Understanding the Changes in Quality of Semi-Dried Rice Noodles during Storage at Room Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Fermented Rice Flour

2.3. Preparation of Semi-Dried Rice Noodles

2.4. Storage Conditions and Sampling Time of Semi-Dried Rice Noodles

2.5. Determination of Total Plate Count (TPC)

2.6. Determination of Moisture Content and Distribution

2.7. Determination of Cooking Quality

2.7.1. Cooked–Broken Rate Measurements

2.7.2. Cooking Loss Rate and Rehydration Ratio Measurements

2.8. Determination of Color

2.9. Determination of Textural Properties

2.10. Determination of Thermal Properties

2.11. Determination of Crystallinity

2.12. Statistical Analysis

3. Results and Discussion

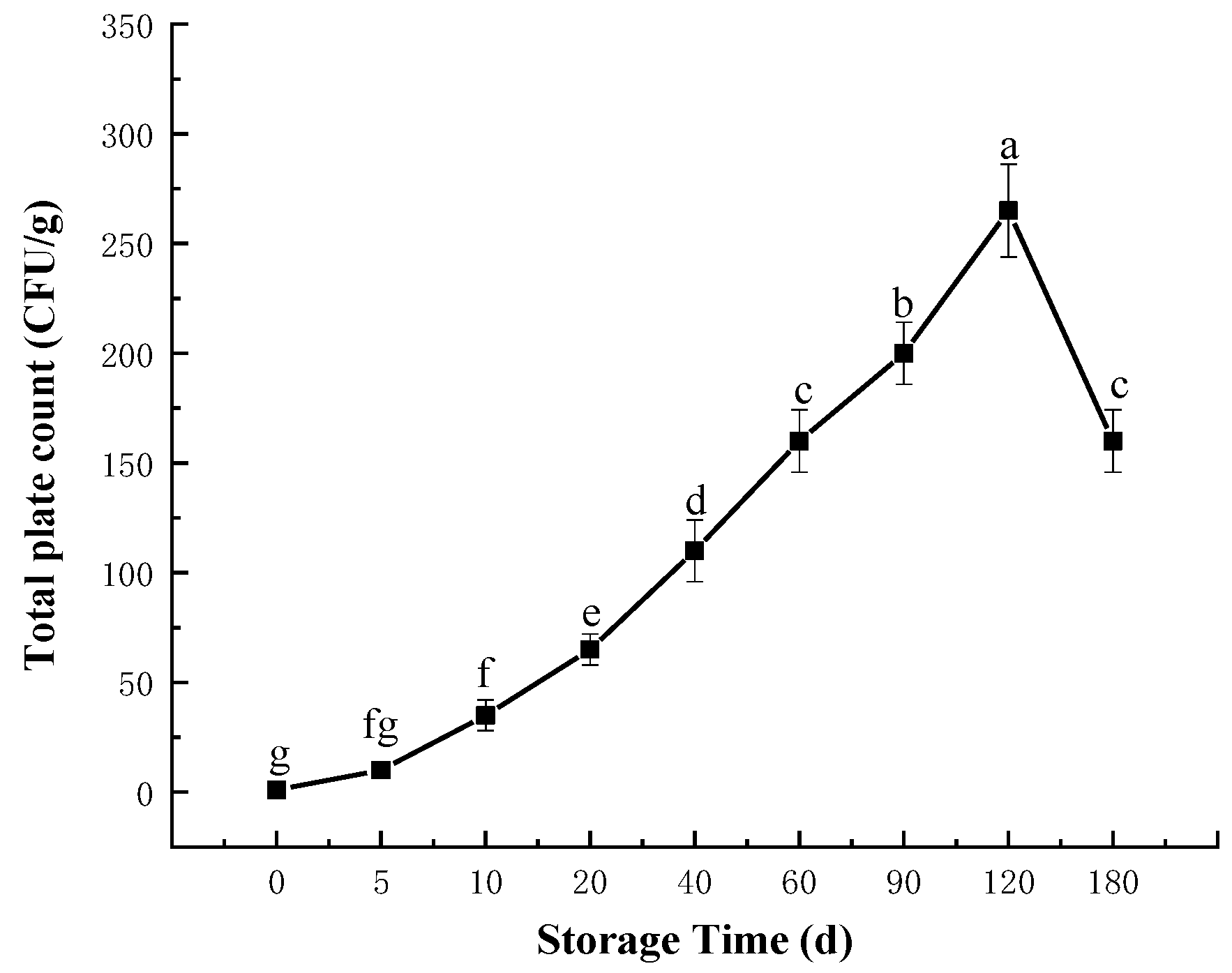

3.1. Changes in Total Plate Count (TPC)

3.2. Changes in Moisture Content and Distribution

3.3. Changes in Cooking Quality

3.4. Changes in Color

3.5. Changes in Textural Properties

3.6. Changes in Thermal Properties

