Influence of Baking Temperature and Formulation on Physical, Sensorial, and Morphological Properties of Pogácsa Cake: An Image Analysis Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Sample Preparation

2.2.2. Physical Characteristics

2.2.3. Image Processing

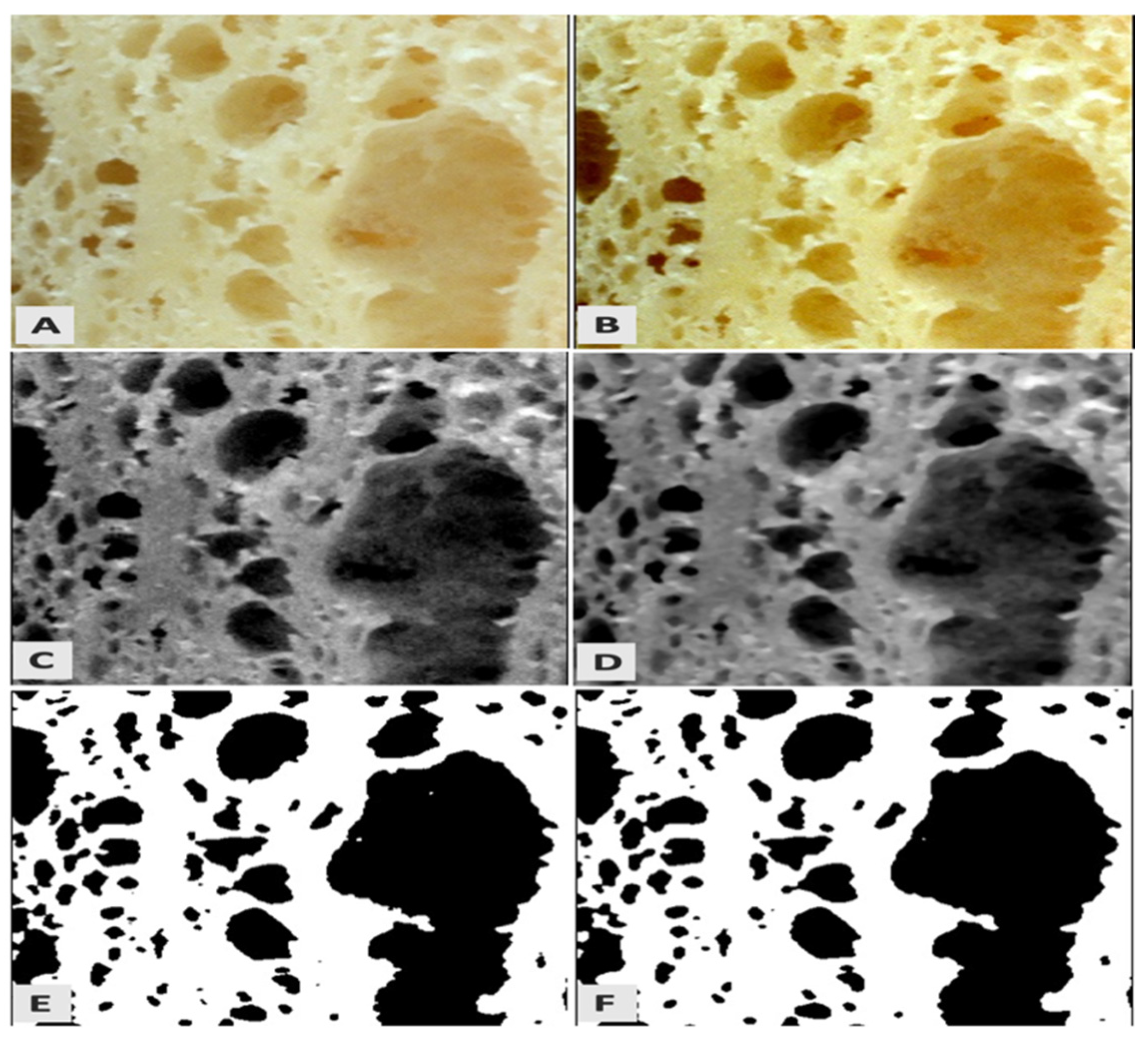

Image Acquisition

Pore Characteristics Evaluation

2.2.4. Mechanical Texture Analysis

2.2.5. Sensory Profiling

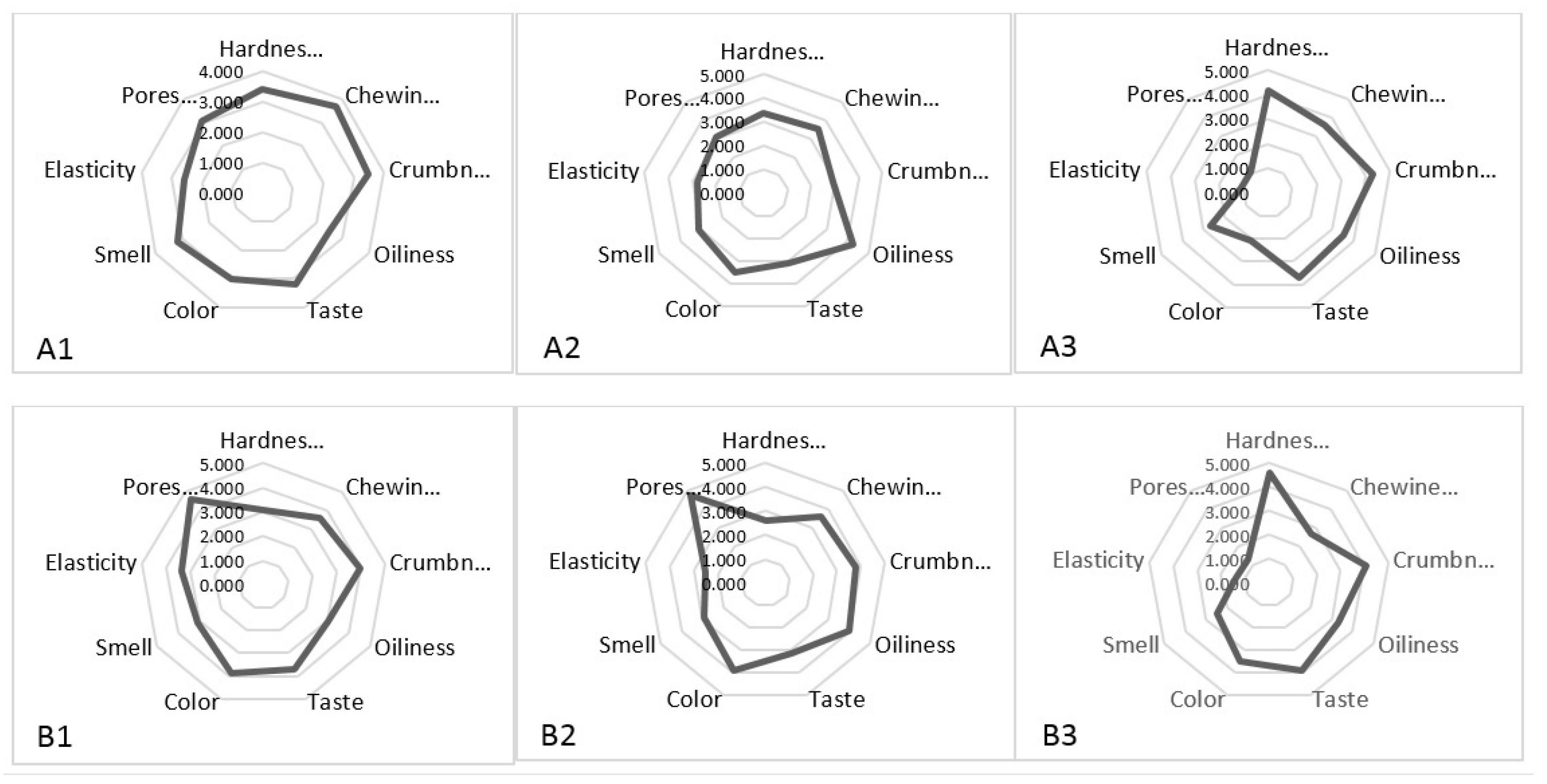

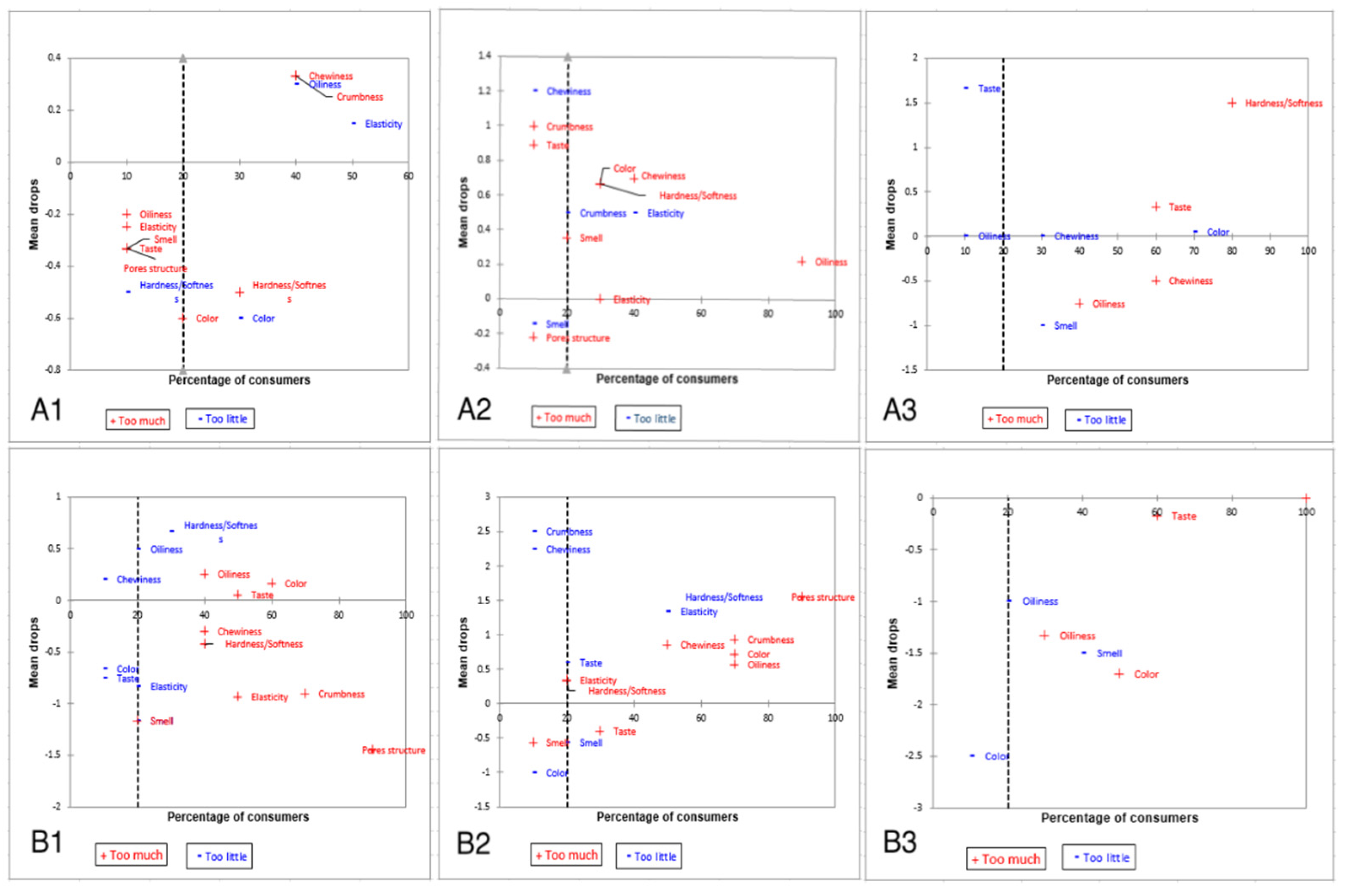

2.2.6. Data and Statistical Analyses

3. Results and Discussion

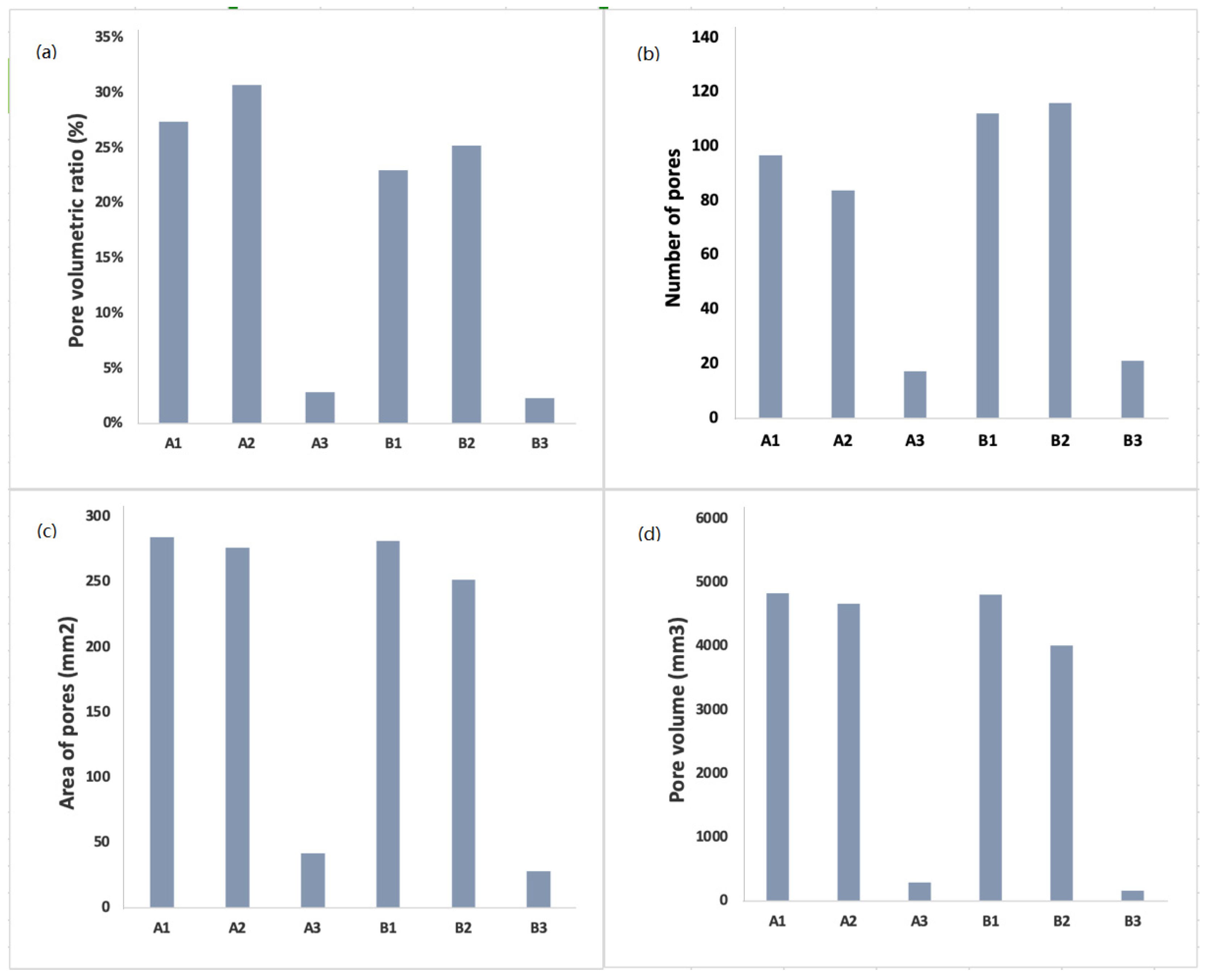

3.1. Pore Characteristics

3.2. Physical and Textural Properties

