Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread

Abstract

1. Introduction

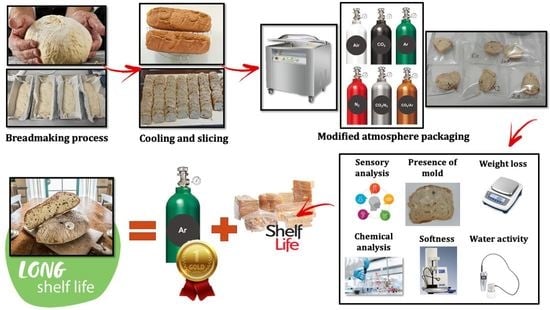

2. Materials and Methods

2.1. Raw Materials

2.2. Breadmaking Process

2.3. Bread Packaging and Storage

2.4. Bread Shelf-Life Assessment

2.4.1. Control of the Gaseous Atmosphere Inside the Packages

2.4.2. Chemical Characterization of Bread

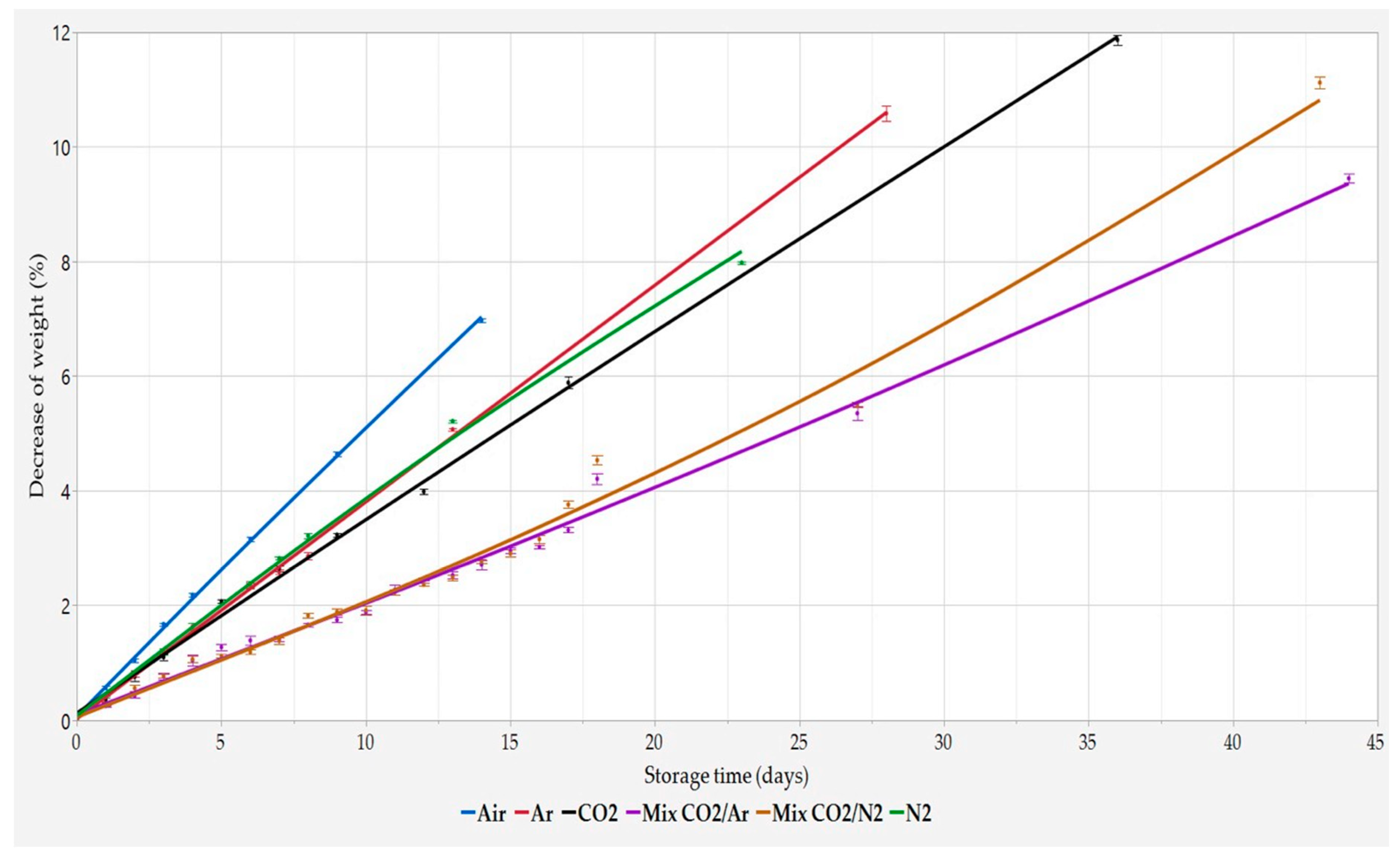

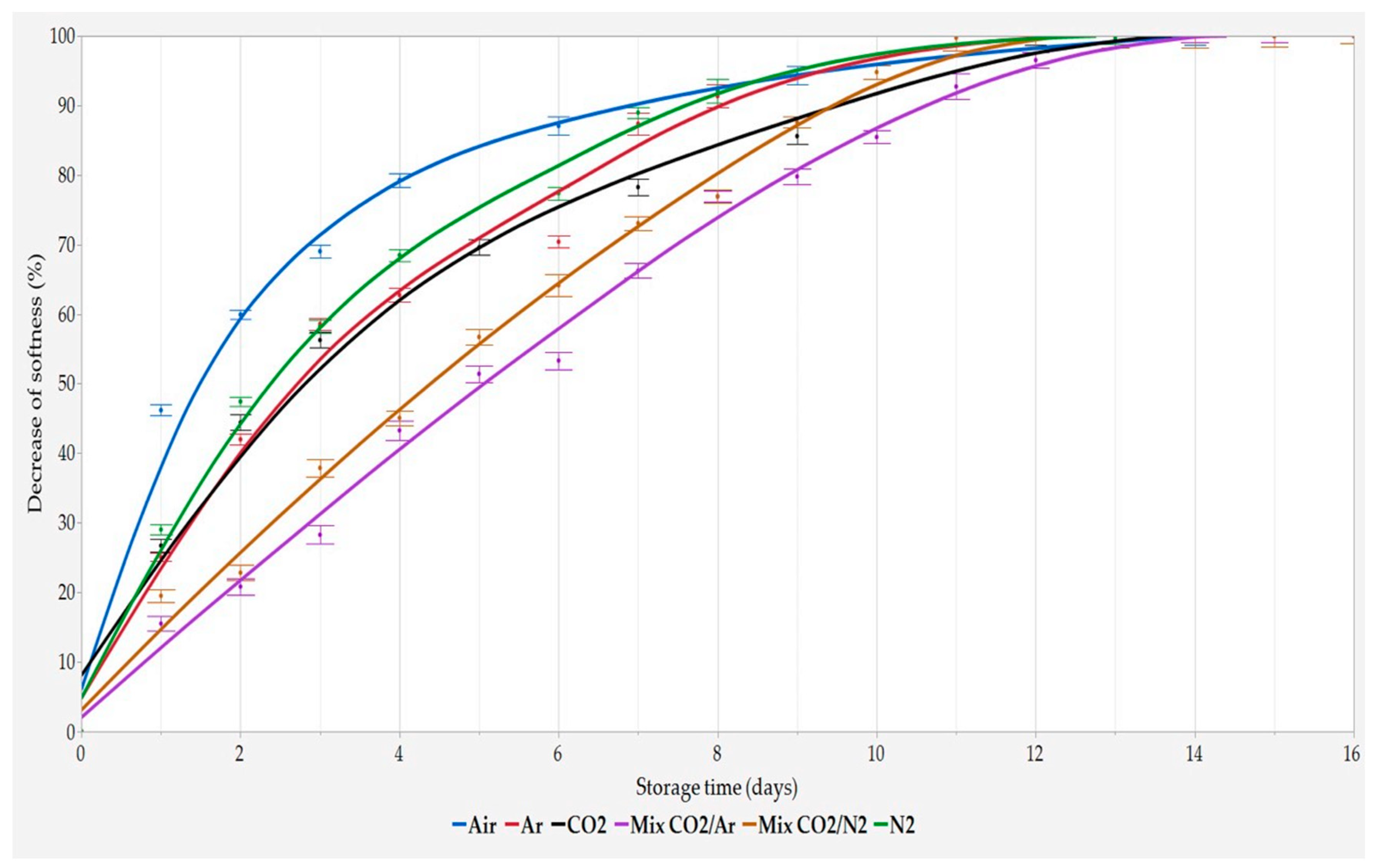

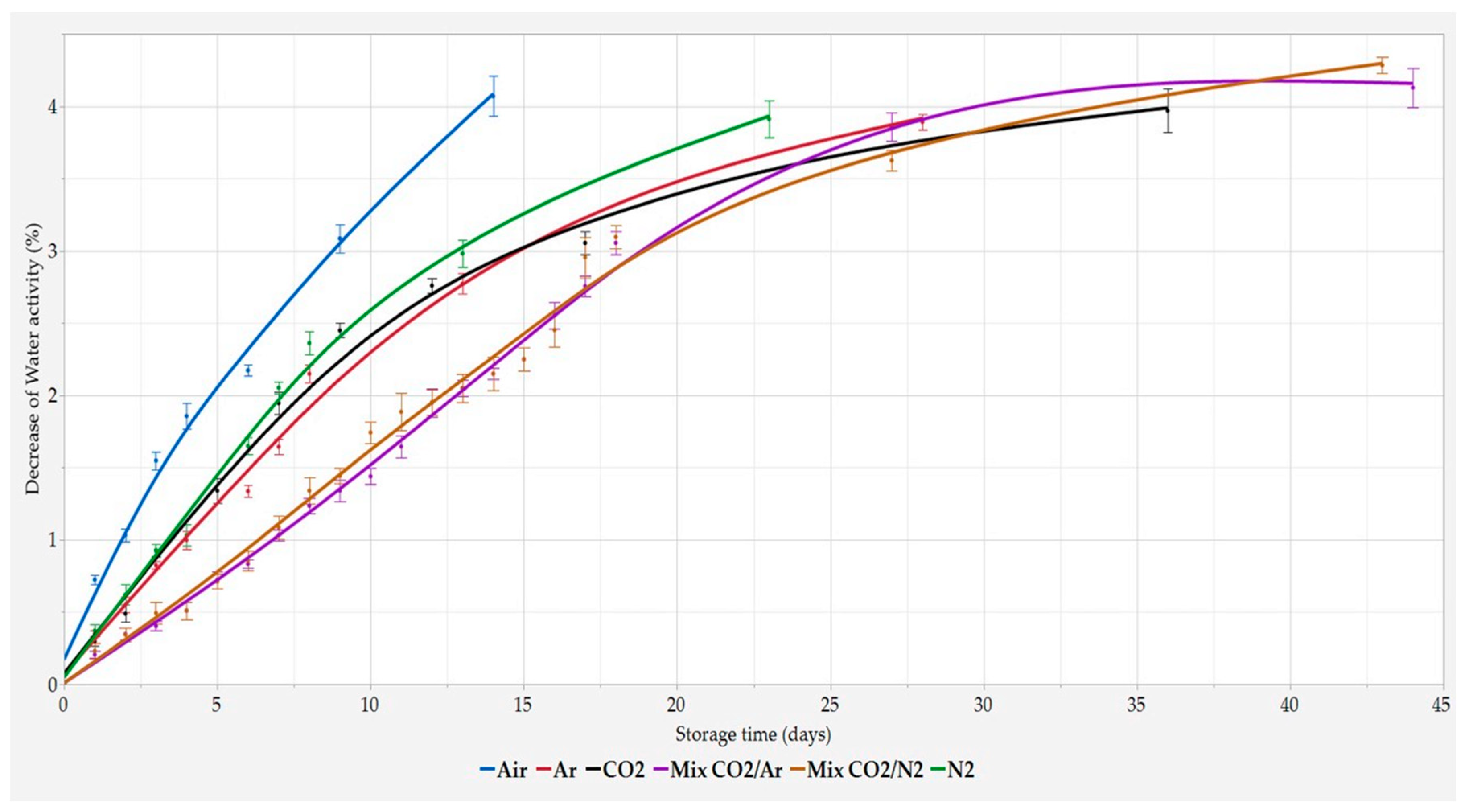

2.4.3. Weight Loss, Crumb Softness, and Water Activity (aw)

2.4.4. Mold Appearance

