Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants

Abstract

1. Introduction

2. Materials and Methods

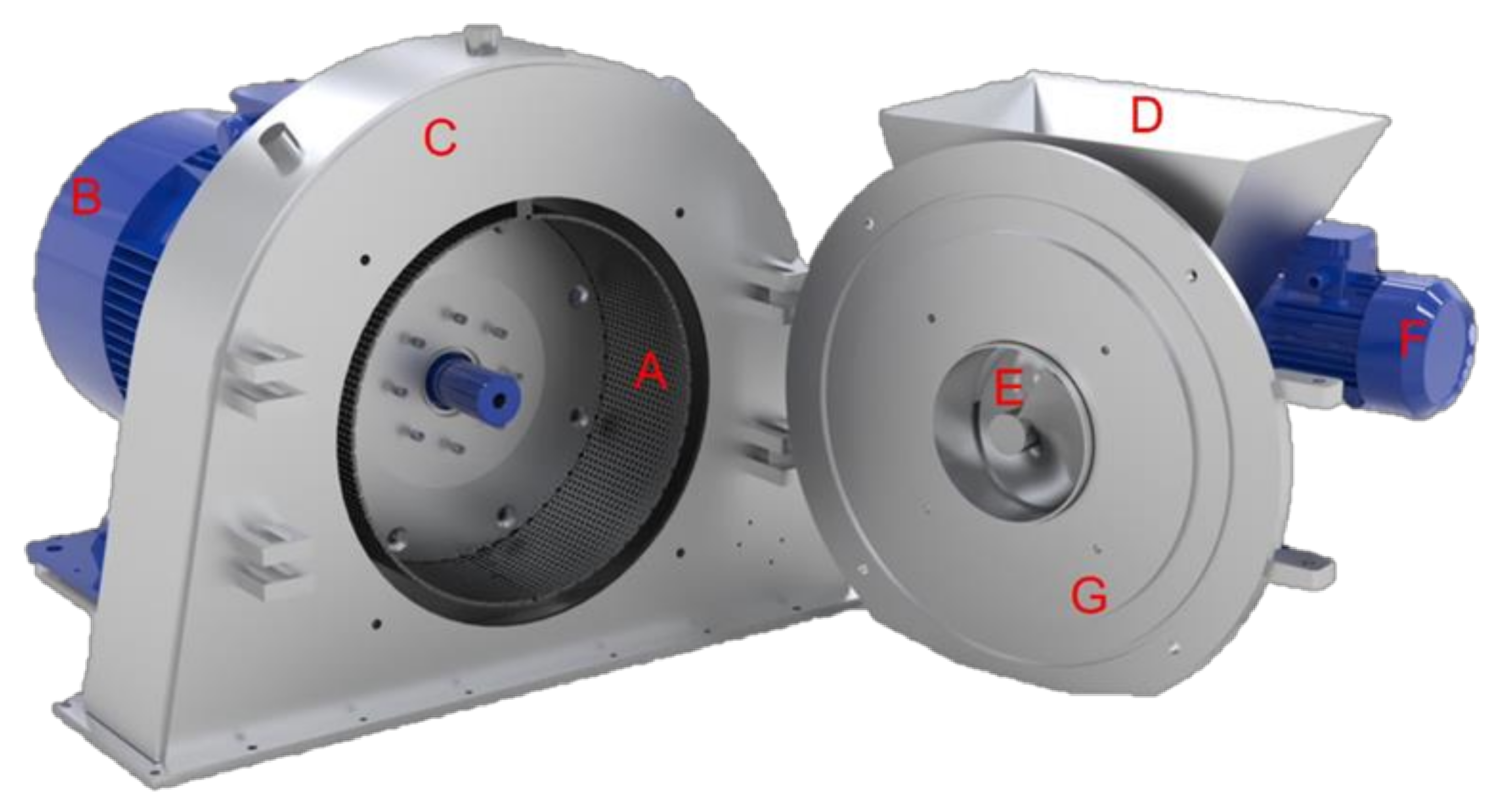

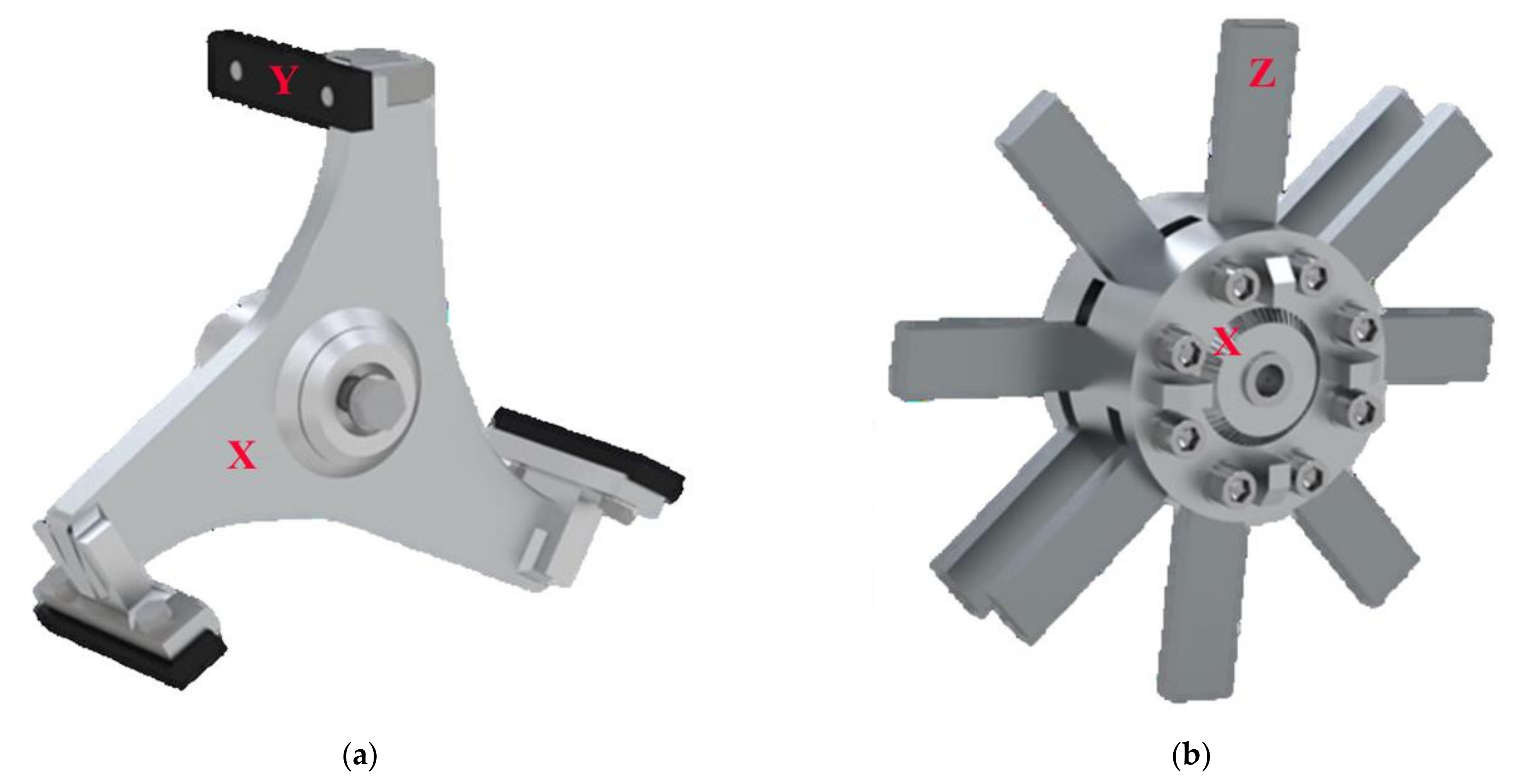

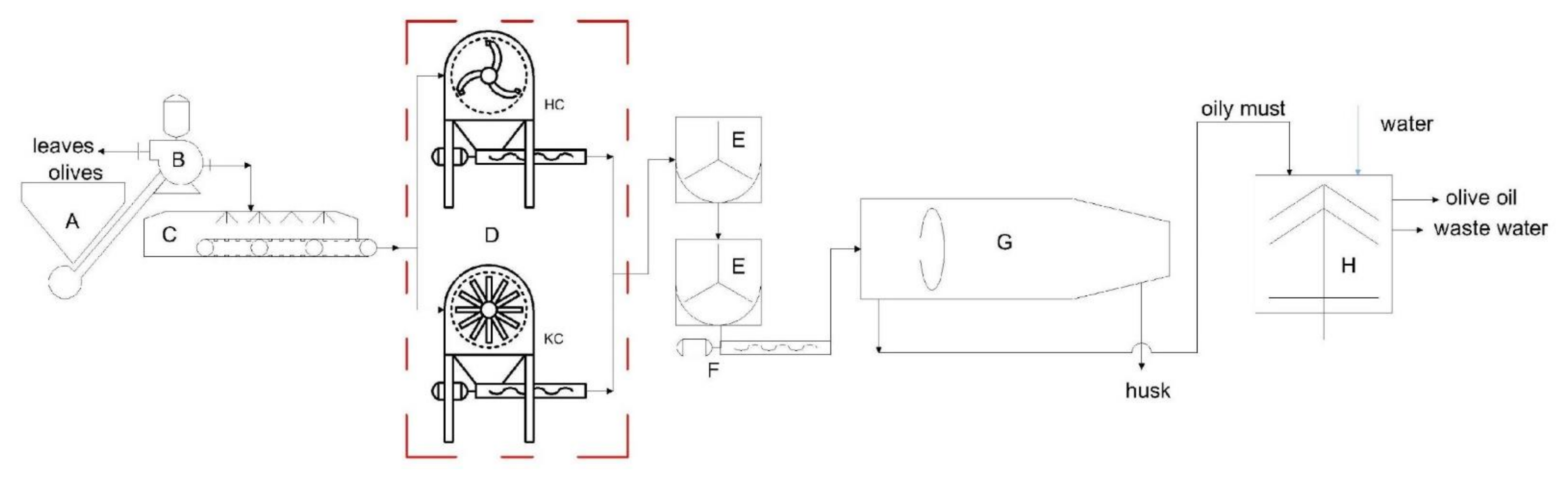

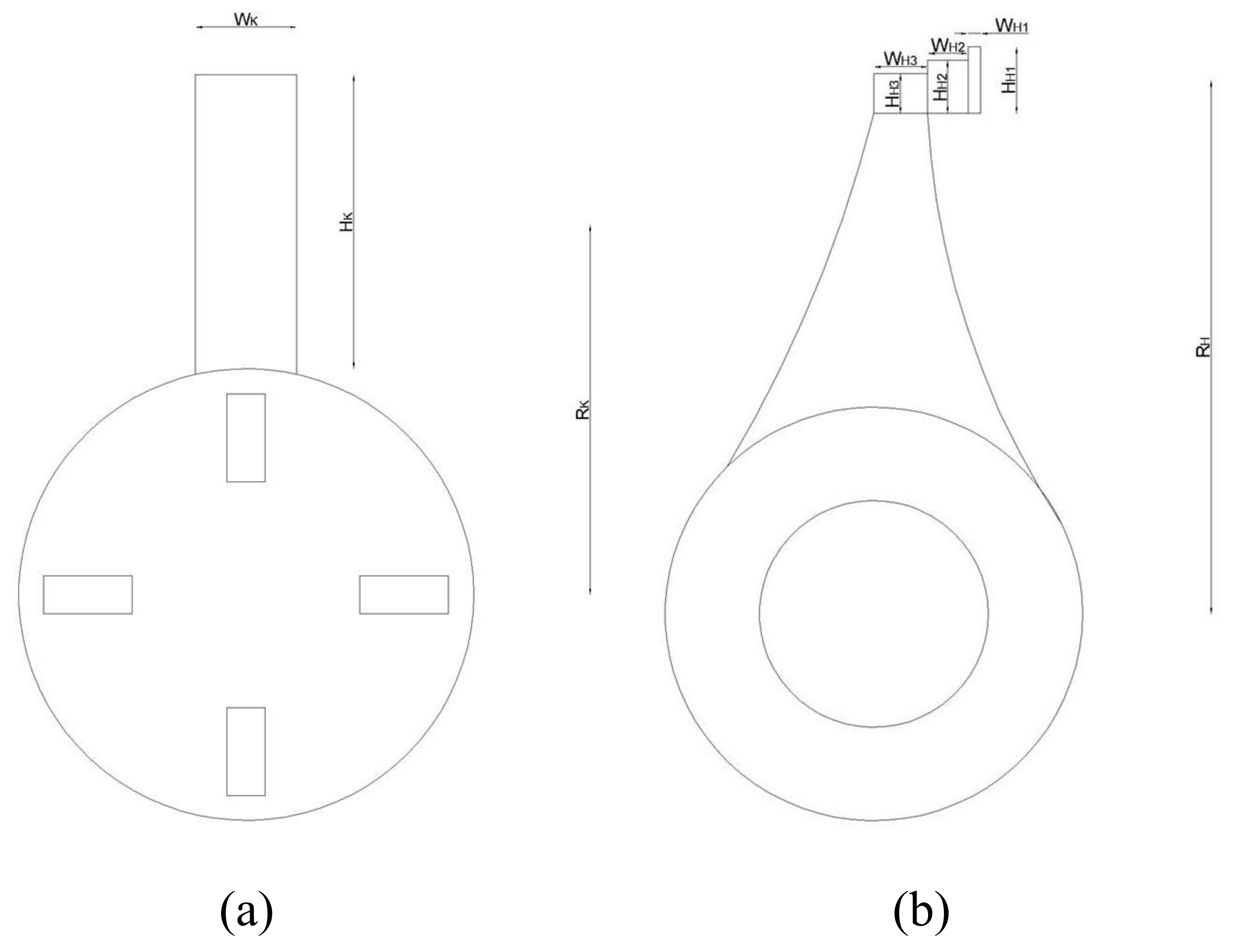

2.1. The Modular Crusher Machine

- -

- a fixed stainless steel grid (with a thickness of 5 mm, depth of 182 mm and diameter of 460 mm) with circular holes, each having a diameter of 6 mm;

- -

- a main electric motor (two-poles, 30 kW, 3000 rpm);

- -

- an external carter to collect the olive paste coming out of the grid, open in the lower part;

- -

- an integrated closing door, screw and hopper system to feed the incoming olives;

- -

- a secondary electric motor (two-poles, 30 kW) and reducer, connected to the screw feeding the olives.

