Major Causes of Variation of External Appearance, Chemical Composition, Texture, and Color Traits of 37 Categories of Cheeses

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design and Cheese Classification

2.2. Descriptions, Measurements, and Sampling of the Cheeses

2.3. Cheese Analyses

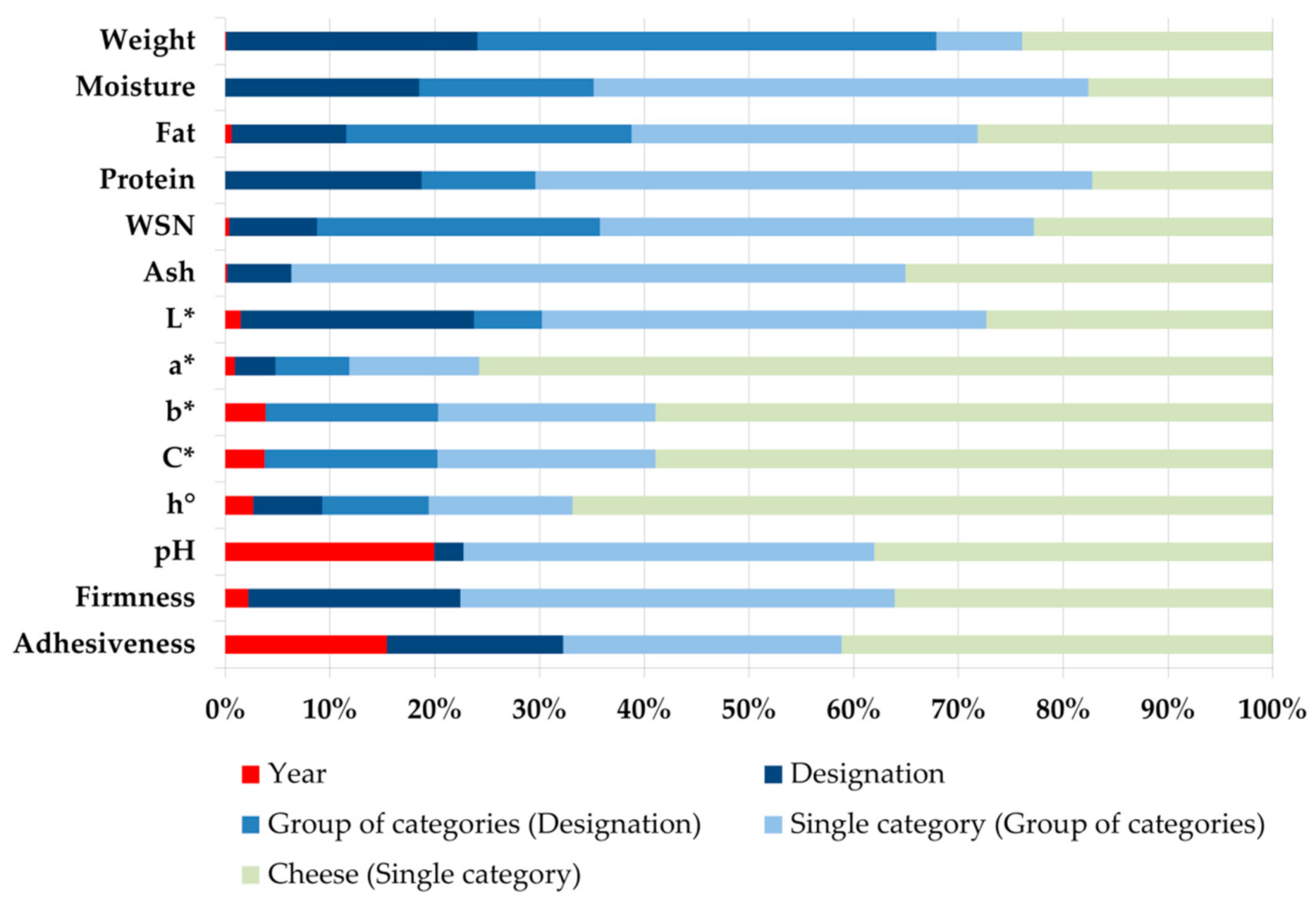

2.4. Statistical Analysis

3. Results

3.1. Shape and Size of the Cheeses

3.2. Chemical Composition of Cheeses

3.3. Cheese Color

3.4. Acidity and Texture of Cheeses

4. Discussion

4.1. Variability in Size and Compositional and Physical Traits of Cheeses

4.2. Characteristics of Mountain Cheeses

4.3. Characteristics of Grana Padano Cheeses

4.4. Characteristics of Pasta Filata Cheeses

4.5. Characteristics of Flavored Cheeses

4.6. Characteristics of the Goat Cheeses

4.7. Implications of the Study and the Need for Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donnelly, C. The Oxford Companion to Cheese; Oxford University Press: Oxford, UK, 2017; ISBN 9780199330881. [Google Scholar]

- Anonymous List of Cheeses. Available online: https://en.wikipedia.org/wiki/List_of_cheeses (accessed on 31 May 2022).

- McSweeney, P.L.H.; Fox, P.F. (Eds.) Advanced Dairy Chemistry; Springer: New York, NY, USA, 2009; ISBN 978-0-387-84864-8. [Google Scholar]

- Hashem, K.M.; He, F.J.; Jenner, K.H.; Macgregor, G.A. Cross-Sectional Survey of Salt Content in Cheese: A Major Contributor To Salt Intake in the UK. BMJ Open 2014, 4, e005051. [Google Scholar] [CrossRef] [PubMed]

- Matera, J.; Luna, A.S.; Batista, D.B.; Pimentel, T.C.; Moraes, J.; Kamimura, B.A.; Ferreira, M.V.S.; Silva, H.L.A.; Mathias, S.P.; Esmerino, E.A.; et al. Brazilian Cheeses: A Survey Covering Physicochemical Characteristics, Mineral Content, Fatty Acid Profile and Volatile Compounds. Food Res. Int. 2018, 108, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Margalho, L.P.; Kamimura, B.A.; Pimentel, T.C.; Balthazar, C.F.; Araujo, J.V.A.; Silva, R.; Conte-Junior, C.A.; Raices, R.S.L.; Cruz, A.G.; Sant’Ana, A.S. A Large Survey of the Fatty Acid Profile and Gross Composition of Brazilian Artisanal Cheeses. J. Food Compos. Anal. 2021, 101, 103955. [Google Scholar] [CrossRef]

- Kędzierska-Matysek, M.; Barłowska, J.; Wolanciuk, A.; Litwińczuk, Z. Physicochemical, Mechanical and Sensory Properties of Long-Ripened Polish and Italian Cheeses and Their Content of Selected Minerals. J. Elem. 2018, 23, 985–998. [Google Scholar] [CrossRef]

