Development of Antimicrobial Cellulose Nanofiber-Based Films Activated with Nisin for Food Packaging Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Bacterial Strains and Culture Conditions

2.2. Preparation of Nisin Solution (Nis)

2.3. Preparation of CNF-Based Films

2.4. Antimicrobial Activity Test

2.5. Scanning Electron Microscopy (SEM) Analysis

2.6. Challenge Test

2.7. Data Analysis

3. Results

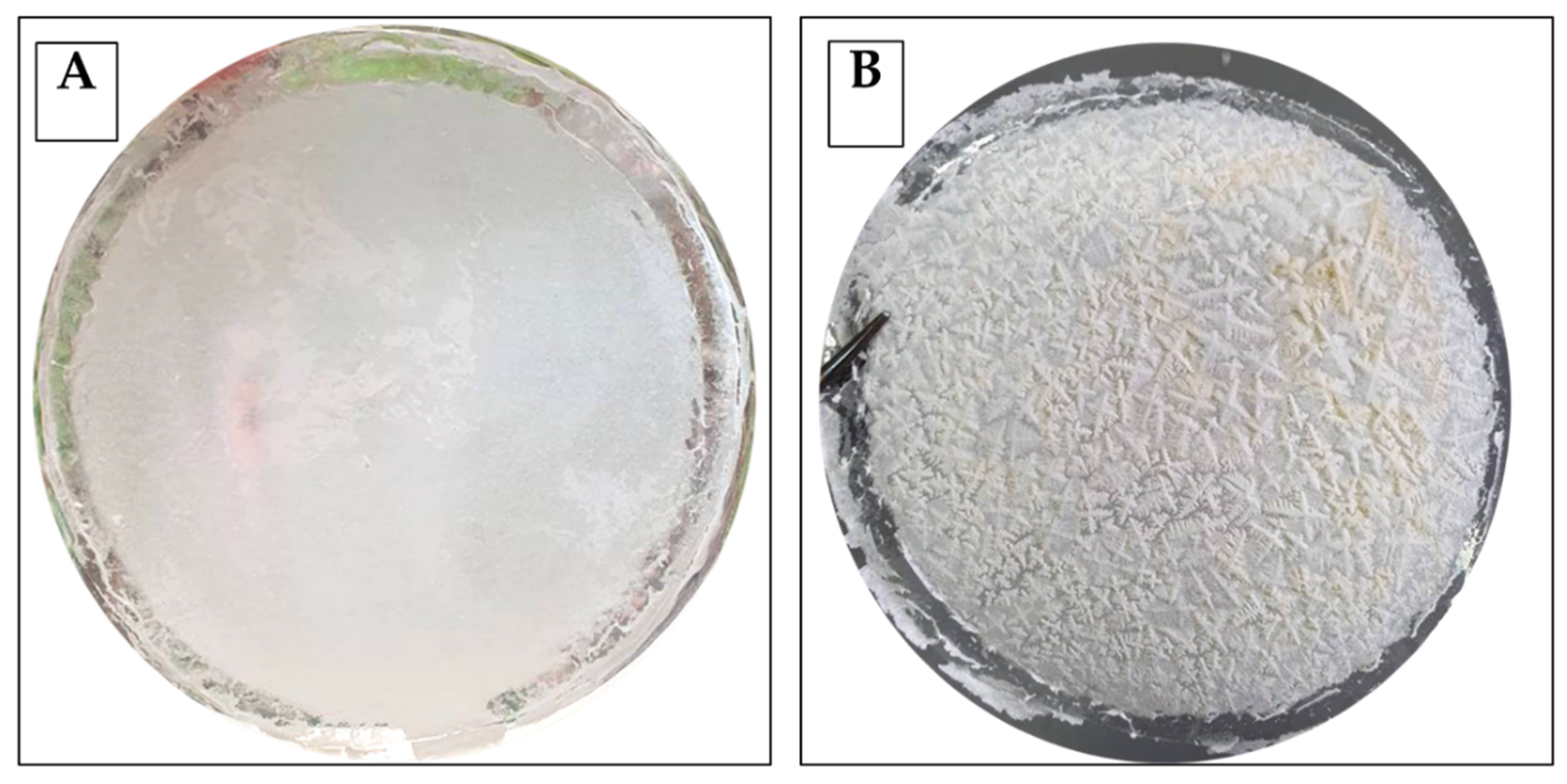

3.1. CNF-Based Films Manufacturing

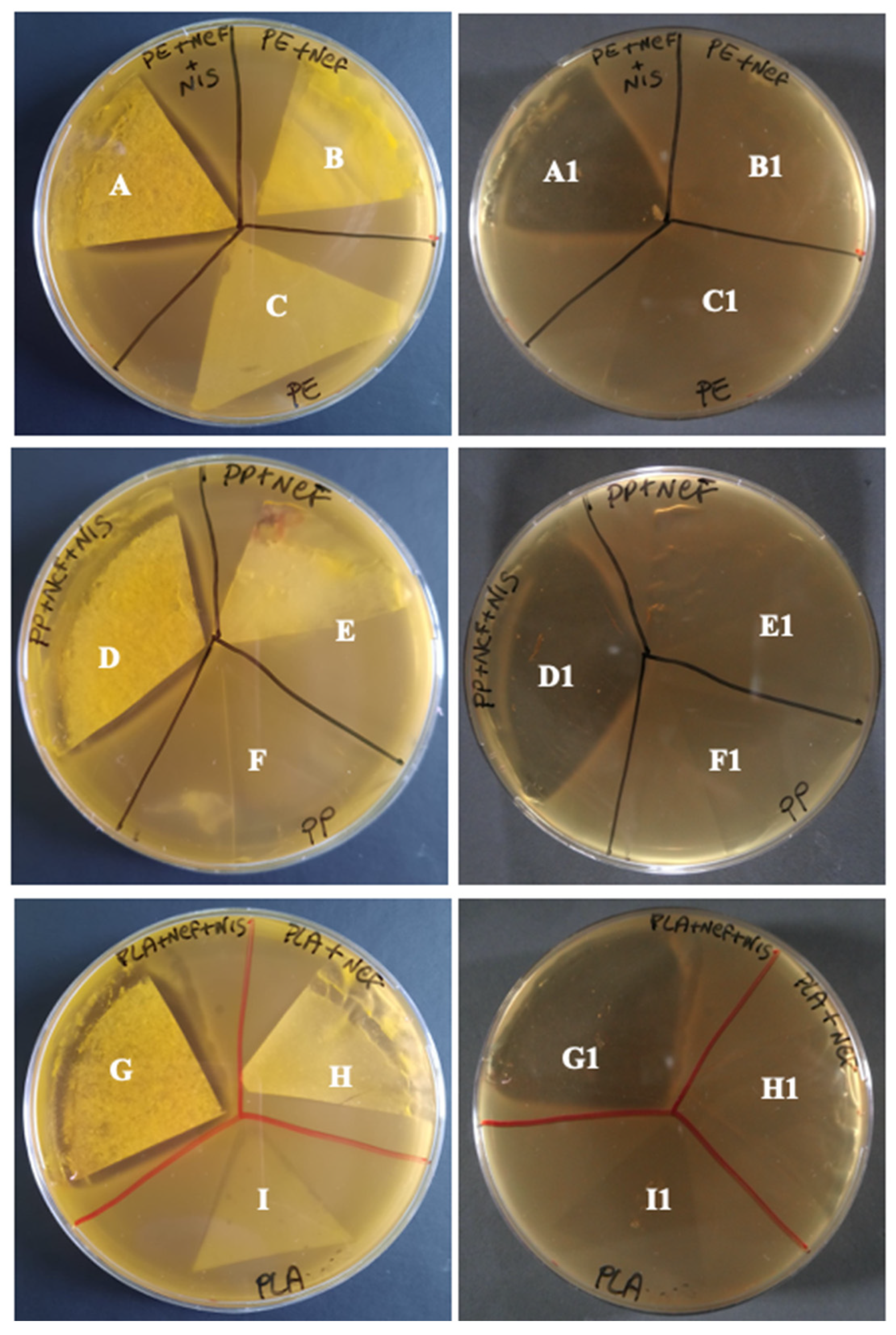

3.2. Antimicrobial Efficacy of CNF-Based Films in Agar Inhibition Assay

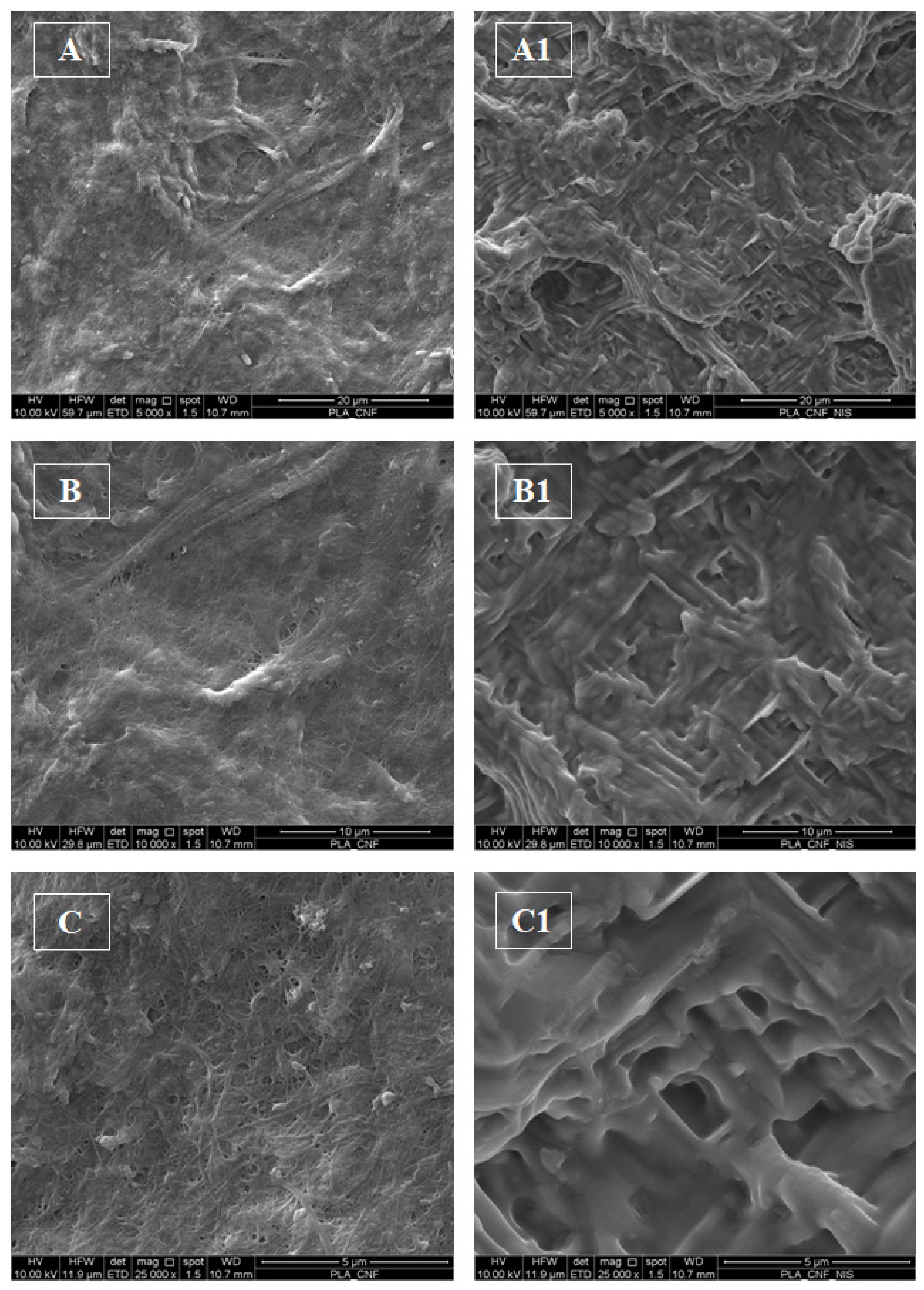

3.3. Surface Characterization of CNF-Based Films

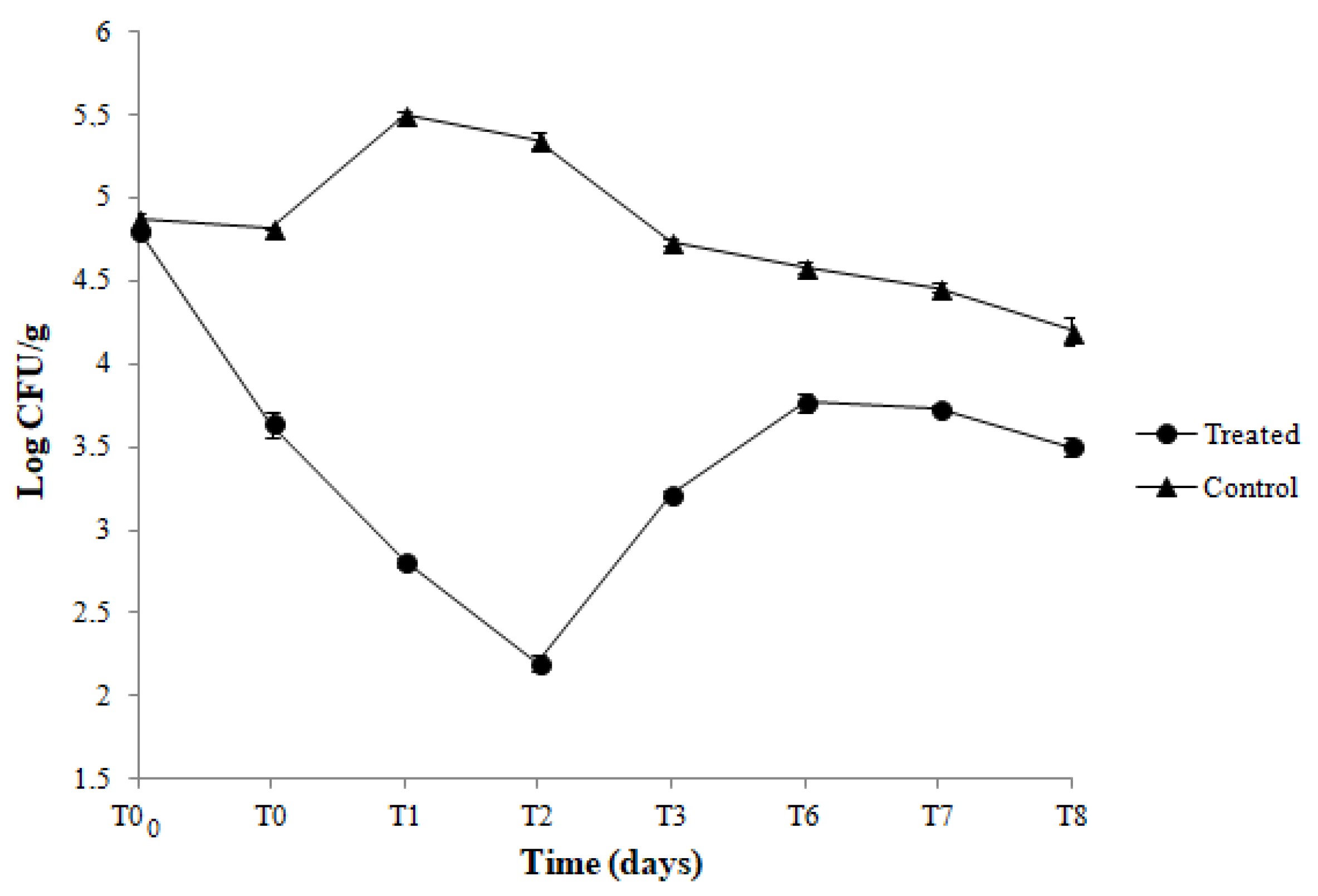

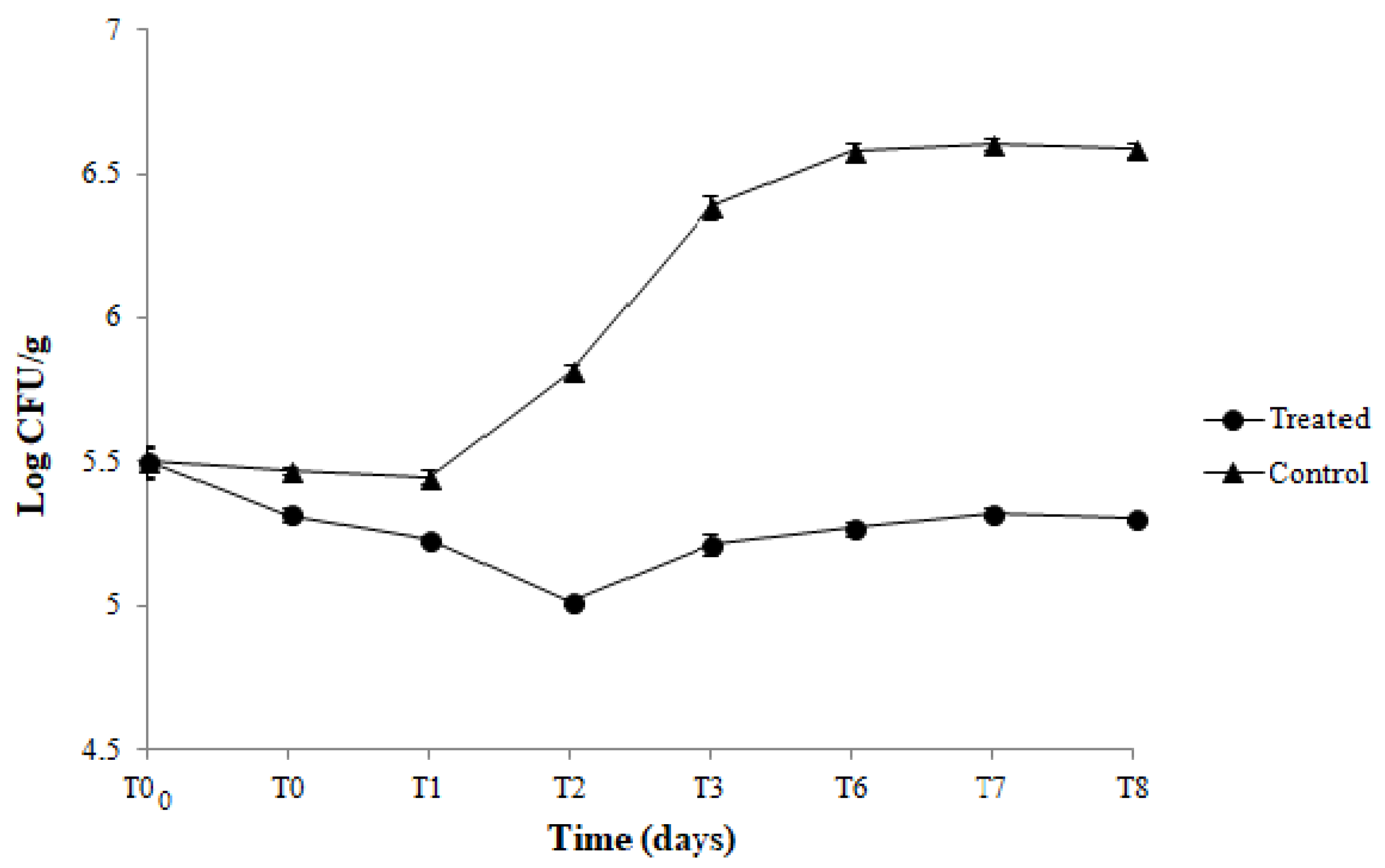

3.4. Antibacterial Effect of CNF-PLA Films in a Food System

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, D.F.; Berk, A. Making cross-racial therapy work: A phenomenological study of clients’ experiences of cross-racial therapy. J. Coun. Psychol. 2009, 56, 521–536. [Google Scholar] [CrossRef] [PubMed]

