Bran-Enriched Milled Durum Wheat Fractions Obtained Using Innovative Micronization and Air-Classification Pilot Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Durum Wheat Cultivars

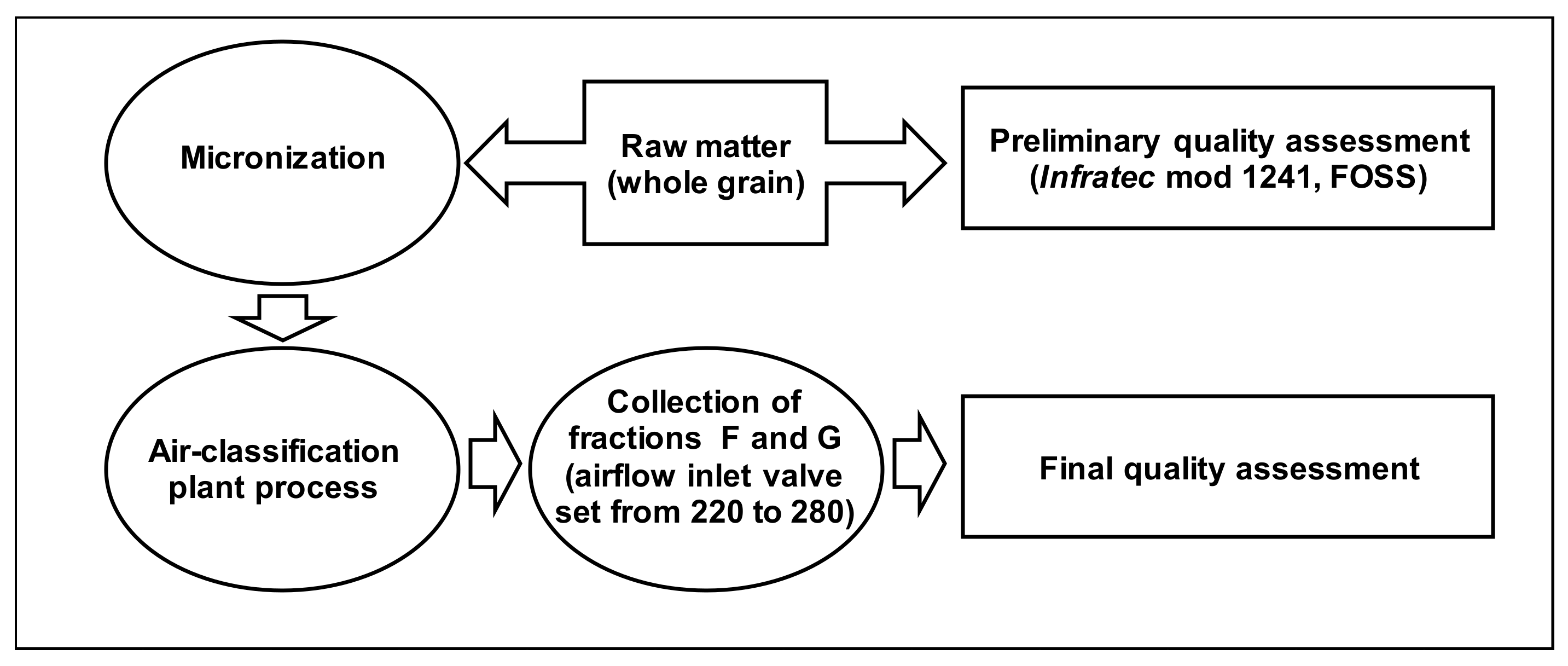

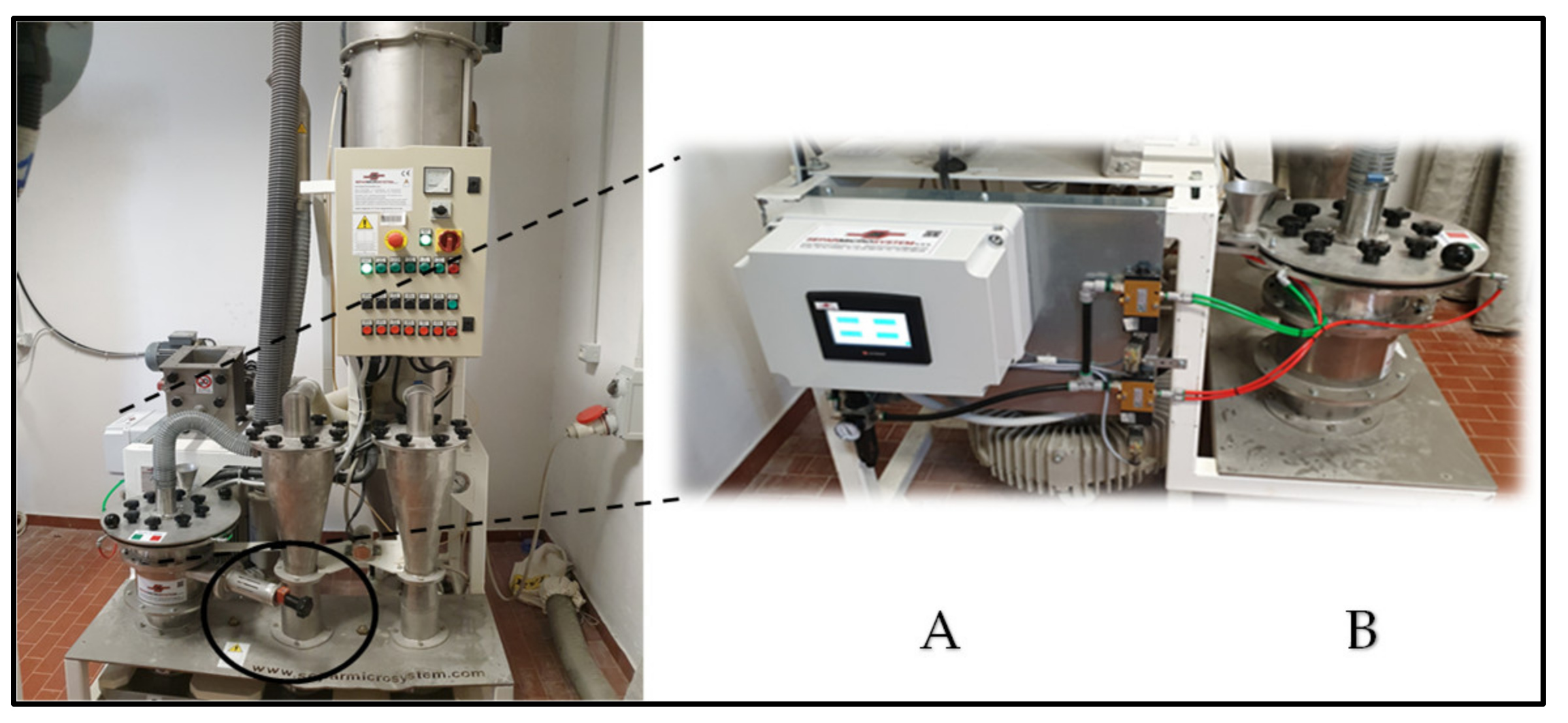

