Rheological Properties, Particle Size Distribution and Physical Stability of Novel Refined Pumpkin Seed Oil Creams with Oleogel and Lucuma Powder

Abstract

:1. Introduction

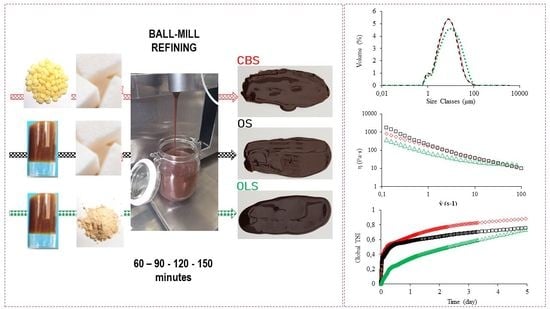

2. Materials and Methods

2.1. Materials

Cream Preparation

2.2. Granulometric Measurement

2.3. Rheological Measurement

2.4. Oil Binding Capacity, Water Activity and Colour

2.5. Turbiscan Stability

2.6. Data Analysis

3. Results

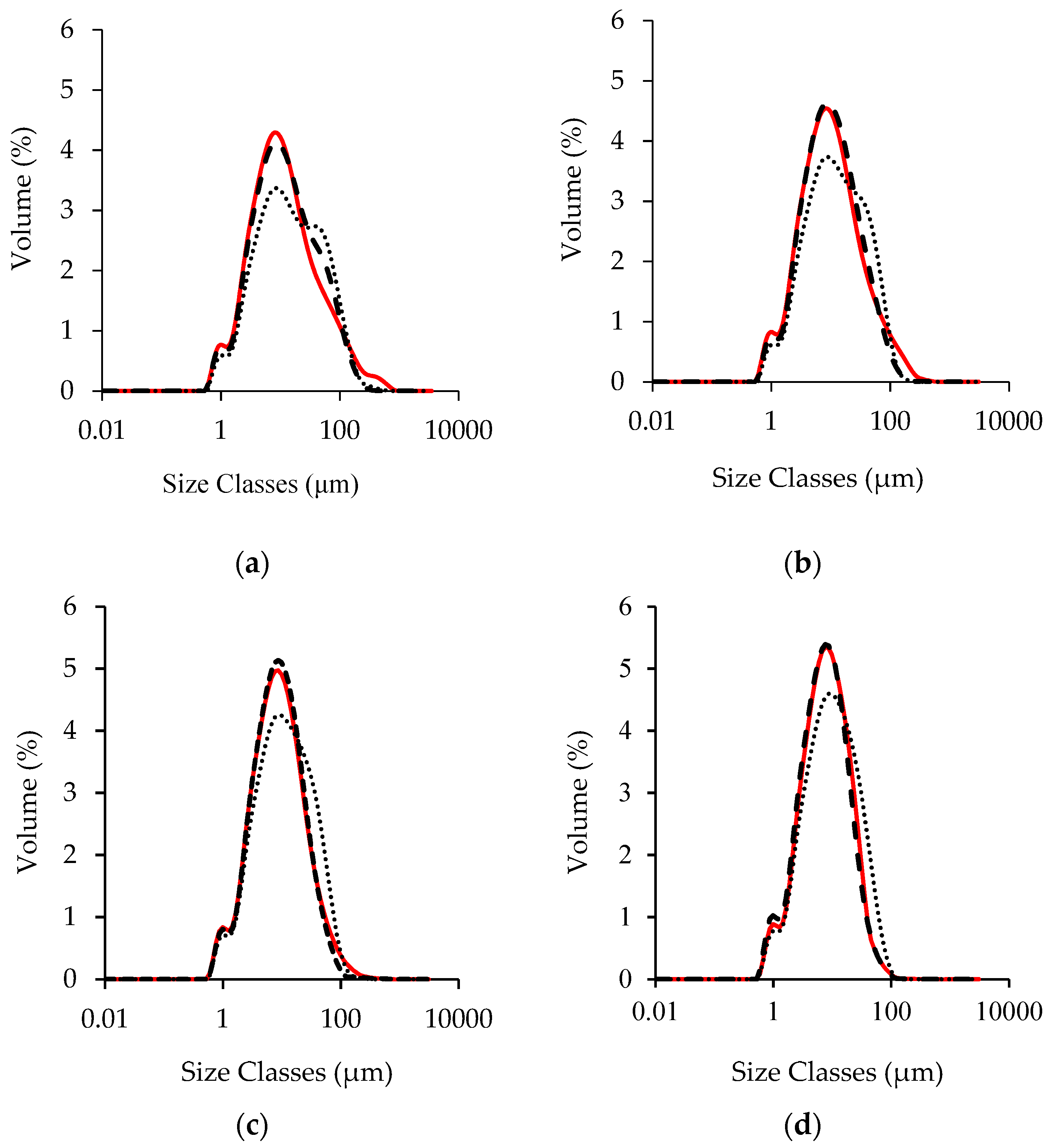

3.1. Particle Size Distribution

3.2. Rheological Properties

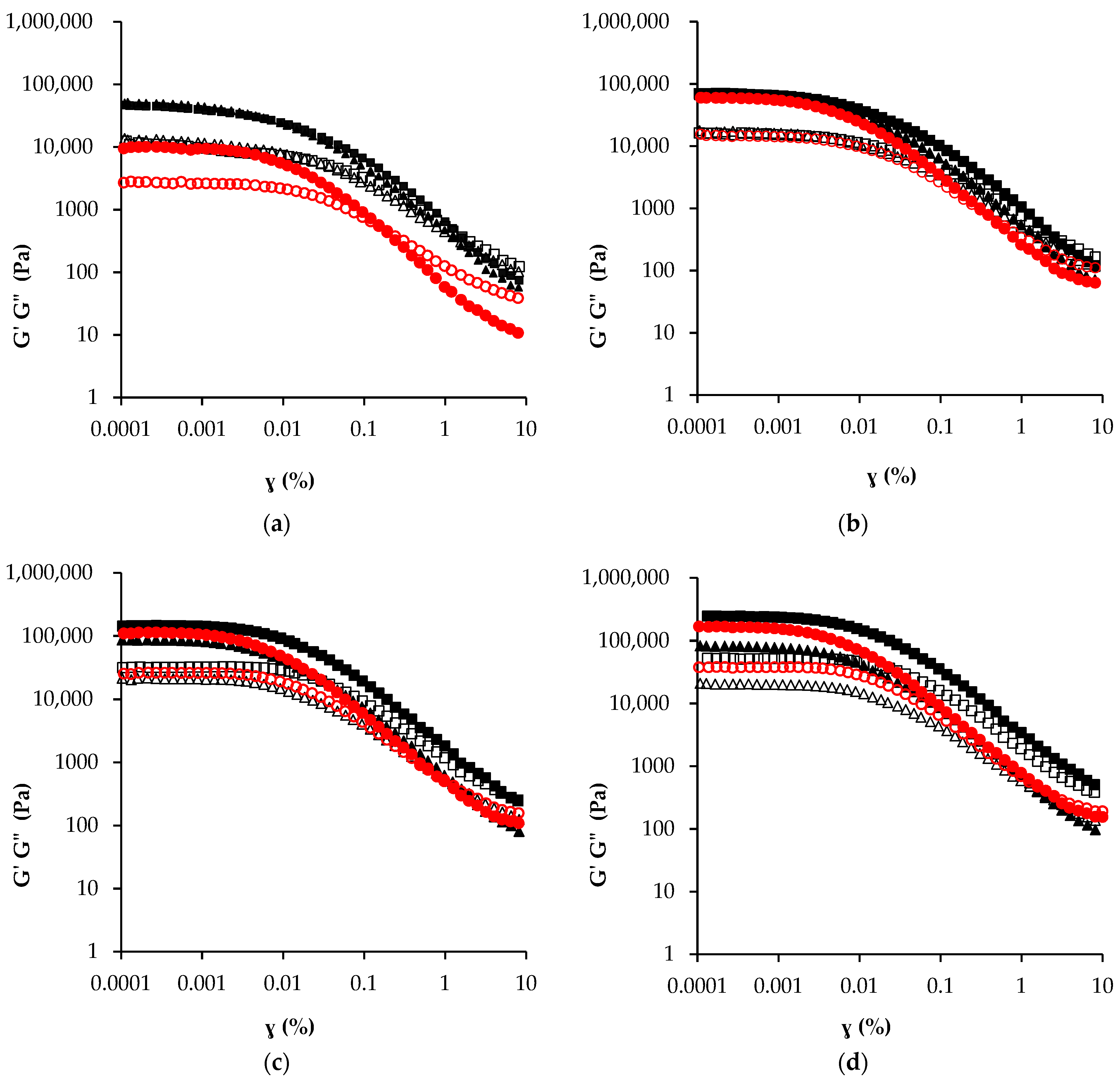

3.2.1. Dynamic Rheological Measurements

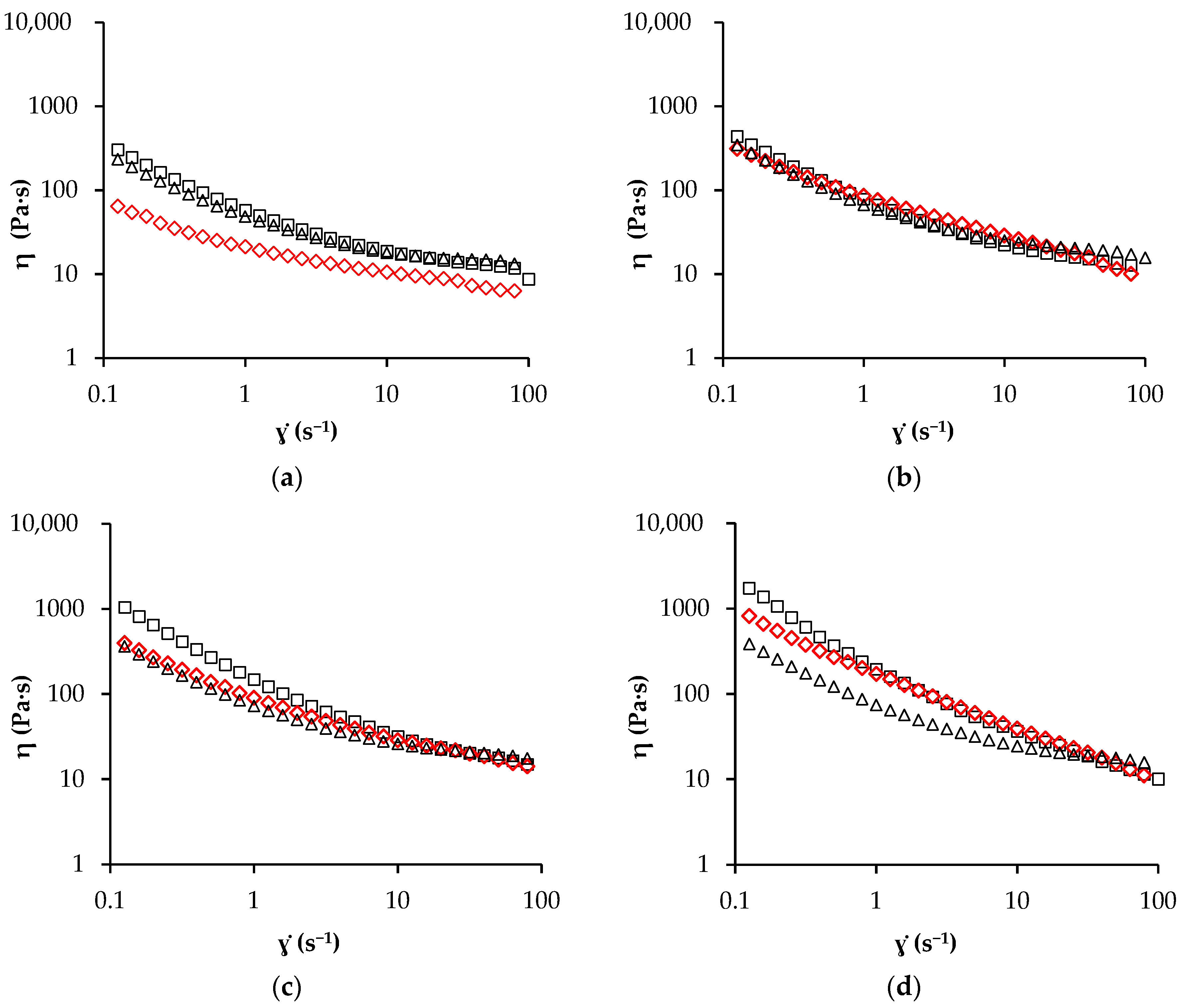

3.2.2. Steady Shear Measurement

3.3. Oil Binding Capacity, Water Activity and Colour

3.4. Turbiscan Stability Index

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Micha, R.; Mozaffarian, D. Saturated fat and cardiometabolic risk factors, coronary heart disease, stroke, and diabetes: A fresh look at the evidence. Lipids 2010, 45, 893–905. