Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean

Abstract

:1. Introduction

2. Materials and Methods

2.1. Beans

2.2. Pre-Cooked Process

2.3. Gelatinization Analysis

2.4. Sensory Evaluation

2.5. The Comprehensive Score

2.6. Optimal Condition Verification

2.7. Evaluation under Optimal Conditions

2.7.1. Texture Profile Analysis

2.7.2. Proximate Composition Analysis

2.7.3. Polarized Light Optical Microscopy and Scanning Electron Microscopy

2.7.4. Infrared Transmission (FT-IR)

2.7.5. X-ray Diffraction (XRD)

2.8. Data Analysis

3. Results and Discussion

3.1. Optimum Process Conditions for Microwave Pre-Gelatinization

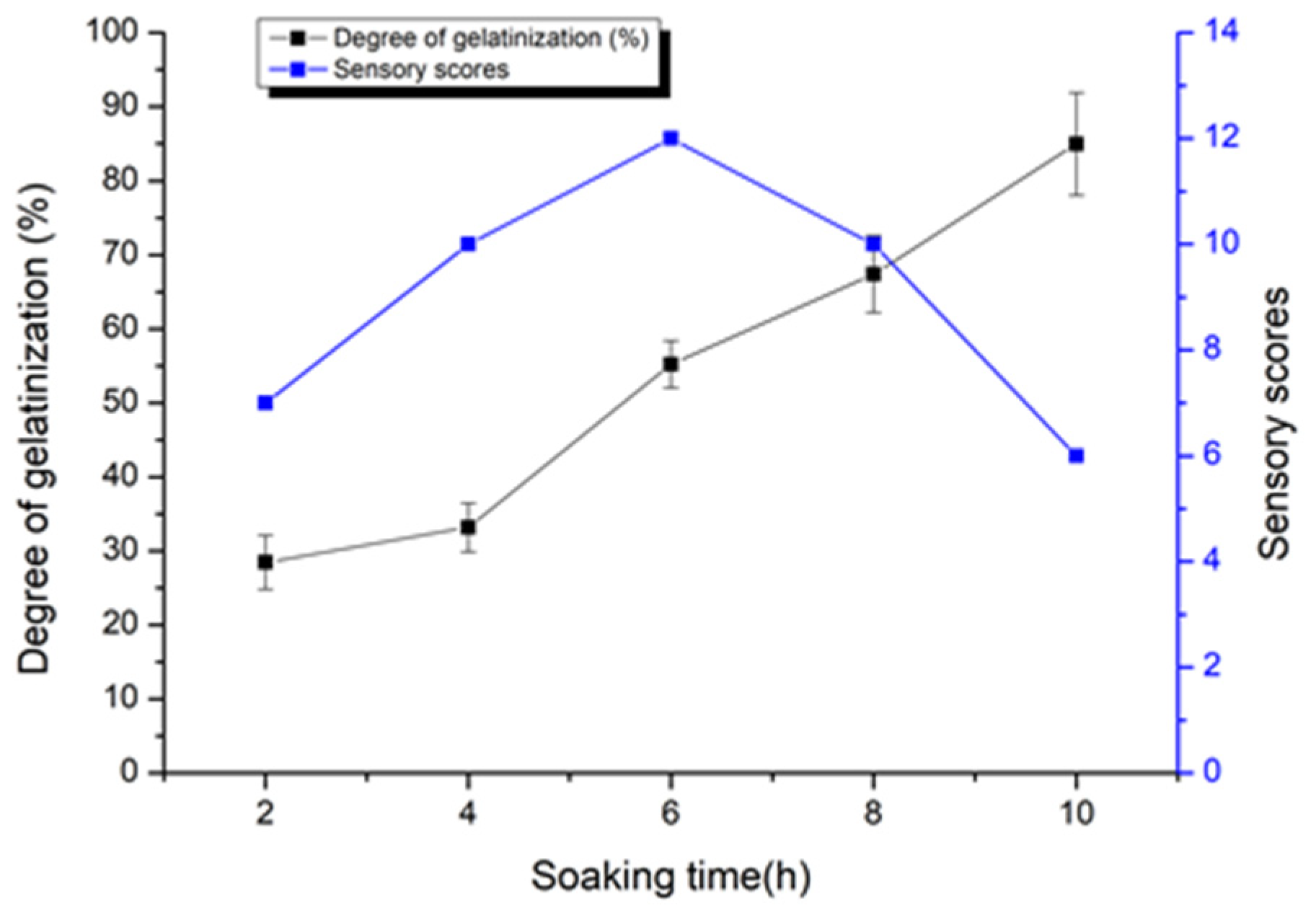

3.1.1. Determining Levels of Independent Variables for Microwave Pre-Gelatinization

3.1.2. Optimization of Process Conditions

3.2. Composition of Untreated Adzuki Beans and Pre-Cooked Adzuki Beans

3.2.1. Nutrient Analysis

3.2.2. Texture Analysis

3.3. Starch Structure of Samples

SEM and Polarizing Microscope

3.4. Starch Structure

3.4.1. X-ray Crystal Structure Analysis

3.4.2. FT-IR Crystal Structure Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, J.; Zhang, W.; Zhou, L.N.; Mingqing, H.; Xiaoqin, Z.; Huiyou, X. Advances in studies on chemical constitute and pharmacological activities of Adzuki. Chin. Tradit. Herb. Drugs 2021, 52, 4433–4442. [Google Scholar]

- Yoshida, Y.; Marubodee, R.; Ogiso-Tanaka, E.; Iseki, K.; Isemura, T.; Takahashi, Y.; Muto, C.; Naito, K.; Kaga, A.; Okuno, K.; et al. Salt tolerance in wild relatives of adzuki bean, Vigna angularis (Willd.) Ohwi et Ohashi. Genet. Resour. Crop Evol. 2015, 63, 627–637. [Google Scholar] [CrossRef] [Green Version]