- Salgado, P.; Di Giorgio, L.; Musso, Y.S.; Mauri, A. Recent Developments in smart food packaging focused on biobased and biodegradable polymers. Front. Sustain. Food Syst. 2021, 5, 630393. [Google Scholar] [CrossRef]

- Labuza, T.P.; Breene, W.M. Applications of “active packaging” for improvement of shelf-life and nutritional quality of fresh and extended shelf-life foods. J. Food Process. Preserv. 1989, 13, 1–69. [Google Scholar] [CrossRef]

- Mauriello, G.; Villani, F. Bacteriocins in plastics. In Antimicrobial Polymers; Lagaro, J.M., Ocio, M.J., López-Rubio, A., Eds.; John Wiley & Sons, Inc.: New York, NY, USA, 2012; Volume 6, pp. 117–147. [Google Scholar]

- Silva, F.A.G.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-based composites for food packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, G.; Xiao, H. Biodegradable polymers and green-based antimicrobial packaging materials: A mini-review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, G.W.; Molaei, R.; Priyadarshi, R.; Han, S. Cellulose nanofiber-based coating film integrated with nitrogen-functionalized carbon dots for active packaging applications of fresh fruit. Postharvest Biol. Technol. 2022, 186, 111845. [Google Scholar] [CrossRef]

- Al-Tayyara, N.A.; Youssefb, A.M.; Al-Hindia, R. Antimicrobial food packaging based on sustainable bio-based materials for reducing foodborne pathogens: A review. Food Chem. 2020, 310, 125915. [Google Scholar] [CrossRef]

- Sánchez, L.A.; El-Haddad, E.; Mahmoud, D.; Miller, M.J.; Karam, L. Invited review: Advances in nisin use for preservation of dairy products. J. Dairy Sci. 2020, 103, 2041–2052. [Google Scholar] [CrossRef]

- Yildirim, S.; Rocker, B.; Pettersen, M.; Nygaard, J.; Ayhan, A.; Rutkaite, R.; Radusin, T.; Marcos, B.; Coma, V. Active packaging applications for food. CRFSFS 2018, 17, 165–199. [Google Scholar] [CrossRef]