2.2. Experimental Design

2.3. Particle Size Measurement

2.4. Impact Estimation by Energy Conservation and Comminution Theory

2.5. Moisture and Oil Content of Olives and Pomace

2.6. Extractability

2.7. VOO Chemical Analysis

2.7.1. Solvents and Reference Compounds

2.7.2. Legal Quality Parameters

2.7.3. Phenolic Compounds

2.7.4. Volatile Compounds

2.7.5. Data Processing

3. Results and Discussion

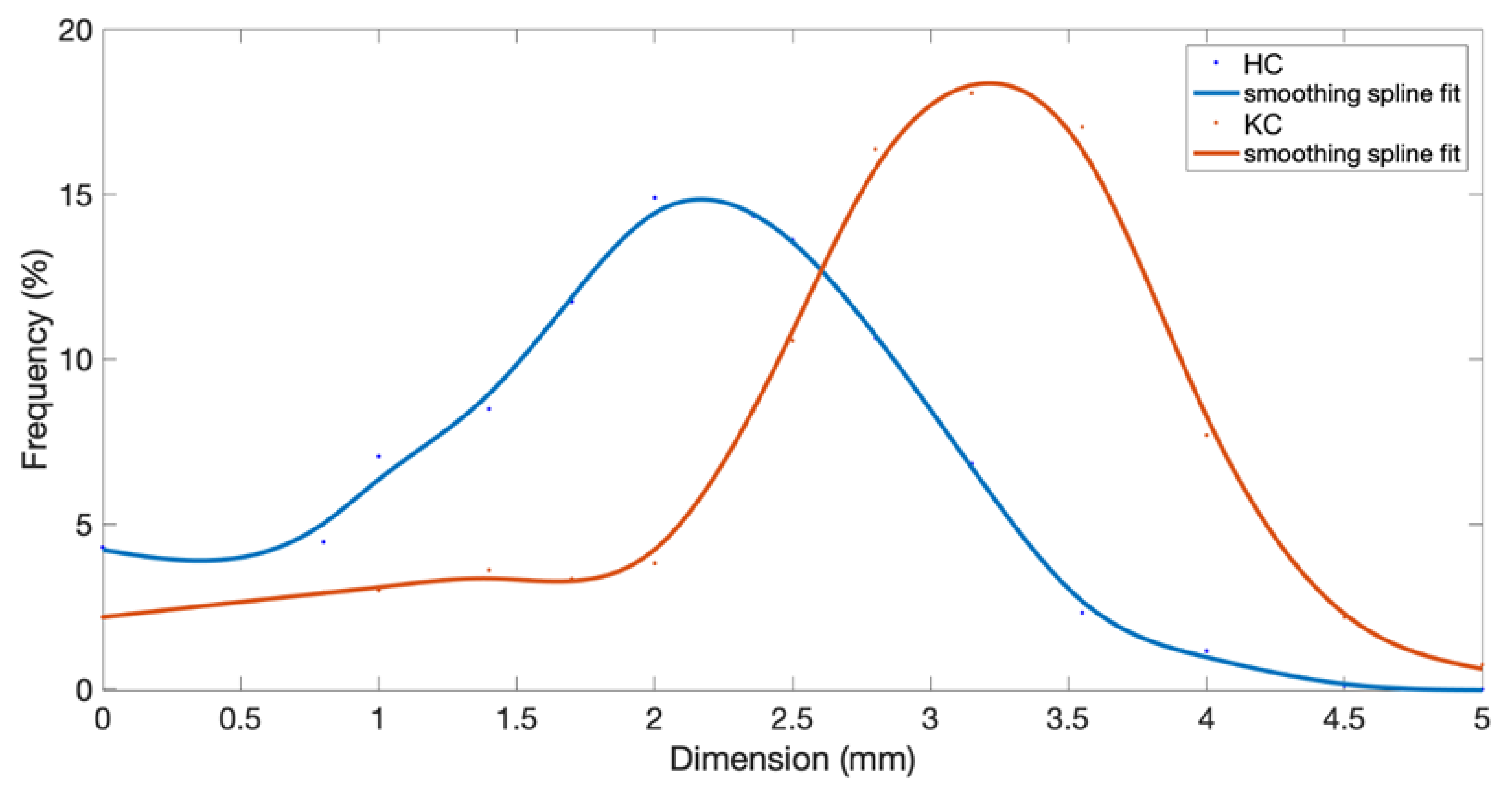

3.1. Pit Particle Size Distribution

3.2. Average Energy Impact and Temperature Comparison

3.3. Quantitative Evaluation

3.4. Qualitative Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petrakis, C. Olive oil extraction. In Olive Oil: Chemistry and Technology; Boskou, D., Ed.; AOCS Press: Urbana, IL, USA, 2006; pp. 191–223. [Google Scholar]

- Aguilera, M.P.; Beltran, G.A.; Sanchez-Villasclaras, S.; Uceda, M.; Jimenez, A. Kneading olive paste from unripe ‘Picual’ fruits: I. Effect on oil process yield. J. Food Eng. 2010, 97, 533–538. [Google Scholar] [CrossRef]

- Boncinelli, P.; Catalano, P.; Cini, E. Olive paste rheological analysis. Trans. ASABE 2013, 56, 237–244. [Google Scholar] [CrossRef]

- Leone, A. Olive milling and pitting. In The Extra-Virgin Olive Oil Handbook; Peri, C., Ed.; Wiley: Hoboken, NJ, USA, 2014; pp. 117–126. [Google Scholar]

- Tamborrino, A. Olive paste malaxation. In The Extra-Virgin Olive Oil Handbook; Peri, C., Ed.; Wiley: Hoboken, NJ, USA, 2014; pp. 127–137. [Google Scholar]

- Tamborrino, A.; Perone, C.; Mojaed, H.; Romaniello, R.; Berardi, A.; Catalano, P.; Leone, A. Combined continuous machine to condition olive paste: Rheological characterization of olive paste. Chem. Eng. Trans. 2021, 87, 283–288. [Google Scholar] [CrossRef]

