Physicochemical and Sensory Characteristics of Sausages Made with Grasshopper (Sphenarium purpurascens) Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Preparation of Sphenarium purpurascens’s Flour

2.3. Sausage Preparation

2.4. Analysis of Texture and Color

2.5. Near-Infrared Analysis

2.6. Sensory Evaluation

2.7. Statistical Analyses

3. Results

3.1. Characterization of the Flour of Grasshopper

3.2. Texture and Color Analysis

3.3. Near-Infrared Analysis of Sausages

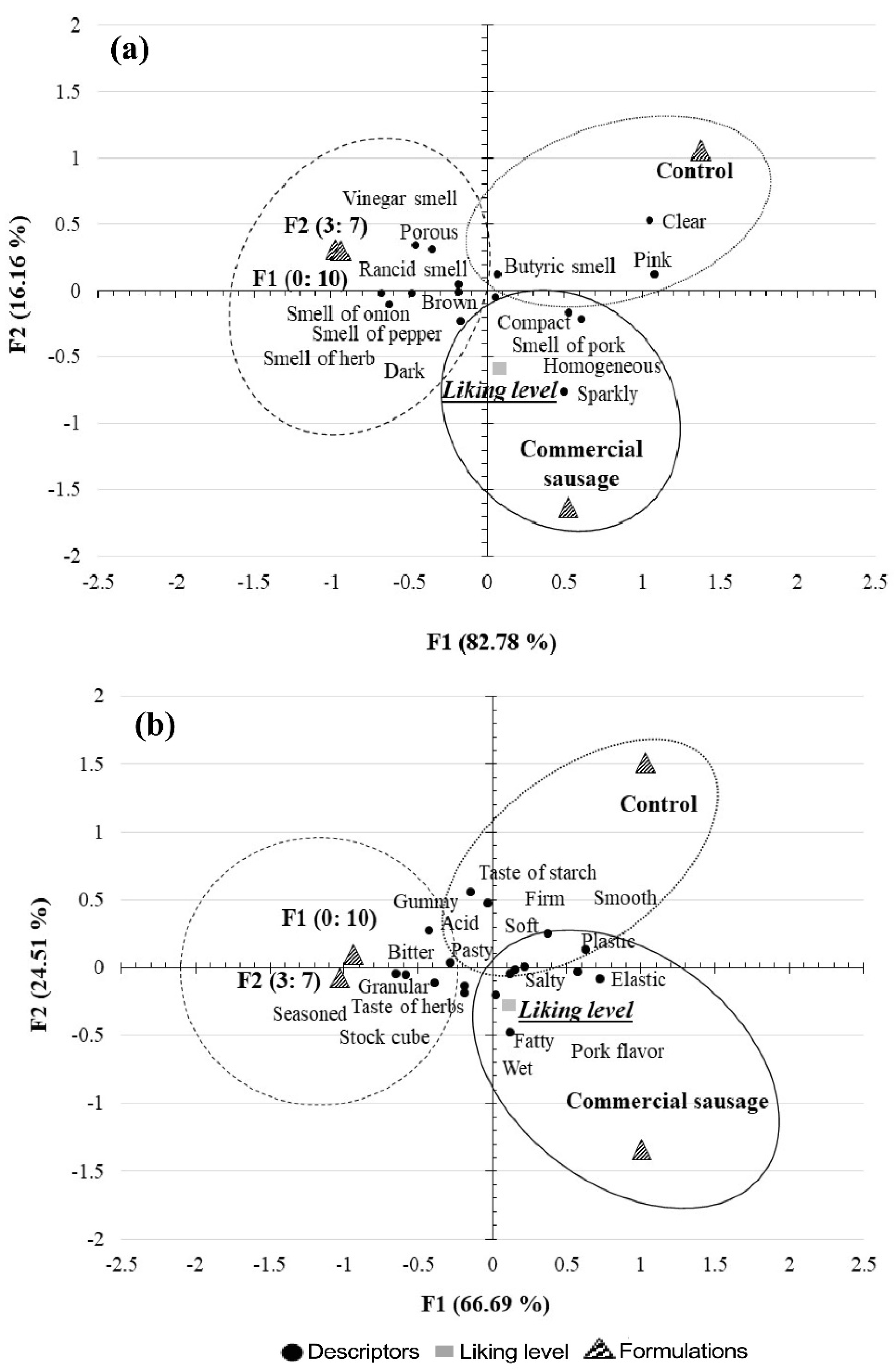

3.4. Sensory Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Huis, A.; Van Itterbeeck, J.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insects: Future Prospects for Food and Feed Security (No. 171); Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; pp. 1–5. Available online: https://edepot.wur.nl/258042 (accessed on 1 December 2021).

- Sosa, D.A.T.; Fogliano, V. Potencial of insect-derived ingredients for food applications. In Insect Physiology and Ecology; Schields, V.D.C., Ed.; IntechOpen: London, UK, 2017; pp. 215–231. [Google Scholar] [CrossRef] [Green Version]

- Da Silva Lucas, A.J.; De Oliveira, L.M.; Da Rocha, M.; Prentice, C. Edible insects: An alternative of nutritional, functional and bioactive compounds. Food Chem. 2020, 311, 126022. [Google Scholar] [CrossRef] [PubMed]

- Gahukar, R.T. Edible insects collected from forests for family livelihood and wellness of rural communities: A review. Glob. Food Sec. 2020, 25, 100348. [Google Scholar] [CrossRef]

- Mariutti, L.R.B.; Rebelo, K.S.; Bisconsin-Junior, A.; De Morais, J.S.; Magnani, M.; Maldonade, I.R.; Cazarin, C.B.B. The use of alternative food sources to improve health and guarantee access and food intake. Food Res. Int. 2021, 149, 110709. [Google Scholar] [CrossRef] [PubMed]