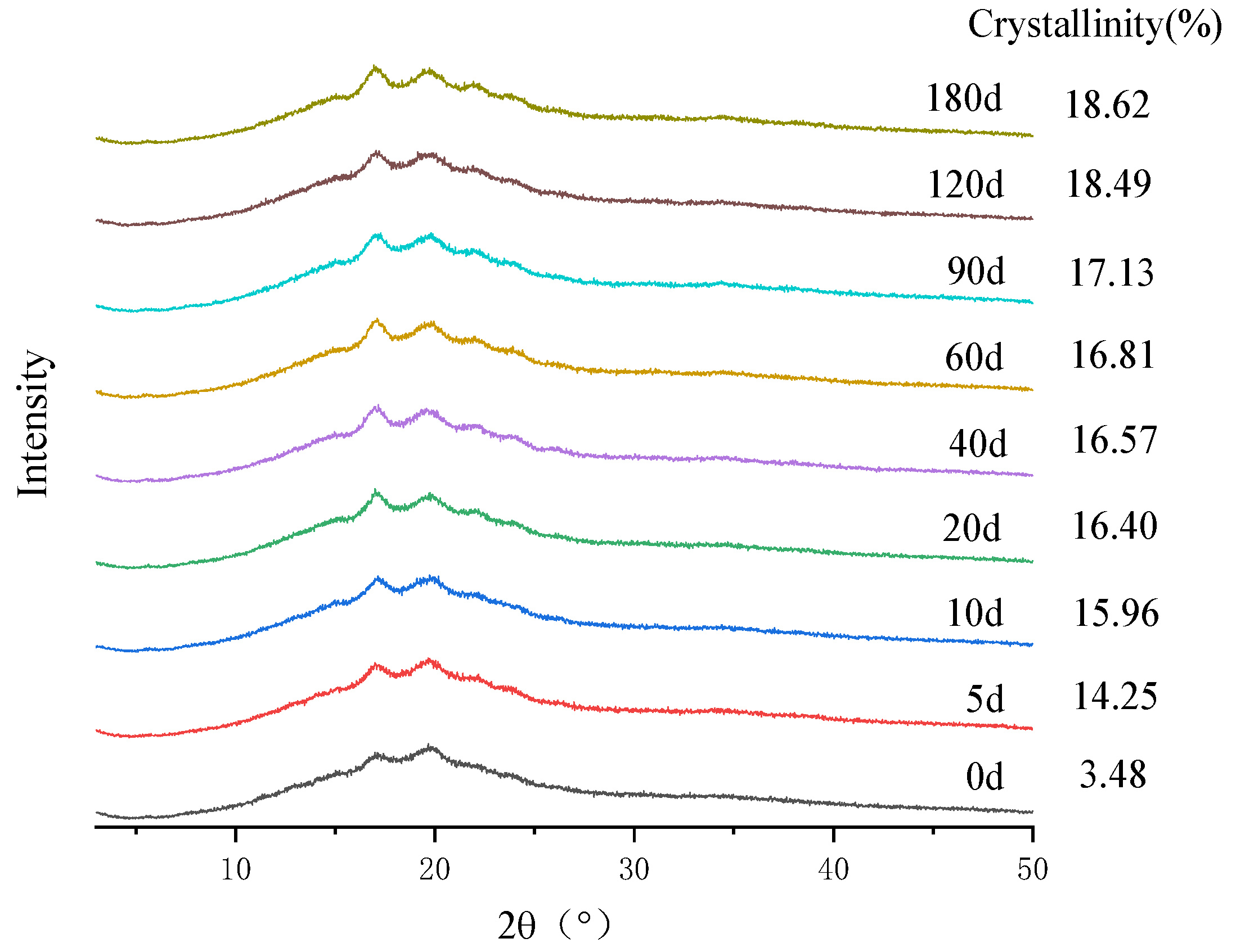

3.7. Changes in Crystallinity

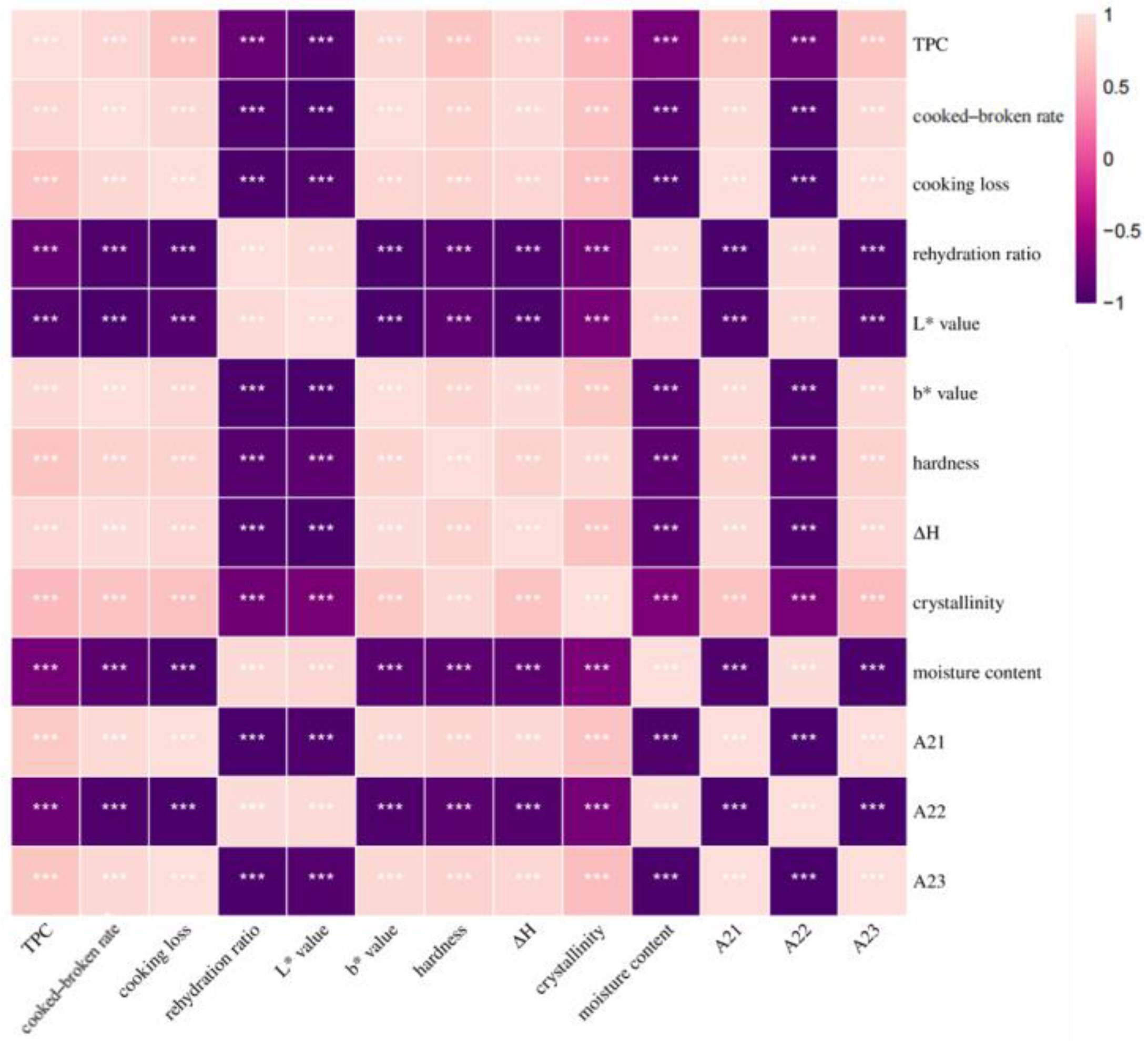

3.8. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fu, M.; Sun, X.; Wu, D.; Meng, L.; Feng, X.; Cheng, W.; Gao, C.; Yang, Y.; Shen, X.; Tang, X. Effect of partial substitution of buckwheat on cooking characteristics, nutritional composition, and in vitro starch digestibility of extruded gluten-free rice noodles. LWT 2020, 126, 109332. [Google Scholar] [CrossRef]

