Substituting Fat with Olive Oil, Mash Potato, or a Gelatin Matrix in Low-Salt-Content Dry-Fermented Sausages

Abstract

:1. Introduction

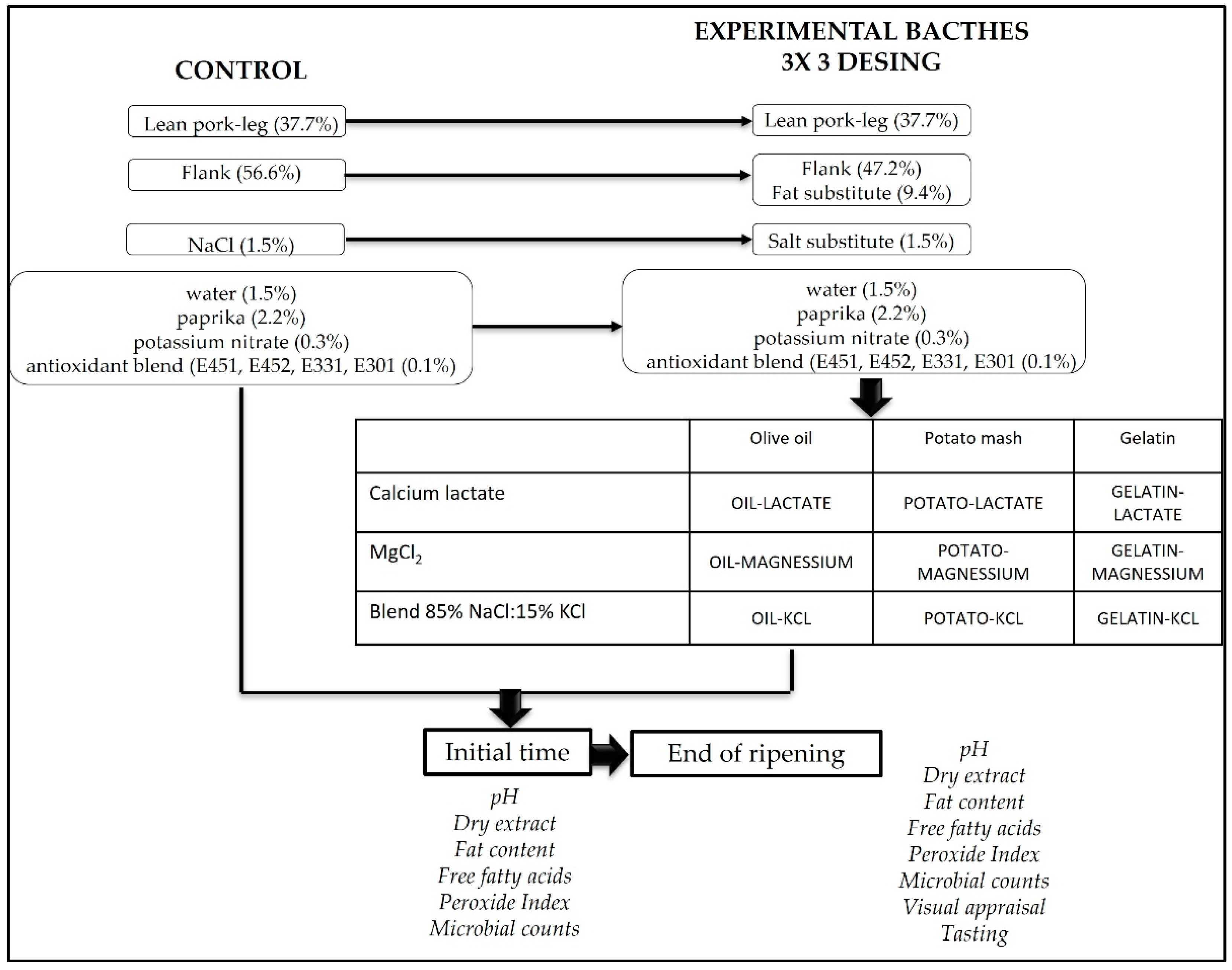

2. Materials and Methods

2.1. Sausage Processing and Sampling

2.2. Methodological Procedures

2.3. Microbial Analysis

2.4. Consumer Appraisal

2.5. Statistical Analysis

3. Results

3.1. Physicochemical Analysis: pH, Dry Matter, Fat Content, Free Fatty Acid Content, and Peroxide Index

3.2. Microbiology

3.3. Consumer Tests

3.3.1. Visual

3.3.2. Tasting

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Corral, S.; Salvador, A.; Flores, M. Salt reduction in slow fermented sausages affects the generation of aroma active compounds. Meat Sci. 2013, 93, 776–785. [Google Scholar] [CrossRef]

