E-nose, E-tongue Combined with GC-IMS to Analyze the Influence of Key Additives during Processing on the Flavor of Infant Formula

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

2.2. GC–IMS Analysis

2.3. E-nose Analysis

2.4. E-tongue Analysis

2.5. Statistical Analysis

3. Results and Discussion

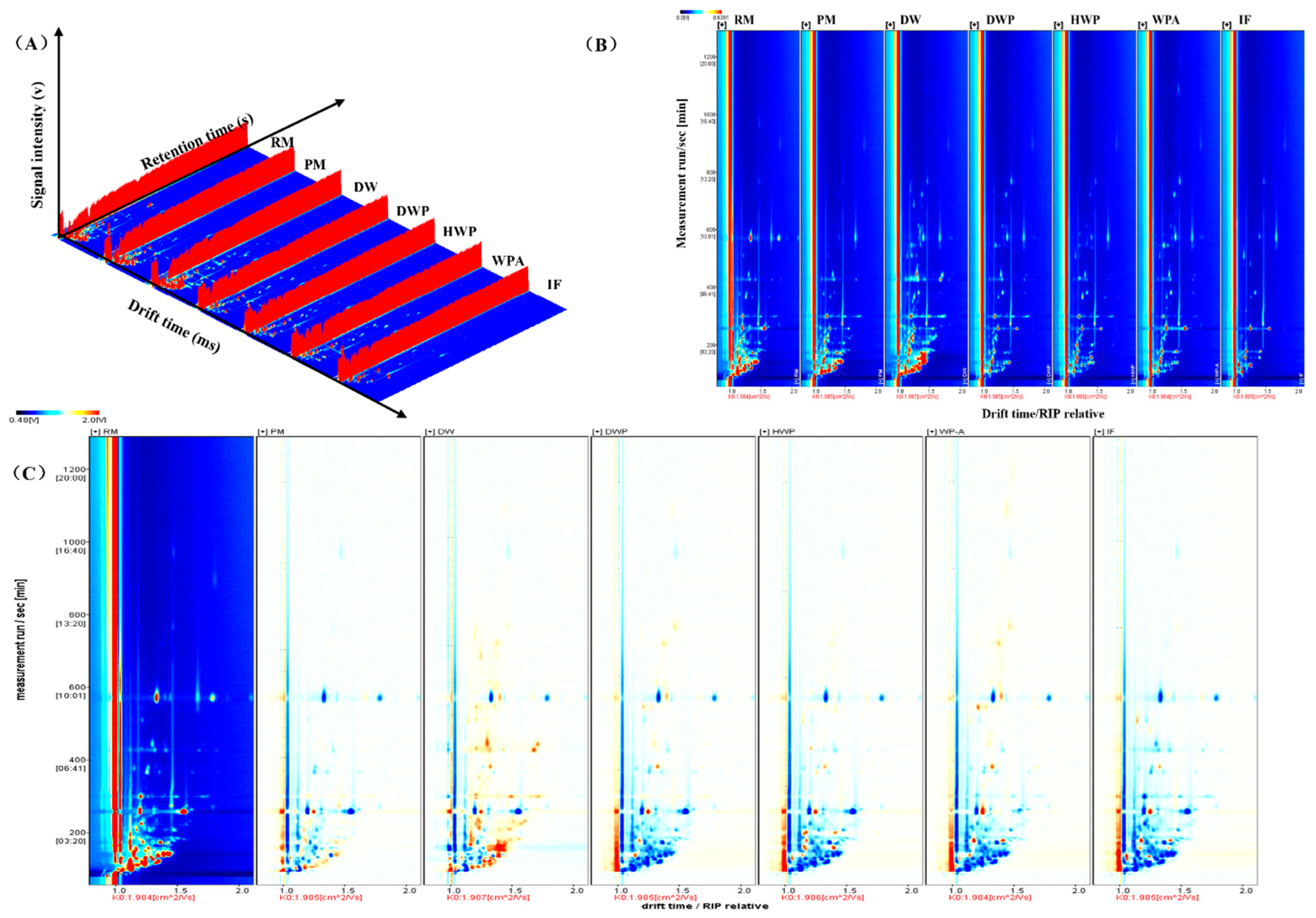

