRPs) and procedures based on the HACCP principles, including the facilitation/flexibility of the implementation in certain food businesses. Off. J. Eur. Union L 2016, 278, 1–32. [Google Scholar]

- National Research Council. An Evaluation of the Role of Microbiological Criteria for Foods and Food Ingredients; National Academic Press: Washington, DC, USA, 1985. [Google Scholar]

- Codex Alimentarius. General Principles of Food Hygiene, Update. Available online: https://www.fao.org/fao-whocodexalimentarius/shproxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXC%2B1-1969%252FCXC_001e.pdf (accessed on 17 October 2021).

- Codex Alimentarius Commission Recommended International Code of Practice General Principles of Food Hygiene. CAC/RCP Rev. 2003. CXC 1-1969. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXC%2B1-1969%252FCXC_001e.pdf (accessed on 18 October 2021).

- Bernard, D.; Scott, V.N. Hazard Analysis and Critical Control. Point System: Use in Controlling Microbiological Hazards. In Food Microbiology: Fundamentals and Frontiers, 3rd ed.; American Society of Microbiology: Washington, DC, USA, 2007; pp. 971–985. [Google Scholar]

- Mortimore, S.; Wallace, C. HACCP: A Practical Approach; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Dominguez, R.A.; Espinosa, M.d.M.; Dominguez, M.; Romero, L. Lean 6S in Food Production: HACCP as a Benchmark for the Sixth S “Safety”. Sustainability 2021, 13, 12577. [Google Scholar] [CrossRef]

- Gehring, K.B.; Kirkpatrick, R. Hazard Analysis and Critical Control Points (HACCP). In Food Safety Engineering; Springer: Cham, Switzerland, 2020; pp. 191–204. [Google Scholar]

- Hulebak, K.L.; Schlosser, W. Hazard analysis and critical control point (HACCP) history and conceptual overview. Risk Anal. 2002, 22, 547–552. [Google Scholar] [CrossRef] [PubMed]

- Vela, A.R.; Fernández, J.M. Barriers for the developing and implementation of HACCP plans: Results from a Spanish regional survey. Food Control 2003, 14, 333–337. [Google Scholar] [CrossRef]

- European Parliament. Regulation (EC) No 852/2004 of the European Parliament and of The Council of 29 April 2004 on the hygiene of foodstuffs. Off. J. Eur. Union L 2004, 139, 1–54. [Google Scholar]

- Panghal, A.; Chhikara, N.; Sindhu, N.; Jaglan, S. Role of Food Safety Management Systems in safe food production: A review. J. Food Saf. 2018, 38, e12464. [Google Scholar] [CrossRef]

- Panisello, P.J.; Quantick, P.C. Technical barriers to hazard analysis critical control point (HACCP). Food Control 2001, 12, 165–173. [Google Scholar] [CrossRef]

- Consejo Regulador de Vinos de Madrid Denominación de Origen Protegida. Available online: https://www.comunidad.madrid/transparencia/unidad-organizativa-responsable/consejo-regulador-denominacion-origen-vinos-madrid (accessed on 18 October 2021).

- Abascal, E.; Grande, I. Análisis De Encuestas; ESIC Editorial: Madrid, Spain, 2005; pp. 26–29. [Google Scholar]

- Arribas Fernández, E. Memoria. Available online: https://vinosdemadrid.es/ (accessed on 18 October 2021).

- Benito, S. The Management of Compounds that Influence Human Health in Modern Winemaking from an HACCP Point of View. Fermentation 2019, 5, 33. [Google Scholar] [CrossRef] [Green Version]

- Magan, N. Mycotoxin contamination of food in Europe: Early detection and prevention strategies. Mycopathologia 2006, 162, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Chen, Y.; Liu, S.; Yang, H.; Chen, C.; Chen, Y. Establishment the critical control point methodologies of seven major food processes in the catering industry to meet the core concepts of ISO 22000:2018 based on the Taiwanese experience. J. Food Saf. 2019, 39, e12691. [Google Scholar] [CrossRef]

- Organisation Internationale de la Vigne et du Vin. International Enological Codex; Organisation Internationale de la Vigne et du Vin.: Paris, France, 2022. [Google Scholar]

- Allen, I.E.; Seaman, C.A. Likert scales and data analyses. Qual. Prog. 2007, 40, 64–65. [Google Scholar]

- Wakita, T.; Ueshima, N.; Noguchi, H. Psychological distance between categories in the Likert scale: Comparing different numbers of options. Educ. Psychol. Meas. 2012, 72, 533–546. [Google Scholar] [CrossRef]

- Bendig, A.W. The reliability of self-ratings as a function of the amount of verbal anchoring and of the number of categories on the scale. J. Appl. Psychol. 1953, 37, 38. [Google Scholar] [CrossRef]

- Baş, M.; Yüksel, M.; Çavuşoğlu, T. Difficulties and barriers for the implementing of HACCP and food safety systems in food businesses in Turkey. Food Control 2007, 18, 124–130. [Google Scholar] [CrossRef]