- Cicognini, F.M.; Rossi, F.; Sigolo, S.; Gallo, A.; Prandini, A. Conjugated Linoleic Acid Isomer (Cis9,Trans11 and Trans10,Cis12) Content in Cheeses from Italian Large-Scale Retail Trade. Int. Dairy J. 2014, 34, 180–183. [Google Scholar] [CrossRef]

- Biango-Daniels, M.N.; Wolfe, B.E. American Artisan Cheese Quality and Spoilage: A Survey of Cheesemakers’ Concerns and Needs. J. Dairy Sci. 2021, 104, 6283–6294. [Google Scholar] [CrossRef]

- European-Union Regulation (EU) No 1151/2012 of the European Parliament and of the Council of 21 November 2012 on Quality Schemes for Agricultural Products and Foodstuffs. Available online: https://eur-lex.europa.eu/eli/reg/2012/1151/oj/eng (accessed on 31 May 2022).

- Bonfatti, V.; Di Martino, G.; Cecchinato, A.; Vicario, D.; Carnier, P. Effects of β-κ-Casein (CSN2-CSN3) Haplotypes and β-Lactoglobulin (BLG) Genotypes on Milk Production Traits and Detailed Protein Composition of Individual Milk of Simmental Cows. J. Dairy Sci. 2010, 93, 3797–3808. [Google Scholar] [CrossRef]

- Gobbetti, M.; Neviani, E.; Fox, P.; Varanini, G.M. The Cheeses of Italy: Science and Technology; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783319898544. [Google Scholar]

- Stocco, G.; Cipolat-Gotet, C.; Ferragina, A.; Berzaghi, P.; Bittante, G. Accuracy and Biases in Predicting the Chemical and Physical Traits of Many Types of Cheeses Using Different Visible and Near-Infrared Spectroscopic Techniques and Spectrum Intervals. J. Dairy Sci. 2019, 102, 9622–9638. [Google Scholar] [CrossRef]

- Bittante, G.; Patel, N.; Cecchinato, A.; Berzaghi, P. Invited Review: A Comprehensive Review of Visible and near-Infrared Spectroscopy for Predicting the Chemical Composition of Cheese. J. Dairy Sci. 2022, 105, 1817–1836. [Google Scholar] [CrossRef]

- CIE. Recommendations on Uniform Color Spaces, Color-Difference Equations, and Metric Color Terms; CIE Publication: Paris, France, 1977. [Google Scholar]

- Dias, C.; Mendes, L. Protected Designation of Origin (PDO), Protected Geographical Indication (PGI) and Traditional Speciality Guaranteed (TSG): A Bibiliometric Analysis. Food Res. Int. 2018, 103, 492–508. [Google Scholar] [CrossRef]

- Trmčić, A.; Ralyea, R.; Meunier-Goddik, L.; Donnelly, C.; Glass, K.; D’Amico, D.; Meredith, E.; Kehler, M.; Tranchina, N.; McCue, C.; et al. Consensus Categorization of Cheese Based on Water Activity and PH—A Rational Approach to Systemizing Cheese Diversity. J. Dairy Sci. 2017, 100, 841–847. [Google Scholar] [CrossRef] [PubMed]

- Lamichhane, P.; Kelly, A.L.; Sheehan, J.J. Symposium Review: Structure-Function Relationships in Cheese. J. Dairy Sci. 2018, 101, 2692–2709. [Google Scholar] [CrossRef] [PubMed]

- Law, B.A.; Tamine, A.Y. (Eds.) Technology of Cheesemaking, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2010; ISBN 9781405182980. [Google Scholar]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science; Springer: New York, NY, USA, 2017. [Google Scholar]

- Putranto, A.; Woo, M.W.; Selomulya, C.; Chen, X.D. An Accurate Account of Mass Loss during Cheese Ripening Described Using the Reaction Engineering Approach (REA)-Based Model. Int. J. Food Sci. Technol. 2018, 53, 1397–1404. [Google Scholar] [CrossRef]

- Buchin, S.; Martin, B.; Dupont, D.; Bornard, A.; Achilleos, C. Influence of the Composition of Alpine Highland Pasture on the Chemical, Rheological and Sensory Properties of Cheese. J. Dairy Res. 1999, 66, 579–588. [Google Scholar] [CrossRef]

- Bovolenta, S.; Corazzin, M.; Saccà, E.; Gasperi, F.; Biasioli, F.; Ventura, W. Performance and Cheese Quality of Brown Cows Grazing on Mountain Pasture Fed Two Different Levels of Supplementation. Livest. Sci. 2009, 124, 58–65. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Cipolat-Gotet, C.; Stocco, G.; Valorz, C.; Bazzoli, I.; Sturaro, E.; Ramanzin, M.; Bittante, G. Cheesemaking in Highland Pastures: Milk Technological Properties, Cream, Cheese and Ricotta Yields, Milk Nutrients Recovery, and Products Composition. J. Dairy Sci. 2016, 99, 9631–9646. [Google Scholar] [CrossRef]

- O’Callaghan, T.F.; Mannion, D.T.; Hennessy, D.; McAuliffe, S.; O’Sullivan, M.G.; Leeuwendaal, N.; Beresford, T.P.; Dillon, P.; Kilcawley, K.N.; Sheehan, J.J.; et al. Effect of Pasture versus Indoor Feeding Systems on Quality Characteristics, Nutritional Composition, and Sensory and Volatile Properties of Full-Fat Cheddar Cheese. J. Dairy Sci. 2017, 100, 6053–6073. [Google Scholar] [CrossRef]

- Mucchetti, G.; Pugliese, A.; Paciulli, M. Characteristics of Some Important Italian Cheeses: Parmigiano Reggiano, Grana Padano, Mozzarella, Mascarpone and Ricotta. In Mediterranean Foods: Composition and Processing; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- da Silva Duarte, V.; Lombardi, A.; Corich, V.; Giacomini, A. Assessment of the Microbiological Origin of Blowing Defects in Grana Padano Protected Designation of Origin Cheese. J. Dairy Sci. 2022, 105, 2858–2867. [Google Scholar] [CrossRef]

- Bittante, G.; Cologna, N.; Cecchinato, A.; de Marchi, M.; Penasa, M.; Tiezzi, F.; Endrizzi, I.; Gasperi, F.; De Marchi, M.; Penasa, M.; et al. Monitoring of Sensory Attributes Used in the Quality Payment System of Trentingrana Cheese. J. Dairy Sci. 2011, 94, 5699–5709. [Google Scholar] [CrossRef]