- European Food Safety Authority. Opinion of the scientific panel on food additives, flavourings, processing aids and materials in contact with food on a request from the commission related to the use of nisin (E 234) as a food additive. EFSA J. 2006, 314, 1–16. [Google Scholar]

- Santosa, R.C.S.; Otonia, C.G.; Moraesa, A.R.F.; Souzac, V.; Medeirosa, E.; Espitiad, P.; Piresa, A.; Coimbra, J.; Soares, N.F.F. Nisin and other antimicrobial peptides: Production, mechanisms of action, and application in active food packaging. Innov. Food Sci. Emerg. Technol. 2018, 48, 179–194. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, H.; Wu, M.; Ma, J.; Lu, P. Bio-based antimicrobial packaging from sugarcane bagasse nanocellulose/nisin hybrid films. Int. J. Biol. Macromol. 2020, 161, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Mauriello, G.; De Luca, E.; La Storia, A.; Villani, F.; Ercolini, D. Antimicrobial activity of a nisin-activated plastic film for food packaging. Lett. Appl. Microbiol. 2005, 41, 464–469. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Kennedy, J.F.; Peng, J.L.; Yie, X.; Xie, B.J. Preparation and performance evalua-tion of glucomannan-chitosan-nisin ternary antimicrobial blend film. Carbohydr. Polym. 2006, 65, 488–494. [Google Scholar] [CrossRef]

- Jin, T.; Zhang, H. Biodegradable polylactic acid polymer with nisin for use in antimicrobial food packaging. J. Food Sci. 2008, 73, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Lopresti, F.; Botta, L.; La Carrubba, V.; Di Pasquale, L.; Settanni, L.; Gaglio, R. Combining carvacrol and nisin in biodegradable films for antibacterial packaging applications. Int. J. Biol. Macromol. 2021, 193, 117–126. [Google Scholar] [CrossRef]

- Saini, S.; Sillard, C.; Naceur, M.; Bras, G. Nisin anchored cellulose nanofibers for long term antimicrobial active food packaging. RSC Adv. 2016, 6, 12422–12430. [Google Scholar] [CrossRef]

