Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries

Abstract

1. Introduction

2. Materials and Methods

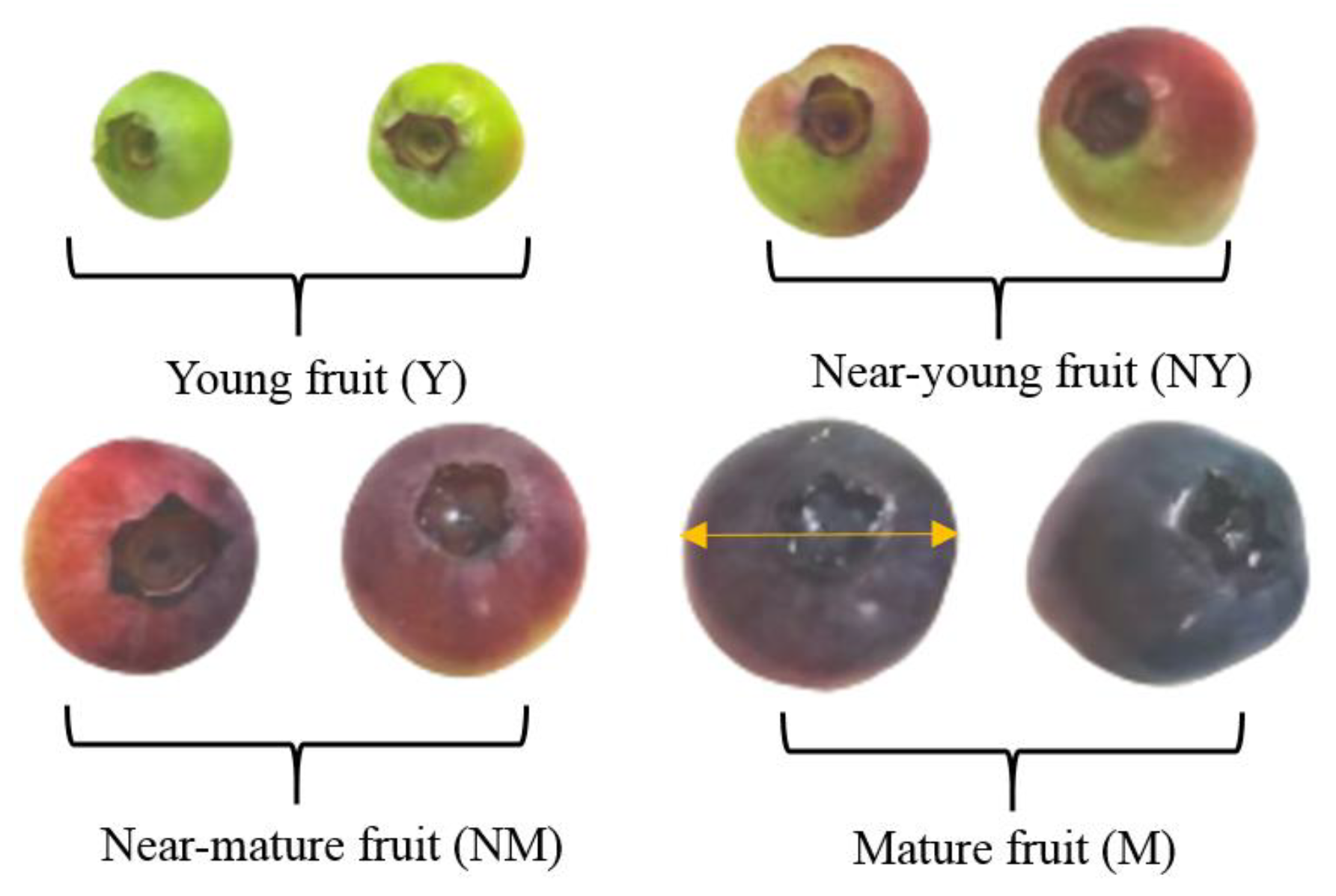

2.1. Material Preparation

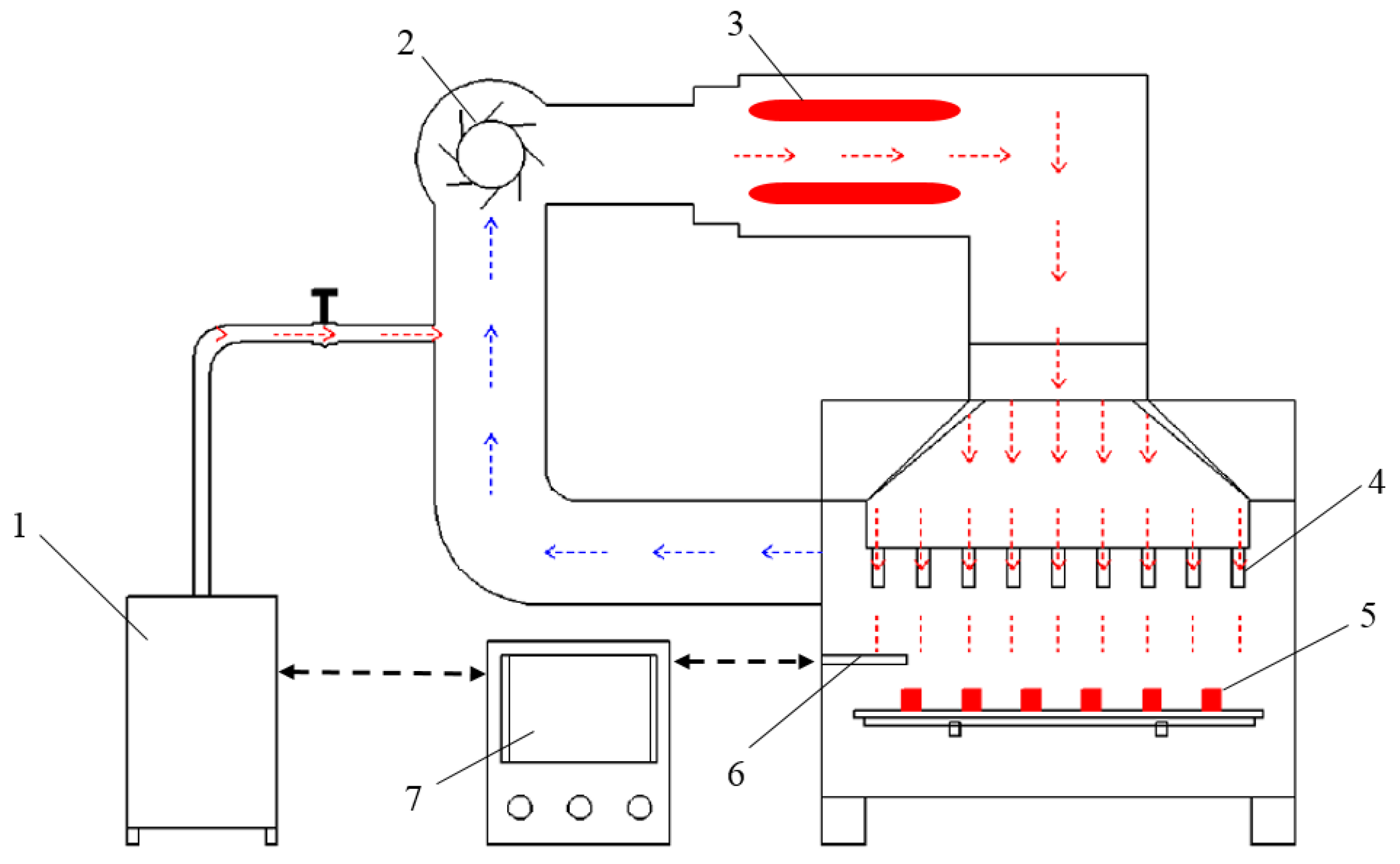

2.2. Design of Processing Equipment

2.3. Sequential HHAIB and HAIR Processing Experiments