- Worku, A.; Sahu, O. Significance of fermentation process on biochemical properties of Phaseolus vulgaris (red beans). Biotechnol. Rep. 2017, 16, 5–11. [Google Scholar] [CrossRef] [PubMed]

- Jhan, J.K.; Chang, W.F.; Wang, P.M.; Chou, S.T.; Chung, Y.C. Production of fermented red beans with multiple bioactivities using co-cultures of Bacillus subtilis and Lactobacillus delbrueckii subsp. bulgaricus. LWT-Food Sci. Technol. 2015, 63, 1281–1287. [Google Scholar] [CrossRef]

- Umeo, T.; Sachiko, H.; Filis, M. Procyanidins in rice cook ed with adzuki bean and their contribution to the reduction of nitrite to nitric oxide (•NO) in artificial gastric juice. Int. J. Food Sci. Nutr. 2020, 71, 63–73. [Google Scholar]

- Ni, P.; Shen, Q. Process research of mixed beans with cooked rice. Food Sci. Technol. 2017, 08, 140–146. [Google Scholar]

- Vidal-Valverde, C.; Sierra, I.; Frias, J.; Prodanov, M.; Sotomayor, C.; Hedley, C.L.; Urbano, G. Nutritional evaluation of lentil flours obtained after short-time soaking processes. Eur. Food Res. Technol. 2002, 215, 138–144. [Google Scholar] [CrossRef]

- Sun, J.T.; Zhang, Z.C.; Hu, J.H. Study on physicochemical properties of prematured cereals. Food Sci. Technol. 2020, 45, 221–224. [Google Scholar]

- Chi, Z.P.; Chi, Y.P.; Chi, Y.K.; Diao, J.J.; Chen, H.S. Optimization of microwave preparation of sorghum resistant starch. China Food Addit. Mag. 2021, 8, 1–7. [Google Scholar]

- Yuan, M.Y. Problems and special effects of microwave application in food processing. Food Sci. Technol. 2021, 24, 177–178. [Google Scholar]