3.3. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rathnayake, H.A.; Navaratne, S.B.; Navaratne, C.M. Porous crumb structure of leavened baked products. Int. J. Food Sci. 2018, 2018, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Amani, H.; Firtha, F.; Jakab, I.; Baranyai, L.; Badak-Kerti, K. Nondestructive evaluation of baking parameters on pogácsa texture. J. Texture Stud. 2021, 52, 510–519. [Google Scholar] [CrossRef] [PubMed]

- Esteller, M.S.; Zancanaro, O.; Palmeira, C.N.S.; Da Silva, L.; Suzana, C. The effect of kefir addition on microstructure parameters and physical properties of porous white bread. Eur. Food Res. Technol. 2006, 222, 26–31. [Google Scholar] [CrossRef]

- Pahlavan, A.; Kamani, M.H.; Elhamirad, A.H.; Sheikholeslami, Z.; Armin, M.; Amani, H. Rapid quality assessment of bread using developed multivariate models: A simple predictive modeling approach. Prog. Agri. Eng. Sci. 2020, 16, 1–10. [Google Scholar] [CrossRef]

- Puerta, P.; Garzón, R.; Rosell, C.M.; Fiszman, S.; Laguna, L.; Tárrega, A. Modifying gluten-free bread’s structure using different baking conditions: Impact on oral processing and texture perception. LWT 2021, 140, 110718. [Google Scholar] [CrossRef]

- Lassoued, N.; Babin, P.; della Valle, G.; Devaux, M.F.; Réguerre, A.L. Granulometry of bread crumb grain: Contributions of 2D and 3D image analysis at different scale. Food Res. Int. 2007, 40, 1087. [Google Scholar] [CrossRef]