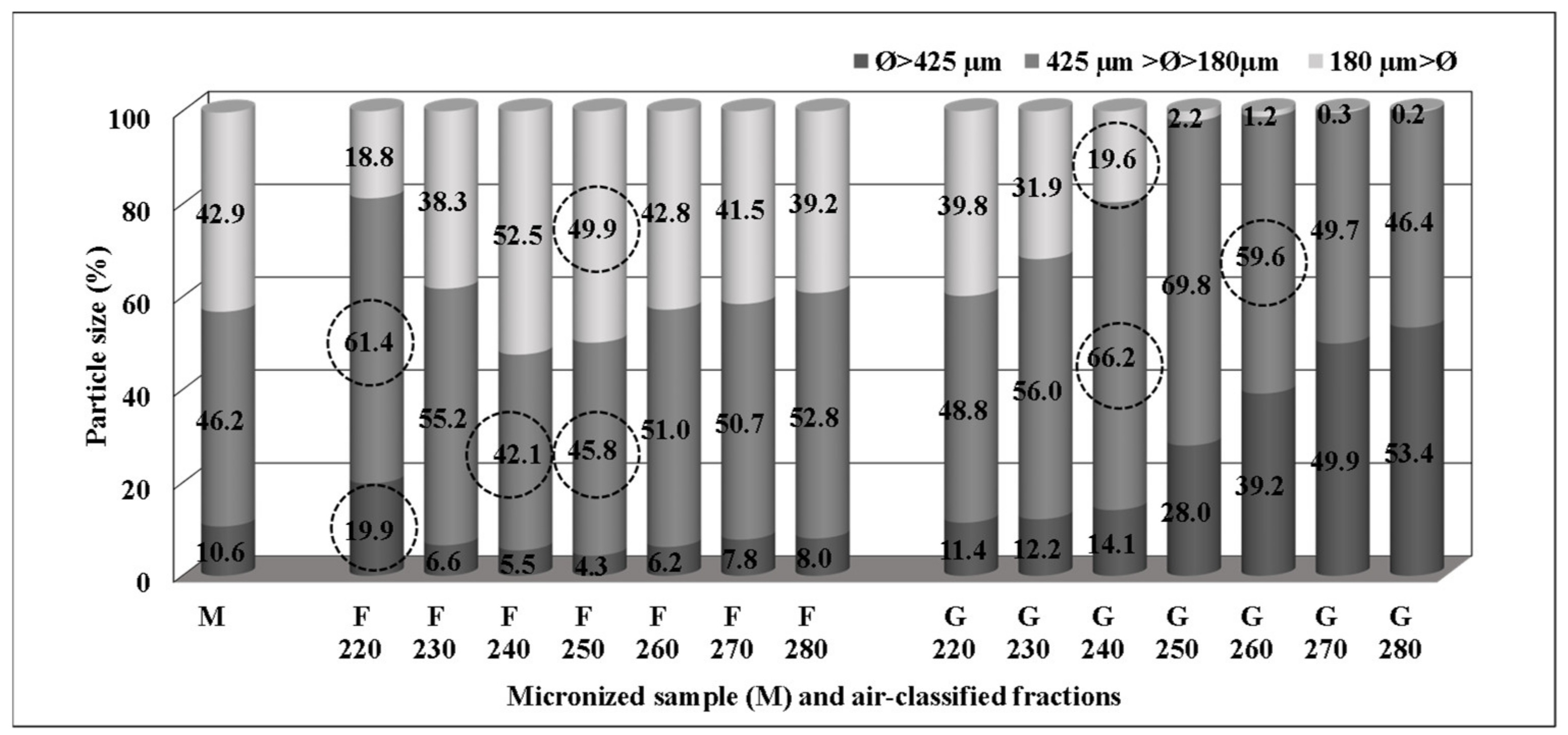

2.2. Micronization of Grain Samples and Air Classification of Milling Fractions

2.3. Quality Analysis

2.4. Statistical Analysis

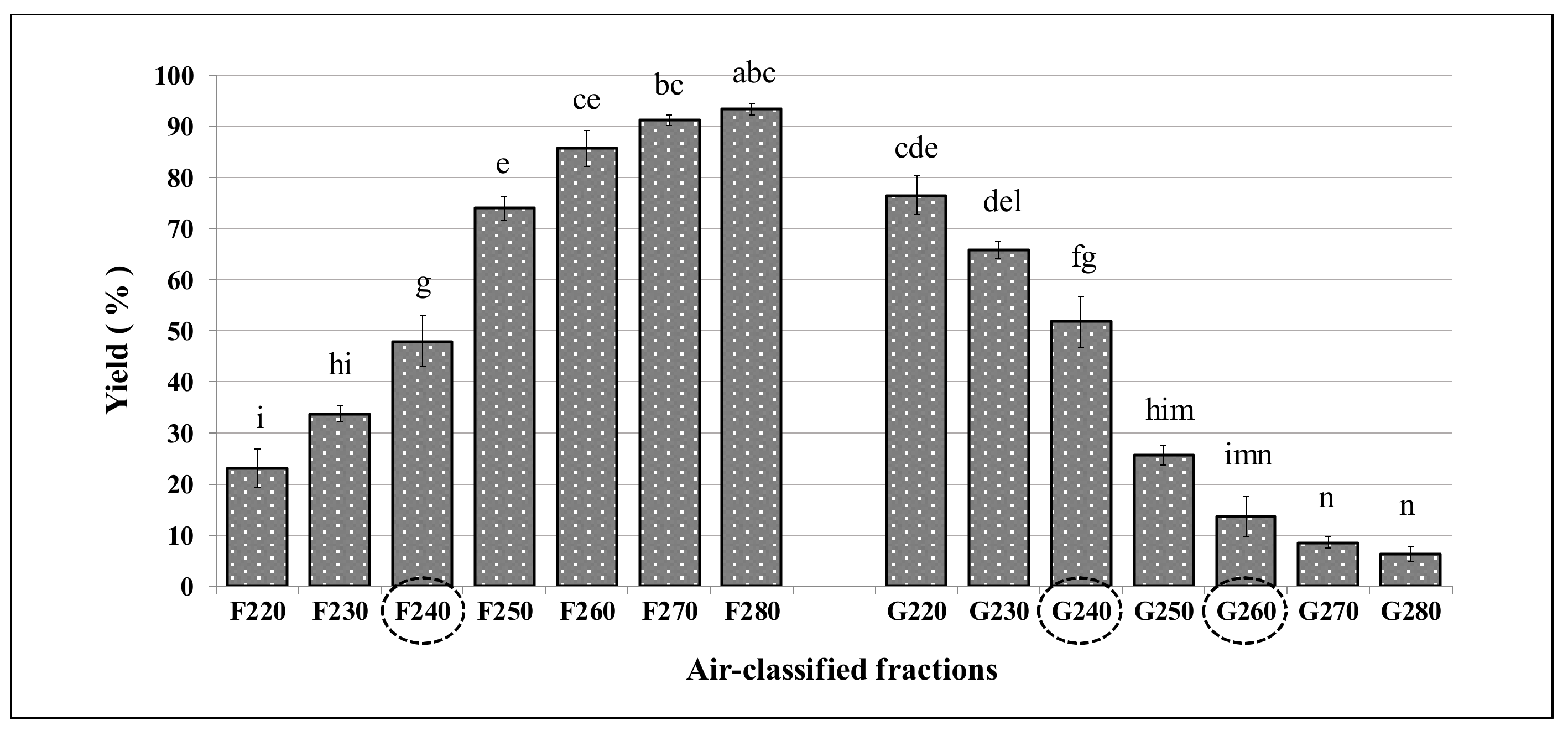

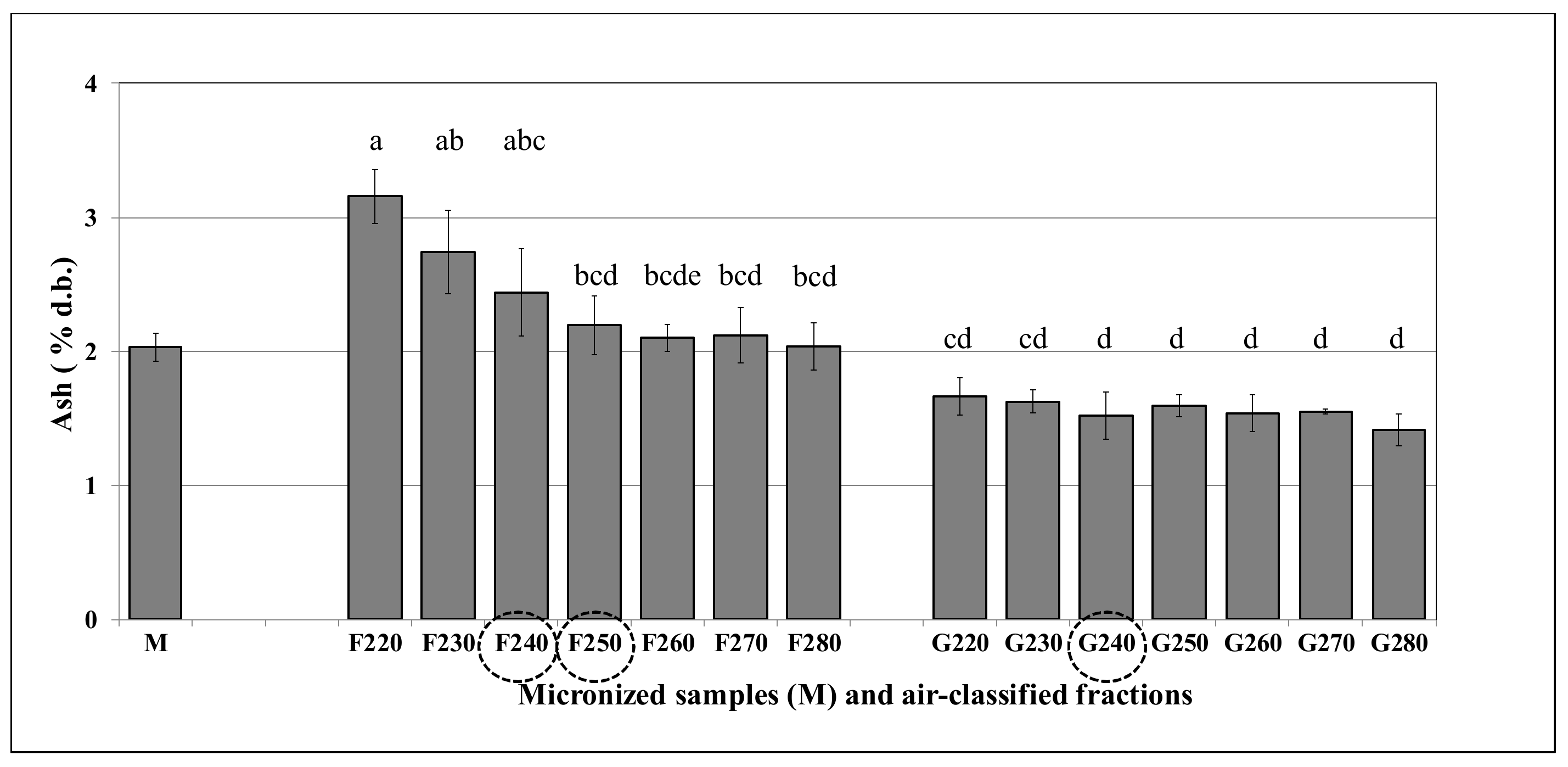

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hammami, R.; Sissons, M. Durum wheat Products: Couscous. In Wheat Quality for Improving Processing and Human Health; Igregas, G., Ikeda, T., Guzman, C., Eds.; Springer: Cham, Switzerland, 2020; pp. 345–366. [Google Scholar]

- Laddomada, B.; Durante, M.; Minervini, F.; Garbetta, A.; Cardinali, A.; D’Antuono, I.; Caretto, S.; Blanco, A.; Mita, G. Phytochemical characterization and anti-inflammatory activity of extracts from the whole-meal flour of Italian durum wheat cultivars. Int. J. Mol. Sci. 2015, 16, 3512–3527. [Google Scholar] [CrossRef]

- Shewry, P.R.; Hassall, K.L.; Grausgruber, H.; Andersson, A.A.M.; Lampi, A.M.; Piironen, V.; Rakszegi, M.; Ward, J.L.; Lovegrove, A. Do modern types of wheat have lower quality for human health? Nutr. Bull. 2020, 45, 362–373. [Google Scholar] [CrossRef] [PubMed]