- Song, L.L.; Ma, M.T.; Xu, Y.J.; Chen, X.J.; Xu, Z.K.; Sui, Z.Q. Research progress in the effect of thermal treatments on the structural and physicochemical properties of starch. Sci. Technol. Cereals Oils Foods 2021, 3, 111–117. [Google Scholar]

- Yang, K.S.; Yoon, Y.J.; Lee, M.S.; Lee, W.J.; Kim, J.H. Further carbonization of anisotropic and isotropic pitch-based carbons by microwave irradiation. Carbon 2002, 40, 897–903. [Google Scholar] [CrossRef]

- Aguilera, Y.; Esteban, R.M.; Benitez, V.; Molla, E.; Martin-Cabrejas, M.A. Starch, functional properties, and microstructural characteristics in chickpea and lentil as affected by thermal processing. Agric. Food Chem. 2009, 57, 10682–10688. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Hatcher, D.; Tyler, R.; Toews, R.; Gawalko, E. Effect of cooking on the composition of beans (Phaseolus vulgaris L.) and chickpeas (Cicer arietinum L.). Food Res. Int. 2010, 43, 589–594. [Google Scholar] [CrossRef]

- Liu, Y.; Ragaee, S.; Marcone, M.F.; Abdel-Aal, E.M. Effect of different cooking methods and heating solutions on nutritionallyimportant starch fractions and flatus oligosaccharides in selected pulses. Cereal Chem. 2020, 97, 1216–1226. [Google Scholar] [CrossRef]

- Martín-Cabrejas, M.A.; Díaz, M.F.; Aguilera, Y.; Benítez, V.; Mollá, E.; Esteban, R.M. Influence of germination on the soluble carbohydrates and dietary fibre fractions in non-conventional legumes. Food Chem. 2008, 107, 1045–1052. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.W.; Shi, X.M. Effect of microwave heat moisture treatment on physicochemical properties of Canna edulis Ker starch. J. Sci. Food Agric. 2009, 89, 653–664. [Google Scholar] [CrossRef]

- Triveni, R.; Shamala, T.R.; Rastogi, N.K. Optimised production and utilisation of exopolysaccharide from Agrobacterium radiobacter. Process Biochem. 2001, 36, 787–795. [Google Scholar] [CrossRef]

- Bardajee, G.R.; Azimi, S.; Sharifi, M.B. Application of central composite design for methyl red dispersive solid phase extraction based on silver nanocomposite hydrogel: Microwave assisted synthesis. Microchem. J. 2017, 133, 358–369. [Google Scholar] [CrossRef]

- Champagne, E.T.; Lyon, B.G.; Min, B.K.; Vinyard, B.T.; Bett, K.L.; Barton, F.E.; Webb, B.D.; McClung, A.M.; Moldenhauer, K.A.; Linscombe, S.; et al. Effects of Postharvest Processing on Texture Profile Analysis of Cooked Rice. Cereal Chem. 1998, 2, 181–186. [Google Scholar] [CrossRef]

- Dunn, C. Applied Multivariate Statistical Analysis; Taylor & Francis: Oxford, UK, 2012; Volume 31, pp. 265–266. [Google Scholar]

- Maningat, C.C.; Seib, P.A. Understanding the physicochemical and functional properties of wheat starch in various foods. Cereal Chem. 2010, 87, 305–314. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Wang, L.P.; Tian, X.H.; Wu, W.G.; Tan, B. Research progress on the relationship between extrusion and physicochemical properties of starch. Grain Oil Food Sci. Technol. 2016, 24, 13–17. [Google Scholar]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Palav, T.; Seetharaman, K. Mechanism of starch gelatinization and polymer leaching during microwave heating. Carbohydr. Polym. 2006, 65, 364–370. [Google Scholar] [CrossRef]

