Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods

Abstract

:1. Introduction

1.1. Food Away from Home (FAFH) vs. Food Packaging Technology

1.2. Food, Energy, Environment Trilemma

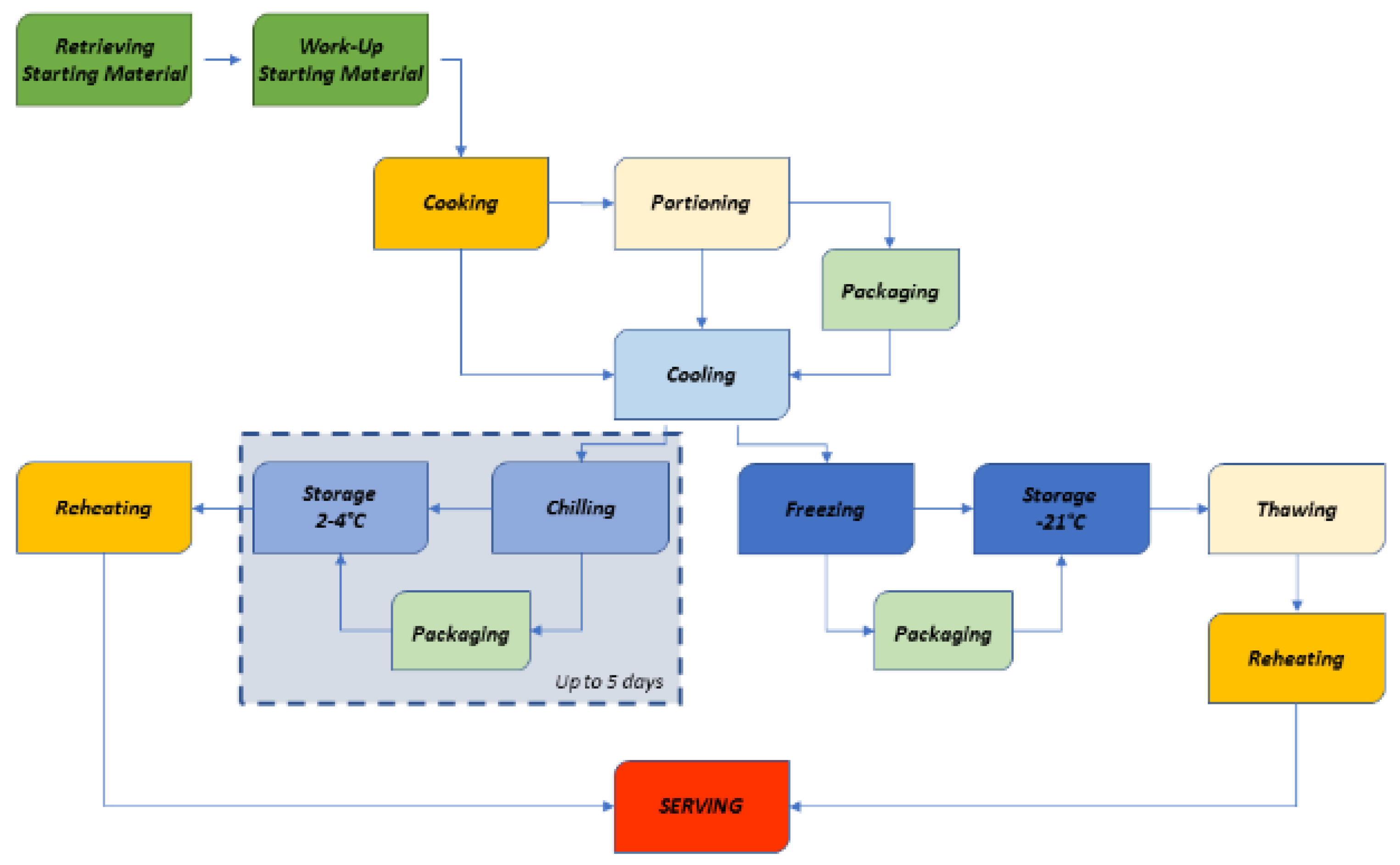

2. The Cook–Chill Technology

2.1. Retrieving and Work-Up of Raw Materials

2.2. Cooking

2.3. Cooling

3. Patent in Cook–Chill Technology

3.1. Cook–Chill Apparatus

3.2. Cooker/Rethermalizer Systems

3.3. Storage

3.4. Procedures

4. The Shelf-Life of Foods

4.1. Shelf-Life Definition

4.2. Law Regulation on Shelf-life

4.3. Methods to Improve Food Shelf-Life

- Sustainable packaging involves environmentally friendly technologies that are socially acceptable and economically advantageous.