- Kasunmala, I.; Navaratne, S.; Wickramasinghe, I. Effect of process modifications and binding materials on textural properties of rice noodles. Int. J. Gastron. Food Sci. 2020, 21, 100217. [Google Scholar] [CrossRef]

- Li, Y.; Liang, J.; Yang, M.; Chen, J.; Han, B. Traditional Chinese rice noodles: History, classification, and processing methods. Cereal Foods World. 2015, 60, 123–127. [Google Scholar] [CrossRef] [Green Version]

- Diez, A.M.; Santos, E.M.; Jaime, I.; Rovira, J. Effectiveness of combined preservation methods to extend the shelf life of Morcilla de Burgos. Meat Sci. 2009, 81, 171–177. [Google Scholar] [CrossRef]

- Tong, L.-T.; Gao, X.; Lin, L.; Liu, Y.; Zhong, K.; Liu, L.; Zhou, X.; Wang, L.; Zhou, S. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015, 62, 45–49. [Google Scholar] [CrossRef]

- Gacula, M., Jr. The design of experiments for shelf life study. J. Food Sci. 1975, 40, 399–403. [Google Scholar] [CrossRef]

- Tantala, J.; Meethongchai, S.; Suethong, W.; Ratanasumawong, S.; Rachtanapun, C. Mold-free shelf-life extension of fresh rice noodles by synergistic effects of chitosan and common food preservatives. Food Control. 2022, 133, 108597. [Google Scholar] [CrossRef]

- Bai-Ngew, S.; Chuensun, T.; Wangtueai, S.; Phongthai, S.; Jantanasakulwong, K.; Rachtanapun, P.; Sakdatorn, V.; Klunklin, W.; Regenstein, J.M.; Phimolsiripol, Y. Antimicrobial activity of a crude peptide extract from lablab bean (Dolichos lablab) for semi-dried rice noodles shelf-life. Qual. Assur. Saf. Crops Foods 2021, 13, 25–33. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Tangnonthaphat, T. Effects of packaging types and storage temperatures on the shelf life of fresh rice noodles under vacuum conditions. Chiang Mai J. Sci. 2011, 38, 579–589. [Google Scholar]

- Low, Y.K.; Mohd Esah, E.; Cheng, L.H. The impact of glucono delta-lactone (GDL) on rice flour pasting properties and GDL′s dipping effects on the quality of rice noodles. J. Food Process. Preserv. 2021, 45, e14944. [Google Scholar] [CrossRef]

- Shi, F.; Zhao, H.; Song, H.; Guo, W.; Wang, L.; Cui, X.; Zhang, W.; Li, S. Effects of electron-beam irradiation on inoculated Listeria innocua, microbiological and physicochemical quality of fresh noodles during refrigerated storage. Food Sci. Nutr. 2020, 8, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Jin, L.; Xu, X.-H.; Shan, C.-S.; Chen, Z.-G. Long-term storage and temperature induced quality changes of industrial-scale wet starch noodles. LWT 2022, 153, 112504. [Google Scholar] [CrossRef]

- Xue, W.; Zhang, C.; Wang, K.; Guang, M.; Chen, Z.; Lu, H.; Feng, X.; Xu, Z.; Wang, L. Understanding the deterioration of fresh brown rice noodles from the macro and micro perspectives. Food Chem. 2021, 342, 128321. [Google Scholar] [CrossRef] [PubMed]

- GB 4789.2-2016; Food Micro-Biological Examination: Aerobic Plate Count. Code of National Food Safety Standard of China. China National Standards: Shenzhen, China, 2016; p. 6.

- Qiao, C.-C.; Tian, X.-H.; Wang, L.-X.; Jiang, P.; Zhai, X.-T.; Wu, N.-N.; Tan, B. Quality characteristics, texture properties and moisture migration of fresh brown rice noodles under different storage and temperatures conditions. J. Cereal Sci. 2022, 104, 103434. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, Y.; Lv, C.; Wu, W.; Qin, S. Study on optimization of removing cadmium by lactobacillus fermentation and its effect on physicochemical and quality properties of rice noodles. Food Control 2019, 106, 106740. [Google Scholar] [CrossRef]

- Li, M.; Zhu, K.-X.; Sun, Q.-J.; Amza, T.; Guo, X.-N.; Zhou, H.-M. Quality characteristics, structural changes, and storage stability of semi-dried noodles induced by moderate dehydration: Understanding the quality changes in semi-dried noodles. Food Chem. 2016, 194, 797–804. [Google Scholar] [CrossRef]