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.Y.; Lim, J.; Lee, J.; Hwang, H.S.; Lee, S. Utilization of oleogels as a replacement for solid fat in aerated baked goods: Physicochemical, rheological, and tomographic characterization. J. Food Sci. 2017, 82, 445–452. [Google Scholar] [CrossRef] [PubMed]

- Borriello, A.; Masi, P.; Cavella, S. Novel pumpkin seed oil-based oleogels: Development and physical characterization. LWT-Food Sci. Technol. 2021, 152, 112165. [Google Scholar] [CrossRef]

- Tallima, H.; El Ridi, R. Arachidonic acid: Physiological roles and potential health benefits—A review. J. Adv. Res. 2018, 11, 33–41. [Google Scholar] [CrossRef]

- Borriello, A.; Miele, N.A.; Masi, P.; Aiello, A.; Cavella, S. Effect of fatty acid composition of vegetable oils on crystallization and gelation kinetics of oleogels based on natural wax. Food Chem. 2022, 375, 131805. [Google Scholar] [CrossRef]

- Patel, A.I.; Moghadam, S.D.; Freedman, M.; Hazari, A.; Fang, M.L.; Allen, I.E. The association of flavored milk consumption with milk and energy intake, and obesity: A systematic review. Prev. Med. 2018, 111, 151–162. [Google Scholar] [CrossRef]

- Di Monaco, R.; Miele, N.A.; Cabisidan, E.K.; Cavella, S. Strategies to reduce sugars in food. Curr. Opin. Food Sci. 2018, 19, 92–97. [Google Scholar] [CrossRef]

- Banasiak, K. Formulating with fruit. Food Prod. Des. 2003, 13, 37–56. [Google Scholar]

- Dini, I. Flavonoid glycosides from Pouteria obovata (R. Br.) fruit flour. Food Chem. 2011, 124, 884–888. [Google Scholar] [CrossRef]

- Rojo, L.E.; Villano, C.M.; Joseph, G.; Schmidt, B.; Shulaev, V.; Shuman, J.L.; Raskin, I. Original contribution: Wound healing properties of nut oil from Pouteria lucuma. J. Cosmet. Dermatol. 2010, 9, 185–195. [Google Scholar] [CrossRef] [Green Version]