- Silva, W.M.F.; Biduski, B.; Lima, K.O.; Pinto, V.Z.; Hoffmann, J.F.; Vanier, N.L.; Dias, A.R.G. Starch digestibility and molecular weight distribution of proteins in rice grains subjected to heat-moisture treatment. Food Chem. 2017, 219, 260–267. [Google Scholar] [CrossRef] [PubMed]

- Mateosaparicio, I.; Mateospeinado, C.; Jiménezescrig, A. Multifunctional antioxidant activity of polysaccharide fractions from the soybean byproduct okara. Carbohydr. Polym. 2010, 82, 245–250. [Google Scholar] [CrossRef] [Green Version]

- Hoffer, L.J. Human Protein and Amino Acid Requirements. Jpen J. Parenter. Enter. Nutr. 2016, 40, 460. [Google Scholar] [CrossRef]

- Singh, N.; Kaur, M.; Sandhu, K.S.; Guraya, H.S. Physicochemical, Thermal, Morphological and Pasting Properties of Starches from some Indian Black Gram (Phaseolus mungo L.) Cultivars. Starch-Stärke 2010, 56, 535–544. [Google Scholar] [CrossRef]

- Agrawal, S.; Raigar, R.K.; Mishra, H.N. Effect of combined microwave, hot air, and vacuum treatments on cooking characteristics of rice. J. Food Process Eng. 2019, 42, e13038. [Google Scholar] [CrossRef]

- Wang, N.; Daun, J.K.; Malcolmson, L.J. Relationship between physicochemical and cooking properties, and effects of cooking on antinutrients, of yellow field peas (Pisum sativum). J. Sci. Food Agric. 2003, 83, 1228–1237. [Google Scholar] [CrossRef]

- Naito, S.; Ogawa, T. Tensipresser Precision in Measuring Cooked Rice Adhesiveness. J. Texture Stud. 2010, 29, 325–335. [Google Scholar] [CrossRef]

- Fiszman, S.M.; Pons, M.; Damásio, M. New Parameters For Instrumental Texture Profile Analysis: Instantaneous And Retarded Recoverable Springiness. J. Texture Stud. 2010, 29, 499–508. [Google Scholar] [CrossRef]

- Witek, M.; Węglarz, W.; De Jong, L.; Van Dalen, G.; Blonk, J.; Heussen, P.; Van Velzen, E.; Van As, H.; Van Duynhoven, J. The structural and hydration properties of heat-treated rice studied at multiple length scales. Food Chem. 2010, 120, 1031–1040. [Google Scholar] [CrossRef]

- Xu, X.; Chen, Y.; Luo, Z.; Lu, X. Different variations in structures of A- and B-type starches subjected to microwave treatment and their relationships with digestibility. LWT 2019, 99, 179–187. [Google Scholar] [CrossRef]

- Chavez-Murillo, C.E.; Orona-Padilla, J.L.; de la Rosa Millan, J. Physicochemical, functional properties and ATR-FTIR digestion analysis of thermally treated starches isolated from black and bayo beans. Starch-Starke 2019, 71, 3–4. [Google Scholar] [CrossRef]

- Cai, C.; Wei, C. In situ observation of crystallinity disruption patterns during starch gelatinization. Carbohydr. Polym. 2013, 92, 469–478. [Google Scholar] [CrossRef]

- Cai, J.; Cai, C.; Man, J.; Zhou, W.; Wei, C. Structural and functional properties of c-type starches. Carbohydr. Polym. 2014, 101, 289–300. [Google Scholar] [CrossRef]

- Cheetham, N.W.H.; Tao, L. Solid statenmr studies on the structural and conformational properties of natural maize starches. Carbohydr. Polym. 1998, 36, 285–292. [Google Scholar] [CrossRef]

- Wei, H.; Liang, B.; Chai, Y.; Xue, L.; Wang, X.; Yin, X. Effect of Different Heat Treatments on Physicochemical Properties and Structural and Digestibility of Water Caltrop Starch. Starch-Stärke 2020, 72, 9–10. [Google Scholar] [CrossRef]