- Ruusunen, M.; Vainionpaa, J.; Lyly, M.; Lahteenmaki, L.; Niemisto, M.; Ahvenainen, R.; Puolanne, E. Reducing the sodium content in meat products: The effect of the formulation in low-sodium ground meat patties. Meat Sci. 2005, 69, 53–60. [Google Scholar] [CrossRef]

- Desmond, E. Reducing salt: A challenge for the meat industry. Meat Sci. 2006, 74, 188–196. [Google Scholar] [CrossRef]

- Guardia, M.D.; Guerrero, L.; Gelabert, J.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of small calibre fermented sausages with 50% substitution of nacl by mixtures of kcl and potassium lactate. Meat Sci. 2008, 80, 1225–1230. [Google Scholar] [CrossRef]

- de Carvalho, F.A.L.; Munekata, P.E.S.; Pateiro, M.; Campagnol, P.C.B.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT 2020, 122, 109052. [Google Scholar] [CrossRef]

- Dominguez, R.; Pateiro, M.; Agregan, R.; Lorenzo, J.M. Effect of the partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J. Food Sci. Technol. 2017, 54, 26–37. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Sánchez-Muniz, F.J.; Olmedilla-Alonso, B. Design and development of meat-based functional foods with walnut: Technological, nutritional and health impact. Food Chem. 2010, 123, 959–967. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; González-Rodríguez, R.M.; Sánchez, M.; Amado, I.R.; Franco, D. Effects of natural (grape seed and chestnut extract) and synthetic antioxidants (buthylatedhydroxytoluene, bht) on the physical, chemical, microbiological and sensory characteristics of dry cured sausage “chorizo”. Food Res. Int. 2013, 54, 611–620. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Chilled storage characteristics of low-fat, n-3 pufa-enriched dry fermented sausage reformulated with a healthy oil combination stabilized in a konjac matrix. Food Control 2013, 31, 158–165. [Google Scholar] [CrossRef]

- Shin, D.J.; Yim, D.G.; Kwon, J.A.; Kim, S.S.; Lee, H.J.; Jo, C. Effect of cutting time and cooking temperature on physicochemical properties of chicken breast meat emulsion sausage with olive oil. Poult. Sci. 2022, 101, 101554. [Google Scholar] [CrossRef]

- Zampouni, K.; Soniadis, A.; Dimakopoulou-Papazoglou, D.; Moschakis, T.; Biliaderis, C.G.; Katsanidis, E. Modified fermented sausages with olive oil oleogel and nacl–kcl substitution for improved nutritional quality. LWT 2022, 158, 113172. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jiménez-Colmenero, F.; Pasqualin Cavalheiro, C.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- Magra, T.; Soultos, N.; Dovas, C.; Papavergou, E.; Lazou, T.; Apostolakos, I.; Dimitreli, G.; Ambrosiadis, I. Dry fermented sausages with total replacement of fat by extra virgin olive oil emulsion and indigenous lactic acid bacteria. Food Technol. Biotechnol. 2021, 59, 267–281. [Google Scholar] [CrossRef] [PubMed]

- de Souza Paglarini, C.; de Figueiredo Furtado, G.; Honório, A.R.; Mokarzel, L.; da Silva Vidal, V.A.; Ribeiro, A.P.B.; Cunha, R.L.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- Alejandre, M.; Poyato, C.; Ansorena, D.; Astiasaran, I. Linseed oil gelled emulsion: A successful fat replacer in dry fermented sausages. Meat Sci. 2016, 121, 107–113. [Google Scholar] [CrossRef]

- Jiménez-Colmenero, F.; Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Ruiz-Capillas, C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, pufa-enriched, dry fermented sausages. LWT-Food Sci. Technol. 2013, 51, 158–163. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Effect of preformed konjac gels, with and without olive oil, on the technological attributes and storage stability of merguez sausage. Meat Sci. 2013, 93, 351–360. [Google Scholar] [CrossRef]

