Investigation of Pulsed Electric Field Conditions at Low Field Strength for the Tenderisation of Beef Topside

Abstract

:1. Introduction

2. Materials and Methods

2.1. Meat Sampling and Preparation

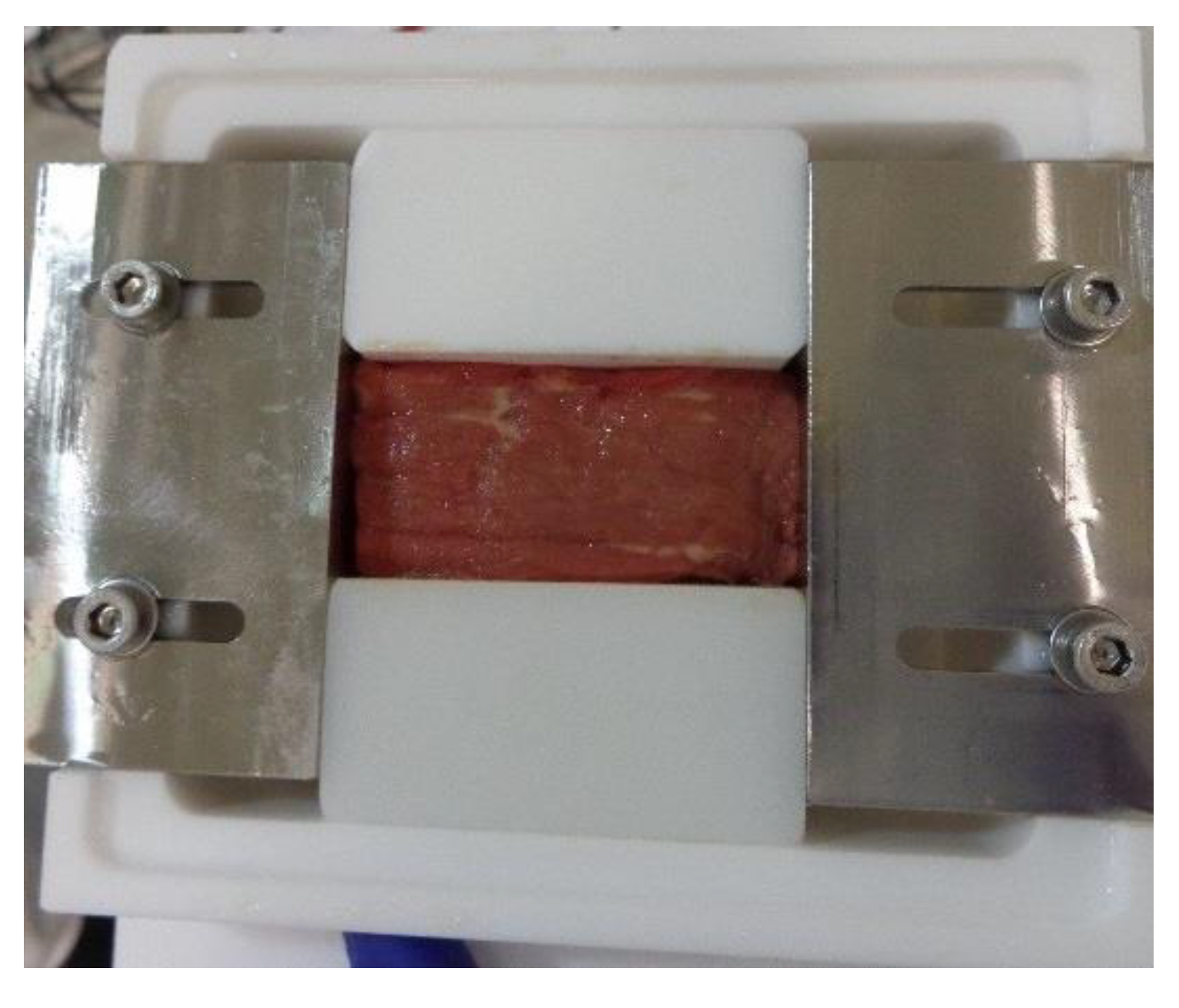

2.2. PEF Treatment

2.3. Measurement of pH

2.4. Colour Measurement

2.5. Texture Measurement

2.6. Drip Loss and Cook Loss

2.7. Statistical Analysis

3. Results

3.1. Immediate Effect of PEF Treatment on Meat Properties

3.2. Effect of PEF Treatment on Meat Tenderness and Other Quality Parameters at 1 and 14 Days of Storage

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mennecke, B.E.; Townsend, A.M.; Hayes, D.J.; Lonergan, S.M. A study of the factors that influence consumer attitudes toward beef products using the conjoint market analysis tool. J. Anim. Sci. 2007, 85, 2639–2659. [Google Scholar] [CrossRef] [PubMed]