- Taiti, C.; Colzi, I.; Azzarello, E.; Mancuso, S. Discovering a volatile organic compound fingerprinting of Pouteria lucuma fruits. Fruits 2017, 72, 131–138. [Google Scholar] [CrossRef]

- Durakova, A.; Bogoeva, A.; Yanakieva, V.; Gogova, T.; Dimov, I.; Krasteva, R.; Dosheva, K. Storage studies of subtropical fruit Lucuma in powdered form. Bulg. J. Agric. Sci. 2019, 25, 1287–1292. [Google Scholar]

- Belščak-Cvitanović, A.; Komes, D.; Dujmović, M.; Karlović, S.; Biškić, M.; Brnčić, M.; Ježek, D. Physical, bioactive and sensory quality parameters of reduced sugar chocolates formulated with natural sweeteners as sucrose alternatives. Food Chem. 2015, 167, 61–70. [Google Scholar] [CrossRef] [PubMed]

- Miele, N.A.; Borriello, A.; Fidaleo, M.; Masi, P.; Cavella, S. Modeling grinding kinetics of fat based anhydrous pastes. J. Food Eng. 2020, 268, 109732. [Google Scholar] [CrossRef]

- Macias-Rodriguez, B.A.; Velikov, K.P. Elastic reinforcement and yielding of starch-filled lipid gels. Food Struct. 2022, 32, 100257. [Google Scholar] [CrossRef]