- Pieniazek, F.; Messina, V. Texture and color analysis of freeze-dried potato (cv. Spunta) using instrumental and image analysis techniques. Int. J. Food Prop. 2017, 20, 1422. [Google Scholar] [CrossRef] [Green Version]

- Amani, H.; Badak-Kerti, K.; Khaneghah, A.M. Current progress in the utilization of smartphone-based imaging for quality assessment of food products: A review. Crit. Rev. Food Sci. Nutr. 2020, 1–3. [Google Scholar] [CrossRef] [PubMed]

- Grillo, O.; Rizzo, V.; Saccone, R.; Fallico, B.; Mazzaglia, A.; Venora, G.; Muratore, G. Use of image analysis to evaluate the shelf life of bakery products. Food Res. Int. 2014, 62, 514–522. [Google Scholar] [CrossRef]

- Romano, A.; Toraldo, G.; Cavella, S.; Masi, P. Description of leavening of bread dough with mathematical modeling. J. Food Eng. 2007, 83, 142–148. [Google Scholar] [CrossRef]

- Kandpal, L.; Lee, J.; Bae, J.; Lohumi, S.; Cho, B.-K. Development of a low-cost multi-waveband LED illumination imaging technique for rapid evaluation of fresh meat quality. Appl. Sci. 2019, 9, 912. [Google Scholar] [CrossRef] [Green Version]

- Ghasemi-Varnamkhasti, M.; Lozano, J. Electronic nose as an innovative measurement system for the quality assurance and control of bakery products: A review. Eng. Agric. Environ. Food 2016, 9, 365–374. [Google Scholar] [CrossRef]