- Grunert, K.G.; Bredahl, L.; Brunsø, K. Consumer perception of meat quality and implications for product development in the meat sector—A review. Meat Sci. 2004, 66, 259–272. [Google Scholar] [CrossRef]

- Tatum, J.D.; Belk, K.E.; George, M.H.; Smith, G.C. Identification of quality management practices to reduce the incidence of retail beef tenderness problems: Development and evaluation of a prototype quality system to produce tender beef. J. Anim. Sci. 1999, 77, 2112–2118. [Google Scholar] [CrossRef] [PubMed]

- Tatum, J.D.; Smith, G.C.; Belk, K.E. New approaches for improving tenderness, quality, and consistency of beef. J. Anim. Sci. 2000, 77, 1–10. [Google Scholar] [CrossRef]

- Thompson, J. Managing meat tenderness. Meat Sci. 2002, 62, 295–308. [Google Scholar] [CrossRef]

- Warner, R.D.; Wheeler, T.L.; Ha, M.; Li, X.; Bekhit, A.E.; Morton, J.; Vaskoska, R.; Dunshea, F.R.; Liu, R.; Purslow, P.; et al. Meat tenderness: Advances in biology, biochemistry, molecular mechanisms and new technologies. Meat Sci. 2021, 185, 108657. [Google Scholar] [CrossRef]

- Bolumar, T.; Enneking, M.; Toepfl, S.; Heinz, V. New developments in shockwave technology intended for meat tenderization: Opportunities and challenges. A review. Meat Sci. 2013, 95, 931–939. [Google Scholar] [CrossRef]

- Barbosa-Canovas, G.V.; Tapia, M.P.C. Novel Food Processing Technologies; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Doona, C.J.; Kustin, K.; Feeherry, F.E. Case Studies in Novel Food Processing Technologies: Innovations in Processing, Packaging, and Predictive Modelling; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing Limited: Sawston, UK, 2010. [Google Scholar]

- Toepfl, S.; Siemer, C.; Saldaña-Navarro, G.; Heinz, V. Overview of Pulsed Electric Fields Processing for Food. In Emerging Technologies for Food Processing; Sun, D.-W., Ed.; Elsevier: London, UK, 2015; pp. 93–114. [Google Scholar]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Kemp, C.M.; Sensky, P.L.; Bardsley, R.G.; Buttery, P.J.; Parr, T. Tenderness—An enzymatic view. Meat Sci. 2010, 84, 248–256. [Google Scholar] [CrossRef]

- Bekhit, A.E.-D.A.; van de Ven, R.; Suwandy, V.; Fahri, F.; Hopkins, D.L. Effect of Pulsed Electric Field Treatment on Cold-Boned Muscles of Different Potential Tenderness. Food Bioprocess Technol. 2014, 7, 3136–3146. [Google Scholar] [CrossRef]

- Bekhit, A.E.-D.A.; Suwandy, V.; Carne, A.; van de Ven, R.; Hopkins, D.L. Effect of repeated pulsed electric field treatment on the quality of hot-boned beef loins and topsides. Meat Sci. 2016, 111, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Suwandy, V.; Carne, A.; van de Ven, R.; Bekhit, A.E.-D.A.; Hopkins, D.L. Effect of pulsed electric field on the proteolysis of cold boned beef M. Longissimus lumborum and M. Semimembranosus. Meat Sci. 2015, 100, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Suwandy, V.; Carne, A.; van de Ven, R.; Bekhit, A.E.-D.A.; Hopkins, D.L. Effect of pulsed electric field treatment on hot-boned muscles of different potential tenderness. Meat Sci. 2015, 105, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Suwandy, V.; Carne, A.; van de Ven, R.; Bekhit, A.E.-D.A.; Hopkins, D.L. Effect of Pulsed Electric Field Treatment on the Eating and Keeping Qualities of Cold-Boned Beef Loins: Impact of Initial pH and Fibre Orientation. Food Bioprocess Technol. 2015, 8, 1355–1365. [Google Scholar] [CrossRef]

- Suwandy, V.; Carne, A.; van de Ven, R.; Bekhit, A.E.-D.A.; Hopkins, D.L. Effect of Repeated Pulsed Electric Field Treatment on the Quality of Cold-Boned Beef Loins and Topsides. Food Bioprocess Technol. 2015, 8, 1218–1228. [Google Scholar] [CrossRef]

- Arroyo, C.; Lascorz, D.; O’Dowd, L.; Noci, F.; Arimi, J.; Lyng, J.G. Effect of Pulsed Electric Field treatments at various stages during conditioning on quality attributes of beef longissimus thoracis et lumborum muscle. Meat Sci. 2015, 99, 52–59. [Google Scholar] [CrossRef]