- Fidaleo, M.; Mainardi, S.; Nardi, R. Modeling the refining process of an anhydrous hazelnut and cocoa paste in stirred ball mills. Food Bioprod. Process. 2017, 105, 147–156. [Google Scholar] [CrossRef]

- Fidaleo, M.; Miele, N.A.; Mainardi, S.; Armini, V.; Nardi, R.; Cavella, S. Effect of refining degree on particle size, sensory and rheological characteristics of anhydrous paste for ice creams produced in industrial stirred ball mill. Food Sci. Technol. 2017, 79, 242–250. [Google Scholar] [CrossRef]

- Konar, N.; Bingol, I. Effect of ball-mill process on some quality parameters of chocolate and compound chocolate: A modelling approach. J. Food Process Eng. 2019, 42, e13154. [Google Scholar] [CrossRef]

- Lončarević, I.; Pajin, B.; Petrović Sakac, M.J.; Zarić Rakin, M.; Petrović, J.; Torbica, A. Influence of Rapeseed and Sesame Oil on Crystallization and Rheological Properties of Cocoa Cream Fat Phase and Quality of Final Product. J. Texture Stud. 2016, 57, 224–246. [Google Scholar] [CrossRef]

- Pajin, B.; Zaric, D.; Dokic, L.; Seres, Z.; Simovic, D.S.; Omorjan, R.; Loncarevic, I. Influence of emulsifiers on the optimization of processing parameters of refining milk chocolate in the ball mill. Acta Period. Technol. 2011, 42, 101–110. [Google Scholar] [CrossRef]

- Toker, O.S.; Zorlucan, F.T.; Konar, N.; Daglıoglu, O.; Sagdic, O.; Sener, D. Investigating the effect of production process of ball mill refiner on some physical quality parameters of compound chocolate: Response surface methodology approach. Int. J. Food Sci. 2017, 52, 788–799. [Google Scholar] [CrossRef]

- Cavella, S.; Miele, N.A.; Fidaleo, M.; Borriello, A.; Masi, P. Evolution of particle size distribution, flow behaviour and stability during mill ball refining of a white chocolate flavouring paste. LWT-Food Sci. Technol. 2020, 132, 109910. [Google Scholar] [CrossRef]

- Armini, V.; Miele, N.A.; Albero, M.; Sacchi, R.; Cavella, S. Formula optimization approach for an alternative ready-to-use therapeutic food. LWT-Food Sci. Technol. 2018, 98, 148–153. [Google Scholar] [CrossRef]

- Zhao, W.; Zihao, W.; Xue, C. Recent advances on food-grade oleogels: Fabrication, application and research trends. Crit. Rev. Food Sci. Nutr. 2021. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, G. Corn oil-based oleogels with different gelation mechanisms as novel cocoa butter alternatives in dark chocolate. J. Food Eng. 2019, 263, 114–122. [Google Scholar] [CrossRef]

- Sun, P.; Xia, B.; Ni, Z.; Wang, Y.; Elam, E.; Thakur, K.; Ma, Y.; Wei, Z. Characterization of functional chocolate formulated using oleogels derived from β-sitosterol with γ-oryzanol/lecithin/stearic acid. Food Chem. 2021, 360, 130017. [Google Scholar] [CrossRef] [PubMed]

- Bascuas, S.; Espert, M.; Llorca, E.; Quiles, A.; Salvador, A.; Hernando, I. Structural and sensory studies on chocolate spreads with hydrocolloid-based oleogels as a fat alternative. LWT-Food Sci. Technol. 2021, 135, 110228. [Google Scholar] [CrossRef]

- Doan, C.D.; Patel, A.R.; Tavernier, I.; De Clercq, N.; Van Raemdonck, K. The feasibility of wax-based oleogel as a potential co-structurant with palm oil in low-saturated fat confectionery fillings. Eur. J. Lipid Sci. Technol. 2016, 118, 1903–1914. [Google Scholar] [CrossRef]

- Fayaz, G.; Goli, S.A.H.; Kadivar, M.; Valoppi, F.; Barba, L.; Calligaris, S.; Nicoli, M.C. Potential application of pomegranate seed oil oleogels based on monoglycerides, beeswax and propolis wax as partial substitutes of palm oil in functional chocolate spread. LWT-Food Sci. Technol. 2017, 86, 523–529. [Google Scholar] [CrossRef]