2.4.5. Sensory Analyses

2.5. Statistical Analysis

3. Results and Discussion

3.1. Weight Loss, Softness of the Crumb, and Water Activity Trend

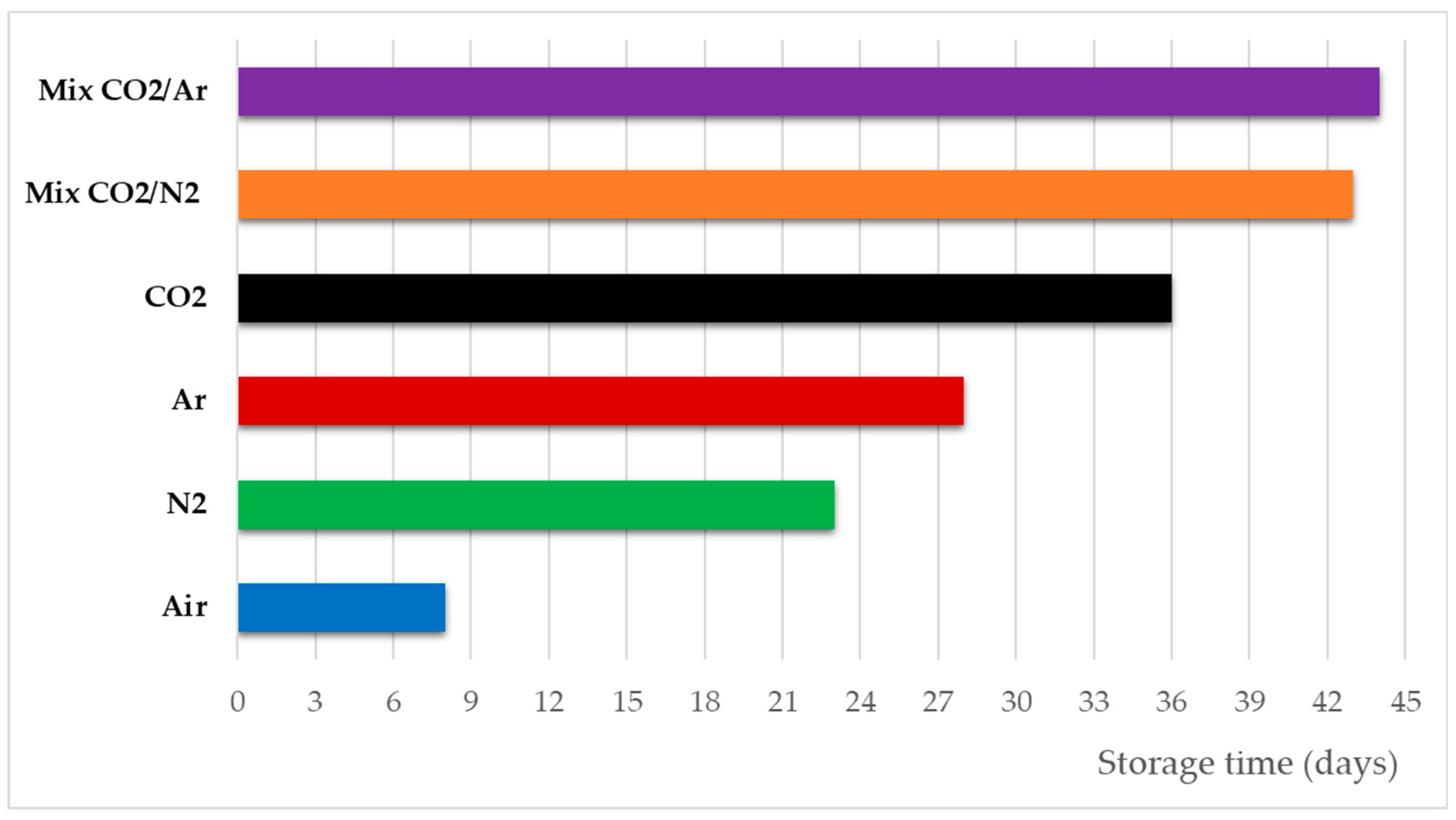

3.2. Mold Appearence

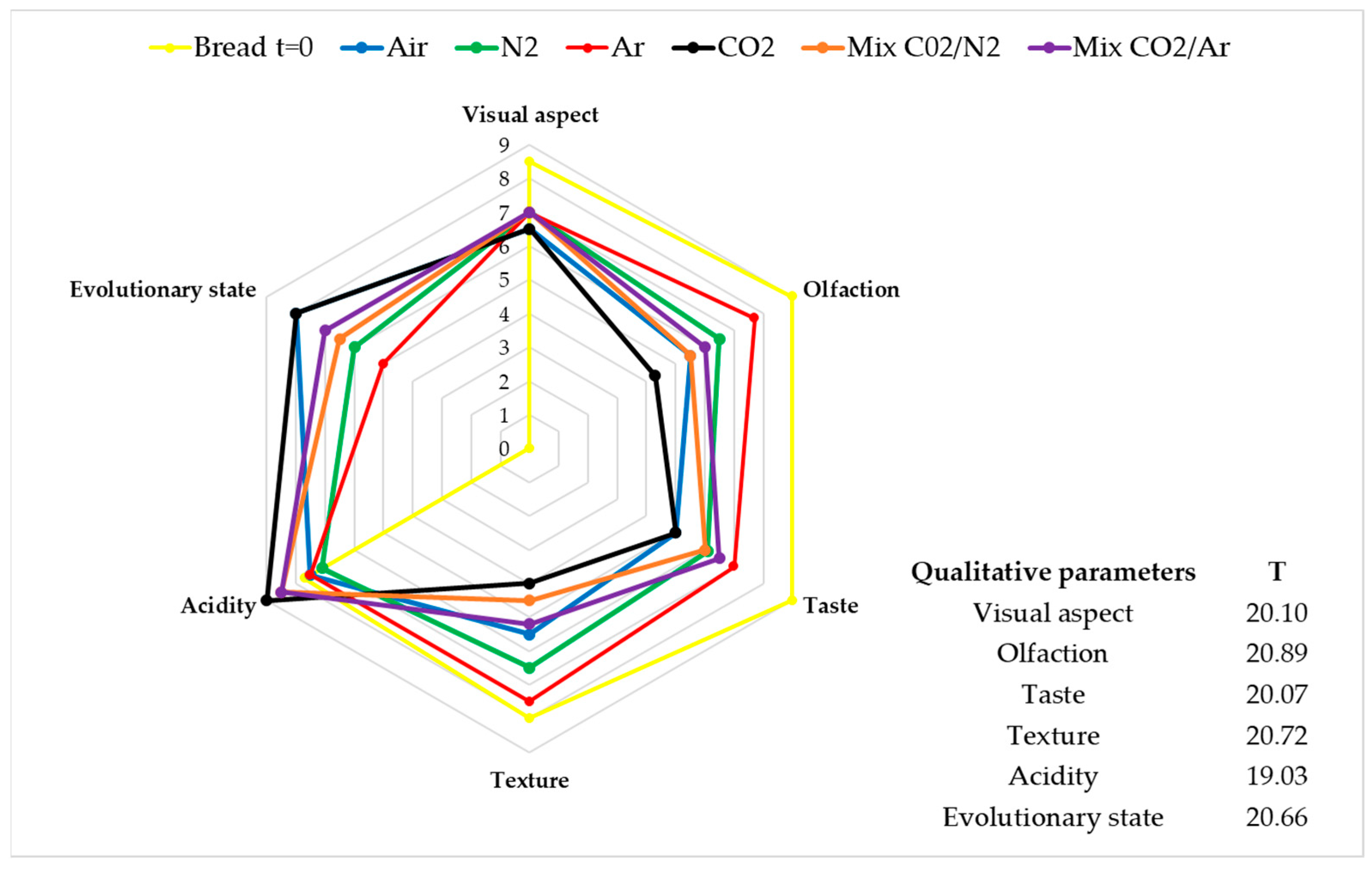

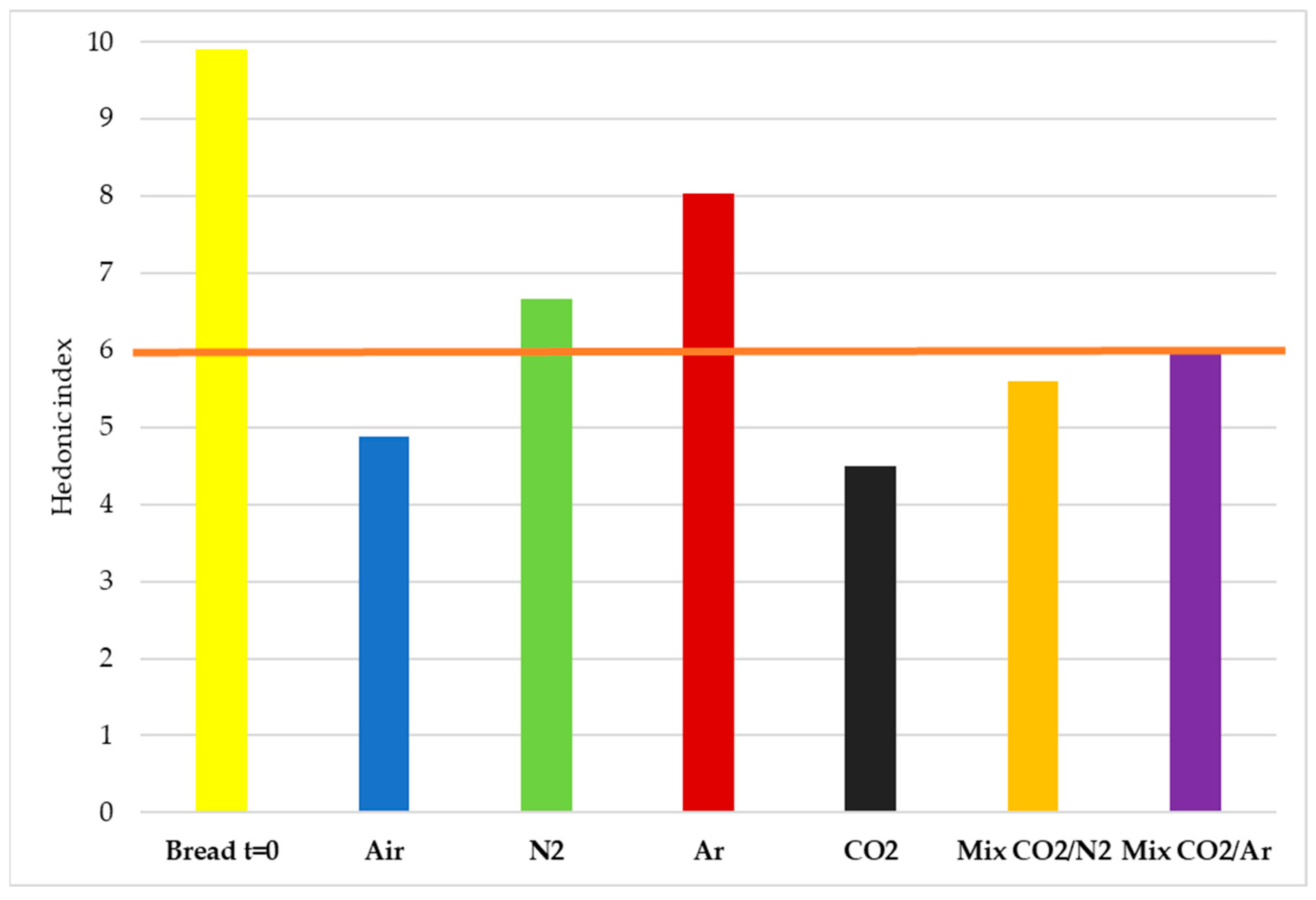

3.3. Sensory Evaluation

3.4. Chemical Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sacchi, G.; Belletti, G.; Biancalani, M.; Lombardi, G.V.; Stefani, G. The valorisation of wheat production through locally-based bread chains: Experiences from Tuscany. J. Rural Stud. 2019, 71, 23–35. [Google Scholar] [CrossRef]

- Belletti, G.; Casabianca, F.; Marescotti, A. Local food quality and local resources. In Local Agri-Food Systems in a Global World: Market, Social and Environmental Challenges; Cambridge Scholars Publishing: Newcastle upon Tyne, UK, 2012; p. 278. [Google Scholar]

