Nutritional and Technological Optimization of Wheat-Chickpea- Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Blend Preparation and Mixture Experimental Design

2.3. Nutritional Composition Analysis

2.3.1. Mineral Content

2.3.2. Total Phenolic Content

2.3.3. Estimation of DPPH Scavenging Activity

2.4. Determination of Technological Quality Parameters

2.5. Optimal Blend

2.6. Rheological Quality and Bread Making Procedure of the Optimal Flour Blend

2.7. Breadmaking

2.8. Sensorial Analysis of the Optimal Blend Bread

2.9. Statistical Analysis

3. Results and Discussion

3.1. Nutritional Composition of Flour Mixtures

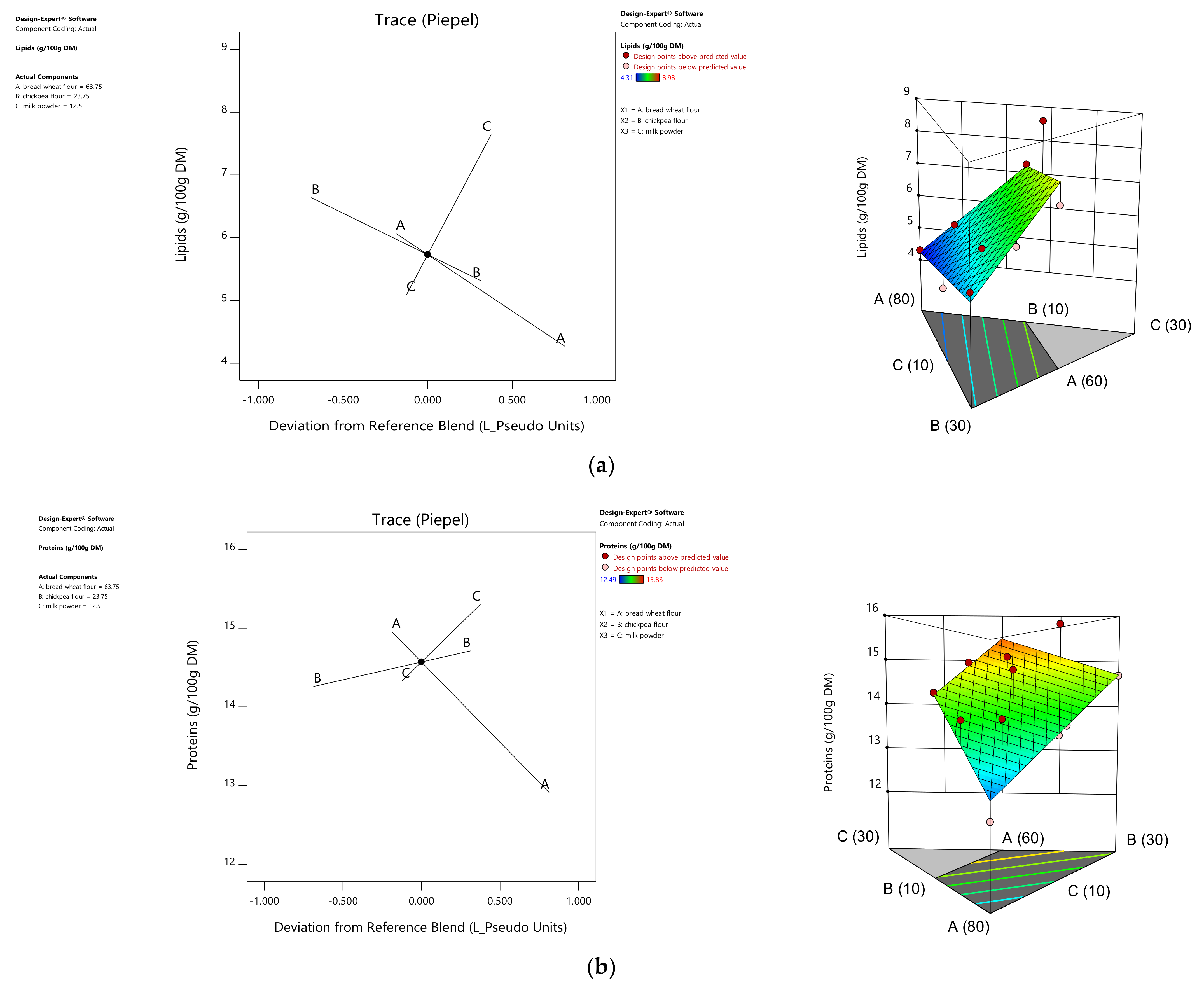

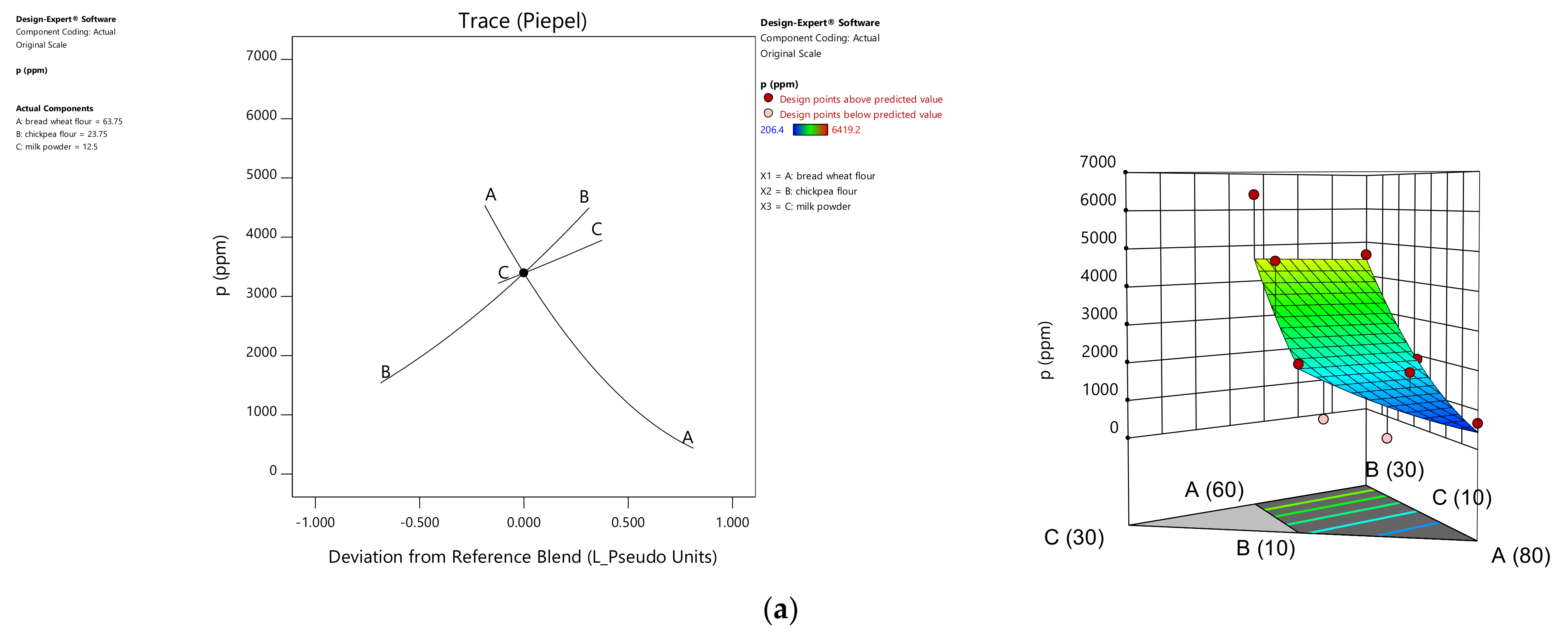

3.1.1. Macronutrient Content

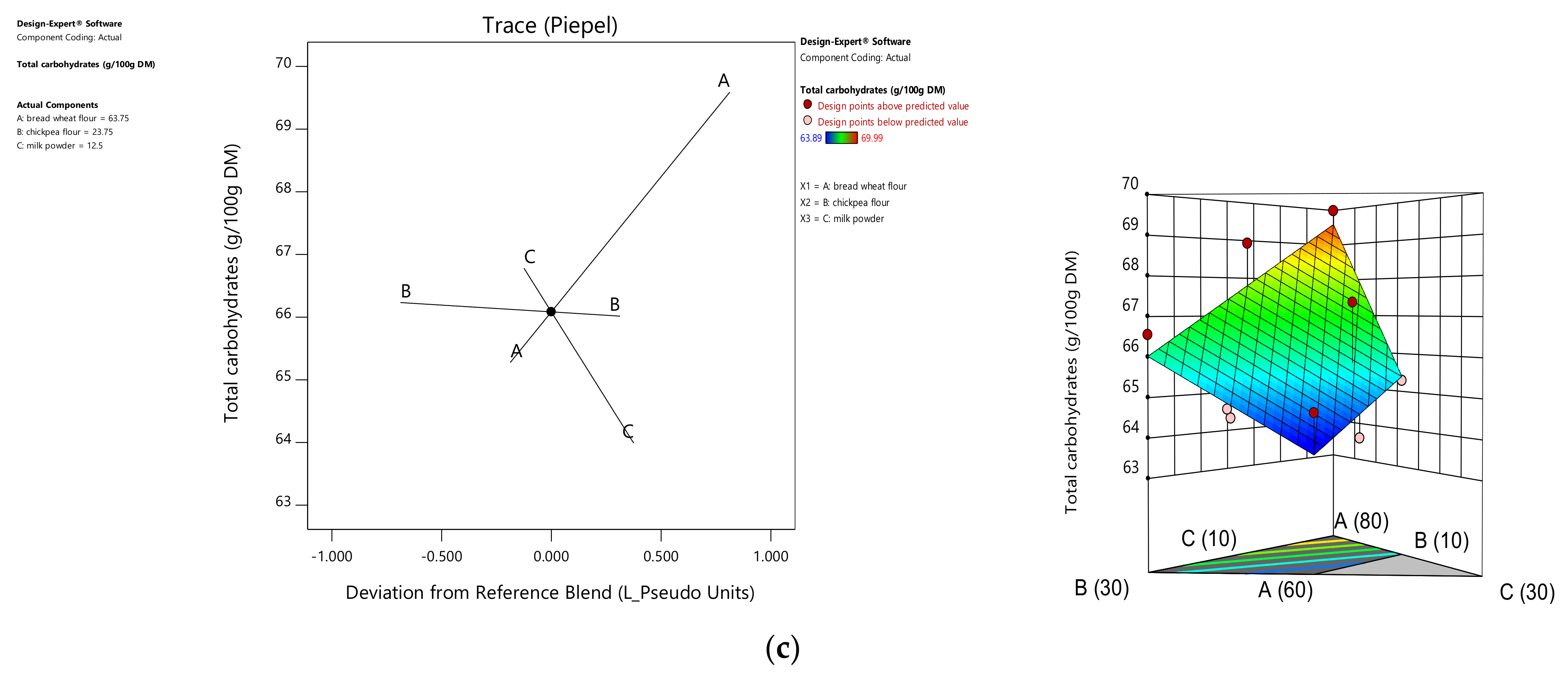

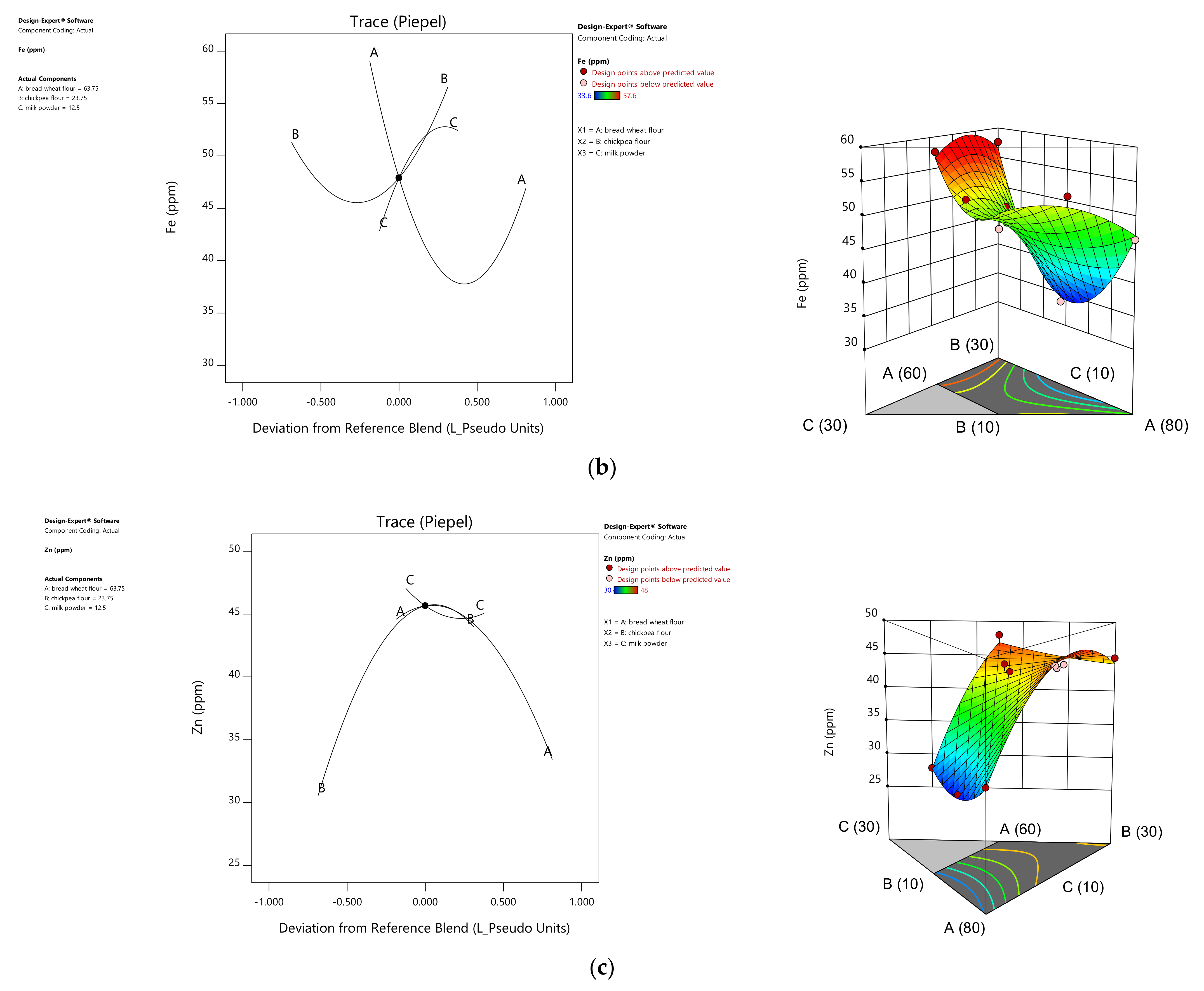

3.1.2. Mineral Composition

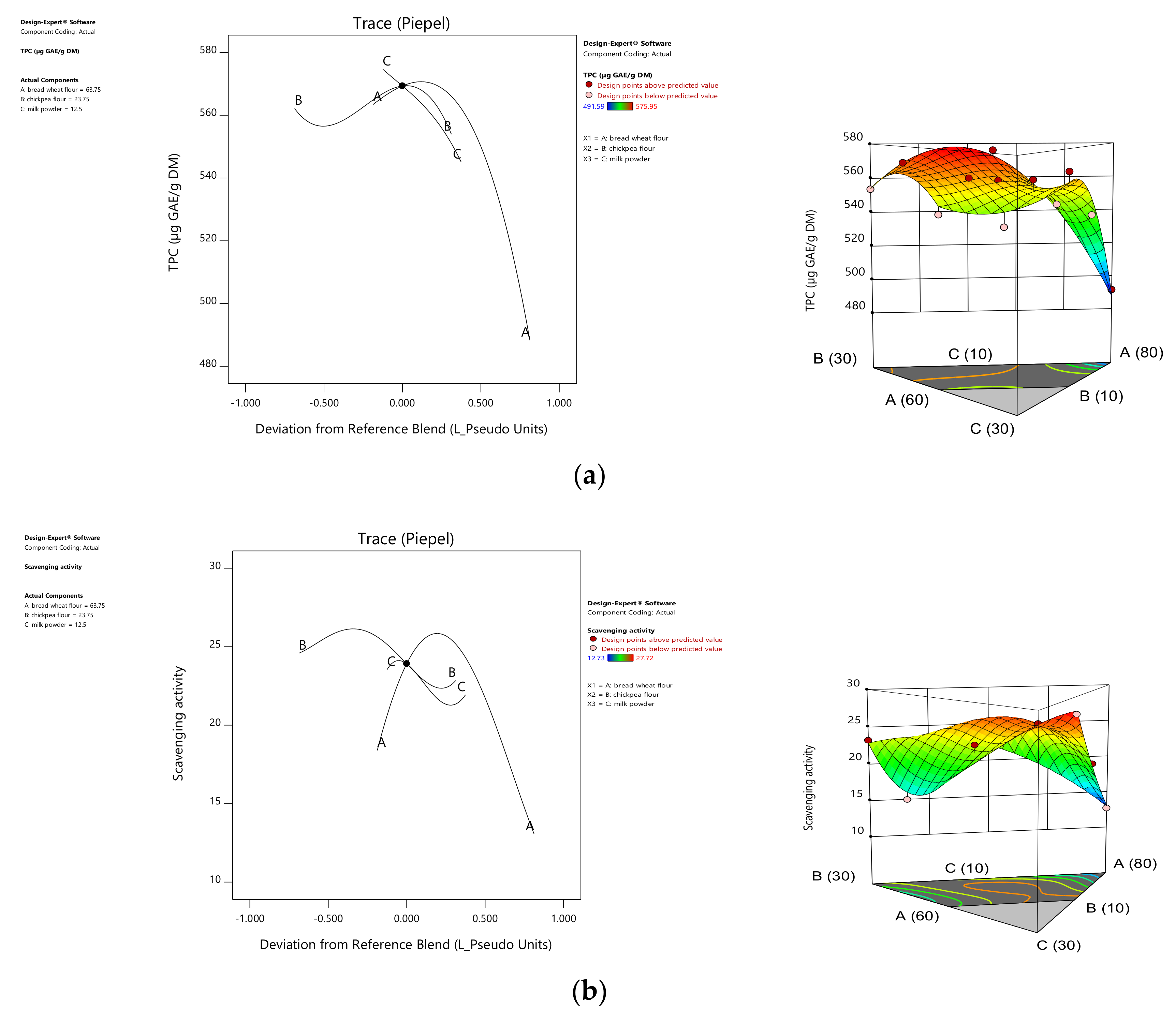

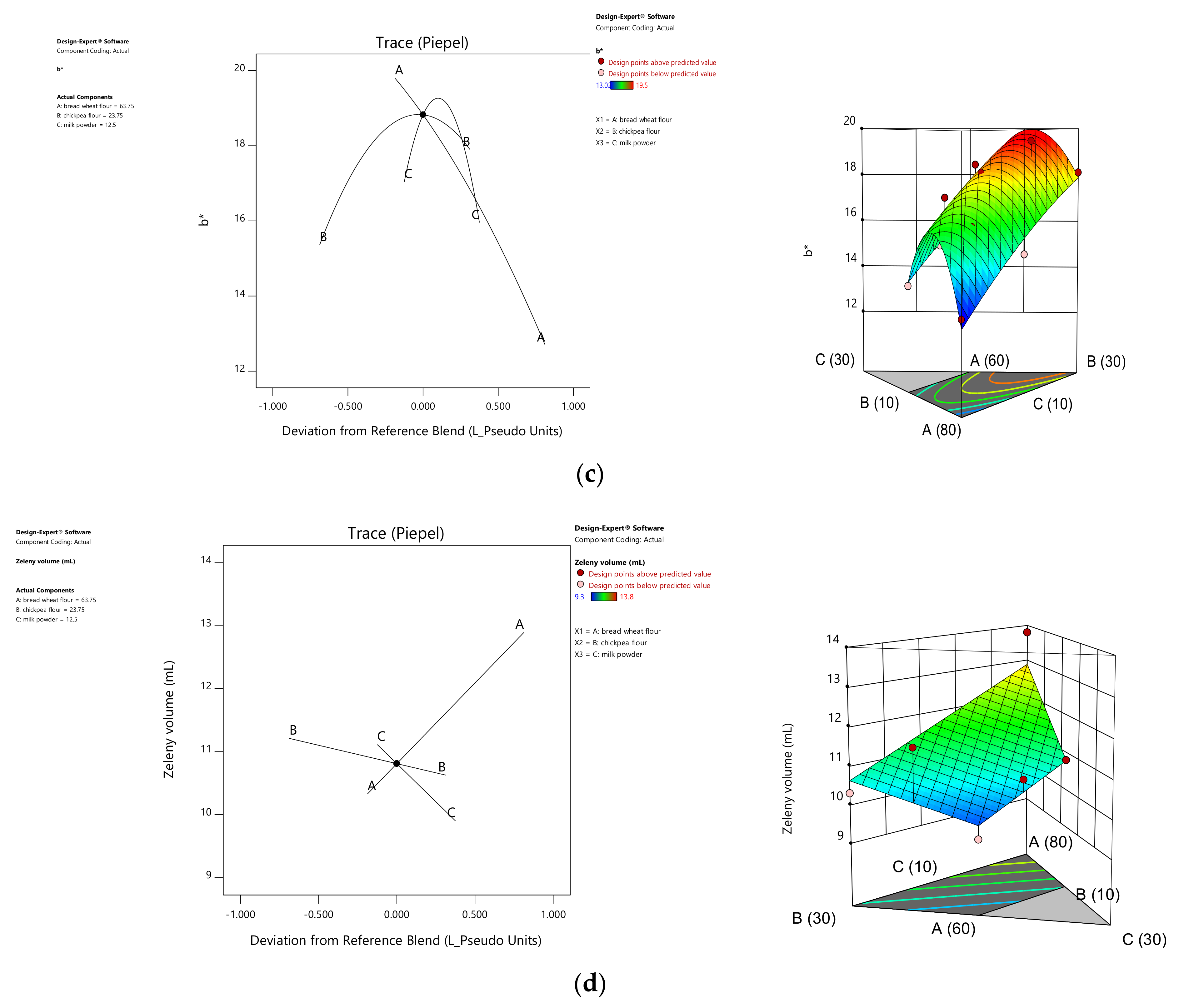

3.1.3. Total Polyphenols and Scavenging Activity of Blend Preparation

