The Effects of Storage Time and Environmental Storage Conditions on Flour Quality, Dough Rheology, and Biscuit Characteristics: The Case Study of a Traditional Italian Biscuit (Biscotto di Prato)

Abstract

:1. Introduction

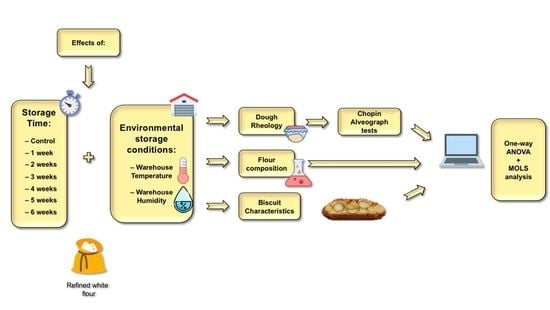

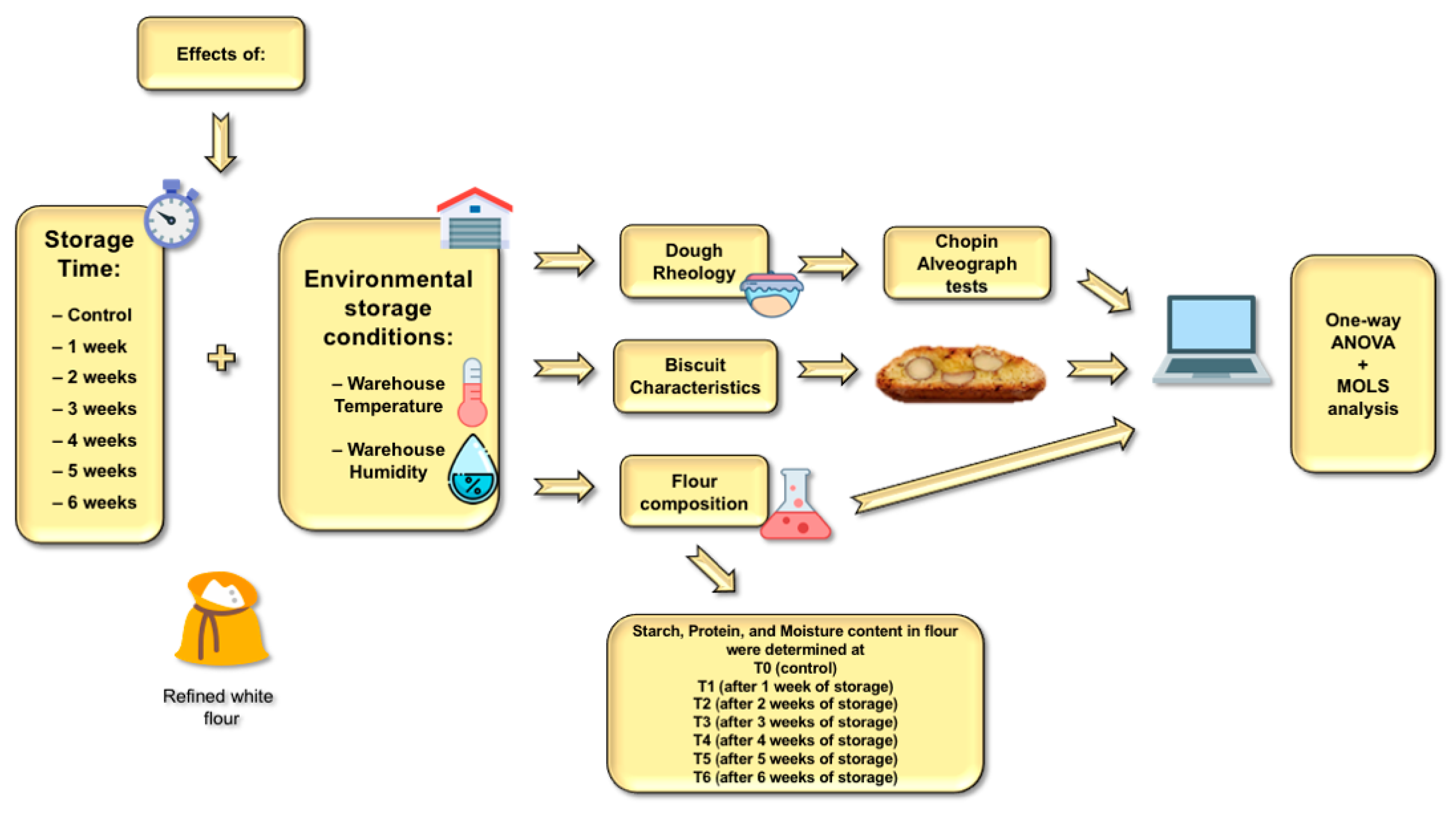

2. Materials and Methods

2.1. Raw Materials

2.2. Environmental Storage Conditions Measurement

2.3. Flour Characterization

2.4. Rheological Properties

2.5. Biscuit Production Process and Characterization

2.6. Statistical Analysis

3. Results and Discussion

3.1. Results of Flours Characterization and Environmental Storage Conditions

3.2. Dough Rheological Properties

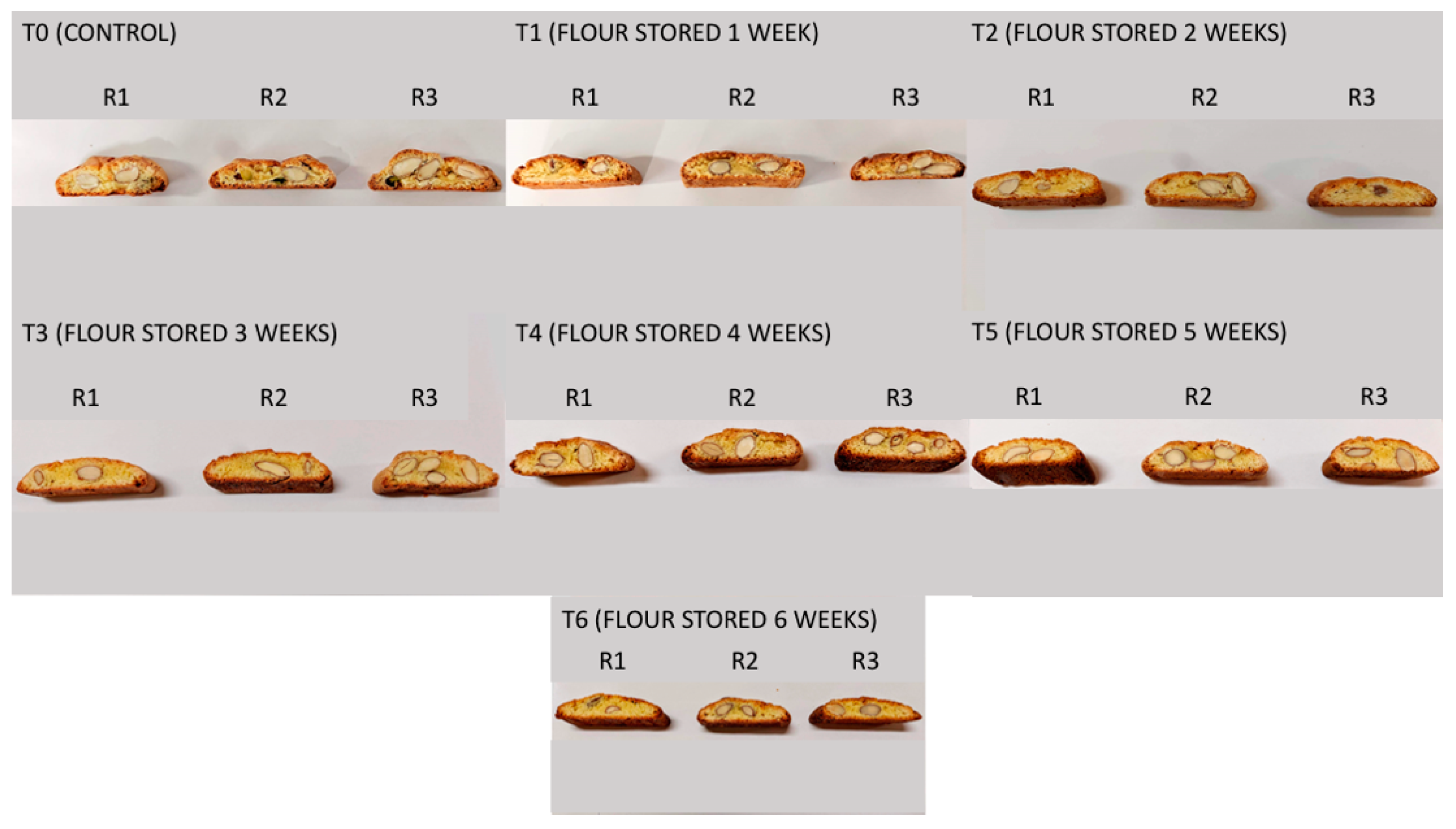

3.3. Biscuit Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cappelli, A.; Lupori, L.; Cini, E. Baking technology: A systematic review of machines and plants and their effect on final products, including improvement strategies. Trends Food Sci. Technol. 2021, 115, 275–284. [Google Scholar] [CrossRef]

- Pasqualone, A. Traditional flat breads spread from the Fertile Crescent: Production process and history of baking systems. J. Ethn. Foods 2018, 5, 10–19. [Google Scholar] [CrossRef]