- Perone, C.; Romaniello, R.; Leone, A.; Berardi, A.; Catalano, P.; Tamborrino, A. CFD analysis of a tube-in-tube heat exchanger to pre-heat olive pastes. Chem. Eng. Trans. 2021, 87, 253–258. [Google Scholar] [CrossRef]

- Tamborrino, A.; Clodoveo, M.L.; Leone, A.; Amirante, P.; Paice, A.G. The malaxation process: Influence on olive oil quality and the effect of the control of oxygen concentration in virgin olive oil. In Olives and Olive Oil in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Eds.; Elsevier: Amsterdam, The Netherlands; Academic Press: Cambridge, MA, USA, 2010; pp. 77–83. [Google Scholar]

- Eleni, P.K.; Despoina, G.; Stylianos, E. Olive oil droplet coalescence during malaxation. J. Food Eng. 2019, 240, 99–104. [Google Scholar]

- Catalano, P.; Caponio, F. Machines for olive paste preparation producing quality virgin olive oil. Eur. J. Lipid Sci. Technol. 1996, 98, 408–412. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Zagaria, R.; Sabella, E.; De Bellis, L.; Tamborrino, A. Machining effects of different mechanical crushers on pit particle size and oil drop distribution in olive paste. Eur. J. Lipid Sci. Technol. 2015, 117, 1271–1279. [Google Scholar] [CrossRef]

- Romaniello, R.; Leone, A.; Tamborrino, A. Specification of a new de-stoner machine: Evaluation of machining effects on olive paste’s rheology and olive oil yield and quality. J. Sci. Food Agric. 2017, 97, 115–121. [Google Scholar] [CrossRef]

- Squeo, G.; Tamborrino, A.; Pasqualone, A.; Leone, A.; Paradiso, V.M.; Summo, C.; Caponio, F. Assessment of the Influence of the Decanter Set-up During Continuous Processing of Olives at Different Pigmentation Index. Food Bioprocess Technol. 2017, 10, 592–602. [Google Scholar] [CrossRef]

- Fregapane, G.; Salvador, M. Production of superior quality extra virgin olive oil modulating the content and profile of its minor components. Food Res. Int. 2013, 54, 1907–1914. [Google Scholar] [CrossRef]

- Hachicha Hbaieb, R.; Kotti, F.; García-Rodríguez, R.; Gargouri, M.; Sanz, C.; Pérez, A.G. Monitoring endogenous enzymes during olive fruit ripening and storage: Correlation with virgin olive oil phenolic profiles. Food Chem. 2015, 174, 240–247. [Google Scholar] [CrossRef] [PubMed]

- Taticchi, A.; Esposto, S.; Veneziani, G.; Urbani, S.; Selvaggini, R.; Servili, M. The influence of the malaxation temperature on the activity of polyphenoloxidase and peroxidase and on the phenolic composition of virgin olive oil. Food Chem. 2013, 136, 975–983. [Google Scholar] [CrossRef] [PubMed]

- Tamborrino, A.; Servili, M.; Leone, A.; Romaniello, R.; Perone, C.; Veneziani, G. Partial de-stoning of olive paste to increase olive oil quality, yield, and sustainability of the olive oil extraction process. Eur. J. Lipid Sci. Technol. 2020, 122, 2000129. [Google Scholar] [CrossRef]

- Caponio, F.; Gomes, T.; Summo, C.; Pasqualone, A. Influence of the type of olive-crusher used on the quality of extra virgin olive oils. Eur. J. Lipid Sci. Technol. 2003, 105, 201–206. [Google Scholar] [CrossRef]

- Inarejos-Garcí, A.M.; Salvador, M.D.; Fregapane, G. Effect of crushing on olive paste and virgin olive oil minor components. Eur. Food Res. Technol. 2011, 232, 441–451. [Google Scholar] [CrossRef]

- Servili, M.; Montedoro, G.F. Contribution of phenolic compounds to virgin olive oil quality. Eur. J. Lipid Sci. Technol. 2002, 104, 602–613. [Google Scholar] [CrossRef]

- Servili, M.; Esposto, S.; Taticchi, A.; Urbani, S.; Veneziani, G.; Di Maio, I.; Sordini, B.; Selvaggini, R. Improvements on olive oil extraction plants in relation to oil quality. In Proceedings of the 4th International Conference on “Olive Culture and Biotechnology of Olive Tree Products”, Chania, Greece, 31 October–4 November 2011. [Google Scholar]

- Leone, A.; Romaniello, R.; Peri, G.; Tamborrino, A. Development of a new model of olives de-stoner machine: Evaluation of electric consumption and kernel characterization. Biomass Bioenergy 2015, 81, 108–116. [Google Scholar] [CrossRef]

- Beltran, G.; Uceda, M.; Jimenez, A.; Aguilera, M.P. Olive oil extractability index as a parameter for olive cultivar characterisation. J. Sci. Food Agric. 2003, 83, 503–506. [Google Scholar] [CrossRef]

- Romaniello, R.; Tamborrino, A.; Leone, A. Development of a centrifugal separator for grape marc: Effect of the blade position and rotor speed on grape seed separation performance. Heliyon 2019, 5, e01314. [Google Scholar] [CrossRef]

- Nikolov, S. Modelling and simulation of particle breakage in impact crushers. Int. J. Miner. Process. 2004, 74, S219–S225. [Google Scholar] [CrossRef]