- Ferreira Ignácio Câmara, A.K.; Midori Ozaki, M.; Santos, M.; Silva Vidal, V.A.; Oliveira Ribeiro, W.; de Souza Paglarini, C.; Bernardinelli, O.D.; Sabadini, E.; Rodrigues Pollonio, M.A. Olive oil-based emulsion gels containing chia (Salvia hispanica L.) mucilage delivering healthy claims to low-saturated fat bologna sausages. Food Struct. 2021, 28, 100187. [Google Scholar] [CrossRef]

- Muguerza, E.; Ansorena, D.; Bloukas, J.G.; Astiasarán, I. Effect of fat level and partial replacement of pork backfat with olive oil on the lipid oxidation and volatile compounds of greek dry fermented sausages. J. Food Sci. 2003, 68, 1531–1536. [Google Scholar] [CrossRef]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasarán, I.; Bloukas, J. Effect of fat level and partial replacement of pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Bloukas, J.; Astiasarán, I. Effect of replacing pork backfat with pre-emulsified olive oil on lipid fraction and sensory quality of chorizo de pamplona—a traditional spanish fermented sausage. Meat Sci. 2001, 59, 251–258. [Google Scholar] [CrossRef]

- Panea, B.; Ripoll, G. Substituting fat with soy in low-salt dry fermented sausages. NFS J. 2021, 22, 1–5. [Google Scholar] [CrossRef]

- Josquin, N.M.; Linssen, J.P.; Houben, J.H. Quality characteristics of dutch-style fermented sausages manufactured with partial replacement of pork back-fat with pure, pre-emulsified or encapsulated fish oil. Meat Sci. 2012, 90, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Munekata, P.E.S.; Pateiro, M.; Campagnol, P.C.B.; Dominguez, R. Healthy spanish salchichon enriched with encapsulated n-3 long chain fatty acids in konjac glucomannan matrix. Food Res. Int. 2016, 89, 289–295. [Google Scholar] [CrossRef]

- Garcia-Garcia, E.; Totosaus, A. Low-fat sodium-reduced sausages: Effect of the interaction between locust bean gum, potato starch and kappa-carrageenan by a mixture design approach. Meat Sci. 2008, 78, 406–413. [Google Scholar] [CrossRef]

- Alves, L.; Lorenzo, J.M.; Goncalves, C.A.A.; Santos, B.A.D.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef]

- Feng, T.; Ye, R.; Zhuang, H.; Rong, Z.; Fang, Z.; Wang, Y.; Gu, Z.; Jin, Z. Physicochemical properties and sensory evaluation of mesona blumes gum/rice starch mixed gels as fat-substitutes in chinese cantonese-style sausage. Food Res. Int. 2013, 50, 85–93. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef]

- Barbut, S.; Wood, J.; Marangoni, A. Quality effects of using organogels in breakfast sausage. Meat Sci. 2016, 122, 84–89. [Google Scholar] [CrossRef]

- Barbut, S.; Wood, J.; Marangoni, A. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 2016, 122, 155–162. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Serra, X.; Guardia, M.D.; Miklos, R.; Lametsch, R.; Arnau, J. Effect of the type of fat on the physicochemical, instrumental and sensory characteristics of reduced fat non-acid fermented sausages. Meat Sci. 2013, 93, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Panea, B.; Ripoll, G. Pig feedstuff effect on the physicochemical and sensory properties of low-salt, dry-fermented sausages. Anim. Sci. J. 2020, 91, e13458. [Google Scholar] [CrossRef]

- Koutsopoulos, D.A.; Koutsimanis, G.E.; Bloukas, J.G. Effect of carrageenan level and packaging during ripening on processing and quality characteristics of low-fat fermented sausages produced with olive oil. Meat Sci. 2008, 79, 188–197. [Google Scholar] [CrossRef]

- BOE. Métodos oficiales de análisis de productos cárnicos. In Boletín Oficial Estado, de 28 de Agosto de 1979, Anexo II.; BOE: Madrid, Spain, 1979; pp. 20233–20240. [Google Scholar]

- Aguirrezábal, M.; Mateo, J.; Domınguez, M.; Zumalacárregui, J. The effect of paprika, garlic and salt on rancidity in dry sausages. Meat Sci. 2000, 54, 77–81. [Google Scholar] [CrossRef]

- ISO, E. 15214. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Colony-Count Technique at 30 Degrees C.; ICS: Geneva, Switzerland, 1998; p. 300. [Google Scholar]

- ESOMAR. Cc/Esomar International Code on Market & Social Research. Available online: http://www.esomar.org/knowledge-and-standards/codes-and-guidelines.php (accessed on 20 July 2022).