- Walker, E.; Pritchard, C.; Forsythe, S. Hazard analysis critical control point and prerequisite programme implementation in small and medium size food businesses. Food Control 2003, 14, 169–174. [Google Scholar] [CrossRef]

- Ramalho, V.; de Moura, A.P.; Cunha, L.M. Why do small business butcher shops fail to fully implement HACCP? Food Control 2015, 49, 85–91. [Google Scholar] [CrossRef]

- Woh, P.Y.; Thong, K.L.; Behnke, J.M.; Lewis, J.W.; Mohd Zain, S.N. Evaluation of basic knowledge on food safety and food handling practices amongst migrant food handlers in Peninsular Malaysia. Food Control 2016, 70, 64–73. [Google Scholar] [CrossRef]

- Martinez-Rodriguez, A.J.; Carrascosa, A.V. HACCP to control microbial safety hazards during winemaking: Ochratoxin A. Food Control 2009, 20, 469–475. [Google Scholar] [CrossRef]

- Jevšnik, M.; Hlebec, V.; Raspor, P. Food safety knowledge and practices among food handlers in Slovenia. Food Control 2008, 19, 1107–1118. [Google Scholar] [CrossRef]

- Chen, H.; Liou, B.; Hsu, K.; Chen, C.; Chuang, P. Implementation of food safety management systems that meets ISO 22000:2018 and HACCP: A case study of capsule biotechnology products of chaga mushroom. J. Food Sci. 2021, 86, 40–54. [Google Scholar] [CrossRef] [PubMed]

| Number | Principle | Description |

|---|---|---|

| Principle 1 | Perform a hazard analysis | Hazards should be identified and the associated risks that accompany them should be assessed at each stage of the production system and possible control measures should be described. |

| Principle 2 | Determine Critical Control Points (CCPs) | Critical control points must be determined. |

| Principle 3 | Set critical boundaries | A critical limit must be associated with each control measure to ensure that critical control points (CCPs) are under control. |

| Principle 4 | Establish a surveillance system | A surveillance system should be implemented to ensure that CCPs are within critical limits and therefore under control |

| Principle 5 | Establish corrective measures | Corrective measures to be taken when the surveillance system detects that a CCP is outside the control limits should be established |

| Principle 6 | Establish verification procedures | Verification procedures should be established to confirm that the HACCP is functioning effectively and correctly. |

| Principle 7 | Establish a system of registration and documentation | A system of record should be established on all procedures performed and the associated records. |

| Wine Annual Production | Percentage of Wineries Over Total | GMP Workers Training (%) | PPRs Workers Knowledge (%) | ||||

|---|---|---|---|---|---|---|---|

| All | More than 50% | None | All | More than 50% | None | ||

| up to 25,000 L/year | 23.8 | 50 | 0 | 50 | 40 | 20 | 20 |

| between 25,001 and 100,000 L/year | 47.6 | 36 | 55 | 9 | 50 | 50 | 0 |

| between 100,001 and 250,000 L/year | 23.8 | 60 | 40 | 0 | 80 | 20 | 0 |

| between 250,001 and 500,000 L/year | 4.8 | 100 | 0 | 0 | 100 | 0 | 0 |

| Percentage of total wineries | 100 | 48 | 38 | 14 | 62 | 33 | 5 |

| Annual Wine Production | Percentage of Wineries Over Total | Annual Budget PPRs | ||

|---|---|---|---|---|

| Annual Specification (%) | No Detail (%) | None (%) | ||

| up to 25,000 L/year | 23.8 | 20 | 20 | 60 |

| between 25,001 and 100,000 L/year | 47.6 | 0 | 82 | 18 |

| between 100,001 and 250,000 L/year | 23.8 | 40 | 60 | 0 |

| between 250,001 and 500,000 L/year | 4.8 | 100 | 0 | 0 |

| Percentage of total wineries | 100 | 24 | 62 | 14 |

| Frequencies | Always (3) | Usually (2) | Hardly Ever (1) | Never (0) | High Variability | |

|---|---|---|---|---|---|---|

| Winemaking Steps | Variable/Critical Control Point (CCP) | |||||

| 1. Harvest and grape transportation | VAR1.1 Grape inspection previous harvest in vineyards. | Y | ||||

| VAR1.2 Grape inspection during harvest in vineyards. | ||||||

| VAR1.3 Transportation time of harvest from vineyards to winery. | Y | |||||

| 2. Harvest reception in the winery | VAR2.1 Presence of fungicide residues and/or pesticides in grapes. | Y | ||||

| VAR2.2 Presence of mycotoxins from grape rot. | ||||||

| VAR2.3 Contamination by metals (Cadmium, Lead, Arsenic) in grapes. | Y | |||||

| VAR2.4 Contamination by plant residues, dust and/or metal elements. | ||||||

| 3. Pre-hatching treatments | VAR3.1 Vat cleaning to eliminate residues of microorganisms. | |||||

| VAR3.2 No residues of cleaning and disinfection products in vats. | ||||||

| 4. Grapes crushing and must pumping | VAR4.1 Time that remains the must in the crusher after crushing. | Y | ||||