- Moghaddam, M.R.A.; Rafe, A.; Taghizadeh, M. Kinetics of color and physical attributes of cookie during deep-fat frying by image processing techniques. J. Food Process. Preserv. 2015, 39, 91–99. [Google Scholar] [CrossRef]

- Salehi, F. Effect of common and new gums on the quality, physical, and textural properties of bakery products: A review. J. Texture Stud. 2019, 51, 361–370. [Google Scholar] [CrossRef] [PubMed]

- Jerome, R.E.; Singh, S.K.; Dwivedi, M. Process analytical technology for bakery industry: A review. J. Food Process Eng. 2019, 42, e13144. [Google Scholar] [CrossRef]

- Jha, P.K.; Chevallier, S.; Cheio, J.; Rawson, A.; Le-Bail, A. Impact of resting time between mixing and shaping on the dough porosity and final cell distribution in sandwich bread. J. Food Eng. 2017, 194, 15–23. [Google Scholar] [CrossRef]

- Rahimi, J.; Baur, J.; Singh, A. Digital imaging as a tool to study the structure of porous baked foods. J. Cereal Sci. 2020, 95, 103084. [Google Scholar] [CrossRef]

- Ghaitaranpour, A.; Mohebbi, M.; Koocheki, A. Characterizing the cellular structure of air and deep fat fried doughnut using image analysis techniques. J. Food Eng. 2018, 237, 231–239. [Google Scholar] [CrossRef]

- Preichardt, L.D.; Vendruscolo, C.T.; Gularte, M.A.; Moreira, A.D.S. The role of xanthan gum in the quality of gluten free cakes: Improved bakery products for coeliac patients.Int. J. Food Sci. Technol. 2011, 46, 2591. [Google Scholar] [CrossRef]

- Bolin, H.R.; Huxsoll, C.C. Effect of preparation procedures and storage parameters on quality retention of salad-cut lettuce. J. Food Sci. 1991, 56, 60–62. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 9th ed.; American Association of Cereal Chemists: St Paul, MN, USA, 1995. [Google Scholar]

- Codex Alimentarius Hungaricus. Hungarian Food Book (Magyar Élelmiszerkönyv). Bakery Products with Distinctive Quality Indication; Trade Magazine: Budapest, Hungary, 2002; pp. 2–103. [Google Scholar]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kamani, M.H.; Meera, M.S.; Bhaskar, N.; Modi, V.K. Partial and total replacement of meat by plant-based proteins in chicken sausage: Evaluation of mechanical, physico-chemical and sensory characteristics. J. Food Sci. Technol. 2019, 56, 2660–2669. [Google Scholar]

- ISO 8589; Sensory analysis—General guidance for the design of test rooms. International Organization for Standardization: Geneva, Switzerland, 1990.

- Bagdi, A.; Tóth, B.; Lorincz, R.; Szendi, S.; Gere, A.; Kókai, Z.; Sipos, L.; Tömösközi, S. Effect of aleurone-rich flour on composition, baking, textural, and sensory properties of bread. LWT Food Sci. Technol. 2016, 65, 762–769. [Google Scholar] [CrossRef]

- Iserliyska, D.; Dzhivoderova, M.; Nikovska, K. Application of penalty analysis to interpret jar data—A case study on orange juices. Curr. Trends Nat. Sci. 2017, 6, 6–12. [Google Scholar]

- Rahimi, J.; Ngadi, M.O. Inter-particle space fractions in fried batter coatings as influenced by batter formulation and pre-drying time. LWT Food Sci. Technol. 2014, 57, 486–493. [Google Scholar] [CrossRef]

- Sun, D. Computer Vision Technology for Food Quality Evaluation; Academic Press: London, UK, 2016. [Google Scholar]