- Youssef, J.; Spence, C. Introducing diners to the range of experiences in creative Mexican cuisine, including the consumption of insects. Int. J. Gastron. Food Sci. 2021, 25, 100371. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Alcántar-Vázquez, J.P.; Zúñiga-Marroquín, T.; Juárez-Barrientos, J.M. Insects as an alternative source of protein: A review of the potential use of grasshopper (Sphenarium purpurascens Ch.) as a food ingredient. Eur. Food Res. Technol. 2019, 245, 2613–2620. [Google Scholar] [CrossRef]

- Cohen, J.H.; Schuster, P.K. To eat chapulines in Oaxaca, Mexico: One food, many flavors. In Taste, Politics, and Identities in Mexican Food; Ayora-Diaz, S.I., Ed.; Bloomsbury Books: London, UK, 2019; pp. 131–144. Available online: https://www.researchgate.net/publication/329786330_To_Eat_Chapulines_in_Oaxaca_Mexico_One_Food_Many_Flavors_in_Taste_Politics_and_Identities_in_Mexican_Food_edited_by_Steffan_Igor_Ayora-Diaz_Bloomsbury_books_Available_February_2019 (accessed on 1 January 2022).

- Shelomi, M. The meat of affliction: Insects and the future of food as seen in Expo 2015. Trends Food Sci. Technol. 2016, 56, 175–179. [Google Scholar] [CrossRef]

- Cuj-Laines, R.; Hernández-Santos, B.; Reyes-Jaquez, D.; Delgado-Licon, E.; Juárez-Barrientos, J.M.; Rodríguez-Miranda, J. Physicochemical properties of ready-to-eat extruded nixtamalized maize-based snacks enriched with grasshopper. Int. J. Food Sci. 2018, 53, 1889–1895. [Google Scholar] [CrossRef]

- Paul, A.; Frederich, M.; Uyttenbroeck, R.; Hatt, S.; Malik, P.; Lebecque, S.; Danthine, S. Grasshoppers as a food source? A review. Biotechnol. Agron. Société Et Environ. 2016, 20, 337–352. [Google Scholar] [CrossRef]