- Intelligent packaging involves the use of package integrated devices such as RFID (radio frequencies identification) tags, time or temperature indicators and sensors for tracking activities or sensing the internal or external environment of the package and monitoring the product quality.

- Active packaging utilizes advanced technologies that actively modify the inner atmosphere of the package in order to extend the shelf-life of the stored product.

- Responsive food packaging in which particular materials are able to react against unfavorable stimuli in order to preserve the food quality [73].

5. Food Active Packaging

- Polymers that incorporate organic compounds.

- Polymers that incorporate inorganic compounds.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dai, T.; Yang, Y.; Lee, R.; Fleischer, A.S.; Wemhoff, A.P. Life cycle environmental impacts of food away from home and mitigation strategies—A review. J. Environ. Manag. 2020, 265, 110471. [Google Scholar] [CrossRef] [PubMed]

- Keeble, M.; Adams, J.; Sacks, G.; Vanderlee, L.; White, C.M.; Hammond, D.; Burgoine, T. Use of Online Food Delivery Services to Order Food Prepared Away-From-Home and Associated Sociodemographic Characteristics: A Cross-Sectional, Multi-Country Analysis. Int. J. Environ. Res. Public Health 2020, 17, 5190. [Google Scholar] [CrossRef] [PubMed]

- Manning, P.; Taylor, G.; Hanley, M.E. Bioenergy, Food Production and Biodiversity—An Unlikely alliance? Glob. Chang. Biol. Bioenergy 2014, 7, 570–576. [Google Scholar] [CrossRef]

- Takacs, B.; Borrion, A. The Use of Life Cycle-Based Approaches in the Food Service Sector to Improve Sustainability: A Systematic Review. Sustainability 2020, 12, 3504. [Google Scholar] [CrossRef]

- IEA Report. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 31 October 2020).

- Tilman, D.; Socolow, R.; Foley, J.A.; Hill, J.; Larson, E.; Lynd, L.; Pacala, S.; Reilly, J.; Searchinger, T.; Somerville, C.; et al. Beneficial Biofuels–The Food, Energy, and Environment Trilemma. Science 2009, 325, 270–271. [Google Scholar] [CrossRef] [Green Version]

- Da Rosa, F.S.; Lunkes, R.J.; Spigarelli, F.; Compagnucci, L. Environmental Innovation and the Food, Energy and Water Nexus in the Food Service Industry. Resour. Conserv. Recycl. 2021, 166, 105350–105359. [Google Scholar] [CrossRef]

- Gormley, R.; Tansey, F. Sous Vide and Cook-Chill processing. In Handbook of Food Safety Engineering; Sun, D.V., Ed.; Wiley-Blackwel: Hoboken, NJ, USA, 2011; pp. 468–496. ISBN 978−1−444−33334−3. [Google Scholar] [CrossRef]

- James, C.; Onarinde, B.A.; James, S.J. The Use and Performance of Household Refrigerators: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 160–179. [Google Scholar] [CrossRef] [PubMed]

- Lund, B.; Baird-Parker, A.C.; Baird-Parker, T.C.; Gould, G.W.; Gould, G.W. (Eds.) Microbiological Safety and Quality of Food; Springer Science & Business Media: Berlin, Germany, 2000; Volume 1. [Google Scholar]

- Adams, M.R.; Moss, M.O.; McClure, P. Food Microbiology, 4th ed.; The Royal Society of Chemistry: Cambridge, UK, 2015. [Google Scholar]

- Szymkowiak, A.; Guzik, P.; Kulawik, P.; Zając, M. Attitude-behaviour Dissonance Regarding the Importance of Food Preservation for Customers. Food Qual. Prefer. 2020, 84, 103935–103943. [Google Scholar] [CrossRef]

- Chamchong, M.; Datta, K. Thawing of Foods in a Microwave Oven: I. Effect of Power levels and power cycling. J. Microwave Power 1999, 34, 9–21. [Google Scholar] [CrossRef]