- Pagani, M.A.; Marti, A.; Bottega, G. Wheat Milling and Flour Quality Evaluation. In Bakery Products Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 17–53. ISBN 9781119967156. [Google Scholar]

- Cappelli, A.; Cini, E. Challenges and Opportunities in Wheat Flour, Pasta, Bread, and Bakery Product Production Chains: A Systematic Review of Innovations and Improvement Strategies to Increase Sustainability, Productivity, and Product Quality. Sustainability 2021, 13, 2608. [Google Scholar] [CrossRef]

- Cappelli, A.; Guerrini, L.; Parenti, A.; Palladino, G.; Cini, E. Effects of wheat tempering and stone rotational speed on particle size, dough rheology and bread characteristics for a stone-milled weak flour. J. Cereal Sci. 2020, 91, 102879. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. Stone milling versus roller milling: A systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends Food Sci. Technol. 2020, 97, 147–155. [Google Scholar] [CrossRef]

- Venturi, M.; Cappelli, A.; Pini, N.; Galli, V.; Lupori, L.; Granchi, L.; Cini, E. Effects of kneading machine type and total element revolutions on dough rheology and bread characteristics: A focus on straight dough and indirect (biga) methods. LWT 2022, 153, 112500. [Google Scholar] [CrossRef]

- Parenti, O.; Carini, E.; Marchini, M.; Tuccio, M.G.; Guerrini, L.; Zanoni, B. Wholewheat bread: Effect of gradual water addition during kneading on dough and bread properties. LWT 2021, 142, 111017. [Google Scholar] [CrossRef]

- Cappelli, A.; Canessa, J.; Cini, E. Effects of CO2 snow addition during kneading on thermoregulation, dough rheological properties, and bread characteristics: A focus on ancient and modern wheat cultivars. Int. J. Refrig. 2020, 117, 52–60. [Google Scholar] [CrossRef]

- Venturi, M.; Galli, V.; Pini, N.; Guerrini, S.; Sodi, C.; Granchi, L. Influence of different leavening agents on technological and nutritional characteristics of whole grain breads obtained from ancient and modern flour varieties. Eur. Food Res. Technol. 2021, 247, 1701–1710. [Google Scholar] [CrossRef]

- Di Silvestro, R.; Di Loreto, A.; Marotti, I.; Bosi, S.; Bregola, V.; Gianotti, A.; Quinn, R.; Dinelli, G. Effects of flour storage and heat generated during milling on starch, dietary fibre and polyphenols in stoneground flours from two durum-type wheats. Int. J. Food Sci. Technol. 2014, 49, 2230–2236. [Google Scholar] [CrossRef]