- Bittante, G.; Cecchinato, A.; Cologna, N.; Penasa, M.; Tiezzi, F.; De Marchi, M. Factors Affecting the Incidence of First-Quality Wheels of Trentingrana Cheese. J. Dairy Sci. 2011, 94, 3700–3707. [Google Scholar] [CrossRef]

- Bava, L.; Bacenetti, J.; Gislon, G.; Pellegrino, L.; D’Incecco, P.; Sandrucci, A.; Tamburini, A.; Fiala, M.; Zucali, M. Impact Assessment of Traditional Food Manufacturing_ The Case of Grana Padano Cheese.Pdf. Sci. Total Environ. 2018, 626, 1200–1209. [Google Scholar] [CrossRef] [PubMed]

- Ah, J.; Tagalpallewar, G.P. Functional Properties of Mozzarella Cheese for Its End Use Application. J. Food Sci. Technol. 2017, 54, 3766–3778. [Google Scholar] [CrossRef] [PubMed]

- Stocco, G.; Pazzola, M.; Dettori, M.L.; Paschino, P.; Bittante, G.; Vacca, G.M. Effect of Composition on Coagulation, Curd Firming, and Syneresis of Goat Milk. J. Dairy Sci. 2018, 101, 9693–9702. [Google Scholar] [CrossRef] [PubMed]

- Vacca, G.M.; Stocco, G.; Dettori, M.L.; Summer, A.; Cipolat-Gotet, C.; Bittante, G.; Pazzola, M. Cheese Yield, Cheesemaking Efficiency, and Daily Production of 6 Breeds of Goats. J. Dairy Sci. 2018, 101, 7817–7832. [Google Scholar] [CrossRef]

- Pazzola, M.; Stocco, G.; Dettori, M.L.; Bittante, G.; Vacca, G.M. Effect of Goat Milk Composition on Cheesemaking Traits and Daily Cheese Production. J. Dairy Sci. 2019, 102, 3947–3955. [Google Scholar] [CrossRef]

- Bittante, G.; Amalfitano, N.; Bergamaschi, M.; Patel, N.; Haddi, M.L.; Benabid, H.; Pazzola, M.; Vacca, G.M.; Tagliapietra, F.; Schiavon, S. Composition and Aptitude for Cheese-Making of Milk from Cows, Buffaloes, Goats, Sheep, Dromedary Camels, and Donkeys. J. Dairy Sci. 2022, 105, 2132–2152. [Google Scholar] [CrossRef]

- Vacca, G.M.; Stocco, G.; Dettori, M.L.; Pira, E.; Bittante, G.; Pazzola, M. Milk Yield, Quality, and Coagulation Properties of 6 Breeds of Goats: Environmental and Individual Variability. J. Dairy Sci. 2018, 101, 7236–7247. [Google Scholar] [CrossRef]

- Pazzola, M.; Stocco, G.; Paschino, P.; Dettori, M.L.; Cipolat-Gotet, C.; Bittante, G.; Vacca, G.M. Modeling of Coagulation, Curd Firming, and Syneresis of Goat Milk from 6 Breeds. J. Dairy Sci. 2018, 101, 7027–7039. [Google Scholar] [CrossRef]

- Barbé, F.; Ménard, O.; Gouar, Y.L.; Buffière, C.; Famelart, M.H.; Laroche, B.; Feunteun, S.L.; Rémond, D.; Dupont, D. Acid and Rennet Gels Exhibit Strong Differences in the Kinetics of Milk Protein Digestion and Amino Acid Bioavailability. Food Chem. 2014, 143, 1–8. [Google Scholar] [CrossRef]

- Nageshvar, P.; Amalfitano, N.; Bittante, G. Fresh Cheese Cooked: Comparison of Cheese-Making Efficiency and Quality of Roasted Acid-Heat Coagulated Paneer and Rennet Coagulated Tosella/Schiz from Cow and Buffalo Milk. Pers. Commun. 2022; unpublished. [Google Scholar]

- Bishop, R.R. Cheese Innovation: Market Driven vs. Regulatory Standards. Aust. J. Dairy Technol. 2006, 61, 196–197. [Google Scholar]

- Chowdhury, R.; Warnakula, S.; Kunutsor, S.; Krowe, F.; Ward, H.A.; Johnson, L.; Franco, O.H.; Butterworth, A.S.; Forouhl, N.G.; Thompson, S.G.; et al. Association of Dietary, Circulating, and Supplement Fatty Acids with Coronary Risk. Ann. Intern. Med. 2014, 160, 398–407. [Google Scholar] [CrossRef] [PubMed]

- Dehghan, M.; Mente, A.; Zhang, X.; Swaminathan, S.; Li, W.; Mohan, V.; Iqbal, R.; Kumar, R.; Wentzel-Viljoen, E.; Rosengren, A.; et al. Associations of Fats and Carbohydrate Intake with Cardiovascular Disease and Mortality in 18 Countries from Five Continents (PURE): A Prospective Cohort Study. Lancet 2017, 390, 2050–2062. [Google Scholar] [CrossRef] [PubMed]

- Astrup, A.; Magkos, F.; Bier, D.M.; Brenna, J.T.; de Oliveira, M.C.; Hill, J.O.; King, J.C.; Mente, A.; Ordovas, J.M.; Volek, J.S.; et al. Saturated Fats and Health: Facts and Feelings. J. Am. Coll. Cardiol. 2020, 76, 844–857. [Google Scholar] [CrossRef]

- van Lingen, H.J.; Crompton, L.A.; Hendriks, W.H.; Reynolds, C.K.; Dijkstra, J. Meta-Analysis of Relationships between Enteric Methane Yield and Milk Fatty Acid Profile in Dairy Cattle. J. Dairy Sci. 2014, 97, 7115–7132. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Bittante, G. Detailed Fatty Acid Profile of Milk, Cheese, Ricotta and by Products, from Cows Grazing Summer Highland Pastures. J. Dairy Res. 2017, 84, 329–338. [Google Scholar] [CrossRef]

- Bittante, G.; Bergamaschi, M. Enteric Methane Emissions of Dairy Cows Predicted from Fatty Acid Profiles of Milk, Cream, Cheese, Ricotta, Whey, and Scotta. Animals 2020, 10, 61. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Aprea, E.; Betta, E.; Biasioli, F.; Cipolat-Gotet, C.; Cecchinato, A.; Bittante, G.; Gasperi, F. Effects of Dairy System, Herd within Dairy System, and Individual Cow Characteristics on the Volatile Organic Compound Profile of Ripened Model Cheeses. J. Dairy Sci. 2015, 98, 2183–2196. [Google Scholar] [CrossRef]