- Melo-Ruiz, V.; Sandoval-Trujillo, H.; Quirino-Barreda, T.; Sánchez-Herrera, K.; Díaz-García, R.; Calvo-Carrillo, C. Chemical composition and amino acids content of five species of edible Grasshoppers from Mexico. Emir. J. Food Agric. 2015, 27, 654–658. [Google Scholar] [CrossRef]

- Ibarra-Herrera, C.C.; Acosta-Estrada, B.; Chuck-Hernández, C.; Serrano-Sandoval, S.N.; Guardado-Félix, D.; Pérez-Carrillo, E. Nutritional content of edible grasshopper (Sphenarium purpurascens) fed on alfalfa (Medicago sativa) and maize (Zea mays). CYTA J. Food 2020, 18, 257–263. [Google Scholar] [CrossRef] [Green Version]

- Rumpold, B.A.; Schlüter, O.K. Potential and challenges of insects as an innovative source for food and feed production. Innov. Food Sci. Emerg. Technol. 2013, 17, 1–11. [Google Scholar] [CrossRef]

- Gravel, A.; Doyen, A. The use of edible insect proteins in food: Challenges and issues related to their functional properties. Innov. Food Sci. Emerg. Technol. 2020, 59, 102272. [Google Scholar] [CrossRef]

- Hleap, J.I.; Cardona, L.; Agudelo, J.; Gomez, A. Parámetros fisicoquímicos, microbiológicos y sensoriales de salchichas elaboradas con inclusión de quitosano. Rev. UDCA Actual. Divulg. Cient. 2015, 118, 455–464. Available online: https://revistas.udca.edu.co/index.php/ruadc/article/view/176 (accessed on 1 November 2021).

- Association of Official Analytical Chemists. Official Methods of Analysis of AOAC, 17th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2000; Volume 41. [Google Scholar]

- Urbina, P.; Marin, C.; Sanz, T.; Rodrigo, D.; Martinez, A. Effect of HHP, enzymes and gelatin physicochemical factors of gels made by using protein isolated from common cricket (Acheta domesticus). Foods 2021, 10, 858. [Google Scholar] [CrossRef] [PubMed]

- Martinez, O.; Salmeron, J.; Guillen, M.D.; Casas, C. Texture profile analysis of meat products treated with commercial liquid smoke flavourings. Food Control 2004, 15, 457–461. [Google Scholar] [CrossRef]

- De Matos, A.D.; Magli, M.; Marangon, M.; Curioni, A.; Pasini, G.; Vincenzi, S. Use of verjuice as an acidic salad seasoning ingredient: Evaluation by consumers’ liking and Check-All-That-Apply. Eur. Food Res. Technol. 2018, 244, 2117–2125. [Google Scholar] [CrossRef]

- Sánchez, C.N.; Domínguez-Soberanes, J.; Escalona-Buendía, H.B.; Graff, M.; Gutiérrez, S.; Sánchez, G. Liking product landscape: Going deeper into understanding consumers’ hedonic evaluations. Foods 2019, 8, 461. [Google Scholar] [CrossRef] [Green Version]

- Jaeger, S.R.; Beresford, M.K.; Paisley, A.G.; Antúnez, L.; Vidal, L.; Cadena, R.S.; Ares, G. Check-all-that-apply (CATA) questions for sensory product characterization by consumers: Investigations into the number of terms used in CATA questions. Food Qual. Prefer. 2015, 42, 154–164. [Google Scholar] [CrossRef]

- Jaeger, S.R.; Chheang, S.L.; Jin, D.; Roigard, C.M.; Ares, G. Check-all-that-apply (CATA) questions: Sensory term citation frequency reflects rated term intensity and applicability. Food Qual. Prefer. 2020, 86, 103986. [Google Scholar] [CrossRef]

- Kinyuru, J.N.; Kenji, G.M.; Njoroge, M.S. Process development, nutrition and sensory qualities of wheat buns enriched with edible termites (Macrotermes subhylanus) from Lake Victoria region, Kenya. Afr. J. Food Agric. Nutr. Dev. 2009, 9, 1739–1750. [Google Scholar] [CrossRef] [Green Version]