3.2. Technological Quality of Flour Mixture

3.3. Blend Optimization

3.4. Farinograph Test

3.5. Sensory Profile of Optimized Bread

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bassett, C.; Boye, J.; Tyler, R.; Oomah, B.D. Molecular, functional and processing characteristics of whole pulses and pulse fractions and their emerging food and nutraceutical applications. Food Res. Int. 2010, 43, 2268. [Google Scholar] [CrossRef]

- Jain, A.K.; Kumar, S.; Panwar, J.D.S. Antinutritional factors and their detoxification in pulses-a review. Energy (K Cal) 2009, 139, 90–94. [Google Scholar]

- Tosh, S.M.; Yada, S. Dietary fibres in pulse seeds and fractions: Characterization, functional attributes, and applications. Food Res. Int. 2010, 43, 450–460. [Google Scholar] [CrossRef]

- Leterme, P. Recommendations by health organizations for pulse consumption. Br. J. Nutr. 2002, 88, 239–242. [Google Scholar] [CrossRef] [PubMed]

- Lal, R. Improving soil health and human protein nutrition by pulses-based cropping systems. Adv. Agron. 2017, 145, 167–204. [Google Scholar]

- Tsao, R.; Shahidi, F. Commemoration of the International Year of Pulses 2017; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Abu-Ghannam, N.; Gowen, A. Pulse-based food products. Pulse Foods Process. Qual. Nutraceutical Appl. 2011, 141, 249–278. [Google Scholar]

- Rizzello, C.G.; Coda, R.; Gobbetti, M. Use of sourdough fermentation and nonwheat flours for enhancing nutritional and healthy properties of wheat-based foods. In Fermented Foods in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2017; pp. 433–452. [Google Scholar]

- Jukanti, A.K.; Gaur, P.M.; Gowda, C.L.L.; Chibbar, R.N. Nutritional quality and health benefits of chickpea (Cicer arietinum L.): A review. Br. J. Nutr. 2012, 108, S11–S26. [Google Scholar] [CrossRef] [PubMed]

- De Camargo, A.C.; Favero, B.T.; Morzelle, M.C.; Franchin, M.; Alvarez-Parrilla, E.; de la Rosa, L.A.; Geraldi, M.V.; Marostica Junior, M.R.; Shahidi, F.; Schwember, A.R. Is