- Li, M.; Xie, F.; Hasjim, J.; Witt, T.; Halley, P.; Gilbert, R.G. Establishing whether the structural feature controlling the mechanical properties of starch films is molecular or crystalline. Carbohydr. Polym. 2015, 117, 262–270. [Google Scholar] [CrossRef]

- Holse, M.; Larsen, F.H.; Hansen, Å.; Engelsen, S.B. Characterization of marama bean (Tylosema esculentum) by comparative spectroscopy: NMR, FT-Raman, FT-IR and NIR. Food Res. Int. 2011, 44, 373–384. [Google Scholar] [CrossRef]

- Habeych, E.; Guo, X.; Van Soest, J.; Van der Goot, A.J.; Boom, R. On the applicability of flory–huggins theory to ternary starch–water–solute systems. Carbohydr. Polym. 2009, 77, 703–712. [Google Scholar] [CrossRef]

| Level | Factor | ||

|---|---|---|---|

| A Soaking Time /h | B Microwave Power /w | C Microwave Time /s | |

| 1 | 2 | 600 | 70 |

| 2 | 4 | 700 | 80 |

| 3 | 6 | 800 | 90 |

| 4 | 8 | 900 | 100 |

| 5 | 10 | 1000 | 110 |

| No. | A (h) | B (W) | C (s) | Gelatinization/% | Sensory Score | Comprehensive Score |

|---|---|---|---|---|---|---|

| 1 | 6 | 800 | 90 | 66.63 | 11 | 0.85 |

| 2 | 6 | 800 | 90 | 64.61 | 10 | 0.67 |

| 3 | 6 | 800 | 70 | 43.68 | 7 | 0.15 |

| 4 | 4 | 700 | 100 | 51.62 | 8 | 0.36 |

| 5 | 6 | 800 | 90 | 64.51 | 11 | 0.79 |

| 6 | 8 | 700 | 100 | 65.75 | 9 | 0.60 |

| 7 | 6 | 1000 | 90 | 80.20 | 7 | 0.54 |

| 8 | 4 | 900 | 80 | 64.49 | 7 | 0.33 |

| 9 | 2 | 800 | 90 | 33.74 | 7 | 0.00 |

| 10 | 6 | 800 | 90 | 65.34 | 11 | 0.80 |

| 11 | 6 | 800 | 90 | 65.51 | 10 | 0.76 |

| 12 | 8 | 900 | 100 | 79.47 | 9 | 0.78 |

| 13 | 6 | 800 | 90 | 64.31 | 10 | 0.75 |

| 14 | 8 | 900 | 80 | 54.84 | 10 | 0.60 |

| 15 | 6 | 600 | 90 | 60.33 | 8 | 0.45 |

| 16 | 4 | 700 | 80 | 34.12 | 8 | 0.17 |

| 17 | 10 | 800 | 90 | 79.40 | 10 | 0.83 |

| 18 | 6 | 800 | 110 | 78.97 | 7 | 0.45 |

| 19 | 4 | 900 | 100 | 71.56 | 8 | 0.53 |

| 20 | 8 | 700 | 80 | 42.33 | 9 | 0.38 |

| Sum of Square | df | Mean-Square | F | p | Significant | ||

|---|---|---|---|---|---|---|---|

| Gelatinization | Module | 2909.40 | 3 | 969.80 | 15.61 | <0.0001 | Significant |