- Roehe, R.; Lavín, P.; Batten, G.; Andrés, S. Application of near infrared reflectance spectroscopy to predict meat and meat products quality: A review. Meat Sci. 2009, 83, 175–186. [Google Scholar] [CrossRef]

- Dias, C.M.; Nunes, H.P.; Melo, T.M.M.V.; Rosa, H.J.D.; Silva, C.C.G.; Borba, A.E.S. Application of Near Infrared Reflectance (NIR) spectroscopy to predict the moisture, protein, and fat content of beef for gourmet hamburger preparation. Livest Sci. 2021, 254, 104772. [Google Scholar] [CrossRef]

- Santos, S.; Oliveira, A.; Lopes, C. Systematic review of saturated fatty acids on inflammation and circulating levels of adipokines. Nutr. Res. 2013, 33, 687–695. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bohrer, B.M. Nutrient density and nutritional value of meat products and non-meat foods high in protein. Trends Food Sci. Technol. 2017, 65, 103–112. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Jung, S.; Sung, J.M.; Jang, H.W.; Choi, Y.S. Physicochemical and textural properties of emulsions prepared from the larvae of the edible insects Tenebrio molitor, Allomyrina dichotoma, and Protaetia brevitarsis seulensis. J. Anim. Sci. Technol. 2021, 63, 417–425. [Google Scholar] [CrossRef] [PubMed]

- Hlongwane, Z.T.; Slotow, R.; Munyai, T.C. Nutritional composition of edible insects consumed in Africa: A systematic review. Nutrients 2020, 12, 2786. [Google Scholar] [CrossRef] [PubMed]

- Lautenschläger, T.; Neinhuis, C.; Kikongo, E.; Henle, T.; Förster, A. Impact of different preparations on the nutritional value of the edible caterpillar Imbrasia epimethea from northern Angola. Eur Food Res Technol. 2017, 243, 769–778. [Google Scholar] [CrossRef]

- De Carvalho, N.M.; Madureira, A.R.; Pintado, M.E. The potential of insects as food sources—A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 3642–3652. [Google Scholar] [CrossRef]

- Nishinari, K.; Kohyama, K.; Kumagai, H.; Funami, T.; Bourne, M.C. Parameters of texture profile analysis. Food Sci. Technol. Res. 2013, 19, 519–521. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.W.; Setyabrata, D.; Lee, Y.; Jones, O.G.; Kim, Y.H.B. Effect of house cricket (Acheta domesticus) flour addition on physicochemical and textural properties of meat emulsion under various formulations. J. Food Sci. 2017, 82, 2787–2793. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.S.; Choi, Y.S.; Hwang, K.E.; Kim, T.K.; Lee, C.W.; Shin, D.M.; Han, S.G. Physicochemical properties of meat batter added with edible silkworm pupae (Bombyx mori) and transglutaminase. Korean J. Food Sci. Anim. Resour. 2017, 37, 351–359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innovative Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Smarzyński, K.; Sarbak, P.; Musia, S.; Jezowski, P.; Piatek, M.; Kowalczewski, P.L. Nutritional analysis and evaluation of the consumer acceptance of pork pâté enriched with cricket powder Preliminary study. Open Agric. 2019, 4, 159–163. [Google Scholar] [CrossRef]

- Kim, T.K.; Lee, M.H.; Yong, H.I.; Jung, S.; Paik, H.D.; Jang, H.W.; Choi, Y.S. Effect of Interaction between Mealworm Protein and Myofibrillar Protein on the Rheological Properties and Thermal Stability of the Prepared Emulsion Systems. Foods 2020, 9, 1443. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.S.; Kim, T.K.; Choi, H.D.; Park, J.D.; Sung, J.M.; Jeon, K.H.; Paik, H.D.; Kim, Y.B. Optimization of replacing pork meat with yellow worm (Tenebrio molitor L.) for frankfurters. Korean J. Food Sci. Anim. Resour. 2017, 37, 617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torruco-Uco, J.G.; Hernández-Santos, B.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Juárez-Barrientos, J.M.; Rodríguez-Miranda, J. Chemical, functional and thermal characterization, and fatty acid profile of the edible grasshopper (Sphenarium purpurascens Ch.). Eur. Food Res. Technol. 2019, 245, 285–292. [Google Scholar] [CrossRef]