- Galli, F.; Venturi, F.; Bartolini, F.; Gava, O.; Zinnai, A.; Chiara, S.; Andrich, G.; Brunori, G. Shaping food systems towards improved nutrition A case study on Tuscan Bread Protected Designation of Origin. Int. Food Agribus. Manag. Rev. 2017, 20, 533–552. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Z.; Guo, X.; Wang, F.; Huang, J.; Sun, B.; Wang, X. Sourdough improves the quality of whole-wheat flour products: Mechanisms and challenges—A review. Food Chem. 2021, 360, 130038. [Google Scholar] [CrossRef] [PubMed]

- Malandrin, V.; Rossi, A.; Dvortsin, L.; Galli, F. The Evolving Role of Bread in the Tuscan Gastronomic Culture. In Gastronomy and Culture; Csobán, K., Könyves, H.E., University of Debrecen, Litográfia Nyomda, Eds.; University of Pisa: Pisa, Italy, 2015; pp. 10–23. ISBN 9789634738282. [Google Scholar]

- Galli, F.; Brunori, G. Sustainability Performance of Food Chains: Linking Biodiversity and Nutritional Value in Italian Wheat to Bread Chains. Adv. Food Secur. Sustain. 2017, 2, 137–163. [Google Scholar] [CrossRef]

- Taglieri, I.; Macaluso, M.; Bianchi, A.; Sanmartin, C.; Quartacci, M.F.; Zinnai, A.; Venturi, F. Overcoming bread quality decay concerns: Main issues for bread shelf life as a function of biological leavening agents and different extra ingredients used in formulation. A review. J. Sci. Food Agric. 2021, 101, 1732–1743. [Google Scholar] [CrossRef]

- Taglieri, I.; Sanmartin, C.; Venturi, F.; Macaluso, M.; Zinnai, A.; Tavarini, S.; Serra, A.; Conte, G.; Flamini, G.; Angelini, L.G. Effect of the leavening agent on the compositional and sensorial characteristics of bread fortified with flaxseed cake. Appl. Sci. 2020, 10, 5235. [Google Scholar] [CrossRef]

- Venturi, F.; Sanmartin, C.; Taglieri, I.; Nari, A.; Andrich, G. Effect of the baking process on artisanal sourdough bread-making: A technological and sensory evaluation. Agrochimica 2016, 60, 186–198. [Google Scholar] [CrossRef]

- Rasmussen, P.H.; Hansen, A. Staling of wheat bread stored in modified atmosphere. LWT Food Sci. Technol. 2001, 34, 487–491. [Google Scholar] [CrossRef]

- Zingale, S.; Guarnaccia, P.; Matarazzo, A.; Lagioia, G.; Ingrao, C. Science of the Total Environment A systematic literature review of life cycle assessments in the durum wheat sector. Sci. Total Environ. 2022, 844, 157230. [Google Scholar] [CrossRef]

- Brancoli, P.; Lundin, M.; Bolton, K.; Eriksson, M. Bread loss rates at the supplier-retailer interface—Analysis of risk factors to support waste prevention measures. Resour. Conserv. Recycl. 2019, 147, 128–136. [Google Scholar] [CrossRef]

- Upasen, S.; Wattanachai, P. Packaging to prolong shelf life of preservative-free white bread. Heliyon 2018, 4, e00802. [Google Scholar] [CrossRef] [PubMed]

- Kotsianis, I.S.; Giannou, V.; Tzia, C. Production and packaging of bakery products using MAP technology. Trends Food Sci. Technol. 2002, 13, 319–324. [Google Scholar] [CrossRef]

- Gutiérrez, L.; Sánchez, C.; Batlle, R.; Nerín, C. New antimicrobial active package for bakery products. Trends Food Sci. Technol. 2009, 20, 92–99. [Google Scholar] [CrossRef]

- Axel, C.; Zannini, E.; Arendt, E.K. Mold spoilage of bread and its biopreservation: A review of current strategies for bread shelf life extension. Crit. Rev. Food Sci. Nutr. 2017, 57, 3528–3542. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, U.; Vodovotz, Y.; Courtney, P.; Pascall, M.A. Extended shelf life of soy bread using modified atmosphere packaging. J. Food Prot. 2006, 69, 693–698. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.P.; Ooraikul, B.; Koersen, W.J.; Jackson, E.D.; Lawrence, R.A. Novel approach to oxygen control in modified atmosphere packaging of bakery products. Food Microbiol. 1986, 3, 315–320. [Google Scholar] [CrossRef]

- Stamatis, N.; Arkoudelos, J. Quality assessment of Scomber colias japonicus under modified atmosphere and vacuum packaging. Food Control 2007, 18, 292–300. [Google Scholar] [CrossRef]

- El Halouat, A.; Debevere, J.M. Effect of water activity, modified atmosphere packaging and storage temperature on spore germination of moulds isolated from prunes. Int. J. Food Microbiol. 1997, 35, 41–48. [Google Scholar] [CrossRef]