- Bergamaschi, M.; Cipolat-Gotet, C.; Cecchinato, A.; Schiavon, S.; Bittante, G. Chemometric Authentication of Farming Systems of Origin of Food (Milk and Ripened Cheese) Using Infrared Spectra, Fatty Acid Profiles, Flavor Fingerprints, and Sensory Descriptions. Food Chem. 2020, 305, 125480. [Google Scholar] [CrossRef]

| PDO CHEESE Cheese Category | N | Fat 1 | Heat 2 | Culture Type 3 | Curd Cutting Size 4 | Curd Cooking °C | Curd Pressing | Cheese Salting 5 | Ripening Time (Months) | Paste Firmness 6 | Eyes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ASIAGO: | 115 | ||||||||||

| -fresco (pressato) | 45 | full-fat | yes/no | milk | walnut | 44 ± 2 | yes | var | <1 | soft | large |

| -stagionato-mezzano | 28 | skim | yes/no | milk | hazel | 47 ± 2 | yes | brine | 4–10 | firm | small |

| -stagionato-vecchio | 19 | skim | yes/no | milk | hazel | 47 ± 2 | yes | brine | 10–15 | hard | rare |

| -stagionato-stravecchio | 23 | skim | yes/no | milk | hazel | 47± 2 | yes | brine | >15 | v-hard | rare |

| CASATELLA TREV. 7 | 27 | full-fat | yes | milk | walnut | no | yes | var | 0.2 | v-soft | rare |

| GRANA PADANO: | 35 | ||||||||||

| -Grana Padano | 17 | skim | no | whey | rice | 56 | no | brine | 12–20 | v-hard | no |

| -Grana Padano riserva | 18 | skim | no | whey | rice | 56 | no | brine | >20 | v-hard | no |

| MONTASIO: | 72 | ||||||||||

| -fresco | 29 | full-fat | yes/no | milk, st | rice | 42–48 | yes | salt/brine | 2–4 | soft | small |

| -mezzano | 23 | full-fat | yes/no | milk, st | rice | 42–48 | yes | salt/brine | 5–10 | firm | small |

| -stagionato | 20 | full-fat | yes/no | milk, st | rice | 42–48 | yes | salt/brine | >10 | hard | small |

| MONTE VERONESE: | 52 | ||||||||||

| -latte intero | 21 | full-fat | yes/no | milk, st | rice | 43–45 | no | brine | 0.8–1.5 | soft | med. |

| -d’allevo-mezzano | 18 | skim | no | milk, st | rice | 46–48 | no | brine | 3–6 | firm | small |

| -d’allevo-vecchio | 13 | skim | no | milk, st | rice | 46–48 | no | brine | >12 | hard | small |

| PIAVE | 6 | 3.5% | yes | milk/whey | rice | 44–47 | yes | brine | 1–24 | s-hard | no |

| PROVOLONE 8: | 14 | ||||||||||

| -dolce | 7 | full-fat | yes | whey, st | var | - | no | brine | 2–3 | soft | small |

| -piccante | 7 | full-fat | yes | whey, st | var | - | no | brine | ≥3 | firm | small |

| CHEESE GROUP Cheese Category | N | Milk Fat 1 | Heat Treat 2 | Cheese Ripening Time (Months) | Cheese Paste Firmness | Notes |

|---|---|---|---|---|---|---|

| TRADITIONAL CHEESES: | 136 | |||||

| -Morlacco del Grappa | 30 | skim | yes/no | 1–3 | soft | from Monte Grappa |

| -Malga fresco | 42 | skim | no | 2–6 | firm | from Alpine pastures |

| -Malga vecchio | 19 | skim | no | >12 | very hard | from Alpine pastures |

| -Formaggio inbriago | 45 | full-fat | yes/no | 2–6 | firm | in marc/must/wine |

| PASTA FILATA CHEESES: | 44 | |||||

| -Mozzarella | 20 | full-fat | yes | <1 | fresh | stretched curd cheese |

| -Pasta filata molle | 13 | full-fat | yes | 1–3 | soft | stretched curd cheese |

| -Pasta filata | 11 | full-fat | yes/no | 3–12 | hard | stretched curd cheese |

| FLAVORED CHEESES: | 128 | |||||

| -Formaggi al pepe o peperoncino | 40 | full-fat | yes | var. | var. | with pepper or chili |

| -Formaggi con erbe fieno e spezie | 43 | full-fat | yes | var. | var. | with herbs, hay, or spices |

| -Formaggi affumicati | 22 | full-fat | yes | var. | var. | smoked cheeses |

| -Formaggi erborinati | 19 | full-fat | yes | var. | var. | blue cheeses |

| -Formaggi alla birra o balsamico | 4 | full-fat | yes | var. | var. | matured in beer or balsamic vinegar |

| GOAT CHEESES: | 54 | |||||

| -Caprino a coagulazione acida | 19 | full-fat | yes | <1 | fresh | acid coagulation |

| -Caprino a coagulazione presamica | 35 | full-fat | yes | var. | var. | rennet coagulation |

| OTHER CHEESES: | 367 | |||||

| -Freschi, freschissimi | 57 | full-fat | yes | <1 | fresh | very fresh, no rind |