2.4. Drying Time

2.5. Specific Energy Consumption (SEC)

2.6. Rehydration Capacity

2.7. Ascorbic Acid Content

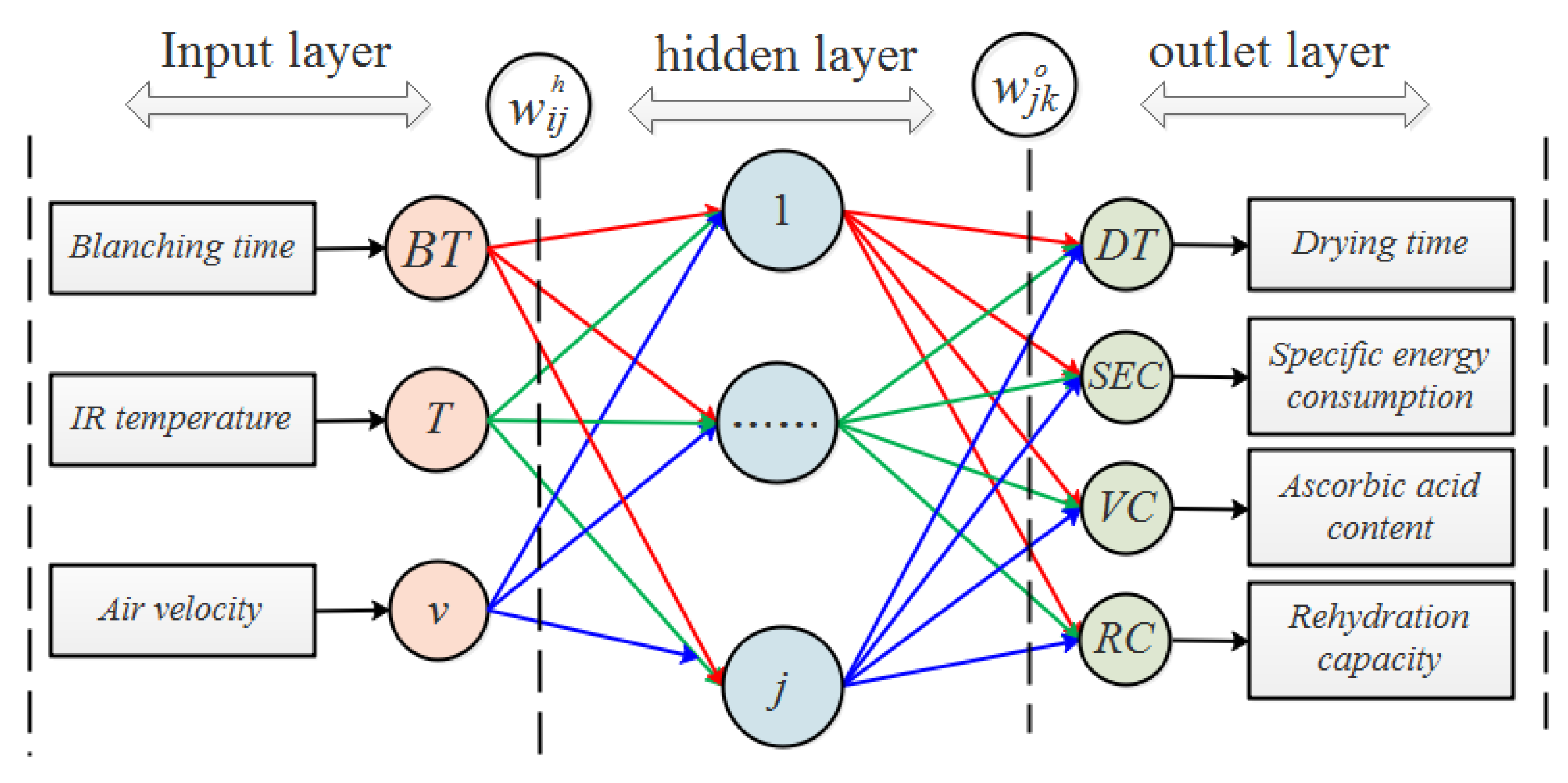

2.8. Artificial Neural Network (ANN) Model

2.9. Multiobjective Optimization

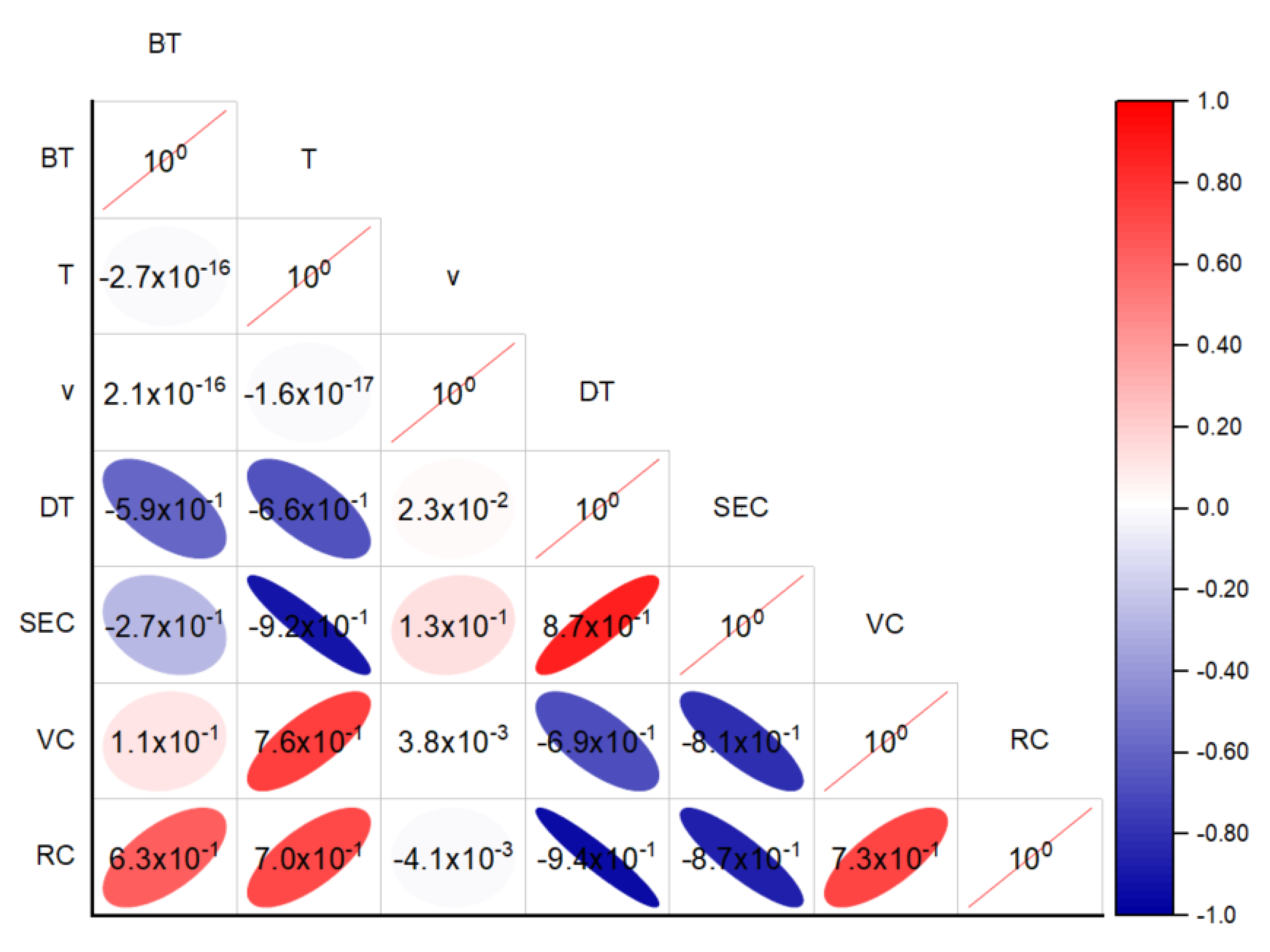