- Patel, A.; Desai, S.S.; Mane, V.K.; Enman, J.; Rova, U.; Christakopoulos, P.; Matsakas, L. Futuristic food fortification with a balanced ratio of dietary ω-3/ω-6 omega fatty acids for the prevention of lifestyle diseases. Trends Food Sci. Technol. 2022, 120, 140–153. [Google Scholar] [CrossRef]

- Sogari, G.; Menozzi, D.; Mora, C. Sensory-liking expectations and perceptions of processed and unprocessed insect products. Innov. Food Sci. Emerg. Technol. 2018, 9. [Google Scholar] [CrossRef]

- Barton, A.; Richardson, C.D.; McSweeney, M.B. Consumer attitudes toward entomophagy before and after evaluating cricket (Acheta domesticus) based protein powders. J. Food Sci. Technol. 2020, 85, 781–788. [Google Scholar] [CrossRef]

- Dion-Poulin, A.; Turcotte, M.; Lee-Blouin, S.; Perreault, V.; Provencher, V.; Doyen, A.; Turgeon, S.L. Acceptability of insect ingredients by innovative student chefs: An exploratory study. Int. J. Gastron. Food Sci. 2021, 24, 100362. [Google Scholar] [CrossRef]

| Ingredients (%) | Formulations 1 | ||||

|---|---|---|---|---|---|

| Control | F1 | F2 | F3 | F4 | |

| Pork meat | 50 | 50 | 50 | 50 | 50 |

| Frozen lard | 15 | 15 | 15 | 15 | 15 |

| Sodium chloride | 2 | 2 | 2 | 2 | 2 |

| Sodium nitrate | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Phosphate mixture Hamine® | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Potato starch (PS) | 10 | 0 | 3 | 5 | 7 |

| Grasshopper flour (GF) | 0 | 10 | 7 | 5 | 3 |

| Parameters | Formulations 1 | ||||

|---|---|---|---|---|---|

| Control | F1 | F2 | F3 | F4 | |

| Hardness (N) | 14.44 ± 0.97 A | 17.71 ± 1.29 A,B,C | 21.95 ± 1.1 C | 17.19 ± 2.74 B | 20.54 ± 1.07 B,C |

| Springiness (mm) | 2.19± 0.13 A | 3.22 ± 0.35 B | 3.35 ± 0.04 B | 3.32 ± 0.11 B | 3.41 ± 0.05 B |

| Cohesiveness | 0.83 ± 0.01 A | 0.74 ± 0.09 A | 0.73 ± 0.02 A | 0.82 ± 0.12 A | 0.72 ± 0.01 A |

| Gumminess (N) | 8.39 ± 0.71 A | 13.23 ± 0.88 B | 15.59 ± 0.39 C | 14.37 ± 0.64 BC | 15.06± 0.29 C |

| Chewiness (mJ) | 18.38 ± 0.42 A | 43.16 ± 0.87 B | 52.22 ± 0.65 D | 45.64 ± 0.39 C | 51.43 ± 0.45 D |