- Vandivabal, R.; Jayas, D.S. Non-uniform Temperature Distribution During Microwave Heating of Food Materials. A Review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Lyashchuk, Y.O.; Novak, A.I.; Kostrova, Y.B.; Shibarshina, O.Y.; Evdokimova, O.V.; Kanina, I.V. The study of persistence of microorganisms and parasites in food products. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 640, p. 062002. [Google Scholar]

- D’SA, E.M.; Harrison, M.A.; Williams, S.E.; Broccoli, M.H. Effectiveness of Two Cooking Systems in Destroying Escherichia coli O157: H7 and Listeria monocytogenes in Ground Beef Patties. J. Food Prot. 2000, 63, 894–899. [Google Scholar] [CrossRef]

- Roh, S.H.; Oh, Y.J.; Lee, S.Y.; Kang, J.H.; Min, S.C. Inactivation of Escherichia coli O157: H7, Salmonella, Listeria monocytogenes, and Tulane virus in Processed Chicken Breast Via Atmospheric In-package Cold Plasma Treatment. LWT-Food Sci. Technol. 2020, 127, 109429. [Google Scholar] [CrossRef]

- Baker, R.C.; Hogarty, S.; Poon, W.; Vadehra, D.V. Survival of Salmonella typhimurium and Staphylococcus aureus in eggs cooked by different methods. Poult. Sci. 1983, 62, 1211–1216. [Google Scholar] [CrossRef]

- Soni, A.; Smith, J.; Thompson, A.; Brightwell, G. Microwave-induced Thermal Sterilization-A Review on History, Technical Progress, Advantages and Challenges as Compared to the Conventional Methods. Trends Food Sci. Technol. 2020, 97, 433–442. [Google Scholar] [CrossRef]

- Rhee, M.S.; Lee, S.Y.; Hillers, V.N.; McCURDY, S.M.; Kang, D.H. Evaluation of Consumer-style Cooking Methods for Reduction of Escherichia coli O157: H7 in Ground Beef. J. Food Prot. 2003, 66, 1030–1034. [Google Scholar] [CrossRef]

- Mattick, K.L.; Bailey, R.A.; Jørgensen, F.; Humphrey, T.J. The Prevalence and Number of Salmonella in Sausages and Their Destruction by Frying, Grilling or Barbecuing. J. Appl. Microbiol. 2002, 93, 541–547. [Google Scholar] [CrossRef]

- Avens, T.S.; Albright, S.N.; Morton, A.S.; Prewitt, B.E.; Kendall, P.A.; Sofos, J.N. Destruction of Microorganisms on Chicken Carcasses by Steam and Boiling Water Immersion. Food Control 2002, 13, 445–450. [Google Scholar] [CrossRef]

- Ayadi, M.A.; Makni, I.; Attia, H. Thermal Diffusivities and Influence of Cooking time on Textural, Microbiological and Sensory Characteristics of Turkey Meat Prepared Products. Food Bioprod. Process. 2009, 87, 327–333. [Google Scholar] [CrossRef]

- James, S.J.; James, C. Chilling and Freezing of Food. In Food Processing: Principles and Application, 2nd ed.; Clark, S., Jung, S., Lamsal, B., Eds.; John Wiley and Sons Ltd.: New York, NY, USA, 2014; pp. 79–105. ISBN 9781118846315. [Google Scholar]

- James, S.J.; James, C. Chilled Foods. A Comprehensive Guide, 3rd ed.; Woodhead Publishing Ltd.: Sawston, UK, 2008; Volume 375. [Google Scholar]

- Redding, G.P.; Yang, A.; Shim, Y.M.; Olantunji, J.; East, A. A Review of the Use and Design of Produce Simulations for Horticultural Forced Air Cooling Studies. J. Food Eng. 2016, 190, 80–93. [Google Scholar] [CrossRef]

- Tassou, S.A.; Gowreesunker, B.L.; Parpas, D.; Raeisi, A. Modelling Cold Food Chain Processing and Display Environments. In Modelling Food Processing Operations; Woodhead Publishing Ltd.: Sawston, UK, 2015; pp. 185–208. ISBN 978−1−78242−284−6. [Google Scholar]