chickpea a potential substitute for soybean? Phenolic bioactives and potential health benefits. Int. J. Mol. Sci. 2019, 20, 2644. [Google Scholar] [CrossRef] [PubMed]

- Kalefetoğlu, T.; Macar, O.; Dürdane, İ. Variability in some biochemical and nutritional characteristics in desi and Turkish kabuli chickpea (Cicer arietinum L.) types. Celal Bayar Üniversitesi Fen Bilim. Derg. 2017, 13, 677–680. [Google Scholar] [CrossRef]

- Dalgetty, D.D.; Baik, B. Fortification of bread with hulls and cotyledon fibers isolated from peas, lentils, and chickpeas. Cereal Chem. 2006, 83, 269–274. [Google Scholar] [CrossRef]

- Man, S.; Păucean, A.; Muste, S.; Pop, A. Effect of the chickpea (Cicer arietinum L.) flour addition on physicochemical properties of wheat bread. Bull. UASVM Food Sci. Technol. 2015, 72, 41–49. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough rheology and bread quality of wheat–chickpea flour blends. Ind. Crop. Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Effects of chickpea flour on wheat pasting properties and bread making quality. J. Food Sci. Technol. 2014, 51, 1902–1910. [Google Scholar] [CrossRef] [PubMed]

- Don, C.; Lichtendonk, W.J.; Plijter, J.J.; Hamer, R.J. Understanding the link between GMP and dough: From glutenin particles in flour towards developed dough. J. Cereal Sci. 2003, 38, 157–165. [Google Scholar] [CrossRef]

- Goesaert, H.; Brijs, K.; Veraverbeke, W.S.; Courtin, C.M.; Gebruers, K.; Delcour, J.A. Wheat flour constituents: How they impact bread quality, and how to impact their functionality. Trends Food Sci. Technol. 2005, 16, 12–30. [Google Scholar] [CrossRef]

- Mayorga, B.O.; Gómez, M. Dairy Ingredients. Bakery Products Science and Technology; Zhou, W., Ed.; Wiley Blackwell: West Sussex, UK, 2014; p. 259. [Google Scholar]

- Kenny, S.; Wehrle, K.; Stanton, C.; Arendt, E.K. Incorporation of dairy ingredients into wheat bread: Effects on dough rheology and bread quality. Eur. Food Res. Technol. 2000, 210, 391–396. [Google Scholar] [CrossRef]

