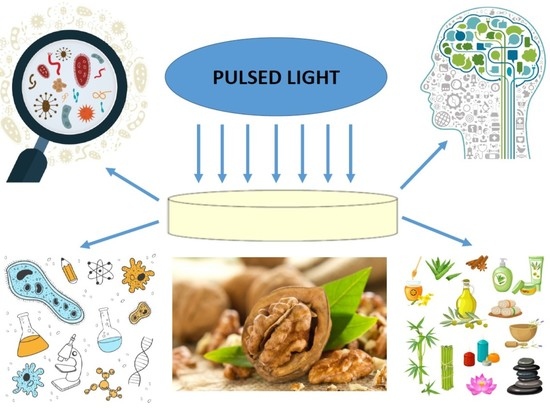

Effect of Pulsed Light on Quality of Shelled Walnuts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Walnut Source and Composition

2.2. Walnut Treatment

2.3. Lipid Oxidation

2.3.1. Thiobarbituric Acid Reactive Substances (TBARS)

2.3.2. Peroxide Value

2.4. Volatile Compounds

- (i)

- Initial temperature of 40 °C and hold for 5 min;

- (ii)

- Ramp of 2 °C/min up to 140 °C;

- (iii)

- Ramp of 5 °C/min up to 210 °C;

- (iv)

- Ramp of 20 °C/min up to 230 °C, and hold 10 min.

2.5. Descriptive Sensory Analysis

2.6. Total Phenolic Compounds and Antioxidant Activity

2.6.1. Total Phenolic Compounds

2.6.2. FRAP Assay

2.6.3. DPPH Assay

2.6.4. ABTS Assay

2.7. Statistical Analysis

3. Results and Discussion

3.1. Lipid Oxidation

3.2. Volatile Compounds

3.3. Descriptive Sensory Analysis

3.4. Total Phenolic Compounds and Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gómez-López, V.M.; Ragaert, P.; Debevere, J.; Devlieghere, F. Pulsed light for food decontamination: A review. Trends Food Sci. Technol. 2007, 18, 464–473. [Google Scholar] [CrossRef]

- Gómez-López, V.M.; Bhat, R.; Pellicer, J.A. Pulsed light. In Electromagnetic Technologies in Food Science; Gómez-López, V.M., Bhat, R., Eds.; Wiley: Oxford, UK, 2022; pp. 200–219. ISBN 978-1-119-75951-5. [Google Scholar] [CrossRef]

- Gómez-López, V.M.; Bolton, J.R. An approach to standardize methods for fluence determination in bench-scale pulsed light experiments. Food Bioprocess Technol. 2016, 9, 1040–1048. [Google Scholar] [CrossRef]

- Harguindeguy, M.; Gómez-Camacho, C.E. Pulsed Light (PL) treatments on almond kernels: Salmonella Enteritidis inactivation kinetics and infrared thermography insights. Food Bioprocess Technol. 2021, 14, 2323–2335. [Google Scholar] [CrossRef] [PubMed]

- Izmirlioglu, G.; Ouyang, B.; Demirci, A. Utilization of pulsed UV light for inactivation of Salmonella Enteritidis on shelled walnuts. LWT Food Sci. Technol. 2020, 134, 110023. [Google Scholar] [CrossRef]

- Rothschild, M. Canada E. coli outbreak tied to walnuts. Food Safety News. 2011. Available online: https://www.foodsafetynews.com/2011/04/canada-e-coli-outbreak-tied-to-walnuts/ (accessed on 1 March 2022).

- Riyaz-Ul-Hassan, S.; Verma, V.; Malik, A.; Qazi, G.N. Microbiological quality of walnut kernels and apple juice concentrate. World J. Microbiol. Biotechnol. 2003, 19, 845–850. [Google Scholar] [CrossRef]