2.10. Statistical Analysis

3. Results and Discussion

3.1. Drying Characteristics

3.2. Specific Energy Consumption

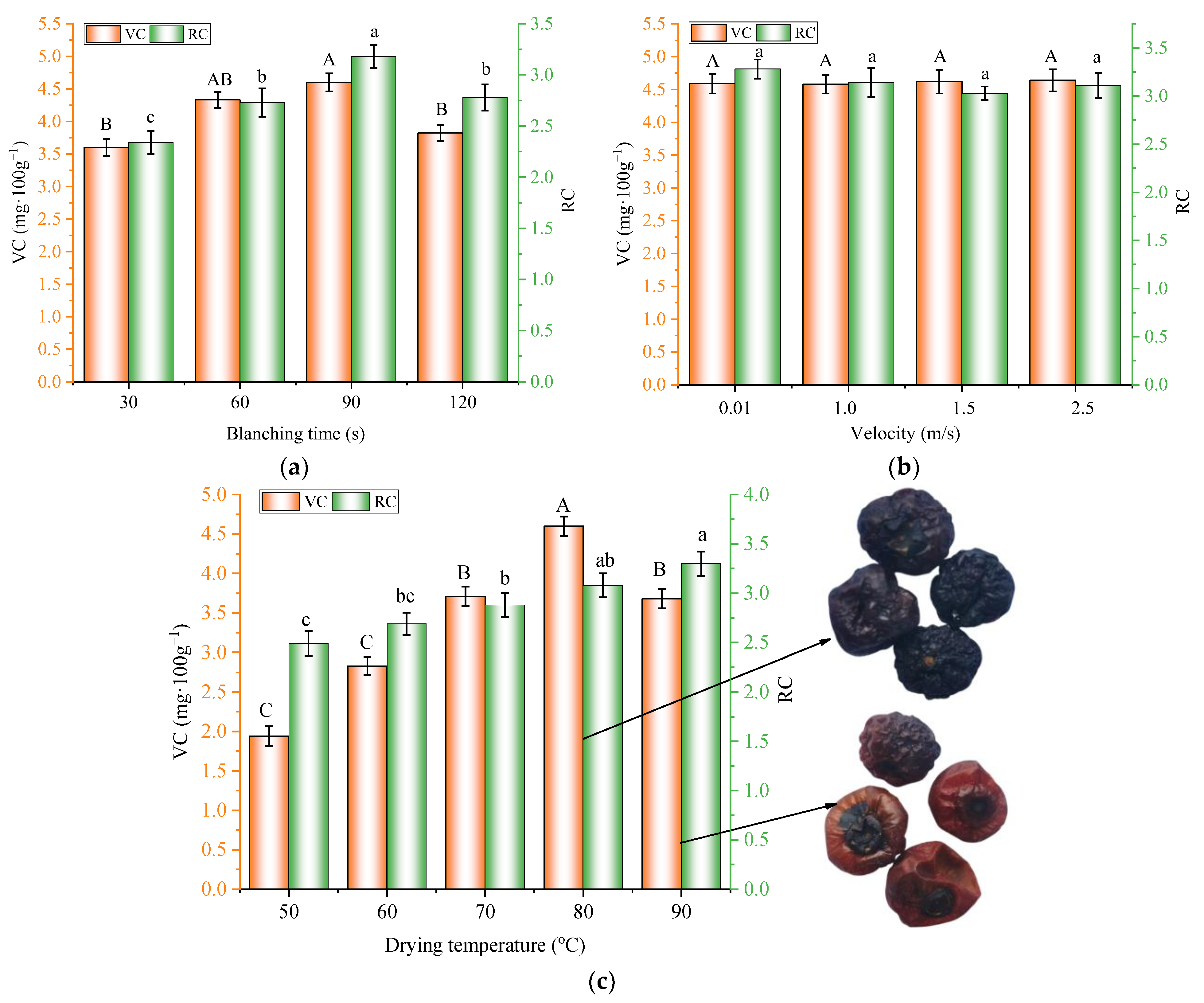

3.3. Ascorbic Acid Content

3.4. Rehydration Capacity

3.5. Construction of ANN Model

3.6. Multiobjective Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amini, G.; Salehi, F.; Rasouli, M. Drying kinetics of basil seed mucilage in an infrared dryer: Application of GA—ANN and ANFIS for the prediction of drying time and moisture ratio. J. Food Process. Preserv. 2021, 45, e15258. [Google Scholar] [CrossRef]