- Moore, M.M.; Schober, T.J.; Dockery, P.; Arendt, E.K. Textural comparisons of gluten-free and wheat-based doughs, batters, and breads. Cereal Chem. 2004, 81, 567–575. [Google Scholar] [CrossRef]

- Arendt, E.; Dal Bello, F. Gluten-Free Cereal Products and Beverages; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 0080557767. [Google Scholar]

- Mathieu, D.; Phan-Tan-Luu, R.; Sergent, M. Criblage et étude des facteurs. LPRAI Marseille 1996. [Google Scholar]

- Buruk Sahin, Y.; Aktar Demirtaş, E.; Burnak, N. Mixture Design: A Review of Recent Applications in the Food Industry. Pamukkale Univ. J. Eng. Sci. 2016, 22, 297–304. [Google Scholar] [CrossRef]

- Akande, A.; Jolayemi, O.S.; Familusi, A.; Idowu, B. Nutritional, antioxidant and sensory properties of rice-based masa enriched with grain amaranth and carrot powder. Ann. Food Sci. Technol. 2018, 19, 645–656. [Google Scholar]

- Kayacier, A.; Yüksel, F.; Karaman, S. Simplex Lattice Mixture Design Approach on Physicochemical and Sensory Properties of Wheat Chips Enriched with Different Legume Flours: An Optimization Study Based on Sensory Properties. LWT-Food Sci. Technol. 2014, 58, 639–648. [Google Scholar] [CrossRef]

- Yuksel, F.; Campanella, O.H. Textural, Rheological and Pasting Properties of Dough Enriched with Einkorn, Cranberry Bean and Potato Flours, Using Simplex Lattice Mixture Design. Qual. Assur. Saf. Crop. Foods 2018, 10, 389–398. [Google Scholar] [CrossRef]

- Yilmaz, M.T.; Yildiz, Ö.; Yurt, B.; Toker, O.S.; Karaman, S.; Baştürk, A. A Mixture Design Study to Determine Interaction Effects of Wheat, Buckwheat, and Rice Flours in an Aqueous Model System. LWT-Food Sci. Technol. 2015, 61, 583–589. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists International 2000, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Thavarajah, D.; Thavarajah, P.; Sarker, A.; Vandenberg, A. Lentils (Lens culinaris medikus subspecies culinaris): A whole food for increased iron and zinc intake. J. Agric. Food Chem. 2009, 57, 5413–5419. [Google Scholar] [CrossRef]

- Alcock, N.W. A hydrogen-peroxide digestion system for tissue trace-metal analysis. Biol. Trace Elem. Res. 1987, 13, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.-E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 5529:2007 Wheat—Determination of the Sedimentation Index—Zeleny Test; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- Derringer, G.; Suich, R. Simultaneous optimization of several response variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; Cereals & Grains Assn: St. Paul, MN, USA, 2000. [Google Scholar]

- Qarooni, J. Flat Bread Technology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1996; ISBN 0412081113. [Google Scholar]

- Peryam, D.R.; Pilgrim, F.J. Hedonic scale method of measuring food preferences. Food Technol. 1957, 11, 9–14. [Google Scholar]

- Sarteshnizi, R.A.; Hosseini, H.; Bondarianzadeh, D.; Colmenero, F.J. Optimization of prebiotic sausage formulation: Effect of using β-glucan and resistant starch by D-optimal mixture design approach. LWT-Food Sci. Technol. 2015, 62, 704–710. [Google Scholar] [CrossRef]

- Ouazib, M.; Dura, A.; Zaidi, F.; Rosell, C.M. Effect of partial substitution of wheat flour by processed (germinated, toasted, cooked) chickpea on bread quality. Int. J. Agric. Sci. Technol. 2016, 11, 1. [Google Scholar] [CrossRef]

- Al-Jahani, A.H. Effect of Buttermilk on the Physicochemical, Rheological, and Sensory Qualities of Pan and Pita Bread. Int. J. Food Sci. 2017, 2017, 2054252. [Google Scholar] [CrossRef]

- Madenci, A.B.; Bilgiçli, N. Effect of whey protein concentrate and buttermilk powders on rheological properties of dough and bread quality. J. Food Qual. 2014, 37, 117–124. [Google Scholar] [CrossRef]

- Alsuhaibani, A. Rheological and nutritional properties and sensory evaluation of bread fortified with natural sources of calcium. J. Food Qual. 2018, 2018, 8308361. [Google Scholar] [CrossRef]

- Cota-Gastélum, A.G.; Salazar-García, M.G.; Espinoza-López, A.; Perez-Perez, L.M.; Cinco-Moroyoqui, F.J.; Martínez-Cruz, O.; Wong-Corral, F.J.; Del-Toro-Sánchez, C.L. Characterization of pasta with the addition of Cicer arietinum and Salvia hispanica flours on quality and antioxidant parameters. Ital. J. Food Sci. 2019, 31, 3. [Google Scholar]

- Khan, I.T.; Nadeem, M.; Imran, M.; Ullah, R.; Ajmal, M.; Jaspal, M.H. Antioxidant properties of Milk and dairy products: A comprehensive review of the current knowledge. Lipids Health Dis. 2019, 18, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Bojňanská, T.; Urminská, D. Influence of natural additives on protein complex of bread. Potravin. Slovak J. Food Sci. 2010, 4, 1–5. [Google Scholar] [CrossRef]

- Yıldırım, A.; Karaboğa, Z.Y. The effects of corn and chickpea flours on the quality of mardin peksimet. In Proceedings of the International Conference on Food, Agriculture and Animal Husbandry, Gaziantep, Turkey, 19–22 September 2019. [Google Scholar]