- Dinkgreve, M.; Paredes, J.; Denn, M.M.; Bonn, D. On different ways of measuring “the” yield stress. J. Non-Newton. Fluid Mech. 2016, 238, 233–241. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Processing Engineering, 2nd ed.; Freeman Press: East Lansing, MI, USA, 1996; pp. 1–91. [Google Scholar]

- Li, Q.; Li, K.; Ni, W.; Li, D.; Chen, W. The effect of grinding time on the performance of gold tailings aerated concrete. Chem. Eng. Trans. 2017, 59, 349–354. [Google Scholar]

- Glicerina, V.; Balestra, F.; Pinnavaia, G.G.; Dalla Rosa, M.; Romani, S. Rheological characteristics of nut creams realized with different types and amounts of fats. J. Food Qual. 2013, 36, 342–350. [Google Scholar] [CrossRef]

- Doan, C.D.; Van De Walle, D.; Dewettinck, K.; Patel, A.R. Evaluating the oil-gelling properties of natural waxes in rice bran oil: Rheological, thermal, and microstructural study. J. Am. Oil Chem. Soc. 2015, 92, 801–811. [Google Scholar] [CrossRef]

- Wright, A.J.; Scanlon, M.G.; Hartel, R.W.; Marangoni, A.G. Rheological properties of milkfat and butter. J. Food Sci. 2001, 66, 1056–1069. [Google Scholar] [CrossRef]

- Palla, C.A.; Wasinger, M.F.; Carrín, M.E. Monoglyceride oleogels as fat replacers in filling creams for sandwich cookies. J. Sci. Food Agric. 2021, 101, 2398–2405. [Google Scholar] [CrossRef]

- Larsson, R.G. The Structure and Rheology of Complex Fluids, 1st ed.; Oxford University Press: New York, NY, USA, 1999; pp. 261–323. [Google Scholar]

- Coussot, P.; Ancey, C. Rheophysical Classification of Concentrated Suspensions and Granular Pastes. Phys. Rev. 1999, 59, 4445. [Google Scholar] [CrossRef]

- Babin, H.; Dickinson, E.; Chisholm, H.; Beckett, S. Interactions in dispersions of sugar particles in food oils: Influence of emulsifier. Food Hydrocoll. 2005, 19, 513–520. [Google Scholar] [CrossRef]

- Beckett, S.T. Chocolate Flow Properties. In Industrial Chocolate Manufacture and Use, 4th ed.; Beckett, S.T., Ed.; Blackwell Publishing Ltd.: West Sussex, UK, 2009; Volume 10, pp. 224–245. [Google Scholar]

- Miele, N.A.; Armini, V.; Troccoli, A.M.; Puleo, S.; Paduano, A.; Sacchi, R.; Cavella, S. Sensory evaluation and volatile compounds of an alternative ready-to-use therapeutic food for malnourished children. J. Food Sci. 2020, 85, 1265–1273. [Google Scholar] [CrossRef]

- Patel, A.R.; Rajarethinem, P.S.; Gredowska, A.; Turhan, O.; Lesaffer, A.; De Vos, W.H.; Van de Walle, D.; Dewettinck, K. Edible applications of shellac oleogels: Spreads, chocolate paste and cakes. Food Funct. 2014, 5, 645–652. [Google Scholar] [CrossRef]

- Afoakwa, E.; Paterson, A.; Fowler, M. Effects of particle size distribution and composition on rheological properties of dark chocolate. Eur. Food Res. Technol. 2008, 226, 1259–1268. [Google Scholar] [CrossRef]

- Aydemir, O. Utilization of different oils and fats in cocoa hazelnut cream production. J. Food Process. Preserv. 2019, 43, e13930. [Google Scholar] [CrossRef]

- Taylor, J.E.; Van Damme, I.; Johns, M.L.; Routh, A.F.; Wilson, D.I. Shear rheology of molten crumb chocolate. J. Food Sci. 2009, 74, E55–E61. [Google Scholar] [CrossRef] [PubMed]

), OS (

), OS (  ) and OLS (

) and OLS (  ), at different refining times 60 (a), 90 (b), 120 (c) and 150 (d) min.

), at different refining times 60 (a), 90 (b), 120 (c) and 150 (d) min.