| L* | 37.45 ± 0.83 C | 26.33 ± 0.81 A | 28.01 ± 3.03 A,B | 30.48 ± 0.82 A,B | 33.46 ± 1.74 B,C |

| a* | 11.02 ± 0.13 B | 10.35 ± 0.64 B | 10.60 ± 0.29 B | 8.21 ± 0.20 A | 8.84 ± 0.27 A |

| b* | 11.08 ± 0.12 A | 12.17 ± 0.92 A | 12.12 ± 0.38 A | 12.37 ± 0.24 A | 11.45 ± 0.46 A |

| Parameters (%) | Formulations 6 | ||||

|---|---|---|---|---|---|

| Control | F1 | F2 | F3 | F4 | |

| Moisture | 65.71 ± 0.08 A | 66.84 ± 0.23 B | 67.71 ± 0.50 C | 66.96 ± 0.07 B | 67.06 ± 0.13 B,C |

| Fat | 13.94 ± 0.26 C,D | 14.27 ± 0.13 D | 13.36 ± 0.25 A,B | 13.68 ± 0.02 B,C | 13.01 ± 0.07 A |

| Protein | 10.35 ± 0.11 A | 15.37 ± 0.27 E | 13.34 ± 0.10 D | 12.79 ± 0.10 C | 12.25 ± 0.17 B |

| Ashes | 2.53 ± 0.10 A | 3.41 ± 0.02 D | 3.05 ± 0.02 B | 3.19 ± 0.04 C | 3.21 ± 0.01 C |

| Salt | 1.55 ± 0.09 A | 2.64 ± 0.02 C | 2.28 ± 0.02 B | 2.34 ± 0.02 B | 2.38 ± 0.02 B |

| aw | 0.98 ± 0.01 A | 0.98 ± 0.01 A | 0.98 ± 0.01 A | 0.97 ± 0.01 A | 0.97 ± 0.01 A |

| BEFFE 1 | 9.77 ± 0.16 A | 13.08 ± 0.23 D | 11.83 ± 0.23 C | 11.25 ± 0.06 B | 10.98 ± 0.23 B |

| MUFA 2 | 6.70 ± 0.07 C | 6.45 ± 0.06 B | 6.07 ± 0.10 A | 6.16 ± 0.02 A | 6.07 ± 0.05 A |

| PUFA 3 | 1.82 ± 0.02 D | 1.68 ± 0.01 C | 1.56 ± 0.01 B | 1.56 ± 0.01 B | 1.49 ± 0.01 A |

| NPN 4 | 0.72 ± 0.04 A | 1.44 ± 0.03 C | 1.42 ± 0.04 C | 1.09 ± 0.07 B | 0.68 ± 0.02 A |

| SFA 5 | 4.91 ± 0.07 C | 4.72 ± 0.06 B | 4.46 ± 0.09 A | 4.46 ± 0.02 A | 4.36 ± 0.03 A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cruz-López, S.O.; Álvarez-Cisneros, Y.M.; Domínguez-Soberanes, J.; Escalona-Buendía, H.B.; Sánchez, C.N. Physicochemical and Sensory Characteristics of Sausages Made with Grasshopper (Sphenarium purpurascens) Flour. Foods 2022, 11, 704. https://doi.org/10.3390/foods11050704

Cruz-López SO, Álvarez-Cisneros YM, Domínguez-Soberanes J, Escalona-Buendía HB, Sánchez CN. Physicochemical and Sensory Characteristics of Sausages Made with Grasshopper (Sphenarium purpurascens) Flour. Foods. 2022; 11(5):704. https://doi.org/10.3390/foods11050704

Chicago/Turabian StyleCruz-López, Salvador O., Yenizey M. Álvarez-Cisneros, Julieta Domínguez-Soberanes, Héctor B. Escalona-Buendía, and Claudia N. Sánchez. 2022. "Physicochemical and Sensory Characteristics of Sausages Made with Grasshopper (Sphenarium purpurascens) Flour" Foods 11, no. 5: 704. https://doi.org/10.3390/foods11050704

APA StyleCruz-López, S. O., Álvarez-Cisneros, Y. M., Domínguez-Soberanes, J., Escalona-Buendía, H. B., & Sánchez, C. N. (2022). Physicochemical and Sensory Characteristics of Sausages Made with Grasshopper (Sphenarium purpurascens) Flour. Foods, 11(5), 704. https://doi.org/10.3390/foods11050704