- Faridnia, F.; Bekhit, A.E.-D.A.; Niven, B.; Oey, I. Impact of pulsed electric fields and post-mortem vacuum ageing on beef longissimus thoracis muscles. Int. J. Food Sci. Technol. 2014, 49, 2339–2347. [Google Scholar] [CrossRef]

- Faridnia, F.; Ma, Q.L.; Bremer, P.J.; Burritt, D.J.; Hamid, N.; Oey, I. Effect of freezing as pre-treatment prior to pulsed electric field processing on quality traits of beef muscles. Innov. Food Sci. Emerg. Technol. 2015, 29, 31–40. [Google Scholar] [CrossRef]

- O’Dowd, L.P.; Arimi, J.M.; Noci, F.; Cronin, D.A.; Lyng, J.G. An assessment of the effect of pulsed electrical fields on tenderness and selected quality attributes of post rigour beef muscle. Meat Sci. 2013, 93, 303–309. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Morton, J.D.; Mason, S.L.; Bekhit, A.E.A. Current and future prospects for the use of pulsed electric field in the meat industry. Crit. Rev. Food Sci. Nutr. 2019, 59, 1660–1674. [Google Scholar] [CrossRef]

- Gomez, B.; Munekata, P.E.S.; Gavahian, M.; Barba, F.J.; Marti-Quijal, F.J.; Bolumar, T.; Campagnol, P.C.B.; Tomasevic, I.; Lorenzo, J.M. Application of pulsed electric fields in meat and fish processing industries: An overview. Food Res. Int. 2019, 123, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Randhawa, M.A.; Carne, A.; Mohamed Ahmed, I.A.; Barr, D.; Reid, M.; Bekhit, A.E.-D.A. Effect of low and high pulsed electric field on the quality and nutritional minerals in cold boned beef M. longissimus et lumborum. Innov. Food Sci. Emerg. Technol. 2017, 41, 135–143. [Google Scholar] [CrossRef]

- Buckow, R.; Schroeder, S.; Berres, P.; Baumann, P.; Knoerzer, K. Simulation and evaluation of pilot-scale pulsed electric field (PEF) processing. J. Food Eng. 2010, 101, 67–77. [Google Scholar] [CrossRef]

- Bouton, P.E.; Harris, P.V. A comparison of some objective methods used to assess meat tenderness. J. Food Sci. 1972, 37, 218–221. [Google Scholar] [CrossRef]

- Bouton, P.E.; Harris, P.V.; Shorthose, W.R. Effect of ultimate pH upon the water-holding capacity and tenderness of mutton. J. Food Sci. 1971, 36, 435–439. [Google Scholar] [CrossRef]

- R-Core-Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienne, Austria, 2014; Available online: www.R-project.org (accessed on 30 August 2022).

- Anderson, M.J.; Lonergan, S.M.; Fedler, C.A.; Prusa, K.J.; Binning, J.M.; Huff-Lonergan, E. Profile of biochemical traits influencing tenderness of muscles from the beef round. Meat Sci. 2012, 91, 247–254. [Google Scholar] [CrossRef]

- Calkins, C.R.; Sullivan, G. Ranking of beef muscles for tenderness. Beef Facts 2007, 1–6. [Google Scholar]

- Gudmundsson, M.; Hafsteinsson, H. Effect of electric field pulses on microstructure of muscle foods and roes. Trends Food Sci. Technol. 2001, 12, 122–128. [Google Scholar] [CrossRef]

- Starkey, C.P.; Geesink, G.H.; Collins, D.; Hutton Oddy, V.; Hopkins, D.L. Do sarcomere length, collagen content, pH, intramuscular fat and desmin degradation explain variation in the tenderness of three ovine muscles? Meat Sci. 2016, 113, 51–58. [Google Scholar] [CrossRef]

| Treatment Conditions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | Voltage # | Current # | Pulse Width # | Energy Pulse ## | No Pulses | Energy Input ## | Specific Energy Input ## |