3.1. Volatile Organic Compounds Result

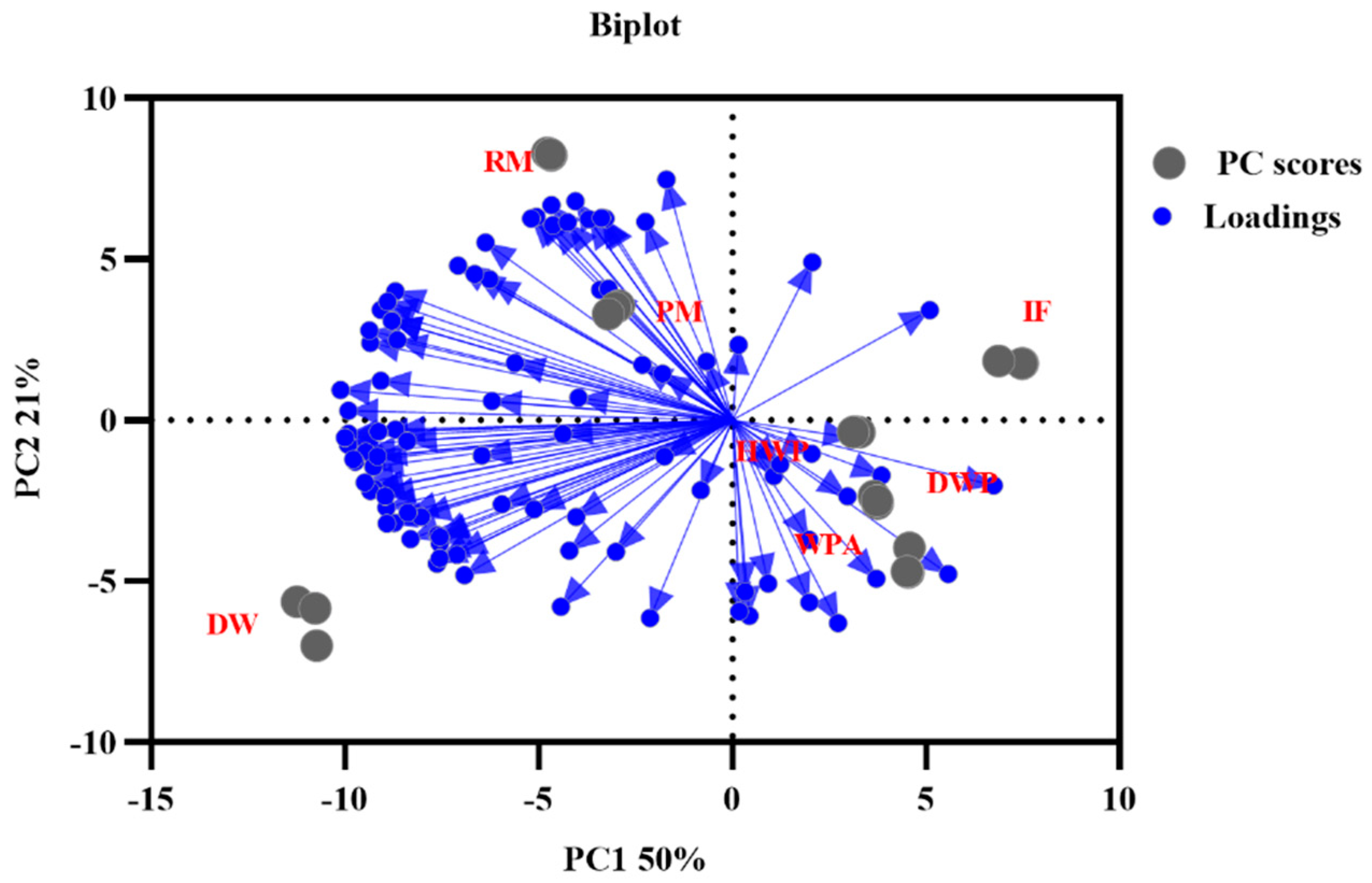

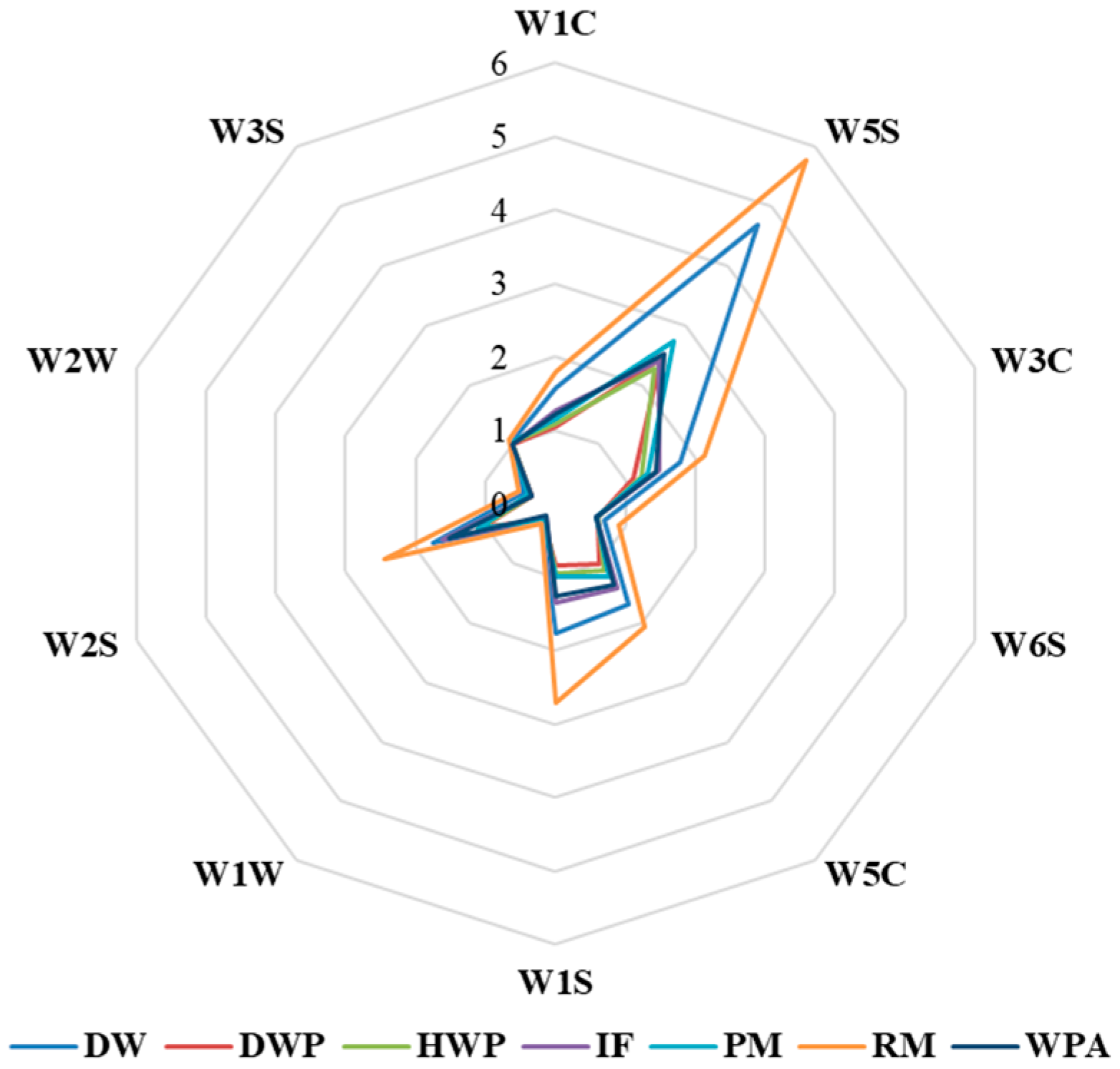

3.2. E-nose Analysis Results

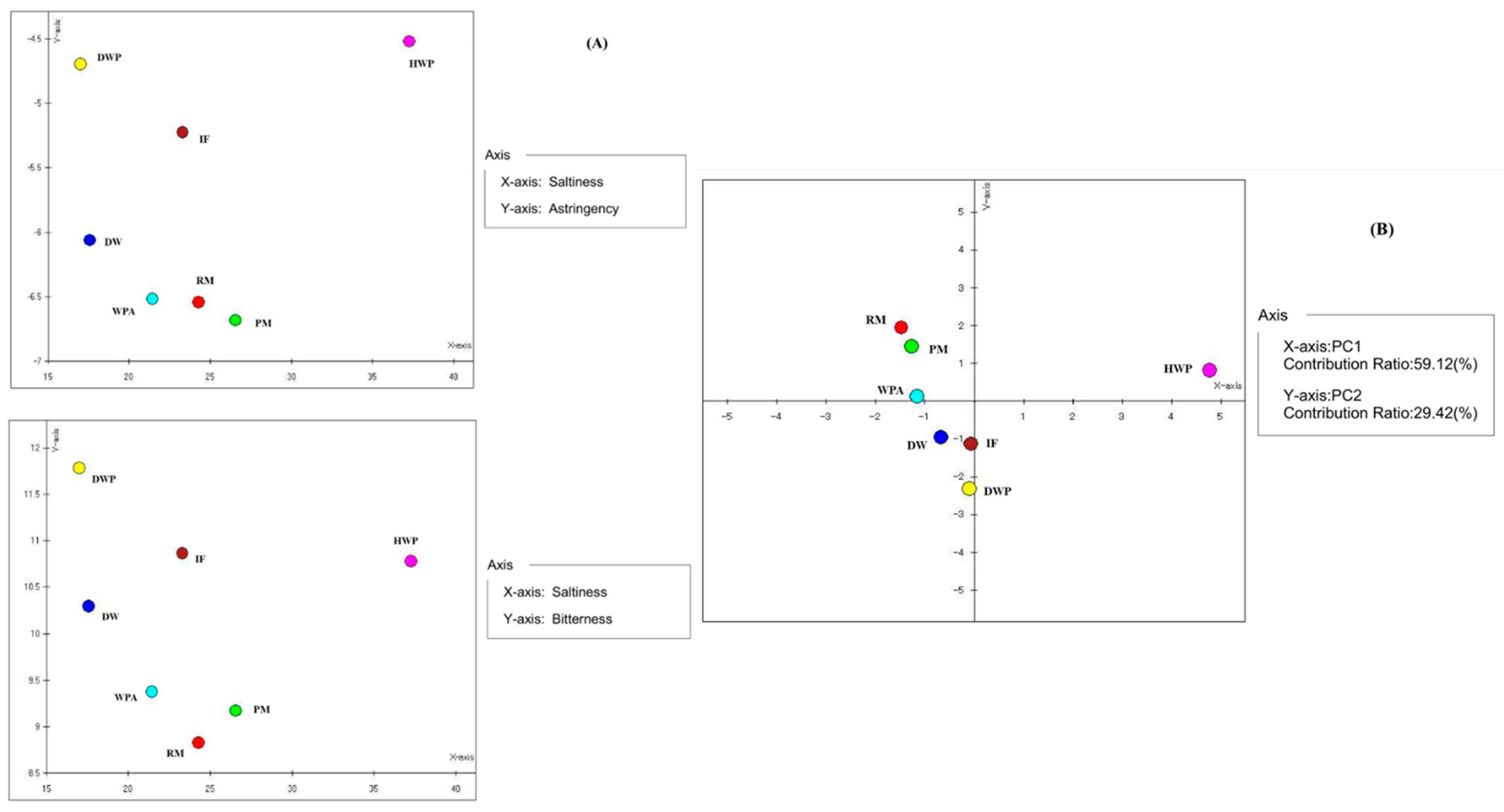

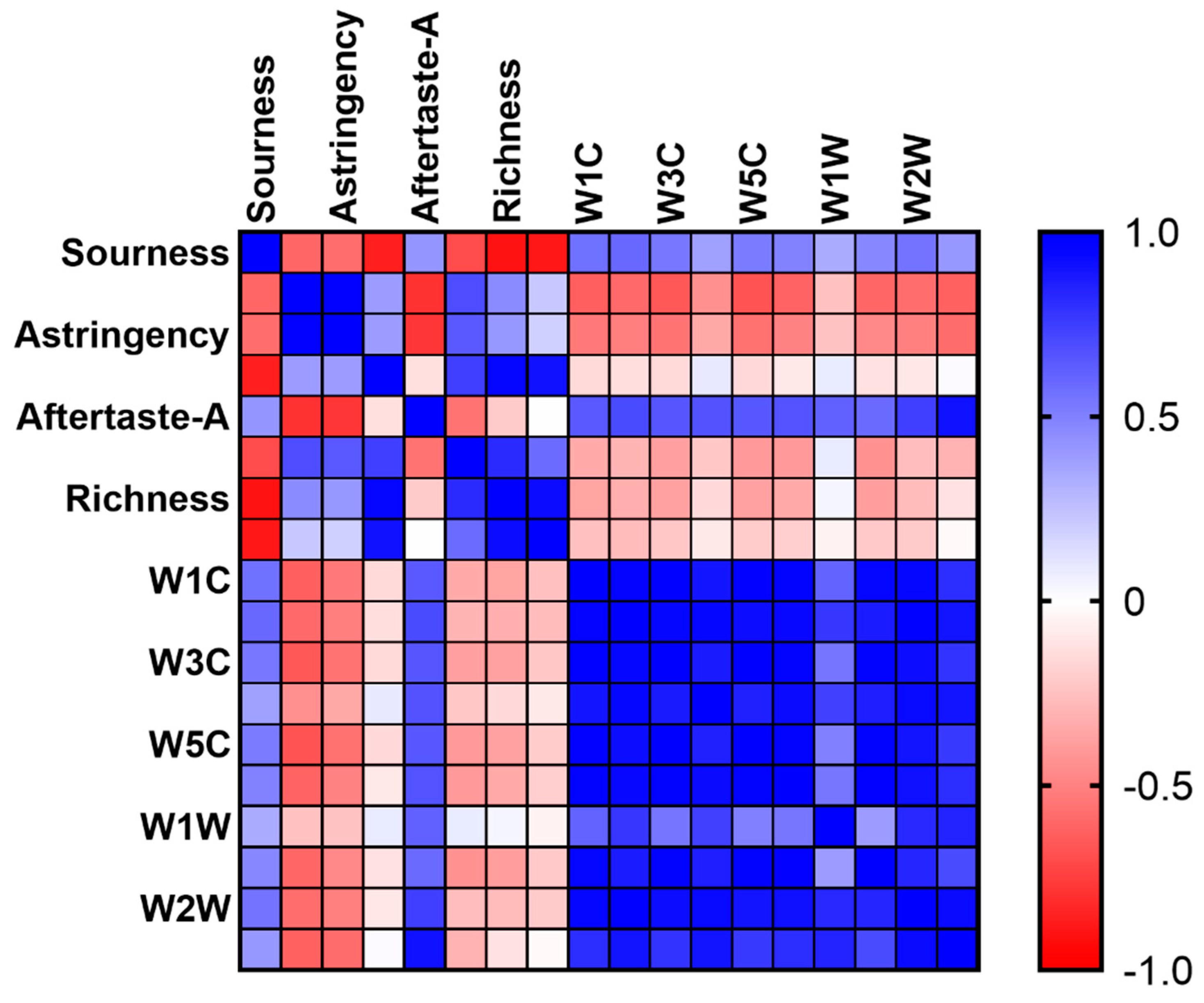

3.3. E-tongue Analysis Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, P.; Low, M.Y.; Zhou, W. Design of experiments and regression modelling in food flavour and sensory analysis: A review. Trends Food Sci. Technol. 2018, 71, 202–215. [Google Scholar] [CrossRef]

- Su, X.Q.; Tortorice, M.; Ryo, S.; Li, X.; Waterman, K.; Hagon, A.; Yin, Y. Sensory lexicons and formation pathways of off-aromas in dairy ingredients: A review. Molecules 2020, 25, 569. [Google Scholar] [CrossRef] [PubMed]

- Jeleń, H.H.; Majcher, M.; Dziadas, M. Microextraction techniques in the analysis of food flavor compounds: A review. Anal. Chim. Acta 2012, 738, 13–26. [Google Scholar] [CrossRef]

- Mennella, J.A.; Jagnow, C.P.; Beauchamp, G.K. Prenatal and postnatal flavor learning by human infants. Pediatr. Res. 2001, 107, E88. [Google Scholar] [CrossRef]

