Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemical Reagents

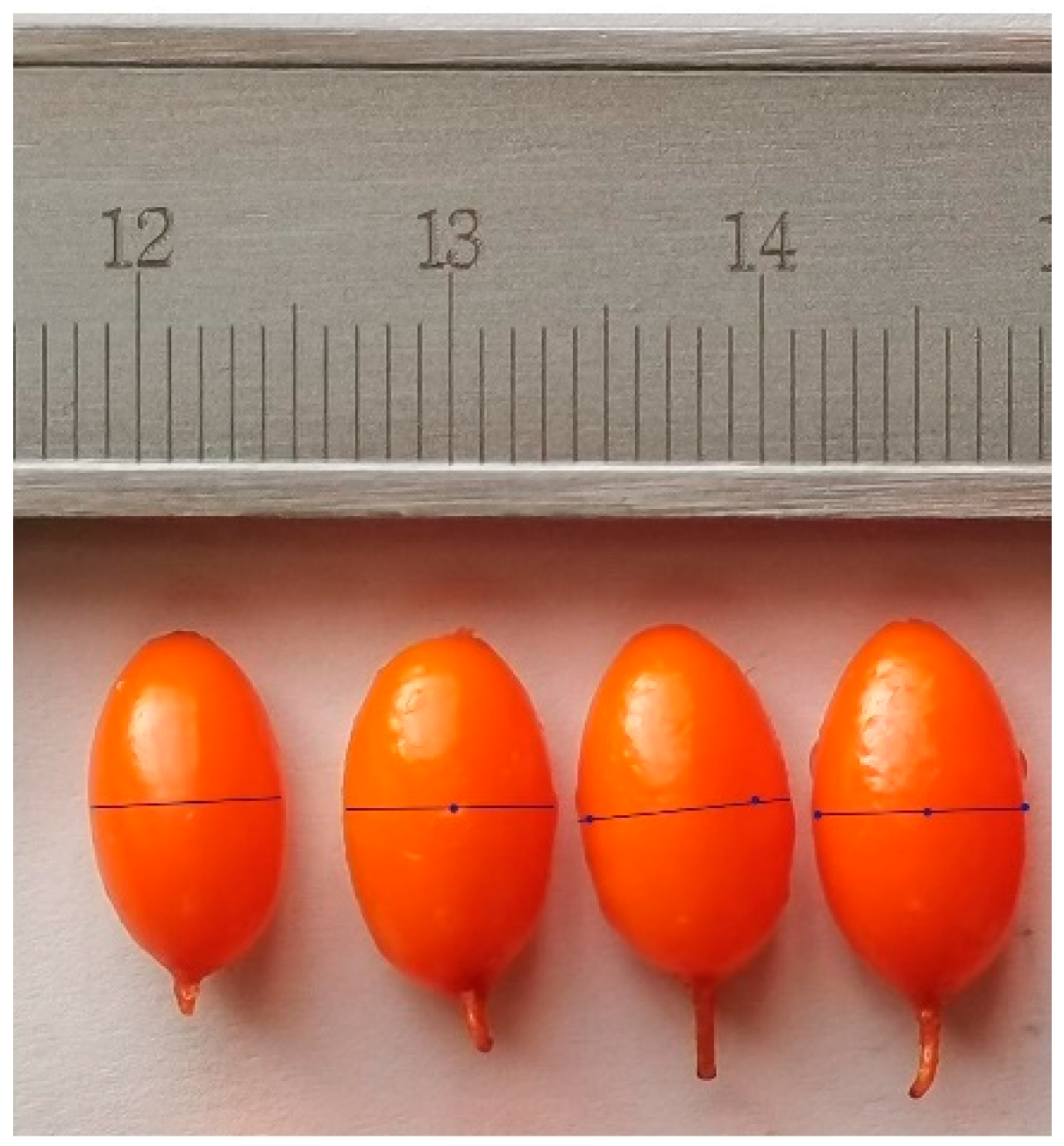

2.2. Pretreatment Methods

- (i)

- The control group (CG). Without any pretreatment and dried by HAD were used as the control group. It means that the seabuckthorn berries only need to be frozen for 12 h at −18 °C and quickly transferred to HAD.

- (ii)

- Prick holes in the skin (PH). The only difference from the control group was that pricking holes (number, 1, 3, 6; abbreviation, PH1, PH3, PH6) in the skin of frozen seabuckthorn berries quickly using a homemade metal needle with a diameter of 0.9 × 10−3 m before HAD.

- (iii)

- Ultrasonic-assisted alkali (UA). The seabuckthorn berries were placed in a beaker with 3% Na2CO3 and introduced into an ultrasonic bath (Ultrasonic Instruments, KQ5200DE, Kunshan, China) for 5, 10, 15 min separately (abbreviation, UA5, UA10, UA15); the frequency and power of ultrasound were 40 kHz and 200 W, respectively. The temperature during UA was noted to be always lower than 30 °C. Then, they were washed three times with tap water and dried with tissues. Finally, they were frozen for 12 h at −18 °C and quickly transferred to HAD.

- (iv)

- The combination of ultrasonic-assisted alkali and pricking holes in the skin (UA + PH). UA + PH was carried out for each set of ultrasonic time in combination with each number of pricking holes, therefore making a total of 9 trail sets such as- (UA5 + PH1, UA5 + PH3, UA5 + PH6, UA10 + PH1, UA10 + PH3, UA10 + PH6, UA15 + PH1, UA15 + PH3, UA15 + PH6). This method includes the following steps: finishing the work of UA until the frozen time’s over, pricking holes quickly before HAD.