| (kV/cm) | (Hz) | (ms) | (V) | (A) | (µs) | (J/pulse) | (J) | (J/g) | |

| 0.25 | 100 | 50 | 1504 | 9.3 | 10 | 0.14 | 5000 | 698 | 12.0 |

| 0.25 | 20 | 50 | 1488 | 9.3 | 10 | 0.14 | 5000 | 690 | 11.9 |

| 0.25 | 100 | 30 | 1488 | 9.4 | 10 | 0.14 | 3000 | 421 | 7.2 |

| 0.25 | 20 | 30 | 1488 | 11.4 | 10 | 0.17 | 3000 | 507 | 8.7 |

| 0.25 | 100 | 10 | 1504 | 8.3 | 10 | 0.13 | 1000 | 125 | 2.2 |

| 0.25 | 20 | 10 | 1488 | 9.4 | 10 | 0.14 | 1000 | 141 | 2.4 |

| 0.50 | 100 | 50 | 3136 | 21.1 | 10 | 0.66 | 5000 | 3312 | 57.0 |

| 0.50 | 20 | 50 | 3104 | 22.7 | 10 | 0.71 | 5000 | 3526 | 60.6 |

| 0.50 | 100 | 30 | 3104 | 22.1 | 10 | 0.69 | 3000 | 2056 | 35.4 |

| 0.50 | 20 | 30 | 3168 | 16.3 | 10 | 0.52 | 3000 | 1551 | 26.7 |

| 0.50 | 100 | 10 | 3136 | 18.2 | 10 | 0.57 | 1000 | 572 | 9.8 |

| 0.50 | 20 | 10 | 3136 | 17.3 | 10 | 0.54 | 1000 | 542 | 9.3 |

| 1.00 | 100 | 50 | 6160 | 56.8 | 10 | 3.50 | 5000 | 17494 | 300.9 |

| 1.00 | 20 | 50 | 6160 | 54.6 | 10 | 3.36 | 5000 | 16817 | 289.2 |

| 1.00 | 100 | 30 | 6240 | 52.6 | 10 | 3.28 | 3000 | 9847 | 169.4 |

| 1.00 | 20 | 30 | 6240 | 51.6 | 10 | 3.22 | 3000 | 9660 | 166.1 |

| 1.00 | 100 | 10 | 6320 | 47.2 | 10 | 2.98 | 1000 | 2983 | 51.3 |

| 1.00 | 20 | 10 | 6400 | 44.0 | 10 | 2.82 | 1000 | 2816 | 48.4 |

| Control (untreated) | - | - | - | - | - | - | - | ||

| Treatment Conditions | Meat Properties # | |||||||

|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | ΔpH | ΔT | ΔWeight ## | |||

| (kV/cm) | (Hz) | (ms) | (°C) | (g) | ||||

| SE | SE | SE | ||||||

| 0.25 | 100 | 50 | −0.05 | 0.02 | 3.6 | 0.3 | −0.5 | 0.2 |

| 0.25 | 20 | 50 | −0.03 | 0.04 | 3.7 | 0.4 | −0.4 | 0.1 |

| 0.25 | 100 | 30 | −0.06 | 0.01 | 2.3 | 0.2 | −0.5 | 0.1 |

| 0.25 | 20 | 30 | −0.03 | 0.03 | 2.7 | 0.2 | −0.4 | 0.1 |

| 0.25 | 100 | 10 | −0.04 | 0.02 | 1.8 | 0.4 | −0.4 | 0.1 |

| 0.25 | 20 | 10 | −0.03 | 0.02 | 1.7 | 0.3 | −0.2 | 0.2 |

| 0.50 | 100 | 50 | −0.08 | 0.01 | 13.3 | 0.6 | −0.3 | 0.1 |

| 0.50 | 20 | 50 | −0.08 | 0.02 | 13.8 | 0.6 | −0.5 | 0.1 |

| 0.50 | 100 | 30 | −0.07 | 0.02 | 8.4 | 0.3 | −0.3 | 0.1 |

| 0.50 | 20 | 30 | −0.06 | 0.01 | 8.0 | 0.3 | −0.4 | 0.1 |

| 0.50 | 100 | 10 | −0.06 | 0.02 | 3.9 | 0.4 | −0.3 | 0.1 |

| 0.50 | 20 | 10 | −0.05 | 0.02 | 2.9 | 0.4 | −0.4 | 0.1 |

| 1.00 | 100 | 50 | 0.13 ### | - | 49.5 | - | −2.9 | - |

| 1.00 | 20 | 50 | 0.26 ### | - | 67.1 | - | −9.4 | - |

| 1.00 | 100 | 30 | 0.02 | 0.02 | 39.5 | 0.9 | −0.9 | 0.1 |

| 1.00 | 20 | 30 | 0.00 | 0.02 | 36.4 | 1.5 | −0.7 | 0.1 |

| 1.00 | 100 | 10 | −0.06 | 0.02 | 12.5 | 0.5 | −0.4 | 0.2 |

| 1.00 | 20 | 10 | −0.09 | 0.02 | 11.5 | 0.5 | −0.4 | 1.3 |

| Control (untreated) | -- | -- | -- | -- | −0.4 | 0.1 | ||

| Statistical significance #### | ||||||||

| Field strength | *** | *** | - | |||||

| Frequency | - | - | - | |||||

| Treatment time | - | *** | + | |||||

| Processing Conditions | Colour # | |||||||

|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | ΔL* (after–before) | Δa* (after–before) | Δb* (after–before) | |||