- Blessington, T.; Theofel, C.G.; Mitcham, E.J.; Harris, L.J. Survival of foodborne pathogens on inshell walnuts. Int. J. Food Microbiol. 2013, 166, 341–348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davidson, G.R.; Frelka, J.C.; Yang, M.; Jones, T.M.; Harris, L.J. Prevalence of Escherichia coli O157:H7 and Salmonella on inshell California walnuts. J. Food Prot. 2015, 78, 1547–1553. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, L.; Melka, D.; Wang, H.; Laasri, A.; Brown, E.W.; Strain, E.; Allard, M.; Bunning, V.K.; Musser, S.M.; et al. Prevalence of Salmonella in cashews, hazelnuts, macadamia nuts, pecans, pine nuts, and walnuts in the United States. J. Food Prot. 2017, 80, 459–466. [Google Scholar] [CrossRef]

- Little, C.L.; Rawal, N.; de Pinna, E.; McLauchlin, J. Survey of Salmonella contamination of edible nut kernels on retail sale in the UK. Food Microbiol. 2010, 27, 171–174. [Google Scholar] [CrossRef]

- Harris, L.J.; Yada, S.; Beuchat, L.R.; Danyluk, M.D. Inactivation of Microorganisms in Nuts and Nut Pastes—Published Treatments. 2021. Available online: https://ucfoodsafety.ucdavis.edu/low-moisture-foods/nuts-and-nut-pastes (accessed on 1 March 2022).

- Santillana-Farakos, S.M.; Pouillot, R.; Davidson, G.R.; Johnson, R.; Son, I.; Anderson, N.; Van Doren, J.M. A quantitative risk assessment of human salmonellosis from consumption of walnuts in the United States. J. Food Prot. 2019, 82, 45–57. [Google Scholar] [CrossRef]

- Hayes, D.; Angove, M.J.; Tucci, J.; Dennis, C. Walnuts (Juglans regia) chemical composition and research in human health. Crit. Rev. Food Sci. Nutr. 2015, 56, 1231–1241. [Google Scholar] [CrossRef] [PubMed]

- Regueiro, J.; Sánchez-González, C.; Vallverdú-Queralt, A.; Simal-Gándara, J.; Lamuela-Raventós, R.; Izquierdo-Pulido, M. Comprehensive identification of walnut polyphenols by liquid chromatography coupled to linear ion trap–Orbitrap mass spectrometry. Food Chem. 2014, 152, 340–348. [Google Scholar] [CrossRef] [PubMed]

- Ojeda-Amador, R.M.; Salvador, M.D.; Gómez-Alonso, S.; Fregapane, G. Characterization of virgin walnut oils and their residual cakes produced from different varieties. Food Res. Int. 2018, 108, 396–404. [Google Scholar] [CrossRef] [PubMed]

- Gharibzahedi, S.M.T.; Mousavi, S.M.; Hamedi, M.; Khodaiyan, F. Determination and characterization of kernel biochemical composition and functional compounds of Persian walnut oil. J. Food Sci. Technol. 2014, 51, 34–42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- AOAC. Moisture in nuts and nut products. Method 925.40. In Official Methods of Analysis of AOAC International, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 19th ed.; AOAC: Washington, DC, USA, 2009. [Google Scholar]

- FOSS. The Determination of Nitrogen According to Kjeldahl Using Block Digestion and Steam Distillation; Foss Application Note AN 300; FOSS: Höganäs, Sweden, 2003. [Google Scholar]

- Greenfield, H.; Southgate, H.A.T. Food Composition Data. Production, Management and Use, 2nd ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 2003; Available online: https://www.fao.org/3/y4705e/y4705e.pdf (accessed on 1 March 2022).

- AOAC. Fat (crude) in nuts and nut products. Method 948.22. In Official Methods of Analysis of AOAC International, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Pérez-López, A.J.; Rodríguez-López, M.I.; Burló, F.; Carbonell-Barrachina, A.A.; Gabaldón, J.A.; Gómez-López, V.M. Evaluation of pulsed light to inactivate Brettanomyces bruxellensis in white wine and assessment of its effects on color and aromatic profile. Foods 2020, 9, 1903. [Google Scholar] [CrossRef]

- Cudemus, E.; Izquier, A.; Medina-Martínez, M.S.; Gómez-López, V.M. Effects of shading and growth phase on the microbial inactivation by pulsed light. Czech J. Food Sci. 2013, 31, 189–193. [Google Scholar] [CrossRef] [Green Version]