| -Caciotta | 55 | full-fat | yes | 1–2 | soft | <1.0 kg |

| -Latteria | 79 | full-fat | yes | 2–4 | semi-soft | >1.0 kg |

| -Crosta fiorita | 25 | full-fat | yes | 1–4 | soft | moldy rind |

| -Crosta lavata | 18 | full-fat | yes | 2–6 | semi-soft | washed rind |

| -Pasta semidura | 91 | var | yes/no | 3–6 | firm | - |

| -Pasta dura | 42 | var | yes/no | >10 | hard | - |

| PDO CHEESE Cheese Category | Shape | Height cm | Diameter cm | Weight kg |

|---|---|---|---|---|

| ASIAGO: | ||||

| -fresco (pressato) | wheel | 14.5 ± 0.9 | 36.2 ± 1.7 | 13.9 ± 0.6 |

| -stagionato-mezzano | wheel | 10.0 ± 0.7 | 32.9 ± 0.9 | 9.1 ± 0.5 |

| -stagionato-vecchio | wheel | 9.7 ± 0.3 | 32.6 ± 1.1 | 8.8 ± 0.3 |

| -stagionato-stravecchio | wheel | 9.1 ± 0.6 | 31.8 ± 0.7 | 7.9 ± 0.6 |

| CASATELLA TREV. | wheel | 5.3 ± 1.0 | 13.6 1 ± 6.6 | 1.1 ± 1.0 |

| GRANA PADANO: | ||||

| -Grana Padano | wheel | 22.5 ± 0.5 | 42.3 ± 3.4 | 34.7 ± 3.2 |

| -Grana Padano riserva | wheel | 22.1 ± 0.6 | 40.4 ± 0.9 | 34.6 ± 3.9 |

| MONTASIO: | ||||

| -fresco | wheel | 7.9 ± 0.6 | 29.9 ± 0.9 | 6.0 ± 0.5 |

| -mezzano | wheel | 7.7 ± 0.5 | 29.9 ± 1.1 | 5.8 ± 0.5 |

| -stagionato | wheel | 7.4 ± 0.5 | 29.6 ± 1.5 | 5.5 ± 0.5 |

| MONTE VERONESE: | ||||

| -latte intero | wheel | 9.3 ± 0.4 | 33.5 ± 1.3 | 8.6 ± 0.9 |

| -d’allevo-mezzano | wheel | 9.5 ± 0.5 | 31.3 ± 1.2 | 8.0 ± 1.0 |

| -d’allevo-vecchio | wheel | 9.0 ± 0.3 | 31.3 ± 0.8 | 7.6 ± 0.2 |

| PIAVE | wheel | 7.3 ± 0.4 | 29.0 ± 0.8 | 5.5 ± 0.1 |

| PROVOLONE: | ||||

| -dolce | pear | 11.8 ± 0.4 | 21.4 1 ± 1.5 | 5.4 ± 0.2 |

| -piccante | pear | 19.5 ± 2.1 | 22.1 1 ± 1.9 | 9.5 ± 0.3 |

| CHEESE GROUP Cheese Category | Shape | Height cm | Diameter cm | Weight kg |

|---|---|---|---|---|

| TRADITIONAL CHEESES: | ||||

| -Morlacco del Grappa | wheel | 7.7 ± 1.1 | 29.7 ± 3.2 | 5.1 ± 0.8 |

| -Malga fresco | wheel | 8.4 ± 1.7 | 26.9 ± 5.8 | 5.3 ± 3.4 |

| -Malga vecchio | wheel | 8.8 ± 1.1 | 29.1 ± 5.9 | 6.4 ± 2.3 |

| -Formaggio inbriago | variable | 8.1 ± 0.8 | 27.8 ± 4.0 1 | 5.4 ± 1.4 |

| PASTA FILATA CHEESES: | ||||

| -Mozzarella | variable | - | - | 0.2 ± 0.2 |

| -Pasta filata molle | variable | - | - | 0.3 ± 0.2 |

| -Pasta filata | variable | - | - | 5.0 ± 5.1 |

| FLAVORED CHEESES: | ||||

| -Formaggi pepe, peperoncino | wheel | 8.0 ± 2.1 | 17.2 ± 6.2 | 2.4 ± 1.8 |

| -Formaggi con erbe fieno spezie | wheel | 6.8 ± 2.1 | 16.2 ± 6.5 | 1.9 ± 1.8 |

| -Formaggi affumicati | wheel | 7.2 ± 1.1 | 21.4 ± 9.8 | 2.8 ± 2.6 |

| -Formaggi erborinati | wheel | 10.6 ± 2.5 | 16.0 ± 5.9 | 1.9 ± 1.1 |

| -Formaggi alla birra, balsamico | wheel | 8.5 ± 1.0 | 27.0 ± 6.4 | 5.1 ± 1.8 |

| GOAT CHEESES: | ||||

| -Caprino coagulazione acida | variable | 3.8 ± 0.6 | 7.0 ± 2.8 1 | 0.2 ± 0.1 |

| -Caprino coagulazione presamica | wheel | 9.8 ± 4.7 | 20.8 ± 7.5 | 4.6 ± 1.4 |

| OTHER CHEESES: | ||||

| -Freschi, freschissimi | variable | 5.5 ± 2.2 | 12.2 ± 5.3 1 | 0.8 ± 0.7 |

| -Caciotta | wheel | 6.8 ± 1.1 | 14.4 ± 4.1 | 1.1 ± 0.8 |

| -Latteria | wheel | 9.2 ± 3.1 | 30.0 ± 4.5 | 7.0 ± 3.4 |

| -Crosta fiorita | wheel | 5.2 ± 1.3 | 15.1 ± 7.9 | 1.4 ± 1.8 |

| -Crosta lavata | wheel | 7.7 ± 1.2 | 19.0 ± 9.8 | 2.3 ± 1.8 |

| -Pasta semidura | wheel | 8.8 ± 1.4 | 27.6 ± 6.0 | 5.8 ± 2.7 |

| -Pasta dura | wheel | 10.8 ± 4.7 | 31.1 ± 7.3 | 8.7 ± 2.3 |

| PDO CHEESE Cheese Category | Moisture % | Fat % | Protein % | WSN 1 % | Ash % |

|---|---|---|---|---|---|

| ASIAGO: | |||||

| -fresco (pressato) | 41.0 ± 1.7 | 29.9 ± 1.6 | 23.5 ± 1.1 | 5.3 ± 0.4 | 1.9 ± 0.1 |

| -stagionato-mezzano | 34.4 ± 0.9 | 31.9 ± 1.1 | 29.7 ± 1.0 | 6.5 ± 0.2 | 2.0 ± 0.1 |

| -stagionato-vecchio | 31.5 ± 1.2 | 32.9 ± 1.6 | 31.4 ± 1.8 | 7.1 ± 0.3 | 2.0 ± 0.1 |

| -stagionato-stravecchio | 25.9 ± 2.3 | 35.5 ± 2.1 | 31.2 ± 2.2 | 8.4 ± 0.9 | 2.1 ± 0.1 |

| CASATELLA TREV. | 57.3 ± 1.5 | 21.9 ± 1.6 | 14.8 ± 0.9 | 3.3 ± 0.3 | 1.4 ± 0.2 |

| GRANA PADANO: | |||||

| -Grana Padano | 33.9 ± 1.5 | 27.8 ± 1.1 | 35.4 ± 1.3 | 9.8 ± 0.6 | 2.0 ± 0.1 |

| -Grana Padano riserva | 31.6 ± 1.3 | 28.4 ± 0.9 | 36.7 ± 0.6 | 10.4 ± 0.7 | 2.1 ± 0.0 |

| MONTASIO: | |||||

| -fresco | 35.4 ± 2.1 | 32.6 ± 1.5 | 27.1 ± 1.7 | 6.3 ± 0.5 | 2.0 ± 0.1 |

| -mezzano | 33.1 ± 1.0 | 34.2 ± 2.3 | 28.8 ± 1.7 | 6.9 ± 0.6 | 2.0 ± 0.1 |

| -stagionato | 28.2 ± 3.4 | 36.5 ± 2.3 | 28.1 ± 3.3 | 7.9 ± 0.7 | 2.0 ± 0.0 |

| MONTE VERONESE: | |||||

| -latte intero | 38.6 ± 2.3 | 29.7 ± 1.4 | 25.9 ± 1.1 | 5.6 ± 0.4 | 1.8 ± 0.1 |

| -d’allevo-mezzano | 33.8 ± 1.6 | 33.6 ± 1.0 | 27.8 ± 1.5 | 6.8 ± 0.5 | 2.0 ± 0.1 |