| (kV/cm) | (Hz) | (ms) | ||||||

| SE | SE | SE | ||||||

| 0.25 | 100 | 50 | 1.9 | 0.8 | −0.4 | 0.8 | 0.4 | 0.4 |

| 0.25 | 20 | 50 | 1.7 | 1.0 | 0.6 | 1.0 | 1.1 | 0.6 |

| 0.25 | 100 | 30 | 1.7 | 0.8 | −0.4 | 0.5 | 0.4 | 0.3 |

| 0.25 | 20 | 30 | 1.4 | 0.4 | 0.1 | 0.3 | 0.3 | 0.2 |

| 0.25 | 100 | 10 | 1.7 | 0.7 | −0.1 | 0.8 | 0.6 | 0.6 |

| 0.25 | 20 | 10 | 1.2 | 0.8 | 0.4 | 0.5 | 0.3 | 0.5 |

| 0.50 | 100 | 50 | 1.6 | 0.4 | −0.2 | 0.5 | 1.2 | 0.6 |

| 0.50 | 20 | 50 | 0.9 | 0.6 | −0.4 | 0.5 | 0.9 | 0.6 |

| 0.50 | 100 | 30 | 2.0 | 0.5 | −0.3 | 0.8 | 1.1 | 0.4 |

| 0.50 | 20 | 30 | 1.3 | 0.9 | 0.3 | 0.7 | 0.9 | 0.4 |

| 0.50 | 100 | 10 | 2.3 | 1.3 | −0.4 | 0.8 | 1.0 | 0.4 |

| 0.50 | 20 | 10 | 1.5 | 0.3 | 0.2 | 0.4 | 1.0 | 0.5 |

| 1.00 | 100 | 50 | n.d. ## | - | n.d. | - | n.d. | - |

| 1.00 | 20 | 50 | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 100 | 30 | 2.5 | 1.1 | −0.6 | 1.1 | 1.4 | 0.6 |

| 1.00 | 20 | 30 | 1.2 | 0.9 | −2.5 | 0.7 | −0.2 | 0.4 |

| 1.00 | 100 | 10 | 0.3 | 3.7 | −1.9 | 0.7 | 0.7 | 0.5 |

| 1.00 | 20 | 10 | 2.5 | 1.2 | −0.7 | 1.1 | 1.3 | 0.5 |

| Control (untreated) ### | 1.4 | 0.7 | 0.3 | 0.9 | 1.2 | 0.7 | ||

| Statistical significance #### | ||||||||

| Field strength | - | *** | + | |||||

| Frequency | - | - | - | |||||

| Treatment time | - | - | - | |||||

| Processing Conditions | Texture Measurements | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | Peak Force (PF) | Initial Yield (IY) | PF-IY | % PF Reduction # | ||||

| (kV/cm) | (Hz) | (ms) | (N) | (N) | (N) | [%] | ||||

| SE | SE | SE | SE | |||||||

| 0.25 | 100 | 50 | 51.2 | 4.6 | 43.7 | 4.7 | 7.5 | 2.6 | −4.2 | 0.4 |

| 0.25 | 20 | 50 | 45.7 | 4.4 | 35.7 | 5.3 | 10.0 | 3.6 | 6.9 | 0.7 |

| 0.25 | 100 | 30 | 54.5 | 5.6 | 49.6 | 5.5 | 4.9 | 2.9 | −11.0 | 1.1 |

| 0.25 | 20 | 30 | 45.5 | 5.7 | 35.6 | 5.6 | 9.9 | 2.7 | 7.3 | 0.9 |

| 0.25 | 100 | 10 | 50.6 | 4.8 | 45.6 | 5.1 | 5.0 | 2.2 | −3.1 | 0.3 |

| 0.25 | 20 | 10 | 50.7 | 5.0 | 41.6 | 6.0 | 9.1 | 2.5 | −3.2 | 0.3 |

| 0.50 | 100 | 50 | 56.1 | 4.9 | 43.7 | 6.3 | 12.4 | 3.3 | −14.3 | 1.3 |

| 0.50 | 20 | 50 | 45.7 | 4.6 | 36.4 | 5.1 | 9.4 | 2.4 | 6.8 | 0.7 |

| 0.50 | 100 | 30 | 55.6 | 5.1 | 47.9 | 4.7 | 7.7 | 2.9 | −13.3 | 1.2 |

| 0.50 | 20 | 30 | 48.2 | 5.5 | 38.3 | 7.0 | 9.9 | 2.8 | 1.9 | 0.2 |

| 0.50 | 100 | 10 | 52.9 | 4.3 | 43.8 | 4.9 | 9.1 | 3.1 | −7.7 | 0.6 |

| 0.50 | 20 | 10 | 50.7 | 4.8 | 37.2 | 4.8 | 13.5 | 2.9 | −3.4 | 0.3 |

| 1.00 | 100 | 50 | n.d. ## | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 20 | 50 | n.d. ## | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 100 | 30 | 55.5 | 5.2 | 48.9 | 5.6 | 6.5 | 2.3 | −13.0 | 1.2 |