- Harding, J.E.; Cormack, B.E.; Alexander, T.; Alseriler, J.M.; Bloomfield, F.H. Advances in nutrition of the newborn infant. Lancet 2017, 389, 1660–1668. [Google Scholar] [CrossRef]

- Witt, M.; Reutter, K. Embryonic and early fetal development of human taste buds: A transmission electron microscopical study. Anat. Rec. 1996, 246, 507–523. [Google Scholar] [CrossRef]

- Rosenstein, D.; Oster, H. Differential facial responses to four basic tastes in newborns. Child Dev. 1988, 59, 1555–1568. [Google Scholar] [CrossRef]

- Zhang, H.J.; Yuan, Y.S.; Zhu, X.X.; Xu, R.Z.; Shen, H.S.; Zhang, Q.; Ge, X.Z. The effect of different extraction methods on extraction yield, physicochemical properties, and volatile compounds from field muskmelon seed oil. Foods 2022, 11, 721. [Google Scholar] [CrossRef] [PubMed]

- Li, M.Q.; Du, H.T.; Lin, S.Y. Flavor changes of tricholoma matsutake singer under different processing conditions by using HS-GC-IMS. Foods 2021, 10, 531. [Google Scholar] [CrossRef]

- Feng, X.Y.; Wang, H.W.; Wang, Z.R.; Huagn, Y.M.; Jian, Q.K. Discrimination and characterization of the volatile organic compounds in eight kinds of huajiao with geographical indication of China using electronic nose, HS-GC-IMS and HS-SPME-GC–MS. Food Chem. 2022, 375, 131671. [Google Scholar] [CrossRef]

- Hou, H.; Liu, C.; Lu, X.S.; Fang, D.L.; Hu, Q.H.; Zhang, Y.Y.; Zhao, L.Y. Characterization of flavor frame in shiitake mushrooms (Lentinula edodes) detected by HS-GC-IMS coupled with electronic tongue and sensory analysis: Influence of drying techniques. LWT 2021, 146, 111402. [Google Scholar] [CrossRef]

- Niu, Y.W.; Wang, R.L.; Xiao, Z.B.; Zhu, J.C.; Sun, X.X.; Wang, P.P. Characterization of ester odorants of apple juice by gas chromatography-olfactometry, quantitative measurements, odour threshold, aroma intensity and electronic nose. Food Res. Int. 2019, 120, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Li, X.Q.; Yang, Y.H.; Zhu, Y.T.; Jin, Q.; Ben, A.L. A novel strategy for discriminating different cultivation and screening odor and taste flavor compounds in Xinhui tangerine peel using E-nose, E-tongue, and chemometrics. Food Chem. 2022, 384, 132519. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, H.; Wang, C.J.; Yang, X. Volatile component analysis in infant formula using SPME coupled with GC × GC-TOFMS. Anal. Methods 2019, 11, 5017–5022. [Google Scholar] [CrossRef]

- Birch, L.; Anderson, H.; Chiva, M. Acquisition of food preferences and eating patterns in children. In Eating Disorders and Obesity: A Comprehensive Handbook; Danone Institute: Levallois-Perret, France, 2002; pp. 75–79. [Google Scholar]

- Hausner, H.; Philipsen, M.; Skov, T.H.; Petersen, M.A. Characterization of the volatile composition and variations between infant formulas and mother’s milk. Chemosens Percept. 2009, 2, 79–93. [Google Scholar] [CrossRef]

- Alim, A.; Song, H.L.; Raza, A.; Hua, J.C. Identification of bitter constituents in milk-based infant formula with hydrolysed milk protein through a sensory-guided technique. Int. Dairy J. 2020, 110, 104803. [Google Scholar] [CrossRef]

- Yang, P.; Liu, C.; Song, H.L.; Wang, L.J.; Wang, X.Q.; Hua, J.C. Sensory-directed flavor analysis of off-flavor compounds in infant formula with deeply hydrolyzed milk protein and their possible sources. LWT 2020, 119, 108861. [Google Scholar] [CrossRef]

- Golkar, A.; Milani, J.M.; Vasiljevic, T. Altering allergenicity of cow’s milk by food processing for applications in infant formula. Crit. Rev. Food Sci. Nutr. 2019, 59, 159–172. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, D.; Peterson, D.G. Identification of bitter peptides in whey protein hydrolysate. J. Agric. Food Chem. 2014, 62, 5719–5725. [Google Scholar] [CrossRef]

- Chavez-Servin, J.L.; Castellote, A.I.; Lopez-Sabater, M.C. Volatile compounds and fatty acid profiles in commercial milk-based infant formulae by static headspace gas chromatography: Evolution after opening the packet. Food Chem. 2008, 107, 558–569. [Google Scholar] [CrossRef]

- Leksrisompong, P.P.; Miracle, R.E.; Drake, M.A. Characterization of flavor of whey protein hydrolysates. J. Agric. Food Chem. 2010, 58, 6318–6327. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Wang, L.J.; Song, H.L. Detection of odor difference between human milk and infant formula by sensory-directed analysis. Food Chem. 2022, 382, 132348. [Google Scholar] [CrossRef] [PubMed]