| -d’allevo-vecchio | 28.4 ± 2.4 | 34.6 ± 3.7 | 31.3 ± 3.9 | 7.4 ± 0.1 | 2.0 ± 0.0 |

| PIAVE | 27.8 ± 1.4 | 37.2 ± 0.1 | 29.2 ± 0.9 | 9.1 ± 1.3 | 2.1 ± 0.0 |

| PROVOLONE: | |||||

| -dolce | 40.8 ± 2.4 | 28.6 ± 3.3 | 25.0 ± 1.6 | 6.0 ± 0.1 | 2.0 ± 0.1 |

| -piccante | 37.2 ± 0.4 | 30.9 ± 1.0 | 25.3 ± 1.2 | 6.8 ± 0.8 | 2.1 ± 0.1 |

| CHEESE GROUP Cheese Category | Moisture % | Fat % | Protein % | WSN 1 % | Ash % |

|---|---|---|---|---|---|

| TRADITIONAL CHEESES: | |||||

| -Morlacco del Grappa | 50.9 ± 3.1 | 23.1 ± 2.7 | 19.4 ± 2.3 | 4.4 ± 0.5 | 2.0 ± 0.2 |

| -Malga fresco | 38.6 ± 4.4 | 29.0 ± 2.9 | 26.9 ± 2.3 | 6.3 ± 0.8 | 1.8 ± 0.1 |

| -Malga vecchio | 30.9 ± 3.3 | 30.7 ± 3.3 | 32.9 ± 3.7 | 7.6 ± 0.8 | 1.9 ± 0.1 |

| - Formaggio inbriago | 33.5 ± 2.9 | 33.1 ± 2.0 | 29.0 ± 3.0 | 7.8 ± 1.1 | 2.0 ± 0.1 |

| PASTA FILATA CHEESES: | |||||

| -Mozzarella | 60.8 ± 0.2 | 19.9 ± 2.4 | 15.9 ± 1.9 | 3.0 ± 0.3 | 1.3 ± 0.3 |

| -Pasta filata molle | 47.3 ± 13.2 | 27.9 ± 6.9 | 20.3 ± 5.0 | 4.2 ± 1.6 | 1.5 ± 0.4 |

| -Pasta filata | 38.3 ± 6.0 | 27.6 ± 4.2 | 27.6 ± 1.0 | 6.2 ± 1.5 | 2.0 ± 0.1 |

| FLAVORED CHEESES: | |||||

| -Formaggi pepe, peperoncino | 37.4 ± 4.7 | 31.0 ± 2.3 | 25.1 ± 3.5 | 7.9 ± 2.1 | 1.9 ± 0.2 |

| -Formaggi con erbe fieno spezie | 42.2 ± 16.0 | 28.2 ± 6.9 | 22.5 ± 8.0 | 6.6 ± 1.5 | 1.8 ± 0.3 |

| -Formaggi affumicati | 37.4 ± 4.9 | 30.5 ± 3.8 | 25.2 ± 1.7 | 6.0 ± 0.8 | 1.9 ± 0.1 |

| -Formaggi erborinati | 42.4 ± 5.0 | 25.7 ± 4.0 | 25.2 ± 3.9 | 9.4 ± 2.8 | 1.4 ± 0.5 |

| -Formaggi alla birra, balsamico | 35.5 ± 2.5 | 33.0 ± 1.8 | 26.8 ± 2.0 | 8.6 ± 2.8 | 2.1 ± 0.0 |

| GOAT CHEESES: | |||||

| -Caprino coagulazione acida | 66.3 ± 3.9 | 15.5 ± 2.8 | 12.9 ± 1.3 | 3.2 ± 0.3 | 1.2 ± 0.3 |

| -Caprino coagulazione presamica | 44.5 ± 9.4 | 25.2 ± 5.9 | 24.9 ± 5.6 | 6.3 ± 2.2 | 2.0 ± 0.3 |

| OTHER CHEESES: | |||||

| -Freschi, freschissimi | 56.4 ± 4.8 | 23.4 ± 4.0 | 14.5 ± 2.5 | 3.4 ± 0.4 | 1.5 ± 0.3 |

| -Caciotta | 43.3 ± 4.3 | 28.6 ± 3.4 | 21.9 ± 1.6 | 4.9 ± 0.7 | 1.9 ± 0.2 |

| -Latteria | 41.8 ± 3.4 | 29.9 ± 2.9 | 22.8 ± 2.4 | 5.3 ± 0.7 | 1.9 ± 0.2 |

| -Crosta fiorita | 48.9 ± 3.0 | 26.7 ± 3.0 | 19.2 ± 1.5 | 4.4 ± 0.6 | 2.0 ± 0.2 |

| -Crosta lavata | 41.2 ± 5.7 | 30.8 ± 6.2 | 22.0 ± 3.0 | 5.2 ± 1.4 | 2.0 ± 0.1 |

| -Pasta semidura | 35.5 ± 2.9 | 33.4 ± 5.9 | 25.9 ± 2.6 | 6.4 ± 0.9 | 2.0 ± 0.1 |

| -Pasta dura | 30.5 ± 3.2 | 34.1 ± 4.1 | 30.2 ± 3.6 | 8.5 ± 1.5 | 2.0 ± 0.1 |

| PDO CHEESE Cheese Category | L* | a* | b* | C* | h° |

|---|---|---|---|---|---|

| ASIAGO: | |||||

| -fresco (pressato) | 79.1 ± 2.0 | −0.9 ± 0.5 | 13.7 ± 1.5 | 13.7 ± 1.5 | 93.9 ± 2.3 |

| -stagionato-mezzano | 71.8 ± 2.4 | −1.1 ± 0.4 | 11.1 ± 1.4 | 11.2 ± 1.4 | 95.9 ± 2.6 |

| -stagionato-vecchio | 67.1 ± 4.0 | −1.3 ± 0.2 | 11.9 ± 1.8 | 11.9 ± 1.7 | 96.4 ± 1.8 |

| -stagionato-stravecchio | 65.5 ± 4.1 | −1.2 ± 0.5 | 10.4 ± 1.0 | 10.5 ± 1.0 | 96.5 ± 2.6 |