| 1.00 | 20 | 30 | 50.9 | 5.5 | 41.2 | 5.7 | 9.7 | 2.9 | −3.7 | 0.4 |

| 1.00 | 100 | 10 | 51.6 | 5.6 | 41.7 | 6.2 | 9.9 | 2.5 | −5.0 | 0.6 |

| 1.00 | 20 | 10 | 56.5 | 3.8 | 47.8 | 5.1 | 8.7 | 2.9 | −15.2 | 1.0 |

| Control (untreated) | 49.1 | 3.8 | 41.3 | 4.8 | 7.8 | 2.1 | 0.0 | 0.0 | ||

| Statistical significance ### | ||||||||||

| Field strength | *** | + | *** | |||||||

| Frequency | *** | *** | *** | |||||||

| Treatment time | - | - | * | |||||||

| Processing Conditions | Texture Measurements | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | Peak Force (PF) | Initial Yield (IY) | PF-IY | % PF Reduction # | ||||

| (kV/cm) | (Hz) | (ms) | (N) | (N) | (N) | [%] | ||||

| SE | SE | SE | SE | |||||||

| 0.25 | 100 | 50 | 45.7 | 4.5 | 32.4 | 4.2 | 13.3 | 4.0 | 9.6 | 0.9 |

| 0.25 | 20 | 50 | 51.1 | 4.1 | 39.6 | 3.5 | 11.5 | 3.2 | −1.1 | −0.1 |

| 0.25 | 100 | 30 | 53.3 | 2.4 | 41.1 | 3.5 | 12.2 | 3.2 | −5.4 | −0.2 |

| 0.25 | 20 | 30 | 47.7 | 2.8 | 33.9 | 3.6 | 13.7 | 3.6 | 5.8 | 0.3 |

| 0.25 | 100 | 10 | 46.3 | 3.1 | 34.3 | 2.7 | 11.9 | 3.4 | 8.5 | 0.6 |

| 0.25 | 20 | 10 | 45.8 | 3.5 | 32.1 | 3.7 | 13.7 | 2.4 | 9.5 | 0.7 |

| 0.50 | 100 | 50 | 46.2 | 4.6 | 33.7 | 4.8 | 12.6 | 2.8 | 8.6 | 0.9 |

| 0.50 | 20 | 50 | 47.4 | 4.2 | 36.1 | 5.1 | 11.2 | 3.2 | 6.3 | 0.6 |

| 0.50 | 100 | 30 | 50.5 | 3.2 | 39.0 | 4.4 | 11.4 | 3.0 | 0.2 | 0.0 |

| 0.50 | 20 | 30 | 48.8 | 3.9 | 34.4 | 3.7 | 14.4 | 4.0 | 3.5 | 0.3 |

| 0.50 | 100 | 10 | 48.9 | 5.3 | 35.1 | 4.8 | 13.9 | 3.4 | 3.2 | 0.4 |

| 0.50 | 20 | 10 | 50.9 | 3.0 | 38.8 | 3.7 | 12.1 | 3.0 | −0.6 | 0.0 |

| 1.00 | 100 | 50 | n.d. ## | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 20 | 50 | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 100 | 30 | 50.8 | 3.1 | 35.6 | 3.5 | 15.2 | 4.0 | −0.4 | 0.0 |

| 1.00 | 20 | 30 | 47.6 | 4.2 | 33.9 | 4.9 | 13.7 | 3.2 | 5.9 | 0.5 |

| 1.00 | 100 | 10 | 47.4 | 3.8 | 36.6 | 5.0 | 10.8 | 2.7 | 6.3 | 0.5 |

| 1.00 | 20 | 10 | 50.3 | 6.3 | 36.4 | 5.5 | 13.9 | 2.8 | 0.6 | 0.1 |

| Control (untreated) | 50.6 | 3.9 | 35.8 | 4.2 | 14.8 | 3.5 | 0.0 | 0.0 | ||

| Statistical significance ### | ||||||||||

| Field strength | - | * | - | |||||||

| Frequency | - | - | - | |||||||

| Treatment time | * | - | * | |||||||

| Processing Conditions | Quality Parameters | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | pH | Storage Drip Loss | Cook Loss | L* | a* | b* | ||||||

| (kV/cm) | (Hz) | (ms) | (%) | (%) | ||||||||||

| SE | SE | SE | SE | SE | SE | |||||||||

| 0.25 | 100 | 50 | 5.48 | 0.03 | 4.0 | 0.6 | 29.2 | 1.0 | 35.5 | 1.2 | 18.6 | 0.4 | 4.4 | 0.7 |