- Shen, D.Y.; Song, H.L.; Zou, T.T.; Li, M.K. Characterization of odor-active compounds in moso bamboo (Phyllostachys pubescens Mazel) leaf via gas chromatography-ion mobility spectrometry, one-and two-dimensional gas chromatography-olfactory-mass spectrometry, and electronic nose. Food Res. Int. 2022, 152, 110916. [Google Scholar] [CrossRef] [PubMed]

- Yao, W.S.; Cai, Y.X.; Liu, D.Y.; Chen, Y.; Li, J.R.; Zhang, M.C.; Chen, N.; Zhang, H. Analysis of flavor formation during production of Dezhou braised chicken using headspace-gas chromatography-ion mobility spec-trometry (HS-GC-IMS). Food Chem. 2022, 370, 130989. [Google Scholar] [CrossRef]

- Lin, R.R.; Yuan, H.F.; Wang, C.R.; Yang, Q.Y.; Guo, Z.B. Study on the Flavor Compounds of Fo Tiao Qiang under Different Thawing Methods Based on GC–IMS and Electronic Tongue Technology. Foods 2022, 11, 1330. [Google Scholar] [CrossRef] [PubMed]

- Zhan, F.L.; Sun, L.X.; Zhao, G.M.; Li, M.Y.; Zhu, Z.C. Multiple Technologies Combined to Analyze the Changes of Odor and Taste in Daokou Braised Chicken during Processing. Foods 2022, 11, 963. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.X.; Li, N.; Liu, K.Z.; Yang, J.Y.; Zhao, S.G.; Zheng, N.; Zhou, J.H.; Zhang, Y.D.; Wang, J.Q. Effect of Flaxseed Supplementation in Diet of Dairy Cow on the Volatile Organic Compounds of Raw Milk by HS-GC–IMS. Front. Nutr. 2022, 9, 831178. [Google Scholar] [CrossRef]

- Colahan-Sederstrom, P.M.; Peterson, D.G. Inhibition of key aroma compound generated during ultrahigh-temperature processing of bovine milk via epicatechin addition. J. Agric. Food Chem. 2005, 53, 398–402. [Google Scholar] [CrossRef] [PubMed]

- Bendall, J.G. Aroma compounds of fresh milk from New Zealand cows fed different diets. J. Agric. Food Chem. 2001, 49, 4825–4832. [Google Scholar] [CrossRef]

- Manzocchi, E.; Martin, B.; Bord, C.; Verdier-Metz, I.; Bouchon, M.; Maechi, M.D.; Constant, I.; Giller, K.; Kreuzer, M.; Berard, J.; et al. Feeding cows with hay, silage, or fresh herbage on pasture or indoors affects sensory properties and chemical composition of milk and cheese. J. Dairy Sci. 2021, 104, 5285–5302. [Google Scholar] [CrossRef]

- Braggins, T.; Jamieson, P.; Luckman, M.; Nickless, E.; Yang, D.; Andrewes, P. Variability between farms of New Zealand raw bovine milk flavour: Identification and characterisation of odorous outliers. Int. Dairy J. 2020, 111, 104835. [Google Scholar] [CrossRef]

- Jo, Y.; Carter, B.G.; Barbano, D.M.; Drake, M.A. Identification of the source of volatile sulfur compounds produced in milk during thermal processing. J. Dairy Sci. 2019, 102, 8658–8669. [Google Scholar] [CrossRef] [PubMed]

- Hedegaard, R.V.; Kristensen, D.; Nielsen, J.H. Comparison of descriptive sensory analysis and chemical analysis for oxidative changes in milk. J. Dairy Sci. 2006, 89, 495–504. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yi, S.N.; Lu, J.; Pang, X.Y.; Xu, X.X.; Lv, J.P.; Zhang, S.W. Effect of different heat treatments on the Maillard reaction products, volatile compounds and glycation level of milk. Int. Dairy J. 2021, 123, 105182. [Google Scholar] [CrossRef]

- Siciliano, R.A.; Mazzeo, M.F.; Arena, S.; Renzone, G.; Scaloni, A. Mass spectrometry for the analysis of protein lactosylation in milk products. Food Res. Int. 2013, 54, 988–1000. [Google Scholar] [CrossRef]

- Lesme, H.; Rannou, C.; Famelart, M.H.; Bouhalab, S.; Prost, C. Yogurts enriched with milk proteins: Texture properties, aroma release and sensory perception. Trends Food Sci. Technol. 2020, 98, 140–149. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Yang, X.Y.; Jin, H.N.; Feng, X.H.; Tian, F.; Yang, S.; Ren, Y.W.; Man, C.X.; Zhang, w. Shelf-life prediction and chemical characteristics analysis of milk formula during storage. LWT 2021, 144, 111268. [Google Scholar] [CrossRef]

- Li, Y.H.; Zhang, L.W.; Wang, W.J.; Han, X. Differences in particle characteristics and oxidized flavor as affected by heat-related processes of milk powder. J. Dairy Sci. 2013, 96, 4784–4793. [Google Scholar] [CrossRef]

- Banik, D.D.; Medler, K.F. Bitter, sweet, and umami signaling in taste cells: It’s not as simple as we thought. Curr. Opin. Physiol. 2021, 20, 159–164. [Google Scholar] [CrossRef]