- Huang, D.-W.; Chan, Y.-J.; Huang, Y.-C.; Chang, Y.-J.; Tsai, J.-C.; Mulio, A.T.; Wu, Z.-R.; Hou, Y.-W.; Lu, W.-C.; Li, P.-H. Quality Evaluation, Storage Stability, and Sensory Characteristics of Wheat Noodles Incorporated with Isomaltodextrin. Plants 2021, 10, 578. [Google Scholar] [CrossRef]

- Xu, L.; Xie, J.; Kong, X.; Bao, J. Analysis of genotypic and environmental effects on rice starch. 2. Thermal and retrogradation properties. J. Agric. Food Chem. 2004, 52, 6017–6022. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, W.; Gao, S.; Xu, M.; Liu, M.; Wang, X.; Zhang, L.; Zong, W. Effects of konjac glucomannan on the long-term retrogradation and shelf life of boiled wheat noodles. J. Sci. Food Agric. 2022, 102, 644–652. [Google Scholar] [CrossRef]

- Verma, A.K.; Pathak, V.; Umaraw, P.; Singh, V. Storage stability of chicken meat incorporated noodles at ambient temperature under aerobic condition. Fleischwirtsch. Int. J. Meat Prod. Meat Process. 2017, 97, 98–104. [Google Scholar]

- Yang, S.; Shan, C.-S.; Xu, Y.-Q.; Jin, L.; Chen, Z.-G. Dissimilarity in sensory attributes, shelf life and spoilage bacterial and fungal microbiota of industrial-scale wet starch noodles induced by different preservatives and temperature. Food Res. Int. 2021, 140, 109980. [Google Scholar] [CrossRef] [PubMed]

- Ntzimani, A.G.; Giatrakou, V.I.; Savvaidis, I.N. Combined natural antimicrobial treatments (EDTA, lysozyme, rosemary and oregano oil) on semi cooked coated chicken meat stored in vacuum packages at 4 C: Microbiological and sensory evaluation. Innov. Food Sci. Emerg. Technol. 2010, 11, 187–196. [Google Scholar] [CrossRef]

- Li, M.; Zhu, K.; Guo, X.; Peng, W.; Zhou, H. Effect of water activity (aw) and irradiation on the shelf-life of fresh noodles. Innov. Food Sci. Emerg. Technol. 2011, 12, 526–530. [Google Scholar] [CrossRef]

- Hu, Z.; Shao, Y.; Lu, L.; Fang, C.; Hu, X.; Zhu, Z. Effect of germination and parboiling treatment on distribution of water molecular, physicochemical profiles and microstructure of rice. J. Food Meas. Charact. 2019, 13, 1898–1906. [Google Scholar] [CrossRef]

- Chen, L.; Tian, Y.; Tong, Q.; Zhang, Z.; Jin, Z. Effect of pullulan on the water distribution, microstructure and textural properties of rice starch gels during cold storage. Food Chem. 2017, 214, 702–709. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Chen, Z.; Wang, X.; Wang, K.; Li, Y.; Wang, R.; Luo, X.; Li, Y.; Li, J. Effect of annealing on the physico-chemical properties of rice starch and the quality of rice noodles. J. Cereal Sci. 2018, 84, 125–131. [Google Scholar] [CrossRef]

- Ma, M.; Han, C.-W.; Li, M.; Song, X.-Q.; Sun, Q.-J.; Zhu, K.-X. Inhibiting effect of low-molecular weight polyols on the physico-chemical and structural deteriorations of gluten protein during storage of fresh noodles. Food Chem. 2019, 287, 11–19. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Wang, R.; Liu, X.; Zhang, Y.; Zhang, H.; Chi, C. Impact of long-term storage on multi-scale structures and physicochemical properties of starch isolated from rice grains. Food Hydrocoll. 2022, 124, 107255. [Google Scholar] [CrossRef]

- Li, M.; Luo, L.-J.; Zhu, K.-X.; Guo, X.-N.; Peng, W.; Zhou, H.-M. Effect of vacuum mixing on the quality characteristics of fresh noodles. J. Food Eng. 2012, 110, 525–531. [Google Scholar] [CrossRef]