| 0.25 | 20 | 50 | 5.46 | 0.02 | 3.6 | 3.1 | 30.9 | 2.7 | 34.1 | 0.6 | 18.7 | 0.4 | 3.6 | 0.4 |

| 0.25 | 100 | 30 | 5.50 | 0.03 | 3.6 | 0.5 | 29.7 | 1.7 | 36.7 | 0.9 | 20.1 | 0.3 | 5.9 | 0.6 |

| 0.25 | 20 | 30 | 5.44 | 0.01 | 3.6 | 0.9 | 27.6 | 1.4 | 34.5 | 1.2 | 18.7 | 0.4 | 4.0 | 0.7 |

| 0.25 | 100 | 10 | 5.47 | 0.01 | 3.7 | 0.5 | 31.8 | 1.4 | 35.1 | 0.8 | 18.7 | 0.5 | 4.4 | 0.9 |

| 0.25 | 20 | 10 | 5.47 | 0.02 | 5.0 | 2.8 | 29.8 | 1.1 | 35.7 | 1.1 | 19.3 | 0.5 | 4.9 | 0.3 |

| 0.50 | 100 | 50 | 5.51 | 0.04 | 3.1 | 0.4 | 31.1 | 2.0 | 36.3 | 1.3 | 17.5 | 1.0 | 4.5 | 1.0 |

| 0.50 | 20 | 50 | 5.49 | 0.03 | 3.1 | 0.4 | 28.2 | 2.2 | 35.7 | 1.1 | 18.8 | 0.9 | 4.4 | 1.0 |

| 0.50 | 100 | 30 | 5.52 | 0.02 | 2.7 | 0.4 | 29.5 | 1.4 | 35.8 | 0.8 | 17.9 | 1.1 | 4.8 | 0.5 |

| 0.50 | 20 | 30 | 5.45 | 0.02 | 3.6 | 0.5 | 29.4 | 1.3 | 36.4 | 0.8 | 19.1 | 0.5 | 4.9 | 0.8 |

| 0.50 | 100 | 10 | 5.50 | 0.03 | 3.5 | 0.5 | 30.3 | 1.3 | 36.2 | 0.8 | 18.2 | 0.8 | 5.0 | 0.6 |

| 0.50 | 20 | 10 | 5.48 | 0.02 | 2.8 | 0.5 | 30.6 | 1.6 | 30.7 | 3.7 | 18.9 | 0.8 | 5.0 | 1.0 |

| 1.00 | 100 | 50 | n.d. # | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 20 | 50 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 100 | 30 | 5.53 | 0.03 | 4.9 | 0.5 | 29.9 | 1.1 | 36.5 | 0.7 | 20.3 | 0.9 | 5.6 | 0.3 |

| 1.00 | 20 | 30 | 5.53 | 0.01 | 5.0 | 0.3 | 30.8 | 1.3 | 37.2 | 1.2 | 18.4 | 1.2 | 5.4 | 0.8 |

| 1.00 | 100 | 10 | 5.48 | 0.02 | 3.2 | 0.3 | 30.2 | 2.6 | 36.5 | 1.1 | 18.1 | 0.4 | 4.7 | 0.8 |

| 1.00 | 20 | 10 | 5.51 | 0.03 | 3.0 | 0.3 | 30.6 | 1.7 | 37.2 | 0.8 | 18.7 | 0.8 | 5.4 | 0.9 |

| Control (untreated) | 5.49 | 0.02 | 2.7 | 0.3 | 29.1 | 1.2 | 29.1 | 1.2 | 17.7 | 1.0 | 6.6 | 0.5 | ||

| Statistical significance ## | ||||||||||||||

| Field strength | - | - | - | ** | - | - | ||||||||

| Frequency | - | - | - | - | - | - | ||||||||

| Treatment time | - | - | - | - | + | - | ||||||||

| Processing Conditions | Quality Parameters | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Field Strength | Frequency | Treatment Time | pH | Storage Drip Loss | Cook Loss | L* | a* | b* | ||||||

| (kV/cm) | (Hz) | (ms) | (%) | (%) | ||||||||||

| SE | SE | SE | SE | SE | SE | |||||||||

| 0.25 | 100 | 50 | 5.34 | 0.02 | 7.6 | 0.7 | 31.5 | 1.3 | 36.7 | 0.2 | 17.2 | 1.4 | 6.7 | 0.5 |

| 0.25 | 20 | 50 | 5.36 | 0.02 | 8.1 | 0.5 | 31.3 | 1.1 | 37.9 | 1.1 | 16.2 | 0.9 | 6.6 | 0.7 |

| 0.25 | 100 | 30 | 5.34 | 0.03 | 8.1 | 0.7 | 32.2 | 1.1 | 38.7 | 1.0 | 15.7 | 1.2 | 7.2 | 0.7 |