| VAR4.2 Cleaning of crushing equipment. | ||||||

| VAR4.3 No residues of cleaning and disinfection products in vats. | ||||||

| 5. Sulphited and vatted | VAR5.1 Safety and purity of the additives. | Y | ||||

| VAR5.2 No microorganisms in equipment and vats. | ||||||

| 6. Alcoholic fermentation, maceration, vat emptying, pressing, malolactic fermentation | VAR6.1 Concentration of ethylocarbamate in fermented must. | Y | ||||

| VAR6.2 Concentration of sulphur dioxide in fermented must. | ||||||

| VAR6.3 Purity and safety of yeasts. | Y | |||||

| VAR6.4 Temperature during fermentation. | ||||||

| VAR6.5 pH of red wine during malolactic fermentation. | ||||||

| VAR6.6 Hygiene during vat emptying/pressing operations. | ||||||

| VAR6.7 Cleaning of pressing equipment. | Y | |||||

| 7. Racking, clarification, and filtration | VAR7.1 Cleaning procedures for vats and racking equipment. | |||||

| VAR7.2 Maintenance and cleaning of the facilities during racking. | ||||||

| VAR7.3 Purity and safety of agents used as clarifiers of the wine. | Y | |||||

| VAR7.4 No residues of clarifiers in the wine. | Y | |||||

| VAR7.5 No weird elements from filters in the wine. | ||||||

| VAR7.6 Hygiene during clarification and filtering operations. | ||||||

| VAR7.7 No residues of cleaning and disinfection products in vats. | ||||||

| 8. Cold stabilization | VAR8.1 Limit concentrations of metals (traces of As, Cu, Pb) in the wine. | Y | ||||

| VAR8.2 Additives accepted by current food legislation. | ||||||

| 9. Bottling and labelling | VAR9.1 Bottle cleaning procedures. | Y | ||||

| VAR9.2 Cleaning procedures of the bottling line. | ||||||

| VAR9.3 No microorganisms in the bottling line. | Y | |||||

| VAR9.4 No microorganisms in bottle cap. | Y | |||||

| VAR9.5 Correct coding of the label used on the bottles. | ||||||

| VAR9.6 Correct description of allergen information on bottle labels. | ||||||

| VAR9.7 Correct description of P.D.O. information on bottle labels. |

| Annual Wine Production | % Over Total Wineries | Principle 3 | Principle 4 | Principle 5 | Principle 6 | Principle 7 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Critical Limits (%) | Surveillance System (%) | Corrective Measures (%) | Verification Procedure (%) | Registration and Documentation System (%) | |||||||||

| No | Yes (a) | Yes (b) | No | Yes | No | Yes | No | YES | No | Yes (c) | Yes (d) | ||

| up to 25,000 L/year | 25 | 0 | 25 | 75 | 0 | 100 | 25 | 75 | 25 | 75 | 0 | 25 | 75 |

| between 25,001 and 100,000 L/year | 50 | 12.5 | 37.5 | 50 | 12.5 | 87.5 | 50 | 50 | 50 | 50 | 12.5 | 50 | 37.5 |

| between 100,001 and 250,000 L/year | 25 | 0 | 50 | 50 | 0 | 100 | 0 | 100 | 0 | 100 | 0 | 50 | 50 |

| Percentage of total wineries | 100 | 6.2 | 37.5 | 56.3 | 6.2 | 93.8 | 31.3 | 68.7 | 31.3 | 68.7 | 6.2 | 43.8 | 50 |

| Annual Wine Production | % Over Total Wineries | Principle 6 | ||||

|---|---|---|---|---|---|---|

| Frequency (%) | Audits (%) | |||||

| No | Yes | No | Yes (e) | Yes (f) | ||

| up to 25,000 L/year | 28.6 | 25 | 75 | 25 | 25 | 50 |

| between 25,001 and 100,000 L/year | 42.8 | 33.3 | 66.7 | 50 | 33.3 | 16.7 |

| between 100,001 y 250,000 L/year | 28.6 | 25 | 75 | 25 | 25 | 50 |

| Percentage of total wineries | 100 | 28.6 | 71.4 | 35.7 | 28.6 | 35.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Santiago, J.; García, A.I.G.; Gómez-Villarino, M.T. An Evaluation of Food Safety Performance in Wineries. Foods 2022, 11, 1249. https://doi.org/10.3390/foods11091249

López-Santiago J, García AIG, Gómez-Villarino MT. An Evaluation of Food Safety Performance in Wineries. Foods. 2022; 11(9):1249. https://doi.org/10.3390/foods11091249

Chicago/Turabian StyleLópez-Santiago, Jesús, Ana Isabel García García, and María Teresa Gómez-Villarino. 2022. "An Evaluation of Food Safety Performance in Wineries" Foods 11, no. 9: 1249. https://doi.org/10.3390/foods11091249

APA StyleLópez-Santiago, J., García, A. I. G., & Gómez-Villarino, M. T. (2022). An Evaluation of Food Safety Performance in Wineries. Foods, 11(9), 1249. https://doi.org/10.3390/foods11091249