- Abral, H.; Pratama, H.; Handayani, D.; Mahardika, M.; Aminah, I.; Sandrawati, N.; Sugiarti, E.; Muslimin, A.N.; Ilyas, R.A. Antimicrobial edible film prepared from bacterial cellulose nanofibers/starch/chitosan for a food packaging alternative. Int. J. Polym. Sci. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Lamm, M.E.; Li, K.; Qian, J.; Wang, H.; Lavoine, N.; Newman, R.; Gardner, D.J.; Li, T.; Hu, L.; Arthur, J.; et al. Recent advances in functional materials through cellulose nanofiber templating. Adv. Mater. 2021, 33, 2005538. [Google Scholar] [CrossRef]

- Pandey, A. Pharmaceutical and biomedical applications of cellulose nanofbers: A review. Environ. Chem. Lett. 2021, 19, 2043–2055. [Google Scholar] [CrossRef]

- Zhua, Z.; Fua, S.; Lavoineb, N.; Luciab, L.A. Structural reconstruction strategies for the design of cellulose nanomaterials and aligned wood cellulose-based functional materials—A review. Carbohydr. Polym. 2020, 247, 116722. [Google Scholar] [CrossRef] [PubMed]

- Haoa, W.; Wanga, M.; Zhoua, F.; Luoa, H.; Xied, X.; Luoe, F.; Chab, R. A review on nanocellulose as a lightweight filler of polyolefin composites. Carbohydr. Polym. 2020, 243, 116466. [Google Scholar] [CrossRef] [PubMed]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Rahimian Koloor, S.S.; Petru, M. Micro and nanocellulose in polymer composite materials: A review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.A.S.S.; Jimat, D.N.; Nawawi, W.M.F.W.; Sulaiman, S. Antibacterial, mechanical and thermal properties of PVA/starch composite film reinforced with cellulose nanofiber of sugarcane bagasse. Int. J. Sci. Eng. 2022, 47, 5747–5754. [Google Scholar] [CrossRef]

- Imran, M.; Soumaya, E.; Junelles, A.M.R.; Desobry, S. Cellulose derivative based active coatings: Effects of nisin and plasticizer on physico-chemical and antimicrobial properties of hydroxypropyl methylcellulose films. Carbohydr. Polym. 2010, 81, 219–225. [Google Scholar] [CrossRef]

- Hassan, A.E.; Shaimaa, M.F.; Hassan, M.L. Influence of TEMPO-oxidized NFC on the mechanical, barrier properties and nisin release of hydroxypropyl methylcellulose bioactive films. Int. J. Biol. Macromol. 2018, 113, 616–622. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Teng, W.; Liu, B.; Tian, H.; Wang, J. Characterization and long term antimicrobial activity of the nisin anchored cellulose films. Int. J. Biol. Macromol. 2018, 113, 487–493. [Google Scholar] [CrossRef]

- Mapelli, C.; Musatti, A.; Barbiroli, A.; Saini, S.; Beas, J.; Cavicchiolic, D.; Rollinia, M. Cellulose nanofiber (CNF)–sakacin-A active material: Production, characterization and application in storage trials of smoked salmon. J. Sci. Food Agric. 2019, 99, 4731–4738. [Google Scholar] [CrossRef]

- Chen, S.; Wu, M.; Lu, P.; Gao, L.; Yana, S.; Wang, S. Development of pH indicator and antimicrobial cellulose nanofibre packaging film based on purple sweet potato anthocyanin and oregano essential oil. Int. J. Biol. Macromol. 2020, 149, 271–280. [Google Scholar] [CrossRef]

- Soofi, M.; Alizadeh, A.; Hamishehkar, H.; Almasi, H.; Roufegarinejad, L. Preparation of nanobiocomposite film based on lemon waste containing cellulose nanofiber and savory essential oil: A new biodegradable active packaging system. Int. J. Biol. Macromol. 2021, 169, 352–361. [Google Scholar] [CrossRef]

- Kalajahi, S.E.M.; Alizadeh, A.; Hamishehkar, H.; Almasi, H.; Asef, H. Orange juice processing waste as a biopolymer base for biodegradable film formation reinforced with cellulose nanofber and activated with nettle essential oil. J. Polym. Environ. 2022, 30, 258–269. [Google Scholar] [CrossRef]

- Karimia, N.; Alizadeha, A.; Almasib, H.; Hanifiana, S. Preparation and characterization of whey protein isolate/polydextrosebased nanocomposite film incorporated with cellulose nanofiber and L. plantarum: A new probiotic active packaging system. Food Sci. Technol. 2020, 121, 108978. [Google Scholar]