2.3. Microstructure

2.4. Hot Air Drying

2.5. Drying Kinetics

2.6. Color Assessment

2.7. Vitamin C Content

2.8. Total Flavonoid Content (TFC)

2.9. Total Phenolic Content (TPC)

2.10. Rehydration Ratio (RR)

2.11. Comprehensive Evaluation

2.12. Statistical Analysis

3. Results and Discussion

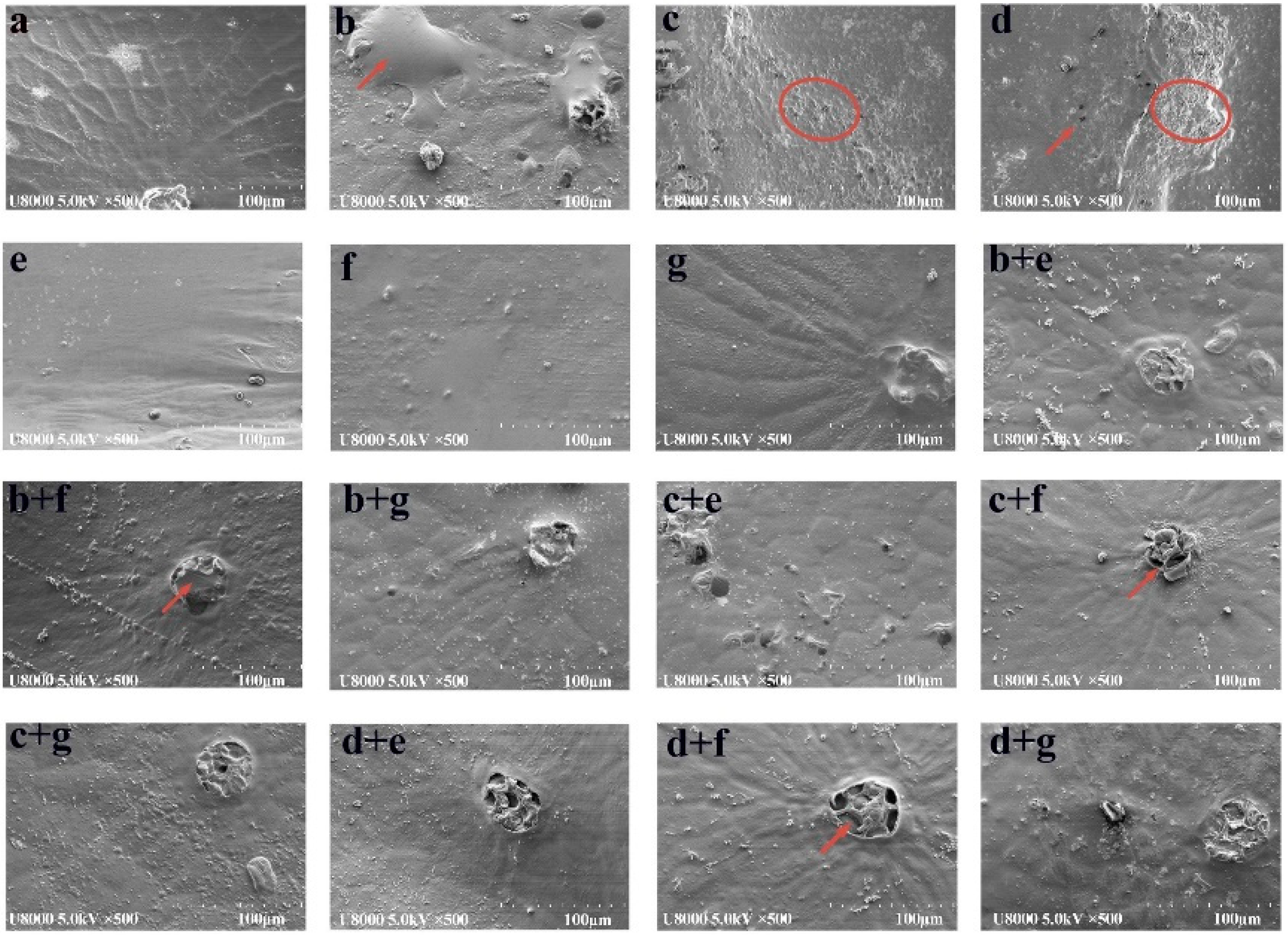

3.1. Effects of Different Pretreatment Methods on the Surface Microstructure

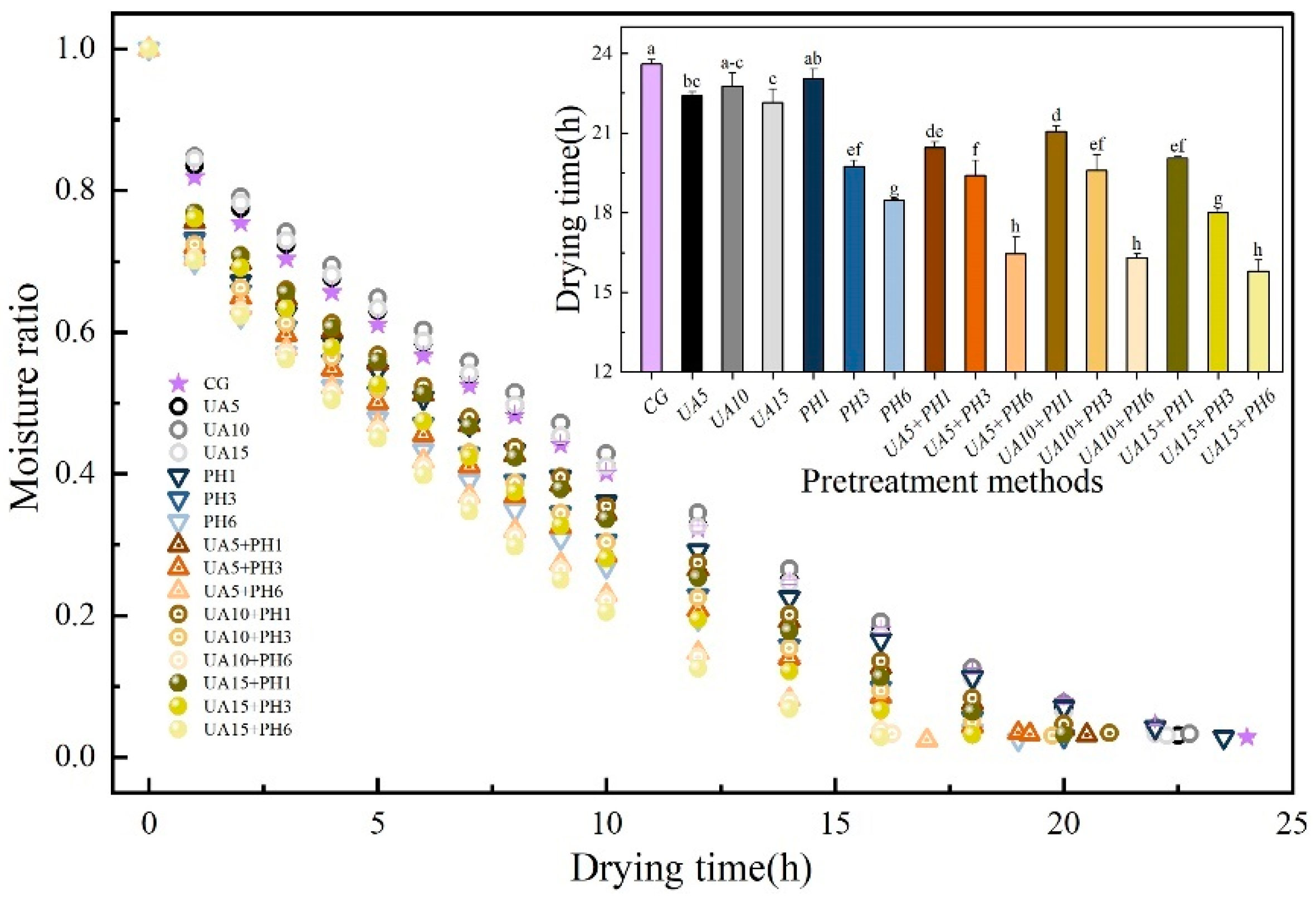

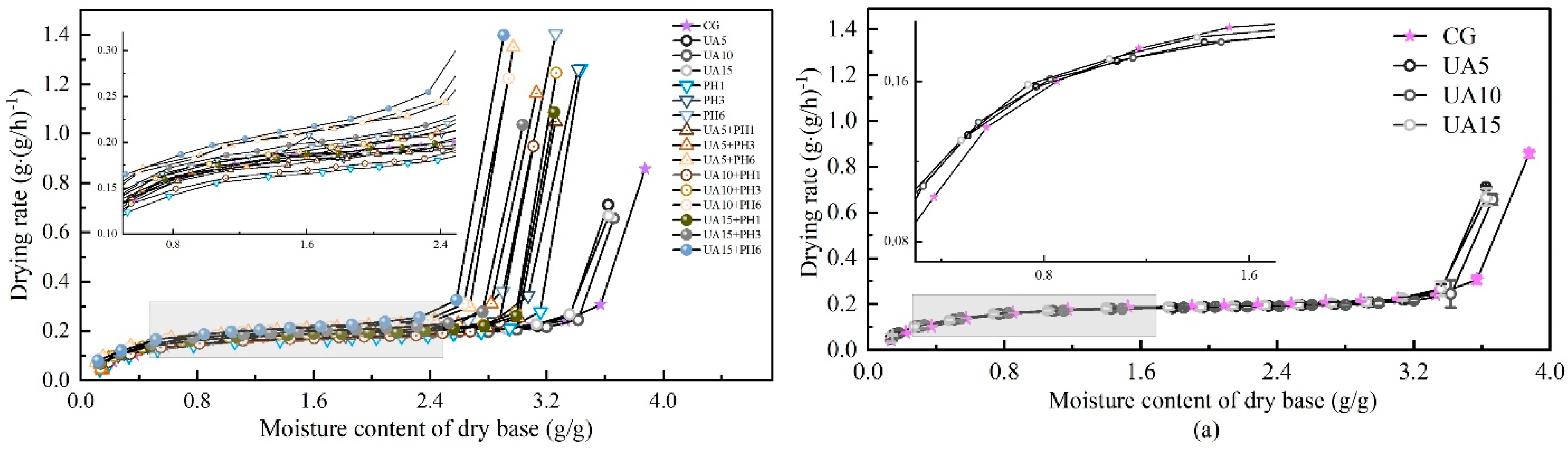

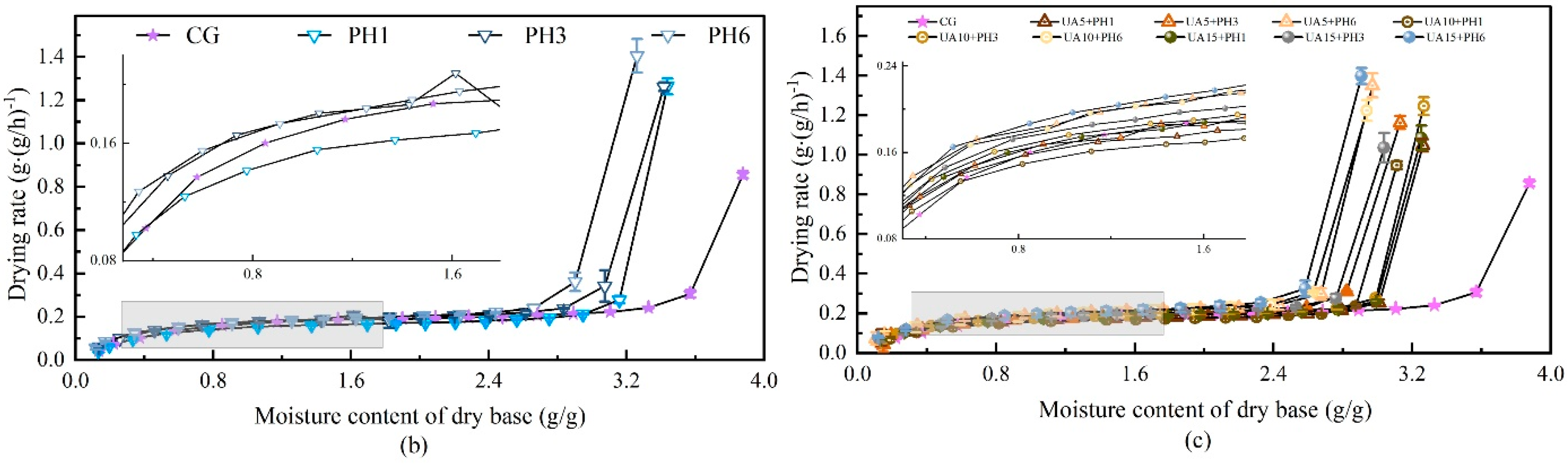

3.2. Effects of Different Pretreatment Methods on Drying Characteristics

3.3. Effects of Different Pretreatment Methods on Color Parameters