- Thamkaew, G.; Sjöholm, I.; Galindo, F.G. A review of drying methods for improving the quality of dried herbs. Crit. Rev. Food Sci. Nutr. 2021, 61, 1763–1786. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhang, M.; Mujumdar, A. Berry drying: Mechanism, pretreatment, drying technology, nutrient preservation, and mathematical models. Food Eng. Rev. 2019, 11, 61–77. [Google Scholar] [CrossRef]

- Tang, M.; Sun, H.; Zhang, Z.; Zhao, J.; Cao, J.; Thakur, K.; He, S. Evaluation of hot water and microwave blanching on qualities and sensory characteristics of water dropwort (Oenanthe javanica DC.). J. Food Process. Preserv. 2019, 43, e14104. [Google Scholar] [CrossRef]

- Geng, Z.; Huang, X.; Wang, J.; Xiao, H.; Yang, X.; Zhu, L.; Xiao, Q.; Qian, Z.; Hu, B. Pulsed vacuum drying of pepper (Capsicum annuum L.): Effect of high-humidity hot air impingement blanching pretreatment on drying kinetics and quality attributes. Foods 2022, 11, 318. [Google Scholar] [CrossRef]

- Wang, J.; Mujumdar, A.S.; Deng, L.Z.; Gao, Z.J.; Xiao, H.W.; Raghavan, G.S.V. High-humidity hot air impingement blanching alters texture, cell-wall polysaccharides, water status and distribution of seedless grape. Carbohydr. Polym. 2018, 194, 9–17. [Google Scholar] [CrossRef]

- Deng, L.Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.H.; Wang, J.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Menon, A.; Stojceska, V.; Tassou, S.A. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, C.; Pan, Z.; Zheng, Z. Vacuum and infrared-assisted hot air impingement drying for improving the processing performance and quality of Poria cocos (Schw.) wolf cubes. Foods 2021, 10, 992. [Google Scholar] [CrossRef]

- Oliver, M.J.; Farrant, J.M.; Hilhorst, H.W.; Mundree, S.; Williams, B.; Bewley, J.D. Desiccation tolerance: Avoiding cellular damage during drying and rehydration. Annu. Rev. Plant Biol. 2020, 71, 435–460. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Q.; Mujumdar, A.S.; Fang, X.M.; Wang, J.; Pei, Y.P.; Wu, W.; Zielinska, M.; Xiao, H.W. High-humidity hot air impingement blanching (HHAIB) efficiently inactivates enzymes, enhances extraction of phytochemicals and mitigates brown actions of chili pepper. Food Control. 2020, 111, 107050. [Google Scholar] [CrossRef]

- Hasan, M.U.; Malik, A.U.; Ali, S.; Imtiaz, A.; Munir, A.; Amjad, W.; Anwar, R. Modern drying techniques in fruits and vegetables to overcome postharvest losses: A review. J. Food Process. Preserv. 2019, 43, e14280. [Google Scholar] [CrossRef]

- Liu, Z.L.; Wei, Z.Y.; Vidyarthi, S.K.; Pan, Z.; Zielinska, M.; Deng, L.Z.; Wang, Q.H.; Xiao, H.W. Pulsed vacuum drying of kiwifruit slices and drying process optimization based on artificial neural network. Dry. Technol. 2020, 39, 405–417. [Google Scholar] [CrossRef]

- Gómez-Salazar, J.A.; Patlán-González, J.; Sosa-Morales, M.E.; Segovia-Hernandez, J.G.; Sánchez-Ramírez, E.; Ramírez-Márquez, C. Multi-objective optimization of sustainable red prickly pear (Opuntia streptacantha) peel drying and biocompounds extraction using a hybrid stochastic algorithm. Food Bioprod. Process. 2022, 132, 155–166. [Google Scholar] [CrossRef]

- Darvishi, H.; Farhudi, Z.; Behroozi-Khazaei, N. Multi-objective optimization of savory leaves drying in continuous infrared-hot air dryer by response surface methodology and desirability function. Comput. Electron. Agric. 2020, 168, 105112. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Martynenko, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-objective optimization of convective drying of apple cubes. Comput. Electron. Agric. 2018, 145, 341–348. [Google Scholar] [CrossRef]

- Raj, G.B.; Dash, K.K. Microwave vacuum drying of dragon fruit slice: Artificial neural network modelling, genetic algorithm optimization, and kinetics study. Comput. Electron. Agric. 2020, 178, 105814. [Google Scholar]

- Li, H.; Lee, W.S.; Wang, K. Identifying blueberry fruit of different growth stages using natural outdoor color images. Comput. Electron. Agric. 2014, 106, 91–101. [Google Scholar] [CrossRef]

- Xiao, H.W.; Bai, J.W.; Sun, D.W.; Gao, Z.J. The application of superheated steam impingement blanching (SSIB) in agricultural products processing–A review. J. Food Eng. 2014, 132, 39–47. [Google Scholar] [CrossRef]