- Mugabi, R.; Byaruhanga, Y.B.; Eskridge, K.M.; Weller, C.L. Performance evaluation of a hammer mill during grinding of maize grains. Agric. Eng. Int. CIGR J. 2019, 21, 170–179. [Google Scholar]

- Caponio, F.; Catalane, P. Hammer crushers vs disk crushers: The influence of working temperature on the quality and preservation of virgin olive oil. Eur. Food Res. Technol. 2001, 213, 219–224. [Google Scholar] [CrossRef]

- Caponio, F.; Leone, A.; Squeo, G.; Tamborrino, A.; Summo, C. Innovative technologies in virgin olive oil extraction process: Influence on volatile compounds and organoleptic characteristics. J. Sci. Food Agric. 2019, 99, 5594–5600. [Google Scholar] [CrossRef] [PubMed]

- Selvaggini, R.; Esposto, S.; Taticchi, A.; Urbani, S.; Veneziani, G.; Di Maio, I.; Sordini, B.; Servili, M. Optimization of the temperature and oxygen concentration conditions in the malaxation during the oil mechanical extraction process of four Italian olive cultivars. J. Agric. Food Chem. 2014, 62, 3813–3822. [Google Scholar] [CrossRef] [PubMed]

- European Commision. Commission Implementing Regulation (EU) 2019/1604 of 27 September 2019 Amending Regulation (EEC) No 2568/91 on the Characteristics of Olive Oil and Olive-Residue Oil and on the Relevant Methods of Analysis; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Taticchi, A.; Esposto, S.; Veneziani, G.; Minnocci, A.; Urbani, S.; Selvaggini, R.; Sordini, B.; Daidone, L.; Sebastiani, L.; Servili, M. High vacuum-assisted extraction affects virgin olive oil quality: Impact on phenolic and volatile compounds. Food Chem. 2021, 342, 128369. [Google Scholar] [CrossRef] [PubMed]

- Taticchi, A.; Selvaggini, R.; Esposto, S.; Sordini, B.; Veneziani, G.; Servili, M. Physicochemical characterization of virgin olive oil obtained using an ultrasoundassisted extraction at an industrial scale: Influence of olive maturity index and malaxation time. Food Chem. 2019, 289, 7–15. [Google Scholar] [CrossRef]

- Alagna, F.; Mariotti, R.; Panara, F.; Caporali, S.; Urbani, S.; Veneziani, G.; Esposto, S.; Taticchi, A.; Rosati, A.; Rao, R.; et al. Olive phenolic compounds: Metabolic and transcriptional profiling during fruit development. BMC Plant Biol. 2012, 12, 162. [Google Scholar] [CrossRef] [PubMed]

- Morrone, L.; Pupillo, S.; Neri, L.; Bertazza, G.; Magli, M.; Rotondi, A. Influence of olive ripening degree and crusher typology on chemical and sensory characteristics of Correggiolo virgin olive oil. J. Sci. Food Agric. 2016, 97, 1443. [Google Scholar] [CrossRef]

- Luaces, P.; Romero, C.; Gutiérrez, F.; Sanz, C.; Pérez, A.G. Contribution of olive seed to the phenolic profile and related quality parameters of virgin olive oil. J. Sci. Food Agric. 2007, 87, 2721–2727. [Google Scholar] [CrossRef]

- Servili, M.; Taticchi, A.; Esposto, S.; Urbani, S.; Selvaggini, R.; Montedoro, G. Effect of olive stoning on the volatile and phenolic composition of virgin olive oil. J. Agric. Food Chem. 2007, 55, 7028–7035. [Google Scholar] [CrossRef]

- Garcia-Rodriguez, R.; Romero-Segura, C.; Sanz, C.; Perez, A.G. Modulating oxidoreductase activity modifies the phenolic content of virgin olive oil. Food Chem. 2015, 171, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Amirante, P.; Clodoveo, M.L.; Dugo, G.; Leone, A.; Tamborrino, A. Advance technology in virgin olive oil production from traditional and de-stoned pastes: Influence of the introduction of a heat exchanger on oil quality. Food Chem. 2006, 98, 797–805. [Google Scholar] [CrossRef]

- Angerosa, F.; Di Giacinto, L. Quality characteristics of virgin olive oil in relation to crushing method. Note II. Riv. Ital. Sostanze Grasse 1995, 72, 1–4. [Google Scholar]

- Manganiello, R.; Pagano, M.; Nucciarelli, D.; Ciccoritti, R.; Tomasone, R.; Di Serio, M.G.; Giansante, L.; Del Re, P.; Servili, M.; Veneziani, G. Effects of ultrasound technology on the qualitative properties of Italian extra virgin olive oil. Foods 2021, 10, 2884. [Google Scholar] [CrossRef] [PubMed]

- Taticchi, A.; Esposto, S.; Servili, M. The basis of the sensory properties of virgin olive oil. In Olive Oil Sensory Science; Monteleone, E., Langstaff, S., Eds.; Wiley-Blackwell: Hoboken, NJ, USA, 2014; pp. 33–54. [Google Scholar]