- Mondal, A.; Buchanan, R.L.; Lo, Y.M. Computational Fluid Dynamics Approaches in Quality and Hygienic Production of Semisolid Low-Moisture Foods: A Review of Critical Factors. J. Food Sci. 2014, 79, 1861–1870. [Google Scholar] [CrossRef] [PubMed]

- Bojacà, G.R.; Schrevens, E.; Suay, R. Analysis of Air Temperature Distribution Inside a Cold Store by Means of Geostatistical Methods. Acta Hortic. 2012, 94, 29–37. [Google Scholar] [CrossRef]

- Lemus-Mandaca, R.A.; Vega-Gálvez, A.; Moraga, N.O. Computational Simulating and Developments Applied to Food Thermal Processing. Food Eng. Rev. 2011, 3, 121–135. [Google Scholar] [CrossRef]

- Lamanna, D.; Menz, R.J. Prepared Meal System with Lower Hotplate Having a Plurality of Heating Zones and an Upper Radiant Heating Element and Operated in Accordance with Pre-Programmed Cooking Programs Selected by a User. U.S. Patent 5,708,255, 13 January 1998. [Google Scholar]

- Hensel, K.J.; Li, Z.K. Toast Oven Having at Least Five Heating Elements. U.S. Patent 8,878,106B2, 3 February 2014. [Google Scholar]

- Breunig, M.; Greiner, M. Method of Conducting at Least One Cooking Process. U.S. Patent 20,140,050,826A1, 20 February 2014. [Google Scholar]

- Cocchi, G.; Lazzarini, R.; Zaniboni, G. Machine and Method for Producing and Dispensing Liquid or Semi-Liquid Consumer Food Products. U.S. Patent 20140220194A1, 24 June 2014. [Google Scholar]

- Pardo, R.J. Cook/Chill Tank. U.S. Patent 5,280,748, 24 February 1992. [Google Scholar]

- Kennedy, B.C. Cooker Utilizing a Peltier Device. U.S. Patent 7,174,720, 13 February 2007. [Google Scholar]

- Alexander, C. Heated or Cooled Dishware and Drinkware. U.S. Patent 10,188,229B2, 14 November 2017. [Google Scholar]

- Alexander, C.; Leith, D.J.; Timperi, M.J.; Wakeham, C.T. Portable Cooler Container with Active Temperature Control. U.S. Patent 10,743,708B2, 13 August 2020. [Google Scholar]

- Dreano, C. Cooking Machine. U.S. Patent 5,005,471, 9 April 1991. [Google Scholar]

- Polster, L.S. Cooker/Rethermalizer. U.S. Patent 5,539,185, 23 July 1996. [Google Scholar]

- Storek, D.; Otillar, R.P.; Sequeira, A.L. Liquid Movement and Control within a Container for Food Preparation. U.S. Patent 20,160,206,136A1, 26 April 2016. [Google Scholar]

- Rosalia, J.A.; Chen, H. Modularized Food Preparation Device and Tray Structure for Use Thereof. U.S. Patent 10,674,855B2, 18 June 2015. [Google Scholar]

- Svensson, S.A. Rethermalizer with Expansible Rack. U.S. Patent 5,706,718, 13 January 1998. [Google Scholar]

- Shei, S.M. Food Warming Apparatus and Method. U.S. Patent 7,105,779B2, 17 November 2005. [Google Scholar]

- Veltrop, L.J.; Schroeder, J.; Hartfelder, C.; Guasta, J. Apparatus and Method for Maintaining Cooked Food in a Ready-to-Use Condition. U.S. Patent 8,096,231B2, 28 December 2010. [Google Scholar]

- Menges, J.A.; Bachert, E.E.; Schmidt, G.E. Cook and Chill Casing. U.S. Patent 20,040,253,399A1, 16 December 2004. [Google Scholar]

- Schif, H.J.; Schiffmann, J.M. Multilayer Planar or Tubular Food Casing or Film. A.U. Patent 2,003,245,922B8, 17 March 2009. [Google Scholar]

- Hynes, K.A. Food Container and Method. U.S. Patent 2,0060,034,986A1, 16 February 2006. [Google Scholar]

- Lyzenga, D.A.; Weber, J.T. Easy-Opening Flexible Film Packaging Products and Manufacturing Methods. E.S. Patent 2,555,259T3, 30 December 2015. [Google Scholar]