- Eliseeva, L.; Gorozhanin, P.; Yurina, O. The study of oxidative processes in walnut fats during storage. Indian J. Sci. Technol. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Buege, J.A.; Aust, S.D. Microsomal lipid peroxidation. Methods Enzymol. 1978, 52, 302–310. [Google Scholar] [CrossRef]

- Noguera-Artiaga, L.; Sánchez-Bravo, P.; Pérez-López, D.; Szumny, A.; Calin-Sánchez, Á.; Burgos-Hernández, A.; Carbonell-Barrachina, Á.A. Volatile, sensory and functional properties of hydrosos pistachios. Foods 2020, 9, 158. [Google Scholar] [CrossRef] [Green Version]

- Noguera-Artiaga, L.; Salvador, M.D.; Fregapane, G.; Collado-González, J.; Wojdyło, A.; López-Lluch, D.; Carbonell-Barrachina, Á.A. Functional and sensory properties of pistachio nuts as affected by cultivar. J. Sci. Food Agric. 2019, 99, 6696–6705. [Google Scholar] [CrossRef]

- Carbonell-Barrachina, A.A.; Memmi, H.; Noguera-Artiaga, L.; del Carmen Gijón-López, M.; Ciapa, R.; Pérez-López, D. Quality attributes of pistachio nuts as affected by rootstock and deficit irrigation. J. Sci. Food Agric. 2015, 95, 2866–2873. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Jiménez, J.; Arranz, S.; Tabernero, M.; Díaz-Rubio, M.E.; Serrano, J.; Goñi, I.; Saura-Calixto, F. Updated methodology to determine antioxidant capacity in plant foods, oils and beverages: Extraction, measurement and expression of results. Food Res. Int. 2008, 41, 274–285. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A.J. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Benzie, I.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Bondet, V.; Brand-Williams, W.; Berset, C. Kinetics and mechanisms of antioxidant activity using the DPPH free radical method. LWT Food Sci. Technol. 1997, 30, 609–615. [Google Scholar] [CrossRef]

- Miller, N.J.; Rice-Evans, C.A. Factors influencing the antioxidant activity determined by the ABTS + radical cation assay. Free Radic. Res. 1997, 26, 195–199. [Google Scholar] [CrossRef]

- Al-Bachir, M. Effect of gamma irradiation on fungal load, chemical and sensory characteristics of walnuts (Juglans regia L.). J. Stored Prod. Res. 2004, 40, 355–362. [Google Scholar] [CrossRef]

- Ramis-Ramos, G. Antioxidants. Synthetic antioxidants. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Elsevier: Amsterdam, The Netherlands, 2003; pp. 265–275. [Google Scholar]

- Hao, J.; Xu, X.-L.; Jin, F.; Regenstein, J.M.; Wang, F.-J. HS-SPME GC–MS characterization of volatiles in processed walnuts and their oxidative stability. J. Food Sci. Technol. 2020, 57, 2693–2704. [Google Scholar] [CrossRef]

- Grosso, A.L.; Riveros, C.; Asensio, C.M.; Grosso, N.R.; Nepote, V. Improving walnuts’ preservation by using walnut phenolic extracts as natural antioxidants through a walnut protein-based edible coating. J. Food Sci. 2020, 85, 3043–3051. [Google Scholar] [CrossRef]

- Mu, H.; Gao, H.; Chen, H.; Fang, X.; Zhou, Y.; Wu, W.; Han, Q. Study on the volatile oxidation compounds and quantitative prediction of oxidation parameters in walnut (Carya cathayensis Sarg. ) Oil. Eur. J. Lipid Sci. Technol. 2019, 121, 1800521. [Google Scholar] [CrossRef]

- Liu, X.; Fan, X.; Wang, W.; Yao, S.; Chen, H. Wetting raw almonds to enhance pulse light inactivation of Salmonella and preserve quality. Food Control 2021, 125, 107946. [Google Scholar] [CrossRef]

- Mexis, S.F.; Kontominas, M.G. Effect of γ-irradiation on the physicochemical and sensory properties of walnuts (Juglans regia L.). Eur. Food Res. Technol. 2009, 228, 823–831. [Google Scholar] [CrossRef]