- Barbano, D.M.; Ma, Y.; Santos, M.V. Influence of raw milk quality on fluid milk shelf life. J. Dairy Sci. 2006, 89, E15–E19. [Google Scholar] [CrossRef]

- Lee, A.P.; Barbano, D.M.; Drake, M.A. The influence of ultra-pasteurization by indirect heating versus direct steam injection on skim and 2% fat milks. J. Dairy Sci. 2017, 100, 1688–1701. [Google Scholar] [CrossRef] [PubMed]

| NO. | Sensor | Performance Description (Sensitivity to) | Main Detection Group | Sensor Corresponding Group Threshold (mL/m3) |

|---|---|---|---|---|

| 1 | W5S | nitrogen oxides | NO2 | 1 |

| 2 | W1S | methyl | CH4 | 100 |

| 3 | W2S | alcohols, ketones, and aldehydes | CO | 100 |

| 4 | W3C | ammonia | C6H6 | 10 |

| 5 | W1C | benzene | C7H8 | 10 |

| 6 | W5C | short-chain aromatic compounds and olefin | C3H8 | 1 |

| 7 | W1W | sulfur compounds | H2S | 1 |

| 8 | W2W | organic sulfides | H2S | 1 |

| 9 | W6S | hydrogen | H2 | 100 |

| 10 | W3S | long-chain alkanes | CH4 | 100 |

| NO. | Sensors | Characteristics |

|---|---|---|

| 1 | CT0 | Saltiness |

| 2 | CA0 | Sourness |

| 3 | AAE | Umami, Richness |

| 4 | AE1 | Astringency, Aftertaste-A |

| 5 | C00 | Bitterness, Aftertaste-B |

| Count | Compound | CAS# | Formula | MW | RI | Rt [s] | Dt [a.u.] |

|---|---|---|---|---|---|---|---|

| Aldehyde | |||||||

| 1 | 2-Methyl-propanal | C78842 | C4H8O | 72.1 | 565.7 | 132.631 | 1.10393 |

| 2 | 3-Methylbutanal | C590863 | C5H10O | 86.1 | 630 | 156.409 | 1.17527 |

| 3 | Pentanal | C110623 | C5H10O | 86.1 | 680.7 | 178.104 | 1.18418 |

| 4 | 2-Pentenal(E) | C1576870 | C5H8O | 84.1 | 757.2 | 232.444 | 1.1137 |

| 5 | Hexanal | C66251 | C6H12O | 100.2 | 786 | 257.663 | 1.25466 |

| 6 | Heptanal | C111717 | C7H14O | 114.2 | 896.6 | 381.103 | 1.33043 |

| 7 | 2-heptenal(E) | C18829555 | C7H12O | 112.2 | 956.9 | 481.55 | 1.25549 |

| 8 | Benzaldehyde | C100527 | C7H6O | 106.1 | 970 | 506.611 | 1.15146 |

| 9 | Octanal | C124130 | C8H16O | 128.2 | 1003.1 | 572.572 | 1.41471 |

| 10 | Phenylacetaldehyde | C122781 | C8H8O | 120.2 | 1063.6 | 684.933 | 1.25699 |

| 11 | n-Nonanal | C124196 | C9H18O | 142.2 | 1101.3 | 765.988 | 1.47438 |

| 12 | (E)-2-Decenal | C3913813 | C10H18O | 154.3 | 1248.9 | 1186.104 | 1.48774 |

| Ketone | |||||||

| 1 | Acetone | C67641 | C3H6O | 58.1 | 467.9 | 103.196 | 1.12659 |

| 2 | 2,3-Butanedione | C431038 | C4H6O2 | 86.1 | 554 | 128.68 | 1.1711 |

| 3 | 2-Butanone | C78933 | C4H8O | 72.1 | 562.2 | 131.427 | 1.06066 |

| 4 | 2-Pentanone | C107879 | C5H10O | 86.1 | 670.9 | 173.711 | 1.12572 |

| 5 | 3-Hydroxy-2-butanone | C513860 | C4H8O2 | 88.1 | 716.1 | 200.549 | 1.0539 |

| 6 | Methyl isobutyl ketone | C108101 | C6H12O | 100.2 | 725 | 207.06 | 1.17904 |

| 7 | 2-Hexanone | C591786 | C6H12O | 100.2 | 774.4 | 247.178 | 1.19207 |

| 8 | Cyclopentanone | C120923 | C5H8O | 84.1 | 787.7 | 259.21 | 1.10492 |

| 9 | 2-Heptanone | C110430 | C7H14O | 114.2 | 885.7 | 366.108 | 1.26143 |

| 10 | Cyclohexanone | C108941 | C6H10O | 98.1 | 894.2 | 377.568 | 1.15368 |

| 11 | 2-Octanone | C111137 | C8H16O | 128.2 | 991 | 549.617 | 1.33151 |

| Esters | |||||||

| 1 | Ethyl propanoate | C105373 | C5H10O2 | 102.1 | 696.4 | 186.891 | 1.14908 |

| 2 | Isobutyl acetate | C110190 | C6H12O2 | 116.2 | 759.4 | 234.244 | 1.2371 |

| 3 | Ethyl butyrate | C105544 | C6H12O2 | 116.2 | 788.3 | 259.726 | 1.20472 |

| 4 | Acetic acid butyl ester | C123864 | C6H12O2 | 116.2 | 793.7 | 264.761 | 1.62477 |