- Schumacher, H. EU Patent Device for Distributing Cooled Foods, in Particular for Large Kitchens. EP 2,090,853A2, 19 August 2009. [Google Scholar]

- Komiya, H.; Kawabata, K. Out-of -Hospital Cooking Management Method and System Therefor. U.S. Patent 20,030,120,506A1, 26 June 2003. [Google Scholar]

- Vilona, M. Pre-Cooked Food Manufacturing System. Patent WO 2,010,091,856A2, 19 August 2010. [Google Scholar]

- Fu, B.; Labuza, T.P. Shelf-life prediction: Theory and application. Food Control 1993, 4, 125–133. [Google Scholar] [CrossRef]

- Man, C.M.D.; Jones, A.A. (Eds.) Shelf-Life Evaluation of Foods; Springer: Berlin, Germany, 1994. [Google Scholar]

- Taormina, P.J.; Hardin, M.D. (Eds.) Food Safety and Quality-Based Shelf-life of Perishable Foods; Springer: Berlin, Germany, 2021. [Google Scholar]

- Standard Guide for Sensory Evaluation Methods to Determine the Sensory Shelf-Life of Consumer Products; ASTM E2454-20 Standard; ASTM: West Conshohocken, PA, USA, 2020.

- Food Safety and Inspection Service. Available online: https://www.fsis.usda.gov (accessed on 2 October 2019).

- 9CFR 317.8 9 CFR § 317.8—False or Misleading Labeling or Practices Generally; Specific Prohibitions and Requirements for Labels and Containers. U.S. Code of Federal Regulation. Available online: https://www.govinfo.gov./app/details/CFR-2021-title9-vol2/CFR-2021-title9-vol2-sec317-8/summary (accessed on 3 June 2021).

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October. 2011. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:304:0018:0063:en:PDF (accessed on 3 June 2021).

- Consolidated Text: Directive 2000/13/EC of the European Parliament and of the Council of 20 March 2000 on the Approximation of the Laws of the Member States Relating to the Labelling, Presentation and Advertising of Foodstuffs. Available online: http://data.europa.eu/eli/dir/2000/13/2013-07-01 (accessed on 3 June 2021).

- Food Safety, European Commission. Available online: https://ec.europa.eu/food/safety/chemical_safety/food_contact_materials/legislation_en (accessed on 30 June 2021).

- Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002, Art. 14. 2002. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02002R0178-20140630&rid=1 (accessed on 3 June 2021).

- Koutsoumanis, K.; Allende, A.; Alvarez-Ordóñez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Davies, R.; De Cesare, A.; Herman, L.; Nauta, M.; et al. Guidance on date marking and related food information: Part 1 (date marking). EFSA J. 2020, 18, 6306–6380. [Google Scholar] [CrossRef]

- Koutsoumanis, K.; Allende, A.; Alvarez-Ordóñez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Davies, R.; De Cesare, A.; Herman, L.; Hilbert, F.; et al. Guidance on date marking and related food information: Part 2 (food information). EFSA J. 2021, 19, 6510–6555. [Google Scholar] [CrossRef]

- Prosapio, V.; Lopez-Quiroga, E. Freeze-Drying Technology in Foods. Foods 2020, 9, 920. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.H.; Wang, W.J.; Zhang, F.; Shao, Z.P.; Guo, L. Formation of the oxidized flavor compounds at different heat treatment and changes in the oxidation stability of milk. Food Sci. Nutr. 2018, 7, 238–246. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, C.; Long, Y.; Chen, Q.; Zhang, W.; Liu, G. Food additives: From functions to analytical methods. Crit. Rev. Food Sci. Nutr. 2021. [Google Scholar] [CrossRef] [PubMed]

- Vaclavik, V.A.; Christian, E.W.; Campbell, T. Food PreservationOpen image in new window. In Essentials of Food Science; Food Science Text Series; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Brody, A.L.; Strupinsky, E.P.; Kline, L.R. Active Packaging for Food Applications; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Robertson, G.L. Food Packaging: Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Sun, D.W. Handbook of Frozen Food Processing and Packaging, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Yam, K.L. The Wiley Encyclopedia of Packaging Technology; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Brandelli, A.; Brum, L.F.W.; Dos Santos, J.H.Z. Nanobiotechnology Methods to Incorporate Bioactive Compounds in Food Packaging. In Nanoscience in Food and Agriculture 2; Ranjan, S., Dasgupta, N., Lichtfouse, E., Eds.; Springer: Cham, Switzerland; Berlin, Germany, 2016; Volume 21. [Google Scholar]