3.4. The Content of Vitamin C

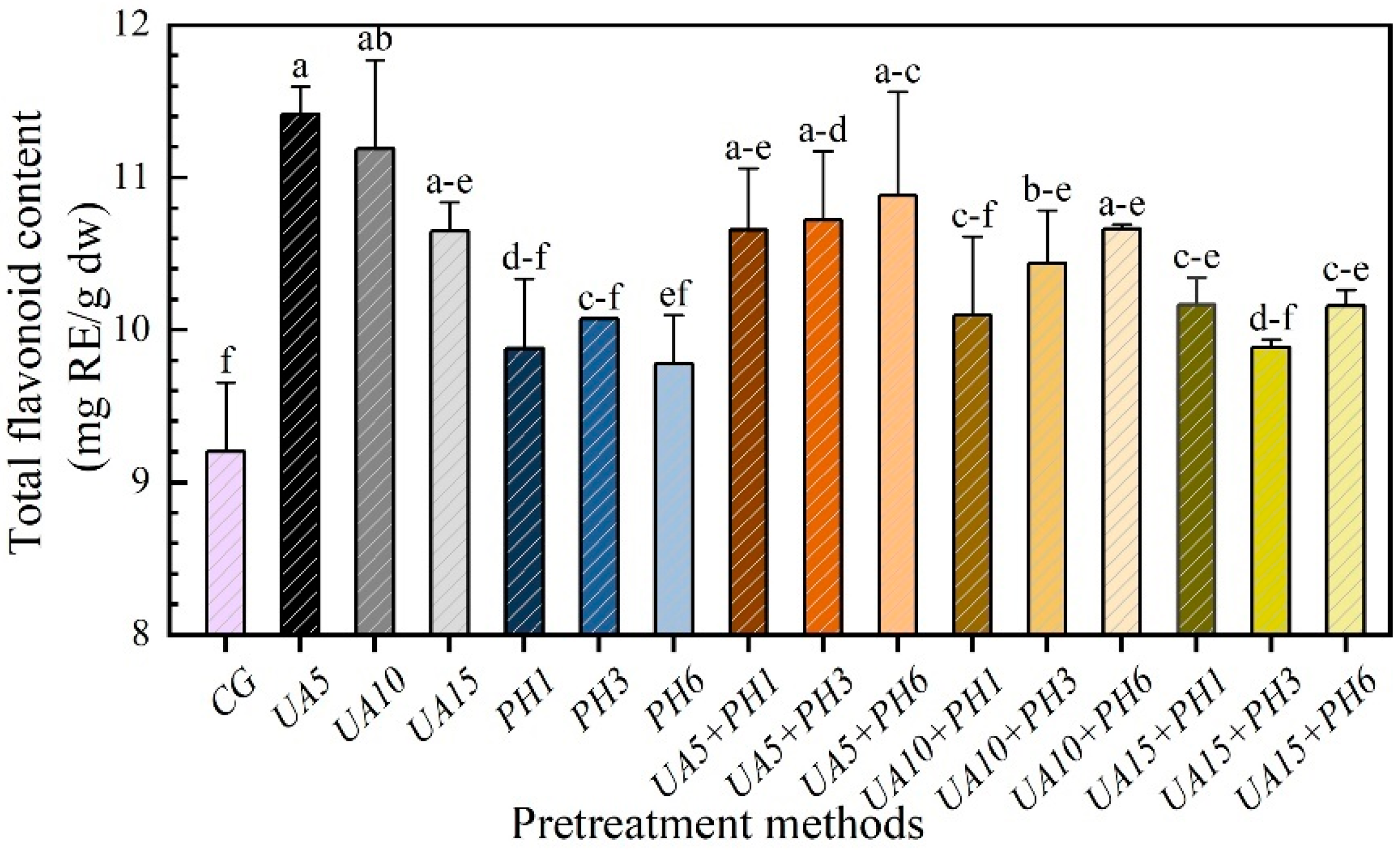

3.5. Total Flavonoid Content (TFC)

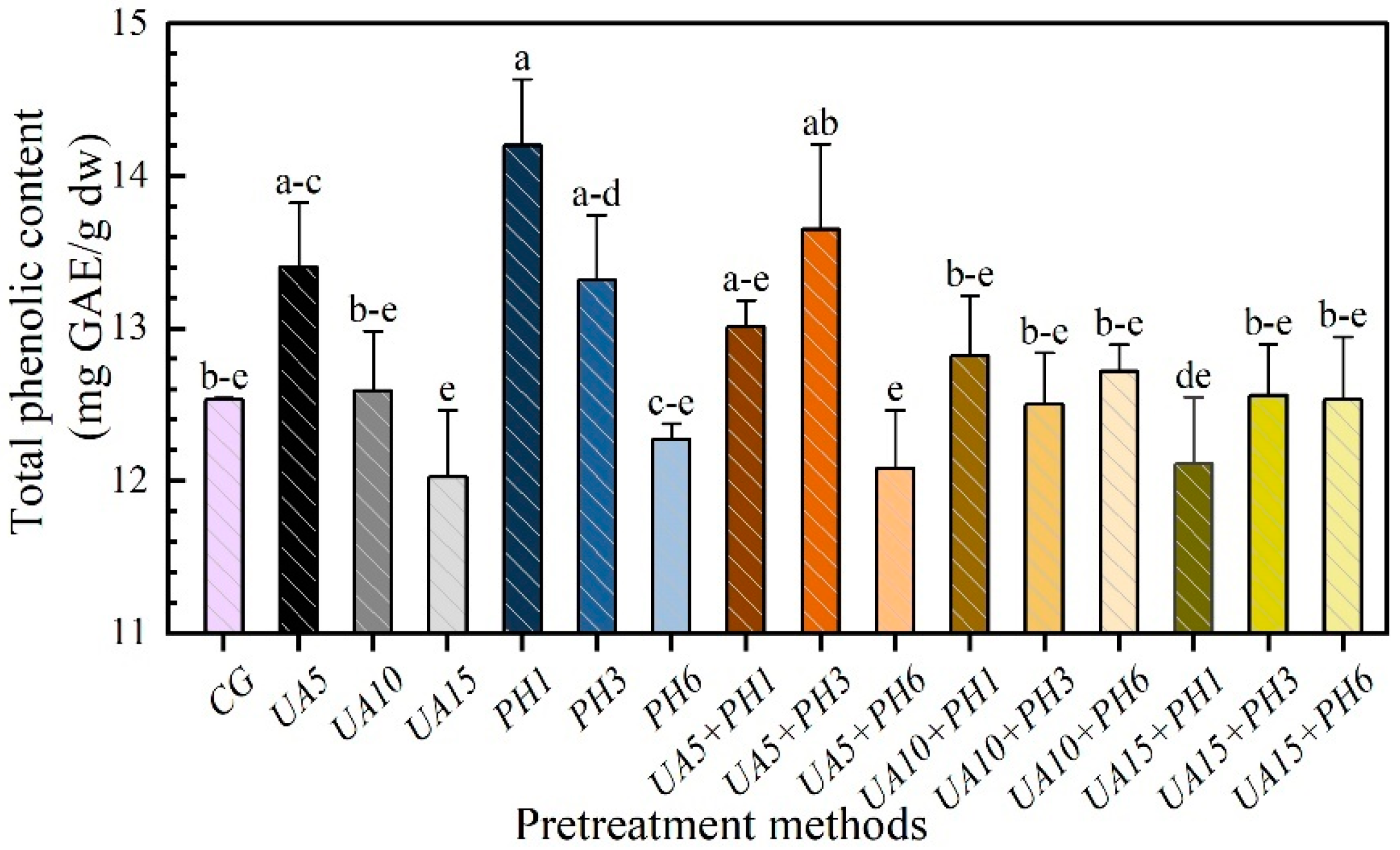

3.6. Total Phenolic Content (TPC)

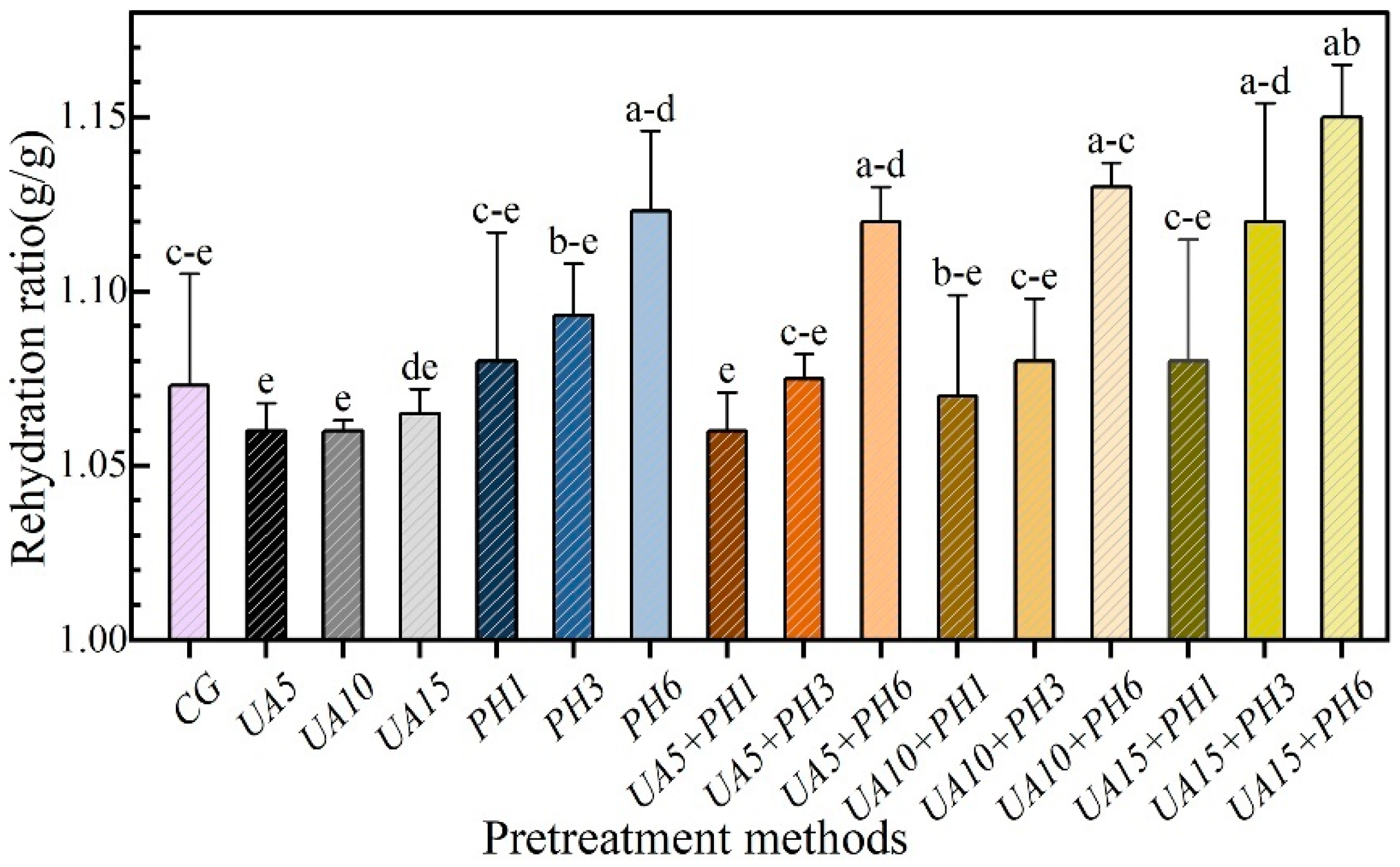

3.7. Rehydration Capacity of Seabuckthorn Berries

3.8. Comprehensive Score

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ciesarová, Z.; Murkovic, M.; Cejpek, K.; Kreps, F.; Tobolková, B.; Koplík, R.; Belajová, E.; Kukurová, K.; Daško, L.; Panovská, Z.; et al. Why is sea buckthorn (Hippophae rhamnoides L.) so exceptional? A review. Food Res. Intl. 2020, 133, 109170. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Wang, S.L.; Liang, C.; Wang, Y.W.; Wen, P.J.; Wang, F.; Qin, G.Q. Acute and subchronic toxicity studies of seabuckthorn (Hippophae rhamnoides L.) oil in rodents. Regul. Toxicol. Pharmacol. 2017, 91, 50–57. [Google Scholar] [CrossRef] [PubMed]

- Ji, M.Y.; Gong, X.; Li, X.; Wang, C.C.; Li, M.H. Advanced research on the antioxidant activity and mechanism of polyphenols from Hippophae species-a review. Molecules 2020, 25, 917. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, P.C. 1H Nuclear Magnetic Resonance (NMR)-Based Metabolome Diversity of Seabuckthorn (H. rhamnoides L.) Berries Originating from Two Geographical Regions of Indian Himalayas. Food Anal. Methods 2022, 15, 157–171. [Google Scholar] [CrossRef]

- Li, J.Y. Design and Experimental Study of Seabuckthorn Infrared Hot Air Drying Oven. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2022. [Google Scholar]

- Khuwijitjaru, P.; Somkane, S.; Nakagawa, K.; Mahayothee, B. Osmotic Dehydration, Drying Kinetics, and Quality Attributes of Osmotic Hot Air-Dried Mango as Affected by Initial Frozen Storage. Foods 2022, 11, 489. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.; Yao, N.N.; Che, F.B.; Ma, Y.; Zhang, T. Effects of 5 Different Drying Methods on Drying Characteristic and Quality of Hippophae rhamnoides L. Sci. Technol. Food Ind. 2022, 43, 41–48. [Google Scholar]