- Campbell, G.M.; Sharp, C.; Wall, K.; Mateos-Salvador, F.; Gubatz, S.; Huttly, A.; Shewry, P. Modelling wheat breakage during roller milling using the double normalized kumaraswamy breakage function: Effects of kernel shape and hardness. J. Cereal Sci. 2012, 55, 415–425. [Google Scholar] [CrossRef]

- Cappelli, A.; Mugnaini, M.; Cini, E. Improving roller milling technology using the break, sizing, and reduction systems for flour differentiation. LWT 2020, 133, 110067. [Google Scholar] [CrossRef]

- Bottega, G.; Caramanico, R.; Lucisano, M.; Mariotti, M.; Franzetti, L.; Ambrogina Pagani, M. The debranning of common wheat (Triticum aestivum L.) with innovative abrasive rolls. J. Food Eng. 2009, 94, 75–82. [Google Scholar] [CrossRef]

- Gili, R.D.; Palavecino, P.M.; Cecilia Penci, M.; Martinez, M.L.; Ribotta, P.D. Wheat germ stabilization by infrared radiation. J. Food Sci. Technol. 2017, 54, 71–81. [Google Scholar] [CrossRef] [Green Version]

- Quayson, E.T.E.T.; Marti, A.; Bonomi, F.; Atwell, W.; Seetharaman, K. Structural Modification of Gluten Proteins in Strong and Weak Wheat Dough as Affected by Mixing Temperature. Cereal Chem. 2016, 93, 189–195. [Google Scholar] [CrossRef]

- Cappelli, A.; Guerrini, L.; Cini, E.; Parenti, A. Improving whole wheat dough tenacity and extensibility: A new kneading process. J. Cereal Sci. 2019, 90, 102852. [Google Scholar] [CrossRef]

- Aljaafreh, A. Agitation and mixing processes automation using current sensing and reinforcement learning. J. Food Eng. 2017, 203, 53–57. [Google Scholar] [CrossRef]

- Cappelli, A.; Parretti, C.; Cini, E.; Citti, P. Development of a new washing machine in olive oil extraction plant: A first application of usability-based approach. J. Agric. Eng. 2019, 50, 134–142. [Google Scholar] [CrossRef] [Green Version]

- Oestersötebier, F.; Traphöner, P.; Reinhart, F.; Wessels, S.; Trächtler, A. Design and Implementation of Intelligent Control Software for a Dough Kneader. Procedia Technol. 2016, 26, 473–482. [Google Scholar] [CrossRef] [Green Version]

- AOAC International. Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- ISO. 27971. Cereals and Cereal Products-Common Wheat (Triticum aestivum L.)-Determination of Alveograph Properties of Dough at Constant Hydratation from Commercial or Test Flours and Testing Millig Methodology; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; AACC: St. Paul, MN, USA, 2000. [Google Scholar]

- Lancelot, E.; Fontaine, J.; Grua-Priol, J.; Le-Bail, A. Effect of long-term storage conditions on wheat flour and bread baking properties. Food Chem. 2021, 346, 128902. [Google Scholar] [CrossRef]

- González-Torralba, J.; Arazuri, S.; Jarén, C.; Arregui, L.M. Influence of temperature and r.h. during storage on wheat bread making quality. J. Stored Prod. Res. 2013, 55, 134–144. [Google Scholar] [CrossRef] [Green Version]

- Cappelli, A.; Cini, E.; Guerrini, L.; Masella, P.; Angeloni, G.; Parenti, A. Predictive models of the rheological properties and optimal water content in doughs: An application to ancient grain flours with different degrees of refining. J. Cereal Sci. 2018, 83, 229–235. [Google Scholar] [CrossRef]