- MacAdam, D.L. Visual sensitivities to color differences in daylight. Josa 1942, 32, 247–274. [Google Scholar] [CrossRef]

- Gómez, M.; Fonseca, S.; Cachaldora, A.; Carballo, J.; Franco, I. Effect of chestnuts intake by celta pigs on lipolytic, oxidative and fatty acid profile changes during ripening and vacuum-packed storage of galician “chorizo”. J. Food Compos. Anal. 2017, 56, 73–83. [Google Scholar] [CrossRef]

- Gomez, M.; Lorenzo, J.M. Effect of fat level on physicochemical, volatile compounds and sensory characteristics of dry-ripened “chorizo” from celta pig breed. Meat Sci. 2013, 95, 658–666. [Google Scholar] [CrossRef]

- Muguerza, E.; Ansorena, D.; Astiasarán, I. Improvement of nutritional properties of chorizo de pamplona by replacement of pork backfat with soy oil. Meat Sci. 2003, 65, 1361–1367. [Google Scholar] [CrossRef]

- Gimeno, O.; Astiasarán, I.; Bello, J. Influence of partial replacement of NaCl with KCl and CaCl2 on microbiological evolution of dry fermented sausages. Food Microbiol. 2001, 18, 329–334. [Google Scholar] [CrossRef]

- Mora-Gallego, H.; Guardia, M.D.; Serra, X.; Gou, P.; Arnau, J. Sensory characterisation and consumer acceptability of potassium chloride and sunflower oil addition in small-caliber non-acid fermented sausages with a reduced content of sodium chloride and fat. Meat Sci. 2016, 112, 9–15. [Google Scholar] [CrossRef]

- Corral, S.; Belloch, C.; Lopez-Diez, J.J.; Salvador, A.; Flores, M. Yeast inoculation as a strategy to improve the physico-chemical and sensory properties of reduced salt fermented sausages produced with entire male fat. Meat Sci. 2017, 123, 1–7. [Google Scholar] [CrossRef]

- Lizaso, G.; Chasco, J.; Beriain, M.J. Microbiological and biochemical changes during ripening of salchichón a spanish dry cured sausage. Food Microbiol. 1999, 16, 219–228. [Google Scholar] [CrossRef]

- Moon, S.-S.; Jin, S.-K.; Hah, K.-H.; Kim, I.-S. Effects of replacing backfat with fat replacers and olive oil on the quality characteristics and lipid oxidation of low-fat sausage during storage. Food Sci. Biotechnol. 2008, 17, 396–401. [Google Scholar]

- Olivares, A.; Navarro, J.L.; Salvador, A.; Flores, M. Sensory acceptability of slow fermented sausages based on fat content and ripening time. Meat Sci. 2010, 86, 251–257. [Google Scholar] [CrossRef]

- Corral, S.; Salvador, A.; Flores, M. Effect of the use of entire male fat in the production of reduced salt fermented sausages. Meat Sci. 2016, 116, 140–150. [Google Scholar] [CrossRef]

- Gimeno, O.; Ansorena, D.; Astiasarán, I.; Bello, J. Characterization of chorizo de pamplona: Instrumental measurements of colour and texture. Food Chem. 2000, 69, 195–200. [Google Scholar] [CrossRef]

- Ordonez, J.A.; Hierro, E.M.; Bruna, J.M.; de la Hoz, L. Changes in the components of dry-fermented sausages during ripening. Crit. Rev. Food Sci. Nutr. 1999, 39, 329–367. [Google Scholar] [CrossRef]

- Bloukas, J.G.; Paneras, E.D.; Fournitzis, G.C. Effect of replacing pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 1997, 45, 133–144. [Google Scholar] [CrossRef]

- Lekjing, S. A chitosan-based coating with or without clove oil extends the shelf life of cooked pork sausages in refrigerated storage. Meat Sci. 2016, 111, 192–197. [Google Scholar] [CrossRef]