- Song, H.Q.; Chen, Q.Q.; Bi, J.F.; Zhou, L.Y.; Yi, J.Y. Effects of Different Drying Methods and Alkali Pretreatment on Drying Characteristics and Quality of Fresh Goji Berries (Lycium barbarum). Food Sci. 2018, 39, 197–206. [Google Scholar]

- Wan, F.X.; Li, W.Q.; Luo, Y.; Wei, B.; Huang, X.P. Effects of ultrasonic pretreatment on far infrared vacuum drying properties and quality of Lycium barbarum. Chin. Tradit. Herb. Drugs 2020, 51, 4654–4663. [Google Scholar]

- Zhang, Q.; Xiao, H.W.; Yang, X.H.; Bai, J.W.; Lou, Z.; Gao, Z.J. Effects of pretreatment on air impingement drying characteristics and product color for line pepper. Trans. CSAE 2012, 28, 276–281. [Google Scholar]

- Chen, F.Y.; Zhang, M.; Devahastin, S.; Yu, D.X. Comparative Evaluation of the Properties of Deep-Frozen Blueberries Dried by Vacuum Infrared Freeze Drying with the Use of CO2 Laser Perforation, ultrasound, and Freezing-Thawing as Pretreatments. Food Bioprocess Technol. 2021, 14, 1805–1816. [Google Scholar] [CrossRef]

- Zhang, B.; Ji, C.Y.; Xu, W.Y.; Jiang, S.J.; Song, Z.; Chen, H. Heat-pump stage-changed drying characteristics and product quality in comparison for seedless thick-skinned grapes under different pretreatment conditions. Jiangsu J. Agric. Sci. 2018, 34, 1144–1152. [Google Scholar]

- Fava, J.; Nieto, A.; Hodara, K.; Alzamora, S.M.; Castro, M.A. A study on structure (micro, ultra, nano), mechanical, and colorchanges of Solanum lycopersicum L. (cherry tomato) fruits induced by hydrogen peroxide andultrasound. Food Bioprocess Technol. 2017, 10, 1324–1336. [Google Scholar] [CrossRef]

- Yao, N.N.; Che, F.B.; Zhang, T.; Li, Y.H.; Zhang, Q.; Zhang, H.; Zhou, J.J.; Wu, X. Comparative analysis of different pretreatment on improving hot air drying effect of seabuckthorn (Hippophae rhamnoides L.). Mod. Food Sci. Technol. 2020, 36, 211–219. [Google Scholar]

- Gao, R.P. Study on Ultrasound Assisted Processing Technology of Tomato Products and Its Working Mechanism. Doctoral Thesis, Southwest University, Chongqing, China, 2019. [Google Scholar]

- Chinese Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China: Part I; China Medical Press: Beijing, China, 2020; p. 260. [Google Scholar]

- Zhao, D.D. Research on Processing Characteristics of Wolfberry and Theory Analysis and Appilication of Heat Pump Drying System. Doctoral Thesis, China Agricultural University, Beijing, China, 2016. [Google Scholar]

- Ojediran, J.O.; Okonkwo, C.E.; Olaniran, A.F.; Iranloye, Y.M.; Adewumi, A.D.; Erinle, O.; Afolabi, Y.T.; Adeyi, O.; Adeyi, A. Hot air convective drying of hog plum fruit (Spondias mombin): Effects of physical and edible-oil-aided chemical pretreatments on drying and quality characteristics. Heliyon 2021, 7, e08312. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Coşkun, S.; Doymaz, İ.; Tunçkal, C.; Erdoğan, S. Investigation of drying kinetics of tomato slices dried by using a closed loop heat pump dryer. Heat Mass. Transfer. 2017, 53, 1863–1871. [Google Scholar] [CrossRef]

- Alibas, I.; Yilmaz, A.; Asik, B.B.; Erdoğan, H. Influence of drying methods on the nutrients, protein content and vitamin profile of basil leaves. J. Food Compos. Anal. 2021, 96, 103758. [Google Scholar] [CrossRef]

- Li, R.F.; Zhao, X.Y.; Gao, Y.D. Determination of Ascorbic Acid Content of Fruits and Vegetables with Red Color by 2,6 - Dichlorophenolindophenol Converse Titration Method. Acta Nutr. Sin. 2012, 34, 507–509. [Google Scholar]

- Wang, W.N. Analysis of Flavonoids in Sea Buckthorn Fruits. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2020. [Google Scholar]

- Heras, R.M.-L.; Heredia, A.; Castelló, M.L.; Andrés, A. Influence of drying method and extraction variables on the antioxidant properties of persimmon leaves. Food Biosci. 2014, 6, 1–8. [Google Scholar] [CrossRef]

- Pirce, F.; Vieira, T.M.F.S.; Augusto-Obara, T.R.; Alencar, S.M.; Romero, F.; Scheuermann, E. Effects of convective drying assisted by ultrasound and osmotic solution on polyphenol, antioxidant and microstructure of murtilla (Ugni molinae Turcz) fruit. J. Food Sci. Technol. 2021, 58, 138–146. [Google Scholar]

- Qiu, Y.; Bi, J.F.; Jin, X.; Hu, L.N.; Lyu, J.; Wu, X.Y. An understanding of the changes in water holding capacity of rehydrated shiitake mushroom (Lentinula edodes) from cell wall, cell membrane and protein. Food Chem. 2021, 351, 129230. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.Y.; Liu, Y.N.; Qiao, X.Q.; Duan, X.; Zhang, L.D.; Liu, D.L. Quality Evaluation of Chinese Yam Drying Powder Based on Variation Coefficient Weight. Food Sci. 2017, 38, 53–59. [Google Scholar]

- Ashtiani, S.-H.M.; Rafiee, M.; Mohebi Morad, M.; Khojastehpour, M.; Khani, M.R.; Rohani, A.; Shokri, B.; Martynenko, A. Impact of gliding arc plasma pretreatment on drying efficiency and physicochemical properties of grape. Innov. Food Sci. Emerg. Technol. 2020, 63, 102381. [Google Scholar] [CrossRef]