), OS (

), OS (  ) and OLS (

) and OLS (  ), at different refining times 60 (a), 90 (b), 120 (c) and 150 (d) min.

), at different refining times 60 (a), 90 (b), 120 (c) and 150 (d) min.

) as a function of refining times.

) as a function of refining times.

| Lucuma Powder | |

|---|---|

| Protein | 5 g |

| Lipids | 4 g |

| Carbohydrates | 25 g |

| Fibers | 3.6 g |

| Calcium | 92 mg |

| Phosphorus | 186 mg |

| Iron | 4.6 mg |

| Vitamin C | 11.6 mg |

| Riboflavin | 0.3 mg |

| Thiamine | 0.2 mg |

| Ingredients | Formulations | ||

|---|---|---|---|

| CBS | OS | OLS | |

| Hazelnut | 45 | 45 | 45 |

| Cocoa powder | 4.9 | 4.9 | 4.9 |

| Saccharose | 32 | 32 | 16 |

| Lucuma powder | - | - | 16 |

| Cocoa butter | 10 | - | - |

| Pumpkin seed oil | 8 | 8 | 8 |

| Oleogel OPCW6 | - | 10 | 10 |

| Salt | 0.1 | 0.1 | 0.1 |

| Sample | Refining Time (min) | γ0 (%) | σ* (Pa) | a (Pa·s b) | b | R2 |

|---|---|---|---|---|---|---|

| CBS | 60 | 0.002 ± 0.00 a | 1.16 ± 0.00 a | 15,547 ± 1332 a | 0.197 ± 0.00 b | 0.98 |

| 90 | 0.001 ± 0.00 a | 4.29 ± 0.27 b | 20,241 ± 1004 b | 0.192 ± 0.00 b | 0.97 | |

| 120 | 0.001 ± 0.00 a | 6.76 ± 0.30 c | 22,236 ± 968 b | 0.188 ± 0.00 b | 0.98 | |

| 150 | 0.006 ± 0.00 b | 11.76 ± 0.01 d | 36,448 ± 1452 c | 0.115 ± 0.01 a | 0.96 | |

| OS | 60 | 0.002 ± 0.00 a | 8.12 ± 0.50 a | 39,616 ± 4146 a | 0.175 ± 0.05 c | 0.98 |

| 90 | 0.002 ± 0.00 a | 12.33 ± 0.48 b | 62,057 ± 4257 b | 0.152 ± 0.05 b | 0.97 | |

| 120 | 0.003 ± 0.00 b | 23.11 ± 0.14 c | 141,118 ± 2375 c | 0.149 ± 0.02 b | 0.92 | |

| 150 | 0.005 ± 0.00 c | 51.33 ± 0.05 d | 219,261 ± 5425 d | 0.131 ± 0.01 a | 0.97 | |

| OLS | 60 | 0.001 ± 0.00 a | 6.46 ± 0.09 a | 38,751 ± 753 a | 0.204 ± 0.02 d | 0.98 |

| 90 | 0.002 ± 0.00 b | 7.31 ± 0.00 b | 53,519 ± 875 b | 0.193 ± 0.01 c | 0.97 | |

| 120 | 0.001 ± 0.00 a | 8.19 ± 0.00 c | 72,452 ± 1008 c | 0.177 ± 0.02 b | 0.97 | |

| 150 | 0.002 ± 0.00 b | 9.18 ± 0.00 d | 73,870 ± 2265 c | 0.169 ± 0.00 a | 0.97 |