- Atarés, L.; Chiralt, A. Essential Oils as Additives in Biodegradable Films and Coatings for Active Food Packaging. Trends Food Sci. Technol. 2016, 48, 51–62. [Google Scholar] [CrossRef]

- Firouz, M.S.; Mohi-Alden, K.; Omid, M. A Critical Review on Intelligent and Active Packaging in the Food Industry: Research and Development. Food Res. Int. 2021, 141, 110113–110137. [Google Scholar] [CrossRef]

- Wrona, M.; Nerín, C. Risk Assessment of Plastic Packaging for Food Applications. In Food Contact Materials Analysis: Mass Spectrometry Techniques; Royal Society of Chemistry: London, UK, 2019; pp. 163–191. ISBN 978-1-78801-124-2. [Google Scholar]

- Wrona, M.; Nerín, C. Polymers/Food Contact and Packaging Materials—Analytical Aspects. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 350–359. ISBN 9780081019849. [Google Scholar]

- Wrona, M.; Nerín, C. Analytical Approaches for Analysis of Safety of Modern Food Packaging: A Review. Molecules 2020, 25, 752. [Google Scholar] [CrossRef] [Green Version]

- Zahra, S.A.; Butt, Y.N.; Nasar, S.; Akram, S.; Fatima, Q.; Ikram, J. Food Packaging in Perspective of Microbial Activity: A Review. J. Microbiol. Biotechnol. Food Sci. 2016, 6, 752–757. [Google Scholar] [CrossRef]

- Otoni, C.G.; Espitia, P.J.P.; Avena-Bustillos, R.J.; McHugh, T.H. Trends in Antimicrobial Food Packaging Systems: Emitting Sachets and Absorbent Pads. Food Res. Int. 2016, 83, 60–73. [Google Scholar] [CrossRef]

- Sahi, S.; Djidjelli, H.; Boukerrou, A. Study of the Properties and Biodegradability of the Native and Plasticized Corn Flour-Filled Low Density Polyethylene Composites for Food Packaging Applications. Mater. Today Proc. 2021, 36, 67–73. [Google Scholar] [CrossRef]

- Ribeiro-Santos, R.; Andrade, M.; de Melo, N.R.; Sanches-Silva, A. Use of Essential Oils in Active Food Packaging: Recent Advances and Future Trends. Trends Food Sci. Technol. 2017, 61, 132–140. [Google Scholar] [CrossRef]

- Langeveld, W.T.; Veldhuizen, E.J.A.; Burt, S.A. Synergy between Essential Oil Components and Antibiotics: A Review. Crit. Rev. Microbiol. 2014, 40, 76–94. [Google Scholar] [CrossRef] [PubMed]

- Aljaafari, M.; Sultan Alhosani, M.; Abushelaibi, A.; Lai, K.S.; Erin Lim, S.H. Essential Oils: Partnering with Antibiotics. In Essential Oils-Oils Nature; IntechOpen Limited: London, UK, 2019. [Google Scholar]

- Pollini, M.; Sannino, A.; Paladini, F.; Sportelli, M.C.; Picca, R.A.; Cioffi, N.; Fracchiolla, G.; Valentini, A. Chapter 14: Combining Inorganic Antibacterial Nanophases and Essential Oils: Recent Findings and Prospects. In Essential Oils and Nanotechnology for Treatment of Microbial Diseases; Rai, M., Zacchino, S., Derita, M.G., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Oxfordshire, UK, 2017; ISBN 9781138630727. [Google Scholar]

- Zigadlo, J.A.; Zunino, M.P.; Pizzolitto, R.P.; Merlo, C.; Omarini, A.; Dambolena, J.S. Chapter 4: Antibacterial and antibiofilm Activities of Essential Oils and Their Components Including Modes of Action. In Essential Oils and Nanotechnology for Treatment of Microbial Diseases; Rai, M., Zacchino, S., Derita, M.G., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Oxfordshire, UK, 2017; ISBN 9781138630727. [Google Scholar]