- Gao, R.P.; Ye, F.Y.; Lu, Z.Q.; Wang, J.J.; Shen, X.L.; Zhao, G.H. A novel two-step ultrasound post-assisted lye peeling regime for tomatoes: Reducing pollution while improving product yield and quality. Ultrason. Sonochemistry 2018, 45, 267–278. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.H.; Huang, X.; Wang, J.; Xiao, H.W.; Yang, X.H.; Zhu, L.C.; Qi, X.C.; Zhang, Q.; Hu, B. Pulsed Vacuum Drying of Pepper (Capsicum annuum L.): Effect of High-Humidity Hot Air Impingement Blanching Pretreatment on Drying Kinetics and Quality Attributes. Foods 2022, 11, 318. [Google Scholar] [CrossRef]

- Xie, Y.K.; Lin, Y.W.; Li, X.Y.; Yang, H.; Han, J.H.; Shang, C.J.; Li, A.Q.; Xiao, H.W.; Lu, F.Y. Peanut drying: Effects of various drying methods on drying kinetic models, physicochemical properties, germination characteristics, and microstructure. Inf. Process. Agric. 2022, in press. [CrossRef]

- Xie, H.; Qi, Y.R.; Wan, N.; Wu, Z.F.; Wang, X.C.; Li, Y.H.; Yang, M. Shrinkage mechanism, influencing factors and control strategies in drying process of Chinese medicinal materials. Chin. Tradit. Herb. Drugs 2022, 53, 2872–2881. [Google Scholar]

- Bai, J.W.; Sun, D.W.; Xiao, H.W.; Mujumdar, A.S.; Gao, Z.J. Novel high-humidity hot air impingement blanching (HHAIB) pretreatment enhances drying kinetics and color attributes of seedless grapes. Innov. Food Sci. Emerg. Technol. 2013, 20, 230–237. [Google Scholar] [CrossRef]

- Zia, M.P.; Alibas, I. Influence of the drying methods on color, vitamin C, anthocyanin, phenolic compounds, antioxidant activity, and in vitro bioaccessibility of blueberry fruits. Food Biosci. 2021, 42, 101179. [Google Scholar] [CrossRef]

- Uğur, H.; Çatak, J.; Mızrak, Ö.F.; Çebi, N.; Yaman, M. Determination and evaluation of in vitro bioaccessibility of added vitamin C in commercially available fruit-, vegetable-, and cereal-based baby foods. Food Chem. 2020, 330, 127166. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, H.W.; Ye, J.H.; Wang, J.; Raghavan, V. Ultrasound Pretreatment to Enhance Drying Kinetics of Kiwifruit (Actinidia deliciosa) Slices: Pros and Cons. Food Bioprocess Technol. 2019, 12, 865–876. [Google Scholar] [CrossRef]

- Wang, P.X.; Cheng, C.X.; Ma, Y.Q.; Zhang, Z.; Jia, M. A literature review of ultrasonic effects in extraction of phenolic compounds from fruits and vegetables. Food Sci. 2019, 40, 338–347. [Google Scholar]

- Lv, Z.L.; Yuan, W.Q.; Zhang, B.L.; Xing, G.L. A review on mass distribution of active components from Hippophae rhamnoides fruits. J. Beijing For. Univ. 2021, 43, 144–152. [Google Scholar]

- Prakash, O.; Baskaran, R.; Chauhan, A.S.; Kudachikar, V.B. Effect of heat processing on phenolics and their possible transformation in low-sugar high-moisture (LSHM) fruit products from Kainth (Pyrus pashia Buch.-ham ex D. Don) fruit. Food Chem. 2022, 370, 130988. [Google Scholar] [CrossRef]

- Zielinska, M.; Michalska, A. Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem. 2016, 212, 671–680. [Google Scholar] [CrossRef]

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef]

- Tkacz, K.; Chmielewska, J.; Turkiewicz, I.P.; Nowicka, P.; Wojdyło, A. Dynamics of changes in organic acids, sugars and phenolic compounds and antioxidant activity of sea buckthorn and sea buckthorn-apple juices during malolactic fermentation. Food Chem. 2020, 332, 127382. [Google Scholar] [CrossRef]

- Aral, S.; Beşe, A.V. Convective drying of hawthorn fruit (Crataegus spp.): Effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chem. 2016, 210, 577–584. [Google Scholar] [CrossRef]

- Wang, J.; Law, C.L.; Nema, P.K.; Zhao, J.H.; Liu, Z.L.; Deng, L.Z.; Gao, Z.J.; Xiao, H.W. Pulsed vacuum drying enhances drying kinetics and quality of lemon slices. J. Food Eng. 2018, 224, 129–138. [Google Scholar] [CrossRef]

- Rawson, A.; Tiwari, B.K.; Tuohy, M.G.; Donnell, C.P.; Brunton, N. Effect of ultrasound and blanching pretreatments on polyacetylene and carotenoid content of hot air and freeze dried carrot discs. Ultrason. Sonochemistry 2011, 18, 1172–1179. [Google Scholar]

- Men, B.H.; Zhao, X.J.; Liang, C. Attribute Recognition Model for Evaluating Water Quality. J. Zhengzhou Univ. 2003, 35, 86–89. [Google Scholar]

- Liu, P.P.; Ren, G.Y.; Duan, X.; Li, L.L.; Zhao, L.J.; Ren, X.; Miao, J.W. The evaluation of the quality and flavor of dried white radish by different drying methods based on coefficient of variation. Food Ferment. Ind. 2022, 48, 218–226. [Google Scholar]

| Pretreatment Methods | L* | a* | b* | ΔE |

|---|---|---|---|---|

Fresh  | 53.54 ± 0.25 a | 25.55 ± 0.30 a | 47.51 ± 0.22 a | -- |

CG  | 28.37 ± 0.48 j | 17.32 ± 0.32 fg | 19.71 ± 0.7 h | 38.4 ± 0.79 a |

UA5  | 30.87 ± 0.27 d | 19.27 ± 0.36 b | 23.82 ± 0.29 d | 33.39 ± 0.35 h |

UA10  | 30.48 ± 0.42 de | 18.62 ± 0.21 d | 23.08 ± 0.37 de | 34.3 ± 0.54 gh |

UA15  | 29.63 ± 0.45 fg | 17.76 ± 0.25 f | 21.45 ± 0.36 g–i | 36.21 ± 0.59 c–f |

PH1  | 28.83 ± 0.48 h–j | 17.4 ± 0.19 fg | 20.72 ± 0.35 ij | 37.34 ± 0.57 a–c |

PH3  | 29.87 ± 0.29 ef | 18.34 ± 0.29 f | 22.29 ± 0.23 e–g | 35.33 ± 0.39 fg |

PH6  | 29.19 ± 0.34 f–i | 17.44 ± 0.32 ef | 21.11 ± 0.21 h–j | 36.82 ± 0.31 b–e |