- Sanguinetti, A.M.; Del Caro, A.; Scanu, A.; Fadda, C.; Milella, G.; Catzeddu, P.; Piga, A. Extending the shelf life of gluten-free fresh filled pasta by modified atmosphere packaging. LWT Food Sci. Technol. 2016, 71, 96–101. [Google Scholar] [CrossRef]

- Taniwaki, M.H.; Hocking, A.D.; Pitt, J.I.; Fleet, G.H. Growth of fungi and mycotoxin production on cheese under modified atmospheres. Int. J. Food Microbiol. 2001, 68, 125–133. [Google Scholar] [CrossRef]

- Sanmartin, C.; Venturi, F.; Macaluso, M.; Nari, A.; Quartacci, M.F.; Sgherri, C.; Flamini, G.; Taglieri, I.; Ascrizzi, R.; Andrich, G.; et al. Preliminary Results About the Use of Argon and Carbon Dioxide in the Extra Virgin Olive Oil (EVOO) Storage to Extend Oil Shelf Life: Chemical and Sensorial Point of View. Eur. J. Lipid Sci. Technol. 2018, 120, 1800156. [Google Scholar] [CrossRef]

- Suppakul, P.; Thanathammathorn, T.; Samerasut, O.; Khankaew, S. Shelf life extension of “fios de ovos”, an intermediate-moisture egg-based dessert, by active and modified atmosphere packaging. Food Control 2016, 70, 58–63. [Google Scholar] [CrossRef]

- Fik, M.; Surówka, K.; Maciejaszek, I.; Macura, M.; Michalczyk, M. Quality and shelf life of calcium-enriched wholemeal bread stored in a modified atmosphere. J. Cereal Sci. 2012, 56, 418–424. [Google Scholar] [CrossRef]

- Zinnai, A.; Venturi, F.; Sanmartin, C.; Andrich, G. Changes in physicochemical and sensory characteristics of fresh bread rolls maintained in different storage conditions. Agrochimica 2012, 56, 140–155. [Google Scholar]

- ISO 712:2009; Cereals and cereal products—Determination of moisture content. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 2171:2007; Cereals, Pulses and By-Products-Determination of Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- ISO 20483:2013; Cereals and pulses—Determination of the Nitrogen Content and Calculation of the Crude Protein Content—Kjeldahl Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 11085:2015; Cereals, Cereals-Based Products and Animal Feeding Stuffs—Determination of Crude Fat and Total Fat Content by the Randall Extraction Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 3093:2009; Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina—Determination of the Falling Number According to Hagberg-Perten. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 21415-2:2015; Wheat and Wheat Flour—Gluten Content—Part 2: Determination of Wet Gluten and Gluten Index by Mechanical Means. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 21415-3:2006; Wheat and Wheat Flour—Gluten Content—Part 3: Determination of Dry Gluten from Wet Gluten by an Oven Drying Method. International Organization for Standardization: Geneva, Switzerland, 2006.

- Novotni, D.; Mutak, N.; Nanjara, L.; Drakula, S.; Čukelj Mustač, N.; Voučko, B.; Ćurić, D. Sourdough fermentation of carob flour and its application in wheat bread. Food Technol. Biotechnol. 2020, 58, 465–474. [Google Scholar] [CrossRef] [PubMed]

- Nivelle, M.A.; Beghin, A.S.; Vrinten, P.; Nakamura, T.; Delcour, J.A. Amylose and amylopectin functionality during storage of bread prepared from flour of wheat containing unique starches. Food Chem. 2020, 320, 126609. [Google Scholar] [CrossRef]

- McCleary, B.V.; Solah, V.; Gibson, T.S. Quantitative measurement of total starch in cereal flours and products. J. Cereal Sci. 1994, 20, 51–58. [Google Scholar] [CrossRef]

- Li, Y.; Ma, D.; Sun, D.; Wang, C.; Zhang, J.; Xie, Y.; Guo, T. Total phenolic, flavonoid content, and antioxidant activity of flour, noodles, and steamed bread made from different colored wheat grains by three milling methods. Crop J. 2015, 3, 328–334. [Google Scholar] [CrossRef]

- ISO 27971:2015; Cereals and Cereal Products—Common Wheat (Triticum aestivum L.)—Determination of Alveograph Properties of Dough at Constant Hydration from Commercial or Test Flours and Test Milling Methodology. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 5530-1:2013; Wheat Flour—Physical Characteristics of Doughs—Part 1: Determination of Water Absorption and Rheological Properties Using a Farinograph. International Organization for Standardization: Geneva, Switzerland, 2013.