- Preziuso, S.M.; Di Serio, M.G.; Biasone, A.; Vito, R.; Mucciarella, M.R.; Di Giovacchino, L. Influence of olive crushing methods on the yields and oil characteristics. Eur. J. Lipid Sci. Technol. 2010, 112, 1345–1355. [Google Scholar] [CrossRef]

- Servili, M.; Piacquadio, P.; De Stefano, G.; Taticchi, A.; Sciancalepore, V. Influence of a new crushing technique on the composition of the volatile compounds and related sensory quality of virgin olive oil, research paper. Eur. J. Lipid Sci. Technol. 2002, 104, 483–489. [Google Scholar] [CrossRef]

- Salas, J.J.; Sanchez, J. The decrease of virgin olive oil flavor produced by high malaxation temperature is due to inactivation of hydroperoxide lyase. J. Agric. Food Chem. 1999, 47, 809–812. [Google Scholar] [CrossRef]

| Dimension | Numerical Value [mm] | Crusher |

|---|---|---|

| WH1 | 5 | HAMMER |

| WH2 | 15 | |

| WH3 | 20 | |

| HH1 | 25 | |

| HH2 | 20 | |

| HH3 | 15 | |

| RH | 200 | |

| WK | 40 | KNIFE |

| HK | 117 | |

| RK | 147 |

| Parameter | Comparison | Equation |

|---|---|---|

| Tool mass (M) | MH = 2.00 MK | MC = ρ VC |

| Radius of center of gravity (R) | RH = 1.36 RK | - |

| Moment of inertia (I) | IH = 3.50 IK | Equation (6) |

| Rotational kinetic energy (E) | EH = 3.50 EK | Equation (5) |

| Mass of olives per tool (M) | MOH = 2.76 MOK | Equation (7) |

| Specific energy (e) | eH = 1.27 eK | Equation (8) |

| Parameter | Comparison | Equation |

|---|---|---|

| Specific energy | eH = 1.25 eK | Equation (10) |

| Mean temperature of the paste | TmH = 1.25–1.27 TmK | Equation (11) |

| Test Conditions | Maturity Index | POMACE | Extractability | |

|---|---|---|---|---|

| Moisture (%) | Oil (% db) | (%) | ||

| HC | 1.6 | 61.00 ± 1.18 a | 5.36 ± 0.54 a | 89.79 ± 1.05 a |

| KC | 60.67 ± 1.07 a | 5.77 ± 0.18 a | 88.86 ± 0.52 a | |

| HC | 2.3 | 64.19 ± 0.64 a | 5.81 ± 0.65 a | 90.73 ± 0.89 a |

| KC | 64.41 ± 0.99 a | 6.39 ± 0.25 a | 89.79 ± 0.61 a | |

| Test Conditions | Maturity Index | Free Acidity (%) | Peroxide Value (meq O2 kg−1) | K232 | K270 | ΔK |

|---|---|---|---|---|---|---|

| Legal limits for EVOO | ≤0.8 | ≤20 | ≤2.50 | ≤0.22 | ≤0.01 | |

| HC | 1.6 | 0.25 ± 0.005 a | 3.1 ± 0.5 a | 1.672 ± 0.040 a | 0.148 ± 0.010 a | −0.028 ± 0.01 a |

| KC | 0.24 ± 0.01 a | 3.2 ± 0.1 a | 1.675 ± 0.037 a | 0.147 ± 0.006 a | −0.009 ± 0.01 a | |

| HC | 2.3 | 0.25 ± 0.00 a | 6.0 ± 0.2 a | 1.751 ± 0.050 a | 0.160 ± 0.010 a | −0.004 ± 0.00 a |

| KC | 0.24 ± 0.02 a | 5.1 ± 1.1 a | 1.722 ± 0.057 a | 0.162 ± 0.003 a | −0.003 ± 0.001 a | |

| Maturity Index 1.6 | Maturity Index 2.3 | |||

|---|---|---|---|---|

| HC | KC | HC | KC | |

| 3.4-DHPEA | 5.2 ± 0.5 a | 4.3 ± 0.6 b | 2.0 ± 0.1 a | 1.8 ± 0.2 a |

| p-HPEA | 7.5 ± 1.1 a | 7.2 ± 0.8 a | 2.1 ± 0.1 a | 1.8 ± 0.3 a |

| Vanillic acid | 0.3 ± 0.1 a | 0.3 ± 0.04 a | 0.2 ± 0.03 a | 0.2 ± 0.02 a |

| 3.4-DHPEA-EDA | 527.1 ± 13.0 b | 767.2 ± 12.8 a | 484.5 ± 17.6 b | 598.2 ± 27.9 a |

| p-HPEA-EDA | 225.8 ± 9.0 b | 278.8 ± 24.3 a | 167.6 ± 8.1 a | 170.2 ± 7.0 a |

| (+)-1-Acetoxypinoresinol | 34.5 ± 1.2 b | 39.6 ± 2.4 a | 28.4 ± 1.0 a | 29 ± 1.1 a |

| (+)-Pinoresinol | 21.3 ± 0.6 b | 23.8 ± 1.0 a | 12.8 ± 0.3 a | 12.8 ± 0.5 a |

| 3.4-DHPEA-EA | 186.2 ± 10.3 b | 246.6 ± 30.5 a | 252.6 ± 4.8 b | 289.5 ± 13.2 a |