| CASATELLA TREV. | 84.0 ± 8.0 | −1.5 ± 1.0 | 10.1 ± 1.9 | 10.3 ± 1.6 | 99.8 ± 9.7 |

| GRANA PADANO: | |||||

| -Grana Padano | 69.6 ± 4.4 | −0.6 ± 0.4 | 11.3 ± 0.6 | 11.3 ± 0.6 | 93.2 ± 2.2 |

| -Grana Padano riserva | 67.5 ± 3.7 | −0.6 ± 0.3 | 11.4 ± 1.3 | 11.4 ± 1.2 | 93.3 ± 1.8 |

| MONTASIO: | |||||

| -fresco | 76.7 ± 1.3 | −0.9 ± 0.4 | 12.9 ± 1.6 | 13.0 ± 1.6 | 94.2 ± 2.2 |

| -mezzano | 73.4 ± 1.9 | −0.9 ± 0.5 | 12.6 ± 2.3 | 12.6 ± 2.3 | 94.5 ± 3.1 |

| -stagionato | 68.3 ± 4.4 | −1.5 ± 0.6 | 11.7 ± 2.0 | 11.8 ± 2.0 | 97.9 ± 3.9 |

| MONTE VERONESE: | |||||

| -latte intero | 74.1 ± 2.2 | 0.1 ± 1.1 | 17.5 ± 4.2 | 17.6 ± 4.1 | 90.6 ± 4.3 |

| -d’allevo-mezzano | 71.7 ± 2.2 | −0.9 ± 0.6 | 11.3 ± 3.2 | 11.4 ± 3.1 | 95.3 ± 3.4 |

| -d’allevo-vecchio | 68.0 ± 3.4 | −1.2 ± 0.8 | 10.1 ± 3.3 | 10.2 ± 3.2 | 98.2 ± 6.8 |

| PIAVE | 66.1 ± 1.7 | −1.6 ± 0.2 | 8.6 ± 0.5 | 8.7 ± 0.5 | 100 ± 1.7 |

| PROVOLONE: | |||||

| -dolce | 79.4 ± 3.1 | −1.0 ± 0.2 | 12.8 ± 0.1 | 12.8 ± 0.1 | 94.4 ± 0.9 |

| -piccante | 76.4 ± 1.7 | −1.1 ± 0.6 | 11.7 ± 0.6 | 11.8 ± 0.5 | 95.2 ± 3.4 |

| CHEESE GROUP Cheese Category | L* | a* | b* | C* | h° |

|---|---|---|---|---|---|

| TRADITIONAL CHEESES: | |||||

| -Morlacco del Grappa | 82.9 ± 3.0 | −0.4 ± 0.6 | 13.8 ± 2.8 | 13.8 ± 2.8 | 92.0 ± 2.6 |

| -Malga fresco | 73.9 ± 5.2 | 0.3 ± 0.6 | 18.3 ± 2.7 | 18.4 ± 2.7 | 89.2 ± 1.9 |

| -Malga vecchio | 65.3 ± 4.0 | −0.9 ± 0.7 | 14.4 ± 2.6 | 14.4 ± 2.5 | 93.8 ± 2.9 |

| - Formaggio inbriago | 72.0 ± 5.3 | −1.2 ± 0.9 | 13.3 ± 2.7 | 13.4 ± 2.6 | 95.9 ± 5.3 |

| PASTA FILATA CHEESES: | |||||

| -Mozzarella | 89.3 ± 3.6 | −1.4 ± 0.5 | 9.4 ± 1.4 | 9.5 ± 1.4 | 98.1 ± 2.5 |

| -Pasta filata molle | 82.7 ± 5.9 | −1.9 ± 1.6 | 12.6 ± 2.8 | 12.8 ± 3.0 | 97.8 ± 4.3 |

| -Pasta filata | 78.8 ± 5.3 | −1.8 ± 0.8 | 12.7 ± 1.1 | 12.9 ± 1.0 | 98.1 ± 4.2 |

| FLAVORED CHEESES: | |||||

| -Formaggi pepe, peperoncino | 76.9 ± 4.5 | −0.1 ± 1.5 | 14.3 ± 3.2 | 14.4 ± 3.1 | 91.8 ± 7.7 |

| -Formaggi con erbe fieno spezie | 78.4 ± 7.9 | −1.3 ± 0.9 | 12.8 ± 2.7 | 12.9 ± 2.6 | 96.7 ± 5.4 |

| -Formaggi affumicati | 77.8 ± 2.9 | −0.9 ± 0.7 | 14.7 ± 2.4 | 14.8 ± 2.3 | 94.3 ± 3.9 |

| -Formaggi erborinati | 85.2 ± 9.9 | −1.0 ± 1.6 | 16.1 ± 13.6 | 16.3 ± 13.4 | 98.1 ± 8.6 |

| -Formaggi alla birra, balsamico | 78.2 ± 7.7 | −0.1 ± 1.7 | 14.3 ± 4.3 | 14.3 ± 4.4 | 91.4 ± 5.6 |

| GOAT CHEESES: | |||||

| -Caprino coagulazione acida | 91.9 ± 5.1 | −1.6 ± 0.5 | 8.7 ± 1.5 | 8.9 ± 1.4 | 100 ± 4.1 |

| -Caprino coagulazione presamica | 80.9 ± 5.8 | −1.8 ± 0.6 | 9.8 ± 1.8 | 10.0 ± 1.7 | 100 ± 4.5 |

| OTHER CHEESES: | |||||

| -Freschi, freschissimi | 88.8 ± 4.3 | −1.0 ± 0.8 | 11.0 ± 2.4 | 11.1 ± 2.4 | 95.9 ± 4.4 |

| -Caciotta | 82.2 ± 4.1 | −0.6 ± 1.1 | 14.7 ± 3.1 | 14.8 ± 3.1 | 92.7 ± 3.8 |

| -Latteria | 79.5 ± 4.2 | −0.9 ± 0.8 | 14.1 ± 3.0 | 14.2 ± 3.0 | 93.9 ± 3.1 |

| -Crosta fiorita | 85.2 ± 2.8 | −1.2 ± 0.8 | 12.3 ± 2.1 | 12.4 ± 2.0 | 95.9 ± 4.8 |

| -Crosta lavata | 80.9 ± 4.6 | −1.3 ± 1.0 | 13.5 ± 2.4 | 13.6 ± 2.3 | 95.9 ± 4.6 |

| -Pasta semidura | 75.6 ± 3.5 | −1.0 ± 0.4 | 13.5 ± 1.8 | 13.5 ± 1.8 | 94.3 ± 2.2 |