- Shahid, Y.; Iqbal, H.M.; Saqib, A.; Salman, K.; Akbar, Q.U.A. Alveograph Rheological parameters in relation to physicochemical attributes as an indicator of wheat flour quality. Int. J. Biol. Biotechnol. 2019, 16, 425–431. [Google Scholar]

- Mastromatteo, M.; Guida, M.; Danza, A.; Laverse, J.; Frisullo, P.; Lampignano, V.; Del Nobile, M.A. Rheological, microstructural and sensorial properties of durum wheat bread as affected by dough water content. Food Res. Int. 2013, 51, 458–466. [Google Scholar] [CrossRef]

- Bardini, G.; Boukid, F.; Carini, E.; Curti, E.; Pizzigalli, E.; Vittadini, E. Enhancing dough-making rheological performance of wheat flour by transglutaminase and vital gluten supplementation. LWT 2018, 91, 467–476. [Google Scholar] [CrossRef]

- Selaković, A.; Nikolić, I.; Dokić, L.; Šoronja-Simović, D.; Šimurina, O.; Zahorec, J.; Šereš, Z. Enhancing rheological performance of laminated dough with whole wheat flour by vital gluten addition. LWT 2021, 138, 110604. [Google Scholar] [CrossRef]

- Wang, M.; Hamer, R.J.; van Vliet, T.; Oudgenoeg, G. Interaction of Water Extractable Pentosans with Gluten Protein: Effect on Dough Properties and Gluten Quality. J. Cereal Sci. 2002, 36, 25–37. [Google Scholar] [CrossRef]

- Quaglia, G. Scienza e Tecnologia Della Panificazione; Chiriotti Editori: Pinerolo, Italy, 1984; pp. 296–306. [Google Scholar]

- Migliorini, P.; Spagnolo, S.; Torri, L.; Arnoulet, M.; Lazzerini, G.; Ceccarelli, S. Agronomic and quality characteristics of old, modern and mixture wheat varieties and landraces for organic bread chain in diverse environments of northern Italy. Eur. J. Agron. 2016, 79, 131–141. [Google Scholar] [CrossRef]

- Ma, F.; Baik, B.-K. Soft wheat quality characteristics required for making baking powder biscuits. J. Cereal Sci. 2018, 79, 127–133. [Google Scholar] [CrossRef]

| Sample | Moisture (g/100 g) | Starch (g/100 g) | Protein (g/100 g) |

|---|---|---|---|

| Flour T0 (control) | 14.60 ± 0.19 | 65.33 ± 1.18 | 13.20 ± 0.25 |

| Flour T1 (1 week of storage) | 15.40 ± 0.21 | 68.26 ± 1.01 | 10.90 ± 0.49 |

| Flour T2 (2 weeks of storage) | 15.10 ± 0.16 | 68.97 ± 1.34 | 11.60 ± 0.36 |

| Flour T3 (3 weeks of storage) | 15.10 ± 0.19 | 69.70 ± 1.51 | 11.50 ± 0.41 |

| Flour T4 (4 weeks of storage) | 15.00 ± 0.11 | 68.60 ± 1.04 | 11.10 ± 0.53 |

| Flour T5 (5 weeks of storage) | 14.80 ± 0.16 | 69.10 ± 1.58 | 12.10 ± 0.46 |

| Flour T6 (6 weeks of storage) | 14.60 ± 0.22 | 70.90 ± 2.16 | 12.30 ± 0.38 |

| Week | Mean Temperature (°C) | Mean Humidity (%) |

|---|---|---|

| Week 0 (control) | 19.73 ± 0.29 | 64.33 ± 1.15 |

| Week 1 | 19.88 ± 0.38 | 57.11 ± 3.01 |

| Week 2 | 20.82 ± 0.59 | 58.00 ± 1.33 |

| Week 3 | 20.47 ± 0.39 | 56.56 ± 3.15 |

| Week 4 | 21.53 ± 0.43 | 55.44 ± 3.53 |

| Week 5 | 23.04 ± 0.81 | 50.00 ± 1.45 |

| Week 6 | 24.67 ± 0.29 | 54.33 ± 3.67 |

| P (Dough Tenacity) | L (Dough Extensibility) | G (Index of Swelling) | W (Deformation Energy) | P/L (Curve Configuration Ratio) | |