- Calabriso, N.; Massaro, M.; Scoditti, E.; Pasqualone, A.; Laddomada, B.; Carluccio, M.A. Phenolic extracts from whole wheat biofortified bread dampen overwhelming 1 inflammatory response in human endothelial cells and monocytes: Major role of VCAM-1 and CXCL-10. Eur. J. Nutr. 2020, 59, 2603–2615. [Google Scholar] [CrossRef]

- Budreviciute, A.; Damiati, S.; Sabir, D.K.; Onder, K.; Schuller-Goetzburg, P.; Plakys, G.; Katileviciute, A.; Khoja, S.; Kodzius, R. Management and Prevention Strategies for Non-communicable Diseases (NCDs) and Their Risk Factors. Front. Public Health 2020, 8, 788. [Google Scholar] [CrossRef] [PubMed]

- Foster, S.; Beck, E.; Hughes, J.; Grafenauer, S. Whole Grains and Consumer Understanding: Investigating Consumers’ Identification, Knowledge and Attitudes to Whole Grains. Nutrients 2020, 12, 2170. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Laddomada, B.; Centomani, I.; Paradiso, V.M.; Minervini, D.; Caponio, F.; Summo, C. Bread making aptitude of mixtures of re-milled semolina and selected durum wheat milling by-products. LWT Food Sci. Technol. 2017, 78, 151–159. [Google Scholar] [CrossRef]

- Onipe, O.O.; Jideani, A.I.O.; Beswa, D. Composition and functionality of wheat bran and its application in some cereal food products. Int. J. Food Sci. Technol. 2015, 50, 2509–2518. [Google Scholar] [CrossRef]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.-L.; Poutanen, K.; Katina, K. Influence of particle size on bioprocess induced changes on technological functionality of wheat bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef]

- Fares, C.; Platani, C.; Baiano, A.; Menga, V. Effects of processing and cooking on phenolic acid profile and antioxidant capacity of durum wheat pasta enriched with debranning fractions of wheat. Food Chem. 2010, 119, 1023–1029. [Google Scholar] [CrossRef]

- Cammerata, A.; Marabottini RAllevato, E.; Aureli, G. Content of minerals and deoxynivalenol in the air-classified fractions of durum wheat. Cereal Chem. 2021. [Google Scholar] [CrossRef]

- Taddei, F.; Galassi, E.; Nocente, F.; Gazza, L. Innovative milling processes to Improve the technological and nutritional quality of parboiled brown rice pasta from contrasting amylose content cultivars. Foods 2021, 10, 1316. [Google Scholar] [CrossRef] [PubMed]

- Martín-García, B.; Verardo, V.; de Cerio, E.D.; del Carmen Razola-Díaz, M.; Messia, M.C.; Marconi, E.; Gómez-Caravaca, A.M. Air classification as a useful technology to obtain phenolics-enriched buckwheat flour fractions. Food Sci. Technol. 2021, 150, 111893. [Google Scholar] [CrossRef]

- Ciccoritti, R.; Taddei, F.; Nicoletti, I.; Gazza, L.; Corradini, D.; D’Egidio, M.G.; Martini, D. Use of bran fractions and debranned kernels for the development of pasta with high nutritional and healthy potential. Food Chem. 2017, 225, 77–86. [Google Scholar] [CrossRef] [PubMed]

- Ficco, D.B.M.; Borrelli, G.M.; Miedico, O.; Giovanniello, V.; Tarallo, M.; Pompa, C.; De Vita, P.; Chiaravalle, A.E. Effects of grain debranning on bioactive compounds, antioxidant capacity and essential and toxinc trace elements in purple durum wheats. LWT Food Sci. Technol. 2020, 118, 108734. [Google Scholar] [CrossRef]

- Sovrani, V.; Blandino, M.; Scarpino, V.; Redyneri, A.; Coïsson, J.D.; Travaglia, F.; Locatelli, M.; Bordiga, M.; Montella, R.; Arlorio, M. Bioactive compound content, antioxidant activity, deoxynivalenol and heavy metal contamination of pearled wheat fractions. Food Chem. 2012, 135, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Laddomada, B.; Del Coco, L.; Durante, M.; Presicce, D.S.; Siciliano, P.A.; Fanizzi, F.P.; Logrieco, A.F. Volatile metabolite profiling of durum wheat kernels contaminated by Fusarium poae. Metabolites 2014, 4, 932–945. [Google Scholar] [CrossRef]