- Ding, C.; Khir, R.; Pan, Z.L.; Wood, D.F.; Venkitasamy, C.; Tu, K.; El-Mashad, H.; Berrios, J. Influence of infrared drying on storage characteristics of brown rice. Food Chem. 2018, 264, 149–156. [Google Scholar] [CrossRef]

- Kumar, C.; Raju, P.N.; Singh, A. Effect of packaging materials and storage temperatures on shelf life of micronutrient fortified milk-cereal based complementary food. J. Packag. Technol. Res. 2017, 1, 135–148. [Google Scholar] [CrossRef]

- Li, M.; Sun, Q.-J.; Han, C.-W.; Chen, H.-H.; Tang, W.-T. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms. Food Chem. 2018, 246, 335–342. [Google Scholar] [CrossRef] [PubMed]

- Yi, C.; Zhu, H.; Bao, J.; Quan, K.; Yang, R. The texture of fresh rice noodles as affected by the physicochemical properties and starch fine structure of aged paddy. LWT 2020, 130, 109610. [Google Scholar] [CrossRef]

- Bo, D.L.; Chung, Y.K.; Da, H.K.; Kim, M.R. Storage Characteristics of Sulgidduk with Cashew (Anacardium occidentale) Powder. J. East Asian Soc. Diet. Life. 2020, 30, 443–452. [Google Scholar]

- Satmalee, P.; Charoenrein, S. Acceleration of ageing in rice stick noodle sheets using low temperature. Int. J. Food Sci. Technol. 2009, 44, 1367–1372. [Google Scholar] [CrossRef]

- Li, W.; Guo, H.; Wang, P.; Tian, X.; Zhang, W.; Saleh, A.S.; Zheng, J.; Ouyang, S.; Luo, Q.; Zhang, G. Physicochemical characteristics of high pressure gelatinized mung bean starch during recrystallization. Carbohydr. Polym. 2015, 131, 432–438. [Google Scholar] [CrossRef]

- Li, M.; Ma, M.; Zhu, K.-X.; Guo, X.-N.; Zhou, H.-M. Delineating the physico-chemical, structural, and water characteristic changes during the deterioration of fresh noodles: Understanding the deterioration mechanisms of fresh noodles. Food Chem. 2017, 216, 374–381. [Google Scholar] [CrossRef]

- Yang, H.; Tang, M.; Wu, W.; Ding, W.; Ding, B.; Wang, X. Study on inhibition effects and mechanism of wheat starch retrogradation by polyols. Food Hydrocoll. 2021, 121, 106996. [Google Scholar] [CrossRef]

| Storage Time (d) | Cooked–Broken Rate (%) | Cooking Loss (%) | Rehydration Ratio (%) |

|---|---|---|---|

| 0 | 2.06 ± 0.10 h | 4.14 ± 0.25 g | 59.14 ± 0.52 a |

| 5 | 2.66 ± 0.27 g | 4.84 ± 0.18 f | 57.57 ± 1.11 b |

| 10 | 3.17 ± 0.08 f | 5.60 ± 0.27 e | 55.55 ± 0.20 c |

| 20 | 3.82 ± 0.36 e | 6.24 ± 0.24 de | 54.49 ± 0.22 cd |

| 40 | 5.33 ± 0.22 d | 6.62 ± 0.03 cd | 53.65 ± 0.15 d |

| 60 | 5.93 ± 0.14 c | 6.94 ± 0.14 c | 53.27 ± 0.12 de |

| 90 | 6.23 ± 0.11 c | 7.24 ± 0.09 bc | 52.35 ± 0.44 e |

| 120 | 7.15 ± 0.48 b | 7.83 ± 0.70 b | 50.62 ± 0.99 f |

| 180 | 7.71 ± 0.19 a | 10.43 ± 0.77 a | 47.84 ± 1.32 g |

| Storage Time (d) | Hardness (g) | Adhesiveness (g·s) | Resilience (%) | Cohesion | Springiness (%) | Chewiness (g) |

|---|---|---|---|---|---|---|

| 0 | 2283.93 ± 175.83 f | 23.12 ± 3.16 d | 41.57 ± 1.40 b | 0.76 ± 0.03 a | 93.37 ± 0.38 a | 1629.22 ± 106.28 e |

| 5 | 3643.42 ± 99.11 e | 36.35 ± 2.84 cd | 42.93 ± 3.05 b | 0.68 ± 0.02 ef | 89.68 ± 2.28 bc | 2222.82 ± 149.82 d |