- Bueno, J.; Demirci, F.; Baser, K.H.C. Chapter 6: Essential Oils against Microbial Resistance Mechanisms Challenges and Applications in Drug Discovery. In Essential Oils and Nanotechnology for Treatment of Microbial Diseases; Rai, M., Zacchino, S., Derita, M.G., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Oxfordshire, UK, 2017; ISBN 9781138630727. [Google Scholar]

- Rosato, A.; Sblano, S.; Salvagno, L.; Carocci, A.; Clodoveo, M.L.; Corbo, F.; Fracchiolla, G. Anti-biofilm Inhibitory Synergistic Effects of Combinations of Essential Oils and Antibiotics. Antibiotics 2020, 9, 637. [Google Scholar] [CrossRef]

- Salvagno, L.; Sblano, S.; Fracchiolla, G.; Corbo, F.; Clodoveo, M.L.; Rosato, A. Antibiotics—Mentha Piperita Essential Oil Synergism Inhibits Mature Bacterial Biofilm. Chem. Today 2020, 38, 49–52. [Google Scholar]

- Rosato, A.; Carocci, A.; Catalano, A.; Clodoveo, M.L.; Franchini, C.; Corbo, F.; Carbonara, G.G.; Carrieri, A.; Fracchiolla, G. Elucidation of the Synergistic Action of Mentha Piperita Essential Oil with Common Antimicrobials. PLoS ONE 2018, 13, e0200902. [Google Scholar] [CrossRef]

- Rosato, A.; Maggi, F.; Cianfaglione, K.; Conti, F.; Ciaschetti, G.; Rakotosaona, R.; Fracchiolla, G.; Clodoveo, M.L.; Franchini, C.; Corbo, F. Chemical Composition and Antibacterial Activity of Seven Uncommon Essential Oils. J. Essent. Oil Res. 2018, 30, 233–243. [Google Scholar] [CrossRef]

- Rosato, A.; Piarulli, M.; Corbo, F.; Muraglia, M.; Carone, A.; Vitali, M.E.; Vitali, C. In Vitro Synergistic Action of Certain Combinations of Gentamicin and Essential Oils. Curr. Med. Chem. 2010, 17, 3289–3299. [Google Scholar] [CrossRef] [PubMed]

- Quesada, J.; Sendra, E.; Navarro, C.; Sayas-Barberá, E. Antimicrobial Active Packaging including Chitosan Films with Thymus vulgaris L. Essential Oil for Ready-to-Eat Meat. Foods 2016, 5, 57. [Google Scholar] [CrossRef] [Green Version]

- Duran, M.; Aday, M.S.; Demirel Zorba, N.N.; Temizkan, R.; Büyükcan, B.; Caner, C. Potential of Antimicrobial Active Packaging ‘containing Natamycin, Nisin, Pomegranate and Grape Seed Extract in Chitosan Coating’ To Extend Shelf-life of Fresh Strawberry. Food Bioprod. Process. 2016, 98, 354–363. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Vitchayakitti, W. Improving Functional Properties of Chitosan Film Sas Active Food Packaging by Incorporating with Propolis. Food Hydrocoll. 2016, 61, 695–702. [Google Scholar] [CrossRef]

- Demitri, C.; De Benedictis, V.M.; Madaghiele, M.; Corcione, C.E.; Maffezzoli, A. Nanostructured Active Chitosan-Based Films for Food Packaging Applications: Effect of Graphene Stacks on Mechanical Properties. Measurement 2016, 90, 418–423. [Google Scholar] [CrossRef]

- Zehetmeyer, G.; Meira, S.M.M.; Scheibel, J.M.; de Oliveira, R.V.B.; Brandelli, A.; Soares, R.M.D. Influence of Melt Processing on Biodegradable Nisin-PBAT Films Intended for Active Food Packaging Applications. J. Appl. Polym. Sci. 2016, 133, 1–10. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M. An Overview on Properties and Applications of poly (butylene adipate-co-terephthalate)–PBAT Based Composites. Polym. Eng. Sci. 2019, 59, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Azeredo, H.M.C.; Rosa, M.F.; Mattoso, L.H.C. Nanocellulose in Bio-based Food Packaging Applications. Ind. Crops Prod. 2017, 97, 664–671. [Google Scholar] [CrossRef]