- EN ISO 2171:2010. Cereals, Pulses and By-Products—Determination of Ash Yield by Incineration (ISO 2171:2007); ISO: Brussels, Belgium, 2007. [Google Scholar]

- Hammer, O.; Harper, D.A.T.; Ryan, P.D. PAST: Paleontological Statistic software package for education and data analysis. Paleontol. Electron. 2001, 4, 1–9. Available online: http://palaeo-electronica.org/2001_1/past/issue1_01.htm. (accessed on 22 June 2001).

- UNI 10709:1998. Durum Wheat Grains. Qualitative Requirements, Classification and Test Methods; UNI: Rome, Italy, 1998. [Google Scholar]

- Alzuwaid, N.T.; Fellows, C.M.; Laddomada, B.; Sissons, M. Impact of wheat bran particle size on the technological and phytochemical properties of durum wheat pasta. J. Cereal Sci. 2020, 95, 103033. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Hemery, Y.M.; Anson, N.M.; Havenaar, R.; Haenen, G.R.M.M.; Noort, M.W.J.; Rouau, X. Dry fractionation of wheat bran increases the bioaccessibility of phenolics acids. Food Res. Int. 2010, 43, 1429–1438. [Google Scholar] [CrossRef]

- Hemdane, S.; Jacobs, P.J.; Dornez, E.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Wheat (Triticum aestivum L.) Bran in Bread Making: A Critical Review. Compr. Rev. Food Sci. food Saf. 2016, 15, 28–42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sandberg, E. The Effect of Durum Wheat Bran Particle Size on the Quality of Bran Enriched Pasta; Swedish University of Agricultural Sciences, Department of Food Science: Uppsala, Sweden, 2015; Series no: 405; Available online: http://stud.epsilon.slu.se (accessed on 8 July 2015).

- Sacchetti, G.; Cocco, G.; Cocco, D.; Neri, L.; Mastrocola, D. Effect of semolina particle size on the cooking kinetics and quality of spaghetti. Procedia Food Sci. 2011, 1, 1740–1745. [Google Scholar] [CrossRef] [Green Version]

| Cultivar | Origin | Test Weight (kg/hL) | Moisture (%) | Protein Content (% db) | Gluten Content (% db) | Yellow Color |

|---|---|---|---|---|---|---|

| Saragolla | Puglia | 81.6 | 10.9 | 12.9 | 8.9 | 13.9 |

| Maestà | Puglia | 81.0 | 10.2 | 15.6 | 11.0 | 15.4 |

| Iride | Puglia | 84.4 | 10.7 | 12.6 | 9.1 | 14.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cammerata, A.; Sestili, F.; Laddomada, B.; Aureli, G. Bran-Enriched Milled Durum Wheat Fractions Obtained Using Innovative Micronization and Air-Classification Pilot Plants. Foods 2021, 10, 1796. https://doi.org/10.3390/foods10081796

Cammerata A, Sestili F, Laddomada B, Aureli G. Bran-Enriched Milled Durum Wheat Fractions Obtained Using Innovative Micronization and Air-Classification Pilot Plants. Foods. 2021; 10(8):1796. https://doi.org/10.3390/foods10081796

Chicago/Turabian StyleCammerata, Alessandro, Francesco Sestili, Barbara Laddomada, and Gabriella Aureli. 2021. "Bran-Enriched Milled Durum Wheat Fractions Obtained Using Innovative Micronization and Air-Classification Pilot Plants" Foods 10, no. 8: 1796. https://doi.org/10.3390/foods10081796

APA StyleCammerata, A., Sestili, F., Laddomada, B., & Aureli, G. (2021). Bran-Enriched Milled Durum Wheat Fractions Obtained Using Innovative Micronization and Air-Classification Pilot Plants. Foods, 10(8), 1796. https://doi.org/10.3390/foods10081796