- Shittu, T.A.; Raji, A.O.; Sanni, L.O. Bread from composite cassava-wheat flour: I. Effect of baking time and temperature on some physical properties of bread loaf. Food Res. Int. 2007, 40, 280–290. [Google Scholar] [CrossRef]

- Eggleston, G.; Omoaka, P.E.; Arowshegbe, A.U. Flour, starch and composite breadmaking quality of various cassava clones. J. Sci. Food Agric. 1993, 62, 49–59. [Google Scholar] [CrossRef]

- Gebreil, S.Y.; Maha, I.; Kamal, A.; Ahmed, E.; Mousa, M. Utilization of amaranth flour in preparation of high nutritional value bakery products ment and enhancement of functional foods. Food Nutr. Sci. 2020, 11, 336. [Google Scholar]

- Kamani, M.H.; Safari, O.; Mortazavi, S.A.; Atash, M.M.S. Predicting the contents of volatile and non-volatile amines in rainbow trout fillet during storage time via image processing technique. Qual. Assur. Saf. Crop. Foods 2015, 7, 589–598. [Google Scholar] [CrossRef]

- Morreale, F.; Garzón, R.; Rosell, C.M. Understanding the role of hydrocolloids viscosity and hydration in developing gluten-free bread. A study with hydroxypropylmethylcellulose. Food Hydrocol. 2018, 77, 629–635. [Google Scholar] [CrossRef]

- Xiong, R.; Meullenet, J.F. A PLS dummy variable approach to assess the impact of jar attributes on liking. Food Qual. Prefer. 2006, 17, 188. [Google Scholar] [CrossRef]

| Sample Name | Baking Temperature (°C) | Cheese (% of Dough) | Cheese MC (%) |

|---|---|---|---|

| A1 | 200 | 33 | 58 |

| A2 | 200 | 33 | 65 |

| A3 | 200 | - | - |

| B1 | 215 | 33 | 58 |

| B2 | 215 | 33 | 65 |

| B3 | 215 | - | - |

| Parameters | A1 | A2 | A3 | B1 | B2 | B3 |

|---|---|---|---|---|---|---|

| Hardness (g) | 571.99 ± 71.19 a | 471.67 ± 43.24 a | 5042 ± 338.91 c | 1441.1 ± 131.65 b | 674.46 ± 57.84 a | 7778.8 ± 851.60 d |

| Cohesiveness | 0.61 ± 0.02 e | 0.54 ± 0.01 d | 0.40 ± 0.03 b | 0.49 ± 0.03 c | 0.53 ± 0.01 d | 0.32 ± 0.02 a |

| Gumminess | 371.43 ± 31.86 c | 259.29 ± 23.70 b | 191.51 ± 11.11 a | 694.81 ± 68.20 d | 359.69 ± 30.10 c | 256.7 ± 20.07 b |

| Chewiness | 309.71 ± 33.79 a | 232.98 ± 26.78 a | 1256.08 ± 36.69 c | 568.98 ± 91.78 b | 311.83 ± 35.57 a | 1526.62 ± 220.53 d |

| Springiness (%) | 86.30 ± 3.05 cd | 89.94 ± 7.83 d | 62.74 ± 3.58 b | 83.61 ± 8.75 c | 85.97 ± 3.13 cd | 55.72 ± 1.83 a |

| Crumb MC (%) | 36.09 ± 3.40 b | 47.18 ± 4.96 c | 15.37 ± 0.61 a | 35.41 ± 0.97 b | 43.66 ± 5.28 c | 14.81 ± 0.37 a |

| Volume (cm3/g) | 63.00 ± 4.58 d | 49.00 ± 1.00 c | 29.00 ± 2.00 b | 61.00 ± 1.00 d | 48.66 ± 2.08 c | 24.33 ± 1.15 a |

| Density | 0.24 ± 0.02 a | 0.29 ± 0.01 b | 0.46 ± 0.00 c | 0.23 ± 0.01 a | 0.27 ± 0.01 ab | 0.62 ± 0.05 d |