| 5 | Ethyl 3-methylbutyrate | C108645 | C7H14O2 | 130.2 | 855.7 | 329.38 | 1.2617 |

| 6 | Ethyl pentanoate | C539822 | C7H14O2 | 130.2 | 896.4 | 380.733 | 1.2681 |

| 7 | Ethyl hexanoate | C123660 | C8H16O2 | 144.2 | 1004 | 574.147 | 1.34172 |

| 8 | Methyl heptanoate | C106730 | C8H16O2 | 144.2 | 1016.7 | 596.043 | 1.35772 |

| 9 | Ethyl octanoate | C106321 | C10H20O2 | 172.3 | 1181.1 | 970.444 | 1.48244 |

| Olefin | |||||||

| 1 | Alpha-Pinene | C80568 | C10H16 | 136.2 | 929.8 | 433.527 | 1.21834 |

| 2 | Beta-Pinene | C127913 | C10H16 | 136.2 | 971.5 | 509.514 | 1.22342 |

| 3 | Myrcene | C123353 | C10H16 | 136.2 | 988.9 | 545.098 | 1.21596 |

| 4 | Alpha-Phellandrene | C99832 | C10H16 | 136.2 | 1009 | 582.713 | 1.2157 |

| Furan | |||||||

| 1 | 2-Acetylfuran | C1192627 | C6H6O2 | 110.1 | 926.8 | 428.438 | 1.12462 |

| 2 | 2-pentylfuran | C3777693 | C9H14O | 138.2 | 988.5 | 544.244 | 1.25556 |

| Alcohol | |||||||

| 1 | Ethanol | C64175 | C2H6O | 46.1 | 437.4 | 95.431 | 1.05592 |

| 2 | Isopentyl alcohol | C123513 | C5H12O | 88.1 | 733.8 | 213.753 | 1.24258 |

| Acid | |||||||

| 1 | 3-Methylbutanoic acid | C503742 | C5H10O2 | 102.1 | 828.7 | 299.497 | 1.20925 |

| CH | Sourness [a.u.] | Saltiness [a.u.] | Bitterness [a.u.] | Astringency [a.u.] | Umami [a.u.] | Aftertaste-A [a.u.] | Aftertaste-B [a.u.] | Richness [a.u.] |

|---|---|---|---|---|---|---|---|---|

| Tasteless | −13 | −6 | 0 | 0 | 0 | 0 | 0 | 0 |

| RM | −46.87 ab | 24.27 c | 8.83 d | −6.54 d | 14.14 e | 0.04 a | 0.31 b | 1.58 bc |

| PM | −48.63 c | 26.52 b | 9.17 d | −6.68 d | 14.76 d | 0.02 b | 0.21 c | 2.36 b |

| DW | −46.2 a | 17.55 e | 10.30 c | −6.06 c | 17.33 b | −0.1 c | 0.24 c | 0.18 d |

| DWP | −47.95 bc | 16.99 e | 11.79 a | −4.70 a | 15.55 c | −0.11 cd | 0.21 c | 0.78 d |

| HWP | −56.92 e | 37.24 a | 10.78 ab | −4.52 a | 18.99 a | −0.13 d | 0.40 a | 8.51 a |

| WP-A | −47.99 bc | 21.42 d | 9.38 d | −6.52 d | 14.86 d | −0.09 c | 0.22 c | 1.22 bcd |

| IF | −49.99 d | 23.27 c | 10.87 b | −5.22 b | 15.00 cd | −0.1 cd | 0.21 c | 0.85 cd |

| p-value | 0 | 0.012 | 0 | 0 | 0.003 | 0.036 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, X.; Guo, H.; Zhang, Y.; Zheng, N.; Liu, H.; Wang, J. E-nose, E-tongue Combined with GC-IMS to Analyze the Influence of Key Additives during Processing on the Flavor of Infant Formula. Foods 2022, 11, 3708. https://doi.org/10.3390/foods11223708

Chi X, Guo H, Zhang Y, Zheng N, Liu H, Wang J. E-nose, E-tongue Combined with GC-IMS to Analyze the Influence of Key Additives during Processing on the Flavor of Infant Formula. Foods. 2022; 11(22):3708. https://doi.org/10.3390/foods11223708

Chicago/Turabian StyleChi, Xuelu, Hongxia Guo, Yangdong Zhang, Nan Zheng, Huimin Liu, and Jiaqi Wang. 2022. "E-nose, E-tongue Combined with GC-IMS to Analyze the Influence of Key Additives during Processing on the Flavor of Infant Formula" Foods 11, no. 22: 3708. https://doi.org/10.3390/foods11223708

APA StyleChi, X., Guo, H., Zhang, Y., Zheng, N., Liu, H., & Wang, J. (2022). E-nose, E-tongue Combined with GC-IMS to Analyze the Influence of Key Additives during Processing on the Flavor of Infant Formula. Foods, 11(22), 3708. https://doi.org/10.3390/foods11223708