- Jeong, S.; Marks, B.P.; Ryser, E.T.; Harte, J.B. The effect of X-ray irradiation on Salmonella inactivation and sensory quality of almonds and walnuts as a function of water activity. Int. J. Food Microbiol. 2012, 153, 365–371. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalogiouri, N.P.; Manousi, N.; Rosenberg, E.; Zachariadis, G.A.; Paraskevopoulou, A.; Samanidou, V. Exploring the volatile metabolome of conventional and organic walnut oils by solid-phase microextraction and analysis by GC-MS combined with chemometrics. Food Chem. 2021, 363, 130331. [Google Scholar] [CrossRef] [PubMed]

- Okatan, V.; Gündeşli, M.A.; Kafkas, N.E.; Attar, Ş.H.; Kahramanoğlu, İ.; Usanmaz, S.; Aşkın, M.A. Phenolic Compounds, Antioxidant Activity, Fatty Acids and Volatile Profiles of 18 Different Walnut (Juglans regia L.) Cultivars and Genotypes. Erwerbs-Obstbau 2022, 1–14. [Google Scholar] [CrossRef]

- SAFC. Flavors and Fragrances; SAFC Specialties: Madrid, Spain, 2011. [Google Scholar]

- Liu, B.; Chang, Y.; Sui, X.; Wang, R.; Liu, Z.; Sun, J.; Chen, H.; Sun, B.; Zhang, N.; Xia, J. Characterization of Predominant Aroma Components in Raw and Roasted Walnut (Juglans regia L.). Food Anal. Methods 2022, 15, 717–727. [Google Scholar] [CrossRef]

- Manousi, N.; Zachariadis, G.A. Determination of Volatile Compounds in nut-based milk alternative beverages by HS-SPME prior to GC-MS analysis. Molecules 2019, 24, 3091. [Google Scholar] [CrossRef] [Green Version]

- Grilo, F.S.; Wang, S.C. Walnut (Juglans regia L.) volatile compounds indicate kernel and oil oxidation. Foods 2021, 10, 329. [Google Scholar] [CrossRef]

- Crowe, T.D.; Crowe, T.W.; Johnson, L.A.; White, P.J. Impact of extraction method on yield of lipid oxidation products from oxidized and unoxidized walnuts. JAOCS 2002, 79, 453–457. [Google Scholar] [CrossRef]

- Clark, R.G.; Nursten, H.E. The sensory analysis and identification of volatiles from walnut (Juglans regia L.) headspace. J. Sci. Food Agric. 1977, 28, 69–77. [Google Scholar] [CrossRef]

- McLeod, A.; Liland, K.H.; Haugen, J.E.; Sørheim, O.; Myhrer, K.S.; Holck, A.L. Chicken fillets subjected to UV-C and pulsed UV light: Reduction of pathogenic and spoilage bacteria, and changes in sensory quality. J. Food Saf. 2018, 38, 12421. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández, M.; Hospital, X.F.; Arias, K.; Hierro, E. Application of pulsed light to sliced cheese: Effect on Listeria inactivation, sensory quality and volatile profile. Food Bioprocess Technol. 2016, 9, 1335–1344. [Google Scholar] [CrossRef]

| Sensory Descriptor | Definition | References and Intensities |

|---|---|---|

| Color | Visual evaluation of color intensity of sample | Pantone 17-1052 TCX = 8.5 |

| Color homogeneity | Distribution of the main color in the sample | % of total of sample |

| Odor and flavor | ||

| Nut overall | The nut-like aromatic that is typical of nuts such as pistachios and almonds. | Nuts Mix “Borges” = 8.0 |

| Walnut | Aromatic reminiscent of walnut | NOW Foods Raw Walnuts = 8.0 |

| Roasted | Dark-brown odor and flavor notes of products cooked without including bitter or burned notes | Roasted peanuts (Planters) = 5.0 |

| Woody | Aroma associated with woody notes such as those associated with dried fruit shells | Whole peanuts (with shell) = 8.5 |

| Earthy | Aroma related to wet dirt | Pomegranate “Mollar de Elche” = 5.0 |

| Rancy | Aroma related to fat rancidity | Standard of the International Olive Council 5 g L−1 = 3.5 |