- Wrona, M.; Cran, M.J.; Nerín, C.; Bigger, S.W. Development and Characterisation of HPMC Films Containing PLA Nanoparticles Loaded with Green Tea Extract for Food Packaging Applications. Carbohydr. Polym. 2017, 156, 108–117. [Google Scholar] [CrossRef] [PubMed]

- Ogiwara, Y.; Roman, M.J.; Decker, E.A.; Goddard, J.M. Iron chelating active packaging: Influence of competing ions and pH value on effectiveness of soluble and immobilized hydroxamate chelators. Food Chem. 2016, 196, 842–847. [Google Scholar] [CrossRef] [PubMed]

- Castro-Mayorga, J.L.; Fabra, M.J.; Lagaron, J.M. Stabilized Nanosilver Based Antimicrobial poly (3-hydroxybutyrate-co-3-hydroxyvalerate) Nanocomposites of Interest in Active Food Packaging. Innov. Food Sci. Emerg. Technol. 2016, 33, 524–533. [Google Scholar] [CrossRef]

- Castro-Mayorga, J.L.; Fabra, M.J.; Pourrahimi, A.M.; Olsson, R.T.; Lagaron, J.M. The Impact of Zinc Oxide Particle Morphology as an Antimicrobial and when Incorporated in poly (3-hydroxybutyrate-co-3-hydroxyvalerate) Films for Food Packaging and Food Contact Surfaces Applications. Food Bioprod. Process. 2017, 101, 32–44. [Google Scholar] [CrossRef] [Green Version]

- Al-Naamani, L.; Dobretsov, S.; Dutta, J. Chitosan-zinc Oxide Nanoparticle Composite Coating for Active Food Packaging Applications. Innov. Food Sci. Emerg. Technol. 2016, 38, 231–237. [Google Scholar] [CrossRef]

- Salarbashi, D.; Mortazavi, S.A.; Noghabi, M.S.; Bazzaz, B.S.F.; Sedaghat, N.; Ramezani, M.; Shahabi-Ghahfarrokhi, I. Development of new Active Packaging Film Made from a Soluble Soybean Polysaccharide Incorporating Zno Nanoparticles. Carbohydr. Polym. 2016, 140, 220–227. [Google Scholar] [CrossRef] [PubMed]

- De Vietro, N.; Conte, A.; Incoronato, A.L.; Del Nobile, M.A.; Fracassi, F. Aerosol-assisted Low Pressure Plasma Deposition of Antimicrobial Hybrid Organic-inorganic Cu-composite Thin Films for Food Packaging Applications. Innov. Food Sci. Emerg. Technol. 2017, 41, 130–134. [Google Scholar] [CrossRef]

- Ahmed, I.; Lin, H.; Zou, L.; Brody, A.L.; Li, Z.; Qazi, I.M.; Pavase, T.R.; Lv, L. A Comprehensive Review on the Application of Active Packaging Technologies to Muscle Foods. Food Control 2017, 82, 163–178. [Google Scholar] [CrossRef]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and Intelligent Packaging in Meat Industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- McMillin, K.W. Advancements in Meat Packaging. Meat Sci. 2017, 132, 153–162. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clodoveo, M.L.; Muraglia, M.; Fino, V.; Curci, F.; Fracchiolla, G.; Corbo, F.F.R. Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods. Foods 2021, 10, 2086. https://doi.org/10.3390/foods10092086

Clodoveo ML, Muraglia M, Fino V, Curci F, Fracchiolla G, Corbo FFR. Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods. Foods. 2021; 10(9):2086. https://doi.org/10.3390/foods10092086

Chicago/Turabian StyleClodoveo, Maria Lisa, Marilena Muraglia, Vincenzo Fino, Francesca Curci, Giuseppe Fracchiolla, and Filomena Faustina Rina Corbo. 2021. "Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods" Foods 10, no. 9: 2086. https://doi.org/10.3390/foods10092086

APA StyleClodoveo, M. L., Muraglia, M., Fino, V., Curci, F., Fracchiolla, G., & Corbo, F. F. R. (2021). Overview on Innovative Packaging Methods Aimed to Increase the Shelf-Life of Cook-Chill Foods. Foods, 10(9), 2086. https://doi.org/10.3390/foods10092086