| A | 782.93 | 1 | 782.93 | 12.60 | 0.0029 | ** | |

| B | 844.74 | 1 | 844.74 | 13.59 | 0.0022 | ** | |

| C | 1281.73 | 1 | 1281.73 | 20.63 | 0.0004 | ** | |

| Residual | 932.73 | 15 | 62.14 | ||||

| Lack of fit | 908.49 | 11 | 82.59 | 13.98 | 0.0106 | Significant | |

| Error | 23.63 | 4 | 5.91 | ||||

| Sum | 3841.53 | 18 | |||||

| Sensory score | Module | 27.40 | 9 | 3.04 | 3.90 | 0.0003 | Significant |

| A | 9.00 | 1 | 9.00 | 11.54 | 0.0275 | * | |

| B | 0.25 | 1 | 0.25 | 0.32 | 0.0079 | ** | |

| C | 0.000 | 1 | 0.000 | 0.000 | 0.5851 | N.S. | |

| AB | 0.50 | 1 | 0.50 | 0.64 | 1.0000 | N.S. | |

| AC | 0.50 | 1 | 0.50 | 0.64 | 0.4440 | N.S. | |

| BC | 0.000 | 1 | 0.000 | 0.000 | 0.4440 | N.S. | |

| A2 | 2.98 | 1 | 2.98 | 3.82 | 1.0000 | N.S. | |

| B2 | 8.66 | 1 | 8.66 | 11.10 | 0.0088 | ** | |

| C2 | 12.61 | 1 | 12.61 | 16.17 | 0.0030 | ** | |

| Residual | 7.02 | 9 | 0.78 | ||||

| Lack of fit | 1.02 | 5 | 0.20 | 0.14 | 0.9747 | N.S. | |

| Error | 6.00 | 4 | 1.50 | ||||

| Sum | 34.42 | 18 | |||||

| Comprehensive score | Module | 0.92 | 9 | 0.10 | 6.10 | 0.0003 | Significant |

| A | 0.43 | 1 | 0.43 | 25.73 | <0.0001 | *** | |

| B | 0.053 | 1 | 0.053 | 3.15 | 0.0310 | * | |

| C | 0.12 | 1 | 0.12 | 7.07 | 0.0041 | ** | |

| AB | 6.9 × 10-4 | 1 | 6.9 × 10-4 | 0.041 | 0.7765 | N.S. | |

| AC | 1.048 × 10-6 | 1 | 1.048 × 10-6 | 6.28 × 10-5 | 0.9912 | N.S. | |

| BC | 3.021 × 10-5 | 1 | 3.021 × 10-5 | 1.81 × 10-3 | 0.9525 | N.S. | |

| A2 | 0.13 | 1 | 0.13 | 7.78 | 0.0009 | ** | |

| B2 | 0.066 | 1 | 0.066 | 3.96 | 0.0048 | N.S. | |

| C2 | 0.25 | 1 | 0.25 | 15.03 | 0.0001 | *** | |

| Residual | 0.15 | 9 | 0.017 | ||||

| Lack of fit | 0.051 | 5 | 0.010 | 0.41 | 0.2319 | N.S. | |

| Error | 0.099 | 4 | 0.025 | ||||

| Sum | 1.07 | 18 |

| Treatments | The Experimental Data | Model Calculated Value | Relative Error | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Gelatinization/% | Sensory Scores | Comprehensive Scores | Gelatinization/% | Sensory Scores | Comprehensive Scores | Gelatinization/% | Sensory Scores | Comprehensive Scores | |