| Ligstroside aglycone | 43.1 ± 2.7 a | 44.3 ± 7.2 a | 30.2 ± 1.3 a | 30.3 ± 1.2 a |

| Total phenols | 1051 ± 21.7 b | 1412 ± 51.7 a | 980.5 ± 27.6 b | 1133.8 ± 45.6 a |

| Oleuropein derivatives | 718.4 ± 16.6 b | 1018.1 ± 33.1 a | 739.1 ± 18.3 b | 889.6 ± 30.9 a |

| Ligstroside derivatives | 276.4 ± 9.4 b | 330.2 ± 25.4 a | 199.9 ± 8.2 b | 202.3 ± 7.1 a |

| Lignans | 55.8 ± 1.3 b | 63.3 ± 2.6 a | 41.3 ± 1.1 a | 41.8 ± 1.2 a |

| Maturity Index 1.6 | Maturity Index 2.3 | |||

|---|---|---|---|---|

| HC | KC | HC | KC | |

| Aldehydes | ||||

| Pentanal | n.d. | n.d. | 89 ± 9 a | 96 ± 2 a |

| (E)-2-Pentenal | 54 ± 4 b | 61 ± 2 a | n.d. | n.d. |

| Hexanal | 771 ± 48 a | 860 ± 151 a | 960 ± 81 a | 924 ± 71 a |

| (E)-2-Hexenal | 14292 ± 609 b | 19039 ± 1947 a | 13267 ± 655 b | 16228 ± 1369 a |

| (E.E)-2.4-Hexadienal | 163 ± 7 b | 229 ± 42 a | 555 ± 34 a | 533 ± 39 a |

| Σ of aldehydes at C5 and at C6 | 15280 ± 611 b | 20188 ± 1954 a | 14870 ± 661 b | 17780 ± 1371 a |

| Alcohols | ||||

| Ethanol | n.d. | n.d. | n.d. | n.d. |

| 1-Pentanol | 70 ± 10 a | 67 ± 5 a | 253 ± 26 a | 256 ± 22 a |

| 1-Penten-3-ol | 379 ± 18a | 363 ± 15a | 567 ± 83a | 244 ± 320a |

| (E)-2-Penten-1-ol | 29 ± 2 b | 33 ± 1 a | 46 ± 4 a | 52 ± 3 a |

| (Z)-2-Penten-1-ol | 299 ± 21 b | 352 ± 28 a | 793 ± 44 a | 791 ± 13 a |

| 1-Hexanol | 4361 ± 374 b | 4964 ± 291 a | 2642 ± 125 a | 2725 ± 237 a |

| (E)-2-Hexen-1-ol | 2417 ± 229 a | 1931 ± 199 b | 1839 ± 101 a | 1728 ± 74 a |

| (Z)-3-Hexen-1-ol | 395 ± 8 a | 334 ± 27 b | 778 ± 16 a | 725 ± 51 a |

| Benzyl alcohol | 74 ± 6 a | 64 ± 4 b | 183 ± 14 a | 166 ± 14 a |

| Phenylethyl Alcohol | 238 ± 17 a | 243 ± 41 a | 621 ± 52 a | 657 ± 14 a |

| Σ of alcohols at C5 and at C6 | 8263 ± 439 a | 8352 ± 357 a | 6919 ± 188 a | 6520 ± 410 a |

| Esters | ||||

| Hexyl acetate | 29 ± 5 a | 33 ± 3 a | 34 ± 2 a | 38 ± 3 a |

| (Z)-3-Hexenyl acetate | 35 ± 4 a | 37 ± 6 a | 39 ± 4 a | 44 ± 3 a |

| Σ of esters at C6 | 64 ± 6 a | 71 ± 6 a | 73 ± 5 a | 82 ± 4 a |

| Ketones | ||||

| 3-Pentanone | 827 ± 57 a | 782 ± 81 a | 710 ± 18 a | 688 ± 56 a |

| 1-Penten-3-one | 201 ± 12 a | 198 ± 20 a | 30 ± 4 a | 26 ± 2 a |

| 6-Methyl-5-hepten-2-one | 17 ± 2 b | 26 ± 3 a | 17 ± 1 a | 12 ± 1 b |

| Σ of ketones at C5 and at C8 | 1045 ± 67 a | 1006 ± 83 a | 756 ± 18 a | 726 ± 56 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamborrino, A.; Perone, C.; Veneziani, G.; Berardi, A.; Romaniello, R.; Servili, M.; Leone, A. Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants. Foods 2022, 11, 3035. https://doi.org/10.3390/foods11193035

Tamborrino A, Perone C, Veneziani G, Berardi A, Romaniello R, Servili M, Leone A. Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants. Foods. 2022; 11(19):3035. https://doi.org/10.3390/foods11193035

Chicago/Turabian StyleTamborrino, Antonia, Claudio Perone, Gianluca Veneziani, Antonio Berardi, Roberto Romaniello, Maurizio Servili, and Alessandro Leone. 2022. "Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants" Foods 11, no. 19: 3035. https://doi.org/10.3390/foods11193035

APA StyleTamborrino, A., Perone, C., Veneziani, G., Berardi, A., Romaniello, R., Servili, M., & Leone, A. (2022). Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants. Foods, 11(19), 3035. https://doi.org/10.3390/foods11193035