- Zabihollahi, N.; Alizadeh, A.; Almasi, H.; Hanifian, S.; Hamishekar, H. Development and characterization of carboxymethyl cellulose based probiotic nanocomposite film containing cellulose nanofiber and inulin for chicken fillet shelf life extension. Int. J. Biol. Macromol. 2020, 160, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Kim, H.C.; Panicker, P.S.; Rhim, J.W.; Kim, J. Cellulose nanofiber-based nanocomposite films reinforced with zinc oxide nanorods and grapefruit seed extract. Nanomaterials 2021, 11, 877. [Google Scholar] [CrossRef]

- Sani, M.A.; Khezerloub, A.; Ehsanic, A. Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. Ind. Crop. Prod. 2018, 124, 300–315. [Google Scholar] [CrossRef]

- Gopi, S.; Amalraj, A.; Judea, S.; Thomas, S.; Guoc, Q. Bionanocomposite films based on potato, tapioca starch and chitosan reinforced with cellulose nanofiber isolated from turmeric spent. J. Taiwan Inst. Chem Eng. 2019, 96, 664–671. [Google Scholar] [CrossRef]

- Sadati, S.M.M.; Ghahfarrokhi, N.S.; Shahrousvand, E.; Rovshandeh, J.M.; Shahrousvand, M. Edible chitosan/cellulose nanofiber nanocomposite films for potential use as food packaging. Mater. Technol. 2021, 37, 1276–1288. [Google Scholar] [CrossRef]

- Sebti, H.; Broughton, J.D.; Coma, V. Physicochemical properties and bioactivity of nisin-containing cross-linked hydroxy propyl methylcellulose films. J. Agric. Food Chem. 2003, 51, 6468–6474. [Google Scholar] [CrossRef]

- Sun, H.; Shao, X.; Zhang, M.; Wang, Z.; Dong, J.; Yu, D. Mechanical, barrier and antimicrobial properties of corn distarch phosphate/nanocrystalline cellulose films incorporated with nisin and ε-polylysine. Int. J. Biol. Macromol. 2019, 136, 839–846. [Google Scholar] [CrossRef]

- Grower, J.L.; Cooksey, K.; Getty, K. Release of nisin from Methylcellulose-Hydroxypropyl Methylcellulose film formed on low-density polyethylene film. J. Food Sci. 2004, 69, 107–111. [Google Scholar] [CrossRef]

- Salmieri, S.; Islam, F.; Khan, R.A.; Hossain, F.M.; Ibrahim, H.M.M.; Lacroix, M. Antimicrobial nanocomposite films made of poly (lactic acid)-cellulose nanocrystals (PLA-CNC) in food applications: Effect of nisin release on the inactivation of Listeria monocytogenes in ham. Cellulose 2014, 21, 1837–1850. [Google Scholar] [CrossRef]

- Russo, F.; Ercolini, D.; Mauriello, G.; Villani, F. Behaviour of Brochothrix thermosphacta in presence of other meat spoilage microbial groups. Food Microbiol. 2006, 23, 797–802. [Google Scholar] [CrossRef] [PubMed]

- Ercolini, D.; Russo, F.; Nasi, A.; Ferranti, P.; Villani, F. Mesophilic and psychrotrophic bacteria from meat and their spoilage potential in vitro and in beef. Appl. Environ. Microbiol. 2009, 75, 1990–2001. [Google Scholar] [CrossRef]

- La Storia, A.; Ercolini, D.; Marinello, F.; Di Pasqua, R.; Villani, F.; Mauriello, G. Atomic force microscopy analysis shows surface structure changes in carvacrol-treated bacterial cells. Res. Microbiol. 2011, 162, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Maresca, D.; De Prisco, A.; La Storia, A.; Cirillo, T.; Esposito, F.; Mauriello, G. Microencapsulation of nisin in alginate beads by vibrating technology: Preliminary investigation. Food Sci. Technol. 2016, 66, 436–443. [Google Scholar] [CrossRef]

- Villani, F.; Pepe, O.; Mauriello, G.; Salzano, G.; Moschetti, G.; Coppola, S. Antimicrobial activity of Staphilococcus xylosus from Italian sausage against Listeria monocytogenes. Appl. Microbiol. 1994, 18, 159–161. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Mattoso, L.H.C.; Wood, D.; Williams, T.G.; Bustilloa, R.A.; Mchugh, T.H. Nanocomposite Edible Films from Mango Puree Reinforced with Cellulose Nanofibers. J. Food Sci. 2009, 74, 31–35. [Google Scholar] [CrossRef]

- Pizzaro, A.; David, R.; Oliver, S.; Fernando, O.L. Effect of cellulose nanofibers concentration on mechanical, optical, and barrier properties of gelatin-based edible films. DYNA 2015, 82, 219–226. [Google Scholar] [CrossRef]

- Lapuz, A.R.; Tsuchikawa, S.; Inagaki, T.; Migo, V. Production of nanocellulose film from abaca fibers. Crystals 2022, 12, 601. [Google Scholar] [CrossRef]