| Basic tastes | ||

| Sweet | The taste stimulated by substances such as sucrose or stevia | Sucrose solution 2.5 g L−1 = 3.5 |

| Bitter | The taste stimulated by substances such as caffeine or quinine | Caffeine solution 1 g L−1 = 3.0 |

| Astringent | The puckering or shrinking of the mouth caused by substances such as alum or tannins. | Alum solution 1.5 g L−1 = 1.5 |

| Aftertaste | Time that the characteristic flavor of walnut remains in the mouth after swallowing or expectorating the sample. | 5 s = 1.0 20 s = 10 |

| Texture | ||

| Hardness | The force required to bite food with molar teeth. Evaluate with the molars and on first bite. | Carrots = 7.5 Land O’Lakes American Cheese = 3.0 |

| Crunchiness | Sound associated with mastication of sample with molars | Cheerios = 7.5 |

| Friability | After chewing, the number of pieces the food breaks into sunke | Carrots fresh = 1.5 Soft brownie Little Debbie = 8.5 |

| Adhesiveness | Amount of product that remains adhered to the teeth after chewing | Mushrooms unpeeled = 2.0 Chocolate MilkyWay bar = 9.5 |

| Oiliness | Oily sensation left in the mouth after chewing the sample | Lay’s potato chips = 8.0 |

| Fluence (J/cm2) | |||||

|---|---|---|---|---|---|

| 0 | 10.7 | 21.4 | 32.1 | 42.8 | |

| Rancidity indicators | |||||

| TBARS 1 (mg MDA 2/L oil) | 0.27 ± 0.07 a | 0.32 ± 0.06 a | 0.27 ± 0.08 a | 0.31 ± 0.07 a | 0.34 ± 0.03 a |

| PV 3 (mmol O2/g oil) | 9.13 ± 0.46 a | 9.13 ± 0.64 a | 9.27 ± 0.46 a | 8.60 ± 0.35 a | 8.73 ± 0.23 a |

| Phenols | |||||

| Total phenols (g GAE 4/l) | 0.70 ± 0.17 a | 0.69 ± 0.16 a | 0.67 ± 0.08 a | 0.60 ± 0.07 a | 0.67 ± 0.14 a |

| Antioxidant capacity | |||||

| FRAP 5 (µM Fe2+ equiv.) | 753 ± 55 a | 531 ± 43 b | 457 ± 21 b | 674 ± 15 a | 495 ± 13 b |

| DPPH (µM equiv. Trolox) | 469 ± 32 a | 464 ± 31 a | 466 ± 29 a | 469 ± 24 a | 462 ± 22 a |

| ABTS (µM equiv. Trolox) | 399 ± 30 a | 396 ± 57 a | 327 ± 36 a | 391 ± 45 a | 336 ± 79 a |

| RT (min) | Compound | Odor Description | KI Exp. | KI Lit | ANOVA | Control | PL |

|---|---|---|---|---|---|---|---|

| 7.199 | Hexanal | Green, woody, grassy | 800 | 801 | *** | 3.02 b | 30.11 a |

| 10.968 | 1-Hexanol | Herbaceous, green | 862 | 865 | *** | 4.43 b | 57.83 a |

| 11.754 | Methyl hexanoate | Fruity | 915 | 915 | *** | 45.55 a | 0.20 b |

| 16.079 | Methyl-2-hexenoate | Fatty | 934 | 933 | NS | 1.02 | 0.08 |

| 16.775 | Benzaldehyde | Bitter almond, cherry, nutty | 936 | 935 | NS | 1.85 | 1.11 |

| 17.846 | 1-Heptanol | Musty, leafy, herbal, green, sweet | 970 | 970 | NS | 0.80 | 0.48 |

| 18.712 | Methyl heptenone | Citrus, green | 992 | 994 | NS | 0.98 | 1.41 |

| 19.803 | Ethyl hexanoate | Fruity | 1002 | 1000 | ** | 5.81 a | 0.34 b |

| 21.439 | β-Cymene | Terpenic | 1025 | 1028 | NS | 1.82 | 0.38 |

| 21.790 | D-Limonene | Citrus, orange, lemon | 1029 | 1031 | *** | 18.20 a | 1.80 b |