| 0.25 | 20 | 30 | 5.31 | 0.04 | 7.9 | 0.5 | 32.1 | 1.6 | 36.1 | 0.9 | 17.3 | 0.9 | 5.5 | 0.9 |

| 0.25 | 100 | 10 | 5.36 | 0.02 | 8.0 | 0.9 | 32.5 | 0.9 | 38.7 | 1.2 | 16.5 | 1.2 | 6.6 | 1.0 |

| 0.25 | 20 | 10 | 5.32 | 0.04 | 8.1 | 0.5 | 32.3 | 1.0 | 36.4 | 0.6 | 17.4 | 0.8 | 5.9 | 0.8 |

| 0.50 | 100 | 50 | 5.37 | 0.02 | 8.2 | 1.0 | 31.1 | 1.1 | 38.0 | 0.8 | 17.2 | 1.1 | 6.5 | 0.5 |

| 0.50 | 20 | 50 | 5.30 | 0.03 | 7.6 | 0.5 | 31.9 | 1.4 | 37.9 | 1.2 | 18.4 | 1.3 | 6.7 | 0.6 |

| 0.50 | 100 | 30 | 5.40 | 0.02 | 7.5 | 0.9 | 31.7 | 1.7 | 37.3 | 0.3 | 18.3 | 0.4 | 6.1 | 0.2 |

| 0.50 | 20 | 30 | 5.35 | 0.03 | 6.9 | 0.4 | 31.8 | 1.9 | 37.4 | 1.0 | 17.1 | 1.2 | 6.5 | 0.7 |

| 0.50 | 100 | 10 | 5.35 | 0.02 | 8.1 | 0.9 | 32.2 | 1.2 | 37.3 | 0.8 | 17.3 | 0.9 | 6.1 | 0.6 |

| 0.50 | 20 | 10 | 5.33 | 0.02 | 8.7 | 0.7 | 31.5 | 0.6 | 38.6 | 1.0 | 15.5 | 0.9 | 7.1 | 1.1 |

| 1.00 | 100 | 50 | n.d.# | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 20 | 50 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1.00 | 100 | 30 | 5.33 | 0.02 | 10.5 | 1.0 | 30.9 | 1.0 | 36.6 | 0.5 | 17.5 | 0.8 | 5.6 | 0.7 |

| 1.00 | 20 | 30 | 5.35 | 0.03 | 8.4 | 0.3 | 31.8 | 1.3 | 37.2 | 0.7 | 16.6 | 1.0 | 6.4 | 0.6 |

| 1.00 | 100 | 10 | 5.35 | 0.03 | 7.2 | 0.9 | 31.7 | 1.6 | 37.1 | 1.1 | 17.0 | 1.4 | 6.3 | 0.9 |

| 1.00 | 20 | 10 | 5.34 | 0.01 | 8.1 | 0.8 | 31.6 | 1.5 | 38.2 | 1.0 | 15.3 | 1.2 | 6.7 | 1.0 |

| Control (untreated) | 5.36 | 0.01 | 7.2 | 0.5 | 32.6 | 0.8 | 37.1 | 1.0 | 16.6 | 1.0 | 5.7 | 0.8 | ||

| Statistical significance ## | ||||||||||||||

| Field strength | - | - | - | - | - | - | ||||||||

| Frequency | - | - | - | - | - | - | ||||||||

| Treatment time | - | - | - | - | - | - | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolumar, T.; Rohlik, B.-A.; Stark, J.; Sikes, A.; Watkins, P.; Buckow, R. Investigation of Pulsed Electric Field Conditions at Low Field Strength for the Tenderisation of Beef Topside. Foods 2022, 11, 2803. https://doi.org/10.3390/foods11182803

Bolumar T, Rohlik B-A, Stark J, Sikes A, Watkins P, Buckow R. Investigation of Pulsed Electric Field Conditions at Low Field Strength for the Tenderisation of Beef Topside. Foods. 2022; 11(18):2803. https://doi.org/10.3390/foods11182803

Chicago/Turabian StyleBolumar, Tomas, Bo-Anne Rohlik, Janet Stark, Anita Sikes, Peter Watkins, and Roman Buckow. 2022. "Investigation of Pulsed Electric Field Conditions at Low Field Strength for the Tenderisation of Beef Topside" Foods 11, no. 18: 2803. https://doi.org/10.3390/foods11182803

APA StyleBolumar, T., Rohlik, B.-A., Stark, J., Sikes, A., Watkins, P., & Buckow, R. (2022). Investigation of Pulsed Electric Field Conditions at Low Field Strength for the Tenderisation of Beef Topside. Foods, 11(18), 2803. https://doi.org/10.3390/foods11182803