- Wen, R.; Hu, Y.; Zhang, L.; Wang, Y.; Chen, Q.; Kong, B. Effect of nacl substitutes on lipid and protein oxidation and flavor development of harbin dry sausage. Meat Sci. 2019, 156, 33–43. [Google Scholar] [CrossRef]

- Wojciak, K.M.; Trząskowska, M.; Kołożyn-Krajewska, D.; Dolatowski, Z.J. Evaluation of technological properties and oxidative stability of organic dry fermented probiotic sausages during long-term storage. J. Vet. Res. 2012, 56, 305–314. [Google Scholar] [CrossRef] [Green Version]

- Chizzolini, R.; Novelli, E.; Zanardi, E. Oxidation in traditional mediterranean meat products. Meat Sci. 1998, 49, S87–S99. [Google Scholar] [CrossRef]

- Aaslyng, M.D.; Vestergaard, C.; Koch, A.G. The effect of salt reduction on sensory quality and microbial growth in hotdog sausages, bacon, ham and salami. Meat Sci. 2014, 96, 47–55. [Google Scholar] [CrossRef]

- Spaziani, M.; Torre, M.D.; Stecchini, M.L. Changes of physicochemical, microbiological, and textural properties during ripening of italian low-acid sausages. Proteolysis, sensory and volatile profiles. Meat Sci. 2009, 81, 77–85. [Google Scholar] [CrossRef]

- Liaros, N.G.; Katsanidis, E.; Bloukas, J.G. Effect of the ripening time under vacuum and packaging film permeability on processing and quality characteristics of low-fat fermented sausages. Meat Sci. 2009, 83, 589–598. [Google Scholar] [CrossRef]

- Campagnol, P.C.; dos Santos, B.A.; Terra, N.N.; Pollonio, M.A. Lysine, disodium guanylate and disodium inosinate as flavor enhancers in low-sodium fermented sausages. Meat Sci. 2012, 91, 334–338. [Google Scholar] [CrossRef]

- Backes, Â.M.; Terra, N.N.; Milani, L.I.G.; de Souza Rezer, A.P.; Lüdtke, F.L.; Cavalheiro, C.P.; Fries, L.L.M. Physico-chemical characteristics and sensory acceptance of italiantype salami with canola oil addition. Semin. Ciências Agrárias 2013, 34, 3709–3720. [Google Scholar] [CrossRef]

- Phelps, T.; Angus, F.; Clegg, S.; Kilcast, D.; Narain, C.; Den Ridder, C. Sensory issues in salt reduction. Food Qual. Prefer. 2006, 17, 633–634. [Google Scholar]

- Dos Santos, B.A.; Campagnol, P.C.B.; Fagundes, M.B.; Wagner, R.; Pollonio, M.A.R. Generation of volatile compounds in brazilian low-sodium dry fermented sausages containing blends of nac1, kc1, and cac12 during processing and storage. Food Res. Int. 2015, 74, 306–314. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Bermúdez, R.; Domínguez, R.; Guiotto, A.; Franco, D.; Purriños, L. Physicochemical and microbial changes during the manufacturing process of dry-cured lacón salted with potassium, calcium and magnesium chloride as a partial replacement for sodium chloride. Food Control 2015, 50, 763–769. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Lorenzo, J.M.; Domínguez, R.; Pateiro, M.; Munekata, P.E.; Campagnol, P.C.; Franco, D. Effect of nacl partial replacement by chloride salts on physicochemical characteristics, volatile compounds and sensorial properties of dry-cured deer cecina. Foods 2021, 10, 669. [Google Scholar] [CrossRef]

- Kim, G.-D.; Hur, S.J.; Park, T.S.; Jin, S.-K. Quality characteristics of fat-reduced emulsion-type pork sausage by partial substitution of sodium chloride with calcium chloride, potassium chloride and magnesium chloride. LWT 2018, 89, 140–147. [Google Scholar] [CrossRef]

- Choi, Y.; Jung, K.; Jo, H.; Nam, K.; Choe, J.; Rhee, M.-S.; Kim, B.-C. Combined effects of potassium lactate and calcium ascorbate as sodium chloride substitutes on the physicochemical and sensory characteristics of low-sodium frankfurter sausage. Meat Sci. 2014, 96, 21–25. [Google Scholar] [CrossRef] [PubMed]