| 23.982 | Sabinene hydrate | Herbal, cooling | 1101 | 1096 | NS | 0.85 | 1.04 |

| 27.601 | Nonanal | Waxy, citrus, green | 1115 | 1105 | *** | 3.10 a | 0.95 b |

| 31.633 | (E)-Pinocarveol | Herbal, woody, pine | 1145 | 1140 | NS | 0.93 | 0.75 |

| 34.432 | Ethyl octanoate | Waxy, sweet, fruity | 1201 | 1206 | NS | 0.73 | 0.20 |

| 34.760 | Dodecane | - | 1206 | 1200 | NS | 1.84 | 0.96 |

| 35.007 | Decanal | Sweet, waxy, orange | 1210 | 1207 | NS | 1.84 | 0.73 |

| 35.681 | Tridecane | - | 1298 | 1300 | NS | 0.50 | 0.24 |

| 40.031 | Dodecane, 4,6-dimethyl- | - | 1327 | 1325 | ** | 3.06 a | 0.84 b |

| 48.395 | Tetradecane | - | 1401 | 1400 | ** | 1.55 a | 0.44 b |

| 49.082 | Isocaryophyllene | Woody, spicy | 1459 | 1461 | ** | 2.22 a | 0.13 b |

| Sensory Descriptor | ANOVA | Control | PL |

|---|---|---|---|

| Appearance | |||

| Color | NS | 5.5 | 6.0 |

| Color homogeneity | NS | 8.0 | 8.0 |

| Odor | |||

| Nut overall | ** | 3.0 b | 3.5 a |

| Walnut | ** | 3.0 b | 3.5 a |

| Roasted | NS | 0.5 | 0.5 |

| Woody | *** | 1.5 a | 1.0 b |

| Earthy | NS | 0.5 | 0.5 |

| Rancy | NS | 0 | 0 |

| Flavor | |||

| Nut overall | ** | 8.0 b | 8.5 a |

| Walnut | *** | 7.5 b | 8.0 a |

| Roasted | NS | 2.2 | 2.5 |

| Woody | NS | 3.5 | 4.0 |

| Earthy | NS | 1.5 | 1.5 |

| Rancy | NS | 0 | 0 |

| Sweet | ** | 2.5 a | 2.0 b |

| Bitter | NS | 3.5 | 3.5 |

| Astringent | NS | 2.5 | 2.0 |

| Aftertaste | ** | 5.0 b | 5.5 a |

| Texture | |||

| Hardness | NS | 5.5 | 5.5 |

| Crunchiness | NS | 6.5 | 6.5 |

| Friability | NS | 7.5 | 7.0 |

| Adhesiveness | NS | 6.0 | 6.5 |

| Oiliness | NS | 2.5 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez-López, V.M.; Noguera-Artiaga, L.; Figueroa-Morales, F.; Girón, F.; Carbonell-Barrachina, Á.A.; Gabaldón, J.A.; Pérez-López, A.J. Effect of Pulsed Light on Quality of Shelled Walnuts. Foods 2022, 11, 1186. https://doi.org/10.3390/foods11091186

Gómez-López VM, Noguera-Artiaga L, Figueroa-Morales F, Girón F, Carbonell-Barrachina ÁA, Gabaldón JA, Pérez-López AJ. Effect of Pulsed Light on Quality of Shelled Walnuts. Foods. 2022; 11(9):1186. https://doi.org/10.3390/foods11091186

Chicago/Turabian StyleGómez-López, Vicente Manuel, Luis Noguera-Artiaga, Fernando Figueroa-Morales, Francisco Girón, Ángel Antonio Carbonell-Barrachina, José Antonio Gabaldón, and Antonio Jose Pérez-López. 2022. "Effect of Pulsed Light on Quality of Shelled Walnuts" Foods 11, no. 9: 1186. https://doi.org/10.3390/foods11091186

APA StyleGómez-López, V. M., Noguera-Artiaga, L., Figueroa-Morales, F., Girón, F., Carbonell-Barrachina, Á. A., Gabaldón, J. A., & Pérez-López, A. J. (2022). Effect of Pulsed Light on Quality of Shelled Walnuts. Foods, 11(9), 1186. https://doi.org/10.3390/foods11091186