- Pasqualone, A.; De Angelis, D.; Squeo, G.; Difonzo, G.; Caponio, F.; Summo, C. The effect of the addition of Apulian black chickpea flour on the nutritional and qualitative properties of durum wheat-based bakery products. Foods 2019, 8, 504. [Google Scholar] [CrossRef] [PubMed]

- Gallagher, E.; Kenny, S.; Arendt, E.K. Impact of dairy protein powders on biscuit quality. Eur. Food Res. Technol. 2005, 221, 237–243. [Google Scholar] [CrossRef]

- Gani, A.; Broadway, A.A.; Ahmad, M.; Ashwar, B.A.; Wani, A.A.; Wani, S.M.; Masoodi, F.A.; Khatkar, B.S. Effect of whey and casein protein hydrolysates on rheological, textural and sensory properties of cookies. J. Food Sci. Technol. 2015, 52, 5718–5726. [Google Scholar] [CrossRef]

- Stauffer, C.E. Principles of Dough Formation In CAUVAIN, SP.; YOUNG, LS Technology of Breadmaking. Lond. Blackie Acad. Prof. 1998, 11, 262–295. [Google Scholar]

- Singh, N.; Harinder, K.; Sekhon, K.S.; Kaur, B. Studies on the improvement of functional and baking properties of wheat-chickpea flour blends. J. Food Process. Preserv. 1991, 15, 391–402. [Google Scholar] [CrossRef]

- Sekhon, K.S.; Singh, N.; NAGI, H.P.S. Effect of pearling and blending on the bread-making properties of sprout-damaged wheat. Cereal Foods World 1992, 37, 715–724. [Google Scholar]

- Papageorgiou, M.; Skendi, A. Flour Quality and Technological Abilities; Engineering Aspects of Cereal and Cereal-Based Products; Taylor & Francis Group, LLC.: Philadelphia, PA, USA, 2014; pp. 117–148. [Google Scholar]

- Gallagher, E.; Gormley, T.R.; Arendt, E.K. Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci. Technol. 2004, 15, 143–152. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Schoenlechner, R.; Berghofer, E. The effects of chickpea on the functional properties of white and whole wheat bread. Int. J. Food Sci. Technol. 2010, 45, 610–620. [Google Scholar] [CrossRef]

- Sanchez, H.D.; Osella, C.A.; De La Torre, M.A. Use of response surface methodology to optimize gluten-free bread fortified with soy flour and dry milk. Food Sci. Technol. Int. 2004, 10, 5–9. [Google Scholar] [CrossRef]

- Sharma, A.; Jana, A.H.; Chavan, R.S. Functionality of milk powders and milk-based powders for end use applications—A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 518–528. [Google Scholar] [CrossRef]

- Miñarro, B.; Albanell, E.; Aguilar, N.; Guamis, B.; Capellas, M. Effect of legume flours on baking characteristics of gluten-free bread. J. Cereal Sci. 2012, 56, 476–481. [Google Scholar] [CrossRef]

- Edwards, W.P. The Science of Bakery Products; Royal Society of Chemistry: Cambridge, UK, 2007; ISBN 1847557791. [Google Scholar]

| Response | Model | p Value | R2 | R2adj | F Value | Prediction Equation (Pseudo Component) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | AB | AC | BC | ABC | A ²BC | AB ²C | ABC ² | |||||||

| Proteins | Linear | 0.0078 | 0.6211 | 0.5453 | 8.19 | 12.91 * | 14.71 * | 16.28 * | ||||||||

| Nutritional composition | Total carbohydrates | Linear | 0.0005 | 0.7798 | 0.7357 | 17.70 | 69.59 ** | 66.02 ** | 61.20 ** | |||||||

| Lipids | Linear | 0.0006 | 0.7722 | 0.7266 | 16.95 | 4.27 ** | 5.32 ** | 10.20 ** | ||||||||

| p | Linear | 0.0055 | 0.6473 | 0.5767 | 9.18 | 16.74 * | 65.87 * | 67.82 * | ||||||||

| Fe | Quadratic | 0.0001 | 0.9593 | 0.8980 | 33.03 | 46.95 ** | 56.59 ** | 33.68 ** | −69.30 *** | 40.21 | 46.23 * | |||||

| Zn | Quadratic | 0.0002 | 0.9541 | 0.9213 | 29.08 | 33.42 *** | 43.96 *** | 52.61 *** | 31.81 ** | −44.17 * | −5.43 | |||||

| TPC | Special Cubic | 0.0045 | 0.9204 | 0.8407 | 11.56 | 488.3 * | 553.93 * | 440.18 * | 206.77 * | 387.88 * | 207.32 | −721.51 * | ||||

| Scavenging activity | Special Quartic | 0.0057 | 0.9755 | 0.9264 | 19.87 | 13.06 * | 22.84 * | 50.12 * | 16.61 * | −13.74 | −66.40 * | 350.83 * | 269.23 | −326.58 | ||

| Technological parameters | Zeleny volume | Linear | 0.0021 | 0.7084 | 0.6539 | 12.15 | 12.89 * | 10.63 * | 8.69 * | |||||||

| Yellow Index b * | Quadratic | 0.0002 | 0.9507 | 0.9155 | 27.01 | 12.69 *** | 17.90 *** | −7.05 *** | 1.55 | 44.04 ** | 44.12 ** | |||||