- Fulladosa, E.; Serra, X.; Gou, P.; Arnau, J. Effects of potassium lactate and high pressure on transglutaminase restructured dry-cured hams with reduced salt content. Meat Sci. 2009, 82, 213–218. [Google Scholar] [CrossRef] [PubMed]

| Batch | Initial Dry Matter (%) | Final Dry Matter (%) | |

|---|---|---|---|

| CONTROL | 53.4 a | 81.7 ab | |

| OIL | LACTATE | 52.6 a | 74.4 f |

| MAGNESIUM | 53.9 a | 75.9 ef | |

| KCL | 52.1 abc | 78.9 cd | |

| POTATO | LACTATE | 49.0 cde | 80.1 bc |

| MAGNESIUM | 50.1 bcd | 77.5 de | |

| KCL | 49.5 bcd | 83.2 b | |

| GELATIN | LACTATE | 48.7 de | 79.9 bc |

| MAGNESIUM | 49.5 bcd | 80.6 bc | |

| KCL | 46.0 e | 83.9 a | |

| Standard error | 0.9 | 0.7 | |

| Fat type effect (p value) | <0.001 | <0.001 | |

| Salt type effect (p value) | 0.076 | <0.001 | |

| Fat type x salt type (p value) | 0.546 | 0.083 | |

| Batch | Fat Content (%) | |

|---|---|---|

| CONTROL | 56.2 a | |

| OIL | LACTATE | 49.5 c |

| MAGNESIUM | 48.8 c | |

| KCL | 51.9 c | |

| POTATO | LACTATE | 54.4 ab |

| MAGNESIUM | 53.6 bc | |

| KCL | 55.8 a | |

| GELATIN | LACTATE | 55.7 a |

| MAGNESIUM | 54.3 ab | |

| KCL | 53.8 b | |

| Standard error | 0.599 | |

| Fat type effect (p value) | <0.001 | |

| Salt type effect (p value) | <0.001 | |

| Fat type x salt type (p value) | 0.006 | |

| Free Fatty Acids (g Oleic Acid/100 g) | Peroxide Index (meqO2/kg) | ||||

|---|---|---|---|---|---|

| Batch | Initial | Final | Initial | Final | |

| CONTROL | 0.11 c | 0.57 d | 1.28 | 3.04 ab | |

| OIL | LACTATE | 0.23 a | 2.80 a | 2.16 | 3.88 a |

| MAGNESIUM | 0.16 ab | 2.34 c | 1.25 | 2.59 ab | |

| KCL | 0.25 a | 2.58 b | 1.71 | 3.78 a | |

| POTATO | LACTATE | 0.18 b | 0.66 d | 1.94 | 2.02 b |

| MAGNESIUM | 0.14 ab | 0.55 d | 1.93 | 2.50 ab | |

| KCL | 0.15 ab | 0.61 d | 2.44 | 3.32 ab | |

| GELATIN | LACTATE | 0.14 ab | 0.67 d | 1.98 | 3.77 a |

| MAGNESIUM | 0.12 c | 0.58 d | 1.43 | 3.06 ab | |

| KCL | 0.13 ab | 0.67 d | 1.96 | 3.10 ab | |

| Standard error | 0.085 | 0.129 | 0.115 | 0.146 | |

| Fat type effect | <0.001 | <0.001 | 0.494 | 0.043 | |

| Salt type effect (p value) | 0.045 | <0.001 | 0.404 | 0.129 | |

| Fat type x salt type (p value) | 0.237 | 0.006 | 0.772 | 0.093 | |

| Total Mesophilic (log UFC/g) | LAB (log UFC/g) | ||||

|---|---|---|---|---|---|

| Batch | Initial | Final | Initial | Final | |

| CONTROL | 5.5 | 7.9 ef | 4.5 | 7.9 c | |

| OIL | LACTATE | 5.4 | 8.5 a | 5.0 | 8.5 a |

| MAGNESIUM | 5.5 | 8.6 a | 5.0 | 8.6 a | |

| KCL | 5.5 | 8.4 ab | 5.1 | 8.5 ab | |

| POTATO | LACTATE | 5.4 | 8.0 de | 4.8 | 7.9 c |

| MAGNESIUM | 5.5 | 8.0 de | 5.0 | 7.9 c | |

| KCL | 5.5 | 7.7 f | 4.9 | 7.7 c | |

| GELATIN | LACTATE | 5.5 | 8.5 a | 5.1 | 8.5 ab |

| MAGNESIUM | 5.6 | 8.3 bc | 5.1 | 8.2 b | |