| C1 | 33.74 | 7 | 0.00 | 37.22 | 7.14 | 0.08 | 0.10 ± 1.81 | 0.02 ± 0.82 | 0.00 ± 0.065 |

| C2 | 51.62 | 8 | 0.36 | 55.90 | 8.24 | 0.35 | 0.08 ± 0.92 | 0.03 ± 0.94 | 0.03 ± 0.032 |

| C3 | 80.19 | 7 | 0.54 | 75.74 | 7.39 | 0.61 | 0.06 ± 2.02 | 0.06 ± 1.25 | 0.13 ± 0.003 |

| C4 | 74.67 | 10 | 0.82 | 71.47 | 10.34 | 0.82 | 0.04 ± 2.11 | 0.03 ± 0.65 | 0.005 ± 0.012 |

| C5 | 79.40 | 10 | 0.83 | 75.20 | 10.14 | 0.74 | 0.05 ± 1.09 | 0.01 ± 0.94 | 0.11 ± 0.007 |

| Protein | Fat | Starch | Moisture | |

|---|---|---|---|---|

| CK | 20.48 a ± 0.35 | 0.72 a ± 0.20 | 49.17 a ± 0.16 | 10.78 a ± 0.15 |

| MT | 20.16 a ± 0.04 | 0.91 a ± 0.18 | 52.78 b ± 0.12 | 10.14 a ± 0.11 |

| ST | 20.22 a ± 0.15 | 0.80 a ± 0.11 | 49.42 a ± 0.21 | 19.05 b ± 0.13 |

| Asp | Thr | Ser | Glu | Gly | Ala | Val | Met | Ile | Leu | Tyr | Phe | Lys | His | Arg | Pro | Sum | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CK | 1.98 | 0.44 | 0.80 | 2.72 | 0.91 | 1.01 | 1.01 | 0.37 | 0.91 | 1.55 | 0.35 | 0.91 | 1.11 | 0.53 | 1.91 | 0.60 | 17.12 |

| MT | 1.95 | 0.43 | 0.74 | 2.62 | 0.90 | 1.06 | 1.01 | 0.40 | 0.90 | 1.54 | 0.27 | 0.90 | 1.06 | 0.52 | 1.84 | 0.57 | 16.73 |

| Hardness/g | Adhesiveness/g.sec−1 | Springiness | Cohesiveness/ss | Gumminess/s | Chewiness | Resilience | |

|---|---|---|---|---|---|---|---|

| Rice | 2108.89 b ± 18.56 | 66.98 a ± 3.27 | 0.61 a ± 0.21 | 0.51 a ± 0.07 | 890.12 a ± 6.54 | 638.16 b ± 5.11 | 0.21 a ± 0.07 |

| CK | 9640.76 a ± 23.54 | 63.17 b ± 5.18 | 0.56 b ± 0.18 | 0.38 b ± 0.09 | 3214.07 c ± 15.78 | 3075.39 a ± 14.64 | 0.21 a ± 0.09 |

| MT | 2246.67 b ± 17.68 | 59.73 c ± 5.34 | 0.47 c ± 0.31 | 0.21 c ± 0.05 | 592.77 b ± 8.67 | 526.54 b ± 6.77 | 0.097 b ± 0.03 |

| Sample | X-ray | Fourier Infrared Spectrum | ||||||

|---|---|---|---|---|---|---|---|---|

| 2θ/° | D | Strength | RC (%) | Crystal Type | Absorbance 1047 cm−1 | Absorbance 1022 cm−1 | Ratio (A(1047 cm−1/1022 cm−1)) | |

| CK | 14.983 | 5.91 | S | 20.34 | A-type | 60.016 | 57.717 | 1.040 |

| 16.895 | 5.24 | S | ||||||

| 23.143 | 3.84 | S | ||||||

| MT | 15.070 | 5.87 | S | 15.26 | A-type | 68.912 | 67.066 | 1.028 |

| 17.081 | 5.19 | S | ||||||

| 23.198 | 3.83 | S | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Xie, X.; Zhang, L.; Hong, Y.; Zhang, G.; Lyu, F. Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean. Foods 2022, 11, 171. https://doi.org/10.3390/foods11020171

Zhang J, Xie X, Zhang L, Hong Y, Zhang G, Lyu F. Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean. Foods. 2022; 11(2):171. https://doi.org/10.3390/foods11020171

Chicago/Turabian StyleZhang, Jianyou, Xuehua Xie, Lyu Zhang, Yiling Hong, Gaopeng Zhang, and Fei Lyu. 2022. "Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean" Foods 11, no. 2: 171. https://doi.org/10.3390/foods11020171

APA StyleZhang, J., Xie, X., Zhang, L., Hong, Y., Zhang, G., & Lyu, F. (2022). Optimization of Microwave Pre-Cooked Conditions for Gelatinization of Adzuki Bean. Foods, 11(2), 171. https://doi.org/10.3390/foods11020171