| Exp No. | Run | Lipids (g/100 g DM) | Proteins (g/100 g DM) | Total Carbohydrates (g/100 g DM) | TPC (µg GAE/g DM) | Scavenging Activity | Zn (ppm) | Fe (ppm) | P (ppm) | Zeleny Volume (mL) | b * |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 12 | 4.31 i | 12.49 h | 69.99 a | 491.59 f | 12.73 f | 33.60 de | 46.40 bc | 660.80 k | 13.80 a | 13.02 b |

| 2 | 2 | 7.27 b | 14.63 d | 65.29 efg | 567.35 ab | 27.72 a | 32.00 de | 48.00 abc | 2059.20 h | 10.80 ab | 13.69 ab |

| 3 | 3 | 5.59 h | 14.69 d | 66.55 cde | 553.48 cd | 23.21 bcd | 44.80 ab | 57.60 a | 4630.40 c | 10.30 ab | 18.11 ab |

| 4 | 8 | 7.10 c | 15.17 b | 64.64 fg | 544.34 de | 20.43 d | 48.00 a | 57.60 a | 6419.20 a | 9.30 b | 16.42 ab |

| 5 | 7 | 5.59 h | 14.26 e | 67.03 cd | 540.18 e | 20.20 d | 30.40 e | 52.80 ab | 206.40 m | 11.30 ab | 15.53 ab |

| 6 | 4 | 4.38 i | 13.76 f | 68.93 ab | 575.95 a | 22.07 cd | 46.40 a | 33.60 d | 1889.60 i | 11.30 ab | 15.00 ab |

| 7 | 13 | 8.98 a | 15.11 bc | 63.89 g | 537.07 e | 24.17 abcd | 40.00 bc | 51.20 abc | 4636.80 b | 10.55 ab | 15.13 ab |

| 8 | 5 | 6.37 e | 15.83 a | 64.50 fg | 570.81 ab | 16.25 e | 43.20 ab | 57.60 a | 2646.40 f | 11.55 ab | 19.11 a |

| 9 | 11 | 6.11 f | 15.04 c | 65.58 defg | 560.44 bc | 25.11 abc | 44.80 ab | 46.40 bc | 2262.40 g | 10.55 ab | 18.23 ab |

| 10 | 10 | 5.62 h | 14.24 e | 67.04 cd | 544.99 de | 23.49 bcd | 36.80 cd | 43.20 cd | 1763.20 j | 11.80 ab | 16.24 ab |

| 11 | 6 | 5.79 g | 13.43 g | 67.36 bc | 561.85 bc | 26.22 ab | 36.80 cd | 48.00 abc | 459.20 l | 10.80 ab | 17.24 ab |

| 12 | 9 | 6.09 f | 13.71 f | 66.14 cdef | 560.96 bc | 23.89 abcd | 44.80 ab | 48.00 abc | 3299.20 e | 10.55 ab | 19.50 a |

| 13 | 1 | 6.68 d | 15.20 b | 64.51 fg | 563.01 abc | 23.67 abcd | 44.80 ab | 49.60 abc | 3372.80 d | 10.30 ab | 18.50 ab |

| Treatments | Dough Development Time | Consistancy | Water Absorption | Stability | Softening Degree |

|---|---|---|---|---|---|

| mn:ss | BU | % | mn:ss | BU | |

| Control(bread wheat dough) | 1:07 a | 553 | 51.8 | 1:09 | 82 a |

| Optimized blend dough | 1:55 b | 527 | 59.0 | 1:44 | 71 b |

| Probability | 0.01 | ns | ns | ns | 0.05 |

| Sensory Quality Scores | ||||||

|---|---|---|---|---|---|---|

| Appearance | Crust | Crumb | Chewiness | Aroma | Taste | |

| Optimized blend bread | 7.6 a | 7.8 a | 6.9 | 7.2 | 7.5 a | 7.7 a |

| Control (100%Bread wheat) | 6.1 b | 6.7 b | 7.0 | 7.3 | 6.2 b | 6.4 b |

| Probability | 0.01 | 0.01 | ns | ns | 0.05 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benali, A.; En-nahli, Y.; Noutfia, Y.; Elbaouchi, A.; Kabbour, M.R.; Gaboun, F.; El Maadoudi, E.H.; Benbrahim, N.; Taghouti, M.; Ouhssine, M.; et al. Nutritional and Technological Optimization of Wheat-Chickpea- Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread. Foods 2021, 10, 1843. https://doi.org/10.3390/foods10081843

Benali A, En-nahli Y, Noutfia Y, Elbaouchi A, Kabbour MR, Gaboun F, El Maadoudi EH, Benbrahim N, Taghouti M, Ouhssine M, et al. Nutritional and Technological Optimization of Wheat-Chickpea- Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread. Foods. 2021; 10(8):1843. https://doi.org/10.3390/foods10081843

Chicago/Turabian StyleBenali, Aouatif, Youness En-nahli, Younès Noutfia, Adil Elbaouchi, Mohammed Rachid Kabbour, Fatima Gaboun, El Haj El Maadoudi, Nadia Benbrahim, Mona Taghouti, Mohammed Ouhssine, and et al. 2021. "Nutritional and Technological Optimization of Wheat-Chickpea- Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread" Foods 10, no. 8: 1843. https://doi.org/10.3390/foods10081843

APA StyleBenali, A., En-nahli, Y., Noutfia, Y., Elbaouchi, A., Kabbour, M. R., Gaboun, F., El Maadoudi, E. H., Benbrahim, N., Taghouti, M., Ouhssine, M., & Kumar, S. (2021). Nutritional and Technological Optimization of Wheat-Chickpea- Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread. Foods, 10(8), 1843. https://doi.org/10.3390/foods10081843