- La Storia, A.; Ercolini, D.; Mauriello, G. Characterization of bacteriocin-coated antimicrobial polyethylene films by atomic force microscopy. J. Food Sci. 2008, 73, 48–54. [Google Scholar] [CrossRef]

- Salim, H.; Kolpakov, P.; Bonn, D.; Shahidzadeh, N. Self-Lifting NaCl Crystals. J. Phys. Chem. Lett. 2020, 11, 7388–7393. [Google Scholar] [CrossRef] [PubMed]

- Suematsu, N.J.; Iwamoto, J.; Ishii, Y.; Yamamoto, A. Dendrite pattern formation of sodium chloride crystal. Materials 2021, 14, 4434. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, R.A.; Santos, T.A.; Azevedo, V.M.; Felix, P.H.C.; Dias, M.V.; Borges, S.V. Bio-nanocomposites for food packaging applications: Effect of cellulose nanofibers on morphological, mechanical, optical and barrier properties. Polym. Int. 2018, 67, 386–392. [Google Scholar] [CrossRef]

- Silveira, M.P.; Silva, H.C.; Pimentel, I.; Poitevin, C.G.; Stuart, A.K.; Carpiné, D.; Jorge, L.M.; Jorge, R.M.M. Development of active cassava starch cellulose nanofiber-basedfilmsincorporated with natural antimicrobial tea tree essential oil. J. Appl. Polym. Sci. 2020, 137, 48726. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffif, H.; Anuar, T.A.T.; Hassan, M.A.; Tsukegi, T. One-pot nanofibrillation of cellulose and nanocomposite production in a twin-screw extruder. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012034. [Google Scholar] [CrossRef]

- Peng, Y.; Nair, S.; Chen, H.; Yan, N.; Cao, J. Effects of lignin content on mechanical and thermal properties of polypropylene composites reinforced with micro particles of spray dried cellulose nanofibrils. ACS Sustain. Chem. Eng. 2018, 6, 11078–11108. [Google Scholar] [CrossRef]

- Anuar, T.A.T.Y.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Tsukeg, T.; Nishida, H. Sustainable one-pot process for the production of cellulose nanofiber and polyethylene/cellulose nanofiber composites. J. Clean. Prod. 2019, 207, 590–599. [Google Scholar] [CrossRef]

- Gitari, B.; Chang, B.P.; Misra, M.; Navabi, A.; Mohanty, A.K. A comparative study on the mechanical, thermal and water barrier properties of PLA nanocomposite films prepared with bacterial nanocellulose and cellulose nanofibrils. Biol. Resour. 2019, 14, 1867–1889. [Google Scholar]

- Wang, Q.; Sun, J.; Zhu, Q.; Liu, J. Structure and properties of polylactic acid biocomposite films reinforced with cellulose nanofibrils. Molecules 2020, 25, 3306. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Ariffif, H.; Anuar, T.A.T.; Hassan, M.A.; Ibrahim, N.A.; Nishida, H. Performance evaluation of cellulose nanofiber with residual hemicellulose as a nanofiller in polypropylene-based nanocomposite. Polymers 2021, 13, 1064. [Google Scholar] [CrossRef]

- Chanda, S.; Bajwa, D. A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices. Rev. Adv. Mater. Sci. 2021, 60, 325–341. [Google Scholar] [CrossRef]

- Fernandez, M.E.L.; Miskolczi, N. Production of cellulose nano-fibers and its application in poly-lactic-acid: Property improvement by new types of coupling agents. Polymers 2022, 14, 1887. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Zhao, H.; Zheng, L.; Duan, Y.; Wu, M.; Yu, X.; Yang, Y. Nanocellulose/nisin hydrogel microparticles as sustained antimicrobial coatings for paper packaging. Appl. Polym. Mater. 2022, 4, 2664–2673. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Gidleyb, M.J.; Dykesc, G.A. Potential of a nisin-containing bacterial cellulose film to inhibit Listeria monocytogenes on processed meats. Food Microbiol. 2008, 25, 471–478. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maresca, D.; Mauriello, G. Development of Antimicrobial Cellulose Nanofiber-Based Films Activated with Nisin for Food Packaging Applications. Foods 2022, 11, 3051. https://doi.org/10.3390/foods11193051

Maresca D, Mauriello G. Development of Antimicrobial Cellulose Nanofiber-Based Films Activated with Nisin for Food Packaging Applications. Foods. 2022; 11(19):3051. https://doi.org/10.3390/foods11193051

Chicago/Turabian StyleMaresca, Diamante, and Gianluigi Mauriello. 2022. "Development of Antimicrobial Cellulose Nanofiber-Based Films Activated with Nisin for Food Packaging Applications" Foods 11, no. 19: 3051. https://doi.org/10.3390/foods11193051

APA StyleMaresca, D., & Mauriello, G. (2022). Development of Antimicrobial Cellulose Nanofiber-Based Films Activated with Nisin for Food Packaging Applications. Foods, 11(19), 3051. https://doi.org/10.3390/foods11193051