- Gélinas, P.; Audet, J.; Lachance, O.; Vachon, M. Fermented Dairy Ingredients for Bread: Effects on Dough Rheology and Bread Characteristics. Cereal Chem. 1995, 72, 151–154. [Google Scholar]

- Nyangena, I.; Owino, W.; Ambuko, J.; Imathiu, S. Effect of selected pretreatments prior to drying on physical quality attributes of dried mango chips. J. Food Sci. Technol. 2019, 56, 3854–3863. [Google Scholar] [CrossRef]

- Al Omari, D.Z.; Abdul-Hussain, S.S.; Ajo, R.Y. Germinated lupin (Lupinus albus) flour improves Arabic flat bread properties. Qual. Assur. Saf. Crop. Foods 2016, 8, 57–63. [Google Scholar] [CrossRef]

- Taglieri, I.; Sanmartin, C.; Venturi, F.; Macaluso, M.; Bianchi, A.; Sgherri, C.; Quartacci, M.F.; De Leo, M.; Pistelli, L.; Palla, F.; et al. Bread fortified with cooked purple potato flour and citrus albedo: An evaluation of its compositional and sensorial properties. Foods 2021, 10, 942. [Google Scholar] [CrossRef] [PubMed]

- Hasted, A. Statistical Analysis of Descriptive Data. In Descriptive Analysis in Sensory Evaluation; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2018; pp. 165–210. ISBN 9781118991657. [Google Scholar]

| Parameters | Units | Flour |

|---|---|---|

| Chemical | ||

| Humidity | % w/w | 10.90 ± 0.30 |

| Ashes | % w/w | 1.37 ± 0.05 |

| Proteins | % w/w | 12.90 ± 0.31 |

| Total fats | % w/w | 2.53 ± 0.53 |

| Total dietary fiber | % w/w | 6.72 ± 0.22 |

| Sucrose | % w/w | 0.96 ± 0.05 |

| Glucose | % w/w | 0.43 ± 0.02 |

| Fructose | % w/w | 0.14 ± 0.01 |

| Maltose | % w/w | 6.28 ± 0.26 |

| Wet gluten | % w/w | 34.12 ± 2.02 |

| Dry gluten | % w/w | 10.94 ± 1.64 |

| Gluten index | % w/w | 75.32 ± 10.01 |

| Amylose | % w/w | 20.83 ± 0.23 |

| Amylopectin | % w/w | 79.23 ± 0.23 |

| Total Starch | % w/w | 83.72 ± 0.52 |

| Total polyphenols | mg gallic acid/kg | 833 ± 17 |

| Technological | ||

| W | 10−4 joules | 255 ± 29 |

| P/L | 3.3 ± 0.8 | |

| P | mm | 152 ± 13 |

| L | mm | 48 ± 9 |

| G | 15.0 ± 1.6 | |

| Falling number | Seconds | 327 ± 26 |

| Water absorption | % | 68.9 ± 0.7 |

| Dough time | Minutes | 4.3 ± 1.5 |

| Stability | Minute | 5.4 ± 2.7 |

| E10 | UF | 58 ± 5 |

| E(ICC) | UF | 90 ± 23 |

| FQN | 75± 2 |

| Parameters | p-Value 1 | t = 0 | Air | CO2 | N2 | Ar | Mix CO2/Ar | Mix CO2/N2 |

|---|---|---|---|---|---|---|---|---|

| % of dry matter (% dm) | *** | 61.63 d | 64.23 a | 63.48 bc | 63.62 b | 63.68 b | 63.34 c | 63.28 c |

| pH | ** | 3.89 a | 3.81 ab | 3.76 c | 3.84 ab | 3.85 ab | 3.78 bc | 3.81 abc |

| Total titratable acidity (meq lactic acid/g dm) | * | 0.032 b | 0.034 ab | 0.036 a | 0.035 ab | 0.035 ab | 0.038 a | 0.036 a |

| Acetic acid (mmol/g dm) | * | 0.062 b | 0.076 ab | 0.086 a | 0.073 ab | 0.072 ab | 0.091 a | 0.093 a |

| Lactic acid (mmol/g dm) | * | 0.052 b | 0.057 ab | 0.060 a | 0.056 ab | 0.057 ab | 0.061 a | 0.059 a |

| Ethanol (mmol/g dm) | n.s. | 0.087 | 0.087 | 0.088 | 0.087 | 0.085 | 0.082 | 0.088 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchi, A.; Taglieri, I.; Zinnai, A.; Macaluso, M.; Sanmartin, C.; Venturi, F. Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread. Foods 2022, 11, 3470. https://doi.org/10.3390/foods11213470

Bianchi A, Taglieri I, Zinnai A, Macaluso M, Sanmartin C, Venturi F. Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread. Foods. 2022; 11(21):3470. https://doi.org/10.3390/foods11213470

Chicago/Turabian StyleBianchi, Alessandro, Isabella Taglieri, Angela Zinnai, Monica Macaluso, Chiara Sanmartin, and Francesca Venturi. 2022. "Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread" Foods 11, no. 21: 3470. https://doi.org/10.3390/foods11213470

APA StyleBianchi, A., Taglieri, I., Zinnai, A., Macaluso, M., Sanmartin, C., & Venturi, F. (2022). Effect of Argon as Filling Gas of the Storage Atmosphere on the Shelf-Life of Sourdough Bread—Case Study on PDO Tuscan Bread. Foods, 11(21), 3470. https://doi.org/10.3390/foods11213470