|---|---|---|---|---|---|

| Flour T0 (control) | 80.73 ± 1.62 | 74.73 ± 11.30 | 19.35 ± 1.37 | 237.87 ± 18.13 | 1.09 ± 0.16 |

| Flour T1 (1 week of storage) | 103.53 ± 1.97 | 63.07 ± 5.66 | 17.66 ± 0.80 | 269.53 ± 15.70 | 1.67 ± 0.17 |

| Flour T2 (2 weeks of storage) | 98.17 ± 3.88 | 72.12 ± 6.18 | 18.85 ± 0.80 | 282.37 ± 7.50 | 1.40 ± 0.16 |

| Flour T3 (3 weeks of storage) | 97.98 ± 5.55 | 69.07 ± 11.23 | 18.04 ± 2.16 | 295.63 ± 24.09 | 1.46 ± 0.18 |

| Flour T4 (4 weeks of storage) | 98.53 ± 3.26 | 58.60 ± 2.03 | 16.82 ± 0.42 | 242.05 ± 12.60 | 1.69 ± 0.02 |

| Flour T5 (5 weeks of storage) | 97.67 ± 1.22 | 60.93 ± 3.38 | 17.26 ± 0.55 | 248.47 ± 11.87 | 1.63 ± 0.13 |

| Flour T6 (6 weeks of storage) | 93.27 ± 2.16 | 59.87 ± 5.68 | 17.16 ± 0.78 | 237.47 ± 19.16 | 1.59 ± 0.15 |

| Sample | Volume (L) | Height (mm) |

|---|---|---|

| Biscuit T0 (control) | 0.0446 ± 0.003 | 17.47 ± 2.09 |

| Biscuit T1 (1 week of flour storage) | 0.0150 ± 0.006 | 15.37 ± 2.08 |

| Biscuit T2 (2 weeks of flour storage) | 0.0189 ± 0.004 | 16.07 ± 0.73 |

| Biscuit T3 (3 weeks of flour storage) | 0.0166 ± 0.003 | 17.58 ± 0.85 |

| Biscuit T4 (4 weeks of flour storage) | 0.0191 ± 0.001 | 18.38 ± 0.98 |

| Biscuit T5 (5 weeks of flour storage) | 0.0170 ± 0.002 | 17.58 ± 2.09 |

| Biscuit T6 (6 weeks of flour storage) | 0.0272 ± 0.002 | 16.88 ± 0.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappelli, A.; Bini, A.; Cini, E. The Effects of Storage Time and Environmental Storage Conditions on Flour Quality, Dough Rheology, and Biscuit Characteristics: The Case Study of a Traditional Italian Biscuit (Biscotto di Prato). Foods 2022, 11, 209. https://doi.org/10.3390/foods11020209

Cappelli A, Bini A, Cini E. The Effects of Storage Time and Environmental Storage Conditions on Flour Quality, Dough Rheology, and Biscuit Characteristics: The Case Study of a Traditional Italian Biscuit (Biscotto di Prato). Foods. 2022; 11(2):209. https://doi.org/10.3390/foods11020209

Chicago/Turabian StyleCappelli, Alessio, Andrea Bini, and Enrico Cini. 2022. "The Effects of Storage Time and Environmental Storage Conditions on Flour Quality, Dough Rheology, and Biscuit Characteristics: The Case Study of a Traditional Italian Biscuit (Biscotto di Prato)" Foods 11, no. 2: 209. https://doi.org/10.3390/foods11020209

APA StyleCappelli, A., Bini, A., & Cini, E. (2022). The Effects of Storage Time and Environmental Storage Conditions on Flour Quality, Dough Rheology, and Biscuit Characteristics: The Case Study of a Traditional Italian Biscuit (Biscotto di Prato). Foods, 11(2), 209. https://doi.org/10.3390/foods11020209