| Sample | Refining Time (min) | Casson Parameters | ||

|---|---|---|---|---|

| σ0 (Pa) | η∞ (Pa·s) | R2 | ||

| CBS | 60 | 4.15 ± 0.01 a | 7.85 ± 0.33 a | 0.99 |

| 90 | 25.45 ± 2.33 b | 13.04 ± 2.32 ab | 0.99 | |

| 120 | 37.00 ± 0.00 c | 10.23 ± 0.00 bc | 0.99 | |

| 150 | 76.82 ± 0.07 d | 14.53 ± 0.86 c | 0.99 | |

| OS | 60 | 26.20 ± 3.05 a | 8.36 ± 0.30 b | 0.99 |

| 90 | 37.20 ± 0.00 b | 7.86 ± 0.02 b | 0.99 | |

| 120 | 83.10 ± 0.10 c | 7.72 ± 0.14 b | 0.99 | |

| 150 | 158.66 ± 0.03 d | 4.91 ± 0.82 a | 0.98 | |

| OLS | 60 | 15.40 ± 3.74 a | 7.72 ± 0.15 a | 0.99 |

| 90 | 29.77 ± 0.00 b | 8.86 ± 0.00 b | 0.99 | |

| 120 | 29.95 ± 0.00 b | 9.51 ± 0.00 b | 0.99 | |

| 150 | 32.11 ± 0.00 b | 10.36 ± 0.43 c | 0.99 | |

| Sample | Refining Time (min) | OBC | Aw | L* | a* | b* |

|---|---|---|---|---|---|---|

| CBS | 60 | 86.66 ± 0.77 a | 0.50 ± 0.00 | 23.05 ± 0.11 a | 14.56 ± 0.10 | 10.53 ± 0.10 a |

| 90 | 90.44 ± 0.22 c | 0.49 ± 0.00 | 24.17 ± 0.05 b | 14.81 ± 0.03 | 11.36 ± 0.09 b | |

| 120 | 90.66 ± 0.00 c | 0.50 ± 0.01 | 25.18 ± 0.08 c | 14.71 ± 0.05 | 12.36 ± 0.12 c | |

| 150 | 88.66 ± 0.38 b | 0.48 ± 0.01 | 27.01 ± 0.04 d | 14.38 ± 0.10 | 13.37 ± 0.08 d | |

| OS | 60 | 85.77 ± 1.17 | 0.49 ± 0.02 | 23.24 ± 0.10 a | 14.48 ± 0.14 | 10.31 ± 0.22 a |

| 90 | 85.77 ± 0.44 | 0.51 ± 0.00 | 24.14 ± 0.06 b | 14.51 ± 0.07 | 11.01 ± 0.08 b | |

| 120 | 86.22 ± 1.16 | 0.45 ± 0.01 | 26.09 ± 0.42 c | 13.95 ± 0.22 | 11.50 ± 0.34 b | |

| 150 | 85.77 ± 1.09 | 0.48 ± 0.01 | 26.89 ± 0.14 d | 14.10 ± 0.03 | 12.61 ± 0.03c | |

| OLS | 60 | 86.50 ± 0.95 | 0.44 ± 0.02 | 20.26 ± 0.85 | 14.23 ± 0.07 | 7.63 ± 0.93 |

| 90 | 86.00 ± 1.15 | 0.42 ± 0.00 | 19.74 ± 0.02 | 14.31 ± 0.07 | 6.67 ± 0.11 | |

| 120 | 87.33 ± 0.38 | 0.43 ± 0.00 | 20.66 ± 0.00 | 14.38 ± 0.10 | 7.30 ± 0.05 | |

| 150 | 86.66 ± 0.77 | 0.43 ± 0.00 | 21.10 ± 0.03 | 14.25 ± 0.01 | 8.20 ± 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borriello, A.; Miele, N.A.; Masi, P.; Cavella, S. Rheological Properties, Particle Size Distribution and Physical Stability of Novel Refined Pumpkin Seed Oil Creams with Oleogel and Lucuma Powder. Foods 2022, 11, 1844. https://doi.org/10.3390/foods11131844

Borriello A, Miele NA, Masi P, Cavella S. Rheological Properties, Particle Size Distribution and Physical Stability of Novel Refined Pumpkin Seed Oil Creams with Oleogel and Lucuma Powder. Foods. 2022; 11(13):1844. https://doi.org/10.3390/foods11131844

Chicago/Turabian StyleBorriello, Angela, Nicoletta Antonella Miele, Paolo Masi, and Silvana Cavella. 2022. "Rheological Properties, Particle Size Distribution and Physical Stability of Novel Refined Pumpkin Seed Oil Creams with Oleogel and Lucuma Powder" Foods 11, no. 13: 1844. https://doi.org/10.3390/foods11131844

APA StyleBorriello, A., Miele, N. A., Masi, P., & Cavella, S. (2022). Rheological Properties, Particle Size Distribution and Physical Stability of Novel Refined Pumpkin Seed Oil Creams with Oleogel and Lucuma Powder. Foods, 11(13), 1844. https://doi.org/10.3390/foods11131844