UA5 + PH1  | 29.89 ± 0.21 ef | 17.72 ± 0.2 f | 22.47 ± 0.28 ef | 35.32 ± 0.32 fg |

UA5 + PH3  | 29.41 ± 0.27 f–h | 17.88 ± 0.49 ef | 21.95 ± 0.55 f–h | 35.98 ± 0.65 d–f |

UA5 + PH6  | 29.59 ± 0.4 fg | 17.58 ± 0.27 fg | 22.29 ± 0.43 e–g | 35.69 ± 0.58 ef |

UA10 + PH1  | 29.19 ± 0.44 f–i | 17.5 ± 0.2 fg | 20.79 ± 0.32 ij | 37.03 ± 0.48 b–d |

UA10 + PH3  | 31.58 ± 0.48 c | 18.8 ± 0.31 cd | 26.1 ± 0.53 c | 31.4 ± 0.74 i |

UA10 + PH6  | 28.95 ± 0.33 g–j | 17.01 ± 0.39 gh | 20.42 ± 0.5 jh | 37.57 ± 0.65 ab |

UA15 + PH1  | 28.56 ± 0.24 ij | 16.71 ± 0.35 h | 19.72 ± 0.5 h | 38.4 ± 0.57 a |

UA15 + PH3  | 29.07 ± 0.33 g–i | 17.63 ± 0.24 f | 21.41 ± 0.43 g–i | 36.64 ± 0.49 b–e |

UA15 + PH6  | 32.92 ± 1.29 b | 18.36 ± 1.04 de | 27.52 ± 2.01 b | 29.61 ± 2.48 j |

| Indicator | Mean | Standard Deviation | Coefficient of Variation | Weight (%) |

|---|---|---|---|---|

| Drying time | 19.953 | 2.482 | 0.124 | 20.5 |

| L* | 29.774 | 1.191 | 0.040 | 6.6 |

| a* | 17.833 | 0.680 | 0.038 | 6.3 |

| b* | 22.178 | 2.147 | 0.097 | 16.0 |

| ΔE | 35.588 | 2.422 | 0.068 | 11.2 |

| vitamin C content | 0.457 | 0.05 | 0.110 | 18.2 |

| TFC | 10.363 | 0.567 | 0.055 | 9.0 |

| TPC | 12.770 | 0.608 | 0.048 | 7.8 |

| RR | 1.090 | 0.029 | 0.027 | 4.4 |

| Pretreatment Method | Drying Time | L* | a* | b* | ΔE | Vitamin C Content | TFC | TPC | RR | Comprehensive Score | Rank |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CG | 0.311 | −0.081 | −0.049 | −0.19 | 0.134 | 0.305 | −0.191 | −0.032 | −0.026 | −0.709 | 15 |

| UA5 | 0.209 | 0.063 | 0.137 | 0.126 | −0.105 | −0.096 | 0.172 | 0.084 | −0.047 | 0.335 | 4 |

| UA10 | 0.239 | 0.04 | 0.075 | 0.069 | −0.062 | 0.074 | 0.135 | −0.024 | −0.047 | 0.145 | 7 |

| UA15 | 0.187 | −0.008 | −0.007 | −0.056 | 0.03 | −0.034 | 0.046 | −0.099 | −0.039 | −0.414 | 13 |

| PH1 | 0.264 | −0.054 | −0.042 | −0.112 | 0.084 | 0.18 | −0.08 | 0.19 | −0.016 | −0.282 | 12 |

| PH3 | −0.017 | 0.005 | 0.048 | 0.008 | −0.012 | 0.333 | −0.048 | 0.073 | 0.005 | 0.453 | 3 |

| PH6 | −0.128 | −0.033 | −0.038 | −0.082 | 0.059 | 0.163 | −0.097 | −0.067 | 0.052 | −0.033 | 9 |

| UA5 + PH1 | 0.042 | 0.007 | −0.011 | 0.023 | −0.013 | −0.068 | 0.048 | 0.032 | −0.047 | −0.045 | 10 |

| UA5 + PH3 | −0.047 | −0.021 | 0.004 | −0.017 | 0.019 | 0.027 | 0.059 | 0.117 | −0.023 | 0.174 | 6 |

| UA5 + PH6 | −0.299 | −0.011 | −0.024 | 0.008 | 0.005 | −0.121 | 0.085 | −0.092 | 0.047 | 0.186 | 5 |

| UA10 + PH1 | 0.094 | −0.033 | −0.032 | −0.107 | 0.069 | −0.077 | −0.044 | 0.007 | −0.031 | −0.48 | 14 |

| UA10 + PH3 | −0.03 | 0.103 | 0.092 | 0.301 | −0.2 | 0.069 | 0.012 | −0.036 | −0.016 | 0.755 | 2 |

| UA10 + PH6 | −0.312 | −0.047 | −0.078 | −0.135 | 0.095 | 0.031 | 0.049 | −0.007 | 0.063 | 0.093 | 8 |

| UA15 + PH1 | 0.008 | −0.069 | −0.107 | −0.189 | 0.134 | −0.322 | −0.033 | −0.088 | −0.016 | −0.966 | 16 |

| UA15 + PH3 | −0.167 | −0.04 | −0.02 | −0.059 | 0.05 | −0.169 | −0.079 | −0.028 | 0.047 | −0.231 | 11 |

| UA15 + PH6 | −0.354 | 0.18 | 0.05 | 0.41 | −0.286 | −0.295 | −0.034 | −0.032 | 0.094 | 1.013 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.; Xu, Y.; Zhu, L.; Geng, Z.; Zhang, Q.; Yang, X. Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes. Foods 2022, 11, 3675. https://doi.org/10.3390/foods11223675

Tan S, Xu Y, Zhu L, Geng Z, Zhang Q, Yang X. Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes. Foods. 2022; 11(22):3675. https://doi.org/10.3390/foods11223675

Chicago/Turabian StyleTan, Shudan, Yu Xu, Lichun Zhu, Zhihua Geng, Qian Zhang, and Xuhai Yang. 2022. "Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes" Foods 11, no. 22: 3675. https://doi.org/10.3390/foods11223675

APA StyleTan, S., Xu, Y., Zhu, L., Geng, Z., Zhang, Q., & Yang, X. (2022). Hot Air Drying of Seabuckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes. Foods, 11(22), 3675. https://doi.org/10.3390/foods11223675