| KCL | 5.1 | 8.2 cd | 4.8 | 8.2 b | |

| Standard error | 0.034 | 0.032 | 0.054 | 0.036 | |

| Fat type effect | 0.252 | <0.001 | 0.547 | <0.001 | |

| Salt type effect (p value) | 0.156 | <0.001 | 0.827 | 0.014 | |

| Fat type x salt type (p value) | 0.094 | 0.005 | 0.690 | 0.019 | |

| Visual Appraisal Test | |||

|---|---|---|---|

| Batch | Score (1–10) | Purchase Intention (% yes) | |

| CONTROL | 6.0 abc | 55.0 | |

| OIL | LACTATE | 5.6 abc | 43.5 |

| MAGNESIUM | 4.4 c | 10.0 | |

| KCL | 4.7 bc | 30.0 | |

| POTATO | LACTATE | 6.6 a | 52.9 |

| MAGNESIUM | 6.8 a | 68.4 | |

| KCL | 6.3 ab | 64.7 | |

| GELATIN | LACTATE | 6.3 abc | 63.2 |

| MAGNESIUM | 6.3 ab | 47.1 | |

| KCL | 6.7 a | 62.5 | |

| Standard error | 0.134 | - | |

| Fat type effect | <0.001 | <0.001 | |

| Salt type effect (p value) | 0.512 | 0.557 | |

| Fat type x salt type (p value) | 0.283 | 0.274 | |

| Consumer’ gender effect (p value) | 0.840 | 0.406 | |

| Consumer’ age effect (p value) | 0.271 | 0.207 | |

| Taste Test | ||||

|---|---|---|---|---|

| Batch | Color | Flavor | Taste | Texture |

| CONTROL | 6.3 | 6.0 ab | 6.6 | 6.0 |

| OIL-LACTATE | 6.2 | 6.2 ab | 5.6 | 5.3 |

| OIL-MAGNESIUM | 5.9 | 5.7 b | 5.4 | 5.0 |

| OIL-KCL | 6.0 | 6.7 a | 5.8 | 5.1 |

| POTATO-LACTATE | 6.3 | 5.6 b | 5.8 | 5.4 |

| POTATO-MAGNESIUM | 5.9 | 5.5 b | 5.8 | 5.0 |

| POTATO-KCL | 6.1 | 5.6 b | 5.3 | 5.2 |

| GELATIN-LACTATE | 6.0 | 5.8 ab | 5.7 | 5.6 |

| GELATIN-MAGNESIUM | 5.8 | 5.4 b | 5.2 | 5.4 |

| GELATIN-KCL | 6.5 | 6.3 ab | 6.0 | 6.2 |

| Standard error | 0.092 | 0.101 | 0.104 | 0.108 |

| Fat type effect | 0.981 | 0.067 | 0.997 | 0.059 |

| Salt type effect (p value) | 0.300 | 0.027 | 0.578 | 0.147 |

| Fat type x salt type (p value) | 0.698 | 0.590 | 0.354 | 0.679 |

| Consumer’ gender effect (p value) | 0.103 | 0.106 | 0.927 | 0.510 |

| Consumer’ age effect (p value) | 0.486 | 0.109 | 0.980 | 0.204 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panea, B.; Ripoll, G. Substituting Fat with Olive Oil, Mash Potato, or a Gelatin Matrix in Low-Salt-Content Dry-Fermented Sausages. Foods 2022, 11, 2833. https://doi.org/10.3390/foods11182833

Panea B, Ripoll G. Substituting Fat with Olive Oil, Mash Potato, or a Gelatin Matrix in Low-Salt-Content Dry-Fermented Sausages. Foods. 2022; 11(18):2833. https://doi.org/10.3390/foods11182833

Chicago/Turabian StylePanea, Begoña, and Guillermo Ripoll. 2022. "Substituting Fat with Olive Oil, Mash Potato, or a Gelatin Matrix in Low-Salt-Content Dry-Fermented Sausages" Foods 11, no. 18: 2833. https://doi.org/10.3390/foods11182833

APA StylePanea, B., & Ripoll, G. (2022). Substituting Fat with Olive Oil, Mash Potato, or a Gelatin Matrix in Low-Salt-Content Dry-Fermented Sausages. Foods, 11(18), 2833. https://doi.org/10.3390/foods11182833