- Zielinska, S.; Cybulska, J.; Pieczywek, P.; Zdunek, A.; Kurzyna-Szklarek, M.; Liu, Z.L.; Staniszewska, L.; Pan, Z.; Xiao, H.W.; Zielinska, M.; et al. The effect of high humidity hot air impingement blanching on the changes in molecular and rheological characteristics of pectin fractions extracted from okra pods. Food Hydrocoll. 2020, 123, 107199. [Google Scholar] [CrossRef]

- Zhang, W.P.; Chen, C.; Pan, Z.; Xiao, H.W.; Xie, L.; Gao, Z.J.; Zheng, Z.A. Design and performance evaluation of a pilot-scale pulsed vacuum infrared drying (PVID) system for drying of berries. Dry. Technol. 2020, 38, 1340–1355. [Google Scholar] [CrossRef]

- Chen, C.; Venkitasamy, C.; Zhang, W.; Khir, R.; Upadhyaya, S.; Pan, Z. Effective moisture diffusivity and drying simulation of walnuts under hot air. Int. J. Heat Mass Transf. 2020, 150, 119283. [Google Scholar] [CrossRef]

- Cadavid, Y.; Echeverri-Uribe, C.; Mejía, C.C.; Amell, A.; Rivas Medina, J.D.; Muñoz Ospina, J.A. Analysis of potential energy savings in a rotary dryer for clay drying using data mining techniques. Dry. Technol. 2022, 40, 1451–1462. [Google Scholar] [CrossRef]

- Feng, Y.; Xu, B.; Yagoub, A.E.A.; Ma, H.; Sun, Y.; Xu, X.; Yu, X.; Zhou, C. Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 2021, 343, 128404. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xiao, H.W.; Ye, J.H.; Wang, J.; Raghavan, V. Ultrasound pretreatment to enhance drying kinetics of kiwifruit (Actinidia deliciosa) slices: Pros and cons. Food Bioprocess Technol. 2019, 12, 865–876. [Google Scholar] [CrossRef]

- Kalathingal, M.S.H.; Basak, S.; Mitra, J. Artificial neural network modeling and genetic algorithm optimization of process parameters in fluidized bed drying of green tea leaves. J. Food Process Eng. 2020, 43, e13128. [Google Scholar] [CrossRef]

- Vural, N.; Yilmazer Hitit, Z.; Ertunç, S. Multi—Objective optimization of drying conditions for the Olea europaea L. leaves with NSGA-II. J. Food Process. Preserv. 2021, 45, e15625. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, H.W.; Fang, X.M.; Mujumdar, A.S.; Vidyarthi, S.K.; Xie, L. Effect of high-humidity hot air impingement blanching and pulsed vacuum drying on phytochemicals content, antioxidant capacity, rehydration kinetics and ultrastructure of Thompson seedless grape. Dry. Technol. 2022, 40, 1013–1102. [Google Scholar] [CrossRef]

- Deng, L.Z.; Pan, Z.; Mujumdar, A.S.; Zhao, J.H.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. High-humidity hot air impingement blanching (HHAIB) enhances drying quality of apricots by inactivating the enzymes, reducing drying time and altering cellular structure. Food Control. 2019, 96, 104–111. [Google Scholar] [CrossRef]

- Jeevarathinam, G.; Pandiselvam, R.; Pandiarajan, T.; Preetha, P.; Krishnakumar, T.; Balakrishnan, M.; Thirupathi, V.; Ganapathy, S.; Amirtham, D. Design, development, and drying kinetics of infrared—Assisted hot air dryer for turmeric slices. J. Food Process Eng. 2022, 45, e13876. [Google Scholar] [CrossRef]

- Putranto, A.; Chen, X.D. Reaction engineering approach modeling of intensified drying of fruits and vegetables using microwave, ultrasonic and infrared-heating. Dry. Technol. 2020, 38, 747–757. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtaghaza, M.H.; Amirnejat, H. Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 2011, 36, 6433–6441. [Google Scholar] [CrossRef]

- Nowak, D.; Lewicki, P.P. Infrared drying of apple slices. Innov. Food Sci. Emerg. Technol. 2020, 5, 353–360. [Google Scholar] [CrossRef]

- Diamante, L.; Durand, M.; Savage, G.P.; Vanhanen, L.P. Effect of temperature on the drying characteristics, colour and ascorbic acid content of green and gold kiwifruits. Int. Food Res. J. 2010, 17, 441–451. [Google Scholar]

- Nadian, M.H.; Abbaspour-Fard, M.H.; Martynenko, A.; Golzarian, M.R. An intelligent integrated control of hybrid hot air-infrared dryer based on fuzzy logic and computer vision system. Comput. Electron. Agric. 2017, 137, 138–149. [Google Scholar] [CrossRef]

- Chen, Q.; Bi, J.; Wu, X.; Yi, J.; Zhou, L.; Zhou, Y. Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short-and medium-wave infrared radiation. LWT 2015, 64, 759–766. [Google Scholar] [CrossRef]

- Deng, L.Z.; Mujumdar, A.S.; Yang, W.X.; Zhang, Q.; Zheng, Z.A.; Wu, M.; Xiao, H.W. Hot air impingement drying kinetics and quality attributes of orange peel. J. Food Process. Preserv. 2020, 44, e14294. [Google Scholar] [CrossRef]