| -Pasta dura | 70.2 ± 7.4 | −1.5 ± 0.8 | 10.9 ± 2.1 | 11.1 ± 2.0 | 98.3 ± 4.8 |

| PDO CHEESE Cheese Category | pH | Firmness, N | Adhesiveness, J−3 |

|---|---|---|---|

| ASIAGO: | |||

| -fresco (pressato) | 5.67 ± 0.19 | 5.5 ± 2.0 | 5.1 ± 2.8 |

| -stagionato-mezzano | 5.80 ± 0.19 | 15.9 ± 4.8 | 13.8± 4.9 |

| -stagionato-vecchio | 5.93 ± 0.32 | 19.0 ± 4.8 | 14.3 ± 5.7 |

| -stagionato-stravecchio | 5.96 ± 0.18 | 20.9 ± 5.1 | 13.4 ± 7.2 |

| CASATELLA TREV. | 5.56 ± 0.15 | 7.1 ± 6.4 | 5.8 ± 0.9 |

| GRANA PADANO: | |||

| -Grana Padano | 5.95 ± 0.28 | 22.2 ± 5.9 | 10.2 ± 2.1 |

| -Grana Padano riserva | 5.98 ± 0.14 | 21.7 ± 12.6 | 10.1 ± 2.9 |

| MONTASIO: | |||

| -fresco | 5.76 ± 0.15 | 12.1 ± 4.2 | 10.2 ± 2.8 |

| -mezzano | 5.87 ± 0.23 | 13.2 ± 3.9 | 10.3 ± 2.9 |

| -stagionato | 5.96 ± 0.31 | 17.6 ± 1.8 | 11.0 ± 1.0 |

| MONTE VERONESE: | |||

| -latte intero | 5.78 ± 0.16 | 7.9 ± 2.9 | 7.1 ± 3.8 |

| -d’allevo-mezzano | 5.66 ± 0.30 | 10.8 ± 3.8 | 8.9 ± 2.6 |

| -d’allevo-vecchio | 6.06 ± 0.23 | 16.2 ± 7.6 | 9.2 ± 2.3 |

| PIAVE | 5.59 ± 0.13 | 26.0 ± 1.9 | 17.0 ± 1.2 |

| PROVOLONE: | |||

| -dolce | 5.21 ± 0.07 | 13.5 ± 9.5 | 8.0 ± 2.1 |

| -piccante | 5.64 ± 0.03 | 11.3 ± 6.4 | 8.2 ± 7.5 |

| CHEESE GROUP Cheese Category | pH | Firmness, N | Adhesiveness, J−3 |

|---|---|---|---|

| TRADITIONAL CHEESES: | |||

| -Morlacco del Grappa | 5.36 ± 0.16 | 3.5 ± 3.1 | 3.2 ± 2.5 |

| -Malga fresco | 5.59 ± 0.19 | 6.4 ± 3.2 | 6.0 ± 2.8 |

| -Malga vecchio | 5.78 ± 0.15 | 14.9 ± 5.0 | 10.3 ± 4.5 |

| - Formaggio inbriago | 5.96 ± 0.18 | 12.5 ± 4.4 | 8.1 ± 2.9 |

| PASTA FILATA CHEESES: | |||

| -Mozzarella | 5.63 ± 0.38 | 3.8 ± 5.8 | 2.1 ± 0.9 |

| -Pasta filata molle | 5.37 ± 0.27 | - | - |

| -Pasta filata | 5.75 ± 0.06 | 11.9 ± 3.7 | 10.2 ± 3.5 |

| FLAVORED CHEESES: | |||

| -Formaggi pepe, peperoncino | 5.63 ± 0.16 | 8.7 ± 6.7 | 5.9 ± 4.4 |

| -Formaggi con erbe fieno spezie | 5.62 ± 0.33 | 8.7 ± 7.7 | 7.1 ± 8.3 |

| -Formaggi affumicati | 5.51 ± 0.14 | 4.9 ± 2.7 | 3.8 ± 2.2 |

| -Formaggi erborinati | 6.61 ± 0.23 | 6.7 ± 4.6 | 6.1 ± 3.2 |

| -Formaggi alla birra, balsamico | 5.41 ± 0.38 | 13.7 ± 8.9 | 7.9 ± 5.0 |

| GOAT CHEESES: | |||

| -Caprino coagulazione acida | 4.70 ± 0.13 | - | - |

| -Caprino coagulazione presamica | 5.52 ± 0.20 | 7.9 ± 5.9 | 6.2 ± 4.8 |

| OTHER CHEESES: | |||

| -Freschi, freschissimi | 5.57 ± 0.46 | 4.8 ± 4.7 | 3.8 ± 2.1 |

| -Caciotta | 5.44 ± 0.23 | 6.0 ± 5.0 | 6.2 ± 4.7 |

| -Latteria | 5.58 ± 0.13 | 5.6 ± 3.5 | 6.0 ± 3.3 |

| -Crosta fiorita | 5.77 ± 0.26 | 2.7 ± 2.3 | 3.3 ± 2.1 |

| -Crosta lavata | 5.51 ± 0.21 | 4.0 ± 3.0 | 3.1 ± 2.7 |

| -Pasta semidura | 5.54 ± 0.26 | 9.9 ± 4.4 | 8.3 ± 3.0 |

| -Pasta dura | 5.90 ± 0.25 | 18.5 ± 9.2 | 12.1 ± 7.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bittante, G.; Amalfitano, N.; Cipolat-Gotet, C.; Lombardi, A.; Stocco, G.; Tagliapietra, F. Major Causes of Variation of External Appearance, Chemical Composition, Texture, and Color Traits of 37 Categories of Cheeses. Foods 2022, 11, 4041. https://doi.org/10.3390/foods11244041

Bittante G, Amalfitano N, Cipolat-Gotet C, Lombardi A, Stocco G, Tagliapietra F. Major Causes of Variation of External Appearance, Chemical Composition, Texture, and Color Traits of 37 Categories of Cheeses. Foods. 2022; 11(24):4041. https://doi.org/10.3390/foods11244041

Chicago/Turabian StyleBittante, Giovanni, Nicolò Amalfitano, Claudio Cipolat-Gotet, Angiolella Lombardi, Giorgia Stocco, and Franco Tagliapietra. 2022. "Major Causes of Variation of External Appearance, Chemical Composition, Texture, and Color Traits of 37 Categories of Cheeses" Foods 11, no. 24: 4041. https://doi.org/10.3390/foods11244041

APA StyleBittante, G., Amalfitano, N., Cipolat-Gotet, C., Lombardi, A., Stocco, G., & Tagliapietra, F. (2022). Major Causes of Variation of External Appearance, Chemical Composition, Texture, and Color Traits of 37 Categories of Cheeses. Foods, 11(24), 4041. https://doi.org/10.3390/foods11244041