| 10 | 3849.56 ± 29.06 de | 45.94 ± 0.63 bc | 48.41 ± 1.89 a | 0.70 ± 0.01 cd | 91.81 ± 1.52 abc | 2454.84 ± 31.45 cd |

| 20 | 4044.39 ± 37.73 cd | 64.81 ± 5.93 b | 49.06 ± 1.43 a | 0.70 ± 0.02 bcd | 89.23 ± 3.14 bc | 2530.73 ± 51.28 c |

| 40 | 4114.26 ± 86.64 c | 67.20 ± 7.28 b | 42.79 ± 2.25 b | 0.65 ± 0.03 f | 89.14 ± 0.34 c | 2376.20 ± 136.13 cd |

| 60 | 4295.04 ± 108.97 c | 60.24 ± 8.61 b | 52.40 ± 3.27 a | 0.73 ± 0.03 abc | 92.35 ± 0.70 ab | 2888.00 ± 109.72 b |

| 90 | 4226.20 ± 158.19 c | 101.12 ± 27.77 a | 53.48 ± 2.95 a | 0.75 ± 0.03 ab | 90.36 ± 1.93 abc | 2847.52 ± 216.74 b |

| 120 | 4742.12 ± 217.66 b | 53.94 ± 4.41 bc | 48.75 ± 2.48 a | 0.69 ± 0.03 cde | 90.40 ± 0.75 abc | 2961.39 ± 208.18 ab |

| 180 | 5179.45 ± 115.05 a | 90.72 ± 6.63 a | 48.43 ± 3.45 a | 0.68 ± 0.02 ef | 92.03 ± 1.22 abc | 3218.39 ± 109.60 a |

| Storage Time (d) | To (°C) | Tp (°C) | Tc (°C) | ∆H (J/g) |

|---|---|---|---|---|

| 0 | 49.87 ± 0.33 f | 58.47 ± 0.53 g | 66.62 ± 0.70 e | 1.67 ± 0.26 g |

| 5 | 50.93 ± 0.64 e | 60.54 ± 0.57 f | 67.33 ± 0.19 d | 1.77 ± 0.27 g |

| 10 | 50.72 ± 0.32 e | 61.34 ± 0.17 e | 69.05 ± 0.37 c | 2.41 ± 0.13 f |

| 20 | 51.90 ± 0.17 d | 61.62 ± 0.06 de | 69.59 ± 0.10 bc | 2.74 ± 0.11 e |

| 40 | 52.47 ± 0.06 cd | 62.05 ± 0.07 cd | 70.02 ± 0.37 b | 3.02 ± 0.03 d |

| 60 | 52.80 ± 0.08 bc | 62.44 ± 0.03 c | 71.08 ± 0.19 a | 3.41 ± 0.03 c |

| 90 | 53.09 ± 0.13 bc | 62.57 ± 0.21 bc | 71.30 ± 0.33 a | 3.71 ± 0.07 b |

| 120 | 53.13 ± 0.19 b | 63.00 ± 0.16 ab | 71.06 ± 0.37 a | 4.04 ± 0.04 a |

| 180 | 53.83 ± 0.59 a | 63.33 ± 0.20 a | 71.26 ± 0.45 a | 4.21 ± 0.03 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, W.; Ding, Y.; Cheng, Y.; Xu, S.; Lin, L. Understanding the Changes in Quality of Semi-Dried Rice Noodles during Storage at Room Temperature. Foods 2022, 11, 2130. https://doi.org/10.3390/foods11142130

Xiao W, Ding Y, Cheng Y, Xu S, Lin L. Understanding the Changes in Quality of Semi-Dried Rice Noodles during Storage at Room Temperature. Foods. 2022; 11(14):2130. https://doi.org/10.3390/foods11142130

Chicago/Turabian StyleXiao, Wen, Yuqin Ding, Ying Cheng, Sili Xu, and Lizhong Lin. 2022. "Understanding the Changes in Quality of Semi-Dried Rice Noodles during Storage at Room Temperature" Foods 11, no. 14: 2130. https://doi.org/10.3390/foods11142130

APA StyleXiao, W., Ding, Y., Cheng, Y., Xu, S., & Lin, L. (2022). Understanding the Changes in Quality of Semi-Dried Rice Noodles during Storage at Room Temperature. Foods, 11(14), 2130. https://doi.org/10.3390/foods11142130