- Wang, H.; Meng, J.S.; Raghavan, G.S.V.; Orsat, V.; Yu, X.L.; Liu, Z.L.; Zheng, Z.A.; Wang, S.Y.; Xiao, H.W. Vacuum-steam pulsed blanching (VSPB) enhances drying quality, shortens the drying time of gingers by inactivating enzymes, altering texture, microstructure and ultrastructure. LWT 2020, 154, 112714. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, H.; Xu, J.; Zhuang, W.; Zheng, B.; Lo, Y.M.; Huang, Z.; Tian, Y. Microwave vacuum drying of lotus (Nelumbo nucifera Gaertn.) seeds: Effects of ultrasonic pretreatment on color, antioxidant activity, and rehydration capacity. LWT 2021, 149, 111603. [Google Scholar] [CrossRef]

- Zielinska, M.; Sadowski, P.; Błaszczak, W. Combined hot air convective drying and microwave-vacuum drying of blueberries (Vaccinium corymbosum L.): Drying kinetics and quality characteristics. Dry. Technol. 2016, 34, 665–684. [Google Scholar] [CrossRef]

- Liu, T.; Liang, S.; Xiong, Q.; Wang, K. Data-based online optimal temperature tracking control in continuous microwave heating system by adaptive dynamic programming. Neural Process. Lett. 2020, 51, 167–191. [Google Scholar] [CrossRef]

| Population Type | Double Vector |

|---|---|

| Population size | 30 × number of variables |

| Crossover function | Intermediate |

| Crossover rate | 90% |

| Migration function | Uniform |

| Mutation rate | 10% |

| Number of generations | 500 × number of variables |

| Pareto front population fraction | 0.30 |

| Selection function | Tournament size = 2 |

| Group | Activation Function of the Hidden Layer | Number of Neurons in the Hidden Layer | Activation Function of the Output Layer | DT | SEC | RC | VC | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RMSE | RMSE | RMSE | RMSE | ||||||||

| 1 | Tansig | 4 | Pureline | 0.8587 | 67 | 0.7969 | 0.8780 | 0.9827 | 0.1187 | 0.8858 | 0.2042 |

| 2 | 6 | 0.9935 | 11 | 0.8926 | 0.4324 | 0.9717 | 0.1330 | 0.9263 | 0.1732 | ||

| 3 | 8 | 0.9854 | 20 | 0.9605 | 0.4328 | 0.9773 | 0.1483 | 0.9889 | 0.0678 | ||

| 4 | 10 | 0.9924 | 18 | 0.9438 | 0.4790 | 0.9745 | 0.1261 | 0.9766 | 0.1204 | ||

| 5 | 4 | Logsig | 0.5721 | 115 | 0.4859 | 1.4736 | 0.6351 | 0.5681 | 0.5237 | 0.5914 | |

| 6 | 6 | 0.6837 | 89 | 0.6270 | 1.0315 | 0.7398 | 0.4637 | 0.5465 | 0.5294 | ||

| 7 | 8 | 0.9003 | 50 | 0.8493 | 0.8160 | 0.8121 | 0.5457 | 0.6394 | 0.5531 | ||

| 8 | 10 | 0.5853 | 110 | 0.6331 | 1.1254 | 0.7102 | 0.4047 | 0.6745 | 0.3672 | ||

| 9 | Logsig | 4 | Pureline | 0.8066 | 64 | 0.8272 | 0.7444 | 0.9713 | 0.1378 | 0.7638 | 0.2926 |

| 10 | 6 | 0.9952 | 12 | 0.9171 | 0.5504 | 0.9734 | 0.1466 | 0.8578 | 0.2423 | ||

| 11 | 8 | 0.9871 | 21 | 0.9182 | 0.6151 | 0.9754 | 0.1568 | 0.8901 | 0.2612 | ||

| 12 | 10 | 0.9916 | 13 | 0.9143 | 0.6262 | 0.9817 | 0.1217 | 0.9439 | 0.1691 | ||

| 13 | 4 | Logsig | 0.7066 | 98 | 0.6498 | 1.1809 | 0.3068 | 0.6656 | 0.3069 | 0.6594 | |

| 14 | 6 | 0.6649 | 100 | 0.7267 | 0.9651 | 0.6338 | 0.4124 | 0.5504 | 0.2915 | ||

| 15 | 8 | 0.5240 | 107 | 0.7017 | 0.9545 | 0.2826 | 0.5857 | 0.4679 | 0.3550 | ||

| 16 | 10 | 0.5659 | 118 | 0.6749 | 1.1610 | 0.8019 | 0.3870 | 0.7407 | 0.3396 | ||

| Types of activation functions | |||||||||||

| Bj | ||||

|---|---|---|---|---|

| 1 | −0.3826 | 1.0233 | 0.1616 | 0.8245 |

| 2 | −2.2399 | −0.2557 | −0.2111 | 1.3641 |

| 3 | 1.3779 | −0.8164 | −2.1741 | 0.1381 |

| 4 | −0.4903 | −0.1129 | −1.0111 | 0.5771 |

| 5 | 1.5830 | 0.0897 | −0.0504 | 0.8454 |

| 6 | −0.2677 | −0.2317 | 2.3441 | 1.2737 |

| 7 | −0.4421 | 1.0577 | 0.1488 | −1.5383 |

| 8 | 0.1699 | −3.7173 | −0.1564 | 3.7802 |

| Pareto ID | BT (s) | T (°C) | v (m/s) | DT (min) | SEC (MJ/kg) | VC (mg/100g) | RC |