| Porosity (%) | 69.63 ± 1.58 e | 53.36 ± 5.15 c | 32.66 ± 3.34 a | 72.75 ± 1.48 f | 62.20 ± 1.49 d | 38.83 ± 6.32 b |

| PVR (%) | 27.43 ± 5.09 c | 30.76 ± 7.67 d | 2.84 ± 0.68 a | 22.97 ± 3.91 b | 25.21 ± 1.65 bc | 2.30 ± 0.53 a |

| Sample | L* | a* | b* | |||

|---|---|---|---|---|---|---|

| Crumb | Crust | Crumb | Crust | Crumb | Crust | |

| A1 | 92.10 ± 1.63 c | 89.80 ± 3.29 c | −0.95 ± 0.49 b | 9.09 ± 1.10 a | 29.38 ± 1.23 d | 52.03 ± 0.54 c |

| A2 | 85.16 ± 1.34 b | 85.98 ± 1.42 b | −0.16 ± 0.01 c | 11.92 ± 0.42 bc | 26.78 ± 2.01 c | 51.83 ± 2.16 c |

| A3 | 83.54 ± 0.49 ab | 71.93 ± 0.15 a | −0.15 ± 0.04 c | 9.94 ± 0.27 ab | 20.71 ± 0.97 a | 40.90 ± 1.15 a |

| B1 | 85.36 ± 1.94 b | 72.92 ± 0.66 a | −1.39 ± 0.08 a | 27.45 ± 2.47 e | 31.90 ± 1.92 d | 49.99 ± 1.94 c |

| B2 | 84.23 ± 0.60 ab | 70.47 ± 2.54 a | −1.12 ± 0.06 ab | 23.61 ± 0.64 d | 30.83 ± 1.09 d | 44.87 ± 1.66 b |

| B3 | 82.22 ± 1.66 a | 69.71 ± 2.75 a | 0.53 ± 0.12 d | 13.20 ± 0.57 c | 24.05 ± 0.56 b | 42.37 ± 1.15 ab |

| Parameters | Hardness (g) | Resilience (%) | Cohesiveness | Springiness (%) | Gumminess | Chewiness | Porosity |

|---|---|---|---|---|---|---|---|

| PVR | −0.90 ** | 0.87 ** | 0.84 ** | 0.87 ** | −0.92 ** | −0.92 ** | 0.71 ** |

| MC | −0.89 ** | 0.83 ** | 0.82 ** | 0.90 ** | −0.92 ** | −0.92 ** | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amani, H.; Baranyai, L.; Badak-Kerti, K.; Mousavi Khaneghah, A. Influence of Baking Temperature and Formulation on Physical, Sensorial, and Morphological Properties of Pogácsa Cake: An Image Analysis Study. Foods 2022, 11, 321. https://doi.org/10.3390/foods11030321

Amani H, Baranyai L, Badak-Kerti K, Mousavi Khaneghah A. Influence of Baking Temperature and Formulation on Physical, Sensorial, and Morphological Properties of Pogácsa Cake: An Image Analysis Study. Foods. 2022; 11(3):321. https://doi.org/10.3390/foods11030321

Chicago/Turabian StyleAmani, Hanieh, László Baranyai, Katalin Badak-Kerti, and Amin Mousavi Khaneghah. 2022. "Influence of Baking Temperature and Formulation on Physical, Sensorial, and Morphological Properties of Pogácsa Cake: An Image Analysis Study" Foods 11, no. 3: 321. https://doi.org/10.3390/foods11030321

APA StyleAmani, H., Baranyai, L., Badak-Kerti, K., & Mousavi Khaneghah, A. (2022). Influence of Baking Temperature and Formulation on Physical, Sensorial, and Morphological Properties of Pogácsa Cake: An Image Analysis Study. Foods, 11(3), 321. https://doi.org/10.3390/foods11030321