|---|---|---|---|---|---|---|---|

| 1 | 93 | 89 | 1.2 | 366.7 | 1.43 | 4.19 | 3.35 |

| 2 | 93 | 88.8 | 1.21 | 369.7 | 1.49 | 4.21 | 3.35 |

| 3 | 93 | 88.5 | 1.24 | 375.5 | 1.56 | 4.24 | 3.35 |

| 4 | 95 | 88.4 | 1.2 | 379.5 | 1.59 | 4.31 | 3.37 |

| 5 | 93 | 86.9 | 1.16 | 387.5 | 1.82 | 4.4 | 3.32 |

| 6 | 95 | 88.7 | 1.1 | 389.0 | 1.53 | 4.27 | 3.37 |

| 7 | 95 | 87.0 | 1.18 | 389.9 | 1.82 | 4.42 | 3.34 |

| 8 | 94 | 85.9 | 1.14 | 397.5 | 2.01 | 4.49 | 3.3 |

| 9 | 93 | 83.2 | 1.19 | 407.7 | 2.5 | 4.71 | 3.24 |

| 10 | 94 | 87.9 | 0.9 | 412.8 | 1.68 | 4.31 | 3.34 |

| 11 | 96 | 83.1 | 1.21 | 419.5 | 2.59 | 4.79 | 3.25 |

| 12 | 94 | 86.6 | 0.89 | 423.5 | 1.92 | 4.43 | 3.32 |

| 13 | 96 | 83.0 | 1.15 | 425.1 | 2.62 | 4.8 | 3.25 |

| 14 | 95 | 87.6 | 0.82 | 430.7 | 1.76 | 4.38 | 3.35 |

| 15 | 95 | 86.0 | 1.54 | 434.5 | 2.35 | 4.5 | 3.32 |

| 16 | 96 | 83.8 | 1.51 | 448.6 | 2.78 | 4.72 | 3.27 |

| 17 | 92 | 89.8 | 0.42 | 457.3 | 1.31 | 4.11 | 3.36 |

| 18 | 93 | 89.8 | 0.35 | 463.0 | 1.29 | 4.13 | 3.37 |

| 19 | 95 | 85.2 | 1.73 | 463.8 | 2.74 | 4.58 | 3.3 |

| 20 | 95 | 89.9 | 0.34 | 472.3 | 1.30 | 4.17 | 3.4 |

| 21 | 95 | 84.5 | 1.85 | 483.4 | 3.04 | 4.65 | 3.29 |

| 22 | 95 | 85.5 | 1.93 | 486.1 | 2.91 | 4.55 | 3.31 |

| 23 | 95 | 84.0 | 1.88 | 492.2 | 3.21 | 4.7 | 3.27 |

| 24 | 95 | 84.4 | 1.99 | 500.5 | 3.23 | 4.66 | 3.29 |

| 25 | 95 | 85.1 | 2.11 | 510.2 | 3.22 | 4.59 | 3.3 |

| 26 | 95 | 84.5 | 2.11 | 513.7 | 3.36 | 4.64 | 3.29 |

| 27 | 95 | 84.5 | 2.16 | 520.5 | 3.43 | 4.65 | 3.29 |

| 28 | 95 | 84.8 | 2.21 | 524.7 | 3.44 | 4.62 | 3.29 |

| 29 | 95 | 84.5 | 2.23 | 529.5 | 3.54 | 4.65 | 3.29 |

| 30 | 95 | 84.6 | 2.35 | 542.0 | 3.66 | 4.64 | 3.29 |

| Results | Operating Conditions | Response Variables | |||||

|---|---|---|---|---|---|---|---|

| BT (s) | T (°C) | v (m/s) | BT (min) | SEC (MJ/kg) | VC (mg/100 g) | RC | |

| Prediction | 93 | 89 | 1.2 | 366.7 | 1.43 | 4.19 | 3.35 |

| Validation | 93 | 89 | 1.2 | 372 | 1.46 | 4.08 | 3.25 |

| Error (%) | 1.43 | 2.06 | 2.70 | 3.08 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, K.; Chen, C. Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries. Foods 2022, 11, 3347. https://doi.org/10.3390/foods11213347

Zhang W, Wang K, Chen C. Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries. Foods. 2022; 11(21):3347. https://doi.org/10.3390/foods11213347

Chicago/Turabian StyleZhang, Weipeng, Ke Wang, and Chang Chen. 2022. "Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries" Foods 11, no. 21: 3347. https://doi.org/10.3390/foods11213347

APA StyleZhang, W., Wang, K., & Chen, C. (2022). Artificial Neural Network Assisted Multiobjective Optimization of Postharvest Blanching and Drying of Blueberries. Foods, 11(21), 3347. https://doi.org/10.3390/foods11213347